Ball Mill Load Classification Method Based on Multi-Scale Feature Collaborative Perception

Abstract

1. Introduction

- (1)

- Insufficient global correlation capture by CNNs: Although CNNs [13] excel at extracting local spatial features, ball mill load variation is a typical time-series dynamic process, and the spectral features at different time steps exhibit strong correlations. However, CNNs struggle to effectively capture the global correlation information in the “time-frequency” dimension.

- (2)

- Limited high-frequency detail extraction and noise resistance of ResNet: ResNet [14] alleviates the gradient vanishing problem of deep networks through residual connections. Nevertheless, under the interference of complex industrial noise, its ability to identify high-frequency vibration details (such as spectral spikes during sudden load changes) is weak, and these details are easily submerged by noise.

- (1)

- An innovative RB-SwinT architecture is designed, realizing for the first time the synchronous and efficient modeling of both “global trends” and “local details” in the time-frequency maps of vibration signals.

- (2)

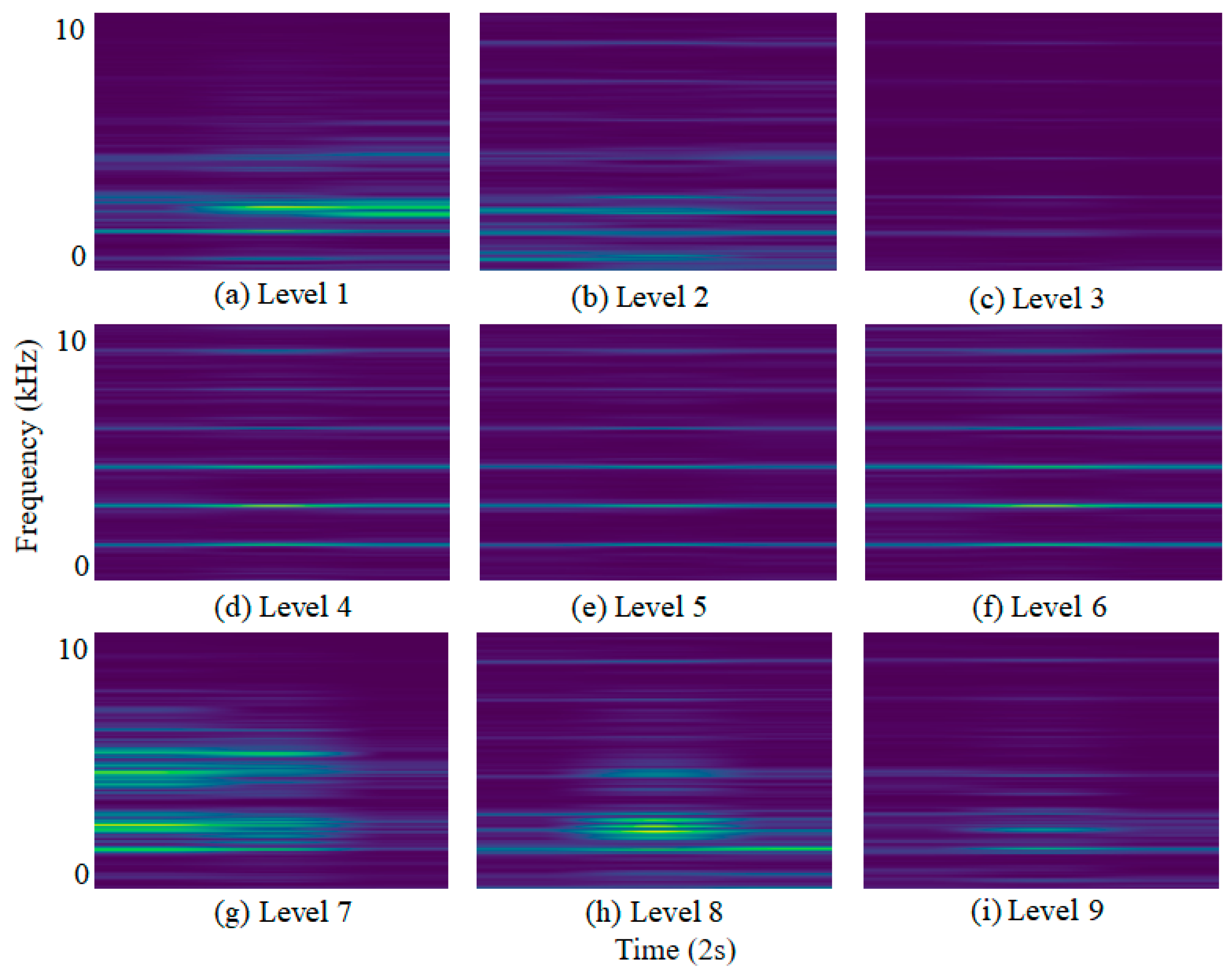

- The problem of classifying one-dimensional industrial vibration signals is successfully transformed into a two-dimensional visual time-frequency map recognition task, and the great application potential of advanced visual Transformer architectures in this field is verified.

- (3)

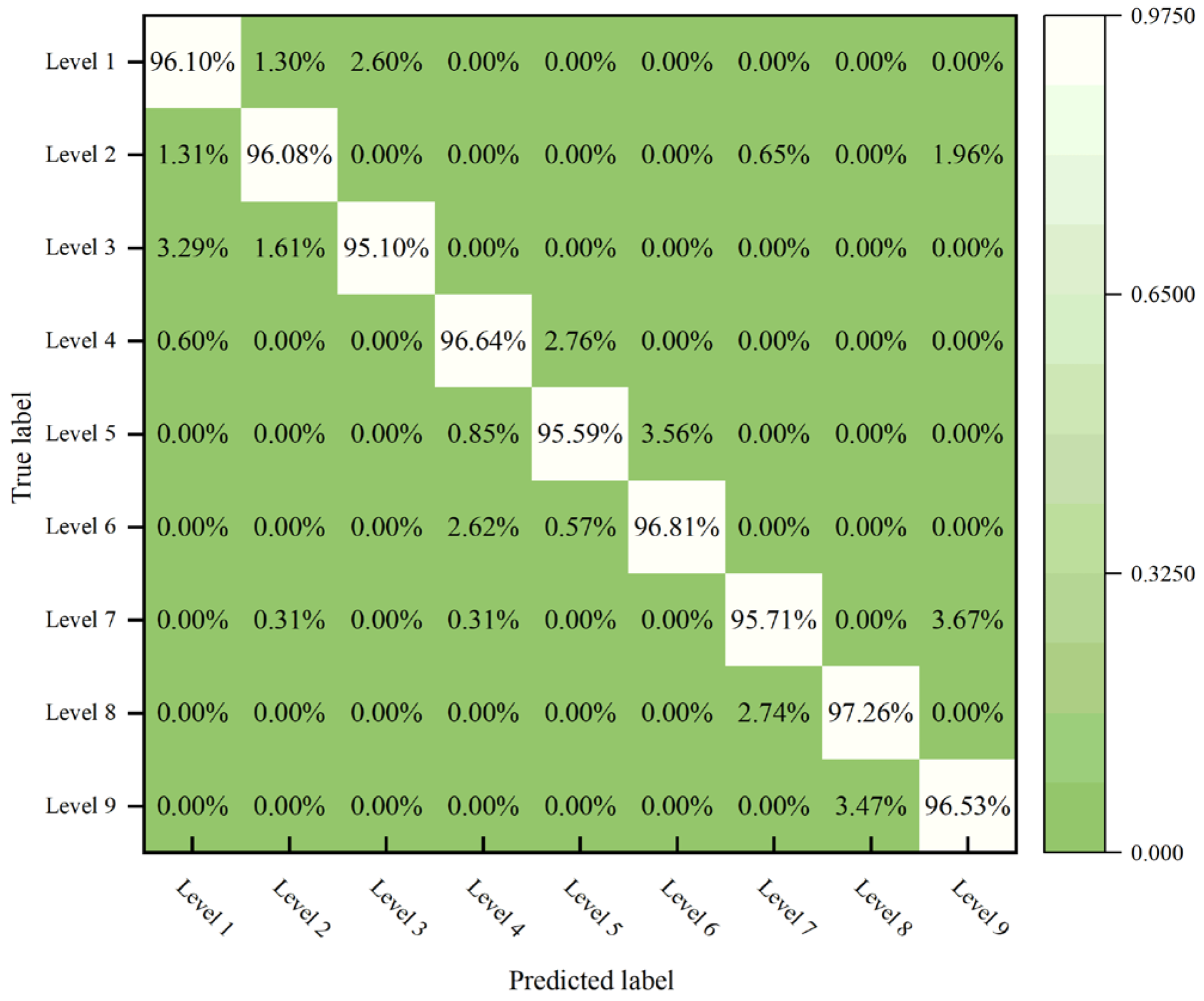

- Dual experimental validation was conducted on the self-constructed ball mill load dataset and the internationally recognized CWRU bearing fault dataset. Experimental results demonstrate that the proposed model not only achieves an accuracy of 96.20% in the 9-class ball mill load identification task but also reaches an accuracy of 99.36% in the 10-class CWRU bearing fault diagnosis task.

