Abstract

Nonpolar hydrocarbon oil (NHO) is one of the most extensively used collectors in the flotation of molybdenite due to its excellent selectivity. However, NHO has low sensibility at pulp temperature. At low temperatures (<283 K), although more kerosene is used, the recovery of molybdenite flotation is still lower than at room temperature. In this study, magnetizing treatment, which is an efficient, low-cost, innovative, and environmentally friendly emulsification method, was used to improve the flotation performance of NHO in low-temperature molybdenite flotation. The test results showed that, compared with unmagnetized kerosene (UMK), the optimum dosage of magnetized kerosene (MK) could be reduced by 11% at 298 K. At the same dosage of kerosene, the flotation recovery of MK was 3% higher than UMK at 278 K. The surface tension measurement results showed that the surface tension of MK rose periodically as the magnetic field intensity increased, and there was a maximum surface tension within each period. Further, the magnetic field intensity had the maximum flotation recovery of molybdenite at the maximum surface tension of MK. Combined with the analysis based on the Girifalco–Good theory and the static drop volume method of interfacial tension, the interfacial tension of kerosene–water was shown to decrease with the increase of the surface tension of kerosene. This finding indicates that the dispersibility of kerosene in pulp could be improved by reducing the size of oil droplets, thereby improving the molybdenite flotation recovery of kerosene at low-temperature pulp. It is helpful to improve the flotation recovery of molybdenite using NHO as a collector for low-temperature pulp (<283 K).

1. Introduction

Nonpolar hydrocarbon oil (NHO) (such as kerosene, diesel oil, solar oil, and transformer oil) is one of the most extensively used collectors in the flotation of molybdenite due to its excellent selectivity [1,2]. Malhotra et al. [3] found that the impurity content in molybdenum concentrate using NHO as a collector for molybdenite was less than that using other types of collectors for molybdenite (such as mercaptan, xanthate, and so on) because NHO can selectively adsorb on the surface of molybdenite by hydrophobic interactions and van der Waals forces [4,5,6,7]. However, NHO has a higher temperature requirement. It has relatively better dispersibility at relatively high temperatures (e.g., >293 K) in the pulp [8,9,10,11]. As the temperature decreases, the dispersibility of NHO subsequently reduces. The effect of temperature on the flotation performance of NHO (e.g., kerosene and diesel oil) has been frequently reported [12,13,14] and is attributed to solubility, which is temperature dependent. The solubility and activity of NHO in pulp are reduced at low temperatures (<283 K). This reduction causes a decrease in its collecting capability and an increase in its dosage at low temperatures, especially during cold winters. This result is also in agreement with the findings of Zhao and Wei et al. [15,16]. Their studies found that the flotation recovery of molybdenite using kerosene as the collector in the winter was 2–5% lower than that in the spring, summer, and autumn. They also found that as the pulp temperature increases, the flotation recovery of molybdenite also gradually increases in cold winter temperatures. More specifically, the flotation recovery could be improved by raising the pulp temperature to room temperature.

In the past, methods of improving the low-temperature flotation performance of nonpolar oil have been rarely reported. However, some studies [15,16,17] found that improving the dispersibility of NHO in water is an effective approach to increasing the flotation recovery of molybdenite using kerosene as a collector in low-temperature pulp. The emulsifying agent [18,19,20], which is a surfactant mixed with NHO, could decrease the interfacial tension of oil–water and increase its dispersibility in water. Further, He-Tian and Zhang [21] found that these surfactants could also adsorb on the surface of other sulfide minerals, which reduces the selectivity of molybdenite against other sulfide minerals in differential flotation. A surfactant added to NHO affects the separating effect between molybdenite and other sulfide minerals, resulting in excess impurities in the molybdenum concentrate. Several reports [22,23,24] found that ultrasonic treatment was also a successful method for improving the dispersibility of NHO in water. Ultrasonic treatment was found to produce small oil droplets and ensure homogenous distribution of oil droplets in water. The size of the oil droplets reduced as the power and time of the ultrasonic treatment increased. However, the emulsified kerosene by ultrasonic treatment had poor stability in water. It was easy to form a layer of oil and water, which made the dispersibility of NHO in water deteriorate again.

