Abstract

In order to comprehensively utilize coal gangue, we present fluidized calcination as a new thermal technology for activating coal gangue and systematical study was conducted in comparison with static calcination. The calcined products obtained by different calcination methods under various temperatures were characterized by the means of X-ray diffraction (XRD), thermal gravimetry-differential scanning calorimeter (TG-DSC), Fourier transform-infrared spectroscopy (FT-IR) and scanning electron microscope-energy dispersive spectrometer (SEM-EDS). Chemical and physical characteristics such as aluminium leaching rate, chemical oxygen demand and whiteness of calcined products were also investigated. The results show that aluminium leaching rate could reach to the maximal value 74.42% at 500 °C by fluidized calcination, while the maximal value of 66.33% could be reached at 600 °C by static calcination. Products by fluidized calcination obtained higher whiteness and lower chemical oxygen demand (COD) under the same calcination temperature. The well-crystallized kaolinite transform to amorphous meta-kaolinite under 600 °C and mullite presence under 1000 °C according to phase transformation, chemical bond variation and microstructure evolution analysis. Fluidized calcination was more efficiently for combustion of carbon/organic matter and dehydroxylation of kaolinite, which might applied in coal gangue industry in future.

1. Introduction

Coal gangue is an associated resource of complex industrial solid waste discharged when coal mining and washing in the production course [1,2]. The amount of coal gangue has already accumulated 3.8 billion tons and increasing at a rate of 0.2 billion tons per year in China, which has caused many serious environmental problems [3,4]. In recent years, many types of research have been conducted to develop its utilization as the abundant mineral resource for the production of paper, rubber, building materials, and chemical products, etc. [5]

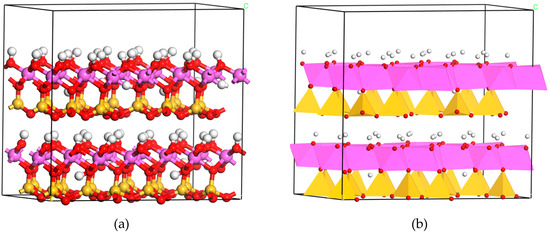

The main mineral composition of coal gangue is kaolinite, carbon/organic matter and iron minerals. Kaolinite (Al2O3∙2SiO2∙2H2O) was phyllosilicate with 1:1 type structure formed by the connection of SiO4 tetrahedral layer and AlO2(OH)4 octahedral layer [6,7,8,9], as shown in Figure 1. In this crystal structure, the Si and Al elements didn‘t have the chemical activity. Thermal activation by the calcination for coal gangue at 600–900 °C as the most common activation method [10,11].

Figure 1.

Model for of crystal structure kaolinite. White ball: H; red ball: O; purple ball: Al; yellow ball: Si. (a) Ball-and-stick model; (b) Polyhedron model.

Combustion of carbon/organic matter and dehydroxylation of kaolinite are two principal reactions in calcination process, after this process, performance indexes such as whiteness and activity of calcined products are significantly improved for industry applications [3,12,13]. The burnout level of carbon/organic matter of calcined products can be measured by the chemical oxygen demand (COD), and the activity of meta-kaolinite can be evaluated by leaching rate of aluminum from meta-kaolinite in hydrochloric acid solution [14,15,16,17,18].

The fluidized bed technology provides the advantages of uniform temperature as well as the high efficiency of heat and mass transfer, which hence widely used in many industries and fields such as alumina calcination and iron ore magnetization roasting [19,20]. In view of this, we considered absorbing these advantages in order to form fluidized calcination technology suitable for the coal gangue utilization.

Prior to this, few research on fluidized calcination of coal gangue have been reported. Therefore, in order to explore the possibility of fluidized calcination for coal gangue, the calcination behaviors by fluidized calcination in comparison with static calcination should be studied comprehensively and systematically. In this paper, the activation behavior, the reaction in the process, performance of products and the phases and structure changes for the fluidized calcination and static calcination were investigated in detail.

