Dual-Channel Parallel Multimodal Feature Fusion for Bearing Fault Diagnosis

Abstract

1. Introduction

- 1.

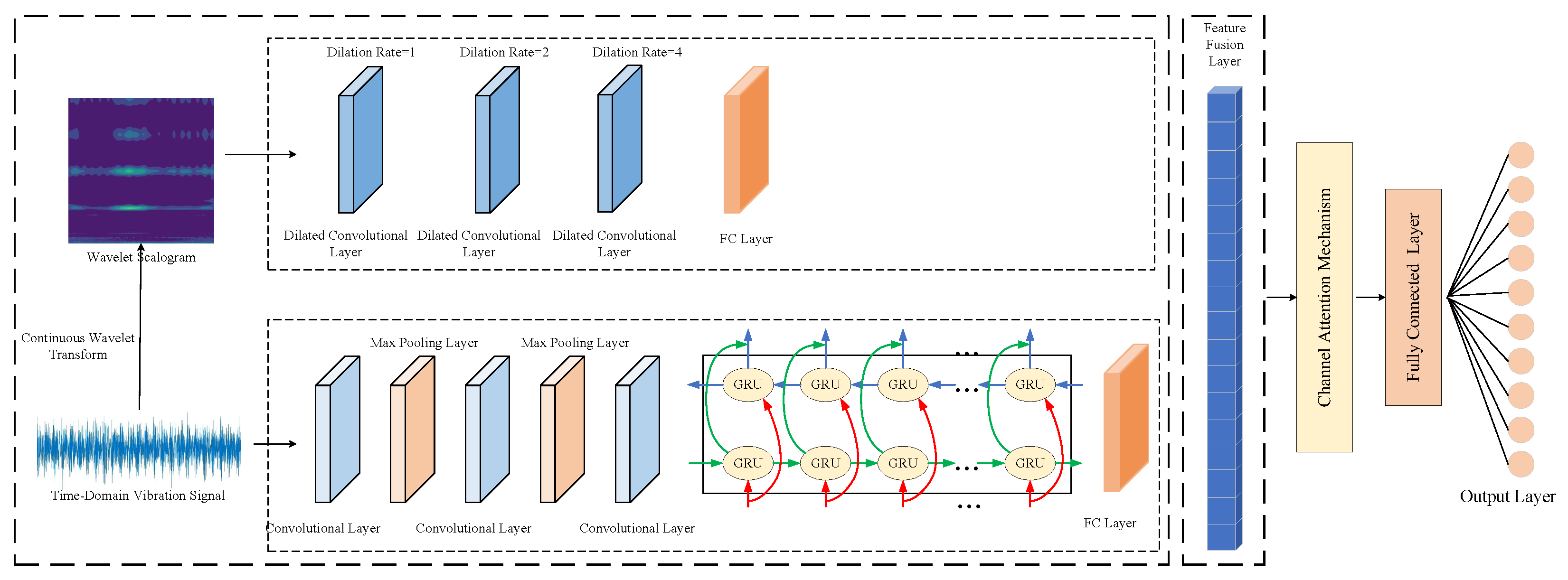

- A dual-channel parallel-architecture-based multi-modal feature fusion method is proposed for bearing fault diagnosis. This framework simultaneously processes raw one-dimensional vibration signals and two-dimensional time–frequency representations through dedicated channels to extract complementary fault features. The parallel integration of heterogeneous modal data enhances feature complementarity and significantly improves the model’s generalization capability.

- 2.

