Slot Number Optimization for Motorcycle Traction Motor Considering Driving Duty Cycle

Abstract

1. Introduction

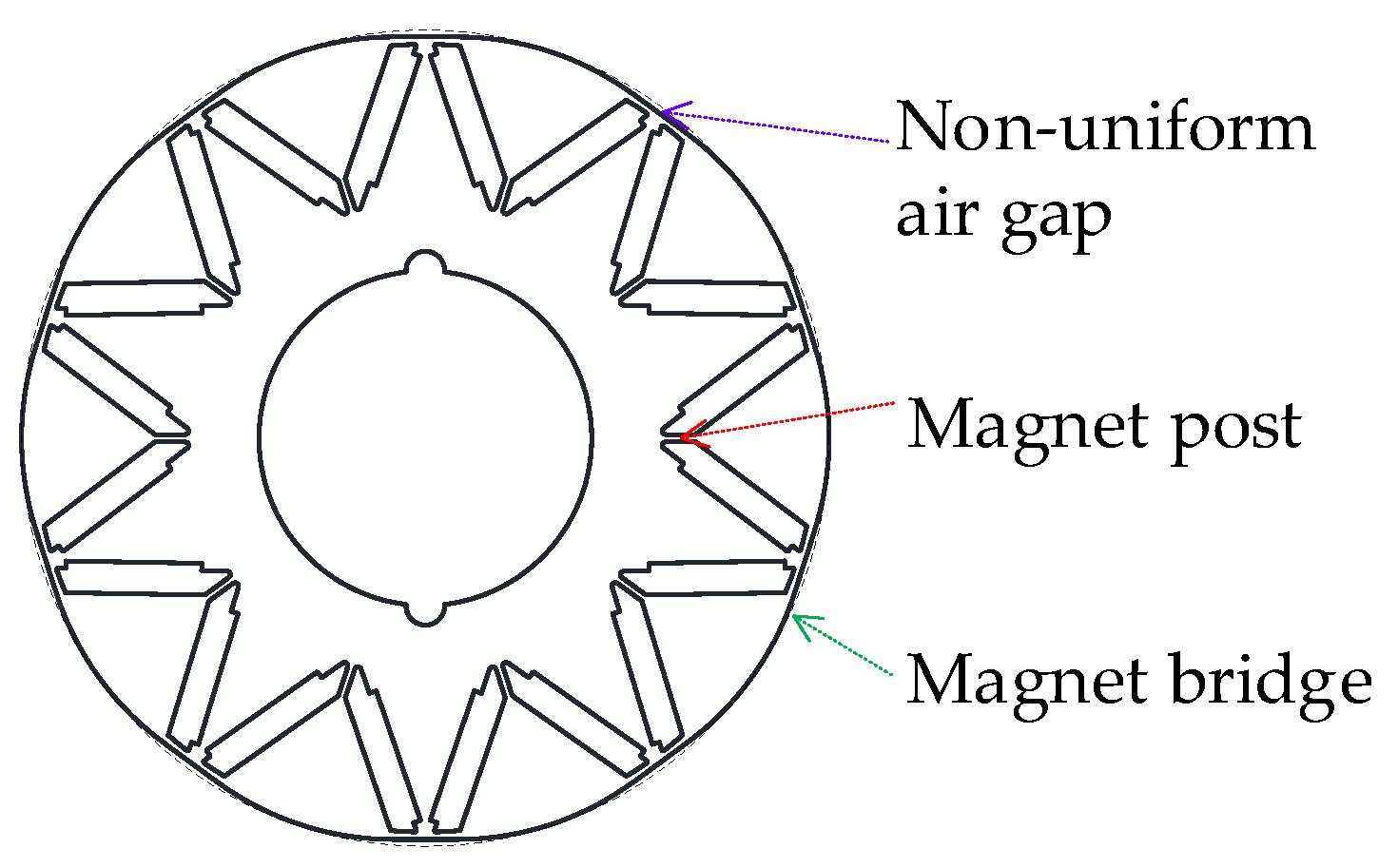

2. Machine Specification and Design Constraints

2.1. Specification of Drive Machine

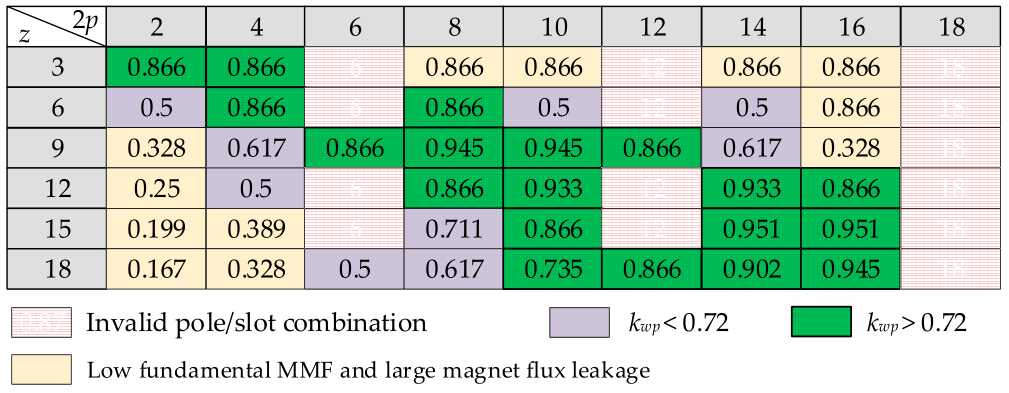

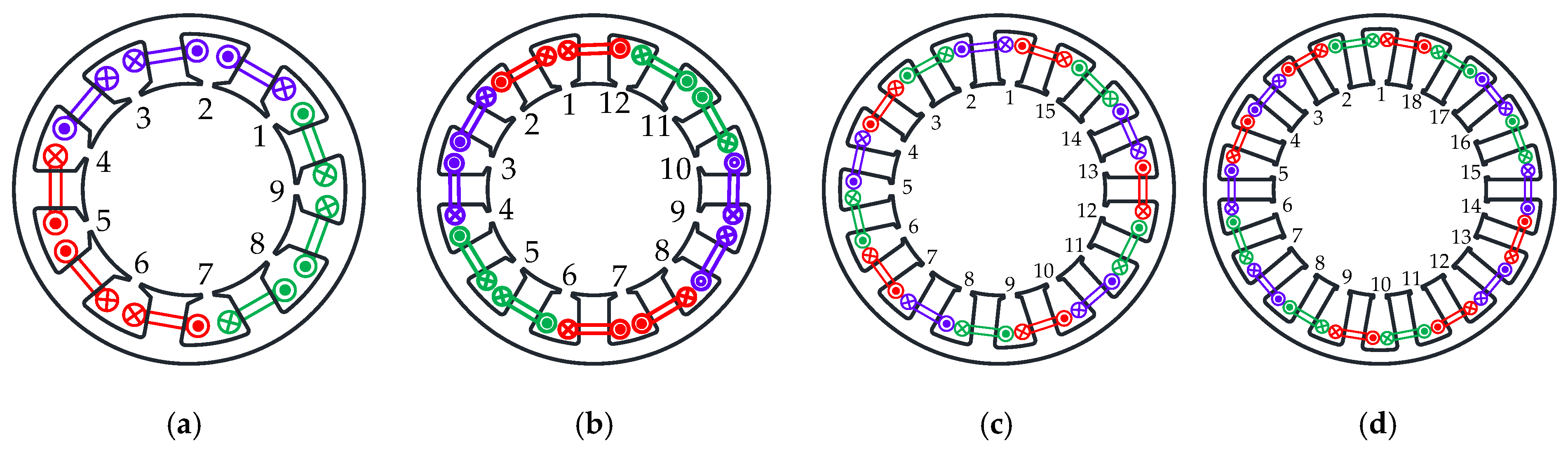

2.2. Design Space of the Slot Number

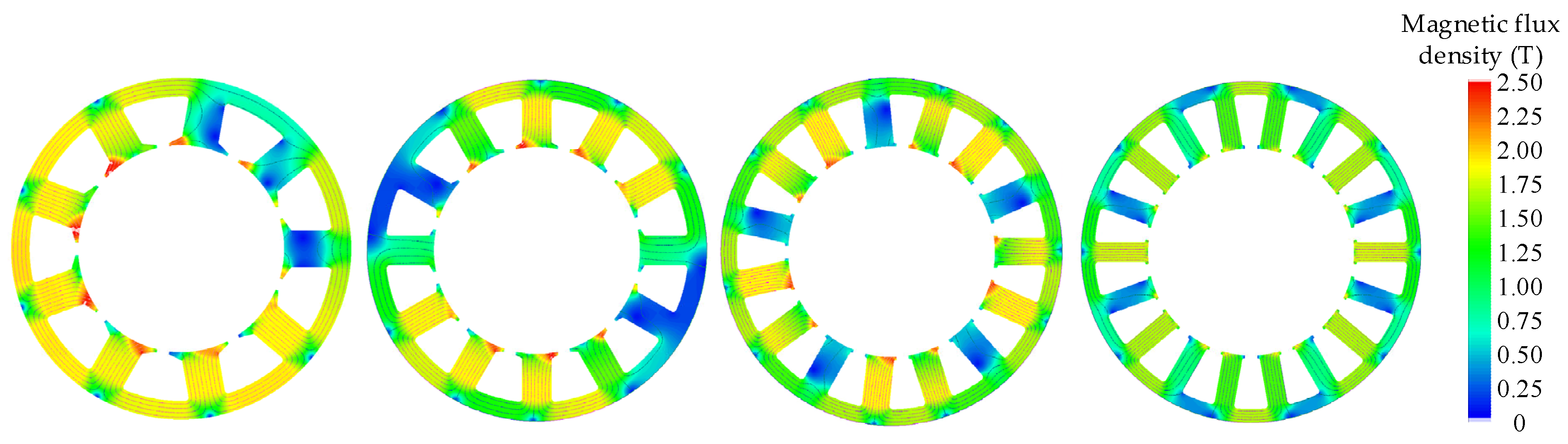