2. Experimental Procedures

2.1. Materials

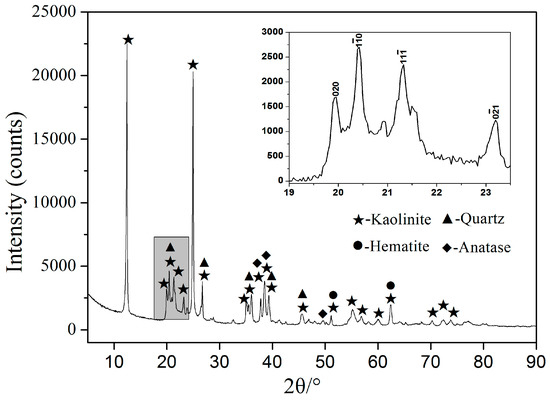

The coal gangue used in this experiment was collected from Shuozhou, Shanxi province. The mineralogical phase is characterized by X-ray diffraction (XRD) as shown in Figure 2. Chemical analysis of the sample was shown in Table 1. It indicates kaolinite and quartz are the major crystallized minerals presented in the raw coal gangue. The ignition loss (LOI) is mainly including adsorbed water, crystal water, carbon and organic matter.

Figure 2.

X-ray diffraction (XRD) pattern of raw coal gangue.

Table 1.

Chemical composition of coal gangue (mass %). VM: Volatile matter; LOI: Loss on ignition.

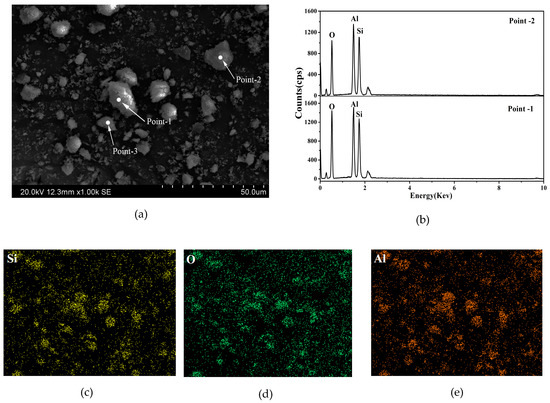

The morphologic features of the raw coal gangue from scanning electron microscope and energy dispersive spectrometer (SEM and EDS) analyses are shown in Figure 3 and Table 2. It can be seen that primary element of the particles are Al, Si and O. The ratio of Al/Si is between 0.92 and 0.96 in the particles, which is close to Al/Si of kaolinite. It demonstrates the particles are mainly kaolinite minerals.

Figure 3.

Scanning electron microscope (SEM) images and energy dispersive spectrometer (EDS) analysis of raw coal gangue. (a) SEM image; (b) spot scanning; (c) surface scanning of Si element; (d) surface scanning of O element; (e) surface scanning of Al element.

Table 2.

EDS analysis of raw coal gangue.

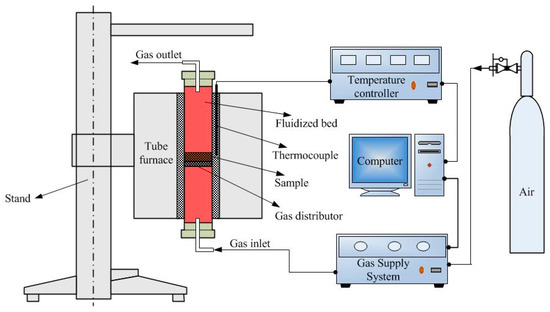

2.2. Calcination Methods

The raw coal gangue was dry grinding for −45 μm, occupying 85% of the specific surface area of 1030 m2/kg with minimum fluidization velocity of 0.08 m/s. The sample was calcined at various temperatures (via 400 to 1000 °C) for 180 min by fluidized calcination and static calcination, respectively. The fluidized calcination experiments were performed in a customized vertical tubular furnace system as shown in Figure 4, the internal diameter of the tubular furnace was 25 mm. During the experiments, the 15 g sample was put on the gas distributor, and the furnace was heated at the rate of 10 °C/min, the air was supplied as the inert gas through the bottom of the tubular furnace at a constant flow rate of 800 mL/min. The static calcination was used closed programmable box-type resistance furnace with the temperature controlled (KSL-1400X; HF-Kejing Materials Technology Co., Ltd., Hefei, China), and the 15 g sample was put in the crucible, and the resistance furnace was heated at the rate of 10 °C/min.