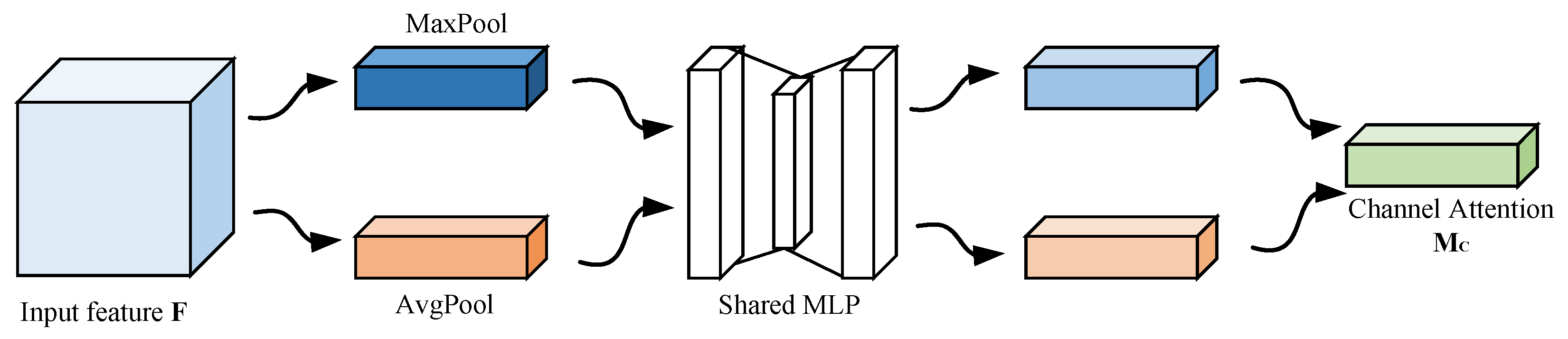

- A channel attention mechanism is incorporated to recalibrate feature channel weights, maximizing utilization of extracted sample features and enhancing the model’s focus on discriminative characteristics.

- 3.

- Comprehensive experimental validation was conducted across multiple benchmark datasets, including comparative analysis, noise robustness tests, and ablation studies. These experiments conclusively demonstrate the validity and efficacy of the proposed dual-channel parallel multi-modal feature fusion method for bearing fault diagnosis, confirming its superiority in this domain.

2. Theoretical Background

2.1. CWT

2.2. CNN

2.3. BiGRU

2.4. Channel Attention

3. Model Construction

3.1. Data Preprocessing

3.2. Model Construction

3.2.1. Model Construction

3.2.2. Diagnostic Workflow

4. Experimental Results

4.1. Dataset

- (1)

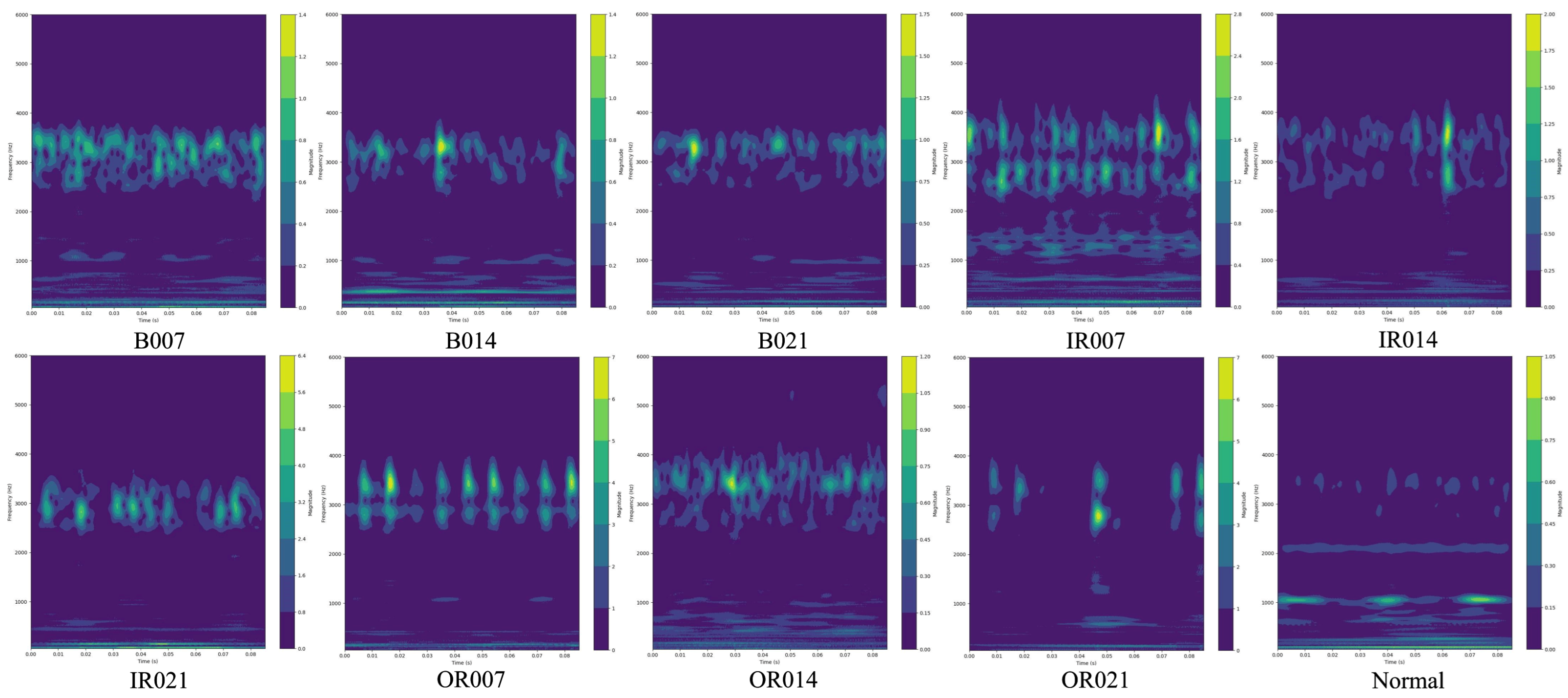

- CWRU: In order to assess the effectiveness of the suggested approach for diagnosing faults in rolling bearings, experiments were conducted using the bearing dataset from Case Western Reserve University (CWRU). The CWRU bearing fault dataset is widely adopted in fault diagnosis and prognosis research, containing vibration data under various fault modes and operating conditions. The experimental platform comprises a three-phase induction motor, torque transducer, dynamometer, and SKF6205 drive-end bearings.

