Abstract

COREX (Coal-Reduction-Extreme) smelting reduction process provides a sustainable developing way for ironmaking industry, but the sources of iron ore materials restrict its development in China. Meanwhile, the application of sinter, which is marked by low manufacture cost and overcapacity in China, to COREX furnace faced proportion limitation due to its worse low temperature reduction degradation performance. This work explored the influence of MgO content on the low-temperature (550 °C) reduction of sinter in reducing conditions simulating COREX shaft furnace. The mineralogical change of sinter containing different content of MgO before and after reduction was analyzed by X-ray diffraction (XRD), optical microscopy, and scanning electron microscopy for revealing the action mechanism of MgO on the low-temperature-reduction of sinter. The results show that increasing MgO (1.36–3.10%) improved the low temperature reduction degradation performance of sinter, and decreased its reduction degree and reduction rate at low temperature. More MgO the sinter contained, less Fe2O3 and SFCA was observed in sinter. Meantime, less Fe2O3 was reduced and the generation of innerstress was restrained during reduction process. The improved RDI (reduction degradation index) in COREX process of sinter by increasing MgO content is a comprehensive result of lowering strength and inhibiting probable reduction of sinter.

1. Introduction

COREX process is the earliest smelting reduction technology that established commercially and realized industrial production. When employing iron ore lumps and pellets as burden, 80–90% of fuel will be non-coking coal. This makes the COREX process less dependent on high-quality coking coal resources compared with traditional iron-making process in blast furnace (BF) [1,2,3,4]. However, the supply shortage and higher price of pellets, which brings about higher cost of hot metal by COREX process restrict its further development in China [5]. The Chinese steel mills innovatively proportioned sinter into the burden of COREX shaft furnace, on considering the surplus production capacity and relative lower fabricating cost of sinter [6]. However, the engineers found a high ratio of sinter in the burden caused problems in the shaft furnace, due to the worse low temperature reduction degradation performance of sinter compared with pellets and lumps. Thus, the proportion ratio of sinter in shaft furnace burden of COREX process was only 20–25%.

Many researchers have investigated the reduction degradation of sinter and its mechanism in reducing condition simulating traditional blast furnace (BF) process. The volumetric expansion generated by the reduction of hematite to magnetite was deemed as the main factor that causes reduction degradation [7,8,9]. Various elements and mineral phases composing the sinter have different effects on the low temperature reduction degradation performance of sinter, including the MgO content of sinter. Previous studies conducted in BF ironmaking process have pointed out that increasing MgO was beneficial to the RDI (reduction degradation index) of sinter. It restrains the transformation of Fe3O4 to Fe2O3 during sintering process and decreases the inner-stress generated during reduction [10,11,12,13,14]. Meantime, increasing MgO content made the reduction index (RI) declines. Considering the obvious differences in reducing conditions between the COREX and BF ironmaking processes, clarifying the effect of MgO on low temperature reduction of sinter in COREX reducing process has great directive significance for improving the RDI and good preparation of sinter for COREX shaft furnace.

In this work, the effect of MgO on low temperature reduction of sinter was studied at reducing condition simulating COREX shaft furnace. Simultaneously, the changes in mineralogy and microstructures of sinter with different levels of MgO content and their internal relation with RDI were analyzed for revealing the action mechanism of MgO content on the low temperature reduction degradation of sinter.

2. Materials and Methods

2.1. Materials

The sinter samples with different content of MgO used in this work were made from magnetite concentrates in laboratorial sinter pot. Several kinds of magnetite concentrates, a few secondary materials, fluxes, coke fines and water were weighted in certain weight proportion. They were mixed and granulated in a 600 mm diameter × 1400 mm length drum pelletizer. Then, the granules were loaded and sintered in a 180 mm diameter × 700 mm length sinter pot. The product sinter was tested for cold strength (tumble strength) according to ISO 3271-1995 [15], and then was crushed and sieved to 10–12.5 mm before reduction experiments. The chemical compositions of sinter samples were designed as follows: 56.08–57.02% Fetotal, 5.7–6.0% SiO2, 10.3–10.8% CaO, basicity (CaO/SiO2) 1.8, 1.33% Al2O3, 1.1% TiO2, and 1.36–3.10% MgO. The MgO content of sinter was adjusted by changing the ratio of dolomite proportioned to the sinter blends, leading to a little fluctuation of Fetotal and SiO2 content. Besides, a reducing agent used in this work was the standard cylinder gas including CO, H2, CO2, and N2.

