Abstract

In this work, laser processing technology was utilized to fabricate micro-textures on the surface of 42CrMo steel to improve its wear resistance under high load conditions and provide an effective method to solve the wear of tooth plates in oil drilling wellhead machinery. Firstly, the friction process of the textured components was conducted by finite element analysis. Additionally, various forms of textures were compared and measured by this method to optimize the shape and parameters of the patterns. Secondly, three types of texture shapes, such as micro-dimples, micro-grooves, and reticular grooves, were created on the surface of 42CrMo steel. Lastly, the tribological characteristics of the micro-textures were analyzed in the dry friction experiments. Compared with the untextured surface, the wear resistance of the textured 42CrMo steel has been improved, and the anti-wear property of the micro-dimples was better than micro-grooves and reticular grooves. Along the direction of friction sliding, the wear of the front end is more worn than the rear end. Micro-dimples with a diameter of 0.8 mm, a spacing of 1.2 mm, and an area occupancy of 34.8% were fabricated at an output power of 200 W and a frequency of 5 Hz. The wear of the textured surface has been reduced by more than 80% in the process of ring-block dry friction with a load of 50 N, a rotation speed of 35 r/min, and a time of 15 min. The wear mechanism is mainly abrasive wear. The results showed that the hardness of the surface could be improved by laser hardening. In addition, micro-dimples on 42CrMo steel can store abrasive particles, mitigate the formation of furrows and reduce the abrasive wear of tooth plates.

1. Introduction

The surface texturing technique has been considered a promising method in tribology applications because it could improve the performance of the friction system, including the wear resistance, the lifespan, and the bearing capacity due to the ability of surface textures to function as micro-containers for lubricant and particles [1]. Therefore, surface texturing has been used to manufacture mechanical components, for example, thrust bearings, cutting tools, piston rings, and seals [2,3,4,5,6,7]. Electric discharge machining (EDM), micro-grinding, and laser surface texturing are applied to fabricate textures on specimen surfaces researchers [8,9,10,11,12]. Compared with the other techniques, laser surface texturing has the advantages of high automation, high repeatability, and fine-scale processing [13].