- (2)

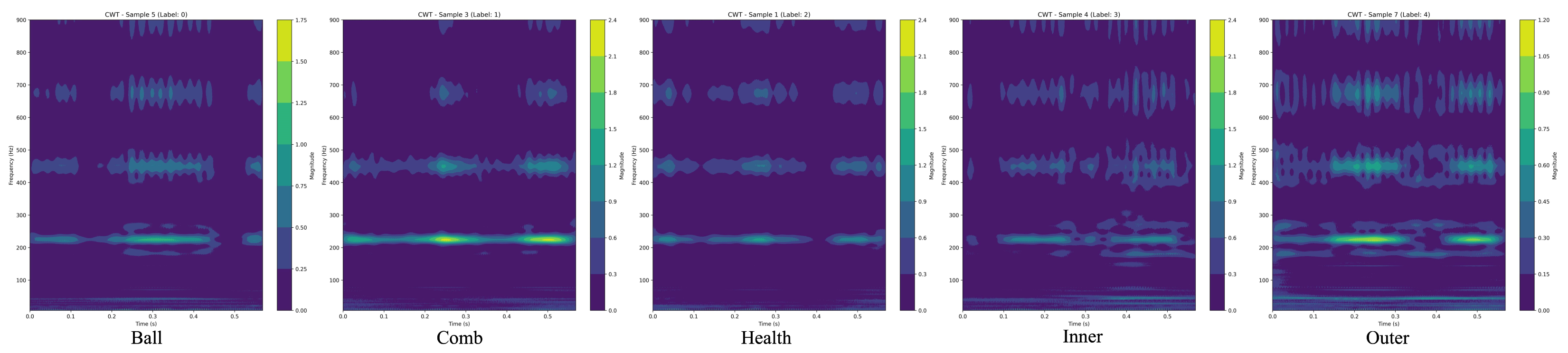

- SEU: The Southeast University (SEU) test rig was equipped with an electric motor, a motor controller, a speed reducer, a planetary gearbox, a brake, and a brake controller. This study utilized a bearing vibration dataset acquired under the operating condition of a 30 Hz (1800 rpm) rotational speed and a 2 V (7.32 Nm) load, with a sampling frequency of 5120 Hz. This dataset encompasses data representing five distinct states: ball fault, inner ring fault, outer ring fault, compound fault, and healthy working state. Specifications for the SEU fault categories are detailed in Table 3.

