Rotor Strength Analysis of FeCo-Based Permanent Magnet High Speed Motor

Abstract

:1. Introduction

2. Analytical Calculation of Rotor Structure and Rotor Strength of HSPMM

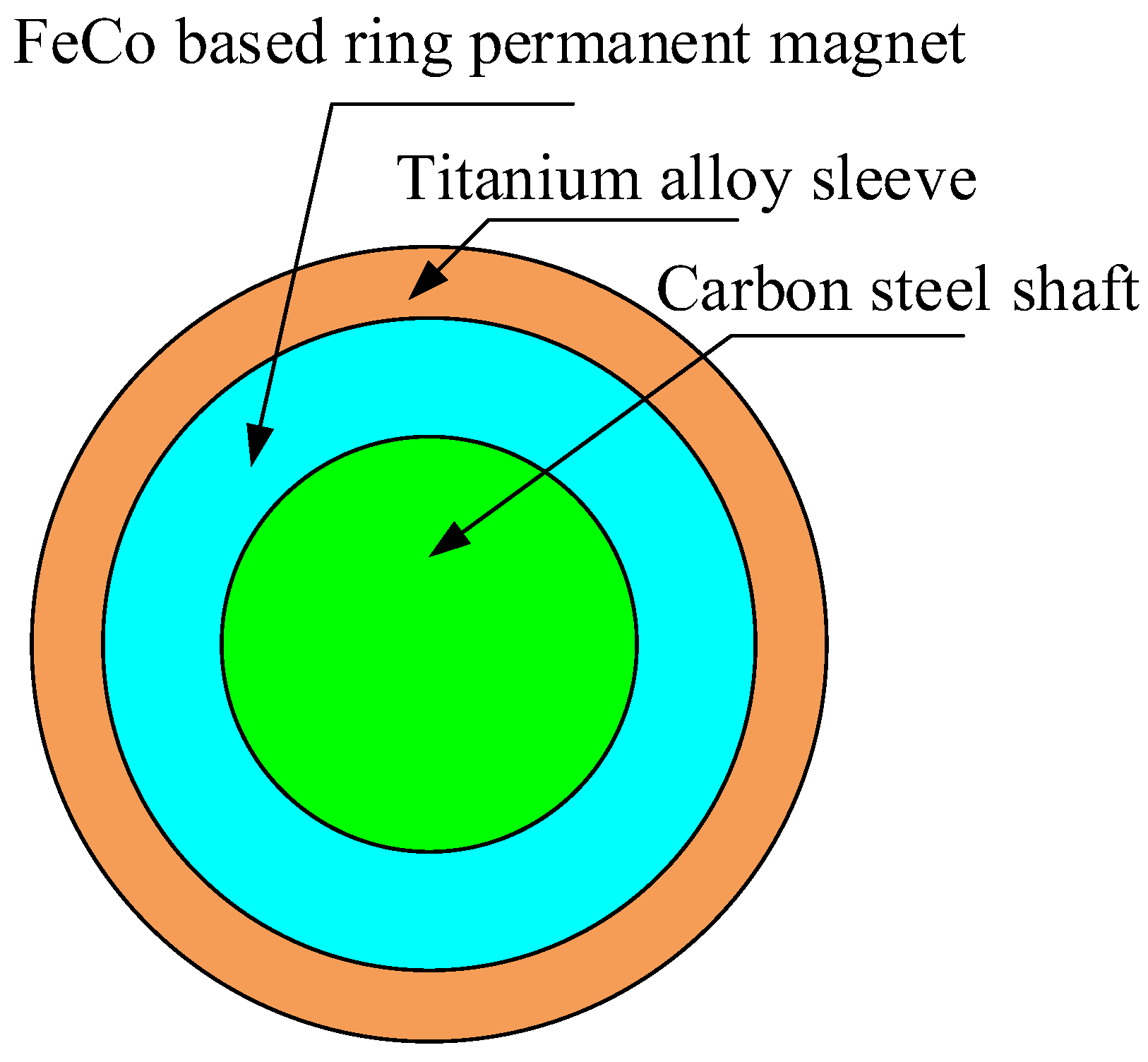

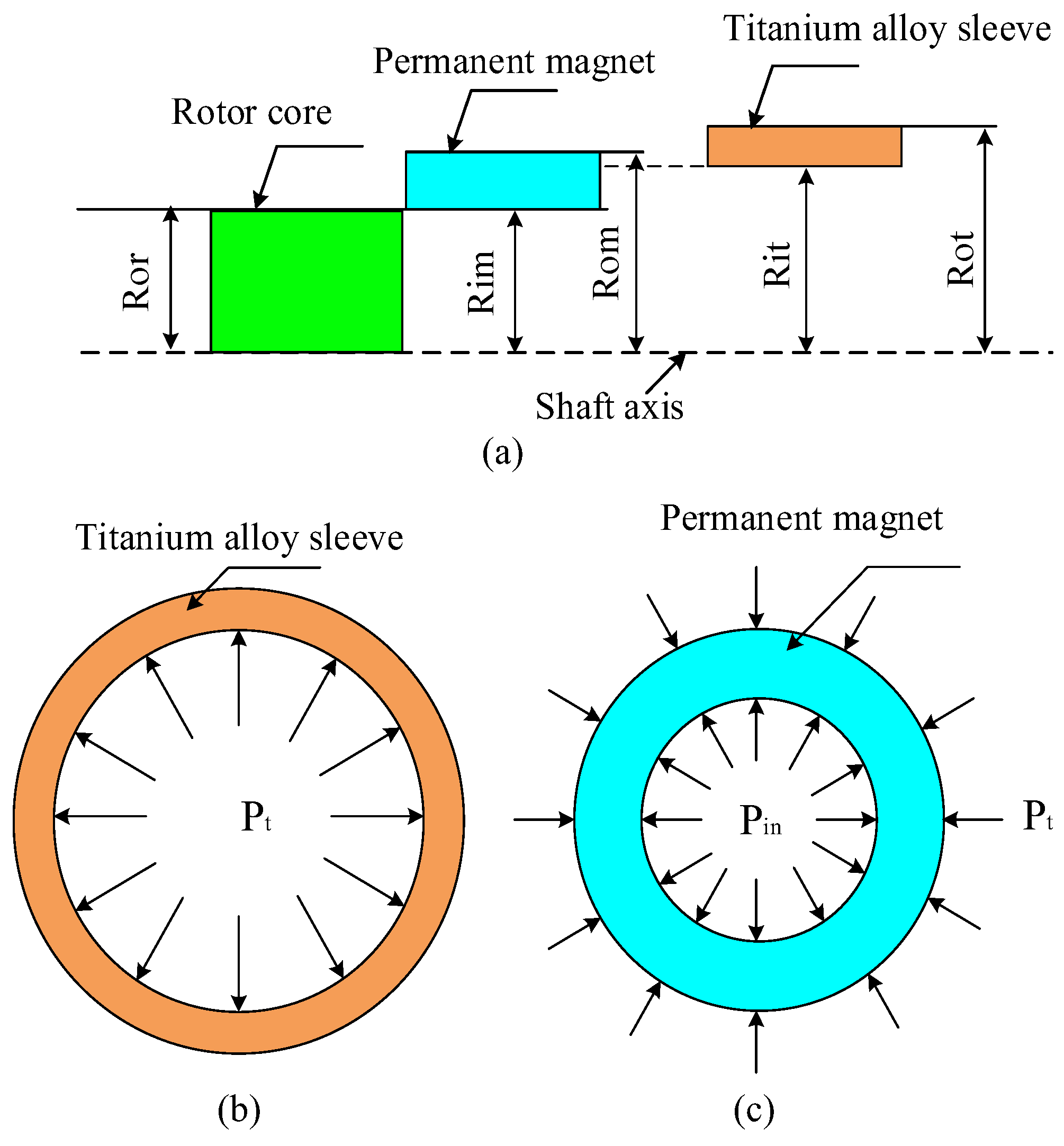

2.1. Rotor Structure of HSPMM