- (4)

- This study has conducted an in-depth analysis of the correlation between the refined recognition results of the model and the physical connotations of load states, explored its application value in indicating critical operating conditions and optimizing operating parameters, thereby enhancing the interpretability and application potential of this method in practical industrial environments.

2. Theoretical Basis

2.1. Short-Time Fourier Transform (STFT) for Time-Frequency Feature Conversion

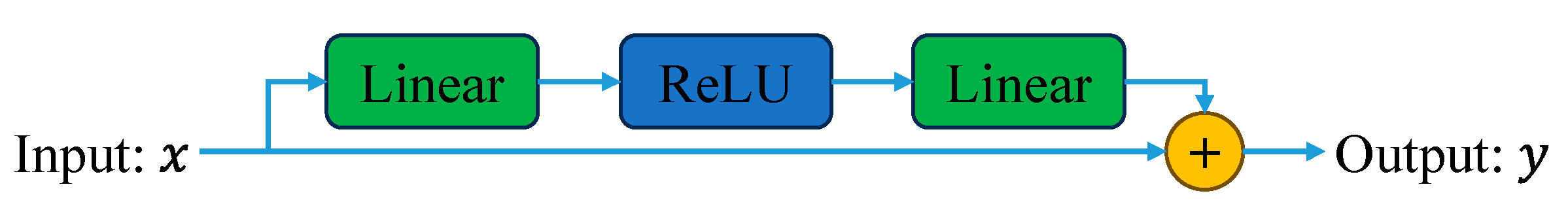

2.2. Residual Block for Gradient Propagation in Deep Networks

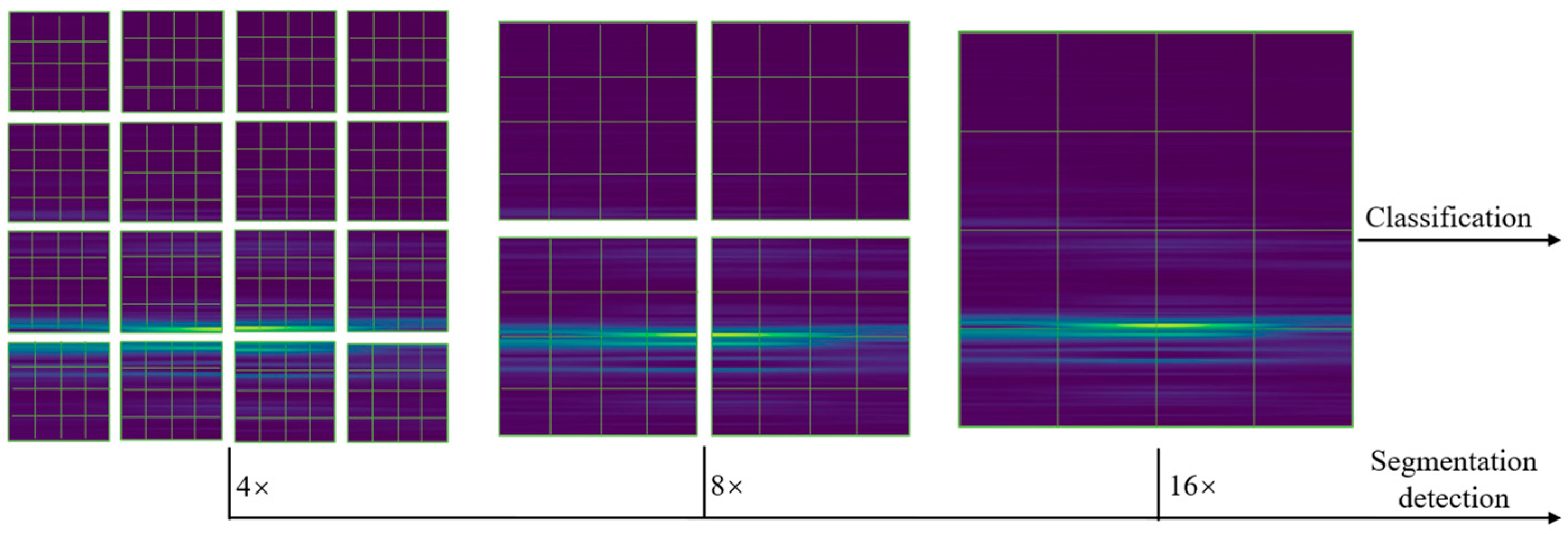

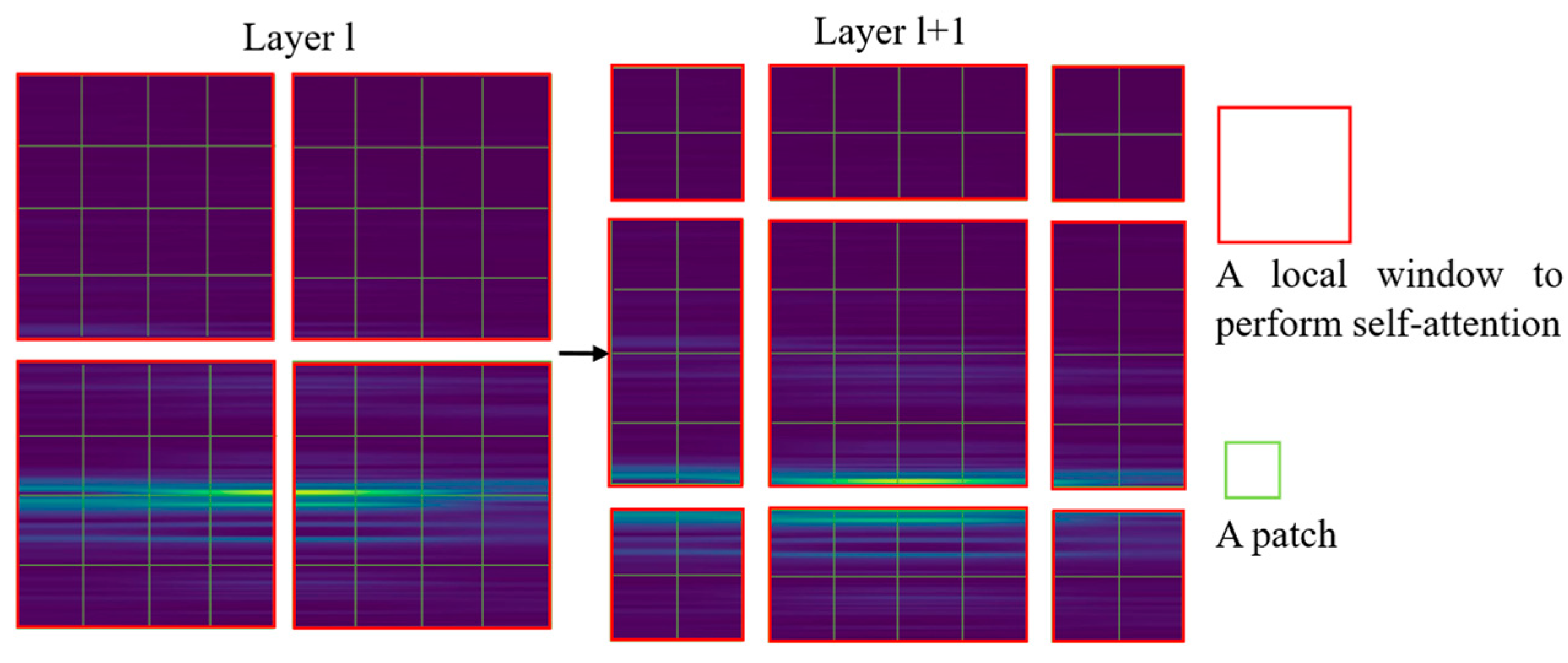