At present, a large number of research on surface texturing has been expected to improve the tribological properties at the interface by reducing the contact area and increasing the lubrication pocket area on the surface. Ran Duan et al. created micro-textures on an Al2O3/TiC ceramic cutting tool and the textured tool to machine the AISI H13 steel in the conventional cooling condition [14]. The results showed that the structures of the surface textures performed with good integrity at different cutting speeds. Youqiang Xing et al. fabricated micro-textures on the surface of an Al2O3/TiC ceramic specimen to investigate the wear mechanism by using a ball-on-disk tribometer. The micro-textures were used in combination with different solid lubricants [15]. Results showed that laser surface textures combined with WS2 solid lubricants could decrease wear and friction significantly. Chi-Wai Chan et al. explored the effects of laser surface treatment on enhancing the properties of commercial Ti6Al4V and CoCrMo alloy implant materials [16]. The results indicated that the laser-treated Ti6A4V surfaces exhibited a noticeable reduction in adhesion. Such properties were attributable to the combined effects of reduced hydrophobicity, thicker and stable oxide films, and the presence of laser-induced textures. Tao Wang et al. produced micro-textures on end faces of two-phase mechanical face seals by using laser surface texturing [17]. They found that the textures with suitable parameters could attain a higher speed in comparison with the seal with a plain end face. Etsion I. et al. investigated the effects of partially laser surface textured piston rings on the fuel consumption and exhaust gas composition of a compression-ignition IC engine [18]. It was found that t the fuel consumption of the partial LST piston rings decreased by 4%. Julius Caesar Puoza et al. fabricated micro-dimples on the surface of the cylinder bore by Nd:YAG laser texturing [19]. The results showed that the cylinder bore with surface textures could effectively decrease the reverse drag power and torque. The fuel consumption was also reduced significantly in comparison with the standard one. Karam Kang researched the effects of surface textures on the punch in the Aluminum can manufacturing process [20]. The micro-textured punches with Ra in the range of 0.15–0.3 μm were preferred over polished and grounded punches to obtain fine surface roughness of the can body sheet. Tatsuhiko Aizawa et al. investigated the Engineering durability of surface texture by exposure testing to air at the atmospheric condition [21]. The testing results showed that modification of the AISI304 surface had sufficient stability for its long-term usage in the air. Georg Schnell et al. created micro-textures on the half-bearing shells of the journal bearings to research the wear mechanism [22].The findings showed that the journal bearings with micro-textures formed a thicker lubricant film than the untextured journal bearings. Jian Zhan et al. manufactured dimples on the cylinder wall to investigate the wear mechanism by using a cylinder liner-piston ring wear tester [23]. The results showed that the distribution angle of the dimples had a significant effect on the tribological characteristics of the cylinder liner-piston ring system. The wear resistance of the system was effectively improved when the dimple distribution angle was 60°. Xingyu Liang et al. studied the effect of partial laser surface texturing on piston rings by simulation and experiment investigation [24]. The results of the study indicated that the micro-dimple textures on both sides of the ring surface can improve the friction coefficient. Kafayat Eniola Hazzan et al. investigated the influence of the laser parameters and the current limitations of laser processing [25]. Laser parameters could affect ect heat-affected zone on the surface of the specimen. The heat-affected zone was related to the surface finish. They found the optimized multi-pass scanning speeds could deliver sufficient energy to process textures to the required depth and profile with minimal defects. Kairui Zheng et al. investigated the effects of micro-textured tools on cutting performances [26]. The results showed that the cutting force was effectively reduced by manufacturing suitable micro-textures on the surface of the cutting tool. Mourier et al. manufactured micro-cavities by laser surface texturing and carried out EHL tests with a tribometer [27]. The results showed that the micro-cavities, whose depth was 300 nm, could get an increase in the thickness of the lubricant film. Shunchu Liu et al. investigated the effects of laser surface textures and lubrication with graphene on the tribological and dynamical performance of non-conformal sliding contacts [28]. The results showed that laser surface textures have a more significant effect on the reduction of frictional vibrations and noise generated from sliding contacts, and laser textures enhanced the frictional reduction performance of lubrication. Zhaoqiang Wang et al. fabricated three kinds of micro-textures on the surface of the valve plates to investigate the effects of textures with different parameters on the tribological characteristics [29]. The experimental results showed that surface textures had significant effects on pressure, load-carrying capacity, and elastic deformation. The square textures were the preferable shape, and the tribological characteristics were improved when the depths of textures were from 20 μm to 50 μm. Akshay Gaikwad et al. investigated the effects of laser texturing on the tribological properties of Ti6Al4V in contact with a ceramic ball [30]. Results showed that wear and friction were reduced for all the textured samples as compared to an untextured surface. Chen Li et al. fabricated surface micro-textures on the electrosurgical blades by the long-pulse fiber laser [31]. The results showed that the electrosurgical blades with surface micro-textures exhibited good performances of adhesion and anti-friction, which minimized the potential danger for the patients. Caraguay et al. created micro-textures on the AISI-A30 carbon steel to study the adhesion strength by using a pull-off test and a shaft load blister test [32]. The results showed that the textured area had a significant effect on the adhesion mechanism of the carbon steel. Tooth plates are the key components of the oil drilling wellhead machinery, which are commonly made of 42CrMo steel. During the operation of the oil drilling wellhead machinery, tooth plates are prone to wear under high pressure. They need to be replaced frequently, which would reduce production efficiency. In this paper, how to reduce wear has been a vital problem. A model of the micro-textured surface friction pairs was established and simulated by the finite element analysis software. Nd: YAG laser was used to fabricate three types of textures on the surface of 42CrMo alloy steel, which were micro-dimples, micro-grooves, and reticular grooves. Then the dry friction experiments were carried out to analyze the influence of surface textures on the wear resistance of 42CrMo steel surface.

2. Finite Element Simulation

2.1. A Model of Friction Pairs

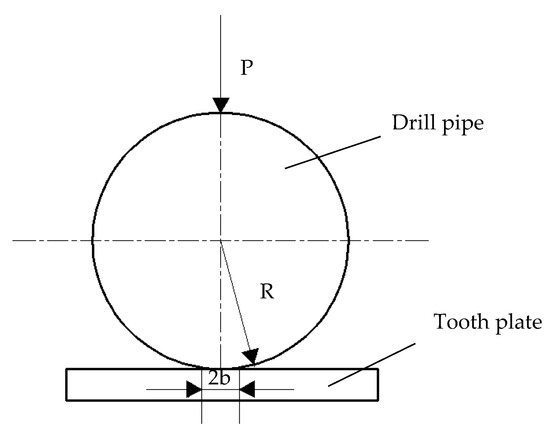

During the operation of the wellhead machinery, the motion pairs consisted of the tooth plate and the drill pipe, which contacted each other and produced relative motion under the external load. Therefore, the friction contact between the tooth plate and the drill pipe could be considered linear sliding friction pairs. Figure 1 shows the schematic diagram of the tooth plate and the drill pipe. It can be seen from Figure 1 that the drill pipe made contact with the tooth plate under load conditions. The load applied on the drill pipe is P. The radius of the drill pipe is R. Elastic moduli of the friction pairs are E1 and E2, respectively. Their Poisson ratios are ε1 and ε2. E′ is the equivalent elastic modulus. b is the half-width of the contact area.