Figure 4.

Schematic of fluidized calcination experimental apparatus.

2.3. Testing Methods

TG-DSC (thermal gravimetry-differential scanning calorimeter) technique was the method widely used to characterize the combustion behavior of the coal gangue powder during calcination. Experiments were carried out in a simultaneous thermal analyzer (Netzsch Scientific Instruments Trading Ltd., Selb, Germany), and the experiment was carried out under air atmosphere from room temperature to 1200 °C at a heating rate of 10 °C/min [13].

The content of Al2O3 of calcined coal gangue was analyzed to determine by the chemical titration. The conventional dichromate method (K2Cr2O7 method) was used to measure chemical oxygen demand (COD) value according to the National Standard of China (JC/T 2156-2012) [21]. The whiteness of calcined coal gangue was measured with the whiteness meter WSB-2 [17].

The leaching processes as follows: 2 g of calcined coal gangue and 50 mL 20 wt % hydrochloric acid solutions were added in a 3-mouth flash with solid–liquid ratio of 1:25 g/mL. The flask was heated to 90 °C in magnetic stirrers and stirred for 60 min. Then the mixture was filtered and washed with deionized water for many times, the filtrate was analyzed to determine aluminum by inductively coupled plasma atomic emission spectrometer (ICP-AES), and the dissolution percentages of Al2O3 were calculated [18,22]. The dissolution of Al3+ in hydrochloric acid solution was the indicator to evaluate the activation efficiency of calcined coal gangue. Leaching of calcined coal gangue in HCl solution with the main reaction:

The phase transformation of calcination products was investigated by PANalytical X’pert PW3040 (PANalytical B.V. Ltd., Almelo, The Netherlands). The operating voltage and current were 40 kV and 40 mA, respectively. The diffraction angle was scanned from 5° to 90°.

The chemical structures of calcined coal gangue under different calcination temperatures were analyzed by Fourier transform infrared spectra using Nicolet 380 FT-IR spectrometer (Thermo Fisher Scientific Ltd., Waltham, MA, USA), and 1 mg sample accompanied with 100 mg KBr usually [23]. The spectra were recorded in the range of 4000–500 with 4 cm−1 resolution.

The morphology and microstructure of calcined products were observed by scanning electron microscopy (SEM; S-3400N; Hitachi, Ltd., Tokyo, Japan) and composition analysis was carried out by energy-dispersive spectrometry (EDS) combined with SEM. At the same time, samples were coated with gold using a sputter coater to increase conductivity prior to SEM characterization [24].

3. Results and Discussion

3.1. Thermal Analysis

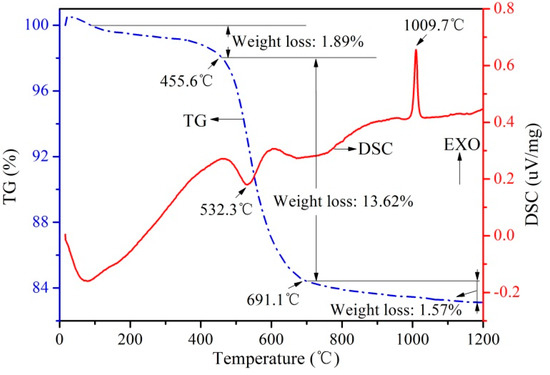

The result of TG-DSC analysis of the sample is presented in Figure 5. The sample undergoes a series of physical and chemical variations with the increasing temperature, and these variations are: The weight loss of 1.89% is attributed to the absorbed water is liberated and the ignitable substances decompose and burn before 455.6 °C. Structural hydroxyl groups were removed from kaolinite by a reorganization of the octahedral layer of kaolinite to meta-kaolinite (Al2O3∙2SiO2) as described by Equation (2), when temperature raised up to a range of 455.6~691.1 °C, resulting in weight loss of about 13.62%.