Therefore, it is important to know how to efficiently raise the dispersibility of NHO in water while ensuring that there are no adverse effects on the separation between molybdenite and other sulfide minerals and that there is enough time to keep the size of the kerosene droplets small in the flotation process of molybdenite. In this study, an efficient, innovative, and environmentally friendly emulsification method was developed. A magnetizing treatment was used as an emulsification method to improve the flotation recovery of molybdenite in low-temperature pulp. The influences of the pulp temperature and the magnetizing treatment on the flotation performance of kerosene and magnetized kerosene (MK) were studied. The relationship among magnetic field intensity, surface tension, and molybdenum recovery was analyzed. The mechanism of the magnetizing treatment in improving the flotation performance of kerosene in low-temperature pulp was investigated.

2. Materials and Methods

2.1. Materials and Reagents

The Mo ore used in this study was collected from China Molybdenum Co., Ltd., Luoyang, Henan Province, China. The chemical composition analysis of the Mo ore was conducted by using inductively coupled plasma mass spectrometry (ICP-MS), and the results are shown in Table 1. The results revealed 0.11 wt % Mo and 0.10 wt % WO3 in the ore sample. The mineralogical composition of the Mo ore (Table 2) was analyzed by the application of X-ray diffraction analysis, which indicated that silicate minerals were the predominant gangue mineral in this ore sample. The reagents used in the experiments are shown in Table 3.

Table 1.

The chemical composition analysis of the Mo ore (wt %).

Table 2.

The mineralogical composition of the actual Mo ore (wt %).

Table 3.

Reagents used in the experiments.

2.2. Grinding and Flotation of Mo Ore

In the bench-scale flotation tests, 1000 g of Mo ore was ground to −74 μm (65 wt %) in an RK/ZQM Φ250 × 100 grinding mill with low-carbon alloy steel balls as the grinding media. The pulp of 30 wt % was transferred into an RK/FGC 3 L hitch groove flotation machine (Wuhan Rock Crush & Grand Equipment Manufacture Co., Ltd., Wuhan, China) and stirred at 1700 rpm for 1 min. Subsequently, 500 g/t of sodium silicate was added and stirred for 2 min. Then, the collector was added and stirred for 2 min. Finally, pine oil was added and stirred for a further 1 min. Flotation was conducted for 5 min (pH = 8–9). Tap water was used as the flotation water for the entire experiment. Three repeat batch-scale flotation tests were conducted under identical conditions. The reported results are the average value of recovery and grade.

2.3. Magnetizing Treatment of Kerosene

The magnetizing treatment of kerosene was conducted with a splint-type magnetic separator from the Northwest Institute of Non-Ferrous Geology. Firstly, the magnetic field intensity was adjusted to the desired value; then, 200 mL kerosene was added into the feeding funnel; meanwhile, the MK was collected using 500 mL beakers at the bottom of the magnetizing device. The process of the magnetizing treatment of kerosene was implemented only once. The retention time of the magnetizing treatment was about 3 s. The collected MK was used for the surface tension and flotation tests. The magnetizing device is shown in Figure 1.

Figure 1.

The device used for kerosene magnetizing treatment.

2.4. Surface Tension Measurements

Based on the Wilhelm platinum plate method, the surface tension was measured with a BZY-2 fully automatic surface tensiometer from Shanghai Equitable Instrument and Meter Factory (Shanhai, China). Firstly, distilled water was used to calibrate the surface tensiometer before surface tension measurements were performed. Secondly, 50 mL of kerosene or MK was added into a special glass dish for the BZY-2 fully automatic surface tensiometer. Thirdly, the glass dish was put on the lifting platform of the surface tensiometer. Fourthly, the platinum plate was gradually immersed in the kerosene by slowly raising the platform until it stopped automatically. Finally, the results were obtained at room temperature (298 K). Three repeat measurements were conducted, and the average surface tension value was reported.