Figure 1.

Schematic diagram of the contact between the tooth plate and the drill pipe.

According to the Hertz contact theory, the half-width of the contact area can be calculated as follows.

The equivalent elastic modulus can be calculated as follows.

Actually, there are eight tooth plates of the same size (100 mm × 40 mm × 20 mm) in the oil drilling wellhead machinery. The drill pipe and the tooth plate are both made of 42CrMo steel. The elastic modulus and the Poisson ratio are 210 GPa and 0.3, respectively. The diameter of the drill pipe is in the range of 88 to 160 mm, and the torque value is in the range of 81,350 to 108,465 N·m. The load is in the range of 508,437.5 to 1,232,556.8 N. It can be calculated that the contact half width of a single tooth plate is in the range of 0.66 to 1.01 mm.

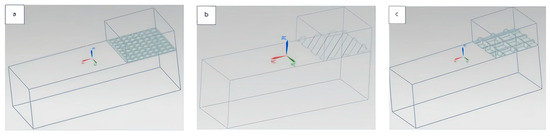

The friction pairs were composed of upper and lower sliding blocks. There are three kinds of micro-textures on the friction surface of the upper sliding blocks. The surface textures included micro-dimples, micro-grooves, and reticular grooves. The models of friction pairs are shown in Figure 2. The sizes of the upper sliding block and the lower sliding block were 10 mm × 10 mm × 5 mm and 30 mm × 10 mm × 10 mm, respectively.

Figure 2.

Friction pairs models. (a) Upper block with micro-dimples; (b) Upper block with micro-grooves; (c) Upper block with reticular grooves.

According to the calculation of the Hertz contact theory, the selective sizes of micro-dimples are a diameter of 0.8 mm, the dimple spacing is 1.2 mm, and the area occupancy of dimples is 34.8%. In order to obtain the same area occupancy of textures, the width of the single micro-groove is set at 0.75 mm. The inclination angle is 45°, and the spacing is 2.3 mm. The width of the reticular groove is 0.75 mm, the angle of the reticular groove is 90°, and the spacing is 3.5 mm. The upper and lower sliding blocks used in this experiment are 42CrMo alloy steel. The material properties are shown in Table 1.

Table 1.

Material properties of 42CrMo.

For the model of friction pairs firstly, the model of the friction pairs was meshed. The mesh units of the upper block specimen and the lower block specimen were set as 0.25 mm and 0.4 mm, respectively. Secondly, initial boundary conditions were set. The positions of all mesh nodes on the bottom of the lower sliding block remained unchanged, and displacement constraints were imposed in X and Y directions. Then load conditions were applied for all mesh units on the upper surface of the upper sliding blocks, and a load of 3 MPa was applied on the surface. All the grid nodes on the lower surface of the upper sliding blocks moved 20 mm along the Y direction. Finally, the contact equivalent stress of the surfaces with different textures was obtained.

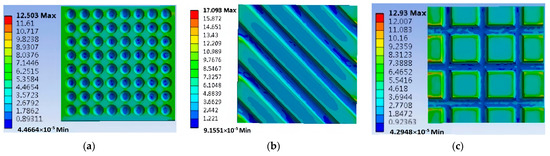

2.2. Simulation Results

According to the load conditions of the sliding friction pairs of the above three different types of micro-textured surfaces, the equivalent contact stresses are obtained, as shown in Figure 3. It can be seen from Figure 3 that stress concentration zones are focused on the left and right sides of the three types of micro-textured surfaces. In addition, the equivalent stresses of the left sides are larger than that of the right sides, which indicates that the left sides of the textured surfaces are more worn than the right sides along the sliding direction. The maximum equivalent stress of the three micro-textured surfaces is 10.275 MPa, 17.093 MPa, and 12.885 MPa, respectively. The stress gradient on the surface of the micro-groove textures is the largest compared with other textures. The simulation results show that the wear resistance of the micro-dimples is better than that of the micro-grooves and the reticular grooves.

Figure 3.

Equivalent stress cloud diagram of sliding frictional contact with different textured surfaces. (a) micro-dimples; (b) micro-grooves; (c) reticular grooves.