2.2. Analytical Calculation of Rotor Strength of HSPMM

3. Comparisons between ACM and FEM

3.1. Rotor Size Parameters of HSPMM

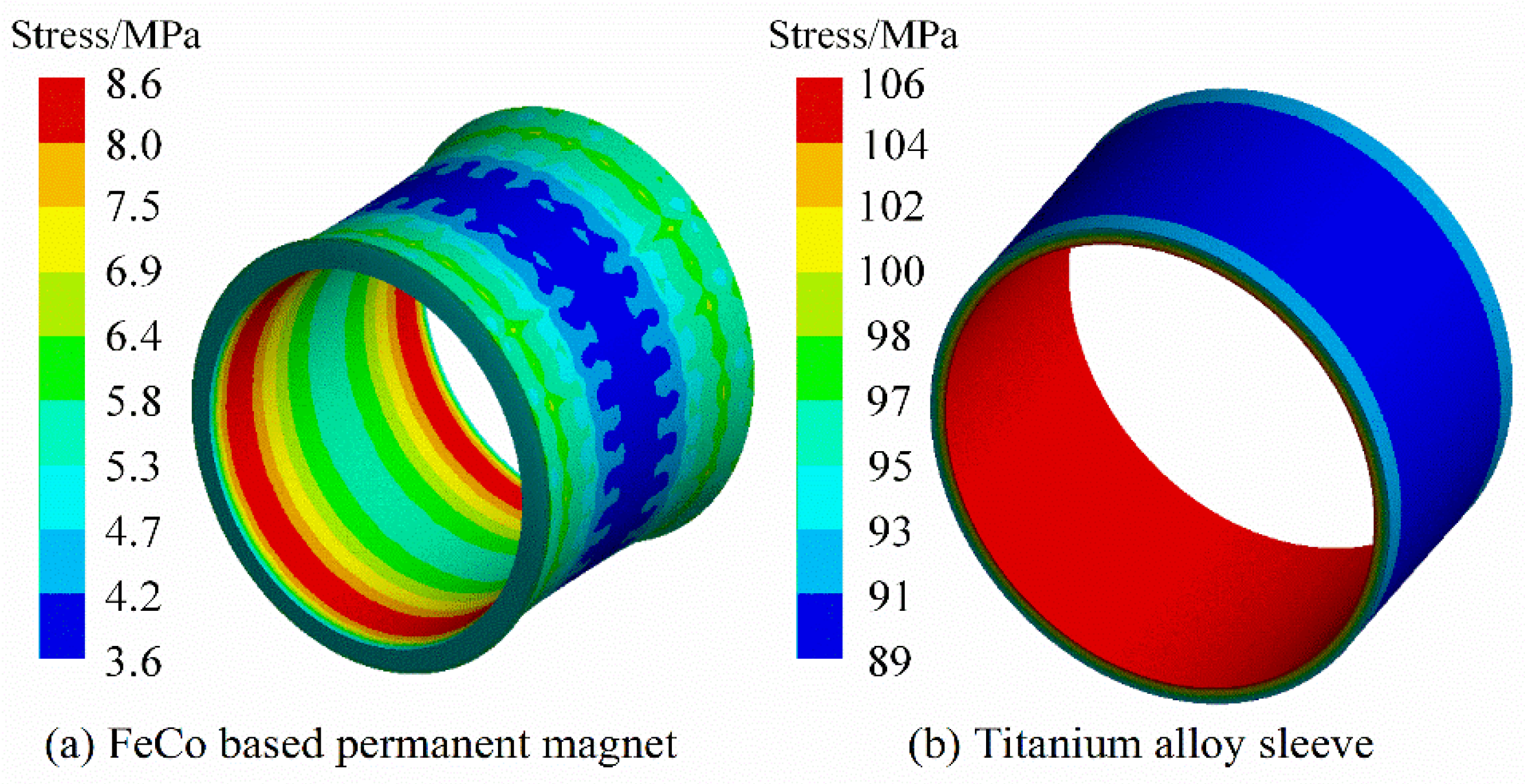

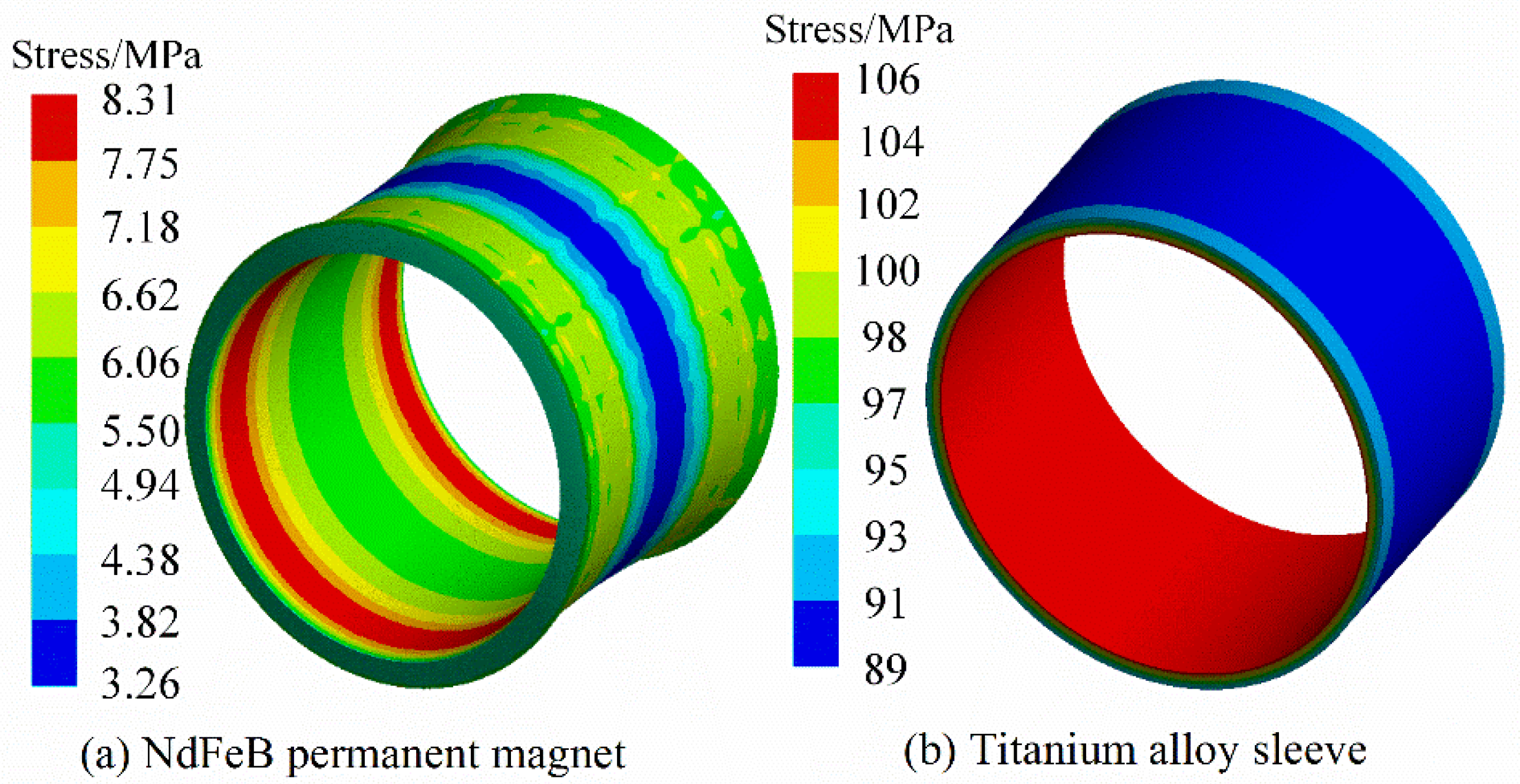

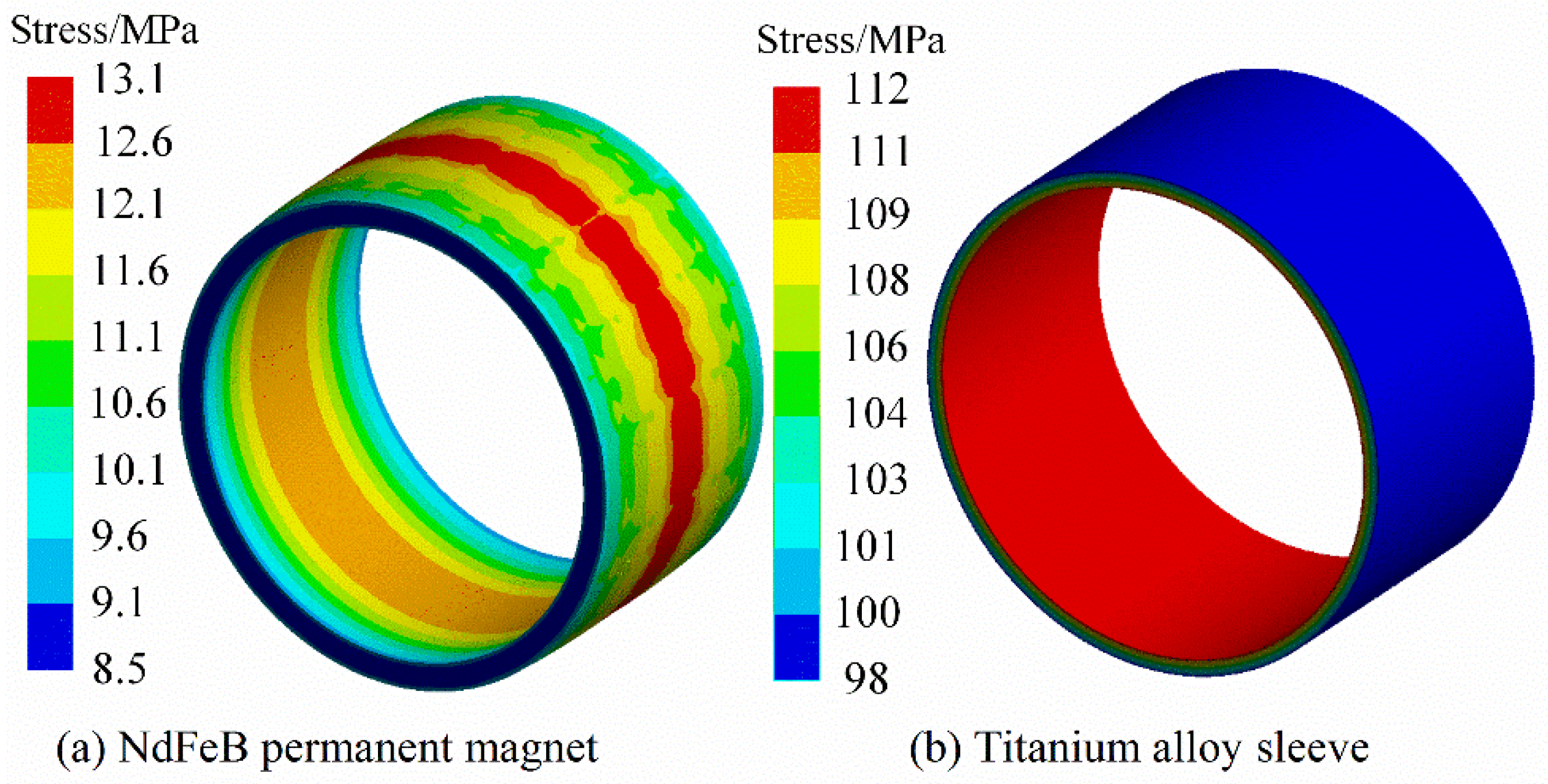

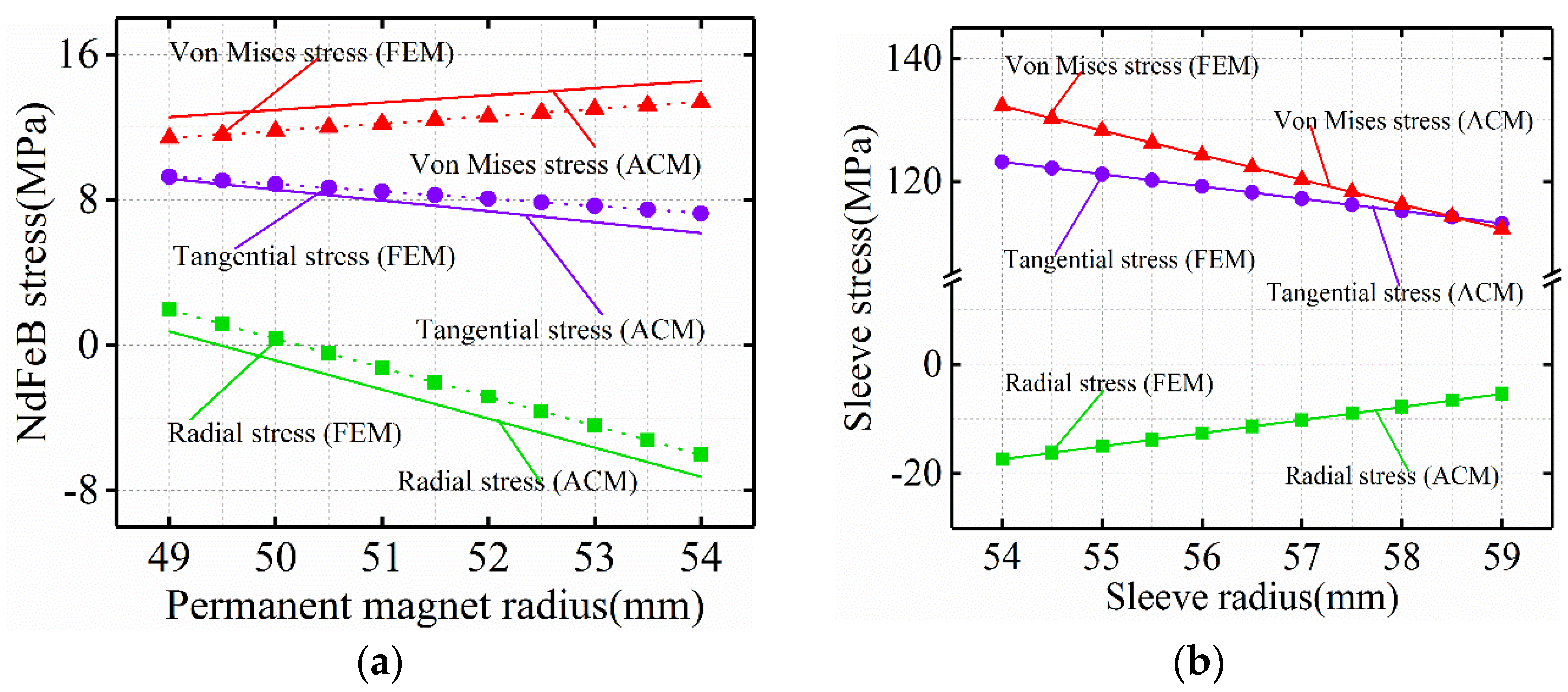

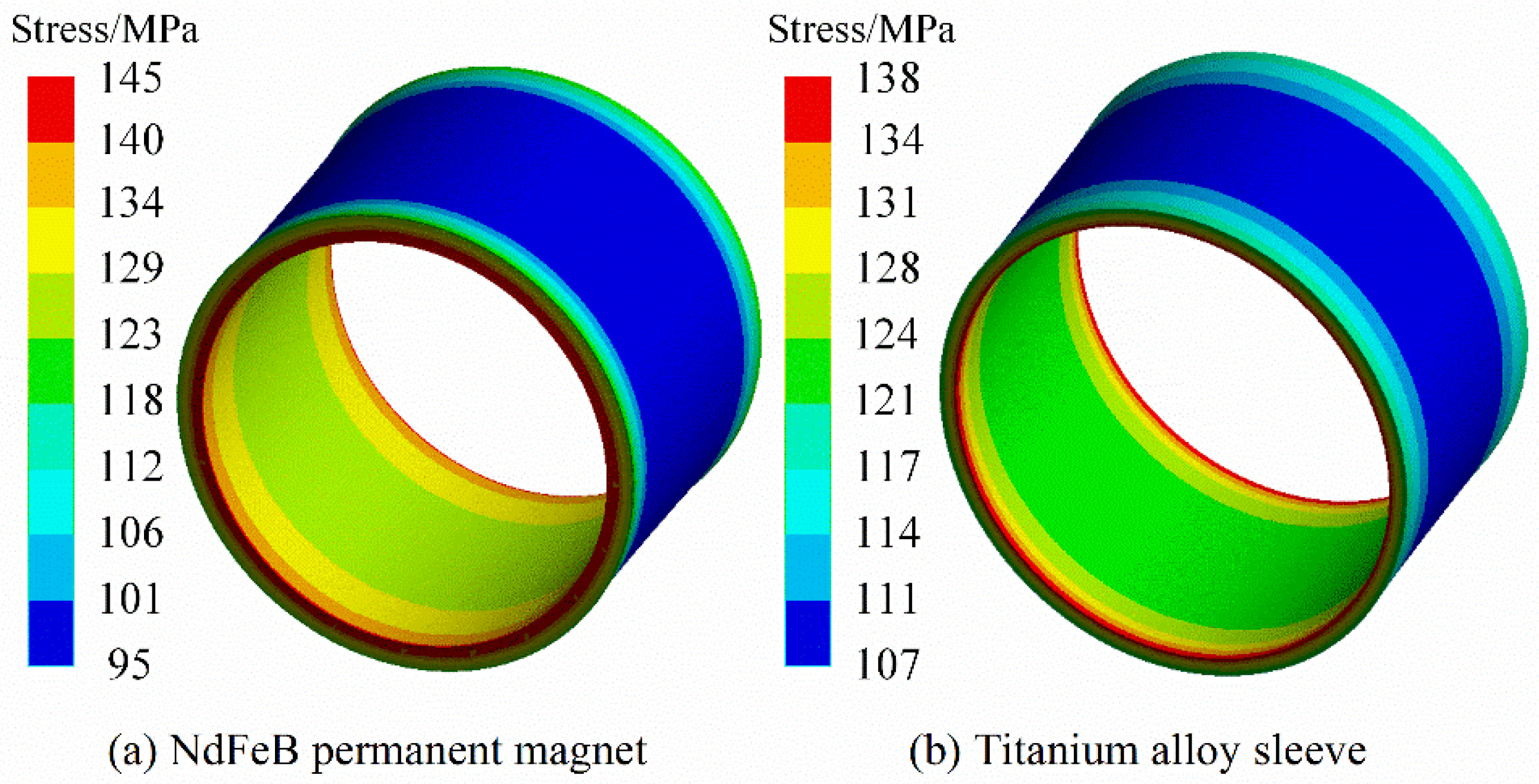