3. Results and Discussion

3.1. The Influence of Magnetizing Treatment on the Optimized Dosage of Kerosene

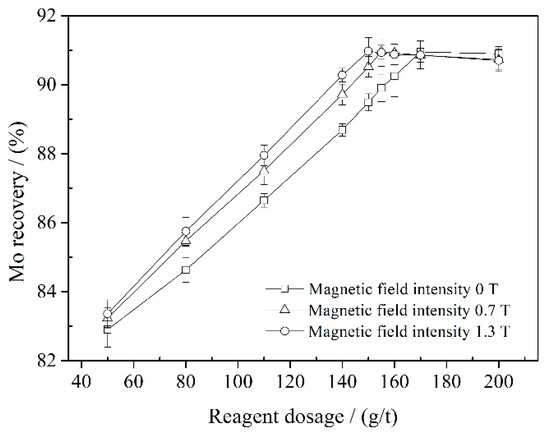

Figure 2 shows the influence of the magnetizing treatment on the optimized dosage of kerosene (298 K). The results illustrate that the molybdenum recovery first increased as the kerosene/MK dosage increased. Then, the recovery curve became flat after the optimized kerosene/MK dosage was obtained. At the magnetic field intensities of 0, 0.7, and 1.3 T, the optimized dosages were 170, 155, and 150 g/t, respectively. The result indicates that the magnetizing treatment affected the optimized kerosene dosage in the flotation of molybdenite. More specifically, the optimized kerosene dosage decreased in the flotation of molybdenite as the magnetic field intensity increased.

Figure 2.

The influence of the magnetizing treatment on the optimized dosage of kerosene (298 K).

3.2. The Influence of Low-Temperature Pulp on the Flotation Performance of Kerosene/MK

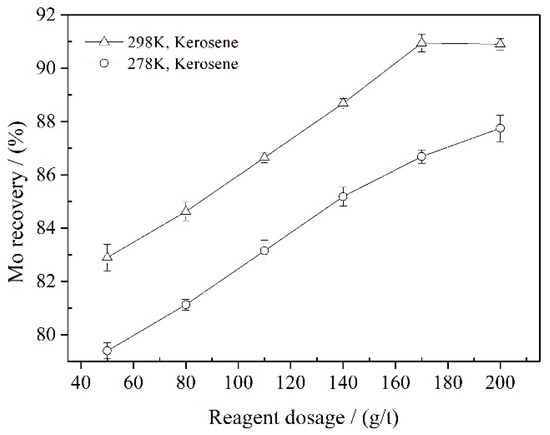

Figure 3 shows the influence of low-temperature pulp on the flotation performance of kerosene. The results indicate that the molybdenum recovery increased as the dosage of kerosene increased at the pulp temperature of 298 K; then, the recovery curve became flat after the dosage was more than 170 g/t. The maximum molybdenum recovery of kerosene as a collector was approximately 91% at 298 K. The molybdenum recovery increased as the dosage of kerosene increased at the pulp temperature of 278 K, and the recovery curve had a lower but clear gradient after the dosage was more than 170 g/t, which was not the same as the tests at the pulp temperature of 298 K. When the dosage of kerosene was equal to the optimum dosage of 170 g/t at 298 K, the molybdenum recovery of kerosene as a collector was 86.7% at 278 K. Even though the dosage of kerosene increased to 200 g/t, the molybdenum recovery was only 87.5% at 278 K. Compared with the tests at a pulp temperature of 298 K, the flotation recovery of kerosene as a collector decreased around 3.5% at 278 K. This indicates that the decrease of pulp temperature had a negative effect on the flotation of molybdenite when kerosene was used as the collector for molybdenite flotation. As the pulp temperature decreases, the flotation recovery of kerosene reduces.

Figure 3.

The influence of low-temperature pulp on the flotation performance of kerosene.

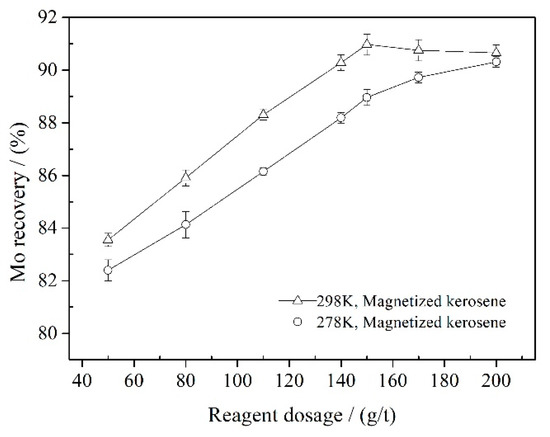

The influence of low-temperature pulp on the flotation performance of MK is provided in Figure 4. The results show that the molybdenum recovery increased as the dosage of MK increased at the pulp temperature of 298 K; then, the recovery curve became flat after the dosage was more than 150 g/t. The maximum molybdenum recovery of MK as a collector was close to 91% at 298 K. The molybdenum recovery increased as the dosage of kerosene increased at the pulp temperature of 278 K, and the recovery curve had a lower but clear gradient after the dosage was larger than 150 g/t, which was different than the tests at the pulp temperature of 298 K. When the dosage of kerosene was equal to the optimum dosage of 150 g/t at 298 K, the molybdenum recovery of kerosene as a collector was 88.96%. However, when the dosage of MK increased to 200 g/t, the molybdenum recovery was 90.3% at 278 K. Compared with the tests at the pulp temperature of 298 K, the recoveries of MK only decreased by about 0.7% at 278 K. At the kerosene dosage of 200 g/t, the flotation recovery of MK was 3% higher than that of unmagnetized kerosene (UMK) at 278 K. This indicates that the sensitivity of MK to pulp temperature is lower than that of kerosene.