Figure 5.

TG and DSC analysis of raw coal gangue under air flow.

The result of TG-DSC analysis of the sample is presented in Figure 5. The sample undergoes a series of physical and chemical variations with the increasing temperature, and these variations are: The weight loss of 1.89% is attributed to the absorbed water is liberated and the ignitable substances decompose and burn before 455.6 °C. Structural hydroxyl groups were removed from kaolinite by a reorganization of the octahedral layer of kaolinite to meta-kaolinite (Al2O3∙2SiO2) as described by Equation (2), when temperature raised up to a range of 455.6~691.1 °C, resulting in weight loss of about 13.62%.

The endothermic peak presented at 532.3 °C in Figure 5 might be contributed by the dehydroxylation of kaolinite and formation of meta-kaolinite; the exothermic peak at 1009.7 °C is due to the transformation of meta-kaolinite into mullite (3Al2O3∙2SiO2) as presented by Equation (3) [25,26,27]. It deduced that kaolinite in coal gangue begins to decompose into amorphous meta-kaolinite at 450 °C and transforms to the crystallized mullite when the temperature reaches up to 1000 °C. The two thermal induced processes can be described by the following reactions [5,28]:

3.2. Chemical and Physical Characteristics

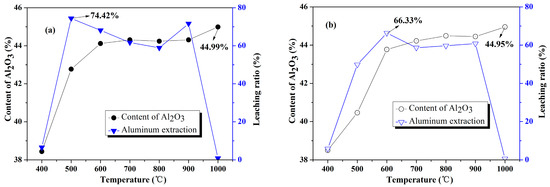

It can be seen from Figure 6, the content of Al2O3 in the fluidized calcination products increased faster and higher than the static calcination products before 600 °C, indicating that the fluidized calcination was better efficiency to obtain high quality products by combustion of carbon, dehydroxylation of kaolinite and removal of other impurities at low temperatures. The Al2O3 content of products by two different calcination methods tended to be stable after 700 °C, which was corresponded well with the thermal analysis. The content of Al2O3 increased to the maximum value 44.99% and 44.95%, respectively at 1000 °C.

Figure 6.

Aluminium leaching rate of calcined products by fluidized calcination (a) and static calcination (b) at various temperatures.

The hydrochloric acid leaching calcination product presents a different behavior by fluidized calcination and static calcination showed in Figure 6. Aluminium leaching rate of calcined products increases with calcination temperature and reaches to the maximal value at 500–600 °C then decreased dramatically when temperature rise to 1000 °C. This was mainly attributed to the formation of meta-kaolinite derived from the dehydration of kaolinite start at 450 °C, which would increase the reactivity of and the aluminium extraction rate of calcined coal gangue [29]. It is noted that aluminium leaching rate from calcined products by fluidized calcination is 25% higher than the leaching rate of static calcination at 500 °C. It implied that the fluidized calcination was more efficient to increase the reactivity of calcined products. Aluminum leaching rate was reduced to a minimum at 1000 °C, which was due to the transformation of meta-kaolinite into mullite.

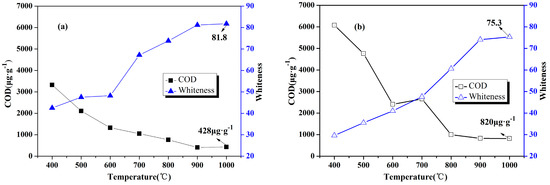

Figure 7 shows that the COD value of fluidized calcination products reduce to 428 μg/g and the whiteness increases to 81.8 as the temperature increased to 1000 °C. Meanwhile, the COD of static calcination product reduces to 820 μg/g and the whiteness increases to 75.3 at the same temperature. The COD value and the whiteness in coal-bearing kaolin are mainly influenced by carbon and organic matter, and they will be reduced or eliminated by combustion as the temperature increased in harmony with thermal analysis. It was found that calcined products could obtain lower COD value and higher whiteness by the fluidized calcination, which suggest that fluidized calcination was more efficient than static calcination for removal of impurities such as carbon and organic matter.