4.2. Comparative Methods and Experimental Results

4.2.1. Comparative Methods

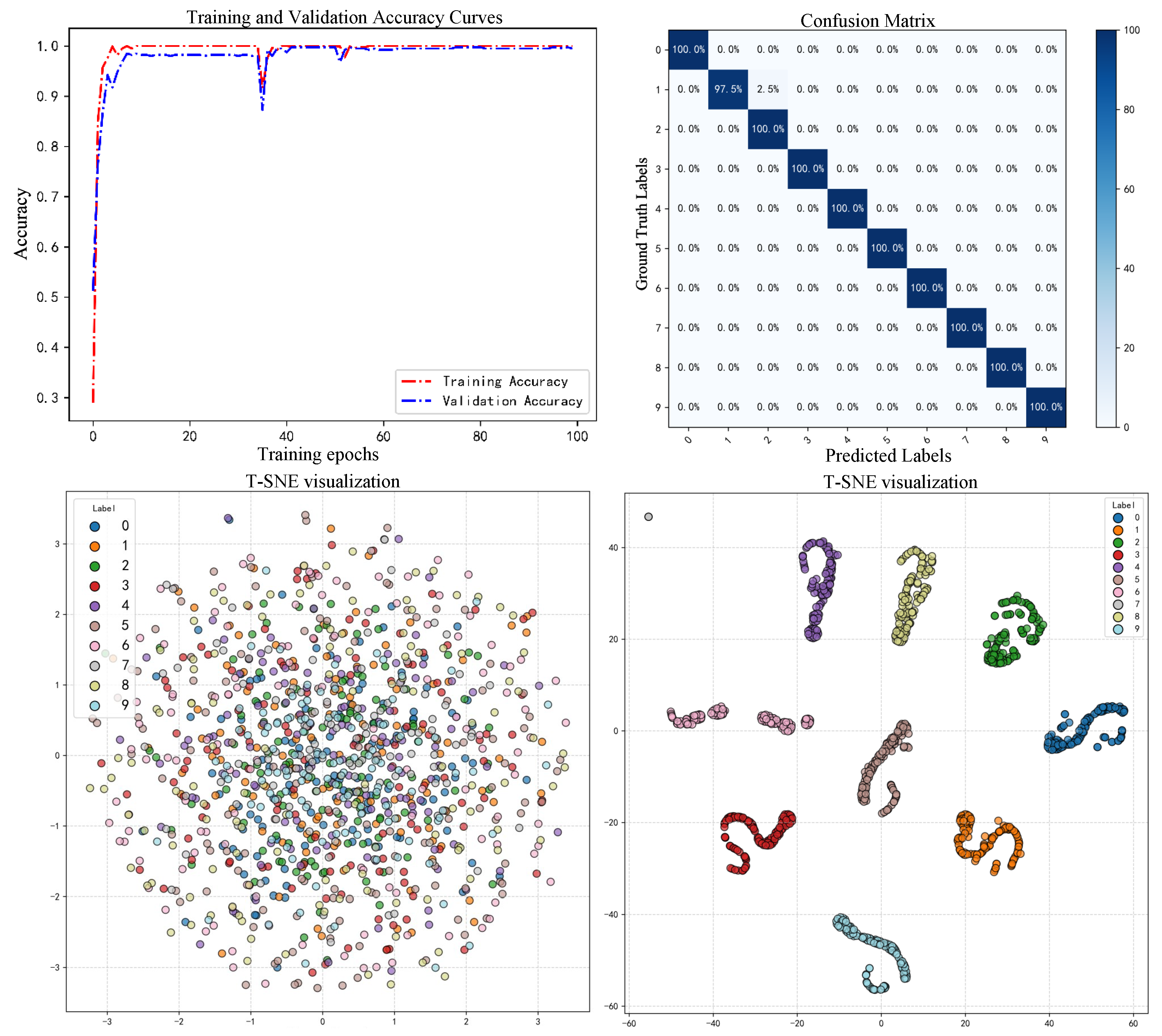

4.2.2. Case 1

4.2.3. Case 2

4.3. Ablation Experiments

5. Conclusions and Future Work

5.1. Conclusions

- 1.