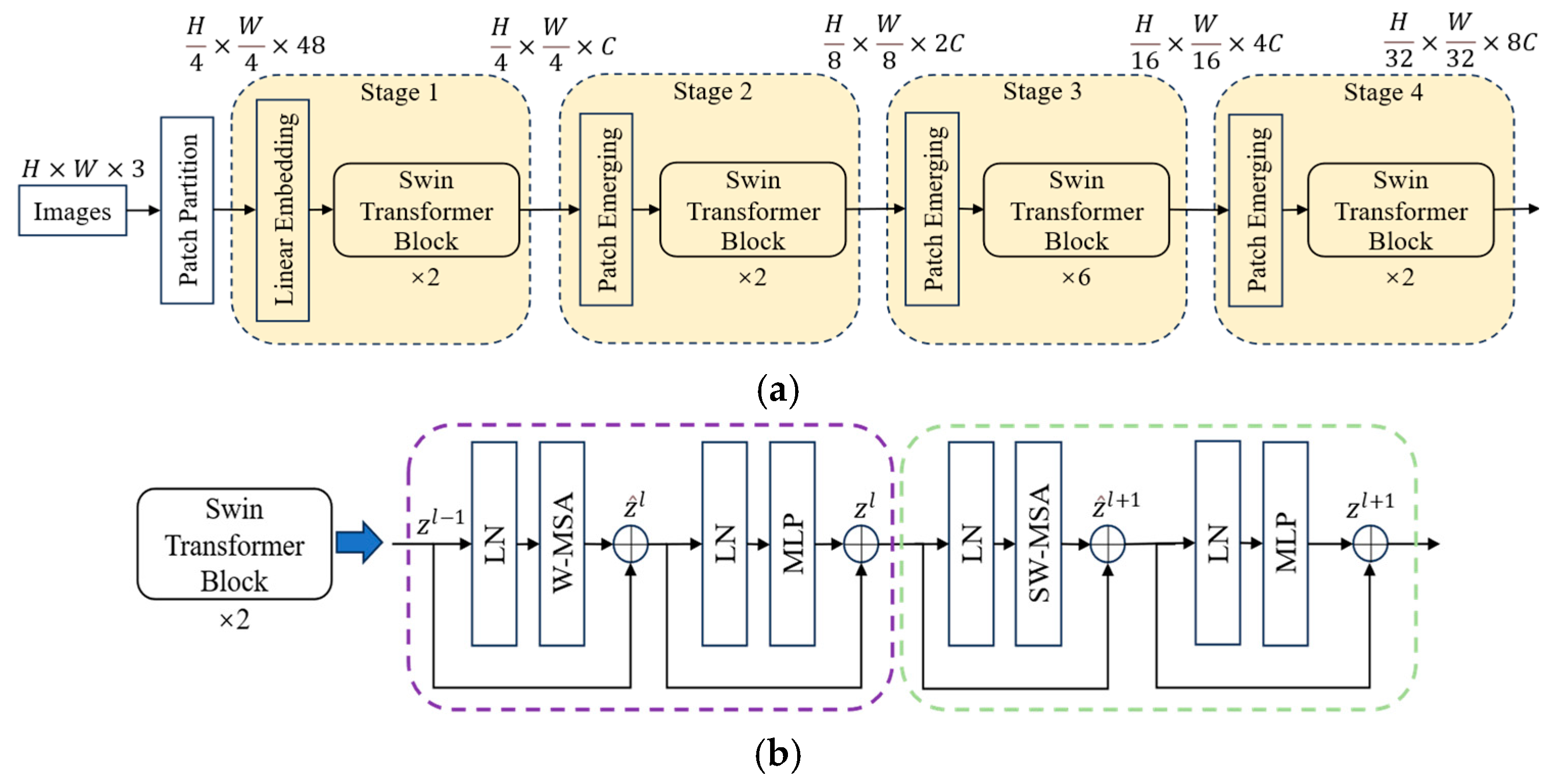

2.3. The Swin Transformer Network Model for Hierarchical Processing of Image Features

3. The Proposed Method

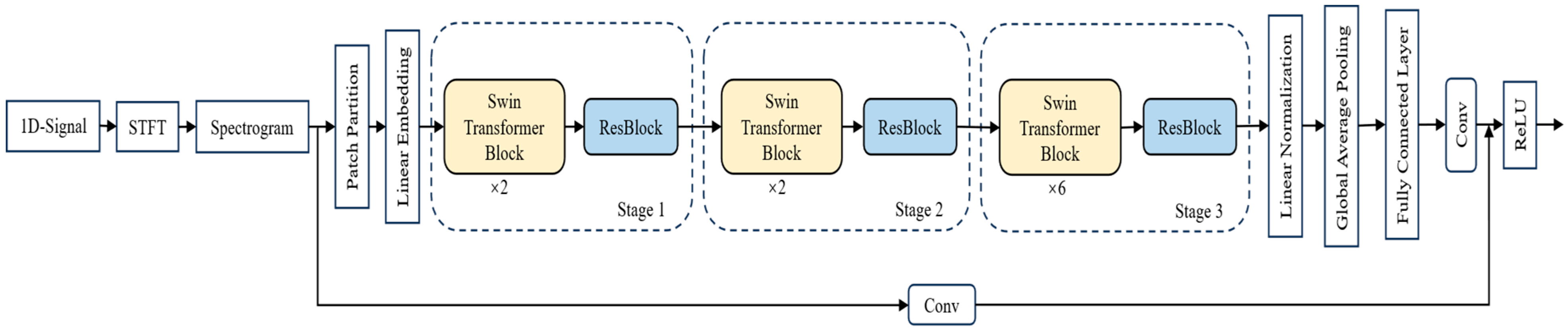

3.1. Overall Architecture and Design Philosophy

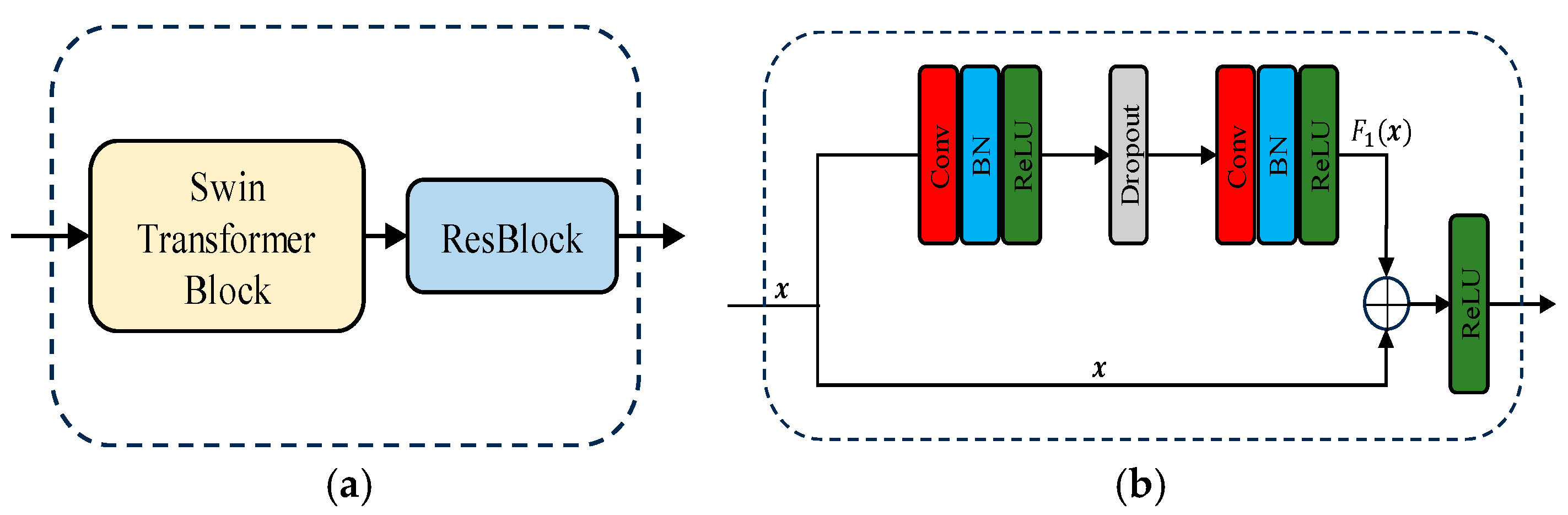

3.2. RB-SwinT Collaborative Perception Architecture

End-to-End Diagnostic Process

4. Ball Mill Load Experiment

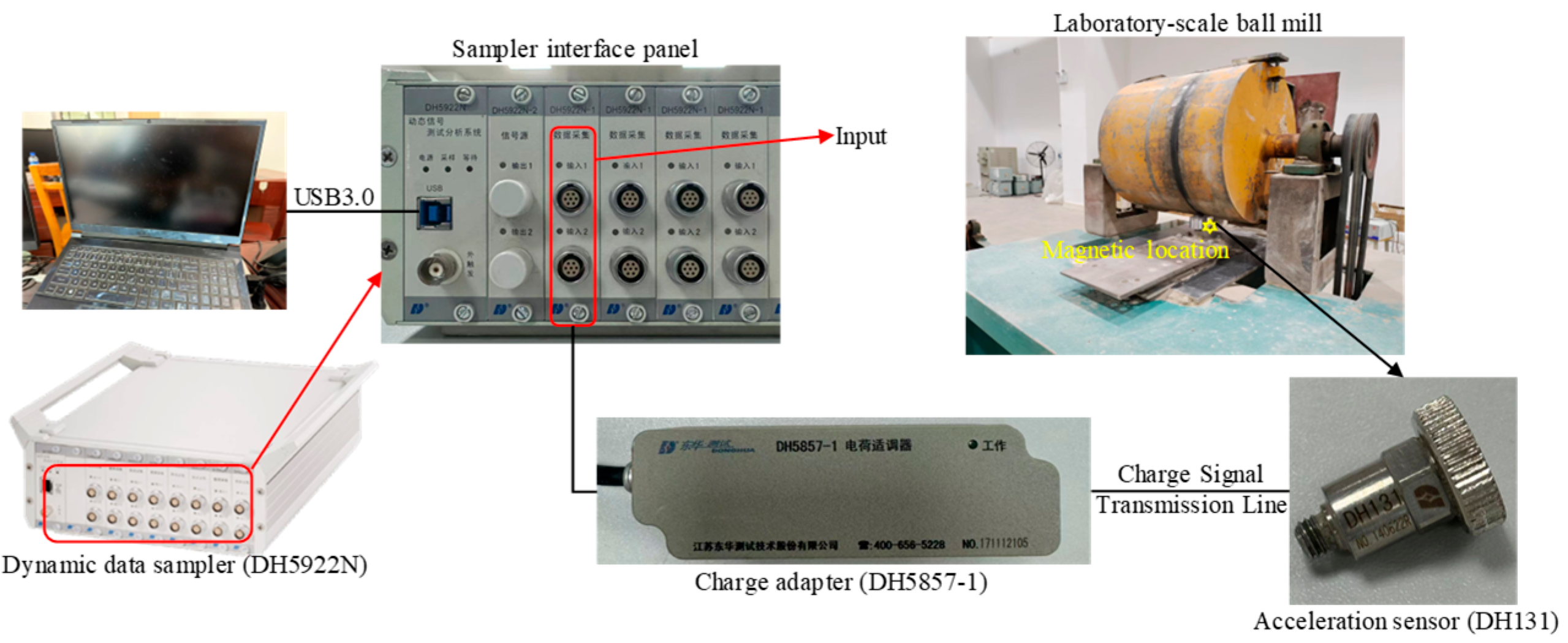

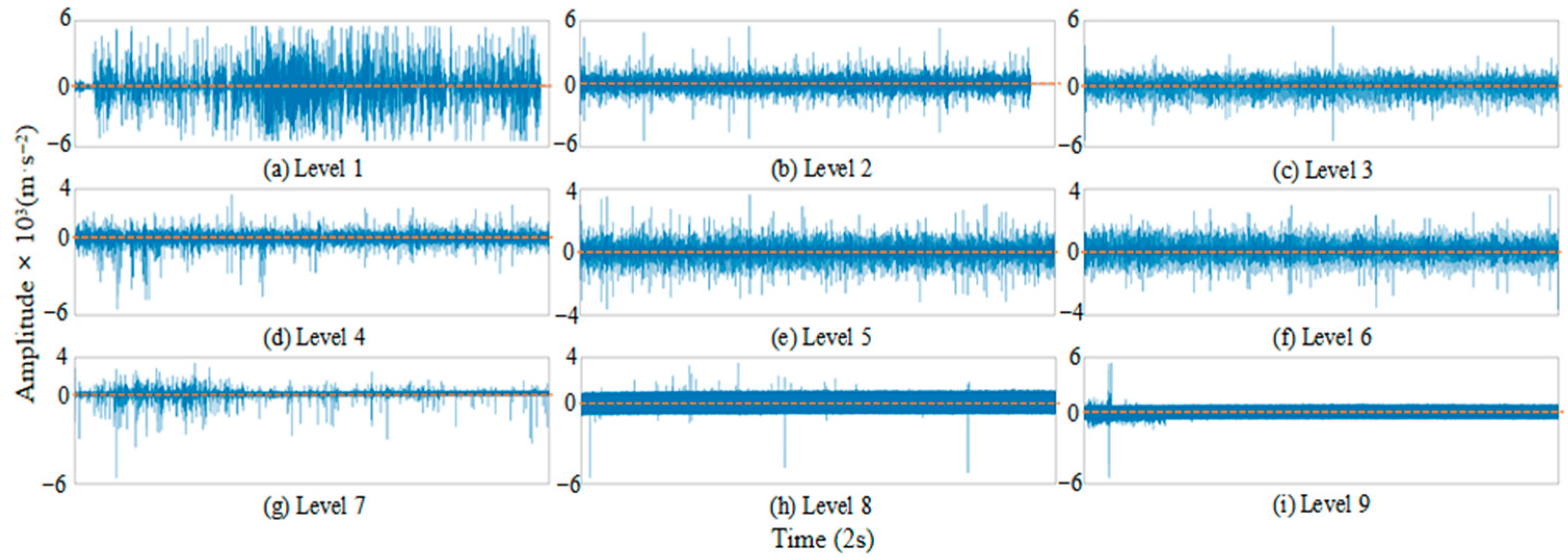

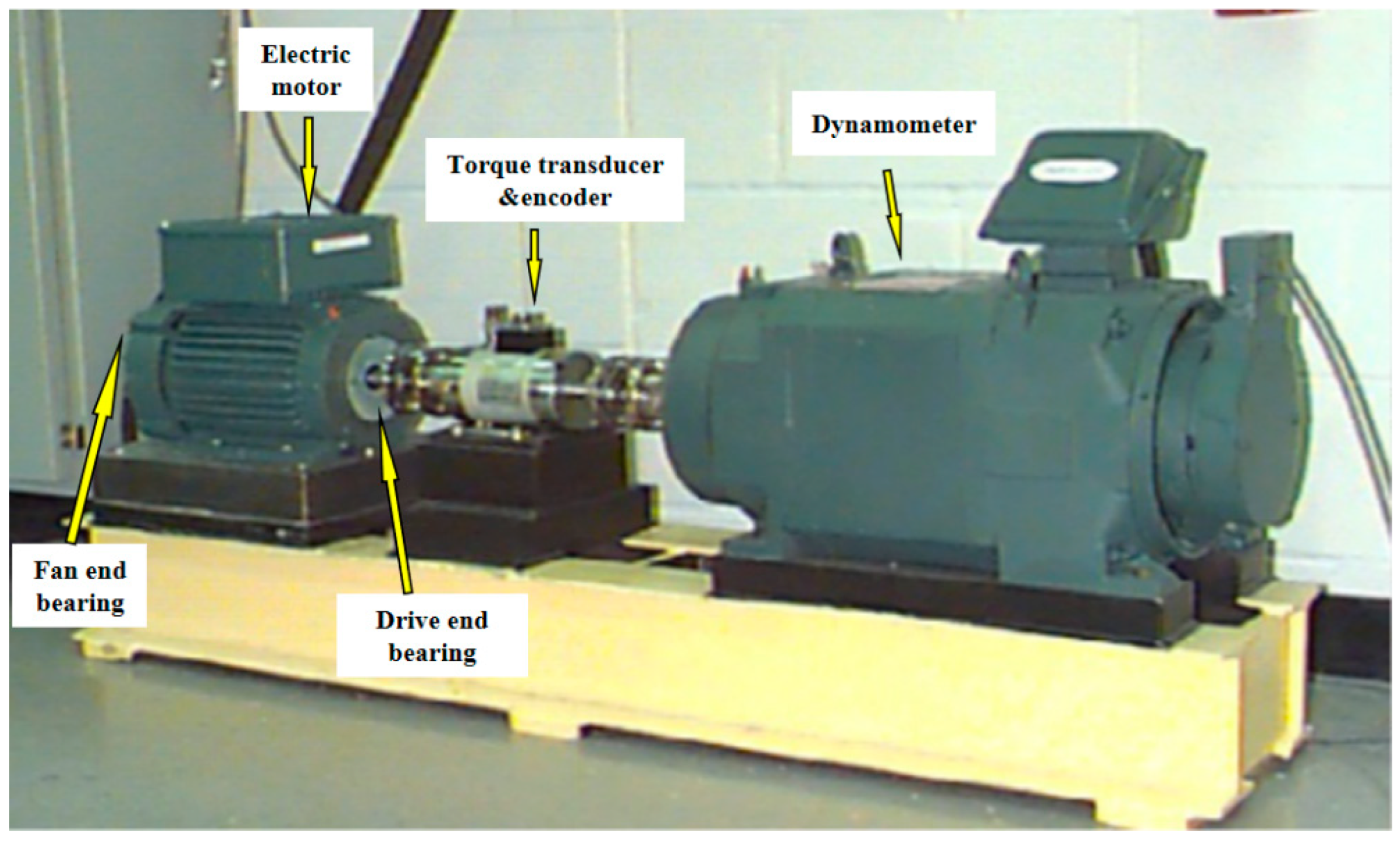

4.1. Experimental Setup and Dataset

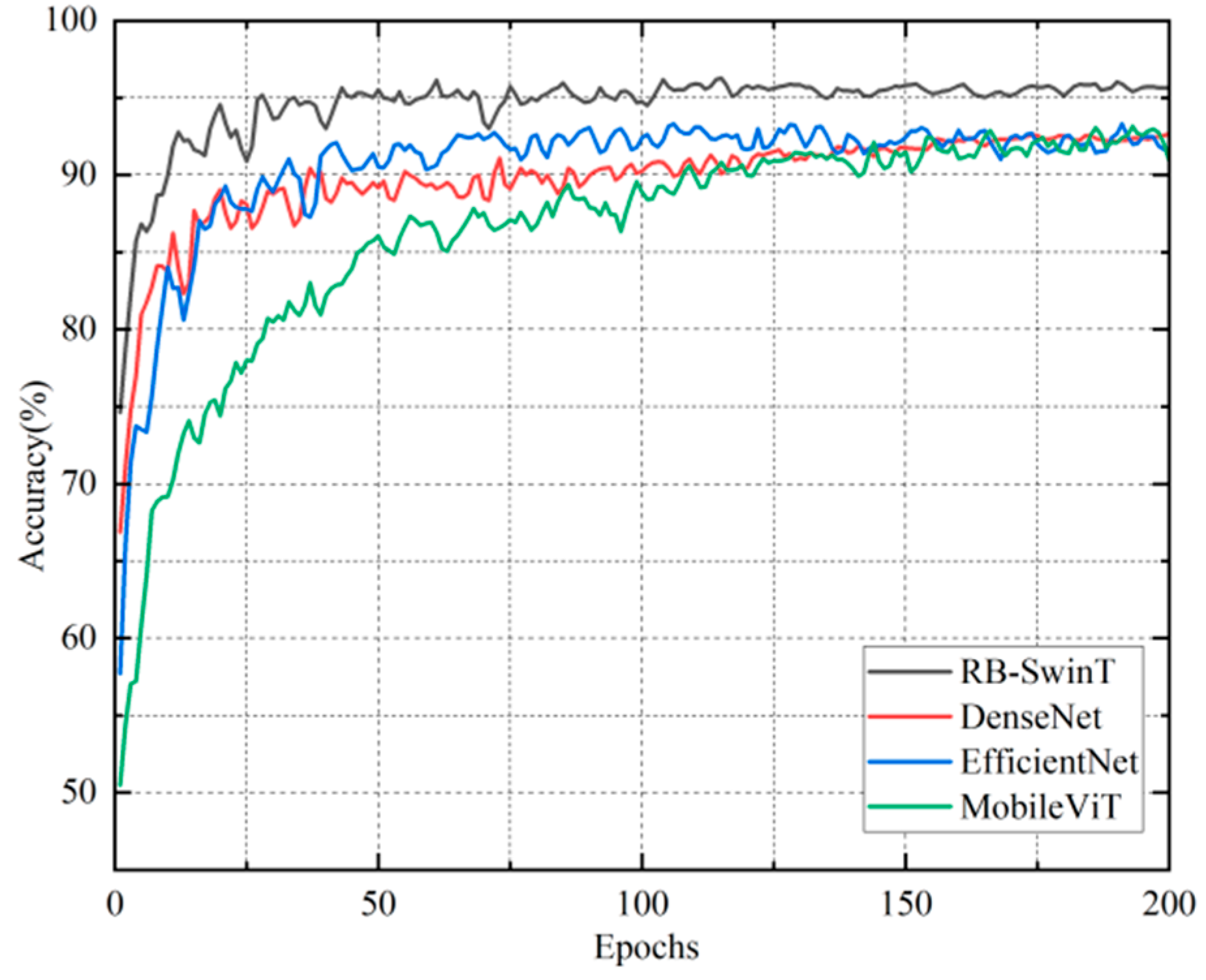

4.2. Comparative Experiments

4.2.1. Comparison of Different Methods with STFT Time-Frequency Maps as Input

