Abstract

Due to the low grade of V2O5 in stone coal, the existing vanadium extraction technologies face challenges in terms of large handling capacity, high acid consumption and production cost. The pre-concentration of vanadium from stone coal before the extraction process is an effective method to reduce cost. In this study, detailed mineral characterization of stone coal was investigated. It has been confirmed that the vanadium mainly occurs in muscovite and illite. A significant demand for an effective pre-concentration process with simple manipulation for discarding quartz and other gangue minerals is expected. Based on the mineralogical study, a new vanadium pre-concentration process using a fine mineral spiral was investigated. The experimental results showed that the separation process, which was comprised of a rougher and scavenger, could efficiently discard quartz, pyrite and apatite. A final concentrate with V2O5 grade of 1.02% and recovery of 89.6% could be obtained, with 26.9% of the raw ore being discarded as final tailings.

1. Introduction

In China, stone coal is a vanadium resource with huge reserves. The gross reserve of vanadium in terms of V2O5 in stone coal is 118 million tons, which accounts for more than 87% of the domestic reserve of vanadium [1,2]. Therefore, many techniques of vanadium extraction from stone coal have been researched and developed by various researchers [3,4]. However, because of the low grade of V2O5 in raw material, the existing extraction technology faces the problem of large handling capacity, high acid consumption and production cost [5,6]. According to the research of Zhao [5], when the V2O5 grade improved from 0.8% to 1.0%, the production cost of 1 t V2O5 could decrease by 5010 CNY and the profit could increase by 36%. The pre-concentration of vanadium from stone coal by beneficiation is an effective method to raise the V2O5 grade and reduce the deleterious elements content, with further reduction of production cost.

Pre-concentrate techniques are dependent on the type of vanadium minerals and associate gangue. The vanadium in stone coal mainly exists in the crystal lattice of muscovite and illite where V(III) and V(IV) replace Al(III) as isomorphism [1,7]. Besides, the small amount of vanadium combines with organic compounds and/or adsorbs on the surface of clay, pyrite and kaolinite [8]. The main gangues in stone coal are quartz, carbonaceous mudstone, and acid consumption minerals, such as apatite, calcite, pyrite and hematite [9]. The pre-concentration of vanadium could reduce the content of acid consumption minerals and the deleterious elements, like Fe, which has harmful effect on the stage of vanadium precipitation [10]. The present techniques used in pre-concentrate of vanadium from stone coal are generally classified into four categories: (i) gravity-flotation; (ii) flotation; (iii) desliming-flotation; (iv) gravity. The gravity-flotation and flotation methods are suitable for the stone coal, which has vanadium mainly exist in muscovite and quartz as the dominant gangue [11,12]. The desliming-flotation method could be used for processing of the stone coal, which has vanadium exists both in muscovite and iron-aluminum oxides minerals. Through this method, desliming was firstly employed for the recovery of the fine fractions, which had a V2O5 grade of 2.5–3.5 times higher than the raw ones. Then flotation recovery of vanadium was carried out for the coarser fractions [13,14,15]. However, due to the harmful effects of carbonaceous mudstone, which will coat the surface of mineral particles, the flotation and its combination process are not satisfactory [16,17]. It can be concluded that the type of stone coal, which contains carbonaceous mudstone, is relatively difficult to pre-concentrate. This study focused on the gravity recovery of vanadium from this type of stone coal.

Since the spiral concentrator’s fully commercial use started in the early 1940s, spirals have been proven to be a cost-effective and efficient means of concentrating a variety of ores [18,19]. In recent years, fine mineral spirals are successfully used for processing fine (<0.1 mm) materials [20,21,22]. Due to the low settling velocities encountered by the very fine mineral particles, smaller bed depth and lamina flow are required for fully separation [20]. Hence, light minerals require a significantly smaller pitch with somewhat larger diameter [23]. Accordingly, Spirals for fine materials of small specific gravity should have significantly small ratio of pitch to diameter (P/D) [24]. However, there was less information on pre-concentration of vanadium from stone coal by fine spiral.

The objective of this work was to investigate a simple gravity process for the possible pre-concentration of vanadium from stone coal. Based on the mineralogical and separation studies, a process flow scheme with two-stage spiral separator circuit was proposed.

2. Experimental

2.1. Materials

Vanadium-bearing stone coal decarbonized in the fluidized bed furnace was obtained from Teng-da Mining and Metallurgy Co. Ltd., Xianning, China. Approximately 500 kg of representative sample was used from a sampling campaign. After three crushing stages (two jaw crushers and a rolls crusher), particle size was reduced to <3.0 mm. Materials were then well mixed and divided into 1 kg samples for characterizations and pre-concentration studies.

2.2. Procedure

The samples were firstly wet ground in a HLXMQ-Φ240 × 90 laboratory ball mill from Wuhan Exploring Machinery Factory (Wuhan, China) at 50 wt % solids for 24 min, until a particle size distribution of <74 μm accounted for 72.2 wt % was achieved. Batch grinding experiments were conducted to determine the grinding curves. Four kilogram ground product was prepared for the rougher separation. Then the ground product was subjected to the separation by a 5 turn laboratory spiral. Batch experiments were conducted to find the optimal operation parameters by single factor test method, and using the parallel test to increase the stability. The optimal operation parameters of the rougher process were the feed rate of 236 L/h, the feed slurry solid concentration of 18 wt % and the wash water of 30 L/h. The products of rougher included concentrate, middling and tailing. The rougher concentrate was the final concentrate for vanadium extraction. The middling was wet reground to a particle size distribution of <74 μm accounted for 65.6 wt %. The reground product was the feed for scavenger. Four kilograms of reground product was prepared for the scavenger separation. The optimal operation parameters of scavenger process were the feed rate of 313 L/h, the feed slurry solid concentration of 15 wt % and the wash water of 0 L/h. The products of scavenger included tailing and concentrate. The tailings of the rougher and scavenger were rejected as final tailings. In the close circuit flowsheet, the scavenger concentrate was recycled to the rougher feed.