Figure 7.

Chemical oxygen demand (COD) and whiteness of calcined products by fluidized calcination (a) and static calcination (b) at various temperatures.

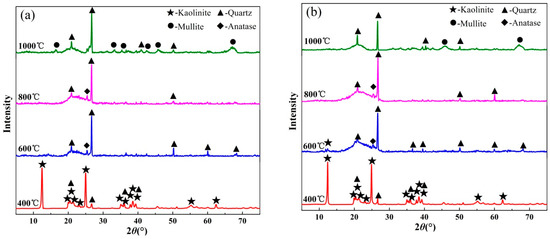

3.3. X-ray Diffraction Analysis

XRD patterns of calcined coal gangue by different calcination methods at various temperatures are shown in Figure 8. The calcination level can be evaluated by the crystallinity of kaolinite and quartz, the two primary diffraction peaks of kaolinite are at 12.4° and 24.9°, and the primary diffraction peak of quartz is at 21°. Accompanied temperature rise, the intense peaks of kaolinite gradually disappear, which caused by the breakages of Al–OH bonds and the dehydroxylation of kaolinite [30]. The intense peak of kaolinite at 12.4° completely disappear at 600 °C by fluidized calcination but remain at 600 °C by static calcination, which means dehydroxylation of kaolinite by fluidized calcination was more effective than static calcination. The kaolinite becomes amorphous from 450 °C and transforms to mullite at 1000 °C, and the fluidized calcination produced more mullite at 1000 °C than the static calcination as shown in Figure 8. It is noted that mullite has low activities, which was also consistent with the analysis results of the thermal analysis and the leaching rate of aluminum. Therefore, the temperature should be controlled accurately in order to get better activity properties.

Figure 8.

XRD patterns of calcined products by fluidized calcination (a) and static calcination (b) at various temperatures.

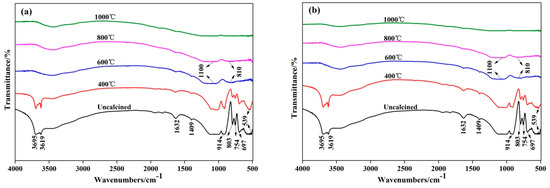

3.4. Fourier Transform Infrared Spectroscopy Analysis

A comparison of the functional groups for calcined products by different calcination methods is determined by FTIR spectra in the region 4000–500 cm−1 and described in Figure 9. FTIR spectra results are important in investigating combustion of carbon/organic matter and dehydroxylation of kaolinite. We can see that calcined products have similar development rules by fluidized calcination and static calcination. According to Hongfei Cheng [23], bands at 3695 and 3619 cm−1 were O–H stretching vibrations, which are the hydroxyl stretching of inner surface hydroxyl and the inner hydroxyl of kaolinite respectively. The band at 1632 cm−1 is attributed to O–H stretching and bending vibrations of absorbed water, indicates that absorbed water present on the raw coal gangue. None of the preceding bands was present on the spectra of calcined product after 600 °C, which suggest suggests that the coal gangue underwent dehydroxylation and produced meta- kaolinite. The disappearance of bands at 914 and 539 cm−1 signifies the breakages of Al–OH and Si–O–Al functional groups in kaolinite. The absence of 803 and 697 cm−1 and appearance of 1100 and 810 cm−1 demonstrates that the depolymerization of silica tetrahedrons. Aromatic CH bond around 756 cm−1 are intense in uncalcined coal gangue and gradually eliminated with the temperature increased, which attributed to combustion of carbonaceous or organic matter and combustion in coal gangue [31].

Figure 9.

Fourier transform infrared spectroscopy spectra of calcined products by fluidized calcination (a) and static calcination (b) at different temperatures.