4.2.2. Comparison of Different Methods Under the RB-SwinT Model

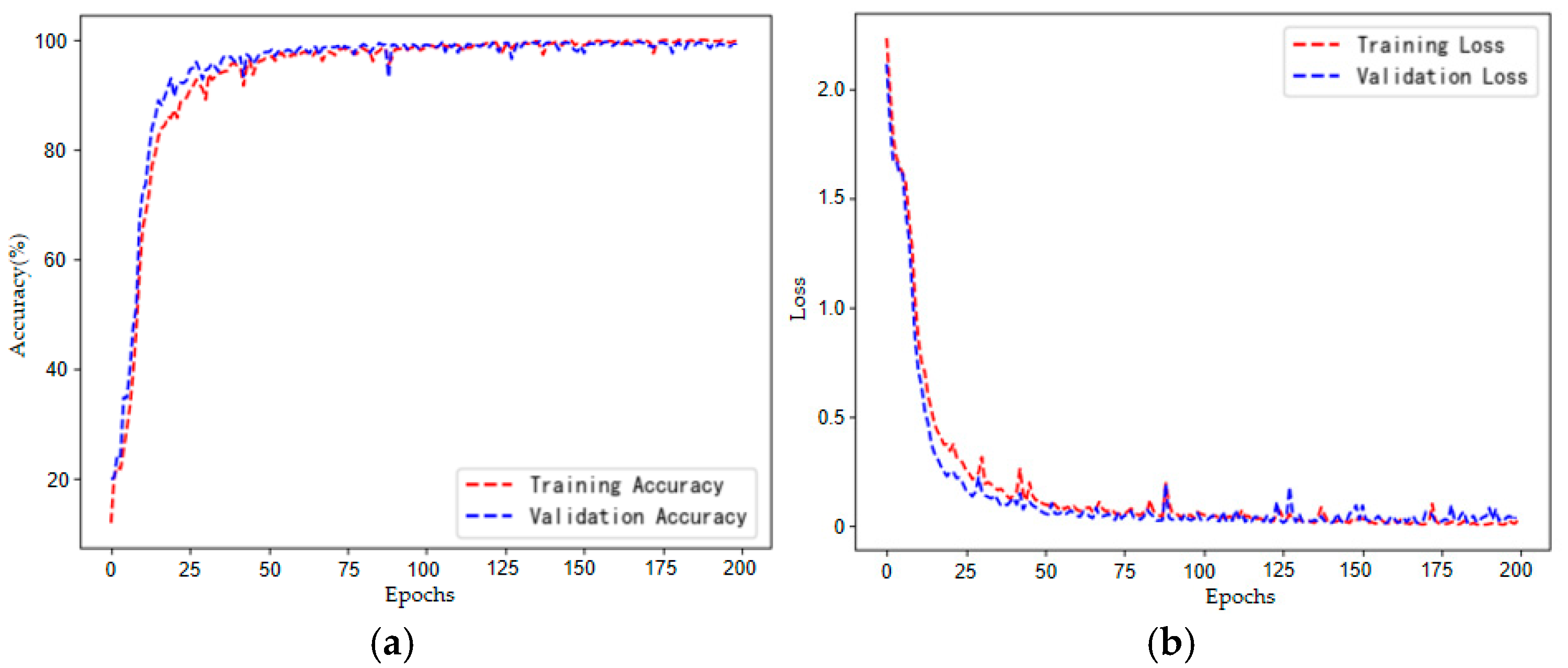

4.2.3. Model Classification Accuracy

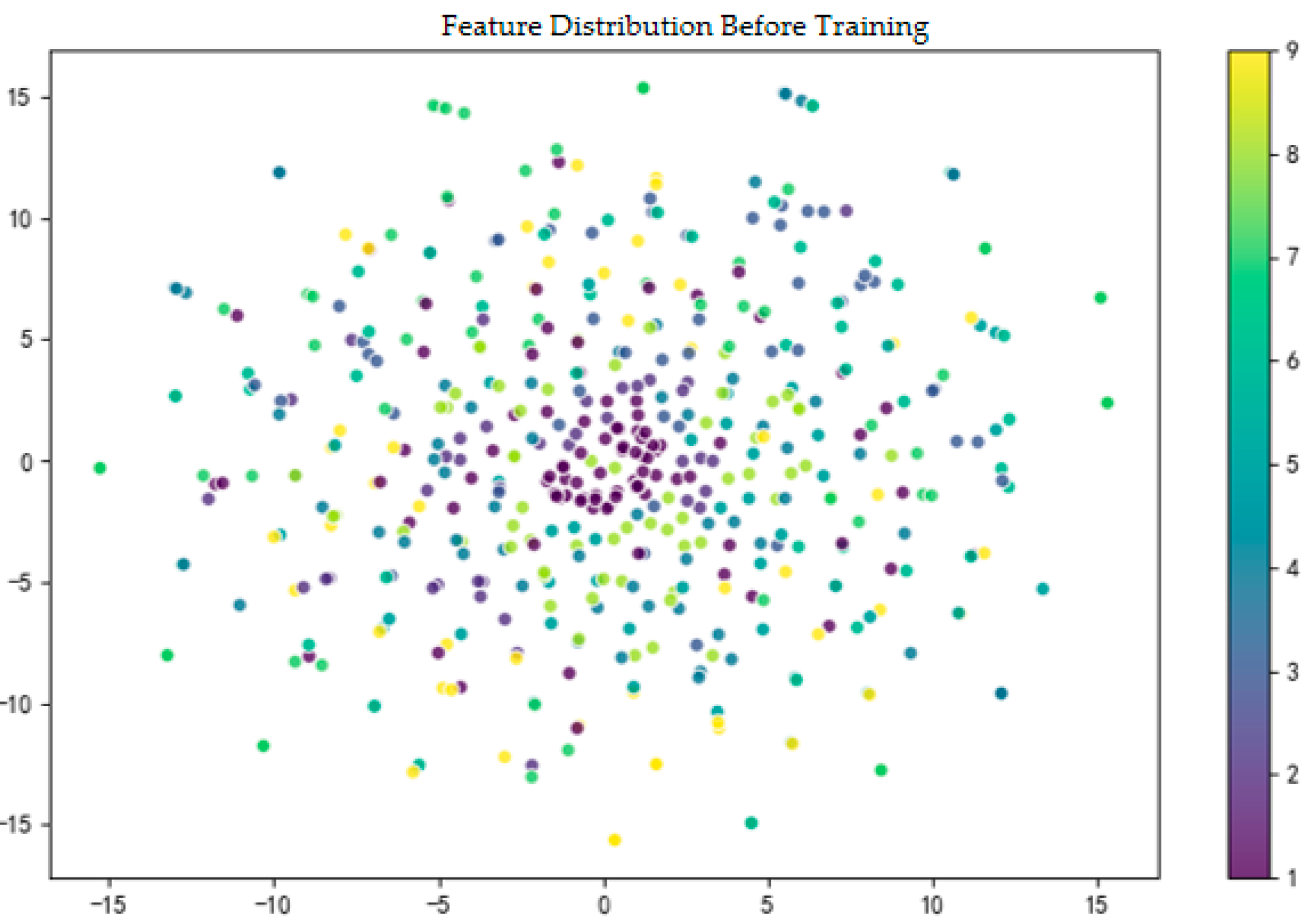

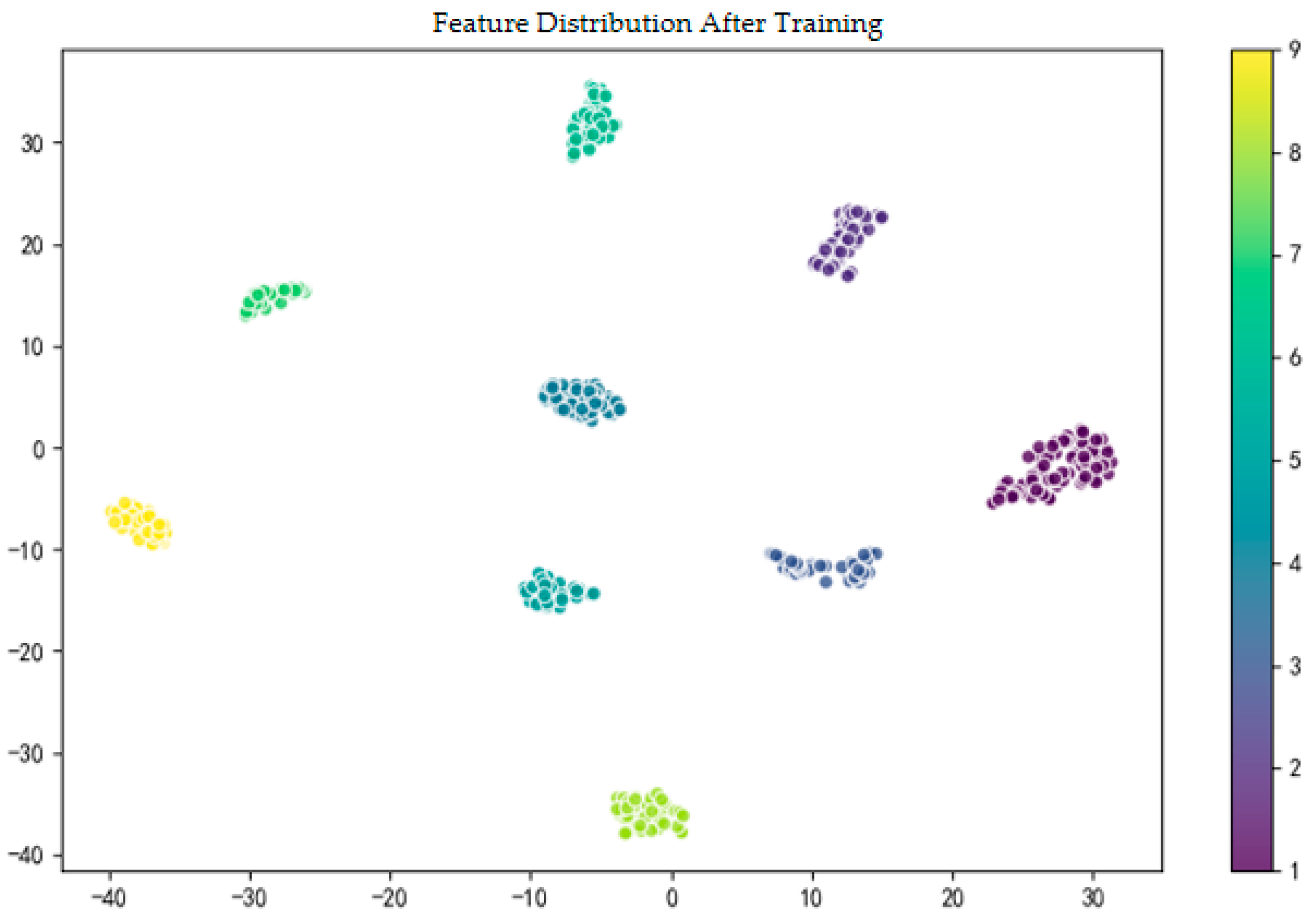

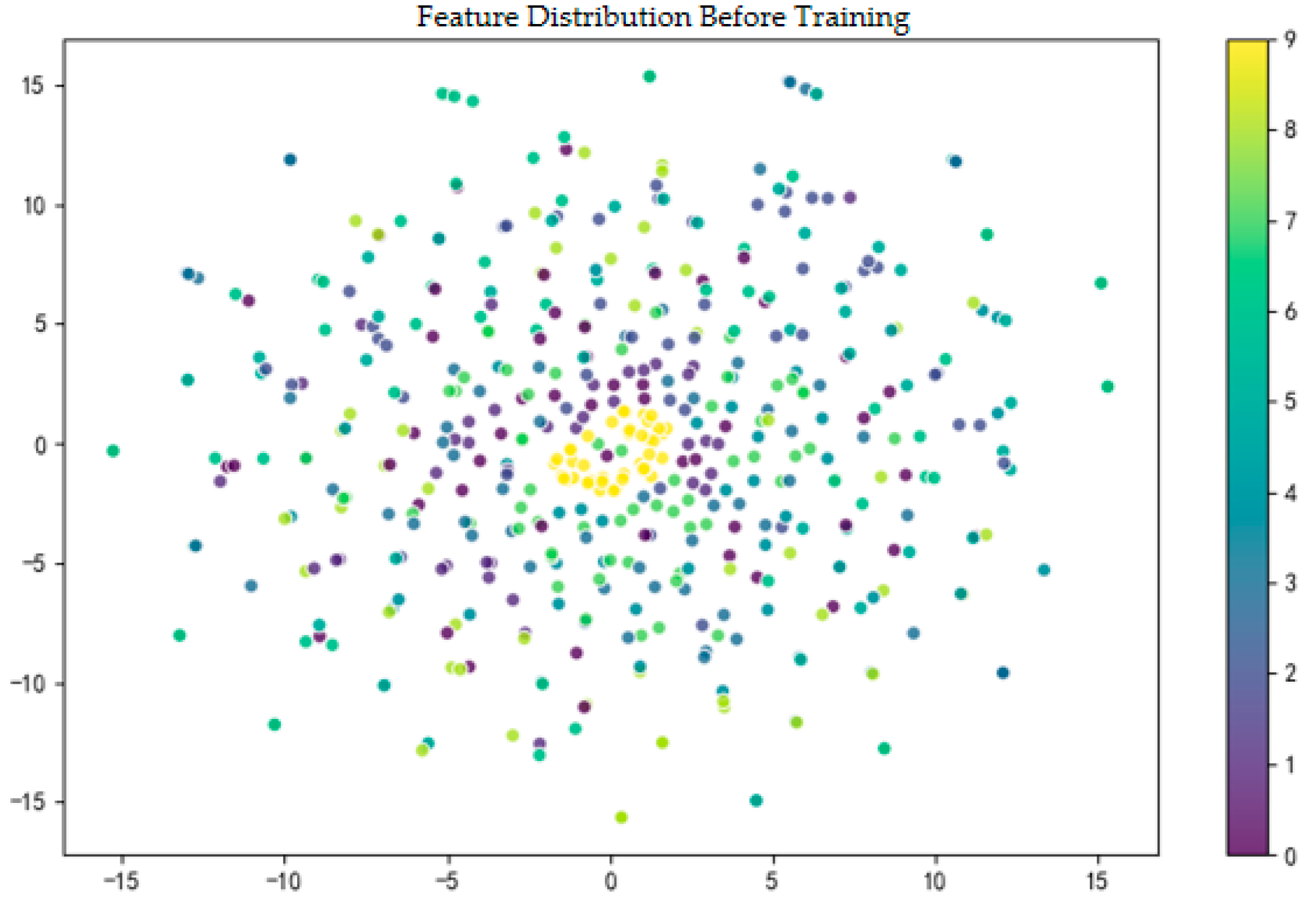

4.3. Visual Analysis of the Feature Extraction Process

4.4. Verification of Model Generalization Ability

- (1)

- Benchmark Dataset and Experimental Settings

- (2)

- Results and Comparative Analysis

5. Discussion

5.1. Analysis of the Core Mechanism for Model Effectiveness

5.2. Rationality of Experimental Design and Characterization of Operating Conditions

5.3. Analysis of Limitations and Outlook on Future Work

- (1)

- Generalizability of Experimental Conditions: The experimental validation of this study was completed on a laboratory-scale dry ball mill. However, in industrial applications, wet grinding conditions are more common. The slurry damping effect introduced by wet grinding may indeed cause changes in the amplitude and high-frequency components of vibration signals. Nevertheless, the “global-local collaborative perception” design philosophy of the proposed model in this paper provides inherent theoretical support for its adaptation to such changes in operating conditions. Firstly, the core of the model lies in learning dynamic “relative patterns” rather than static “absolute features.” The Swin Transformer backbone network learns the “morphological signature” of the entire time-frequency energy distribution, exhibiting good robustness to mere changes in signal amplitude. Secondly, the “global-local collaboration” architecture endows the model with inherent robustness. The integrated Residual Block (ResBlock), acting as a “local detail refiner,” can effectively protect and enhance even weak key discriminative information. Overall, this collaborative learning mechanism for the internal structure and dynamic patterns of signals endows the proposed paradigm with a theoretical basis for adapting to changes in different operating conditions, and provides possibilities for its future application exploration in more complex scenarios such as wet grinding.