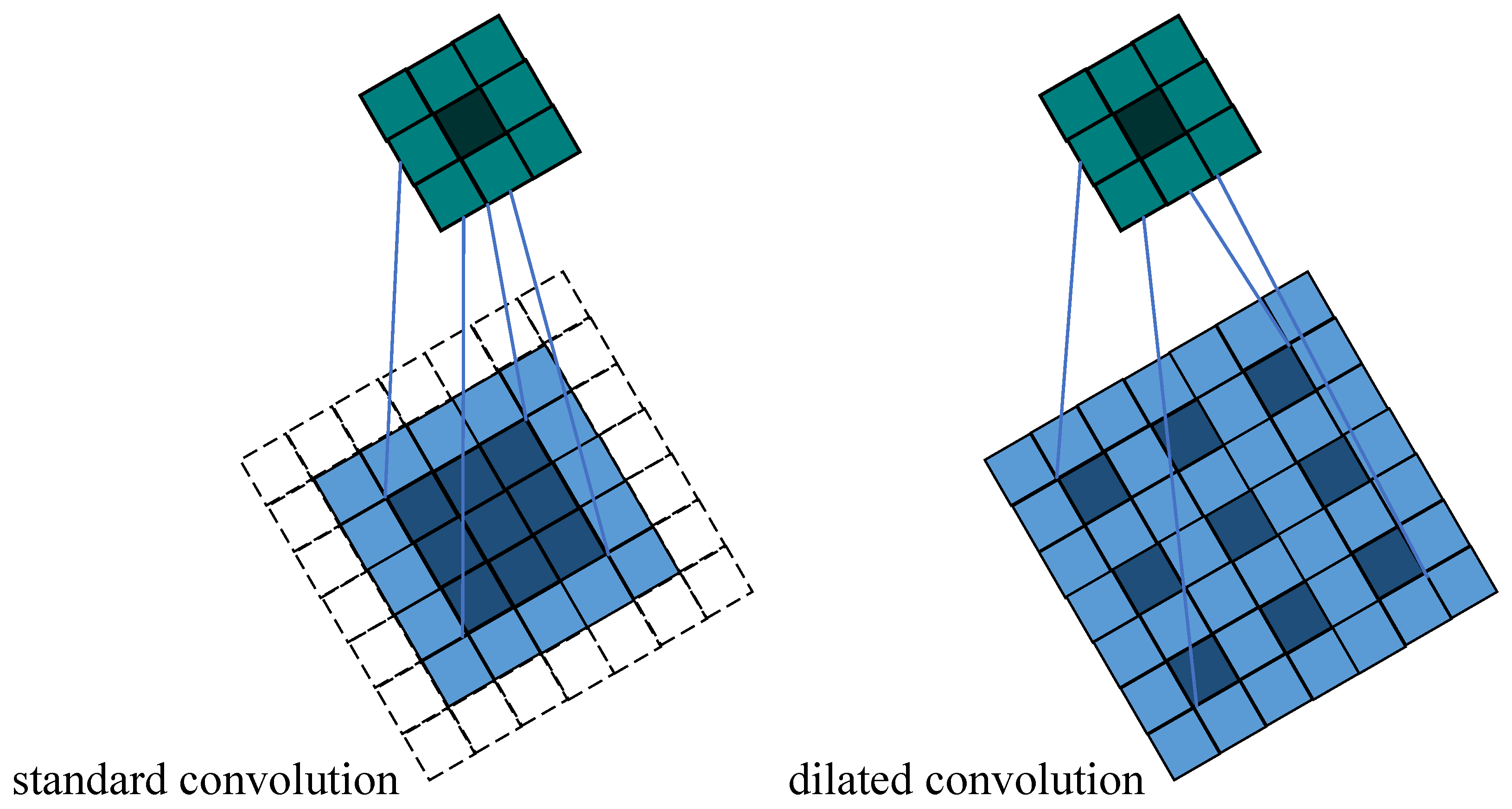

- The proposed dual-channel parallel multi-modal feature fusion model converts the input data into time–frequency images and employs dilated convolution for feature extraction. This approach capitalizes on the strong capability of two-dimensional dilated convolution in capturing image features, where dilated convolution expands the receptive field without reducing spatial resolution, thereby preserving fine-grained image details effectively. In processing one-dimensional signals, a one-dimensional convolutional neural network (1DCNN) is employed for effective local feature identification, succeeded by a bidirectional gated recurrent unit (BiGRU) to analyze intricate time-based relationships within the sequence. The parallel dual-channel architecture effectively exploits both temporal and spatial characteristics of the data, significantly enriching feature representation and achieving high diagnostic accuracy while maintaining strong generalization ability.

- 2.

- The incorporation of a channel attention mechanism after the feature fusion layer enhances the model’s ability to focus on critical fault-related features. By adaptively reweighting channel-wise features, the attention mechanism suppresses interference from redundant or irrelevant features, thereby further improving diagnostic accuracy.

5.2. Future Work

- 1.

- Real-World Data Collection and Validation. We plan to establish collaborations with industrial partners to collect vibration data from operational machinery in real industrial environments. This will include data from various types of rotating equipment operating under diverse working conditions, with natural fault progression being captured rather than artificially induced defects.

- 2.

- Variable Operating Condition Adaptation. A major focus will be on developing adaptive mechanisms that can handle variable operating conditions. We intend to investigate domain adaptation techniques and transfer learning approaches to enhance the model’s robustness when faced with changing rotational speeds, varying loads, and different operational regimes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Wang, S.; Cheng, Y. Fault feature extraction of parallel-axis gearbox based on IDBO-VMD and t-SNE. Appl. Sci. 2023, 14, 289. [Google Scholar] [CrossRef]

- Jyothi, R.; Holla, T.; Uma, R.K.; Jayapal, R. Machine learning based multi class fault diagnosis tool for voltage source inverter driven induction motor. Int. J. Power Electron. Drive Syst. 2021, 12, 1205. [Google Scholar] [CrossRef]

- Ambrozkiewicz, B.; Litak, G.; Georgiadis, A.; Syta, A.; Meier, N.; Gassner, A. Effect of radial clearance on ball bearing’s dynamics using a 2-DOF model. Int. J. Simul. Model. 2021, 20, 513–524. [Google Scholar] [CrossRef]

- Song, B.; Liu, Y.; Fang, J.; Liu, W.; Zhong, M.; Liu, X. An optimized CNN-BiLSTM network for bearing fault diagnosis under multiple working conditions with limited training samples. Neurocomputing 2024, 574, 127284. [Google Scholar] [CrossRef]