2.2. Methods

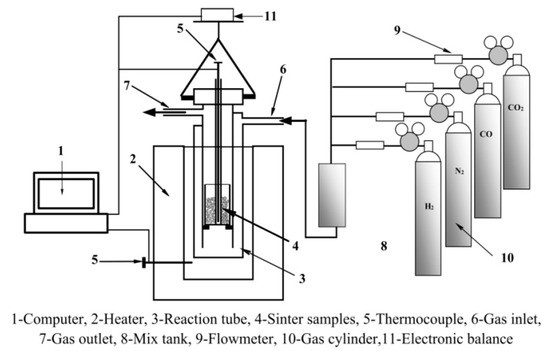

All the reduction experiments were conducted in a static gas-solid reaction apparatus as Figure 1 shows. The size of reduction tube is 75 mm diameter × 800 mm length, and it could resist the temperature above 900 °C. The total mass of sinter sample for each test was 500 g. The sinter samples were put into the reactor tube and heated from air temperature at a heating rate of 10 °C/min under shielding with pure N2 of 5 L/min. The temperature stopped rising after reaching 550 °C, then the reducing gas consisted of 35% CO, 50% CO2, and 15% H2, which is different from the standard reducing atmosphere (20% CO + 20% CO2 + 60% N2) in the traditional BF process, was introduced into the reactor tube with a gas flow of 13.3 L/min. After reducing for 30 min, the reducing gas was replaced by N2 of 5 L/min again and the reactor tube was removed from heat.

Figure 1.

Schematics of experimental apparatus for reduction experiments.

During reduction process, the sinter samples were on-line weighed by electronic balance and recorded by computer. The reduction degree (RD) of sinter at low temperature was calculated, refer to Equation (1):

where m1 and m2 mean the mass (g) of sinter before and after reduction respectively, w1 and w2 mean the of FeO and Fetotal content (%) of sinter, respectively, 0.111 and 0.43 are conversion coefficients for increment of oxygen during oxidation of FeO to Fe2O3 and Fe to Fe2O3 respectively.

After the sinter samples were cooled down to room temperature (<30 °C), they were taken out from reactor tube and charged into a tumbling drum (130 mm diameter × 200 mm length) and rotated for 10 min at a speed of 30 rpm. After tumbling, the samples were sieved with 6.3 mm, 3.15 mm, and 0.5 mm mesh, respectively, to determine the particle size distribution. The RDI was calculated by Equation (2) to Equation (4) as follows:

where M means the mass of sinter samples after reduction, M1 and M2 mean the mass of particles above 6.3 mm and 3.15 mm respectively after tumbling, M3 means the mass of particles below 0.5 mm.

Besides, the X-ray diffraction (XRD) (D/MAX, Osaka, Japan) and optical microscopy (Leica DMI5000M, Leica Camera AG, Wetzlar, Germany) were employed to analyze the changes of mineral composition and microstructure of sinter containing different levels of MgO, before and after reduction. The quantitative analysis of mineral composition and cracks density for sinter sample was given by image analysis software QWin (Version 3.0) of Leica optical microscope [16]. The scanning electron microscopy (SEM) with energy dispersive spectrometer (EDS) (PhenomPro, Waltham, MA, USA) was used to determine the distribution of MgO in sinter.

3. Results and Discussions

3.1. Effect of MgO on the Cold Strength and Low Temperature Reduction Degradation Performance of Sinter

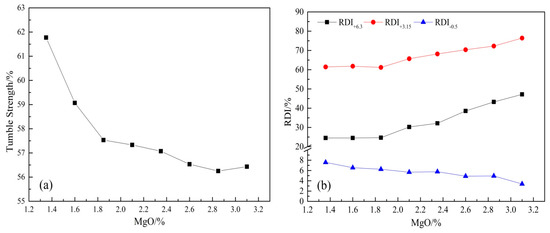

The cold strength (tumble index) of sinter samples with various MgO content and their RDI in condition simulated COREX shaft furnace are shown in Figure 2. Figure 2a suggests that the tumble strength of sinter decreased from 61.87% to 56.43% after the MgO content rose from natural (1.36%) to 3.10%, and the negative effect of increasing MgO content was more obvious before it reaches 1.80%. Figure 2b illustrates that as the MgO increased from 1.36% to 3.10%, the RDI+6.3 rose from 24.52% to 47.19%, RDI+3.15 rose from 61.43% to 76.41% and RDI−0.5 fell from 7.58% to 3.38%. For RDI+6.3 and RDI+3.15 of sinter in simulated COREX shaft furnace condition, their improvements were noticeable, especially after MgO content exceeded 2.10%.

