Basis for a New Life Cycle Inventory for Metals from Mine Tailings Using a Conceptual Model Tool

Abstract

1. Introduction

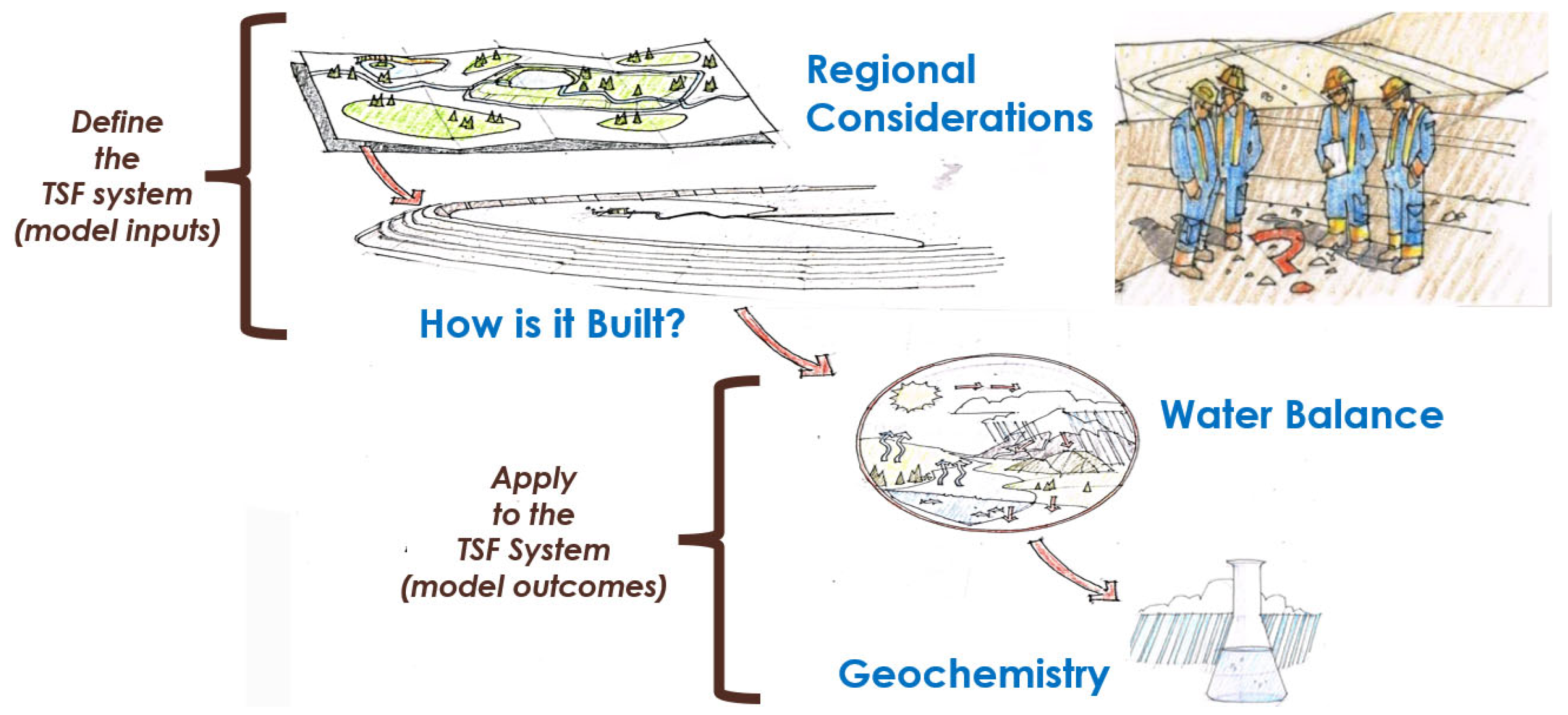

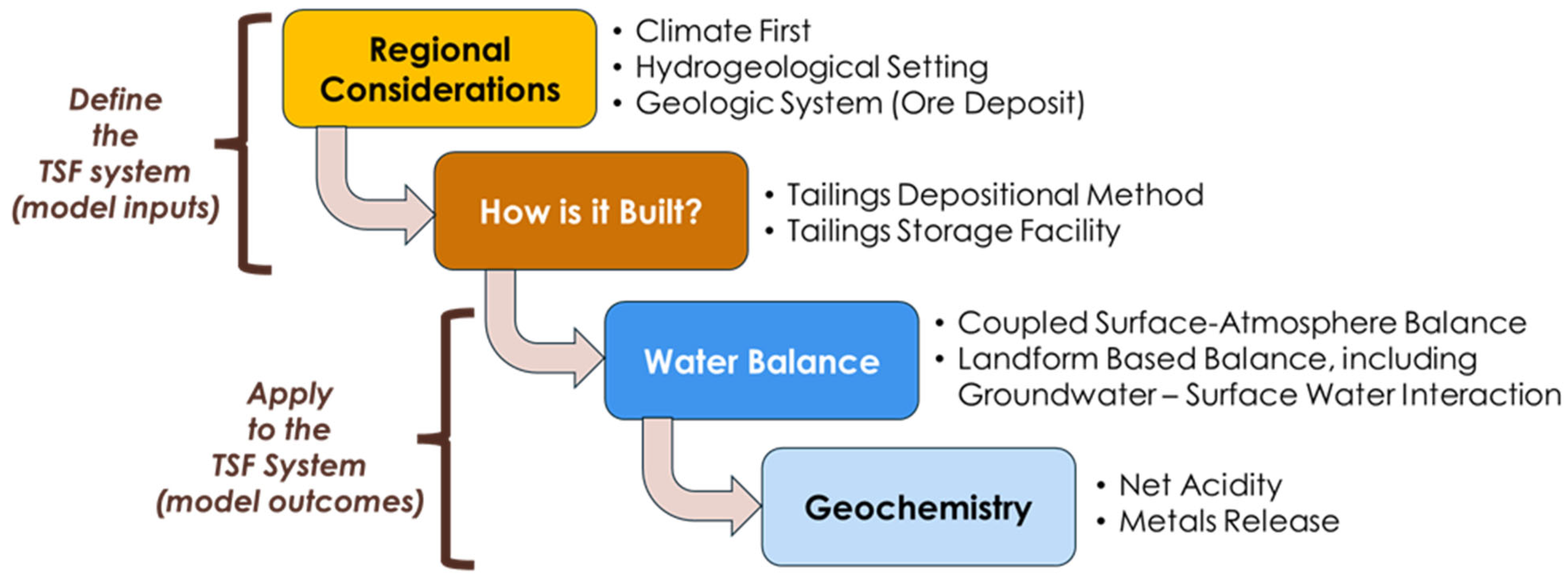

1.1. Conceptual Model Tool Approach

1.2. Overview of Processes

2. Methods