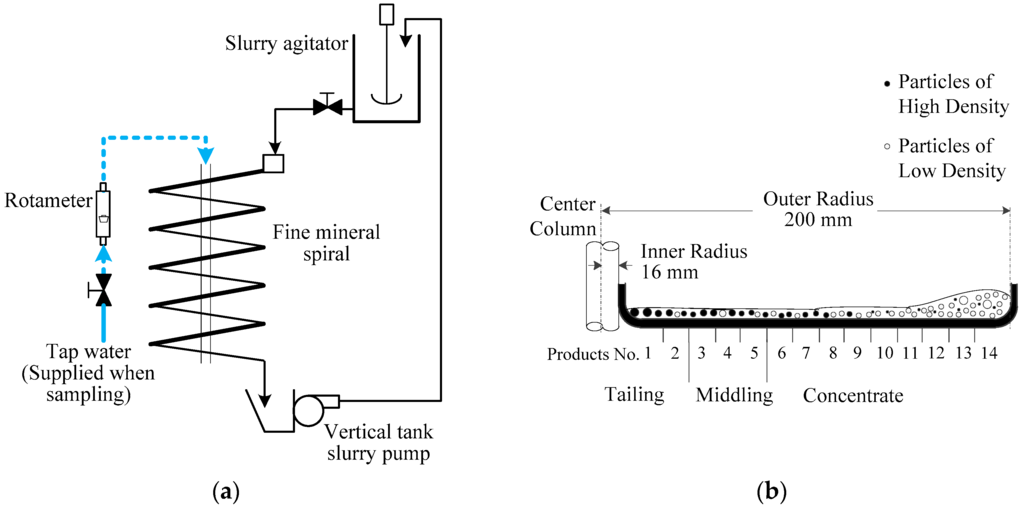

The design data of the laboratory spiral are given in Table 1 and the set-up, used for the experiments, is shown in Figure 1a. In the rougher of spiral, the feed stream was separated into 14 bands at the discharge of the spiral, numbered from 1 to 14. The uniform width of every band was 12 mm. In this study, the gangue was either the minerals of high density or the minerals of high hardness. Hence, high density product (collected from No. 1 to 2) was defined as tailing, middle density product (No. 3 to 5) was defined as middling, and low density product (No. 6 to 14), which contained high muscovite, was defined as concentrate (Figure 1b).

Table 1.

Geometry parameters of the spiral.

Figure 1.

Schematic set-up of spiral (a), and a sectional view of spiral trough flow (b).

2.3. Test Methods

- The chemical composition of the stone coal was detected by the Axios advanced X-ray fluorescence (XRF) analyzer (PANalytical B.V., Almelo, The Netherlands).

- Optical microscopy study was performed using Leica DMLP polarization microscope (Leica, Wetzlar, Germany).

- The X-ray diffraction (XRD) analysis was conducted by using D/Max-RB X-ray diffraction meter (Rigaku, Akishima, Japan) with Cu Kα radiation.

- The vanadium valences of the raw ore were measured on ZDJ-4A automatic potentiometric titrimeter (Shanghai INESA Scientific Instrument Ltd., Shanghai, China) by ammonium ferrous sulfate method [25].

- Sizing analysis was conducted on sub-samples of feed and test products using Mastersizer 2000 laser particle characterization system (Malvern Instruments Ltd., Malvern, UK) and laboratory wet screening method.

- The determination of vanadium grade was measured in accordance with Test Methods of Vanadium in Coal Standard (GB/T 19226-2003) [26].

3. Results and Discussion

3.1. Mineralogical Study of the Raw Ore

3.1.1. Chemical Composition Analysis

The results of chemical composition analysis (Table 2) showed that the main component in the sample is SiO2 and the grade of V2O5 is only 0.81%. Although these are decarbonized samples, there are still 5% C in residues.

Table 2.

Chemical composition of raw sample.