3. Experimental Procedure

3.1. Preparation of Friction Specimen

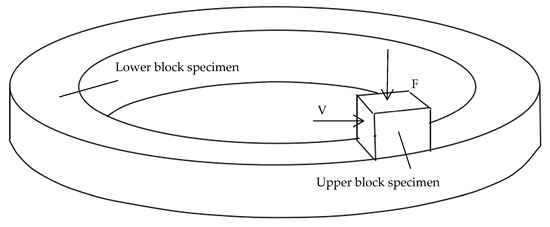

The dry friction test was conducted by the wear testing machine (MMH-5UMT-2, CETR, San Jose, CA, USA). The mechanism of surface contact friction is shown in Figure 4. The lower surface of the upper block specimen contacted the upper surface of the lower block specimen and slid counterclockwise. The upper specimen is a block (20 mm × 20 mm × 10 mm). The lower specimen is a fixed annular block (inner diameter 340 mm, outer diameter 380 mm) with a surface roughness of Ra12.5 μm.

Figure 4.

Schematic diagram of the friction motion of ring-block surface contact.

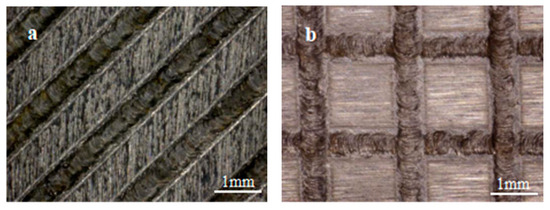

The Nd: YAG laser was used to fabricate the textures at the average laser power of 200 W and a frequency of 5 Hz (DPL20-532, CHUTIAN, Wuhan, China). According to the sizes of the above simulation design, three kinds of micro-structures, which included micro-dimples, micro-grooves, and reticular grooves, were prepared on the friction surface of the upper block specimen. Furthermore, two groups of textured specimens with spacing of 1.5 mm and 1.8 mm were prepared for the micro-dimples. Micro-dimples were fabricated by using the fixed-focusing processing method. The micro-grooves and the reticular grooves were created by utilizing the laser scanning processing method. The work platform was moved during the laser texturing process. Table 2 shows the laser texturing parameters. Due to the existence of molten metal sputtering on the surface of the micro-structure fabricated by laser, the specimen was repeatedly polished with sandpapers (200#–2000#) of different grain sizes after laser texturing. Then, the particles produced from the wear were removed by an ultrasonic cleaning machine (DA-968, DADI, Nanning China). Figure 5 shows the surface morphology of micro-grooves and reticular grooves observed under a three-dimensional microscope with a super depth of field(VHX-2000, Hitachi, Tokyo, Japan). Figure 6 shows the surface morphology of three kinds of micro-dimples with different spacing observed with the scanning electron microscopy (S-3400N, Hitachi, Japan).

Table 2.

Laser texturing parameters.

Figure 5.

Laser textured surface: (a) Micro-grooves with a pitch of 2.3 mm; (b) Reticular grooves with a pitch of 3.5 mm.

Figure 6.

Micro-dimples with different pitch: (a) L = 1.8 mm; (b) L = 1.5 mm; (c) L = 1.2 mm.

3.2. Friction Tests

In the dry friction test, the upper block specimen and the lower block specimen were in dislocation contact. After the friction test, the laser-textured surface of the upper block specimen had an obvious boundary that could distinguish the worn area from the non-worn area. The friction test was designed properly. The initial height of the unworn zone can obtain a uniform reference when the thickness of the worn layer is measured. The load of friction test was set at 50 N, and the rotation speed of the upper block specimen was set at 35 r/min. Each test was repeated 3 times, and each time was 15 min.

For the friction test results, the wear layer thickness can be obtained by observing the three-dimensional morphology of the laser-textured surface of the upper block specimen with an ultra-depth of field three-dimensional microscope. High precision electronic balance was used to weigh the upper block specimen before and after the friction test, and the wear amount could be obtained. The effect of different micro-textures on wear resistance was explored by observing the morphology of the laser-textured surface.

4. Results and Analysis

4.1. Wear Resistance Comparison of Different Laser-Textured Surfaces

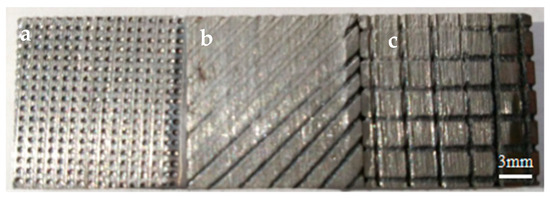

Under the condition of the same textured area occupancy, the wear resistance of three types of laser micro-textured surfaces such as micro-dimples, micro-grooves, and reticular grooves, were compared. Figure 7 is the surface topography of three different laser-textured specimens after the friction test.

Figure 7.

Morphology of different textured surfaces after friction tests. (a) Specimen with micro-dimples; (b) Specimen with micro-grooves; (c) Specimen with reticular grooves.