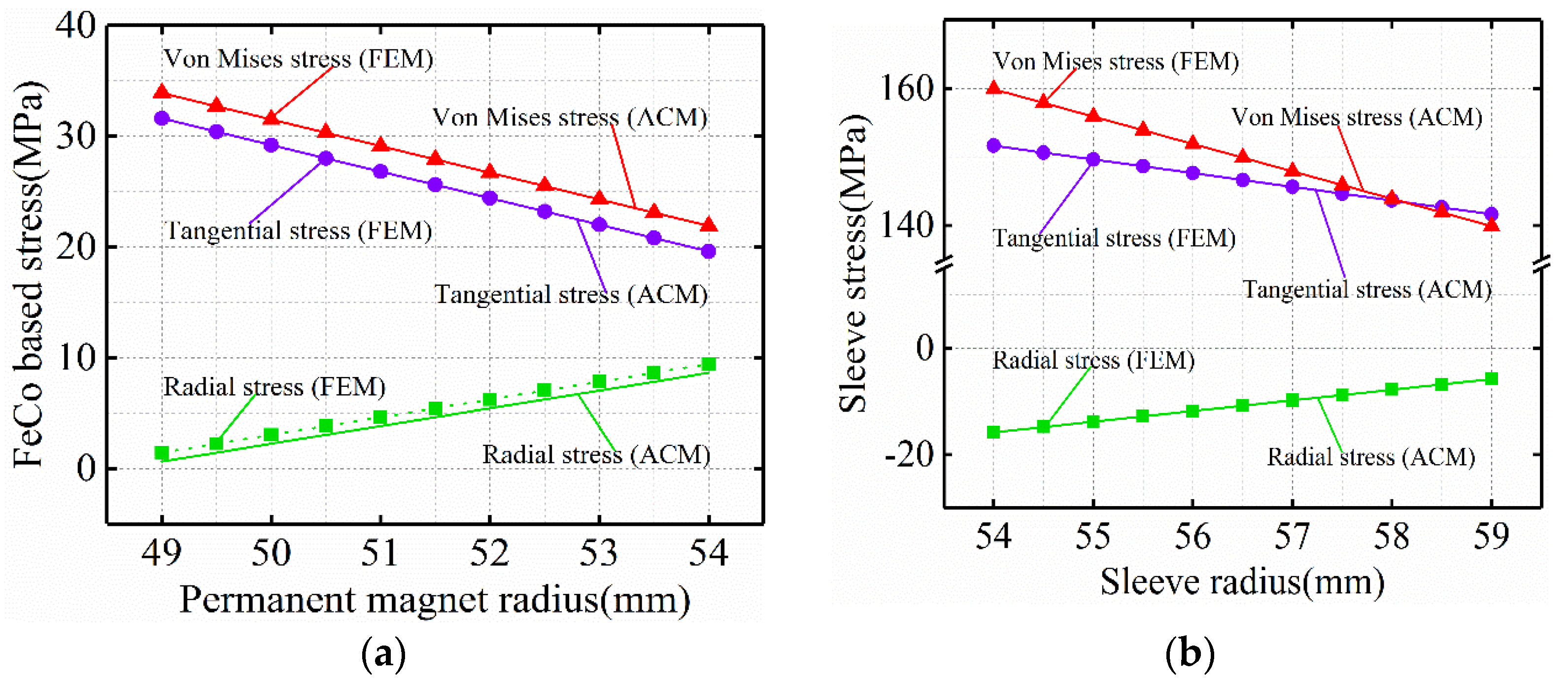

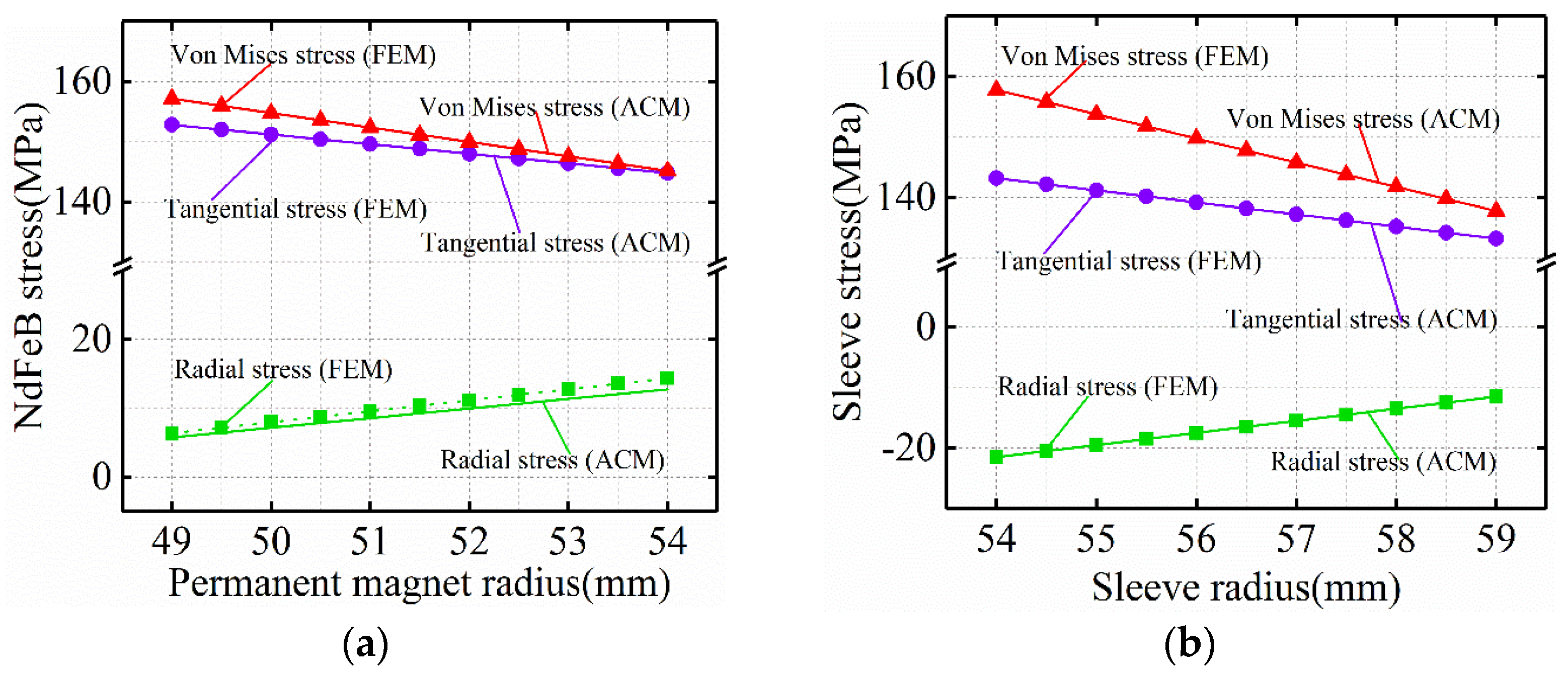

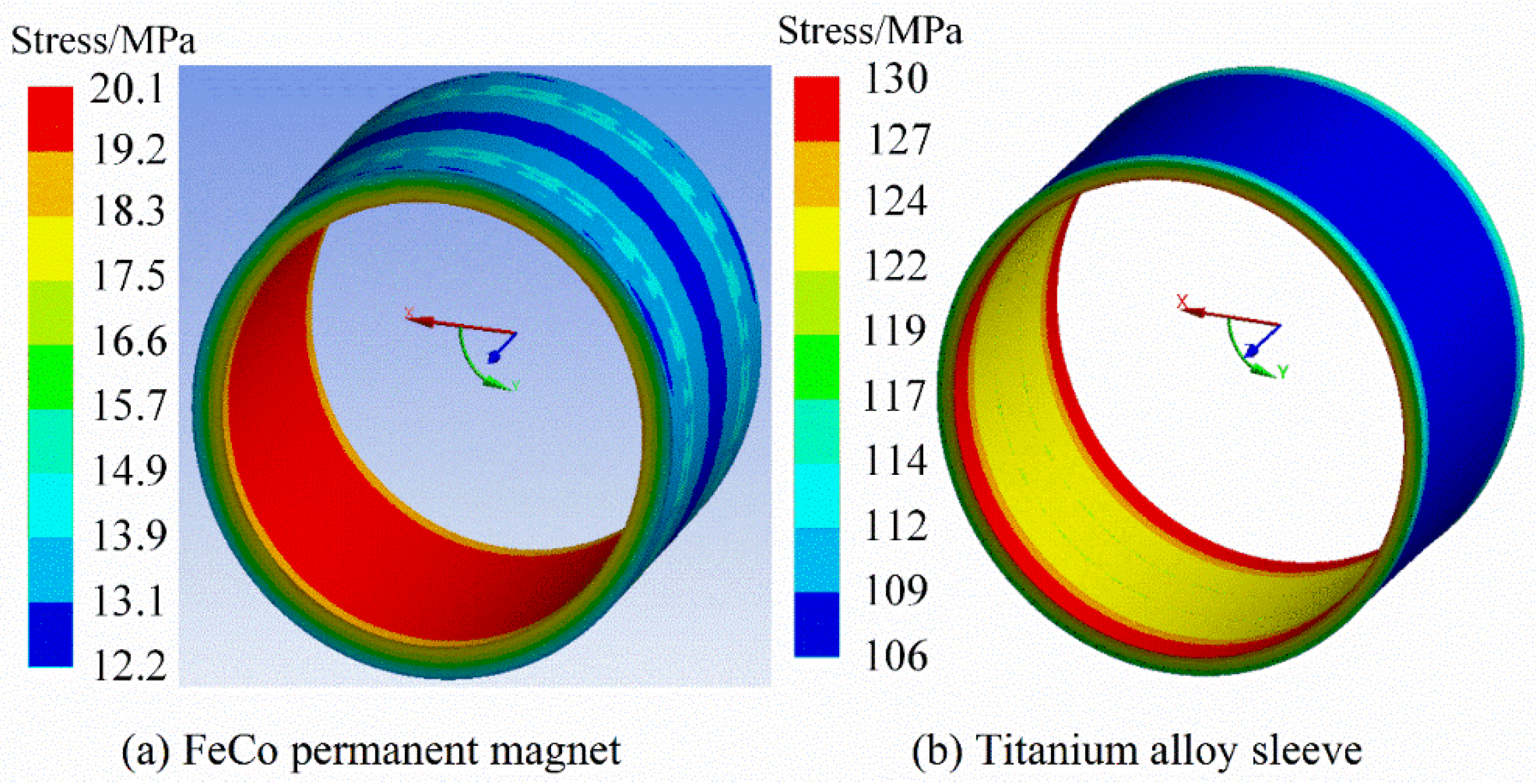

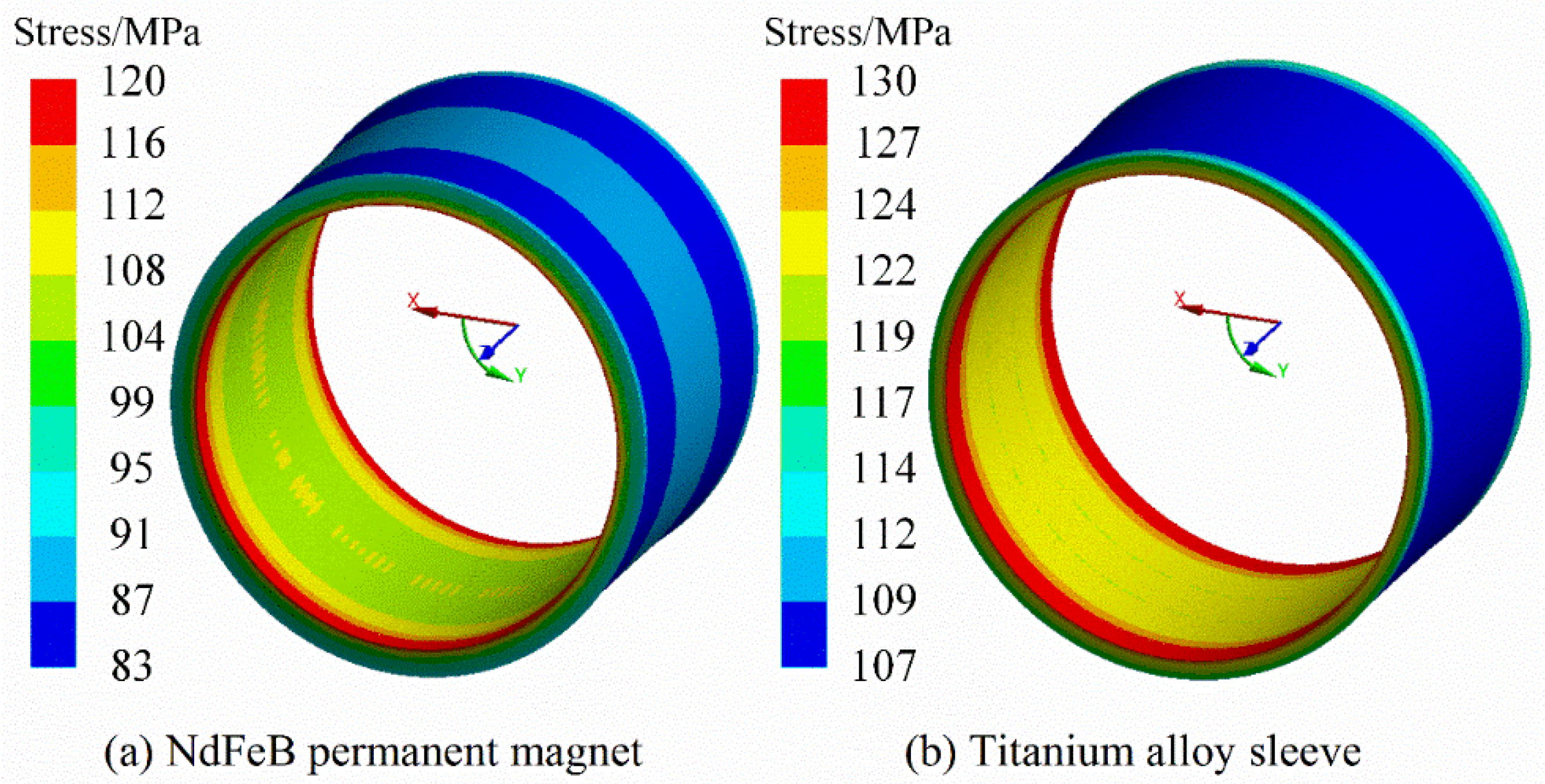

3.2. Stress Analysis of Steady Condition

3.3. Stress Analysis of Cold Rotating Condition

3.4. Stress Analysis of Hot Rotating Condition