3.1.2. Mineral Composition Analysis

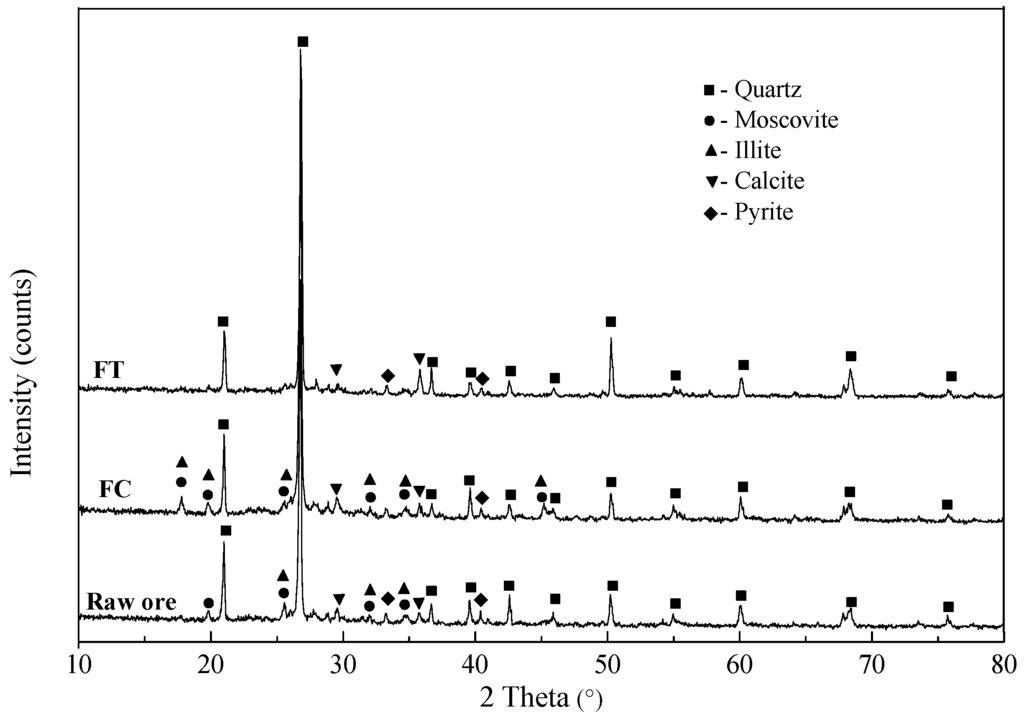

The results of optical mineralogy and the X-ray diffraction (XRD) analysis (Figure 2) revealed that the main mineral phases were quartz, muscovite, illite, calcite and pyrite. The diffraction peaks of muscovite and illite in the final concentrate (FC) were slightly higher than the other ones, indicating that gravity separation could concentrate the muscovite and illite to Final concentrate. The mineral composition of the sample was obtained by the comprehensive analysis of the chemical composition, optical microscopy and XRD. The results are shown in Table 3. The density and Mohs scale of the main minerals are also tabulated in Table 3 [27]. The density, Mohs scale and granularity differences among various minerals were taken into account for mineral separation. Gravity separation may be an appropriate method as a result of the analysis above.

Figure 2.

X-ray diffraction (XRD) pattern of raw sample, the final concentrate (FC) and the final tailings (FT).

Table 3.

Mineral composition of raw sample.

3.1.3. Occurrence of Vanadium

The vanadium in stone coal mainly exists in the crystal lattice of muscovite and illite where V(III) and V(IV) replace Al(III) as isomorphism [1,7]. Besides, the small amount of vanadium combines with organic compounds and/or adsorbs on the surface of minerals like clay, pyrite and kaolinite, etc. [8]. The vanadium valences of the raw ore were measured on ZDJ-4A automatic potentiometric titrimeter (Shanghai INESA Scientific Instrument Ltd.) by ammonium ferrous sulfate method, and the results showed that there are 76.6% V(III), 23.4% V(IV) and no V(V) in this ore. The content of absorbed V was measured by diluted acid leaching method. The result showed that the absorbed state does not exist in the raw ore and it is consistent with the result of the valence measurement.

The occurrence of vanadium was obtained by the comprehensive analysis of the above details and the electron probe micro-analyzer of the raw ore (Table 4). It was indicated that the vanadium occurs as an isomorphism state in muscovite and illite. Hence, the pre-concentration of vanadium could be achieved by separating muscovite and illite from gangue, which has either high density or high hardness.

Table 4.

Electron probe micro-analyzer results of raw ore (%).

3.2. Selective Grinding

From the mineralogical study of the raw ore, it is known that vanadium is mainly distributed in muscovite and illite in the form of an isomorphism. The mohs scale of muscovite and illite is shown below 3 (Table 3). However, gangue like quartz, pyrite, apatite and hematite all have a higher mohs scale than muscovite and illite. Distinguished from lamellar structures of muscovite and illite, gangues particles are mostly irregular or have an angular structure. Due to the differences in the crystal structure and the hardness, muscovite and illite may have different grindability in different grinding media [28,29]. If selective grinding of muscovite and illite is achieved, then not only is energy saved by the reduction of the amount of fines produced, but also muscovite and illite are concentrated to a fine size fraction, which makes subsequent separation or vanadium leaching stages easier and cheaper to operate [30]. According to the research of Ou [31], the grinding in either ball media or short column media was considered as having higher selectivity for cracking lamellar minerals like illite and kaolinite than grinding in roll media. The balls achieved point contact in the grinding process, which made it have higher selectivity for grinding soft and flaky particles than the line contact. Therefore, the particle size of quartz, pyrite, hematite and apatite in the grinding products was greater than muscovite and illite, which created a favorable condition for spiral separation.