It can be seen from Figure 7 that the wear of the specimens with the micro-grooves and the reticular grooves are severer than the specimen with micro-dimples. As can be seen from the simulation results above, the equivalent stresses of the micro-grooves and the reticular are also larger than that of the micro-dimples. The experimental results are consistent with the simulation results.

In addition, three types of textured surfaces show the same wear characteristics. It can be seen the wear of the front end is more worn than the rear end in the direction of friction sliding. As can be seen from the simulation results above, the equivalent stress of the front end is larger than that of the rear end. Thus, the wear mechanism is the same for the different micro-textures. And the wear mechanism is abrasive wear. Under the same condition of area occupancy, the micro-dimples improve the tribological performance significantly in comparison with the other textures.

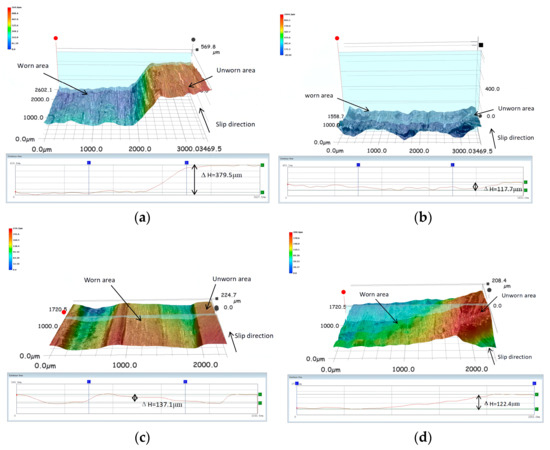

Figure 8 is the three-dimensional surface topography of the untextured specimen surface and three kinds of laser micro-textured surfaces. It can be seen from Figure 8 that the different kinds of specimen surfaces have clear boundaries between the worn areas and the unworn areas. In Figure 8b–d, the worn areas and unworn areas of specimens all have micro-textures. The height differences between the unworn zone and the worn zone in the figure are used to evaluate the thickness of each wearing layer.

Figure 8.

3D morphology of upper work-pieces surface after the friction test: (a) untextured surface; (b) micro-dimples surface; (c) micro-grooves surface; (d) reticular grooves surface.

It can be seen from Figure 8 that the thickness of the wearing layer on the surface of the untextured specimen is the largest, which is 379.5 μm; The wearing layer thickness of three laser-textured surfaces are 117.7 μm, 137.1 μm, and 122.4 μm respectively. Although the bearing areas of the textured surfaces are reduced in comparison with the untextured surface, it can be seen in Figure 8 that the wear of three textured surfaces is less than that of the untextured surface. It shows that the laser micro-textured surface can effectively improve the wear resistance of 42CrMo steel. Under the condition of the same textured area occupancy, micro-dimples are the most reasonable micro-textures for improving the friction properties of 42CrMo steel. The simulation results show that the stress on the surface of the micro-dimple textures is smaller than other surface textures. The wearing layer thickness of the micro-dimple textures is 117.7 μm, which is the lowest in comparison with others. Thus, the wearing layer thicknesses of the friction experiments are consistent with the stress gradients of the simulation.

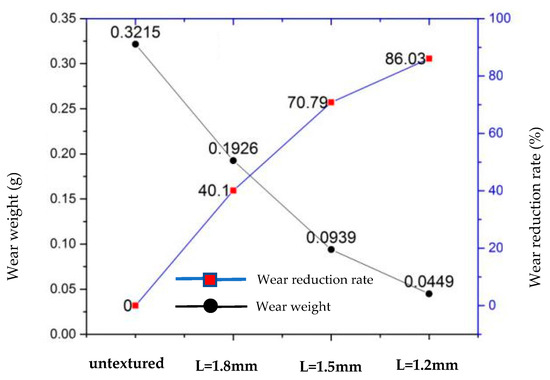

4.2. Wear Resistance Comparison of Laser Textured Surfaces with Different Spacing of Micro-Dimples

The effect of dimple spacing on the wear resistance of textured surfaces is compared and analyzed under the condition of a certain pit diameter. The distances of the three groups are 1.2 mm, 1.5 mm, and 1.8 mm respectively. The average value of the mass difference of the block specimen before and after three friction tests is taken as the friction and wear amount. Figure 9 shows the wear weight and wear reduction rate with untextured and textured surfaces. Compared with the untextured surface, the wear of the textured surface with 1.2 mm spacing is reduced by more than 80%.

Figure 9.

Comparison of wear weight for upper blocks surface friction.