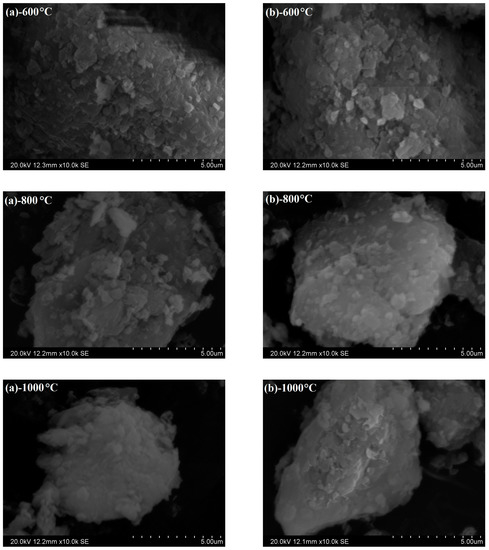

3.5. Scanning Electron Microscope Analysis

Morphology and microstructure evolution analysis of calcined products by different calcination methods are collected in the Figure 10. It can be known from SEM images (a-600 and b-600) that meta-kaolinite had the irregular characteristics of lamellar structures under 600 °C, and more scale-shaped lamellar structures dissociated from the group particle by the fluidized calcination. This might be due to the dehydroxylation of kaolinite and phase transform to meta-kaolinite. The structure of the aluminum oxide octahedral layer was destroyed, while the silicic oxygen tetrahedron preserved the original lamellar structure, which made the meta-kaolinite maintain the majority of lamellar structures. As mentioned in the previous Section 3.2, we could confirm that the leaching rate and react activity of calcined mainly depend on the non-crystallizing degree of kaolinite after calcination. The meta-kaolinite lamellar structure produced the disordered structure at 800 °C, and fluidized calcination products appeared to have more obvious disordered structure. The lamellar structure disappeared by fluidized calcination and a small amount of lamellar structure is still maintained by static calcination at 1000 °C, which coincides well with thermal analysis, meta-kaolinite transformed to mullite when temperature reaches up to 1000 °C. The microstructural evolution demonstrated that activation of coal gangue using calcination with fluidized calcination has the good effect for accelerating crystal transformation and reactivity.

Figure 10.

Scanning Electron Microscope images of calcined products by fluidized calcination (a) and static calcination (b) at different temperatures.

4. Conclusions

Thermal activation of coal gangue by fluidized calcination and static calcination was discussed in this work. The major findings can be concluded as below:

- (1)

- Kaolinite, quartz, unburned carbon and organic matter were the main mineral compositions in the raw coal gangue. TG-DSC analysis indicates that kaolinite begins to decompose into amorphous meta-kaolinite at 450 °C and transforms to mullite as temperature reaches up to 1000 °C.

- (2)

- According to chemical and physical characteristics of calcined products, fluidized calcination products could obtain higher activity, higher whiteness and lower COD under same calcination temperature compared with static calcination.

- (3)

- XRD analysis illustrated that kaolinite peaks at 12.4° disappeared completely at 600 °C and more mullite peaks presence at 1000 °C by fluidized calcination, which was proved by the disappearance of O–H stretching vibration in infrared spectra results. Morphology evolution analysis showed that fluidized calcination could accelerate crystal phase transformation and improve the activity of calcined products.

- (4)

- Combustion of carbon/organic matter and dehydroxylation were more quickly and effectively by fluidized calcination, due to the high efficiency of heat and mass transfer, which could produce product with excellent performance and stable quality.

Acknowledgments

This work was funded by Open Projects of Resarch Research Center of Coal Resources Safe Mining and Clean Utilization, Liaoning (LNTU16KF14) and Natural Science Foundation of China (51674065).