- Jia, L.; Chow, T.W.S.; Yuan, Y. GTFE-Net: A gramian time frequency enhancement CNN for bearing fault diagnosis. Eng. Appl. Artif. Intell. 2023, 119, 105794. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Wang, B.; Habetler, T.G. Deep Learning Algorithms for Bearing Fault Diagnostics—A Review. In Proceedings of the 2019 IEEE 12th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Toulouse, France, 27–30 August 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 257–263. [Google Scholar] [CrossRef]

- Gabor, D. Theory of communication. Part 1: The analysis of information. J. Inst. Electr. Eng. Part III 1946, 93, 429–441. [Google Scholar] [CrossRef]

- Rabiner, L.R.; Schafer, R.W. Digital Process. Speech Signal; Prentice Hall: Englewood Cliffs, NJ, USA, 1978; pp. 121–123. [Google Scholar] [CrossRef]

- Xu, Y.G.; Wang, L.; Hu, A.J.; Yu, G. Time-extracting S-transform algorithm and its application in rolling bearing fault diagnosis. Sci. China Technol. Sci. 2022, 65, 93–942. [Google Scholar] [CrossRef]

- Wang, Z.; Oates, T. Imaging Time-Series to Improve Classification and Imputation. arXiv 2015, arXiv:1506.00327. [Google Scholar] [CrossRef]

- Wen, L.; Gao, L.; Li, X. A New Deep Transfer Learning Based on Sparse Auto-Encoder for Fault Diagnosis. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 136–144. [Google Scholar] [CrossRef]

- Campanharo, A.S.L.O.; Sirer, M.I.; Malmgren, R.D.; Ramos, F.M.; Amaral, L.A.N. Duality between Time Series and Networks. PLoS ONE 2011, 6, e23378. [Google Scholar] [CrossRef]

- Xin, G.; Li, Z.; Jia, L.; Zhong, Q.; Dong, H.; Hamzaoui, N.; Antoni, J. Fault Diagnosis of Wheelset Bearings in High-Speed Trains Using Logarithmic Short-Time Fourier Transform and Modified Self-Calibrated Residual Network. IEEE Trans. Ind. Inform. 2021, 18, 7285–7295. [Google Scholar] [CrossRef]

- Ribeiro Junior, R.F.; dos Santos Areias, I.A.; Campos, M.M.; Teixeira, C.E.; da Silva, L.E.B.; Gomes, G.F. Fault Detection and Diagnosis in Electric Motors Using Convolution Neural Network and Short-Time Fourier Transform. J. Vib. Eng. Technol. 2022, 10, 2531–2542. [Google Scholar] [CrossRef]

- Zhang, R.; Zeng, X. Bearing Fault Diagnosis Based on STFT-SWT and Two-Flow CNN-KNN. In Proceedings of the International Conference on Electronics, Electrical and Information Engineering (ICEEIE 2024), Xi’an, China, 4–6 January 2024; SPIE: Bellingham, WA, USA, 2024; Volume 13445, pp. 430–436. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, X.; Yan, W.; Wang, J. Bearing Fault Diagnosis and Interpretation Based on 2D Images and Convolutional Neural Network. In Proceedings of the 2023 Asia Pacific Signal and Information Processing Association Annual Summit and Conference (APSIPA ASC), Taipei, Taiwan, 31 October–3 November 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 2155–2162. [Google Scholar] [CrossRef]

- Yang, C.; Zheng, L.; Zheng, G.; Wang, J. Rolling Bearing Fault Diagnosis Method Based on GAF-MTF and Deep Residual Network. In Proceedings of the 2024 IEEE International Conference on Sensing, Diagnostics, Prognostics, and Control (SDPC), Taiyuan, China, 2–4 August 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 106–111. [Google Scholar] [CrossRef]

- Guo, L.; Tang, J. Fault Diagnosis of Rolling Bearings Based on MTF-TLResNet34. In Proceedings of the 2023 35th Chinese Control and Decision Conference (CCDC), Yichang, China, 20–22 May 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 4714–4719. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, L.; Huang, Q. Bearing Fault Diagnosis Based on Multi-Channel GAF-MTF and Res2Net. In Proceedings of the 2023 35th Chinese Control and Decision Conference (CCDC), Yichang, China, 20–22 May 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 5321–5327. [Google Scholar] [CrossRef]

- Liu, J.; Tan, Y.; Yang, N.; Gao, Y.; Zhao, W.Q. An Anti-Noise Bearing’s Fault Diagnosis Method Using Adaptive Deconvolution and Mobile ViT. IEEE Sens. J. 2024, 24, 12345–12355. [Google Scholar] [CrossRef]

- Xue, L.; Lei, C.; Jiao, M.; Shi, J.; Li, J. Rolling Bearing Fault Diagnosis Method Based on Self-Calibrated Coordinate Attention Mechanism and Multi-Scale Convolutional Neural Network under Small Samples. IEEE Sens. J. 2023, 23, 10206–10214. [Google Scholar] [CrossRef]