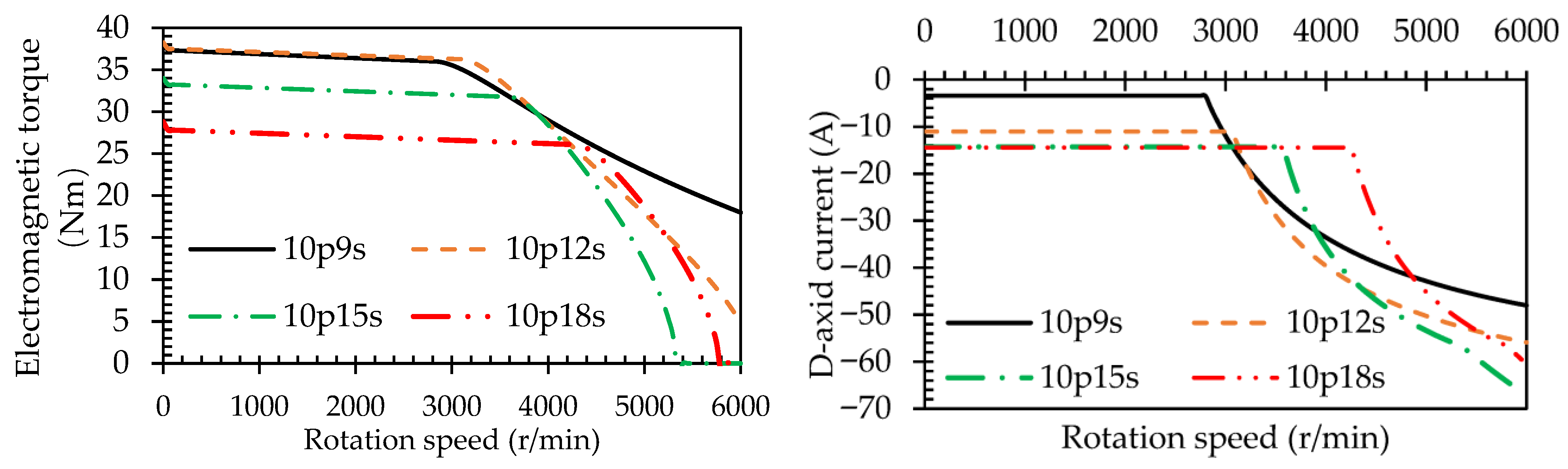

3. Torque Output and Flux-Weakening Capacity

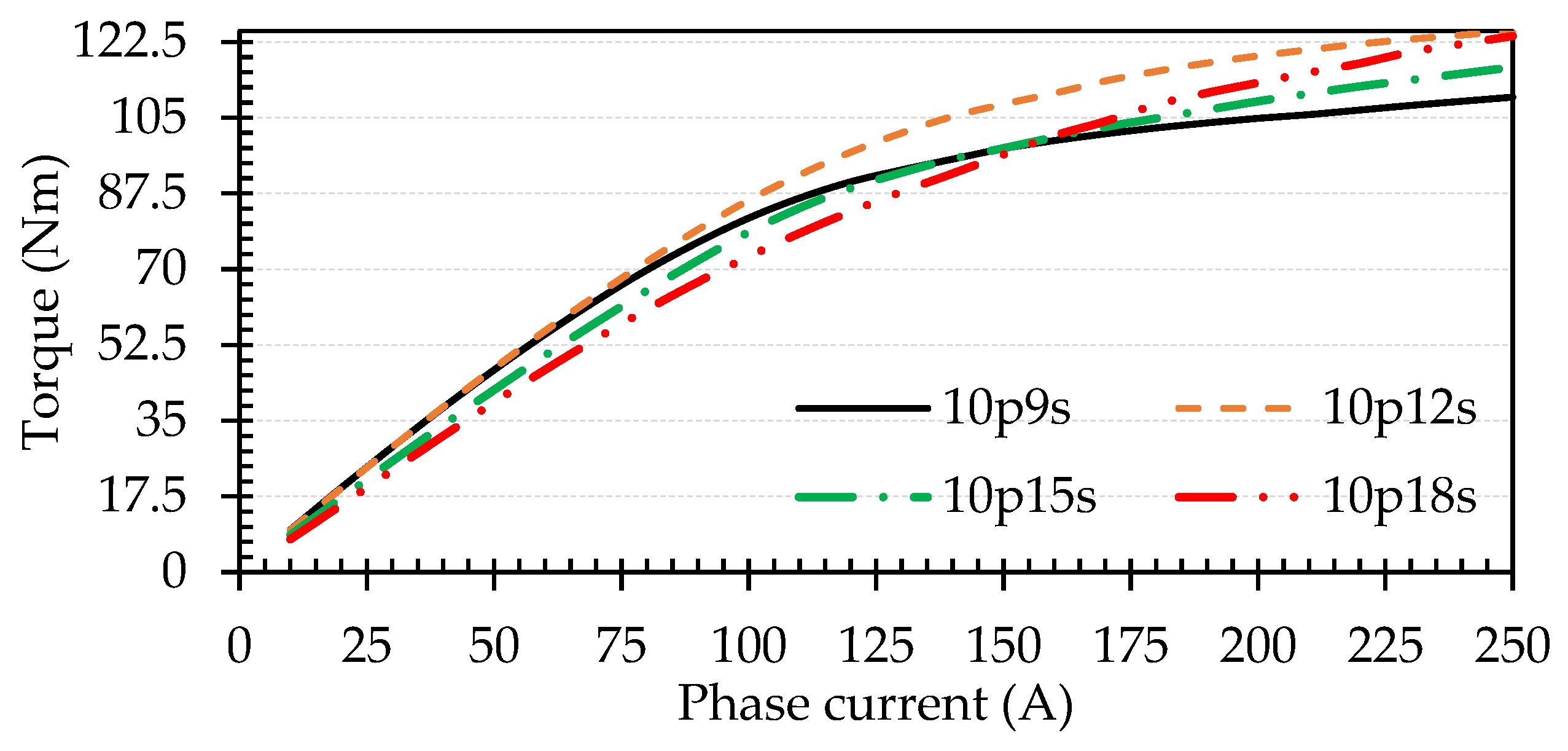

3.1. Torque Overloading Ability

3.2. Flux-Weakening Capacity

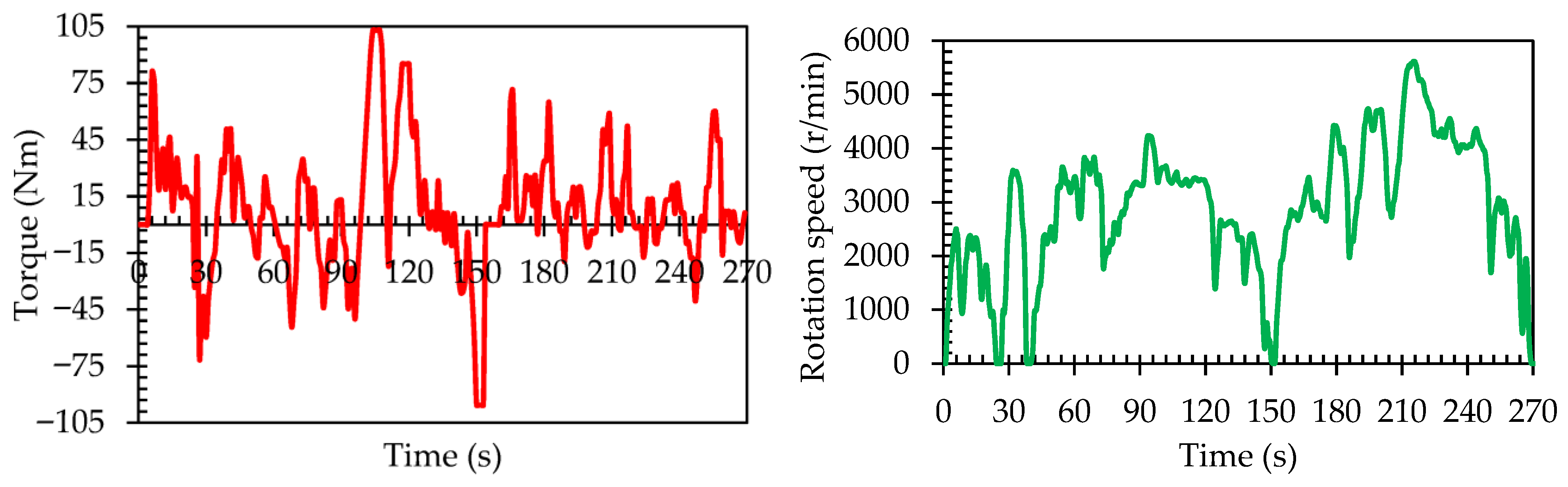

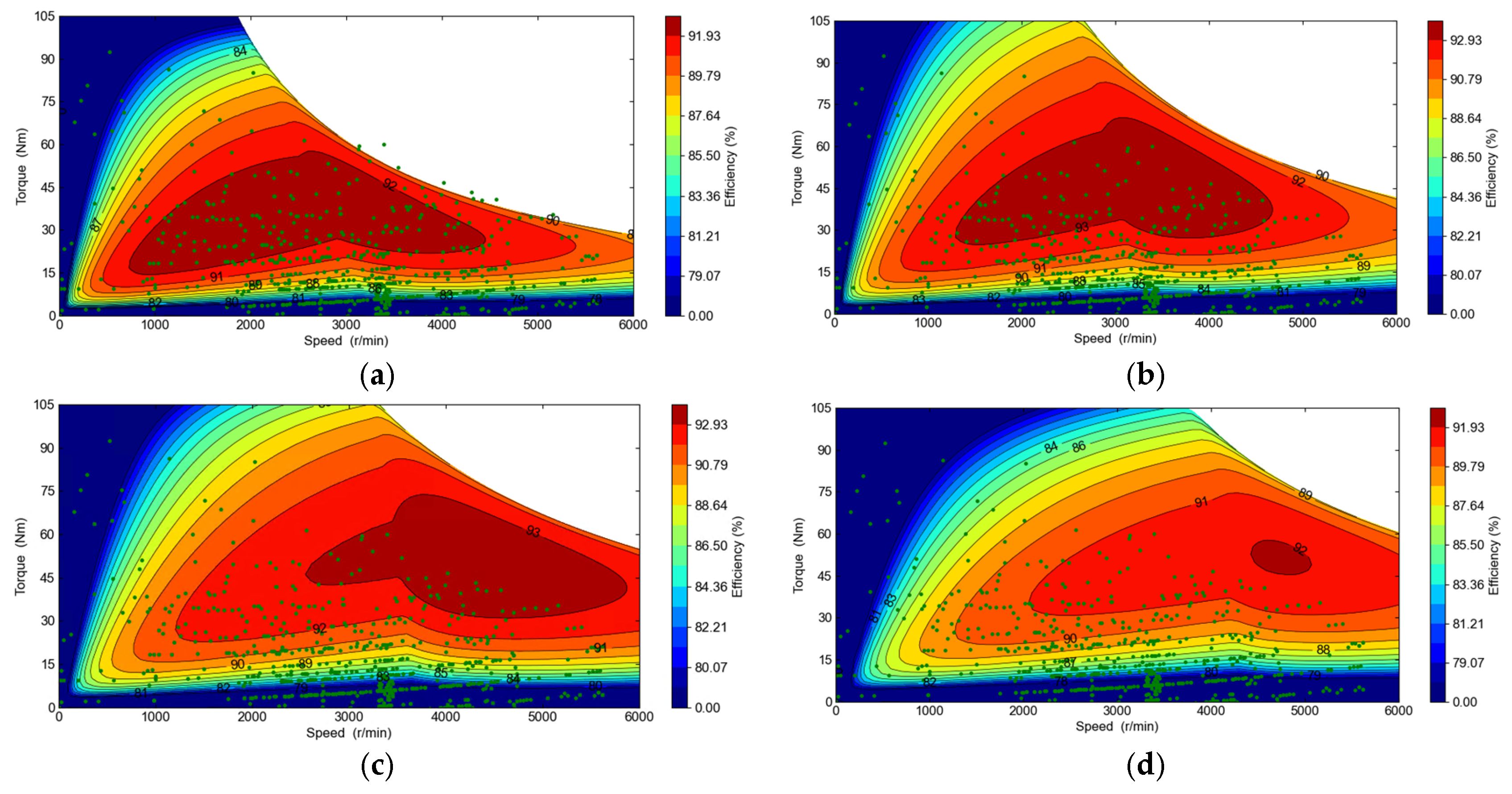

4. Driving Duty Cycle Analysis

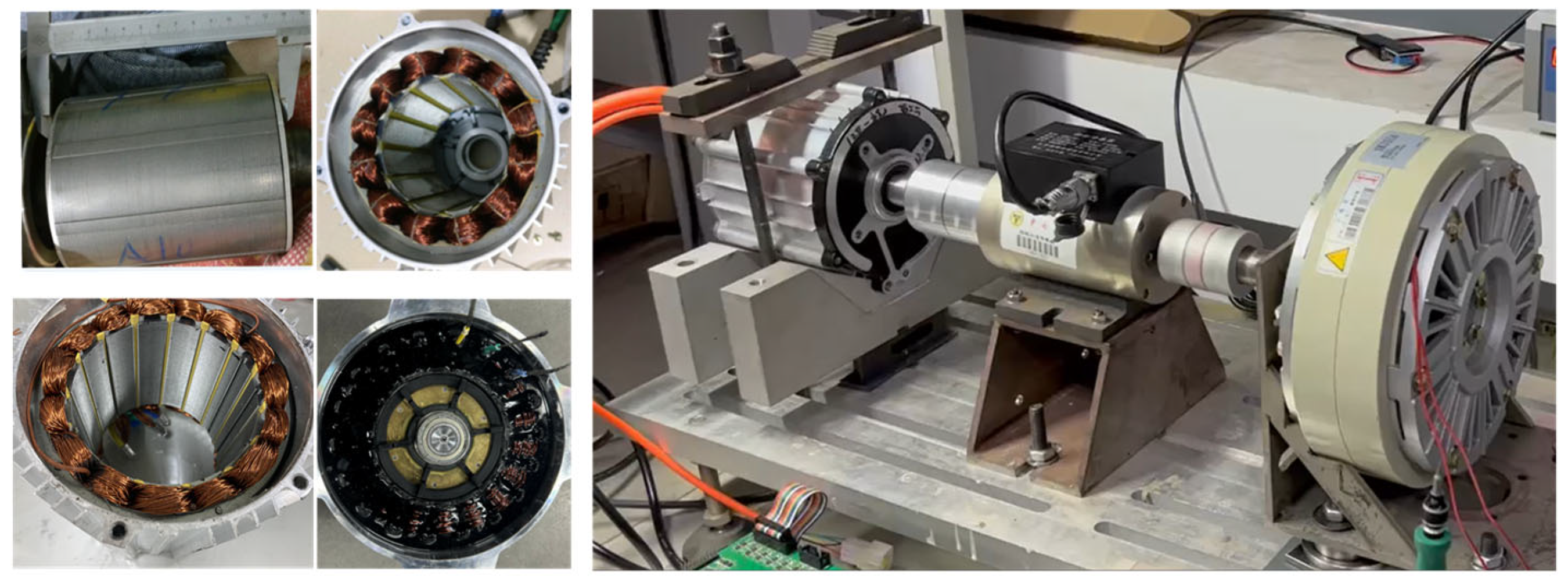

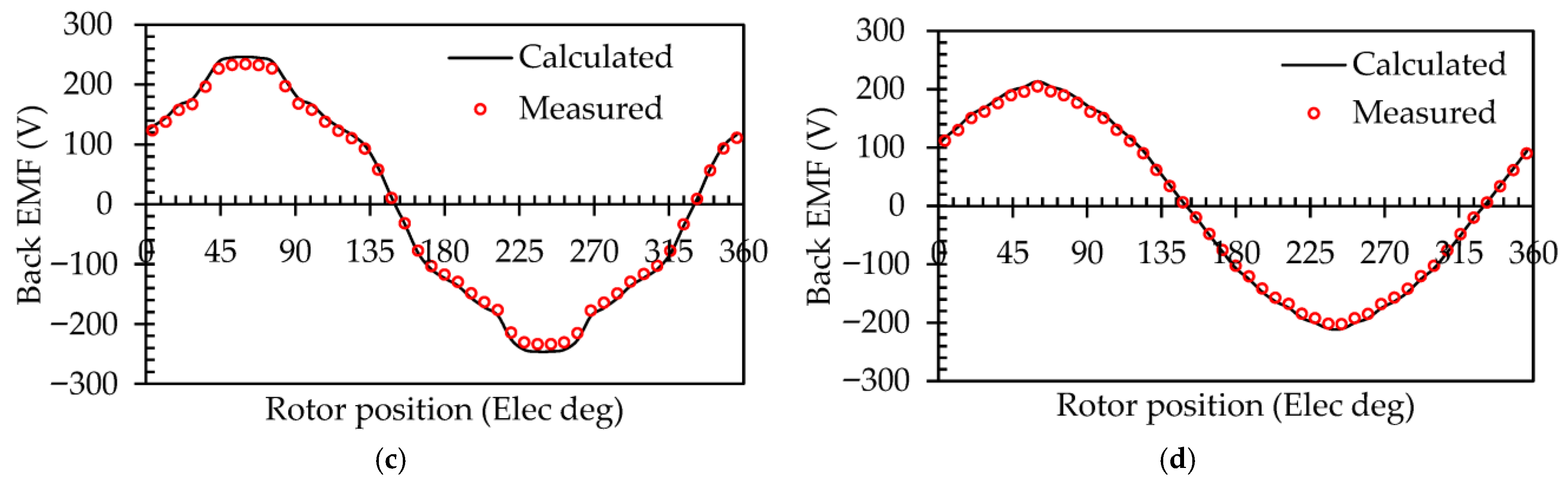