4.3. Wear Mechanism Analysis of Laser-Textured Surface with Micro-Dimples

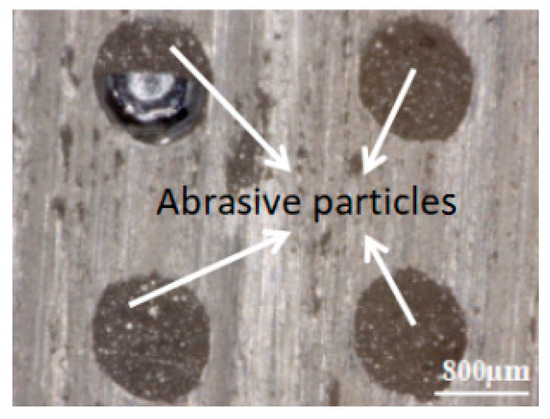

Figure 10 shows the textured specimen with micro-dimples (the diameter of the dimple is 0.8 mm, the spacing is 1.8 mm) after the friction test for 5 min. After the friction test, the specimen was cleaned by ultrasonic cleaning machinery, and there were obvious particles in the dimples, which indicates that a large number of abrasive particles were produced in the process of friction tests. These abrasive particles play an important role in the wear of the specimen. The micro-dimples have the ability to trap debris, which decreases the effect of abrasive wear and improves the tribological properties at the interface.

Figure 10.

Surface morphology of the textured block specimen with micro-dimples after friction experiment.

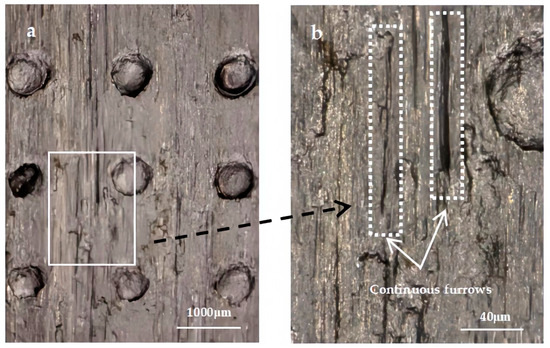

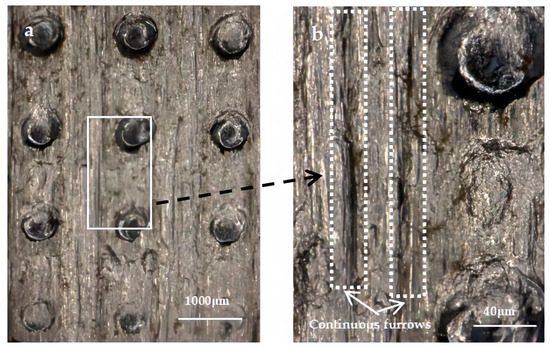

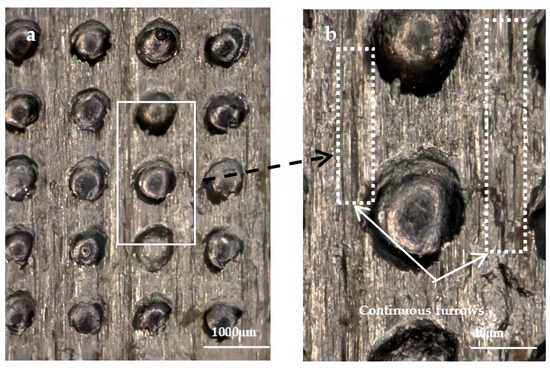

Figure 11, Figure 12 and Figure 13 show the morphology of the specimen after the friction test when the dimple spacings are 1.8 mm, 1.5 mm, and 1.2 mm, respectively. By comparison, it can be found that the surface wear of the three laser-textured specimens with different spacing has similar characteristics. In the vertical direction, which is the friction direction of the specimen, obvious continuous furrows appear in the untextured area among adjacent rows of dimples. In the horizontal direction, there is no furrow among adjacent rows of dimples. It indicates that abrasive wear occurred on the surface of the specimens during the dry friction test, and obvious furrows were formed in the untextured region. While in the textured region, the continuous formation of furrows is prevented by the dimples distributed in the array.

Figure 11.

Wear morphology of micro-dimples surface with a spacing of 1.8 mm. (a) the overall wear morphology; (b) the local wear morphology.

Figure 12.

Wear morphology of micro-dimples surface with a spacing of 1.5 mm. (a) the overall wear morphology; (b) the local wear morphology.

Figure 13.

Wear morphology of micro-dimples surface with a spacing of 1.2 mm. (a) the overall wear morphology; (b) the local wear morphology.