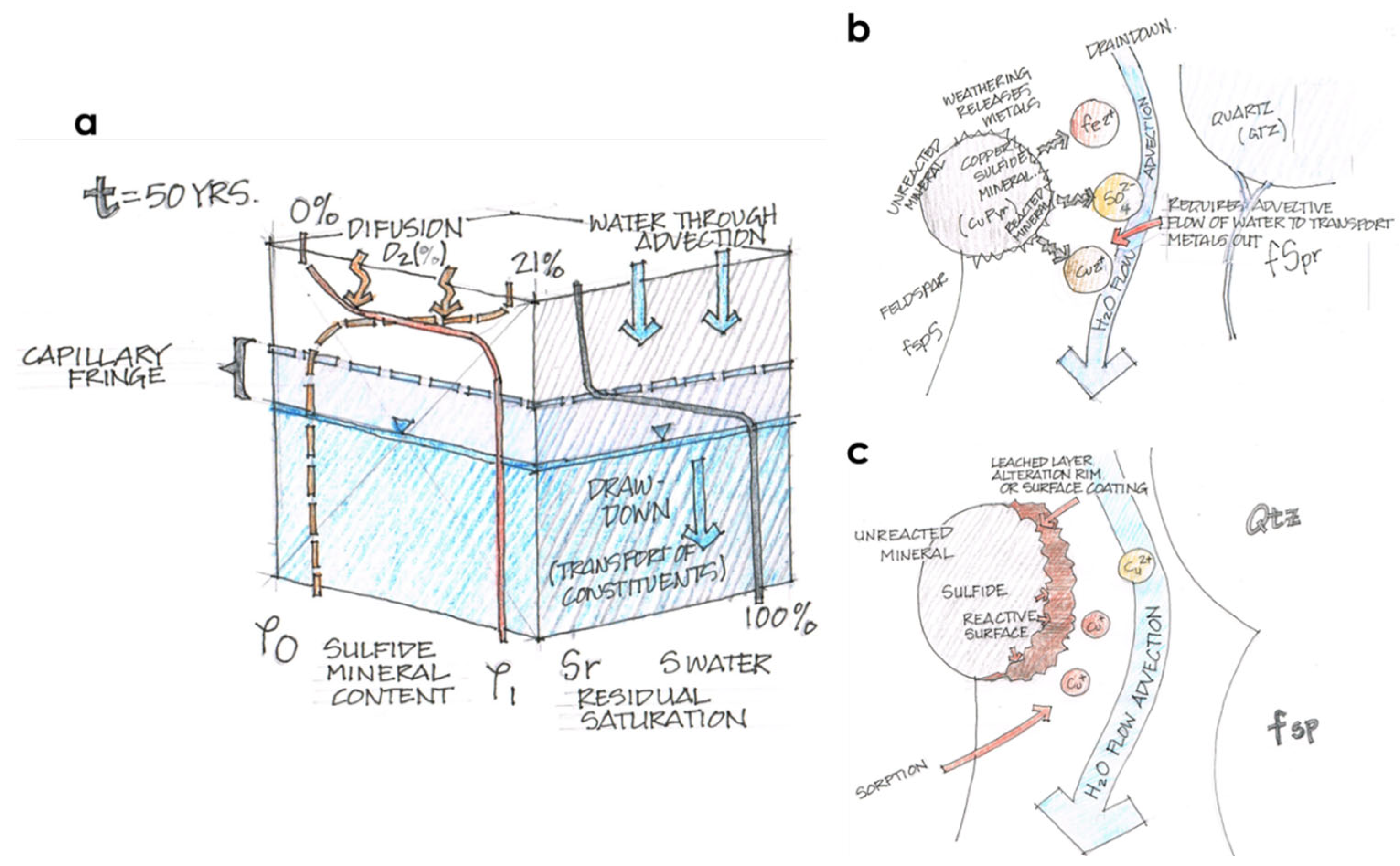

2.1. Temporal Scale

2.2. Binning

- Very Low (VL)

- Low (L)

- Moderate (M)

- High (H)

- Very High (VH)