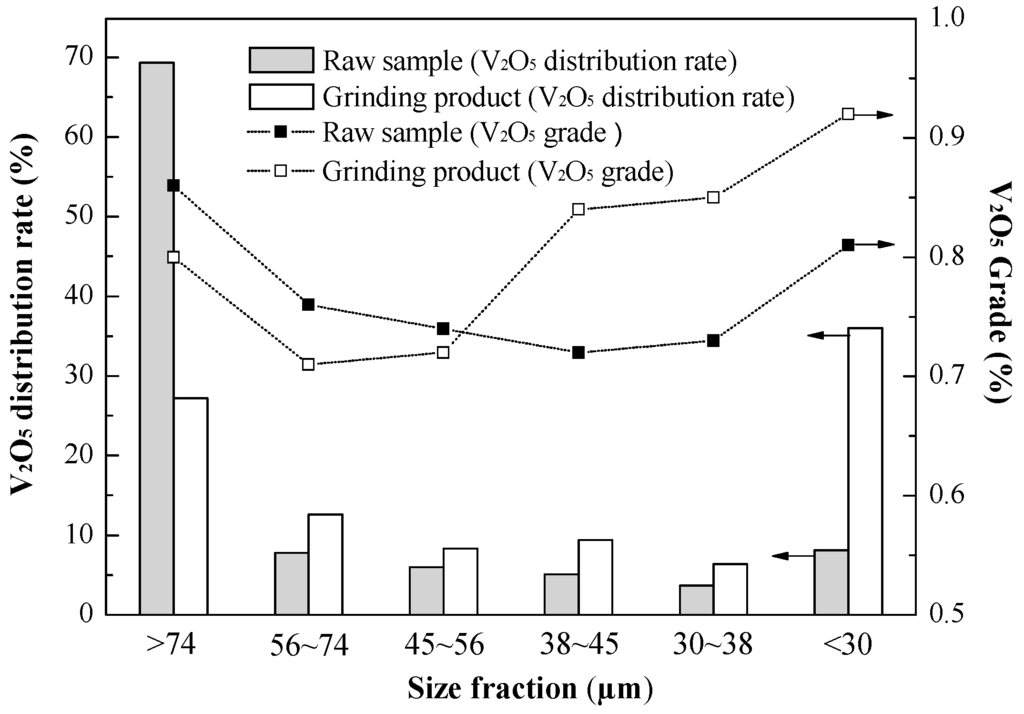

The ground product particle size fraction analysis which was conducted using Mastersizer 2000 laser particle characterization system, showed that the d10, d50 and d90 (diameter at the cumulative undersize of 10%, 50% and 90%) were 8, 53 and 95 μm, respectively. The V2O5 grade in each size fraction of selective grinding product is shown in Figure 3, compared with the raw sample. It was indicated that through selective grinding the V2O5 grade increased in fine fraction (<45 μm), while decreased in coarse fraction (>45 μm). Meanwhile, through selective grinding the maximum difference of V2O5 grade among each size fraction increased from 0.11% to 0.18%. It was indicated that the V2O5 grade was characterized by the grain gradation distribution. However, the lowest grade size fraction still contained 0.69% V2O5, and could not be directly discarded. Therefore, a spiral separation was carried out to further reduce the V2O5 content.

Figure 3.

V2O5 grade and distribution rate of each size fraction of grinding product and the raw sample.

3.3. Gravity Separation

In the spiral separation process, muscovite and illite particles, which have low density and small particle size, are concentrated in a band along the outer side of the stream. The muscovite and illite have slower settling velocity compared with other minerals because of their flaky shape. Hence, the muscovite and illite are swept along in the outer side of the stream [32]. While coarse and light particles of quartz are concentrated in a band along the mid region of the stream, the high density particles of pyrite, hematite and apatite are concentrated in a band along the inner side of the stream. Muscovite and illite particles were washed into light minerals band called concentrate in this study. The mid and heavy mineral bands were called middling and tailing, respectively.