- (2)

- Optimization of Deployment Efficiency: To promote the efficient deployment of the model on resource-constrained industrial edge devices, exploring the lightweighting of the RB-SwinT architecture—such as through techniques like knowledge distillation [35] or network pruning [36]—is also a highly valuable research direction. These subsequent explorations will surely further unlock the potential of the new paradigm proposed in this study.

5.4. Potential Industrial Application Value

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gawde, S.; Patil, S.; Kumar, S.; Kamat, P.; Kotecha, K.; Alfarhood, S. Explainable Predictive Maintenance of Rotating Machines Using LIME, SHAP, PDP, ICE. IEEE Access 2024, 12, 29345–29361. [Google Scholar] [CrossRef]

- Nayak, D.; Das, D.; Behera, S.; Das, S. Monitoring the Fill Level of a Ball Mill Using Vibration Sensing and Artificial Neural Network. Neural Comput. Appl. 2020, 32, 1501–1511. [Google Scholar] [CrossRef]

- Safa, A.; Aissat, S. Exploring the Effects of a New Lifter Design and Ball Mill Speed on Grinding Performance and Particle Behaviour: A Comparative Analysis. Eng. Technol. J. 2023, 41, 991–1000. [Google Scholar] [CrossRef]

- Tang, J.; Yu, W.; Chai, T.; Liu, Z.; Zhou, X. Selective Ensemble Modeling Load Parameters of Ball Mill Based on Multi-Scale Frequency Spectral Features and Sphere Criterion. Mech. Syst. Signal Process. 2016, 66–67, 485–504. [Google Scholar] [CrossRef]

- Xu, H.; Wang, T.; Zou, W.; Zhao, J.; Tao, L.; Zhang, Z. Ball Mill Load Status Identification Method Based on the Convolutional Neural Network, Optimized Support Vector Machine Model, and Intelligent Grinding Media. Chin. J. Eng. 2022, 44, 1821–1831. (In Chinese) [Google Scholar]

- Qing, Z.; Gao, Y.; Wu, C.; Yang, J.; Wang, Q. Feature Extraction Method of Ball Mill Load Based on the Adaptive Variational Mode Decomposition and the Improved Power Spectrum Analysis. Chin. J. Sci. Instrum. 2020, 41, 234–241. (In Chinese) [Google Scholar]

- Wu, Z.; Bai, H.; Yan, H.; Zhan, X.; Guo, C.; Jia, X. Intelligent Fault Diagnosis Method for Gearboxes Based on Deep Transfer Learning. Processes 2022, 11, 68. [Google Scholar] [CrossRef]

- Hermosilla, R.; Valle, C.; Allende, H.; Aguilar, C.; Lucic, E. SAG’s Overload Forecasting Using a CNN Physical Informed Approach. Appl. Sci. 2024, 14, 11686. [Google Scholar] [CrossRef]

- Cai, G.; Xiao, W.; Xu, H.; Wan, J. Subdivision load identification of ball mill based on multi-domain feature extraction and umap-boxgboost. Signal Image Video Process. 2025, 19, 334. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, G.; Xiao, S.; Wang, F.; Li, R.; Pang, Y. A multi-task model for mill load parameter prediction using physical information and domain adaptation: Validation with laboratory ball mill. Miner. Eng. 2025, 222, 109148. [Google Scholar] [CrossRef]

- Huang, P.; Sang, G.; Miao, Q.; Ding, Y.; Jia, M. Soft Measurement of Ball Mill Load Based on Multi-Classifier Ensemble Modelling and Multi-Sensor Fusion With Improved Evidence Combination. Meas. Sci. Technol. 2020, 32, 015105. [Google Scholar] [CrossRef]

- Luo, X.; Dai, C.; Cheng, T.; Cai, G.; Liu, X.; Liu, J. Load identification method of ball mill based on improved EWT multi-scale entropy and KELM. CIESC J. 2020, 71, 1264–1277. (In Chinese) [Google Scholar]

- Zhao, J.; Yang, Y.; Lin, X.; Yang, J.; He, L. Looking Wider for Better Adaptive Representation in Few-Shot Learning. In Proceedings of the AAAI Conference on Artificial Intelligence, Palo Alto, CA, USA, 2–9 February 2021. [Google Scholar]

- Fagbohungbe, O.; Qian, L. The Effect of Batch Normalization on Noise Resistant Property of Deep Learning Models. IEEE Access. 2022, 10, 127728–127741. [Google Scholar] [CrossRef]

- Li, X.; Wan, S.; Liu, S.; Zhang, Y.; Hong, J.; Wang, D. Bearing Fault Diagnosis Method Based on Attention Mechanism and Multilayer Fusion Network. ISA Trans. 2021, 128, 550–564. [Google Scholar] [CrossRef]

- Wylomanska, A.; Zimroz, R.; Janczura, J.; Obuchowski, J. Impulsive noise cancellation method for copper ore crusher vibration signals enhancement. IEEE Trans. Ind. Electron. 2016, 63, 5612–5621. [Google Scholar] [CrossRef]

- Zak, G.; Wylomanska, A.; Zimroz, R. Alpha-stable distribution based methods in the analysis of the crusher vibration signals for fault detection. IFAC-Pap. 2017, 50, 4696–4701. [Google Scholar] [CrossRef]

- Tanaś, W.; Szczepaniak, J.; Kromulski, J.; Szymanek, M.; Tanaś, J.; Sprawka, M. Modal analysis and acoustic noise characterization of a grain crusher. Ann. Agr. Environ. Med. 2018, 25, 433–436. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Lin, Y.; Cao, Y.; Hu, H.; Wei, Y.; Zhang, Z.; Lin, S.; Guo, B. Swin transformer: Hierarchical vision transformer using shifted windows. arXiv 2021, arXiv:2103.14030. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Qin, X.; Sun, Y. Fault diagnosis method for rolling bearings based on short-time Fourier transform and convolution neural network. J. Vib. Shock 2018, 37, 124–131. (In Chinese) [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NA, USA, 26 June–1 July 2016. [Google Scholar]

- Wang, R.; An, S.; Liu, W.; Li, L. Invertible residual blocks in deep learning networks. IEEE Trans. Neural Netw. Learn. Syst. 2024, 35, 10167–10173. [Google Scholar] [CrossRef]

- Tang, J.; Chai, T.Y.; Liu, Z.; Yu, W. Selective ensemble modeling based on nonlinear frequency spectral feature extraction for predicting load parameter in ball mills. Chin. J. Chem. Eng. 2015, 23, 2020–2028. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, Y. Time-frequency multi-domain 1D convolutional neural network with channel-spatial attention for noise-robust bearing fault diagnosis. Sensors 2023, 23, 9311. [Google Scholar] [CrossRef]

- Wu, J.; Luo, W.; Yao, K. Electric motor vibration signal classification using Wigner-Ville distribution for fault diagnosis. Sensors 2025, 25, 1196. [Google Scholar] [CrossRef]

- Yu, H.; Wang, X.; Li, J.; Xue, Y.; Zou, S.; Liu, J. Study on the relationship between grinding medium particle size and ball mill grinding efficiency. Min. Mach. 2020, 48, 32–37. (In Chinese) [Google Scholar]

- Yang, L.; Yang, H. Load identification method of ball mill based on the CEEMDAN-wavelet threshold-PMMFE. Gospod. Surowcami Miner. 2024, 40, 163–180. [Google Scholar] [CrossRef]

- Cai, G.; Liu, X.; Dai, C.; Luo, X. Load state identification method for ball mills based on improved EWT, multiscale fuzzy entropy and AEPSOPNN classification. Processes 2019, 7, 725. [Google Scholar] [CrossRef]

- Smith, W.; Randall, R. Rolling Element Bearing Diagnostics Using the Case Western Reserve University Data: A Benchmark Study. Mech. Syst. Signal Process. 2015, 64–65, 100–131. [Google Scholar] [CrossRef]

- Song, C.; Liang, Y.; Lu, N.; Du, G.; Jia, B. Bearing Fault Diagnosis Method Based on SAVMD and CNN. J. Mech. Strength 2024, 46, 509–517. (In Chinese) [Google Scholar]