Figure 4.

The influence of low-temperature pulp on the flotation performance of MK.

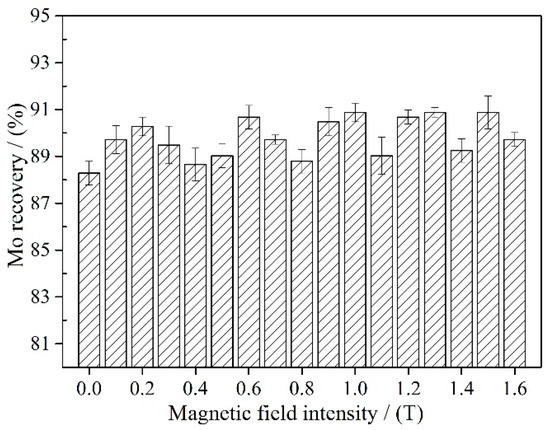

Figure 5 shows the molybdenum recovery of kerosene with different magnetization intensities (278 K). The results show that the molybdenum recovery of kerosene increased and decreased periodically as the magnetic field intensity increased. This indicates that the influence of magnetic field intensity on kerosene performance is not always positive or negative. The flotation performance of MK changed periodically as the magnetic field intensity increased, and within each period (period of the sine wave), there was an optimum magnetic field intensity.

Figure 5.

Molybdenum recovery of kerosene with different magnetization intensities (278 K).

3.3. The Mechanism Analysis of Improving Flotation Performance of Kerosene by Magnetizing Treatment

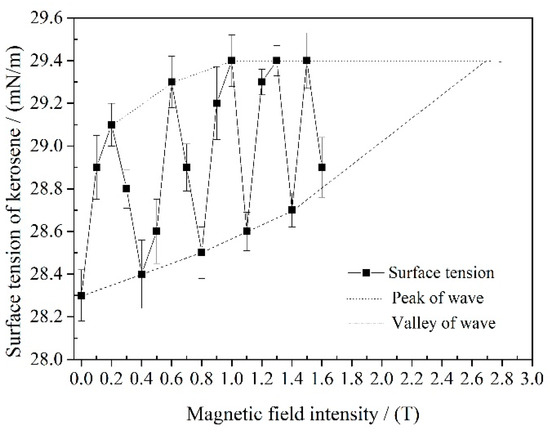

Figure 6 shows the influence of magnetic field intensity on the surface tension of kerosene (298 K). The results show that the surface tension of kerosene increased and decreased periodically with the increasing of the magnetic field intensity. The surface tension of kerosene increased by 0.3–3.7% after the kerosene was modified by a magnetic field. Then, the peaks/troughs of each continuous period were connected sequentially. Two curves on the trend of peak/trough development were obtained. Finally, the curves of peak and trough extension intersected at one point. This indicates that magnetizing treatment can improve the surface tension of kerosene. Further, the surface tension of kerosene may remain at a stable value as the magnetic field intensity increases when the magnetic field strength reaches a specific value.

Figure 6.

The influence of magnetic field intensity on the surface tension of kerosene (298 K).

The results displayed in Figure 5 and Figure 6 show that the influence of magnetic field intensity on the surface tension of kerosene was similar to that of the magnetic field intensity on the flotation performance of kerosene. This indicates that the improvement of kerosene flotation performance by magnetizing treatment may be related to the change of kerosene surface tension.