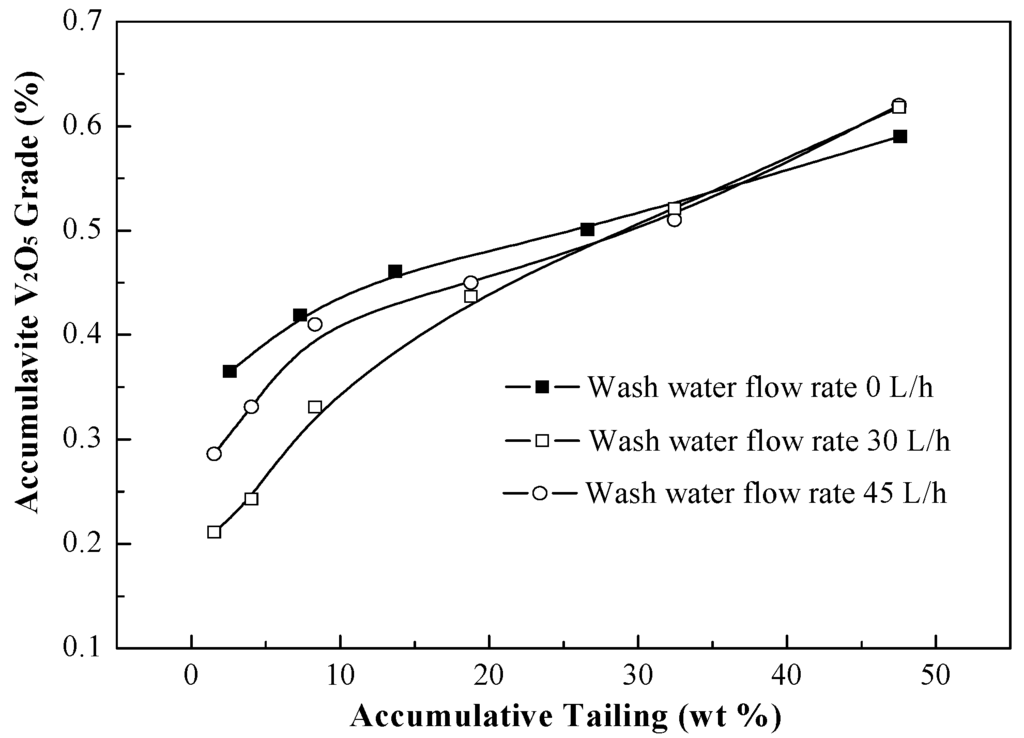

The operation variables were confirmed by single factor test method. In order to avoid the accidental error, parallel samples were collected in each test. The results showed that increasing the feed rate was favorable to vanadium recovery but hampered the vanadium grade. Increasing the feed slurry solid concentration could slightly increase vanadium grade at the expense of recovery. The optimal operating variables of rougher were: feed rate of 236 L/h, and feed slurry solid concentration of 18 wt %. The wash water flow ratio test results (Figure 4) indicated that the wash water addition could wash away entrapped light and small particles from the inner side of the stream from where the tailing was discarded. The wash water flow rate significantly impacted the V2O5 grade of tailing at low wash water flow rate.

Figure 4.

Tailing V2O5 grade vs. tailing mass rate of different wash water flow rate (WWFR: wash water flow rate).

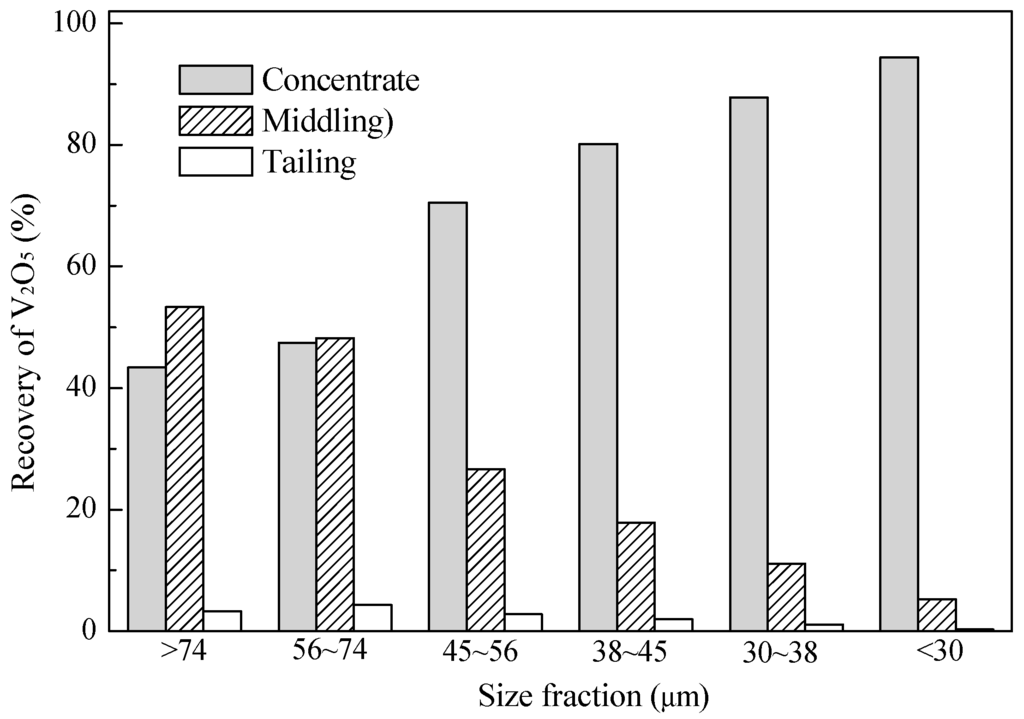

The open circuit gravity separation test results (Table 5) indicated that the V2O5 content increased up to No. 8, and then decreased to No. 14 as the stream number increased. The V2O5 grade of tailing was only of 0.24%, and could be discarded as final tailing. The products analysis of concentrate, tailing and middling was performed. The results tabulated in Table 6 showed that the V2O5 grade of every size fraction above 38 μm in concentrate was higher than 1.0% and V2O5 distribution rate of >38 μm was 44.0% . Meanwhile, the sizes of about 60 wt % of the particles were <38 μm in concentrate. Hence, it was difficult to further increase the V2O5 grade. Although the V2O5 grade of middling was much lower than concentrate and feed, it was still not low enough to discard. The products analysis results (Table 6) showed that the middling has a particle size distribution of <74 μm and accounted for 53 wt %. The middling regrinding and scavenger study results (Table 7) indicated that the V2O5 grade of scavenger tailing was 0.35%, and it, together with the rougher tailing, could be rejected as final tailing (FT). The rougher concentrate was as final concentrate (FC) for leaching. The scavenger concentrate could be recycled to the rougher feed when in the close circuit flowsheet. Furthermore, the V2O5 recovery in concentrate, middling and tailing of each size fraction analysis was analyzed (Table 6). It verified the above mentioned viewpoint, of which selective grinding muscovite and illite could create a favorable condition for spiral separation (Figure 5).

Table 5.

Open circuit separation results of rougher.

Table 6.

Products analysis of concentrate, middling and tailing.

Table 7.

Results of middling regrinding and scavenger.

Figure 5.

V2O5 recovery in concentrate, middling and tailing of each size fraction.