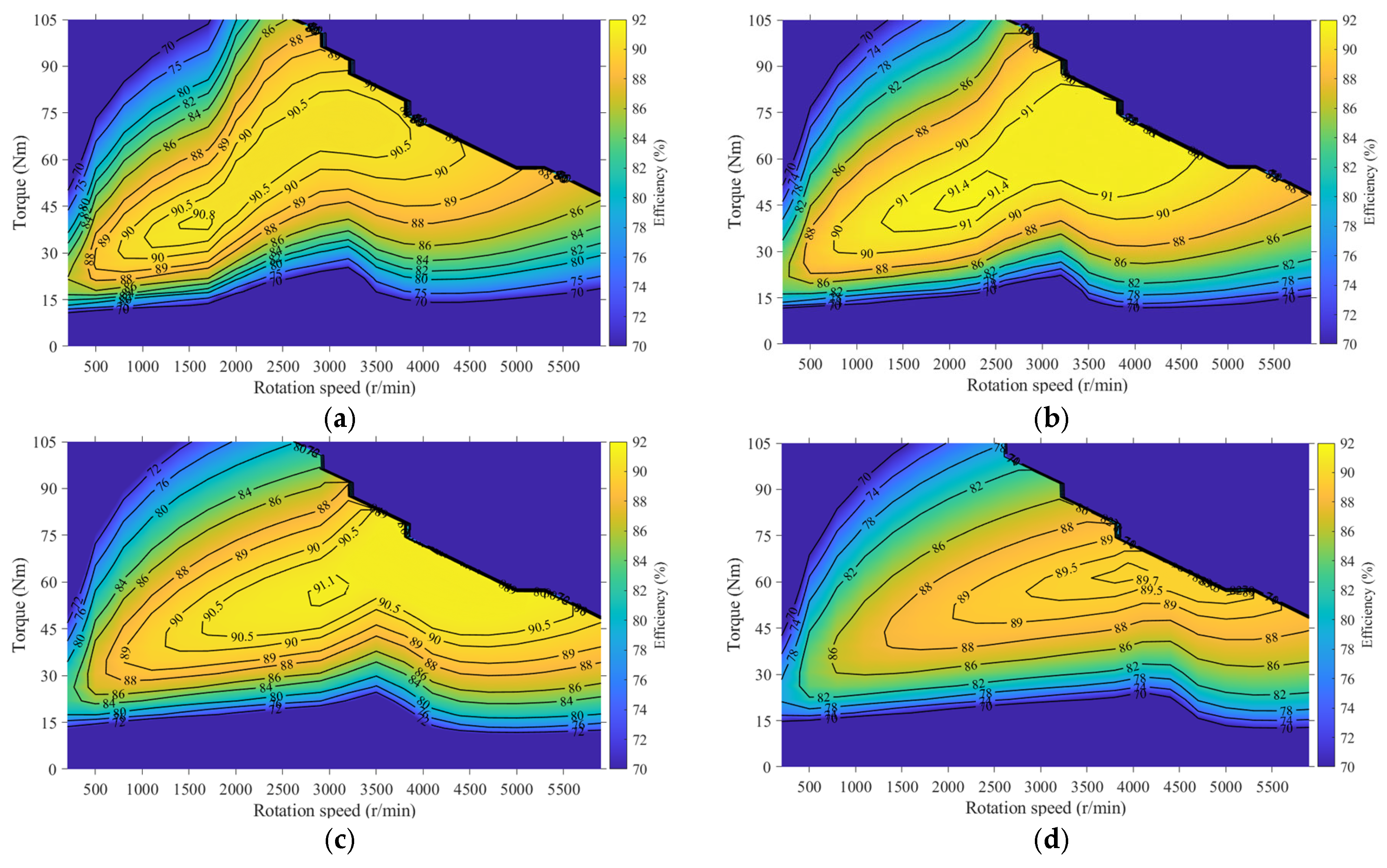

5. Prototyping and Experimental Validations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liang, D.; Zhu, Z.Q.; Li, H. High-Accuracy Lumped-Parameter Thermal Modeling for Fractional-Slot Concentrated-Winding PMSMs Under Short-Circuit Fault Conditions. IEEE Trans. Transp. Electrif. 2025, 11, 9022–9034. [Google Scholar] [CrossRef]