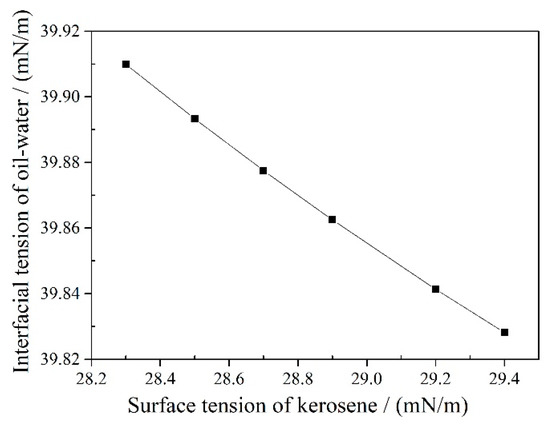

Based on the Girifalco–Good theory [25,26,27], the relationship between surface tension and the interfacial tension of kerosene–water at 298 K is shown in Formula (1) and Figure 7:

where is the interfacial tension of oil–water, is the surface tension of water, is the surface tension of kerosene, and k is the correction factor 1 (k = 0.68).

Figure 7.

The relationship between the surface tension of kerosene and the interfacial tension of kerosene–water (298 K).

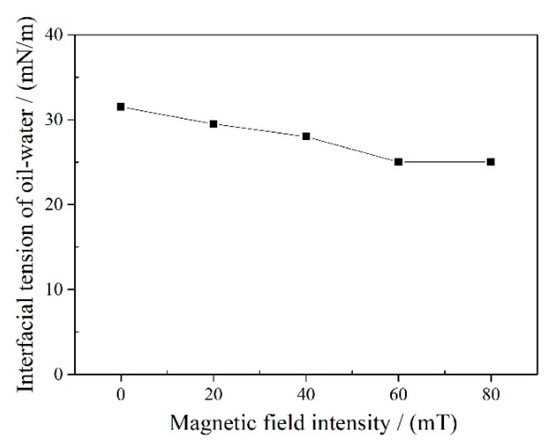

Figure 7 shows that as the surface tension of kerosene increased, the interfacial tension of kerosene–water decreased gradually. By combining the results of Figure 6 and Figure 7, it shows that magnetizing treatment can reduce the interfacial tension of kerosene–water. This is in agreement with Liang et al. (2013) [28], who reported that under the conditions of a magnetic field intensity of 60 mT and a magnetizing treatment time of 30 min at 303 K, the interfacial tension of kerosene–water was reduced by 19.2% (Figure 8). In this work, the magnetizing treatment time was 3 s. Therefore, the interfacial tension of kerosene–water decreased by 2.5%. This also indicates that magnetizing treatment time can affect the interfacial tension of kerosene–water.

Figure 8.

The influence of magnetic field intensity on the interfacial tension of kerosene–water (303 K) [28].

In order to further discuss the influence of the variation of interfacial tension of kerosene–water on the dispersion performance of kerosene in water, the well-known static drop volume method of interfacial tension [29,30,31] was used to analyze the relationship between the interfacial tension of oil–water and the oil drop volume, shown in Formula (2) as follows:

where is the interfacial tension of oil–water, is the density of water, is the density of kerosene, V is the volume of a drop of kerosene, g is the acceleration of gravity, r is the radius of the capillary tube head, π is the circular constant, and is the correction factor 2.

In this formula, the interfacial tension of oil–water is proportional to the oil drop volume in water. As the interfacial tension of oil–water decreases, the oil drop volume in water decreases. Since the interfacial tension of oil–water can decrease by magnetizing treatment, the oil drop volume in water can indirectly decrease by magnetizing treatment. Magnetizing treatment can improve the dispersibility of kerosene in pulp by reducing the size of the oil droplets, which increases the total surface area, thereby reducing the kerosene dosage.

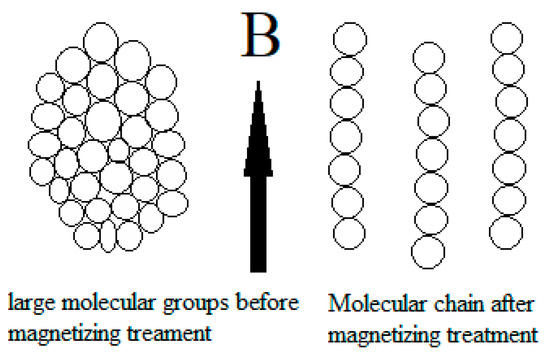

This conclusion can also be explained from the viewpoint of physics [32,33,34,35]. NHO is a kind of diamagnetic substance. An NHO molecule in the external magnetic field can obtain an additional reverse magnetic moment. Combining the ampere rule and magnetic moment theory, the interaction between two parallel magnetic moments is repulsive; the interaction between two magnetic moments arranged on the same line is attractive. Therefore, the NHO molecules, which were agglomerated to form large molecular groups by van der Waals and hydrophobic forces before magnetizing treatment, can be changed to tend to line up, as a molecular chain, by additional magnetic moment repulsion after magnetizing treatment (Figure 9). This also indicates that the dispersion performance of hydrocarbon oil in pulp can be improved by magnetizing treatment.