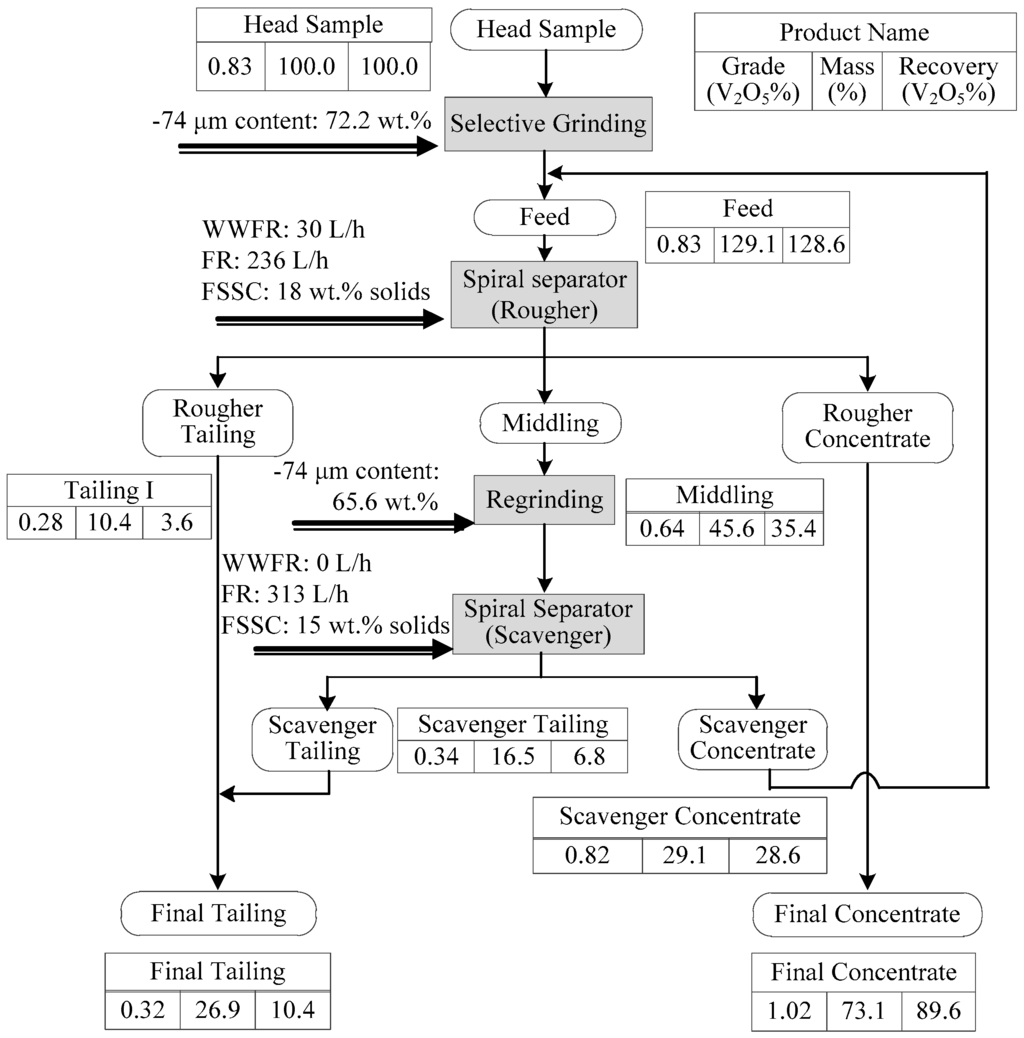

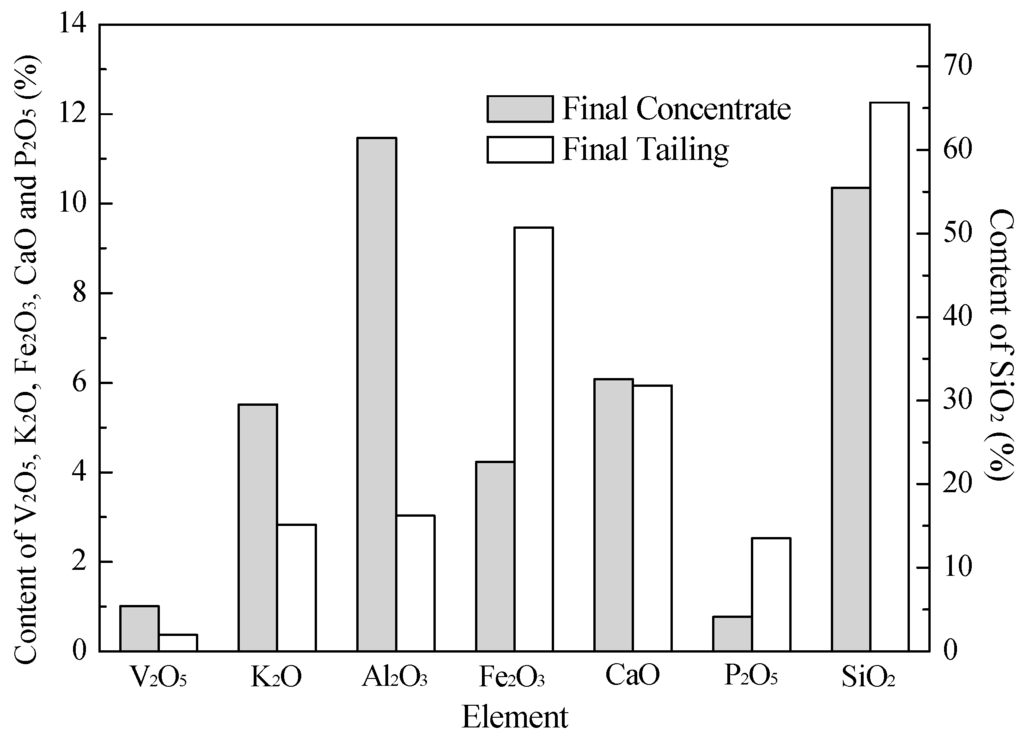

3.4. Flowsheet Test

The detailed flowsheet, along with the mass balance and the process conditions for the pre-concentrate of vanadium from stone coal, was depicted in Figure 6. It could be observed that the V2O5 grade of FT was 0.32%, which was much lower than FC. The loss of V2O5 was 10.4%, while the discarding rate was 26.9%. Combined with the mineral composition of the raw ore (Table 3), XRD analysis (Figure 2) and chemical analysis (Figure 7) of FT and FC, it showed that the P primarily came from apatite, while Fe was come from the iron minerals, which were pyrite and hematite. Muscovite in FC was two times more than that in FT. Apatite and iron minerals in FC were about 1/3 and 3/7 of the content in FT, respectively. It was showed that the pre-concentrate of vanadium from stone coal could improve the V2O5 grade by decreasing the content of gangue minerals, such as quartz, apatite and iron minerals. Furthermore, the apatite and iron minerals were not only the high acid consumption minerals, but also the originate minerals of Fe and P ions. It was indicated that the vanadium pre-concentration could decrease the content of high acid minerals and the content of harmful element.

Figure 6.

Flowsheet for the pre-concentration of vanadium from stone coal (GPD: ground pulp density, WWFR: wash water flow rate, FR: feed rate, FSSC: feed slurry solid concentration).

Figure 7.

Chemical compositions of FT and FC.

4. Conclusions

1. According to the mineralogical study of the raw ore, it was indicated that the mineral composition of raw ore is simple, with vanadium occurring mainly in muscovite and slightly in illite, and quartz as a major impurity. Minor gangue minerals are: pyrite, calcite, kaolinite, coal, apatite and hematite.

2. The results of the gravity separation study showed that the fine spiral of a 0.36 P/D ratio was a useful separator for vanadium pre-concentration from stone coal.

3. A new process comprising two-stage spiral gravity separation has been applied to realize the pre-concentration of vanadium. Through the process, 26.9% of the raw ore could be directly discarded and the V2O5 loss was only 10.4%. In addition to improving the V2O5 grade from 0.8% to 1.0%, the apatite and iron minerals in FC were about 1/3 and 3/7 of the content in FT, respectively.

Acknowledgments