Figure 2.

(a) Effects of MgO on cold strength of sinter; (b) effects of MgO on the RDI of sinter in reducing condition simulated COREX shaft furnace.

The results are similar to that in some previous researches concerning the effects of MgO on the strength of sinter, as well as RDI of sinter in the reduction process simulating BF process. The changes in mineral composition were recognized as the primary reason for the decline in tumble strength and improvement of low temperature degradation performance in most previous researches [10,11,12,13,14].

3.2. Effect of MgO on the Reduction Degree and Reduction Rate of Sinter at Low Temperature

After being reduced for 30 min in condition simulated COREX shaft furnace at low temperature (550 °C), the reduction degree of sinter with different content of MgO is shown in Figure 3a. It shows that when the MgO content increased from natural to 3.10%, the reduction degree of sinter at low temperature decreased from 5.99% to 2.80%. Figure 3b shows the changing reduction degree over time of sinter containing 1.36%, 2.35%, and 3.10% MgO, respectively, from which the different reduction rates of sinter at low reducing temperature could be obtained through curve fitting. The fitting results suggest after the MgO content rose from 1.36% to 3.10%, the reduction rate fell off from 0.2124%/min to 0.1026%/min, decreased by more than 50%.

Figure 3.

(a)Effects of MgO on reduction degree of sinter at low temperature in simulated COREX shaft furnace condition; (b) changing reduction degree over time of sinter.

These results reveal that the reduction of sinter was apparently restrained by increasing MgO content. Previous research noted that the reduction of Fe2O3 to Fe3O4 dominates reducing reaction at 400–550 °C for sinter in reducing condition simulated COREX shaft furnace [5]. This reaction was widely recognized as the root cause for reduction degradation of sinter, because volumetric expansion up to 25% occurred after the hematite (Fe2O3) was reduced to magnetite (Fe3O4) and generated significant inner-stress around reduced area in sinter, which would break the overall structure of sinter [8,9]. Thus, the suppression effect of increasing MgO content on reduction of sinter at low temperature could deservedly decrease the reducing innerstress and then improve the reduction degradation performance of sinter. In terms of the mechanism of suppression effect of MgO on reduction of sinter at low temperature, many relevant researches ascribed it to the changes in mineral composition, or rather in hematite quantity of sinter with increasing MgO content [11,12,13,15].

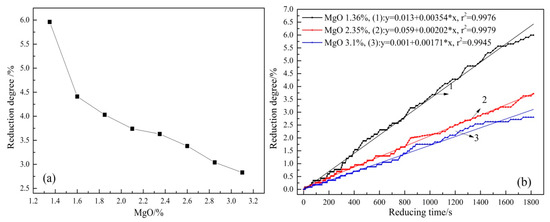

3.3. Microstructure and Mineral Compositions of Sinter with Different Content of MgO

In order to clarify the effect of increasing MgO content on microstructure and mineral compositions of sinter, a series of tests were conducted in the present work. The microstructures of sinter with 1.36% and 3.10% MgO are shown in Figure 4. It shows that the main mineral phase of the two sinter samples include magnetite, hematite, SFCA (silicoferrites of calcium and aluminum) and glass. It is notable that, according to morphological judgment, most of the hematite phase in sinter samples are secondary hematite, which deemed that it would aggravate the reduction degradation of sinter in earlier research work [7,8,9].

Figure 4.

(a) Microstructures of sinter containing 1.36% MgO; (b) microstructures of sinter containing 3.10% MgO.