Figure 9.

Under the magnetic field, the structure of molecular groups of nonpolar hydrocarbon oil (NHO) tends to be a molecular chain [35].

3.4. Economic Estimate

In the economic calculations, the data on improving the flotation recovery, the proportion of kerosene savings, and the kerosene dosage were based on the results of the flotation test in this study. Other data (including working days, the price of kerosene, the throughput of molybdenite flotation in a day, the ore grade, the grade of molybdenite concentrate, the recovery of the cleaning process, and the current price of molybdenum) were based on plant data. We found that using the magnetizing treatment would improve the flotation recovery by about 2%, which would help solve the difficult problem of low flotation recovery using kerosene as a collector in winter (from November to April). In spring, summer, and autumn (from May to October), the magnetizing treatment would decrease the kerosene dosage by about 11%, which would solve the difficult problem of high reagent consumption using kerosene as a collector. This is a significant technological and economic enhancement, as it improves the flotation recovery by about 2% in low-temperature pulp and saves kerosene consumption by about 11% in normal-temperature pulp. The economic estimate of MK as the collector in molybdenite flotation is described by Equations (3)–(5). The annual net profit of MK as the collector in molybdenite flotation should reach about 31,703,512.5 RMB/a:

where, in Equation (3), 9500 RMB/t is the price of kerosene; 170 g/t is the dosage of kerosene; 11% is the proportion of kerosene savings; the 165 days are the working days from May to October; and 50,000 t/day is the throughput of molybdenite flotation. In Equation (4), 0.11%, 50%, and 98% are the ore grade, the grade of molybdenite concentrate, and the recovery of the cleaning process; 85,000 RMB/t is the current price of molybdenum; and 165 days are the working days from November to April.

The savings from using MK (from May to October) = 170 g/t × 11% × 50,000 t/day × 9500 RMB/t × 165 days = 1,465,612.5 RMB

The profit of using MK as the collector in molybdenite flotation (from November to April) = (50,000 t/day × 0.11% × 2% × 98%)/50% × 85,000 RMB/t × 165 days = 30,237,900 RMB

The annual net profit from using MK = 1,465,612.5 + 30,237,900 = 31,703,512.5 RMB/a

4. Conclusions

This study demonstrated an efficient, innovative, low-cost, and environmentally friendly emulsification method for improving the flotation performance of NHO in the molybdenite flotation process at low temperatures. The test results showed that, compared with UMK, the optimum dosage of MK could be reduced by 11% at 298 K. At a kerosene dosage of 200 g/t, the flotation recovery of MK was 3% higher than that of UMK at 278 K. The surface tension measurement results indicated that as the magnetic field intensity increased, the surface tension of MK rose periodically, and there was maximum surface tension within each period. Meanwhile, the magnetic field intensity had the maximum flotation recovery of molybdenite at the maximum surface tension of MK. Combining the analysis of the Girifalco–Good theory and the static drop volume method of interfacial tension, it shown that the interfacial tension of kerosene–water decreased with the increase of the surface tension of kerosene. This finding indicates that the dispersibility of kerosene in pulp could be improved by reducing the size of the oil droplets, thereby improving molybdenite flotation recovery of kerosene at low-temperature pulp. It is helpful to improve the flotation recovery of molybdenite using NHO as a collector for low-temperature pulp (<283 K).

Author Contributions

Conceptualization, H.W. and T.H.; methodology, W.Y.; formal analysis, J.Q.; investigation, J.Q.; data curation, W.Y., X.B., and H.L.; writing—original draft preparation, H.W. and J.Q.; writing—review and editing, H.W.; supervision, X.B.

Funding

This research was funded by the Key Science and Technology Program of Shaanxi Province, China (Grant No. 2018GY-080); the National Natural Science Foundation of China (Grant Nos. 51404185, 51674184, and 51904222); and the Shaanxi Natural Science Basic Research Program (Grant No. 2019JQ-468).