By further comparing the furrow length and depth of the three surfaces, it can be found that the furrow length and depth of the surface with the largest texture area occupancy are smaller than those of the other surfaces, which indicates that with the decrease of the dimple spacing. The abrasive wear on the surface of the specimen is reduced, which is consistent with the test results of the front wear. Based on the above analysis, it can be concluded that the wear resistance mechanism of laser textured surface is that the dimples prevent the continuous formation of furrows, and the effect of micro-dimples increases with the increase of the density of dimples.

5. Conclusions

In this paper, the wear resistance of 42CrMo steel surface with laser micro-texture has been studied. On the basis of the results from the research, the following conclusion can be drawn:

- (1)

- Under the condition of surface contact dry friction, the front end of the textured surface is more worn than the back end along the sliding direction. The wear resistance of laser-textured surfaces with micro-dimples is better than that of micro-grooves and reticular grooves.

- (2)

- Compared with the untextured surface, the wear loss of the textured surface with 1.2 mm spacing and 34.8% area occupancy is reduced by more than 80%.

- (3)

- The main reason for the improvement of the wear resistance of the laser-textured surface is that the micro-dimples can store the abrasive particles and effectively prevent the continuous formation of furrows.

Author Contributions

Conceptualization, H.Z.; methodology, H.Z. and X.P.; investigation, H.Z. and X.P.; resources, X.J.; data curation, X.P.; writing—original draft preparation, X.P.; writing—review and editing, H.Z.; project administration, H.Z.; funding acquisition, H.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China under Grant No. 51205212, Natural Science Fund of Jiangsu Province of China under Grant No. BK2012233, Nantong City Applied Basic Research Project (JC22022074) and Instruments and Equipment Open Fund of Nantong University (KFJN2235).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Schille, J.; Schneider, L.; Mauersberger, S.; Szokup, S.; Hohn, S.; Potschke, J.; Reir, F.; Leidich, E.; Lischner, U. High-Rate Laser Surface Texturing for Advanced Tribological Functionality. Lubricants 2020, 8, 33. [Google Scholar] [CrossRef]

- Agrawal, N.; Sharma, S.C. Micro-grooved hybrid spherical thrust bearing with Non-Newtonian lubricant behaviour. Int. J. Mech. Sci. 2023, 240, 107940. [Google Scholar]

- Tatsuya, S.; Toshiyuki, E. Development of a cutting tool with a nano/micro-textured surface—Improvement of anti-adhesive effect by considering the texture patterns. Precis. Eng. 2009, 33, 425–429. [Google Scholar]

- Tatsuya, S.; Toshiyuki, E. Improving anti-adhesive properties of cutting tool surfaces by nano-/micro-textures. Precis. Eng. 2012, 36, 229–237. [Google Scholar]

- Ryk, G.; Etsion, I. Testing piston rings with partial laser surface texturing for friction reduction. Wear 2006, 261, 792–796. [Google Scholar] [CrossRef]

- Ezhilmaran, V.; Vasa, N.J.; Vijayaraghavan, L. Investigation on generation of laser assisted dimples on piston ring surface and influence of dimple parameters on friction. Surf. Coat. Technol. 2018, 335, 314–326. [Google Scholar]

- Yu, X.Q.; He, S.; Cai, R.L. Frictional characteristics of mechanical seals with a laser-textured seal face. J. Mater. Process. Technol. 2002, 129, 463–466. [Google Scholar]

- Chaudhury, P.; Samantaray, S. Role of Carbon Nano Tubes in Surface Modification on Electrical Discharge Machining—A Review. Mater. Today Proc. 2017, 4, 4079–4088. [Google Scholar]

- Zhou, W.; Tang, J.; Shao, W. Modelling of surface texture and parameters matching considering the interaction of multiple rotation cycles in ultrasonic assisted grinding. Int. J. Mech. Sci. 2020, 166, 105246. [Google Scholar]

- Aurich, J.C.; Egnmann, J.; Schueler, G.M. Micro grinding tool for manufacture of complex structures in brittle materials. CIRP Ann.—Manuf. Technol. 2009, 58, 311–314. [Google Scholar]

- Mao, B.; Siddaiah, A.; Liao, Y.L.; Pradeep, L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar]

- Wang, M.Z.; Kang, W.; Yue, Z.Q.; Zhu, L.N.; She, D.S.; Wang, C.B. Effects of combined treatment of plasma nitriding and laser surface texturing on vacuum tribological behavior of titanium alloy. Mater. Res. Express 2019, 6, 066511. [Google Scholar]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372–373, 21–41. [Google Scholar]