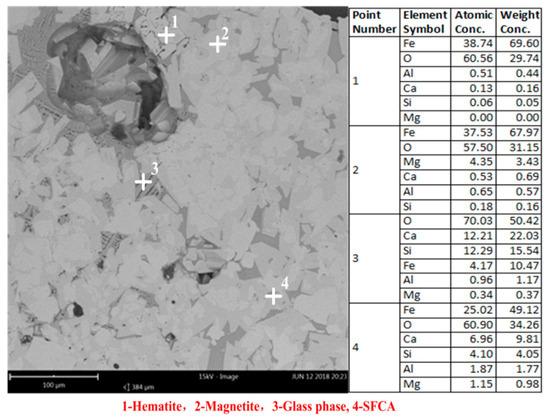

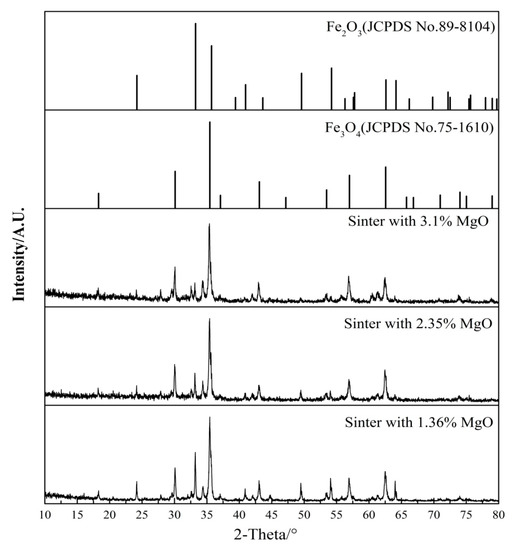

An energy dispersive spectrometer (EDS) measured sinter sample with 3.10% MgO and the results are shown in Figure 5. It indicates that the highest Mg2+ content distributed in the magnetite phase, a few Mg2+ distributed in SFCA and glass phase and no Mg2+ distributed in the hematite. Because Mg2+ has similar ionic radius with Fe2+, it’s prone to diffuse into crystal lattice of magnetite by an isomorphism replacement with Fe2+. It makes magnetite more stable and depresses the oxidation of magnetite during cooling process in sintering [17,18,19]. Then, this will result in decreasing of hematite (Fe2O3) in sinter, which was further confirmed by X-ray diffraction in this work. Figure 6 shows the XRD patterns of sinter samples with different content of MgO. It suggests that, with the increase of MgO in sinter, the diffraction peaks of Fe2O3 (at 24.2°, 33.3°, 41°, 49.6°, 54.2°, and 64.2°) was attenuated obviously, while the diffraction peaks of Fe3O4 keep relative sharp and intense. This could be regarded as a sign that the amount of Fe2O3 existing in sinter decreased when MgO content of sinter increased.

Figure 5.

Distribution of MgO in different minerals inside the sinter with 3.10% MgO.

Figure 6.

XRD patterns of sinter with different content of MgO.

Through image analysis by software QWin of Leica optical microscope, Table 1 further quantitatively shows the mineral compositions of sinter with 1.36%, 2.35%, and 3.10% MgO content, respectively. It reveals after MgO content of sinter rose to 3.10% from 1.36%, the amount of hematite existing in product sinter decreased apparently, as well as the SFCA phase. Meanwhile, the quantity of magnetite and glass phase in product sinter kept rising with increasing MgO content. Besides, the porosity of sinter also increased slightly. The changes in quantity of hematite and magnetite accord well with above results of X-ray diffraction tests.

Table 1.

Mineral compositions of sinter with various MgO contents/area, %.

As is well known, SFCA acts as key bonding phase for fluxed sinter and its formation needs hematite. Given the depressing effect of MgO on formation of hematite during the cooling process, it is not surprising that fewer SFCA phase was observed in sinter with higher MgO content. That is the main reason for the decrease of sinter strength as Figure 2a shows. On the other hand, because the reduction of Fe2O3 to Fe3O4-which causes volumetric expansion and the generates considerable inner-stress in sinter-dominates reducing reaction of sinter at such reducing condition simulated COREX shaft furnace [5], the obvious decrease in hematite quantity could undoubtedly decrease the reduction degree at low temperature of sinter. Meantime, the probable reducing inner-stress generated during reduction was also decreased. Therefore, the improved reduction degradation performance of sinter is together decided, to some extent, by the effects of increasing MgO content on lowering sinter strength and inhibiting probable reduction of sinter at low temperature.