Acknowledgments

Jianbo Yang, Lin Guo, and Nianping Song contributed materials and reagents; Saisai Wu contributed to revising the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- He, T.S.; Wan, H.; Song, N.P.; Guo, L. The influence of composition of nonpolar oil on flotation of molybdenite. Miner. Eng. 2011, 24, 1513–1516. [Google Scholar] [CrossRef]

- He, T.S.; Li, H.; Jin, J.P.; Peng, Y.J.; Wang, Y.B.; Wan, H. Improving fine molybdenite flotation using a combination of aliphatic hydrocarbon oil and polycyclic aromatic hydrocarbon. Results Phys. 2019, 12, 1050–1055. [Google Scholar] [CrossRef]

- Malhotra, D.; Rowe, R.M.; Bhasin, A.K. Evaluation of collectors for molybdenite flotation. Min. Metall. Explor. 1986, 3, 184–186. [Google Scholar] [CrossRef]

- Ornelas Tabares, J.; Madrid Ortega, I.; Reyes Bahena, J.L.; Sánchez López, A.A.; Valdez Pérez, D.; LópezValdivieso, A. Surface properties and floatability of molybdenite. In Proceedings of the 2006 China-Mexico Workshop on Minerals Particle Technology, San Luis Potosí, Mexico, 5–7 December 2006; pp. 115–124. [Google Scholar]

- Hoover, R.; Malhotra, D. Emulsion flotation of molybdenite. In Flotation; Gaudin Memorial, A.M., Ed.; American Institute of Mining, Metallurgical, and Petroleum Engineers: New York, NY, USA, 1976; Volume 1, pp. 485–503. [Google Scholar]

- Wan, H.; Yang, W.; He, T.S.; Yang, J.B.; Guo, L.; Peng, Y.J. The influence of Ca2+ and pH on the interaction between PAHs and molybdenite edges. Minerals 2017, 7, 104. [Google Scholar] [CrossRef]

- Zhou, L. Molybdenite Flotation. Master’s Thesis, Ian Wark Research Institute and University of South Australia, Mawson Lakes, Australia, May 2010; p. 14. [Google Scholar]

- Smit, F.J.; Bhasin, A.K. Relationship of petroleum hydrocarbon characteristics and molybdenite flotation. Int. J. Miner. Process. 1985, 15, 19–40. [Google Scholar] [CrossRef]

- Crozier, R.D. Flotation reagent practice in primary and by-product molybdenite recovery. Min. Mag. 1979, 140, 174–178. [Google Scholar]

- Wang, H.; Gu, G.H.; Fu, J.G.; Hao, Y. Study of the interfacial interactions in the molybdenite floatation system. J. China Univ. Min. Technol. 2008, 18, 82–87. [Google Scholar] [CrossRef]

- Song, S.X.; Lopez-Valdivieso, A.; Ding, Y.Q. Effects of nonpolar oil on hydrophobic flocculation of hematite and rhodochrosite fines. Powder Technol. 1999, 101, 73–80. [Google Scholar] [CrossRef]

- Kitamura, Y.; Huang, Q.F.; Miyachi, A.; Yoshizako, K.; Takahashi, T. Effect of temperature on interfacial tension in kerosene-surfactant-water systems. J. Colloid Interface Sci. 1992, 154, 249–254. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Pascoe, R.D. Effect of temperature on coal flotation performance—A review. Miner. Process. Extr. Metall. Rev. 2005, 26, 31–61. [Google Scholar] [CrossRef]

- Konar, B.B.; Sarkar, G.G.; Chakrava, A.K. Improved coal flotation by use of diesel oil + low temperature carbonization tar fractions as collecting agents. Indian J. Technol. 1968, 6, 269. [Google Scholar]

- Zhao, M.L. Influence of temperature on flotation of molybdenite and its improvement. Met. Ore Dress. Abroad 1991, 22, 86–89. (In Chinese) [Google Scholar]

- Wei, X.; Zhao, Y.L.; Yang, J.; Ren, Y.X.; Yang, W.; Huang, X.T.; Zhang, L.J. Effect of Sodium Oleate on the Adsorption Morphology and Mechanism of Nanobubbles on the Mica Surface. Langmuir 2019, 35, 9239–9245. [Google Scholar]

- Castro, S.; Lopez-Valdivieso, A.; Laskowski, J.S. Review of the flotation of molybdenite. Part I: Surface properties and floatability. Int. J. Miner. Process. 2016, 148, 48–58. [Google Scholar] [CrossRef]

- Ronzio, R.A. The role of surfactants in the flotation of molybdenite at climax. J. Am. Oil Chem. Soc. 1970, 47, 504A. [Google Scholar] [CrossRef]