Author Contributions

Shuai Yuan and Yuexin Han conceived and designed the experiments; Shuai Yuan and Guichen Gong performed the experiments; Shuai Yuan and Yanjun Li analyzed the data; Peng Gao contributed reagents/materials/analysis tools; Shuai Yuan wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hao, G.; Yun, F.; Long, Z.Y.; Sen, Y.; Song, Z. Study on the property and reuse of coal gangue in Liupanshui, Guizhou Province, China. Int. J. Min. Reclam. Environ. 2013, 27, 366–373. [Google Scholar] [CrossRef]

- Liu, S.Y.; Yang, H.M. Composite of coal-series kaolinite and capric—Lauric acid as form-stable phase-change material. Energy Technol. 2015, 3, 77–83. [Google Scholar] [CrossRef]

- Zhou, C.C.; Liu, G.J.; Fang, T.; Lam, P.K.S. Investigation on thermal and trace element characteristics during co-combustion biomass with coal gangue. Bioresour. Technol. 2015, 175, 454–462. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.H.; Dong, X.X.; Chai, B.; Yang, Y. Evaluation of particle size distribution of coal gangue through fractal method in Dongkuang mine, Heshan, China. J. Mater. Civ. Eng. 2014, 26, 1–6. [Google Scholar] [CrossRef]

- Xu, X.H.; Lao, X.B.; Wu, J.F.; Zhang, Y.X.; Xu, X.Y.; Li, K. Microstructural evolution, phase transformation, and variations in physical properties of coal series kaolin powder compact during firing. Appl. Clay Sci. 2015, 115, 76–86. [Google Scholar] [CrossRef]

- Sperinck, S.; Raiteri, P.; Marks, N.; Wright, K. Dehydroxylation of kaolinite to metakaolin—A molecular dynamics study. J. Mater. Chem. 2011, 21, 2118–2125. [Google Scholar] [CrossRef]

- Kuang, J.; Yuan, W.; Li, L.; Hu, J.; Xu, L. Effects of Er(NO3)3, Nd(No3)3 and Y(No3)3 on kinetics of dehydroxylation of kaolinite. Powder Technol. 2016, 301, 581–589. [Google Scholar] [CrossRef]

- Cheng, H.F.; Yang, J.; Liu, Q.F.; Zhang, J.S.; Frost, R.L. A spectroscopic comparison of selected Chinese kaolinite, coal bearing kaolinite and halloysite—A mid-infrared and near-infrared study. Spectrochim. Acta A 2010, 77, 856–861. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.F.; Liu, Q.F.; Yang, J.; Frost, R.L. Thermogravimetric analysis of selected coal-bearing strata kaolinite. Thermochim. Acta 2010, 507–508, 84–90. [Google Scholar] [CrossRef]

- Li, H.J.; Sun, H.H.; Tie, X.C.; Xia, X.J. Dissolution properties of calcined gangue. J. Univ. Sci. Technol. B 2006, 13, 570–576. [Google Scholar] [CrossRef]

- Guo, C.B.; Zou, J.J.; Jiang, Y.S.; Huang, T.P.; Cheng, Y.; Wei, C.D. Thermal activation of coal fly ash by sodium hydrogen sulfate for alumina extraction. J. Mater. Sci. 2014, 49, 4315–4322. [Google Scholar] [CrossRef]

- Ji, H.P.; Fang, M.H.; Huang, Z.H.; Chen, K.; Li, W.J.; Liu, Y.G. Phase transformation of coal gangue by aluminothermic reduction nitridation: Influence of sintering temperature and aluminum content. Appl. Clay Sci. 2014, 101, 94–99. [Google Scholar] [CrossRef]

- Zhou, C.C.; Liu, G.J.; Yan, Z.C.; Fang, T.; Wang, R.W. Transformation behavior of mineral composition and trace elements during coal gangue combustion. Fuel 2012, 97, 644–650. [Google Scholar] [CrossRef]

- Qiao, X.C.; Si, P.; Yu, J.G. A systematic investigation into the extraction of aluminum from coal spoil through kaolinite. Environ. Sci. Technol. 2008, 42, 8541–8546. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Wan, J.; Sun, H.; Li, L. Investigation on the activation of coal gangue by a new compound method. J. Hazard. Mater. 2010, 179, 515–520. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Lv, H.; Yang, X.; Cheng, F. AlCl3⋅6H2O recovery from the acid leaching liquor of coal gangue by using concentrated hydrochloric inpouring. Sep. Purif. Technol. 2015, 151, 177–183. [Google Scholar] [CrossRef]