This research was financially supported by the National Natural Science Foundation of China (No. 51474162) and the Research Project of Chinese Ministry of Education (No. 213025A). We gratefully acknowledge the two anonymous reviewers selected by Minerals who examined the original manuscript; their critical reading and valuable comments greatly improved this article.

Author Contributions

Xin Liu and Yimin Zhang conceived and designed the experiments; Xin Liu performed the experiments; Xin Liu and Kun Sun analyzed the data; Tao Liu and Zhenlei Cai contributed reagents/materials/analysis tools; Xin Liu wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bin, Z.Y. Progress of the research on extraction of vanadium pentoxide from stone coal and market of the V2O5. Hunan Nonferrous Metals 2006, 22, 16–20. (In Chinese) [Google Scholar]

- Cai, Z.L.; Zhang, Y.M.; Liu, T.; Huang, J. Mechanisms of vanadium recovery from stone coal by novel BaCO3/CaO composite additive roasting and acid leaching technology. Minerals 2016, 6, 26. [Google Scholar]

- Wang, M.Y.; Wang, X.W. Research status and prospect of vanadium leaching processes from stone coal. Chin. J. Rare Metals 2010, 1, 90–97. [Google Scholar]

- Xue, N.N.; Zhang, Y.M.; Liu, T.; Huang, J. Study of the dissolution behavior of muscovite in stone coal by oxygen pressure acid leaching. Metall. Mater. Trans. B 2015, 47, 1–8. [Google Scholar]

- Zhao, Y.L.; Zhang, Y.M.; Liu, T.; Chen, T.J.; Bian, Y.; Bao, S.X. Pre-concentration of vanadium from stone coal by gravity separation. Int. J. Miner. Process. 2013, 121, 1–5. [Google Scholar]

- Zhang, Y.M.; Bao, S.X.; Liu, T.; Huang, J.; Chen, T.J. Research status and prospect of vanadium extraction from stone coal in China. Nonferrous Metals Extr. Metall. Sect. 2015, 2, 24–30. (In Chinese) [Google Scholar]

- Zhu, X.B.; Zhang, Y.M.; Huang, J.; Liu, T.; Wang, Y. A kinetics study of multi-stage counter-current circulation acid leaching of vanadium from stone coal. Int. J. Miner. Process. 2012, 114–117, 1–6. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Bao, S.X.; Liu, T.; Chen, T.J.; Huang, J. The technology of extracting vanadium from stone coal in China: History, current status and future prospects. Hydrometallurgy 2011, 109, 116–124. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Hu, Y.J.; Bao, S.X. Vanadium emission during roasting of vanadium-bearing stone coal in chlorine. Miner. Eng. 2012, 30, 95–98. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Y.M.; Liu, T.; Huang, J.; Wang, Y. Effect of impurities on vanadium purification from acid leaching solution of stone coal with solvent extraction process. Nonferrous Metals Extr. Metall. 2013, 5, 27–30. (In Chinese) [Google Scholar]