- Nishkov, I.; Beas, E.; Henriquez, C. Effect of Surfactant Oil Emulsification on the Flotation of Molybdenite for Porphyry Copper Ores. In Proceedings of the X Balkan Mineral Processing Congress, Varna, Bulgaria, 15–20 June 2003; pp. 205–211. [Google Scholar]

- Nishkov, I.; Lazarov, D.; Marinov, M.; Beas, E.; Henriquez, C. Surfactant-Hydrocarbon Oil Emulsions for Molybdenite Flotation. In Proceedings of the IV Meeting of the Southern Hemisphere on Mineral Techenology and III Latin-American Congreess on Froth Flotation, Concepción, Chile, 20–23 November 1994; pp. 319–329. [Google Scholar]

- He Tian, Z.M.; Zhang, W.Z. Study on molybdenite flotation (Ⅱ)-Study on the use of kerosene in flotation. Met. Ore Dress. Abroad 1965, 02, 1–5. (In Chinese) [Google Scholar]

- Sahinoglu, E.; Uslu, T. Use of ultrasonic emulsification in oil agglomeration for coal cleaning. Fuel 2013, 113, 719–725. [Google Scholar] [CrossRef]

- Guo, Z.G.; Wang, S.R.; Wang, X.Y. Emulsification of bio-oil heavy fraction with diesel by mechanical and ultrasonic technologies. Energy Eng. Environ. Eng. 2013, 316–317, 1133–1137. [Google Scholar] [CrossRef]

- Leong, T.S.H.; Wooster, T.J.; Kentish, S.E.; Ashokkumar, M. Minimising oil droplet size using ultrasonic emulsification. Ultrason. Sonochem. 2009, 16, 721–727. [Google Scholar] [CrossRef]

- Good, R.J.; Elbing, E. Generalization of Theory for Estimation of Interfacial Energies. Ind. Eng. Chem. 1970, 62, 54–78. [Google Scholar] [CrossRef]

- Thareja, P.; Velankar, S.S. Interfacial activity of particles at PI/PDMS and PI/PIB interfaces: Analysis based on Girifalco–Good theory. Colloid Polym. Sci. 2008, 286, 1257–1264. [Google Scholar] [CrossRef]

- Buloua, J.; Raynala, J.M.; Vial, J. An interfacial tension treatment with an improved good—Girifalco equation using solubility parameters. J. Colloid Interface Sci. 1984, 98, 168–174. [Google Scholar]

- Liang, P.Z.; Huang, W.L.; Li, L.F.; Yin, W.Y.; Zhang, B.L. Preliminary research about influence of magnetizing treatment of kerosene on air/oil/water interfacial tensions. Guangzhou Chem. Ind. 2013, 41, 92–94. (In Chinese) [Google Scholar]

- Hunsel, J.V.; Joos, P. Study of the dynamic interfacial tension at the oil/water interface. Colloid Polym. Sci. 1989, 267, 1026–1035. [Google Scholar] [CrossRef]

- Pu, B.Y.; Chen, D.H. A study of the measurement of surface and interfacial tension by the Maximum Liquid Drop Volume Method. J. Colloid Interface Sci. 2001, 235, 265–272. [Google Scholar] [CrossRef]

- Sinzato, Y.Z.; Dias, N.J.S.; Cunha, F.R. An experimental investigation of the interfacial tension between liquid-liquid mixtures in the presence of surfactants. Exp. Therm. Fluid Sci. 2017, 85, 370–378. [Google Scholar] [CrossRef]

- Wilson, A.C.M.; Carlos, L.G. Calculation of Critical Points in Gas−Condensate Mixtures under the Influence of Magnetic Fields. Ind. Eng. Chem. Res. 2010, 49, 7610–7619. [Google Scholar]

- Chen, J.B.; Zhu, X.; Tan, D.H.; Wang, K.J. Influence on Electrons Motion by the Magnetic Field Perpendicular to the Motion Plane and New Explanation of Diamagnetism. J. Logist. Eng. Univ. 2015, 31, 66–71. (In Chinese) [Google Scholar]

- Guo, R. An improved method to explain the diamagnetism of materials. College Phys. 2019, 38, 14–18. (In Chinese) [Google Scholar]

- Zhu, W.Z.; Ke, J.X. An investigation into the magnetization mechanism of fuel oil. J. Jimei Navig. Inst. 1994, 12, 37–40 + 21. (In Chinese) [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).