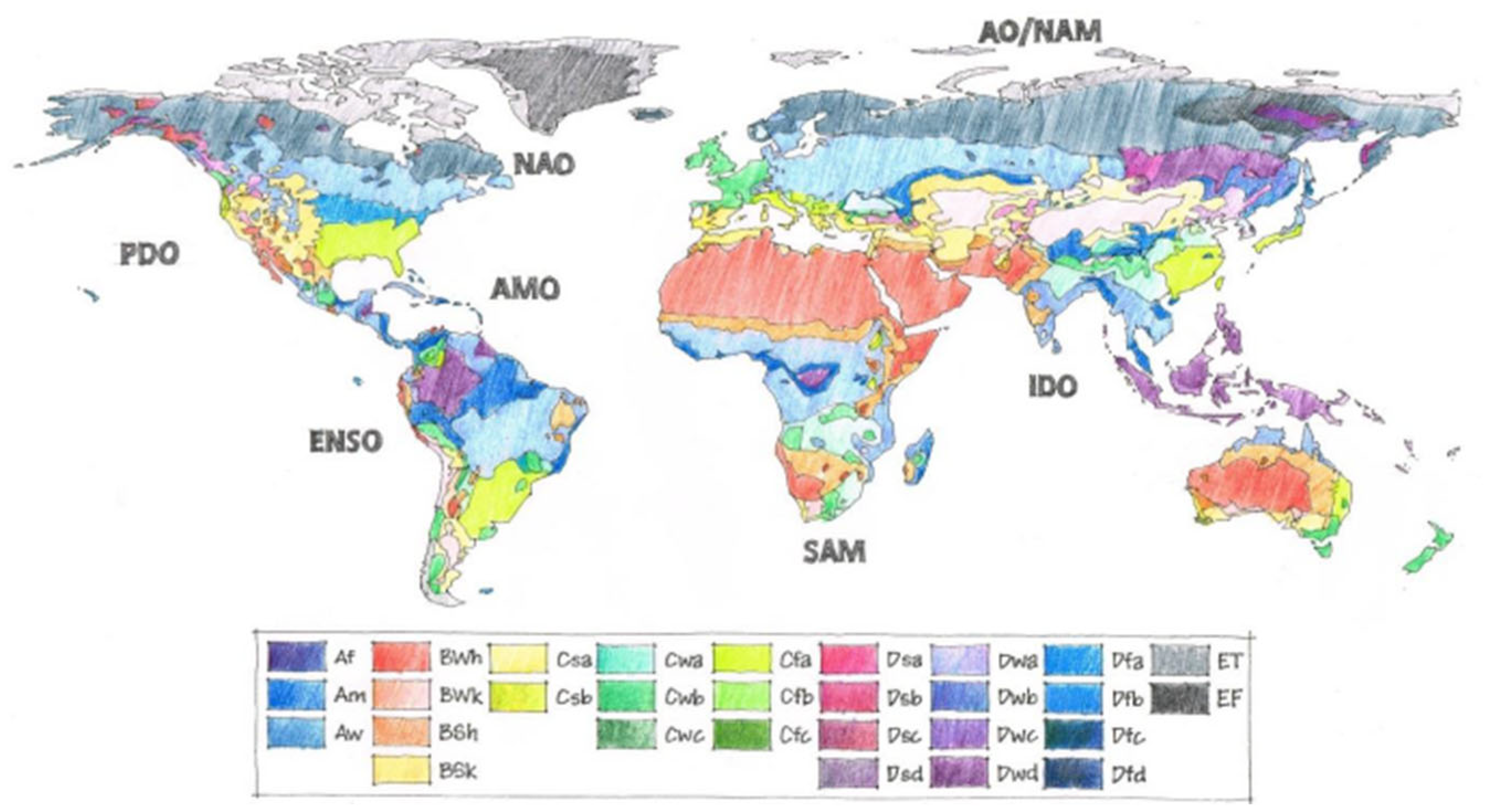

2.3. Regional Considerations

2.3.1. Climate

- Is there a distinct wet and dry season?

- Is cyclic wetting and drying likely, which could enhance near surface tailings oxidation in the dry season and ‘flushing’ due to surface runoff during the wet season or freeze–thaw cycles?

- Is the precipitation (PPT) and/or snow melt greater than potential evapotranspiration (PE) on an annual basis for seasonal periods, and/or for specific months of a year for the site?

- What is the anticipated drain down cycle (timeframe) and consolidation conditions of the TSF following cessation of tailings deposition?

- What is the likelihood and/or frequency of large precipitation events?

- Are drought conditions likely, which could enhance oxygen ingress?

- What are the seasonal patterns, and extent of the ambient temperature range during the year?

- Are there natural drainage (surface or seepage) paths that existed prior to construction that may be influenced by rain events or seasonal rainfall/snow melt? How are these pathways expected to have been impacted or modified through TSF construction and in the final TSF landform?