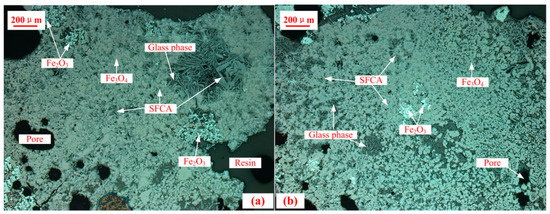

3.4. Mineralogical Changes of Sinter with Different MgO Content after Reduction

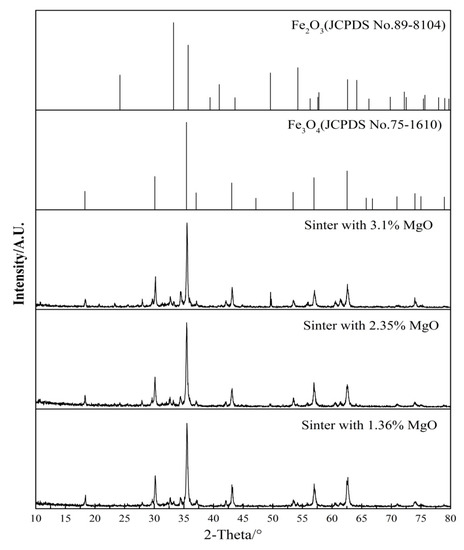

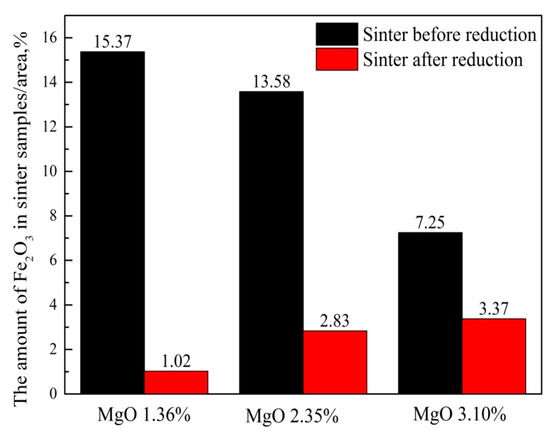

Figure 7 shows the XRD patterns of sinter samples with different MgO content after being reduced at 550 °C for 30 min. It illustrates that there are no obvious distinctions in diffraction peaks of Fe3O4 in reduced sinter with different MgO content. However, in terms of Fe2O3, the situation is different. Compare with sinter containing natural MgO (1.36%), an obscure diffraction peak of Fe2O3 emerges at 24.2° while a conspicuous diffraction peak emerges at 49.6° in sinter containing 3.10% MgO. That implies more Fe2O3 have not been reduced and been remained in sinter with 3.10% MgO. In order to evaluate the proceeding extent for reaction of Fe2O3 to Fe3O4, the quantitative analysis of Fe2O3 and Fe3O4 in reduced sinter samples was made by software QWin of Leica optical microscope further. Figure 8 illustrates the comparisons of the amount of Fe2O3 in sinter samples containing various levels of MgO before and after reduction. During reduction process, the amount of Fe2O3 in sinter samples decreased by 14.35 percent points, 10.72 percent points, and 3.88 percent points successively. It means that less Fe2O3 has been reduced during experiments in sinter contains more MgO. Because the reduction of Fe2O3 to Fe3O4 dominated reducing reaction at such condition presented in this work as noted, the least quantity of Fe2O3 that be reduced during the experiment inevitably brought the lowest reduction degree and reduction rate of sinter with 3.10%.

Figure 7.

XRD patterns of sinter after reducing at 550 °C for 30 min.

Figure 8.

The amount of Fe2O3 in sinter samples containing various levels of MgO.