- Lei, C.; Xia, B.; Xue, L.; Jiao, M.; Zhang, H. Rolling Bearing Fault Diagnosis Method Based on MTF-CNN. J. Vib. Shock 2022, 41, 151–158. (In Chinese) [Google Scholar]

- Zhang, S.; Ji, H.; Liu, Y. Bearing Fault Diagnosis Based on ISCNN-LightGBM. Control Theory Appl. 2023, 40, 753–760. (In Chinese) [Google Scholar]

- Lv, D.; Wang, H.; Che, C. Multiscale Convolutional Neural Network and Decision Fusion for Rolling Bearing Fault Diagnosis. Ind. Lubr. Tribol. 2021, 73, 516–522. [Google Scholar] [CrossRef]

- Tang, X.; Xu, Z.; Wang, Z. A Novel Fault Diagnosis Method of Rolling Bearing Based on Integrated Vision Transformer Model. Sensors 2022, 22, 3878. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, S. A Lightweight Method for Graph Neural Networks Based on Knowledge Distillation and Graph Contrastive Learning. Appl. Sci. 2024, 14, 4805. [Google Scholar] [CrossRef]

- Shah, S.; Berahas, A.; Bollapragada, R. Adaptive Consensus: A Network Pruning Approach for Decentralized Optimization. SIAM J. Optimiz. 2024, 34, 3653–3680. [Google Scholar] [CrossRef]

| Stage | Output Size | Swin-T |

|---|---|---|

| Stage1 | 56 × 56 | concat 4 × 4, 96-d, LN |

| Stage2 | 28 × 28 | concat 4 × 4, 192-d, LN |

| Stage3 | 14 × 14 | concat 4 × 4, 384-d, LN |

| No. | CVR | MBVR | Diameter of Steel Balls (pcs) | Feed Particle Size (1:2:3:4) (kg) | CVR Level | MBVR Level | Classification | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 mm | 40 mm | 50 mm | +3–6 mm | +6–9 mm | +9–13 mm | +13–18 mm | ||||||

| 1 | 0.2 | 0.1 | 26.98 | 22.83 | 17.46 | 0.178 | 0.356 | 0.534 | 0.712 | Low | Low | 1 |

| 2 | 0.2 | 0.3 | 18.62 | 15.76 | 12.05 | 0.369 | 0.737 | 1.106 | 1.475 | Low | Low | |

| 3 | 0.2 | 0.5 | 14.60 | 12.35 | 9.45 | 0.482 | 0.964 | 1.445 | 1.927 | Low | Normal | 2 |

| 4 | 0.2 | 0.7 | 12.37 | 10.46 | 8.00 | 0.571 | 1.143 | 1.714 | 2.285 | Low | Normal | |

| 5 | 0.2 | 0.9 | 10.87 | 9.19 | 7.03 | 0.645 | 1.291 | 1.936 | 2.582 | Low | High | 3 |

| 6 | 0.2 | 1.1 | 9.79 | 8.28 | 6.33 | 0.711 | 1.421 | 2.132 | 2.842 | Low | High | |

| 7 | 0.3 | 0.1 | 38.17 | 32.30 | 24.70 | 0.252 | 0.504 | 0.756 | 1.008 | Normal | Low | 4 |

| 8 | 0.3 | 0.3 | 25.86 | 21.88 | 16.73 | 0.512 | 1.024 | 1.536 | 2.048 | Normal | Low | |

| 9 | 0.3 | 0.5 | 19.55 | 16.55 | 12.65 | 0.645 | 1.291 | 1.936 | 2.581 | Normal | Normal | 5 |

| 10 | 0.3 | 0.7 | 15.72 | 13.30 | 10.17 | 0.726 | 1.453 | 2.179 | 2.905 | Normal | Normal | |

| 11 | 0.3 | 0.9 | 13.14 | 11.12 | 8.50 | 0.781 | 1.561 | 2.342 | 3.123 | Normal | High | 6 |

| 12 | 0.4 | 0.1 | 50.90 | 43.07 | 32.93 | 0.336 | 0.672 | 1.008 | 1.344 | Normal | Low | 4 |

| 13 | 0.4 | 0.3 | 34.48 | 29.18 | 22.31 | 0.683 | 1.365 | 2.048 | 2.731 | Normal | Low | |

| 14 | 0.4 | 0.5 | 26.07 | 22.06 | 16.87 | 0.860 | 1.721 | 2.581 | 3.442 | Normal | Normal | 5 |

| 15 | 0.4 | 0.7 | 20.96 | 17.74 | 13.56 | 0.968 | 1.937 | 2.905 | 3.874 | Normal | Normal | |

| 16 | 0.4 | 0.9 | 17.53 | 14.83 | 11.34 | 1.041 | 2.082 | 3.123 | 4.164 | Normal | High | 6 |

| 17 | 0.5 | 0.1 | 63.62 | 53.83 | 41.17 | 0.420 | 0.840 | 1.260 | 1.680 | High | Low | 7 |

| 18 | 0.5 | 0.3 | 43.10 | 36.47 | 27.89 | 0.853 | 1.707 | 2.560 | 3.414 | High | Low | |

| 19 | 0.5 | 0.5 | 32.59 | 27.58 | 21.09 | 1.076 | 2.151 | 3.227 | 4.302 | High | Normal | 8 |

| 20 | 0.5 | 0.7 | 26.20 | 22.17 | 16.95 | 1.211 | 2.421 | 3.632 | 4.842 | High | Normal | |

| 21 | 0.5 | 0.9 | 21.91 | 18.54 | 14.17 | 1.301 | 2.602 | 3.904 | 5.205 | High | High | 9 |

| 22 | 0.5 | 1.1 | 18.82 | 15.93 | 12.18 | 1.366 | 2.733 | 4.099 | 5.466 | High | High | |

| Technical Index | Value | |

|---|---|---|

| Input impedance | 10 MΩ//40 PF | |

| Input Method | GND, SIN-DC, DIF-DC, AC, IEPE | |

| Fullness value | ±20 mV, ±50 mV, ±100 mV, ±200 mV, ±500 mV, ±1 V, ±2 V, ±5 V, ±10 V, ±20 V | |

| System uncertainty | <0.5% (F.S) (Measurement after half an hour warm-up) | |

| System stability | <0.05%/h (Measurement after half an hour warm-up) | |

| Maximum analysis bandwidth | DC~100 kHz | |

| Operating power | AC power supply | 220 V ± 10 V, 50 Hz |

| DC power supply | 12 V | |

| Maximum power | 150 W | |

| Technical Index Types | Specific Name | Value |

|---|---|---|

| Dynamic indicators | Axial sensitivity | 1.23 pC/m·s−2 |

| Range | 5000 m·s−2 | |

| Maximum lateral sensitivity | <5% | |

| Install resonant frequency | 44 kHz | |

| Insulation resistance | >1010 Ω | |

| Capacitance | ~1300 pF | |

| Environmental parameters | Working temperature range | (−20~120) °C |

| Impact limit | 10,000 m·s−2 | |

| Base strain sensitivity | 0.005 m·s−2/μ ε | |

| Transient temperature response | 0.09 m·s−2/°C | |

| Electromagnetic sensitivity | 40 m·s−2/T |

| Hyperparameter Category | Parameter Name | Specific Setting |

|---|---|---|

| Training Process | Batch Size | 32 |

| Number of Epochs | 200 | |

| Loss Function | Cross-Entropy Loss | |

| Optimizer and Learning Rate | Optimizer | Adam |

| Initial Learning Rate | 1 × 10−4 (0.0001) | |

| LR Schedule | ReduceLROnPlateau | |

| Regularization and Early Stopping | L2 Regularization | 1 × 10−4 |

| Dropout Rate | 0.5 | |

| Early Stopping | Patience = 15 |

| Method | Comprehensive Accuracy |

|---|---|

| RB-SwinT (The method proposed in this paper) | 99.36% |

| SAVMD-CNN | 98.65% |

| MTF-CNN | 98.91% |

| ISCNN-LightGBM | 99.03% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Jiang, Z.; Huang, W.; Yang, L.; Luo, X. Ball Mill Load Classification Method Based on Multi-Scale Feature Collaborative Perception. Machines 2025, 13, 1045. https://doi.org/10.3390/machines13111045

He S, Jiang Z, Huang W, Yang L, Luo X. Ball Mill Load Classification Method Based on Multi-Scale Feature Collaborative Perception. Machines. 2025; 13(11):1045. https://doi.org/10.3390/machines13111045

Chicago/Turabian StyleHe, Saisai, Zhihong Jiang, Wei Huang, Lirong Yang, and Xiaoyan Luo. 2025. "Ball Mill Load Classification Method Based on Multi-Scale Feature Collaborative Perception" Machines 13, no. 11: 1045. https://doi.org/10.3390/machines13111045

APA StyleHe, S., Jiang, Z., Huang, W., Yang, L., & Luo, X. (2025). Ball Mill Load Classification Method Based on Multi-Scale Feature Collaborative Perception. Machines, 13(11), 1045. https://doi.org/10.3390/machines13111045