- Guo, Y.; Li, Y.; Cheng, F.; Wang, M.; Wang, X. Role of additives in improved thermal activation of coal fly ash for alumina extraction. Fuel Process. Technol. 2013, 110, 114–121. [Google Scholar] [CrossRef]

- Cui, L.; Guo, Y.; Wang, X.; Du, Z.; Cheng, F. Dissolution kinetics of aluminum and iron from coal mining waste by hydrochloric acid. Chin. J. Chem. Eng. 2015, 23, 590–596. [Google Scholar] [CrossRef]

- Li, Y.; Wang, R.; Han, Y.; Wei, X. Phase transformation in suspension roasting of oolitic hematite ore. J. Cent. South Univ. 2015, 22, 4560–4565. [Google Scholar] [CrossRef]

- Snellings, R.; Cizer, O.; Horckmans, L.; Durdzinski, P.T.; Dierckx, P.; Nielsen, P.; van Balen, K.; Vandewalle, L. Properties and pozzolanic reactivity of flash calcined dredging sediments. Appl. Clay Sci. 2016, 129, 35–39. [Google Scholar] [CrossRef]

- Building Materials Industry Standard of China. The Determination of COD Value of Fiber Glass Raw Materials and Ingredients; JC/T 2156-2012; Ministry of Industry and Information Technology: Beijing, China, 2012.

- Xiao, J.; Li, F.C.; Zhong, Q.F.; Bao, H.G.; Wang, B.J.; Huang, J.D.; Zhang, Y.B. Separation of aluminum and silica from coal gangue by elevated temperature acid leaching for the preparation of alumina and SiC. Hydrometallurgy 2015, 155, 118–124. [Google Scholar] [CrossRef]

- Cheng, H.; Frost, R.L.; Yang, J.; Liu, Q.; He, J. Infrared and infrared emission spectroscopic study of typical Chinese kaolinite and halloysite. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2010, 77, 1014–1020. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.M.; Zhang, N.; Yao, Y.; Sun, H.H.; Feng, H. Micro-structural characterization of the hydration products of bauxite-calcination-method red mud-coal gangue based cementitious materials. J. Hazard. Mater. 2013, 262, 428–438. [Google Scholar] [CrossRef] [PubMed]

- Cao, Z.; Cao, Y.D.; Dong, H.J.; Zhang, J.S.; Sun, C.B. Effect of calcination condition on the microstructure and pozzolanic activity of calcined coal gangue. Int. J. Miner. Process. 2016, 146, 23–28. [Google Scholar] [CrossRef]

- Zhang, S.H.; Ou, X.M.; Qiang, Y.H.; Niu, J.N.; Komarneni, S. Thermal decomposition behavior and de-intercalation mechanism of acetamide intercalated into kaolinite by thermoanalytical techniques. Appl. Clay Sci. 2015, 114, 309–314. [Google Scholar] [CrossRef]

- White, C.E.; Kearley, G.J.; Provis, J.L.; Riley, D.P. Inelastic neutron scattering analysis of the thermal decomposition of kaolinite to metakaolin. Chem. Phys. 2013, 427, 82–86. [Google Scholar] [CrossRef]

- Ptacek, P.; Soukal, F.; Opravil, T.; Havlica, J.; Brandstetr, J. The kinetic analysis of the thermal decomposition of kaolinite by DTG technique. Powder Technol. 2011, 208, 20–25. [Google Scholar] [CrossRef]

- Guo, Y.; Yan, K.; Cui, L.; Cheng, F. Improved extraction of alumina from coal gangue by surface mechanically grinding modification. Powder Technol. 2016, 302, 33–41. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Zhang, Y.; Sun, J.; Hao, Z. The thermal activation process of coal gangue selected from zhungeer in china. J. Therm. Anal. Calorim. 2016, 126, 1559–1566. [Google Scholar] [CrossRef]

- Zhou, C.C.; Liu, G.J.; Cheng, S.W.; Fang, T.; Lam, P.K.S. Thermochemical and trace element behavior of coal gangue, agricultural biomass and their blends during co-combustion. Bioresour. Technol. 2014, 166, 243–251. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).