- Rudden, I.; Li, G.-J.; Zhu, Z.-Q.; Duke, A.; Clark, R. An Investigation into the Saliency Ratio of Fractional-Slot Concentrated-Winding Generators for Offshore Wind Power. Energies 2025, 18, 2057. [Google Scholar] [CrossRef]

- Xue, H.; Zhang, Z.; Liu, Y.; Gao, H.; Lin, Q.; Lu, C.; Hua, Y. Analysis of Lightweight Dual-Rotor Yokeless-Stator PMSM for Electrified Aircraft Propulsion Considering Thermal Benefits of Heat Pipes. IEEE Trans. Transp. Electrif. 2025, 11, 11030–11040. [Google Scholar] [CrossRef]

- Abdel-Wahed, A.T.; Ullah, Z.; Abdel-Khalik, A.S.; Hamad, M.S.; Ahmed, S.; Elmalhy, N.A. Design and Finite-Element-Based Optimization for a 12-Slot/10-Pole IPM Motor with Integrated Onboard Battery Charger for Electric Vehicle Applications. Machines 2023, 11, 534. [Google Scholar] [CrossRef]

- Wu, D.; Xu, J.; Lin, H. Research on High Thrust Force Characteristics with Proper Fractional-Slot Concentrated Winding for a Ultra-Low Speed Tubular PM Linear Machine. IEEE Trans. Appl. Supercond. 2024, 34, 5206206. [Google Scholar] [CrossRef]

- Veg, L.; Kaska, J.; Skalický, M.; Pechánek, R. A Complex Study of Stator Tooth-Coil Winding Thermal Models for PM Synchronous Motors Used in Electric Vehicle Applications. Energies 2021, 14, 2395. [Google Scholar] [CrossRef]