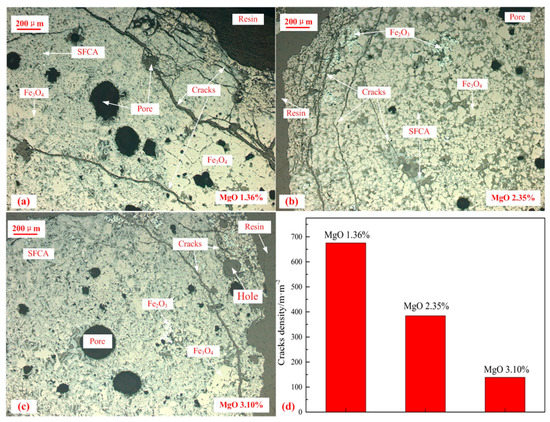

Previous researches reported that reduction degradation of sinter begins with generation and development of cracks in sinter, which has significant influence on the final degradation degree of sinter [8,17]. Figure 9a–c, respectively, shows typical microstructure of sinter samples after reducing at 550 °C for 30 min and these sinter samples contain 1.36%, 2.35%, and 3.10% MgO, respectively. They illustrate that cracks occurred in all sinter samples, but the situations depended on the MgO content of sinter to a great extent. Compared with the other two reduced sinter samples, wider cracks appear in large numbers, and widely distribute in all the mineral phases in outer and middle layers of sinter containing 1.36% MgO. The cracks interweave with each other especially in hematite (transforms to magnetite after reduction) clustered area. The cracks mainly distribute in the outer layers of sinter with 3.10% MgO. Then, further quantitative analyses of cracks density in reduced sinter were done and the result is shown in Figure 9d. It reveals that the cracks density of reduced sinter fell from 675.35 m∙m−2 to 138.63 m∙m−2 after the MgO content of sinter increased from 1.36% to 3.10%. This gives evidence to that stronger inner-stress was generated and released in sinter contains 1.36% MgO during low temperature-reduction process.

Figure 9.

(a) Microstructure of reduced sinter containing 1.36% MgO; (b) microstructure of reduced sinter containing 2.35% MgO; (c) microstructure of reduced sinter containing 3.10% MgO; and (d) crack density of reduced sinter with different MgO content.

According to relevant theory [8], the cracks formed in sinter soon after the start of the reduction. These cracks could provide access for reducing gas to diffuse into the inner parts of sinter and continuously reduce Fe2O3 to Fe3O4, and then new reducing reactions would generate new cracks. This cyclic process makes the cracks develop and extend. Based on the widespread and wider cracks in sinter with 1.36% MgO, it was suggested that reducing process proceeded deeper (corresponding to higher reduction degree at low temperature) and the cracks achieved greater development degree and then make the whole sinter structure to be distorted. While for sinter with 3.10% MgO, lower Fe2O3 phase content might lead to fewer cracks formed at the start of reduction and then the cyclic-reducing process might be limited in the beginning. Consequently, less cracks appeared in sinter with 3.10% MgO after reduction at low temperature.

4. Conclusions

This The influence of MgO on low temperature reduction behaviors and mineralogical changes of sinter before and after reduction were investigated in simulating COREX shaft furnace reducing conditions, and the conclusions were drawn as follows:

(1) As the MgO content of sinter increased from natural (1.36%) to 3.10%, the tumble strength of sinter decreased by 5.44 percentage points, while the RDI+6.3 of sinter increased nearly double. In the meantime, the reduction degree and at reduction rate at low temperature (550 °C) both decreased by over 50%.

(2) Increasing MgO content led to less Fe2O3 was observed in sinter. On the one hand, it led to fewer SFCA phase existed in sinter then decreased the sinter strength. On the other hand, it made the probable reducing inner-stress generated during low-temperature-reduction decrease. The improved RDI in COREX process of sinter by increasing its MgO content is a comprehensive result of lowering strength and inhibiting probable reduction of sinter.

(3) With increased MgO content, the proceeding extent of reducing reaction of Fe2O3 to Fe3O4 declined and less Fe2O3 in sinter was reduced during reduction process. Apart from lowering reduction degree and reduction rate at low temperature of sinter, it remarkably reduced the generation of inner-stress during low-temperature-reduction, which was confirmed by the decreased cracks density and cracks region.

Author Contributions

Data curation, J.P.; Investigation, J.C. and B.S.; Project administration, D.Z. and J.P.; Supervision, D.Z. and J.P.; Writing—original draft, B.S.; Writing—review & editing, D.Z.

Funding

This research was funded by National Natural Science Foundation of China grant number [52574281] and Special Foundation for Innovation Drive Development of Guangxi Province grant number [GuiKe AA18242003].