- Daubechies, I. The wavelet transform, time-frequency localization and signal analysis. IEEE Trans. Inf. Theory 2002, 36, 961–1005. [Google Scholar] [CrossRef]

- Peng, Z.K.; Chu, F.L. Application of the wavelet transform in machine condition monitoring and fault diagnostics: A review with bibliography. Mech. Syst. Signal Process. 2004, 18, 199–221. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Wang, S.; Li, W.; Sarkodie-Gyan, T.; Feng, S. A Hybrid Deep-Learning Model for Fault Diagnosis of Rolling Bearings. Measurement 2021, 169, 108502. [Google Scholar] [CrossRef]

- Diao, N.; Wang, Z.; Ma, H.; Yang, W. Fault Diagnosis of Rolling Bearing under Variable Working Conditions Based on CWT and T-ResNet. J. Vib. Eng. Technol. 2023, 11, 3747–3757. [Google Scholar] [CrossRef]

- Jia, G.-w.; Shi, H.-s.; Lv, H.-j.; Zhang, P.-y.; Xu, W.-q.; Cai, M. Bearing Fault Diagnosis Method Based on CWT-ResNet18. In Proceedings of the 2023 9th International Conference on Fluid Power and Mechatronics (FPM), Wuhan, China, 9–11 August 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Guo, Y.; Zhou, J.; Dong, Z.; She, H.; Xu, W. Research on Bearing Fault Diagnosis Based on Novel MRSVD-CWT and Improved CNN-LSTM. Meas. Sci. Technol. 2024, 35, 095003. [Google Scholar] [CrossRef]

- Jiang, L.; Shi, C.; Sheng, H.; Li, X.; Yang, T. Lightweight CNN architecture design for rolling bearing fault diagnosis. Meas. Sci. Technol. 2024, 35, 126142. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.; Gao, D. Bearing fault diagnosis base on multi-scale CNN and LSTM model. J. Intell. Manuf. 2021, 32, 971–987. [Google Scholar] [CrossRef]

- Wang, X.; Mao, D.; Li, X. Bearing fault diagnosis based on vibro-acoustic data fusion and 1D-CNN network. Measurement 2021, 173, 108518. [Google Scholar] [CrossRef]

- Sinitsin, V.; Ibryaeva, O.; Sakovskaya, V.; Eremeeva, V. Intelligent bearing fault diagnosis method combining mixed input and hybrid CNN-MLP model. Mech. Syst. Signal Process. 2022, 180, 109454. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, J.; Zheng, Y.; Jiang, W.; Zhang, Y. Fault diagnosis of rolling bearings with recurrent neural network-based autoencoders. ISA Trans. 2018, 77, 167–178. [Google Scholar] [CrossRef]

- Jiang, H.; Li, X.; Shao, H.; Zhao, K. Intelligent fault diagnosis of rolling bearings using an improved deep recurrent neural network. Meas. Sci. Technol. 2018, 29, 065107. [Google Scholar] [CrossRef]

- Xu, Z.; Li, Y.F.; Huang, H.Z.; Deng, Z.; Huang, Z. A novel method based on CNN-BiGRU and AM model for bearing fault diagnosis. J. Mech. Sci. Technol. 2024, 38, 3361–3369. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Lu, L.; Cong, S. Rolling Bearing Fault Diagnosis Based on Transfer Learning and Dual-Channel CNN and BiGRU. In Proceedings of the 2024 International Conference on Advanced Robotics and Mechatronics (ICARM), Tokyo, Japan, 8–10 July 2024; pp. 819–824. [Google Scholar] [CrossRef]

- Ren, Y.; Lu, R.; Yuan, G.; Hao, D.; Li, H. Attention-Based Spatiotemporal-Aware Network for Fine-Grained Visual Recognition. Appl. Sci. 2024, 14, 7755. [Google Scholar] [CrossRef]

| One-Dimensional Feature Extraction | Two-Dimensional Feature Extraction | |

|---|---|---|

| Input Data | One-dimensional data (1024, 1) | Two-dimensional data (64, 64, 3) |

| Feature extraction layer | Conv1D (Filters: 8, Kernel size: , Relu) | Conv2D (filters: 32; kernel size: , Dilation = 1, Relu) |

| MaxPool1D (kernel size: 2; stride: 2) | ||

| Conv1D (filters: 16; kernel size: , Relu) | Conv2D (filters: 64; kernel size: ; dilation = 2, Relu) | |