- Wang, K.; Zhu, Z.Q.; Ombach, G.; Koch, M.; Zhang, S.; Xu, J. Electromagnetic Performance of an 18-Slot/10-Pole Fractional-Slot Surface-Mounted Permanent-Magnet Machine. IEEE Trans. Ind. Appl. 2014, 50, 3685–3696. [Google Scholar] [CrossRef]

- Wang, C.; Liu, J.; Han, J.; Zhang, Z.; Jiang, M. Analysis of Bidirectional Magnetic Field Modulation on Concentrated Winding Spoke-Type PM Machines. IEEE Trans. Transp. Electrif. 2024, 10, 6076–6086. [Google Scholar] [CrossRef]

- Aydin, M.; Demir, Y.; Yolacan, E.; Gulec, M.; El-Refaie, A.M. Design and Validation of an Unconventional 39-Slot PM Synchronous Motor with Asymmetric and Unbalanced AC Windings. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 1733–1744. [Google Scholar] [CrossRef]

- Yang, G.; Li, J.; Hua, W. Investigation of Electromagnetic Torque Generation Mechanism in FSCW V-IPM Machines Considering Magnetic Saturation. IEEE Trans. Transp. Electrif. 2025, 11, 6428–6440. [Google Scholar] [CrossRef]

- Chen, Z.; Liang, Z.; Liang, D.; Jia, S. Partial Demagnetization Fault Analysis and Diagnosis for Fractional Slot Concentrated Winding PMSMs Based on DQ-Axis Components. IEEE Trans. Energy Convers. 2025, 40, 1062–1072. [Google Scholar] [CrossRef]

- Yin, H.; Hua, W.; Wu, Z.; Du, J. An Efficient Rotor-Skewing Model for Mitigating Electromagnetic Vibration and Noise in Fractional-Slot Concentrated-Winding Permanent-Magnet Machines. IEEE/ASME Trans. Mechatron. 2025, 30, 818–828. [Google Scholar] [CrossRef]

- Yoon, H.-J.; Jun, S.-B.; Kim, N.-H.; Kim, Y.-J.; Jung, S.-Y. Torque Equation to Predict Torque Harmonic Characteristic of IPMSM According to Winding Arrangement, Number of Phases, and Pole-Slot Combination. J. Electr. Eng. Technol. 2023, 18, 339–346. [Google Scholar] [CrossRef]

- Song, Y.; Liu, G.; Yu, S.; Wang, H.; Zhang, F. Investigation of a Low-Speed High-Torque-Density Direct-Drive External-Rotor PMSM for Belt Conveyor Application. IEEE Access 2023, 11, 110479–110489. [Google Scholar] [CrossRef]

- Wei, F.; Zhu, Z.Q.; Yan, L.; Qi, J. Investigation of Stator/Rotor Pole Number Combinations and PM Numbers in Consequent-Pole Hybrid Excited Flux Reversal Machine. IEEE Trans. Energy Convers. 2022, 37, 2092–2106. [Google Scholar] [CrossRef]

- He, T.R.; Xu, F.; Zhu, Z.Q.; Liang, D.; Bin, H.; Wu, D.; Gong, L.M.; Chen, J.T. Comparison of Toroidal and Tooth-Coil Winding 2-Pole Slotted High-Speed Permanent Magnet Motors. IEEE Trans. Ind. Appl. 2024, 60, 3870–3882. [Google Scholar] [CrossRef]

- Shah, S.H.; Wang, Y.-C.; Shi, D.; Shen, J.-X. Investigation of Torque and Reduction of Torque Ripples through Assisted-Poles in Low-Speed, High-Torque Density Spoke-Type PMSMs. Machines 2024, 12, 327. [Google Scholar] [CrossRef]

- Makarchuk, O.; Całus, D. Power Losses in the Multi-Turn Windings of High-Speed PMSM Electric Machine Armatures. Energies 2025, 18, 3761. [Google Scholar] [CrossRef]

- Liang, X.; Wang, M.; Liu, Y.; Zheng, P.; Gao, J.; Li, W. Research and Analysis of Toroidal and Conventional Windings in Permanent Magnet Synchronous Machine. IEEE Trans. Magn. 2023, 59, 8101706. [Google Scholar] [CrossRef]

- Ciriani, C.; Ali Khan, H.; Mansour, K.; Olivo, M.; Tessarolo, A. A General Approach to the Design of Multi-Layer Fractional-Slot Concentrated Windings with Arbitrary Number of Slots, Poles, and Phases. IEEE Access 2024, 12, 89248–89261. [Google Scholar] [CrossRef]

- Tang, Y.; Chai, F.; Xie, Y.; Cai, W. Design of a Modular In-Wheel Motor with High Fault-Tolerant Performance and Low MMF Space Harmonic. IEEE Trans. Ind. Electron. 2023, 70, 6574–6584. [Google Scholar] [CrossRef]

- Carraro, E.; Bianchi, N.; Zhang, S.; Koch, M. Design and Performance Comparison of Fractional Slot Concentrated Winding Spoke Type Synchronous Motors with Different Slot-Pole Combinations. IEEE Trans. Ind. Appl. 2018, 54, 2276–2284. [Google Scholar] [CrossRef]

- Min, S.G.; Sarlioglu, B. Analysis and Comparative Study of Flux Weakening Capability in Fractional-Slot Concentrated Windings. IEEE Trans. Energy Convers. 2018, 33, 1025–1035. [Google Scholar] [CrossRef]

- Ma, K.; Sun, Y.; Niu, J.; Gao, Y.; Tang, X.; Jiang, X. Design and Optimization of High-Speed Five-Phase Fault-Tolerant Permanent Magnet Motor for Aerospace Applications. IEEE Trans. Ind. Appl. 2025, 61, 6327–6335. [Google Scholar] [CrossRef]