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shalimov, A. The COREX process for making high-quality steels at mini-mills. Metallurgist 2000, 44, 35–39. [Google Scholar]

- Kumar, P.P.; Barman, S.C.; Reddy, B.M.; Sekhar, V.R. Raw materials for COREX and their influence on furnace performance. Ironmak. Steelmak. 2009, 36, 87–90. [Google Scholar] [CrossRef]

- Kumar, P.P.; Gupta, D.; Naha, T.K.; Gupta, S.S. Factors affecting fuel rate in COREX process. Ironmak. Steelmak. 2013, 33, 293–298. [Google Scholar] [CrossRef]

- Guo, Y.L.; Xu, W.R.; Zhu, J.M.; Zhang, J.Y. The burden structure and its consumption in the melter gasifier of the COREX process. Metall. Mater. Trans. B 2013, 44, 1078–1085. [Google Scholar] [CrossRef]

- Shi, B.J.; Zhu, D.Q.; Pan, J.; Xue, Y.X. Reduction behaviors of sinter made from magnetite concentrates in reducing process simulated COREX shaft furnace. In Proceedings of the 8th International Symposium on High-Temperature Metallurgical Processing, San Diego, CA, USA, 26 February–2 March 2017. [Google Scholar]

- Tian, B.S.; Li, W.H. Production practice of blowing-in OY furnace of bayi steel. Xinjiang Iron Steel 2015, 4, 1–4. [Google Scholar]

- Asada, M.; Shima, M.; Omori, Y. Measurement of macro strain in the course of reduction of the skeletal hematite in sinter(sinter). Phys. Rev. C 1984, 30, 1776–1778. [Google Scholar]

- Loo, C.E.; Bristow, N.J. Mechanism of low-temperature reduction degradation of iron ore sinters. Trans. Inst. Min. Metall. Sect. C 1994, 103, 126–135. [Google Scholar]

- Nakajima, R.; Sumigama, T.; Wakimoto, K.; Nagano, S.; Kawata, H.; Sakurai, M. Reduction Degradation behavior of sinter in the blast furnace shaft (blast furnace phenomena). Tetsu-to-Hagane 1987, 73, 1964–1971. [Google Scholar] [CrossRef][Green Version]

- Panigrahy, S.C.; Verstraeten, P.; Dilewijns, J. Influence of MgO addition on mineralogy of iron ore sinter. Metall. Trans. B 1984, 15, 23–32. [Google Scholar] [CrossRef]

- Jiang, X.; Wu, G.S.; Guo, W.; Li, X.G.; Shen, F.M. Effect of MgO on sintering process and metallurgical properties of sinter. Iron Steel 2006, 41, 1–5. [Google Scholar]

- Zhang, M.; Andrade, M.W. Effect of MgO and basicity on microstructure and metallurgical properties of iron ore sinter. In Characterization of Minerals Metals and Materials John; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Gan, Q.; He, Q.; Wen, Y.C. Study on influence of MgO on mineral composition and metallurgical properties of V-bearing titaniferous magnetite sinter. Iron Steel 2008, 43, 7–11. [Google Scholar]

- Guo, Y.F.; Guo, X.M. Effect of MgO on low temperature reduction process of hematite fines sinter. J. Iron Steel Res. 2017, 29, 697–703. [Google Scholar]

- Pan, J.; Shi, B.J.; Zhu, D.Q.; Mo, Y.P. Improving sintering performance of specularite concentrates by pre-briquetting process. ISIJ Int. 2016, 56, 777–785. [Google Scholar] [CrossRef]

- Shi, B.J.; Zhu, D.Q.; Pan, J.; Liu, X.Q. Combined effect of MgO and basicity varied by different dolomite and burnt lime addition on sintering performance of magnetite concentrates. Ironmak. Steelmak. 2019. [Google Scholar] [CrossRef]

- Yadav, U.S.; Pandey, B.D.; Das, B.K.; Jena, D.N. Influence of magnesia on sintering characteristics of iron ore. Ironmak. Steelmak. 2002, 29, 91–95. [Google Scholar] [CrossRef]

- Fan, X.H.; Li, W.Q.; Gan, M.; Chen, X.L.; Yuan, L.S.; Ji, Z.Y.; Yu, Z.Y.; Huang, X.X.; Su, D. Influence and mechanism of MgO on strength of high basicity sinter. J. Cent. South Univ. 2012, 43, 3325–3330. [Google Scholar]

- Li, Q.; Huang, Z.C.; Jiang, T.; Yang, Y.B.; Li, G.H. Effect of dolomite and serpentine on sinter quality and microstructure. Iron Steel 2006, 41, 10–14. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).