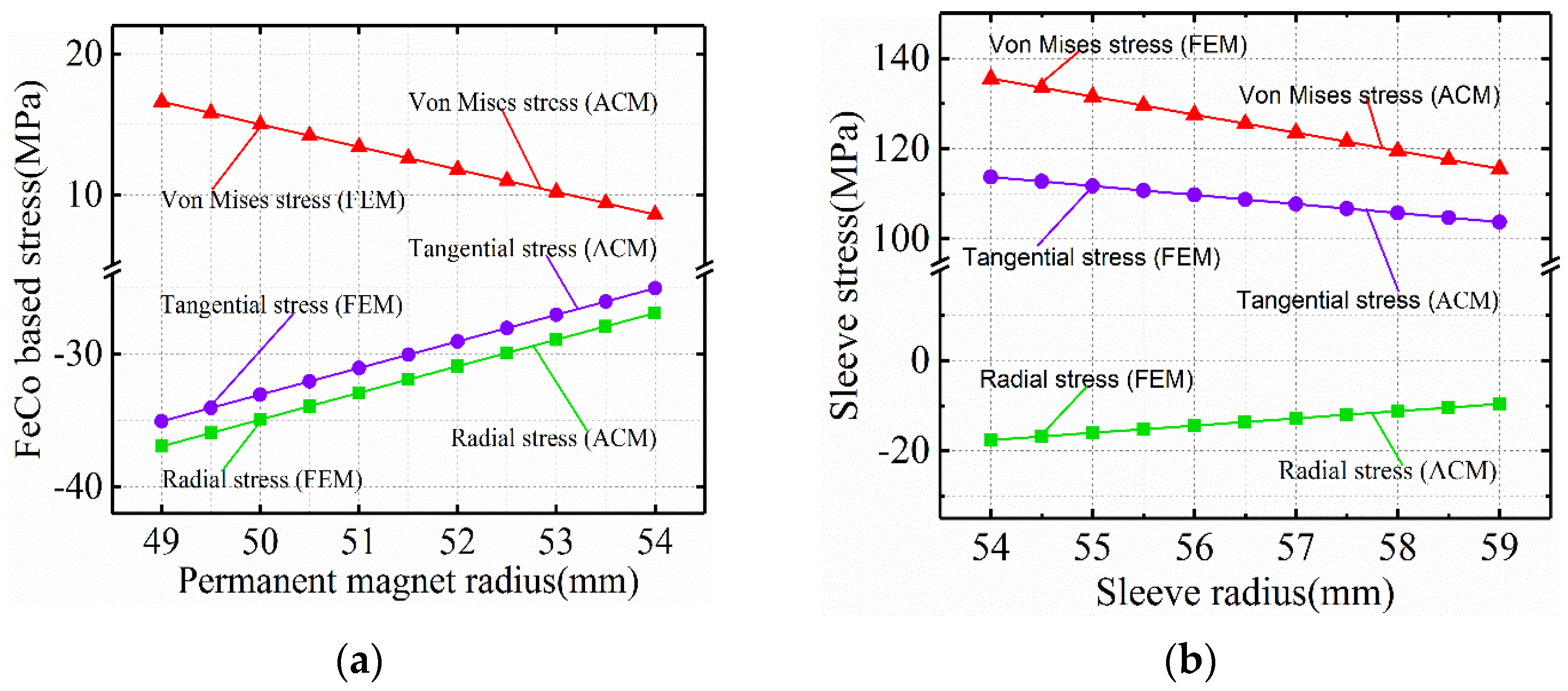

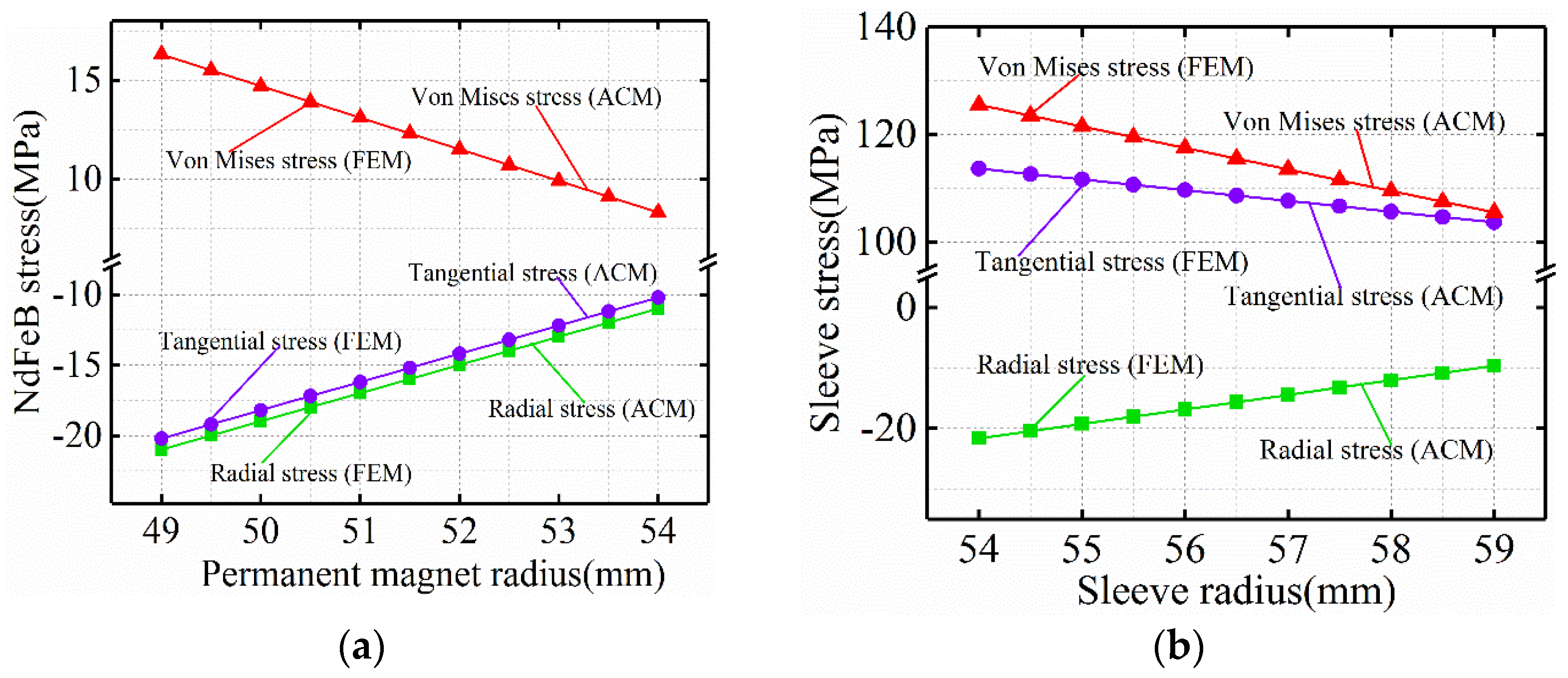

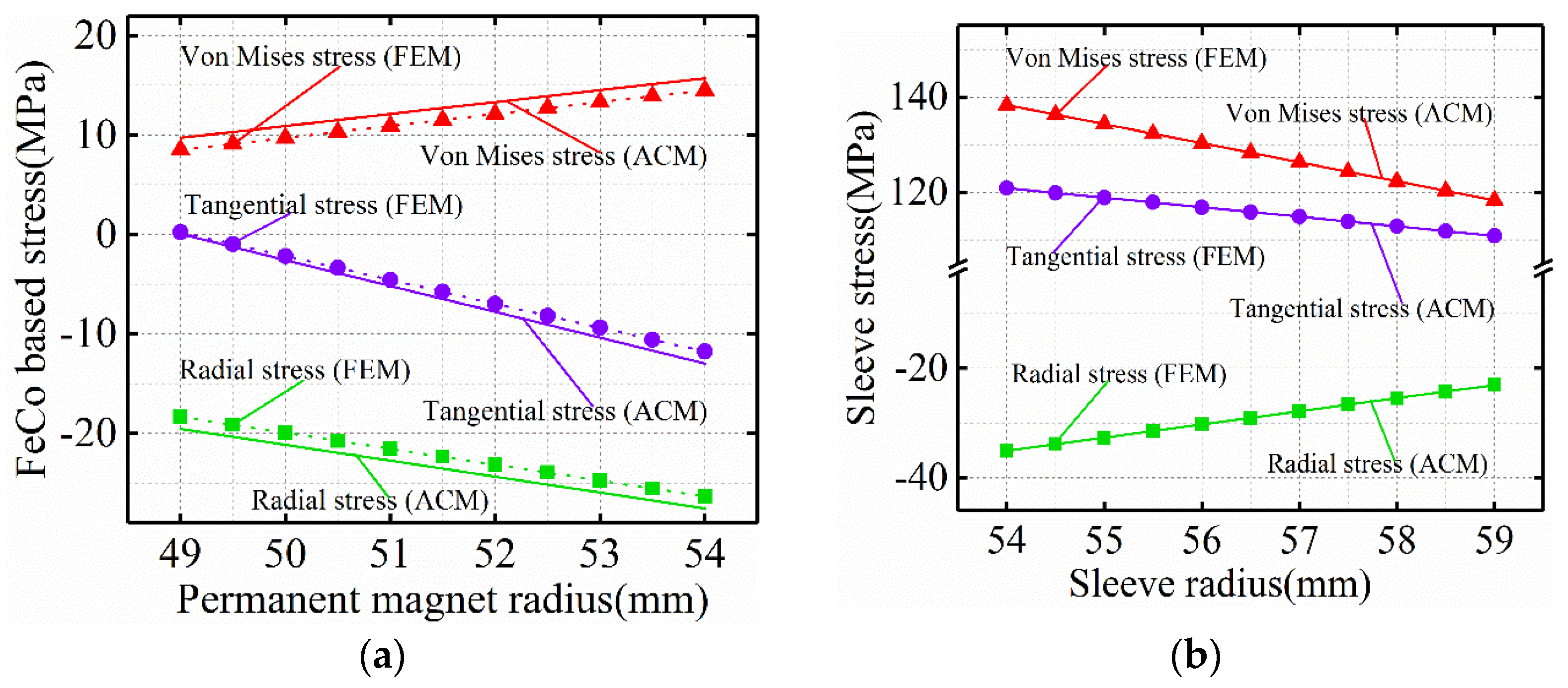

4. Analysis of Influencing Factors of Rotor Stress

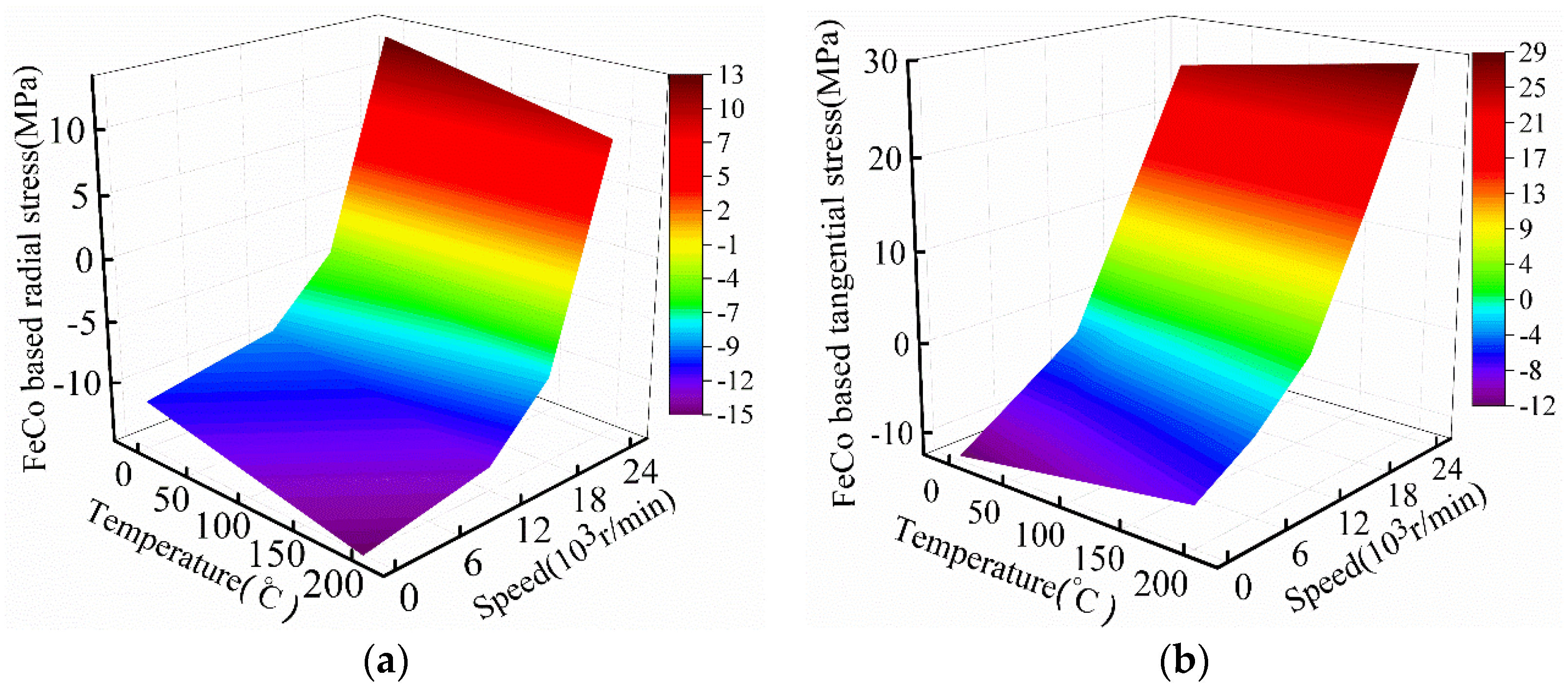

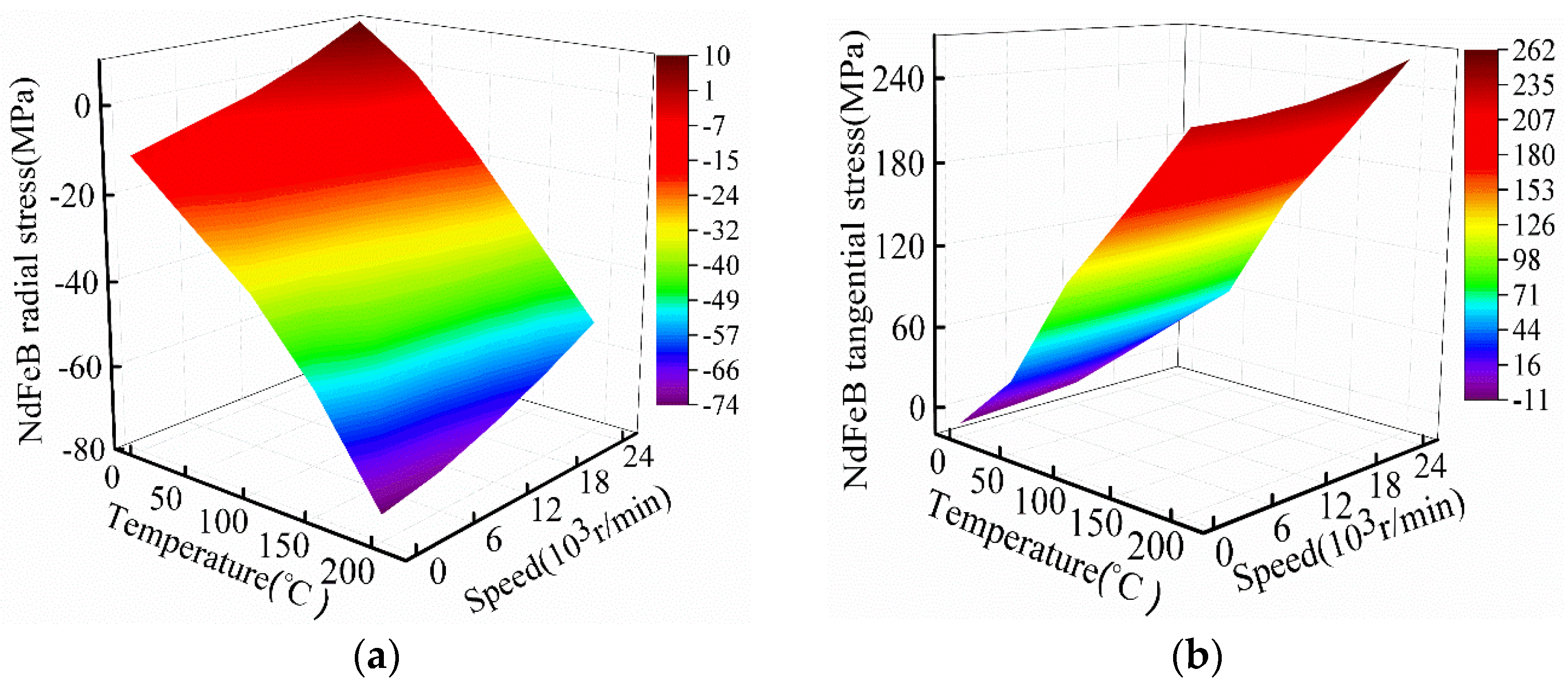

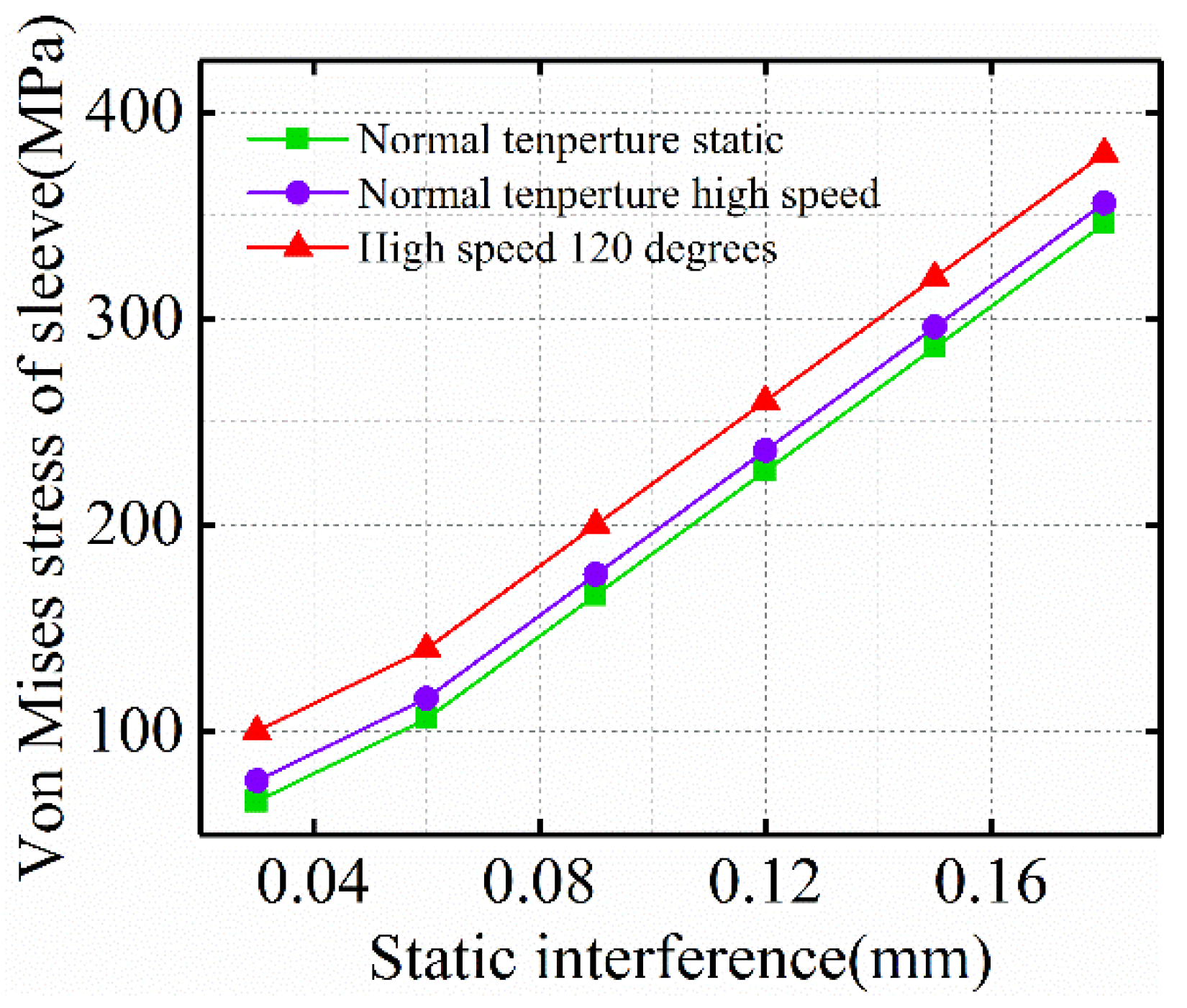