- Chu, C.; Yao, Y.; Huang, Y.; Peng, F.; Zhu, Z.; Cao, Z.; Cavagnino, A. Application and Verification of Spiral Water Cooling for Rotor in High-Power Density Motors. IEEE Trans. Transp. Electrif. 2025, 11, 1245–1256. [Google Scholar] [CrossRef]

- Zhu, S.; Ji, J.; Zhao, W.; Liu, G.; Lee, C.H.T. Vibration Reduction Design of Consequent Pole PM Machine by Symmetrizing Local and Global Magnetic Field. IEEE Trans. Ind. Electron. 2023, 70, 243–254. [Google Scholar] [CrossRef]

- Alberti, L.; Bianchi, N. Theory and Design of Fractional-Slot Multilayer Windings. IEEE Trans. Ind. Appl. 2013, 49, 841–849. [Google Scholar] [CrossRef]

- Zhu, Z.; Ge, W.; Mei, L.; Huang, Y. Variation Regularity of Key Performance Indexes Against the Slot Number of Tooth-Coil PMSMs. J. Electr. Eng. Technol. 2024, 19, 2457–2471. [Google Scholar] [CrossRef]

| Rated power (kW) | 11.4 | Peak power (kW) | 31.6 |

| Rated speed (r/min) | 3000 | Maximum speed (r/min) | 6000 |

| Rated torque @ 40 A (Nm) | 35.0 | Peak torque @220 A (Nm) | 105.0 |

| DC bus voltage (V) | 270.0 | Control method | Field oriented control |

| Winding type | Tooth-coil winding | Winding layer | 2 |

| Stator outer diameter (mm) | 140.0 | Stator stack length (mm) | 120.0 |

| Strands of each coil turn | 10 | Current density @ 40 A (A/mm2) | 6.42 |

| Conductor diameter (mm) | 0.81 | Control strategy | MTPA and FW |

| Machines | D-Axis Inductance Ld (mH) | Magnet Flux Linkage ψm (mWb) | Flux-Weakening Ratio ζ |

|---|---|---|---|

| 10p9s | 1.18 | 93.97 | 0.51 |

| 10p12s | 0.69 | 90.14 | 0.31 |

| 10p15s | 0.30 | 80.82 | 0.15 |

| 10p18s | 0.21 | 71.68 | 0.12 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Motorcycle mass (kg) | 350 | Frontal area (m2) | 1.35 |

| Wheel radius (mm) | 420 | Rolling resistance coefficient | 0.0054 |

| Drag coefficient | 0.26 | Gear ratio | 8 |

| 10p9s | 10p12s | 10p15s | 10p18s | |

|---|---|---|---|---|

| Electrical energy input to motor Emi (Wh) | 315.86 | 305.18 | 314.61 | 316.72 |

| Mechanical energy output via shaft Emo (Wh) | 246.57 | |||

| Electrical energy recovered Ego (Wh) | 76.94 | 81.25 | 78.46 | 77.69 |

| Shaft-generating energy Egi (Wh) | 98.72 | 100.51 | 100.24 | 100.04 |

| Copper loss Pcu (Wh) | 52.54 | 39.96 | 52.04 | 55.84 |

| Iron loss PFe (Wh) | 33.05 | 34.51 | 36.19 | 34.54 |

| Magnet loss Pm (Wh) | 5.48 | 3.4 | 1.59 | 2.12 |

| Average efficiency η (%) | 78.03 | 80.81 | 78.34 | 77.80 |

| Machine | Line Inductance (Calculated, mH) | Line Inductance (Measured, mH) | Line Back-EMF (Calculated, V) | Line Back-EMF (Measured, V) |

|---|---|---|---|---|

| 10p9s | 2.41 | 2.48 | 178.43 | 175.51 |

| 10p12s | 1.61 | 1.66 | 176.29 | 171.92 |

| 10p15s | 1.03 | 1.07 | 160.30 | 156.57 |

| 10p18s | 0.74 | 0.78 | 145.96 | 144.04 |

| 10p9s | 10p12s | 10p15s | 10p18s | |

|---|---|---|---|---|

| Calculated electrical energy input to motor (Wh) | 214.94 | 207.17 | 210.82 | 217.95 |

| Measured electrical energy input to motor (Wh) | 221.59 | 213.58 | 215.55 | 223.39 |

| Calculated mechanical energy output (Wh) | 167.35 | 166.86 | 163.19 | 167.69 |

| Measured mechanical energy output (Wh) | 169.65 | 167.49 | 165.37 | 168.55 |

| Calculated average efficiency (%) | 77.86 | 80.54 | 77.41 | 76.94 |

| Measured average efficiency (%) | 76.56 | 78.42 | 76.72 | 75.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, Y.; Yi, H.; Ouyang, H.; Mei, L.; Sun, Q.; Zhu, Z. Slot Number Optimization for Motorcycle Traction Motor Considering Driving Duty Cycle. Machines 2025, 13, 1046. https://doi.org/10.3390/machines13111046

Gu Y, Yi H, Ouyang H, Mei L, Sun Q, Zhu Z. Slot Number Optimization for Motorcycle Traction Motor Considering Driving Duty Cycle. Machines. 2025; 13(11):1046. https://doi.org/10.3390/machines13111046

Chicago/Turabian StyleGu, Yang, Hui Yi, Huimin Ouyang, Lei Mei, Qiang Sun, and Zichong Zhu. 2025. "Slot Number Optimization for Motorcycle Traction Motor Considering Driving Duty Cycle" Machines 13, no. 11: 1046. https://doi.org/10.3390/machines13111046

APA StyleGu, Y., Yi, H., Ouyang, H., Mei, L., Sun, Q., & Zhu, Z. (2025). Slot Number Optimization for Motorcycle Traction Motor Considering Driving Duty Cycle. Machines, 13(11), 1046. https://doi.org/10.3390/machines13111046