| MaxPool1D (kernel size: 2; stride: 2) | ||

| Dropout | Conv2D (filters: 64; kernel size: ; dilation = 4, Relu) | |

| Conv1D (filters: 8; kernel size: ; Relu) | ||

| Dropout | ||

| Bidirectional (GRU(32)) | ||

| Dropout | ||

| Fusion layer | Feature fusion layer | |

| Attention mechanism | Channel attention mechanism | |

| Dense (128, Relu) | ||

| Fully connected layer | Dense (fault categories, softmax) | |

| Fault Type | Diameter\mm | Motor Load\HP | Label | Size of the Training Set | Size of the Valid Set |

|---|---|---|---|---|---|

| B007 | 0.1778 | 1 | 0 | 120 | Data |

| B014 | 0.3556 | 1 | 1 | 120 | 40 |

| B021 | 0.5334 | 1 | 2 | 120 | 40 |

| IR007 | 0.1778 | 1 | 3 | 120 | 40 |

| IR014 | 0.3556 | 1 | 4 | 120 | 40 |

| IR021 | 0.5334 | 1 | 5 | 120 | 40 |

| OR007 | 0.1778 | 1 | 6 | 120 | 40 |

| OR014 | 0.3556 | 1 | 7 | 120 | 40 |

| OR021 | 0.5334 | 1 | 8 | 120 | 40 |

| Normal | / | / | 9 | 120 | 40 |

| Fault Type | Label | Diameter\mm | Working Condition | Size of the Training Set | Size of the Valid Set |

|---|---|---|---|---|---|

| Ball fault | 0 | 0.508 | ball_30_2.csv | 180 | 60 |

| Compound fault | 1 | 0.508 | comb_30_2.csv | 180 | 60 |

| Health | 2 | / | health_30_2.csv | 180 | 60 |

| Inner ring fault | 3 | 0.508 | inner_30_2.csv | 180 | 60 |

| Outer ring fault | 4 | 0.508 | outer_30_2.csv | 180 | 60 |

| MLP | GRU | LSTM | CNN | Proposed Method | |

|---|---|---|---|---|---|

| −6 db | 64.50% (0.56%) | 77.50% (1.03%) | 75.25% (1.41%) | 76.00% (1.03%) | 87.00% (0.64%) |

| 59.67% (1.17%) | 74.93% (0.90%) | 74.33% (0.87%) | 72.67% (0.75%) | 85.87% (0.58%) | |

| −4 db | 65.25% (0.79%) | 78.00% (0.91%) | 77.00% (0.67%) | 77.50% (0.61%) | 87.75% (0.56%) |

| 61.67% (0.96%) | 76.93% (0.87%) | 75.00% (0.75%) | 73.27% (0.58%) | 86.73% (0.48%) | |

| 0 db | 78.25% (0.50%) | 83.50% (0.48%) | 80.00% (0.32%) | 81.50% (0.43%) | 92.50% (0.43%) |

| 70.00% (0.87%) | 82.07% (0.75%) | 78.33% (0.63%) | 78.13% (0.43%) | 91.67% (0.27%) | |

| 4 db | 80.00% (0.62%) | 86.25% (0.62%) | 84.50% (0.48%) | 84.50% (0.50%) | 94.50% (0.48%) |

| 76.00% (0.90%) | 83.27% (0.87%) | 82.47% (0.64%) | 81.47% (0.59%) | 93.27% (0.38%) | |

| 6 db | 84.25% (0.64%) | 87.75% (0.67%) | 85.50% (0.57%) | 85.75% (0.57%) | 95.2% (0.48%) |

| 77.33% (0.90%) | 84.47% (0.90%) | 83.93% (0.75%) | 82.73% (0.52%) | 94.67% (0.38%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Cai, H.; Yang, X.; Xue, Y.; Ye, J.; Hu, X. Dual-Channel Parallel Multimodal Feature Fusion for Bearing Fault Diagnosis. Machines 2025, 13, 950. https://doi.org/10.3390/machines13100950

Li W, Cai H, Yang X, Xue Y, Ye J, Hu X. Dual-Channel Parallel Multimodal Feature Fusion for Bearing Fault Diagnosis. Machines. 2025; 13(10):950. https://doi.org/10.3390/machines13100950

Chicago/Turabian StyleLi, Wanrong, Haichao Cai, Xiaokang Yang, Yujun Xue, Jun Ye, and Xiangyi Hu. 2025. "Dual-Channel Parallel Multimodal Feature Fusion for Bearing Fault Diagnosis" Machines 13, no. 10: 950. https://doi.org/10.3390/machines13100950

APA StyleLi, W., Cai, H., Yang, X., Xue, Y., Ye, J., & Hu, X. (2025). Dual-Channel Parallel Multimodal Feature Fusion for Bearing Fault Diagnosis. Machines, 13(10), 950. https://doi.org/10.3390/machines13100950