4.1. Influence of External Condition Parameters of Rotor

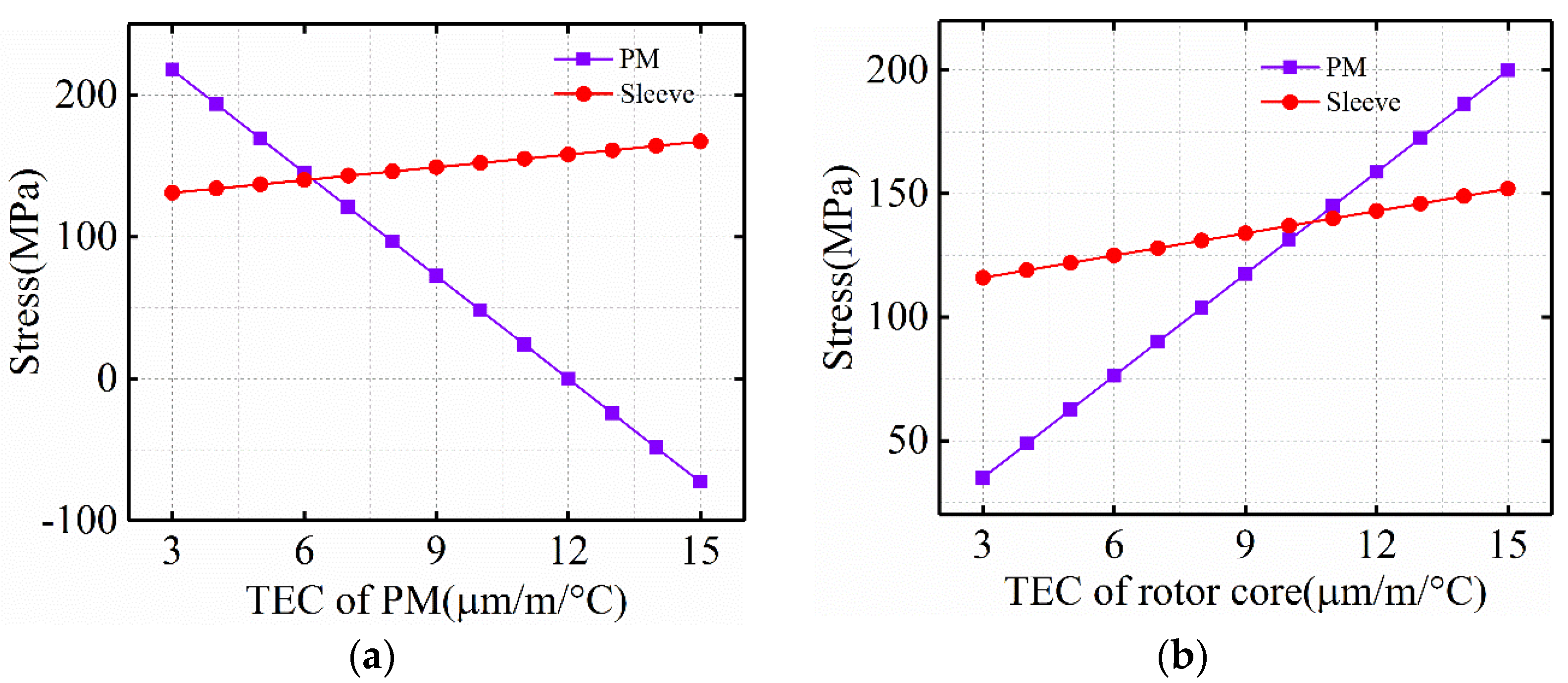

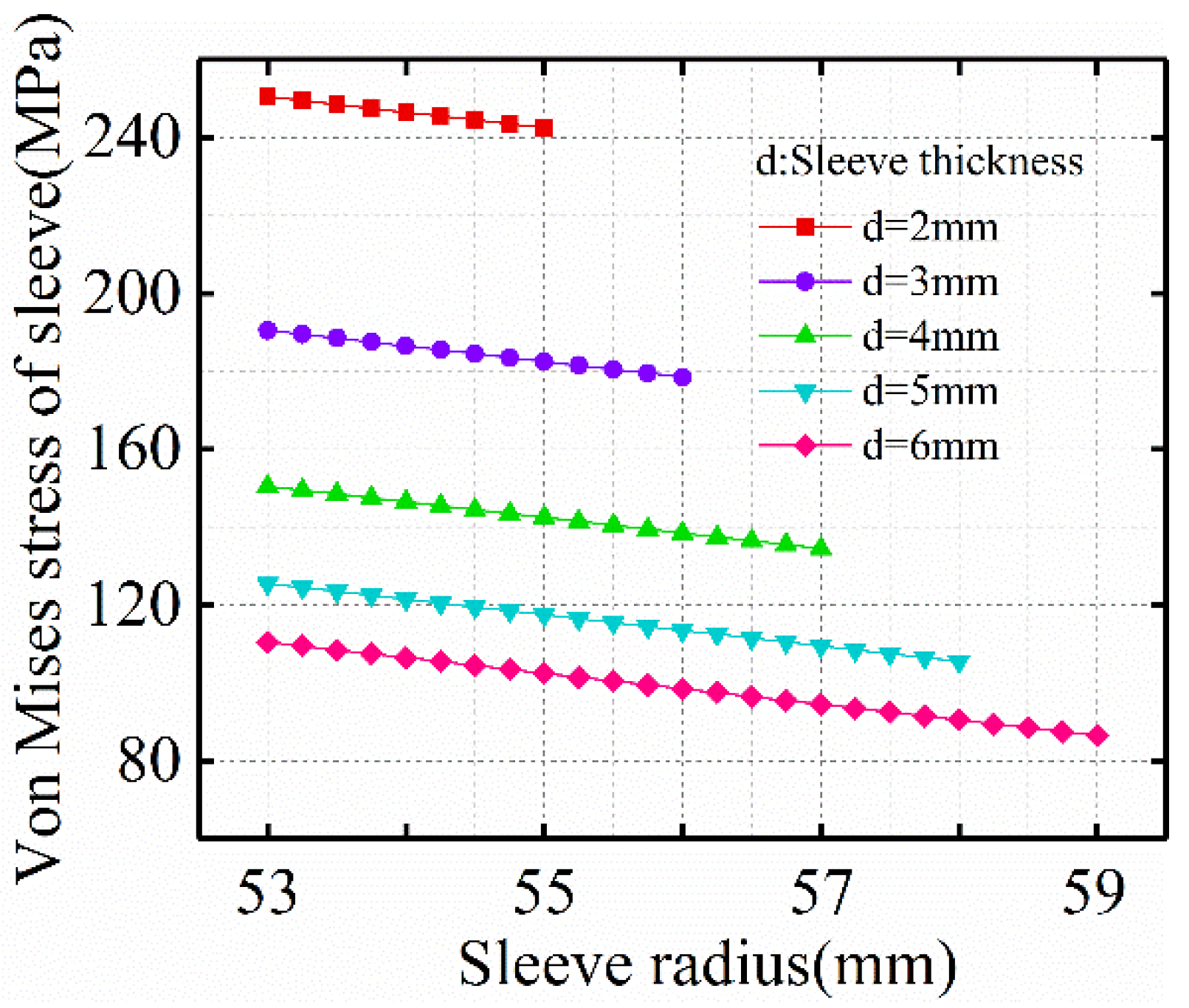

4.2. Influence of Rotor Structural Parameters

5. Motor Testing and Analysis

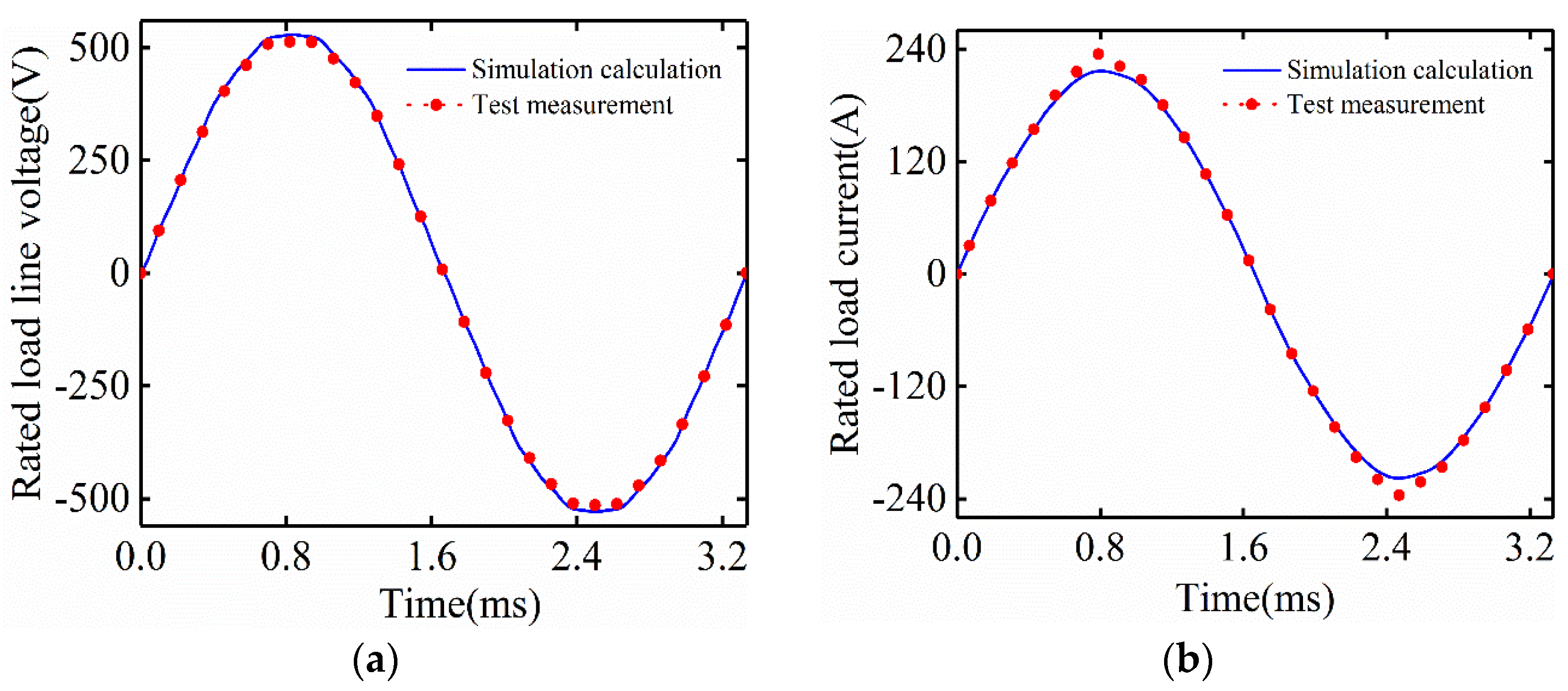

5.1. Electromagnetic and Temperature Characteristic Test

5.2. Times Rated Speed Test

6. Conclusions

- (1)

- In this paper, the structural model of FeCo-based ring PM rotor is proposed. Based on the thick wall cylinder theory, the analytical expression of the stress between the sleeve and the PM is deduced. The influence of speed and temperature on the strength of the high-speed PM rotor is considered in the analytical calculation, and the accuracy of the analytical calculation is verified by the finite element method. The calculation comparison results show that it is necessary to consider the influence of temperature in the strength calculation.