- Duan, R.; Wang, G.; Xing, Y.Q. Investigation of novel multiscale textures for the enhancement of the cutting performance of Al2O3/TiC ceramic cutting tools. Ceram. Int. 2022, 48, 3554–3563. [Google Scholar] [CrossRef]

- Xing, Y.Q.; Deng, J.X.; Wang, X.S.; Meng, R. Effect of laser surface textures combined with multi-solid lubricant coatings on the tribological properties of Al2O3/TiC ceramic. Wear 2015, 342–343, 1–12. [Google Scholar] [CrossRef]

- Chan, C.W.; Carson, L.; Smith, G.C.; Morelli, A.; Lee, S. Enhancing the antibacterial performance of orthopaedic implant materials by fibre laser surface engineering. Appl. Surf. Sci. 2017, 404, 67–81. [Google Scholar] [CrossRef]

- Wang, T.; Huang, W.F.; Liu, X.F.; Li, Y.J.; Wang, Y.M. Experimental study of two-phase mechanical face Seals with lasersurface texturing. Tribol. Int. 2014, 72, 90–97. [Google Scholar] [CrossRef]

- Etsion, I.; Sher, E. Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 2009, 42, 542–547. [Google Scholar] [CrossRef]

- Puoza, J.C.; Zhang, T.Y.; Uba, F.; Yakubu, K.; Awudu, I. Optimization of post-treatment honing parameters of laser textured enginecylinder bore and engine performance. Int. J. Adv. Manuf. Technol. 2023, in press. [Google Scholar]

- Kang, K. Impact of die wear and punch surface textures on aluminum can wall. Wear 2009, 266, 1044–1049. [Google Scholar] [CrossRef]

- Tatsuhiko, A.; Tadahiko, I.; Kenji, W. Femtosecond laser micro-/nano-texturing of stainless steels for surface property control. Micromachines 2019, 10, 512. [Google Scholar]

- Schnell, G.; Studemend, H.; Thomas, R.; Seits, H. Experimental investigations on the friction behavior of partiallyfemtosecond laser-textured journal bearing shells. Tribol. Int. 2023, 188, 108764. [Google Scholar] [CrossRef]

- Zhan, J.; Yang, M.J. Investigation on Dimples Distribution Angle in Laser Texturing of Cylinder–Piston Ring System. Tribol. Trans. 2012, 55, 693–697. [Google Scholar] [CrossRef]

- Liang, X.Y.; Wang, X.H.; Zhang, Z.J. Simulation and experiment investigation on friction reduction by partial laser surface texturing on piston ring. Tribol. Trans. 2019, 11, 109–113. [Google Scholar]

- Hazzan, K.E.; Pacella, M.; See, T.L. Laser processing of hard and ultra-hard materials for micro-machining and surface engineering applications. Micromachines 2021, 12, 895. [Google Scholar] [CrossRef] [PubMed]

- Zheng, K.R.; Yang, F.Z.; Zhang, N. Study on the cutting performance of micro-textured tools on cutting Ti-6Al-4V Titanium alloy. Micromachines 2020, 11, 137. [Google Scholar] [CrossRef]

- Mourier, L.; Mazuyer, D.; Ninove, F.P.; Lubrecht, A.A. Lubrication mechanisms with laser-surface-textured surfaces in elastohydrodynamic regime. Eng. Tribol. 2010, 224, 697–711. [Google Scholar] [CrossRef]

- Liu, S.C.; Sai, Q.Y.; Wang, S.W. Effects of laser surface texturing and lubrication on the vibrational and tribological performance of sliding contact. Lubricants 2022, 10, 10. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Sun, L.T.; Han, B. Study on the thermohydrodynamic friction characteristics of surface-textured valve plate of axial piston pumps. Micromachines 2022, 13, 1891. [Google Scholar] [CrossRef]

- Gaikwad, A.; Vázquez-Martínez, J.M.; Salguero, J.; Iglesias, P. Tribological Properties of Ti6Al4V Titanium Textured Surfaces Created by Laser: Effect of Dimple Density. Lubricants 2022, 10, 138. [Google Scholar]

- Li, C.; Yang, Y.; Yang, L.J.; Zhen, S. Biomimetic Anti-Adhesive Surface Microstructures on Electrosurgical Blade Fabricated by Long-Pulse Laser Inspired by Pangolin Scales. Micromachines 2019, 10, 816. [Google Scholar] [CrossRef] [PubMed]

- Caraguay, S.J.; Pereira, T.S.; Cunha, A.; Pereira, M.; Xavier, F.A. The effect of laser surface textures on the adhesion strength and corrosion protection of organic coatings—Experimental assessment using the pull-off test and the shaft load blister test. Prog. Org. Coat. 2023, 180, 107558. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).