- Li, J.; Ma, J. Technical study of mechanical separation to discard tailings of vanadium ore contained in black rock series. Nonferrous Metals Process. Sect. 2010, 4, 25–28. [Google Scholar]

- Sun, W.; Wang, L.; Cao, X.F.; Liu, R.Q.; Xu, L.H.; Han, H.S. Flotation technology and adsorption mechanism of vanadium extraction from stone coal. Chin. J. Nonferrous Metals 2012, 22, 2069–2074. [Google Scholar]

- Wang, L.; Sun, W.; Liu, R.Q.; Gu, X.C. Flotation recovery of vanadium from low-grade stone coal. Trans. Nonferrous Met. Soc. China 2014, 24, 1145–1151. [Google Scholar]

- Xiang, P.; Feng, Q.M.; Niu, Y.J.; Pan, A.X. Enrichment of vanadium from stone coal in Aksu vanadium mine by ore dressing method. Mater. Res. Appl. 2010, 4, 65–70. (In Chinese) [Google Scholar]

- Gu, X.C.; Sun, W.; Liu, R.Q.; Song, S.B.; Chen, X.Z. Study on mineral processing of a decarburized stone coal in Hunan. Nonferrous Metals Process. Sect. 2014, 5, 67–71. (In Chinese) [Google Scholar]

- Wu, H.L.; Zhao, W.; Li, M.T.; Deng, Z.G.; Ge, H.W.; Wei, C. New craft study on enriching vanadium by means of priority coal flotation from high carbon stone-coal. J. Chin. Rare Earth Soc. 2008, 26, 530–533. [Google Scholar]

- Bian, Y.; Zhang, Y.M.; Ren, L.Y.; Bao, S.X.; Zhao, Y.L.; Liu, X. New process for calcite flotation from high calcium and carbon-type vanadium-bearing stone coal. Chin. J. Rare Met. 2014, 4, 693–702. [Google Scholar]

- Mishara, B.K.; Tripathy, A. A preliminary study of particle separation in spiral concentrators using DEM. Int. J. Miner. Process. 2010, 94, 192–195. [Google Scholar]

- Das, S.K.; Godivalla, K.M.; Panda, L.; Bhattacharya, K.K.; Singh, R.; Mehrotra, S.P. Mathematical modeling of separation characteristics of coal-washing spiral. Int. J. Miner. Process. 2007, 84, 118–132. [Google Scholar] [CrossRef]

- Richards, R.G.; MacHunter, D.M.; Gates, P.J.; Palmer, M.K. Gravity separation of ultra-fine (−0.1 mm) minerals using spiral separators. Miner. Eng. 2000, 13, 65–77. [Google Scholar] [CrossRef]

- Liu, H.Z. Development of BL1500—A spiral chute and its application in tailings retreatment. Mining Metall. 2001, 10, 24–28. (In Chinese) [Google Scholar]

- Liu, X.; Zhang, Y.M.; Liu, T.; Cai, Z.; Chen, T.J.; Sun, K. Beneficiation of a sedimentary phosphate ore by a combination of spiral gravity and direct-reverse flotation. Minerals 2016, 6, 38. [Google Scholar]

- Kapur, P.C.; Meloy, T.P. Spirals observed. Int. J. Miner. Process. 1998, 53, 15–28. [Google Scholar]

- Zhang, Y.M.; Liu, H.Z. Development and application of out-limited H/D helical chute. Multipurp. Util. Miner. Resour. 2000, 5, 43–46. (In Chinese) [Google Scholar]

- Bao, S.X.; Zhang, Y.M.; Huang, J.; Yang, X.; Hu, Y.J. Determination of vanadium valency in roasted stone coal by separate dissolve-potentiometric titration method. MRS Proc. 2012, 1380. [Google Scholar] [CrossRef]

- General Administration of Quality Supervision, Inspection and Quarantine of China. Determination of Vanadium in Coal; GB/T 19226-2003; Standard Press of China: Beijing, China, 2003. (In Chinese)

- Wu, L.; Bai, G.; Yuan, Z. Minerals and Rocks; Chemical Industry Press of China: Beijing, China, 2010; pp. 170–210. (In Chinese) [Google Scholar]

- Zhu, Y.M.; Han, Y.X.; Wang, Z.H.; Tian, W.L. Selective grinding of low grade bauxite in ball mill grinding. Metal Mine 2009, 6, 60–63. [Google Scholar]

- Zhang, G.F.; Feng, Q.M.; Chen, Q.Y.; Zhang, P.M. Study on grinding media of selective grinding of bauxite. J. Cent. South Univ. Sci. Technol. 2004, 4, 552–556. [Google Scholar]

- Liu, J.; Zhang, Y.M.; Huang, J.; Liu, T.; Yuan, Y.Z.; Huang, X.B. Influence of mechanical activation on mineral properties and process of acid leaching from stone coal. Chin. J. Rare Metals 2014, 38, 115–122. [Google Scholar]

- Ou, L.M.; Feng, Q.M.; Lu, Y.P.; Zhang, G.F. Bauxite cracking mode and selective separation of aluminum and silicon minerals. Metal Mine 2005, 2, 28–32. (In Chinese) [Google Scholar]

- Li, Y.C. Test on recleaning of tailing from air-separated fragmental mica. Non Metallic Mines 2002, 25, 39–40. (In Chinese) [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).