- (2)

- Due to the large coefficient of thermal expansion of FeCo-based PM, the effect of rotor temperature on FeCo-based PM stress is much less than that on NdFeB PM stress.

- (3)

- The TEC of the rotating shaft affects the stress distribution when the rotor rotates at high-speed in hot state. The TEC of the rotating shaft is large. When the rotor rotates at high-speed in hot state, the stress on the sleeve and PM is the largest, and the tangential stress of the PM increases significantly, even showing tensile stress.

- (4)

- Using PM materials with large TEC or rotor core with small TEC can greatly reduce the stress of PM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, Y.; Li, L.; Guo, W.; Wang, S. Study on the Rotor Strength of High-Speed Permanent Magnet Motor Considering the Influence of Assembly Pressing Force. Symmetry 2021, 13, 2161. [Google Scholar] [CrossRef]

- Zhao, J.; Lu, Q.; Yang, D. Experimental and Numerical Analysis of Rotor–Rotor Interaction Characteristics inside a Multistage Transonic Axial Compressor. Energies 2022, 15, 2627. [Google Scholar] [CrossRef]

- Du, G.; Xu, W.; Zhu, J.; Huang, N. Rotor Stress Analysis for High-Speed Permanent Magnet Machines Considering Assembly Gap and Temperature Gradient. IEEE Trans. Energy Convers. 2019, 34, 2276–2285. [Google Scholar] [CrossRef]

- Wu, S.; Huang, X.; He, L.; Cui, S.; Zhao, W. Mechanical Strength Analysis of Pulsed Alternator Air-Core Rotor. IEEE Trans. Plasma Sci. 2019, 47, 2387–2392. [Google Scholar] [CrossRef]

- Zhang, F.; Ye, H.; Liu, G.; Qiu, F. Design and analysis of 100 kW high speed permanent magnet synchronous motor. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Asia-Pacific, Busan, Korean, 1–4 June 2016; IEEE: Piscataway, NJ, USA, 2016. [Google Scholar]

- Karmaker, H.; Guedes-Pinto, P.; Chen, E.; Keck, J.; Ledezma, E.; Fox, K.C. High speed MW-rated induction motor drive system. In Proceedings of the IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Fang, H.; Qu, R.; Li, J.; Zheng, P.; Fan, X. Rotor Design for High Speed High-Power Permanent-Magnet Synchronous Machines. IEEE Trans. Ind. Appl. 2017, 53, 3411–3419. [Google Scholar] [CrossRef]

- Jang, G.-H.; Ahn, J.-H.; Kim, B.-O.; Lee, D.-H.; Bang, J.-S.; Choi, J.-Y. Design and Characteristic Analysis of a High-Speed Permanent Magnet Synchronous Motor Considering the Mechanical Structure for High-Speed and High-Head Centrifugal Pumps. IEEE Trans. Magn. 2018, 54, 11. [Google Scholar] [CrossRef]

- Du, G.; Xu, W.; Zhu, J.; Huang, N. Effects of Design Parameters on the Multiphysics Performance of High-Speed Permanent Magnet Machines. IEEE Trans. Ind. Electron. 2020, 67, 3472–3483. [Google Scholar] [CrossRef]

- Du, G.; Huang, N. Multiphysics analysis of high-speed permanent magnet generators for waste heat application. IET Electr. Power Appl. 2020, 14, 937–942. [Google Scholar] [CrossRef]

- Du, G.; Huang, N.; Lei, G.; Zhu, J. Parameter Design for a High-Speed Permanent Magnet Machine under Multiphysics Constraints. IEEE Trans. Energy Convers. 2020, 35, 2025–2035. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Gerada, C. Rotor Eddy Current Loss and Multiphysics Fields Analysis for a High-Speed Permanent Magnet Machine. IEEE Trans. Ind. Electron. 2020, 68, 5100–5111. [Google Scholar] [CrossRef]

- Zhang, F.; Du, G.; Wang, T.; Liu, G.; Cao, W. Rotor Retaining Sleeve Design for a 1.12-MW High-Speed PM Machine. IEEE Trans. Ind. Appl. 2015, 51, 3675–3685. [Google Scholar] [CrossRef] [Green Version]

- Uzhegov, N.; Smirnov, A.; Park, C.H.; Ahn, J.H.; Heikkinen, J.; Pyrhönen, J. Design Aspects of High-Speed Electrical Machines with Active Magnetic Bearings for Compressor Applications. IEEE Trans. Ind. Electron. 2017, 64, 8427–8436. [Google Scholar] [CrossRef]

- Papini, L.; Raminosoa, T.; Gerada, D.; Gerada, C. A High-Speed Permanent-Magnet Machine for Fault-Tolerant Drivetrains. IEEE Trans. Ind. Electron. 2014, 61, 3071–3080. [Google Scholar] [CrossRef]

- Bianchi, N.; Bolognani, S.; Luise, F. Analysis and Design of a PM Brushless Motor for High-Speed Operations. IEEE Trans. Energy Convers. 2005, 20, 629–637. [Google Scholar] [CrossRef]

- Cheng, W.; Geng, H.; Feng, S.; Yu, L. Rotor Strength Analysis of High-speed Permanent Magnet Synchronous Motors. Proc. CSEE 2012, 32, 87–95. [Google Scholar]

- Korkosz, M.; Bogusz, P.; Prokop, J. Complex Performance Analysis and Comparative Study of Very High-Speed Switched Reluctance Motors. IEEE Trans. Magn. 2019, 55, 1–14. [Google Scholar] [CrossRef]

- Chen, L.L.; Zhu, C.S.; Zhong, Z.; Liu, B. Rotor strength analysis for high-speed segmented surface-mounted permanent magnet synchronous machines. IET Electr. Power Appl. 2018, 12, 979–990. [Google Scholar] [CrossRef]

- Borisavljevic, A.; Polinder, H.; Ferreira, J.A. On the Speed Limits of Permanent-Magnet Machines. IEEE Trans. Ind. Electron. 2010, 57, 220–227. [Google Scholar] [CrossRef]

- Burnand, G.; Araujo, D.M.; Perriard, Y. Very-high-speed permanent magnet motors: Mechanical rotor stresses analytical model. In Proceedings of the IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–7. [Google Scholar]

- Pfister, P.D.; Perriard, Y. A 200,000 rpm, 2 kW slotless permanent magnet motor. In Proceedings of the International Conference on Electrical Machines & Systems, Wuhan, China, 17–20 October 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 1–6. [Google Scholar]

- Ahn, J.H.; Cheol, H.; Kim, C.W.; Choi, J.-y. Rotor Design of High-Speed Permanent Magnet Synchronous Motors Considering Rotor Magnet and Sleeve Materials. IEEE Trans. Appl. Supercond. 2017, 28, 1–4. [Google Scholar] [CrossRef]

| Material Property | Rotor Core | FeCo-Based | NdFeB | Titanium |

|---|---|---|---|---|

| Alloy Sleeve | ||||

| Density (kg/m3) | 7850 | 7770 | 7400 | 4500 |

| Elastic modulus (GPa) | 210 | 140 | 160 | 108 |

| Poisson’s ratio | 0.31 | 0.24 | 0.24 | 0.34 |

| Temperature expansion coefficient (µm/m/°C) | 11 | 10 | 6 | 10 |

| Material Property | Rotor Core | FeCo-Based | NdFeB | Titanium Alloy Sleeve |

|---|---|---|---|---|

| Outside diameter (mm) | 94 | 108 | 108 | 118 |

| Inside diameter (mm) | 0 | 94 | 94 | 108 |

| Polar Arc Coefficient | Sleeve Von-Mises Stress (MPa) |

|---|---|

| 0.7 | 103.86~135.82 |

| 0.8 | 104.67~136.35 |

| 0.9 | 105.53~137.18 |

| 1 | 106.78~139.62 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Output power/kW | 100 | Rotor out diameter/mm | 94 |

| Rated speed/rpm | 18,000 | PM thickness/mm | 7 |

| Rated voltage/V | 380 | Sleeve thickness/mm | 5 |

| Mechanical air gap/mm | 2 | Stator slot | 24 |

| Pole number | 2 | pole arc coefficient | 1 |

| Parameter | Calculation | Measurement |

|---|---|---|

| Running time (h) | N/A | 2.5 |

| Speed (rpm/min) | 18,000 | 18,000 |

| Input power (kW) | 107.2 | 107.8 |

| Induced line voltage (V) | 386 | 384 |

| Phase current (A) | 167.1 | 178.6 |

| Power factor | 0.952 | 0.95 |

| Winding temperature (°C) | 96 | 102.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, P.; Ge, B.; Tao, D.; Pan, B.; Wang, Y. Rotor Strength Analysis of FeCo-Based Permanent Magnet High Speed Motor. Machines 2022, 10, 462. https://doi.org/10.3390/machines10060462

Hou P, Ge B, Tao D, Pan B, Wang Y. Rotor Strength Analysis of FeCo-Based Permanent Magnet High Speed Motor. Machines. 2022; 10(6):462. https://doi.org/10.3390/machines10060462

Chicago/Turabian StyleHou, Peng, Baojun Ge, Dajun Tao, Bo Pan, and Yue Wang. 2022. "Rotor Strength Analysis of FeCo-Based Permanent Magnet High Speed Motor" Machines 10, no. 6: 462. https://doi.org/10.3390/machines10060462

APA StyleHou, P., Ge, B., Tao, D., Pan, B., & Wang, Y. (2022). Rotor Strength Analysis of FeCo-Based Permanent Magnet High Speed Motor. Machines, 10(6), 462. https://doi.org/10.3390/machines10060462