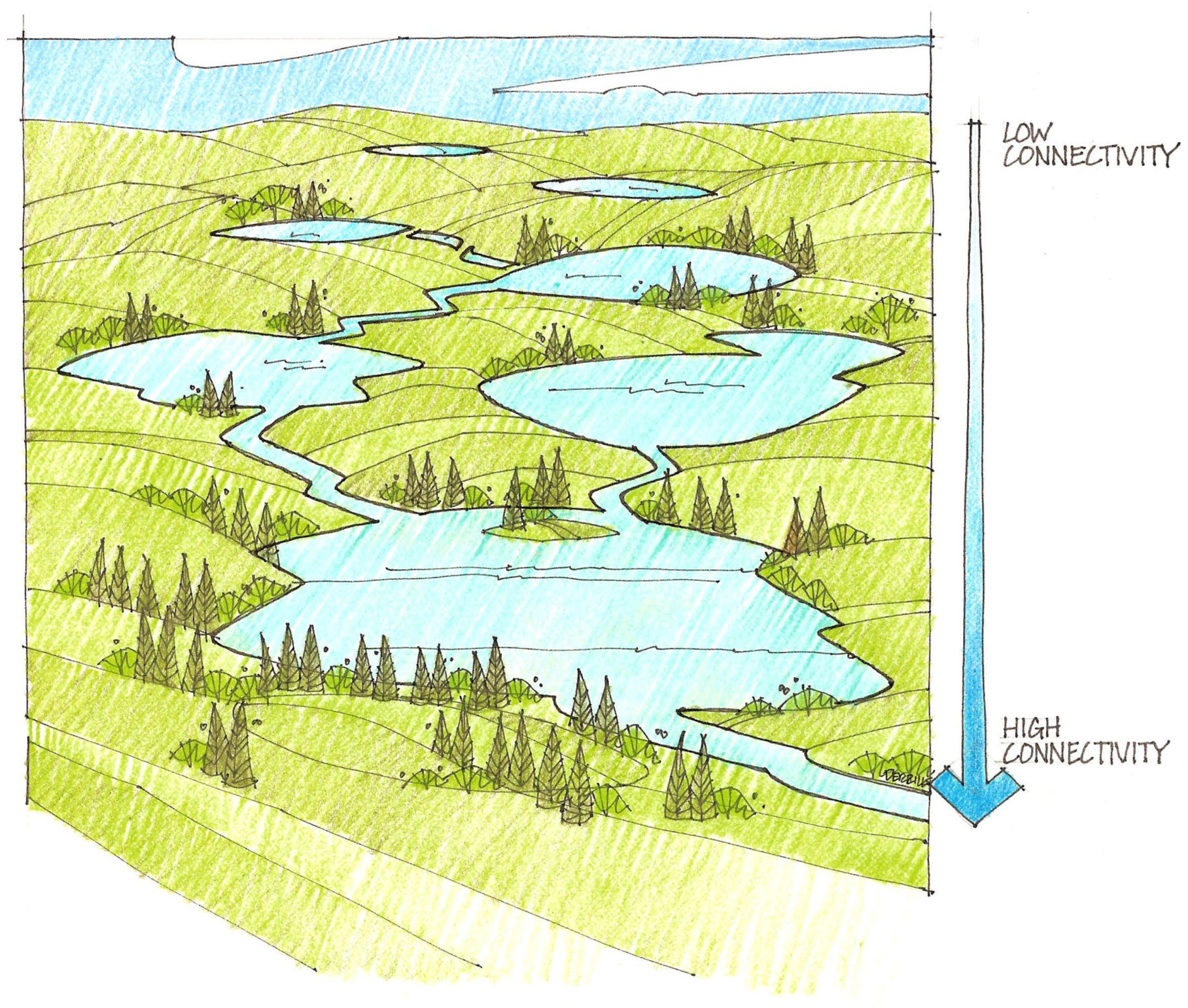

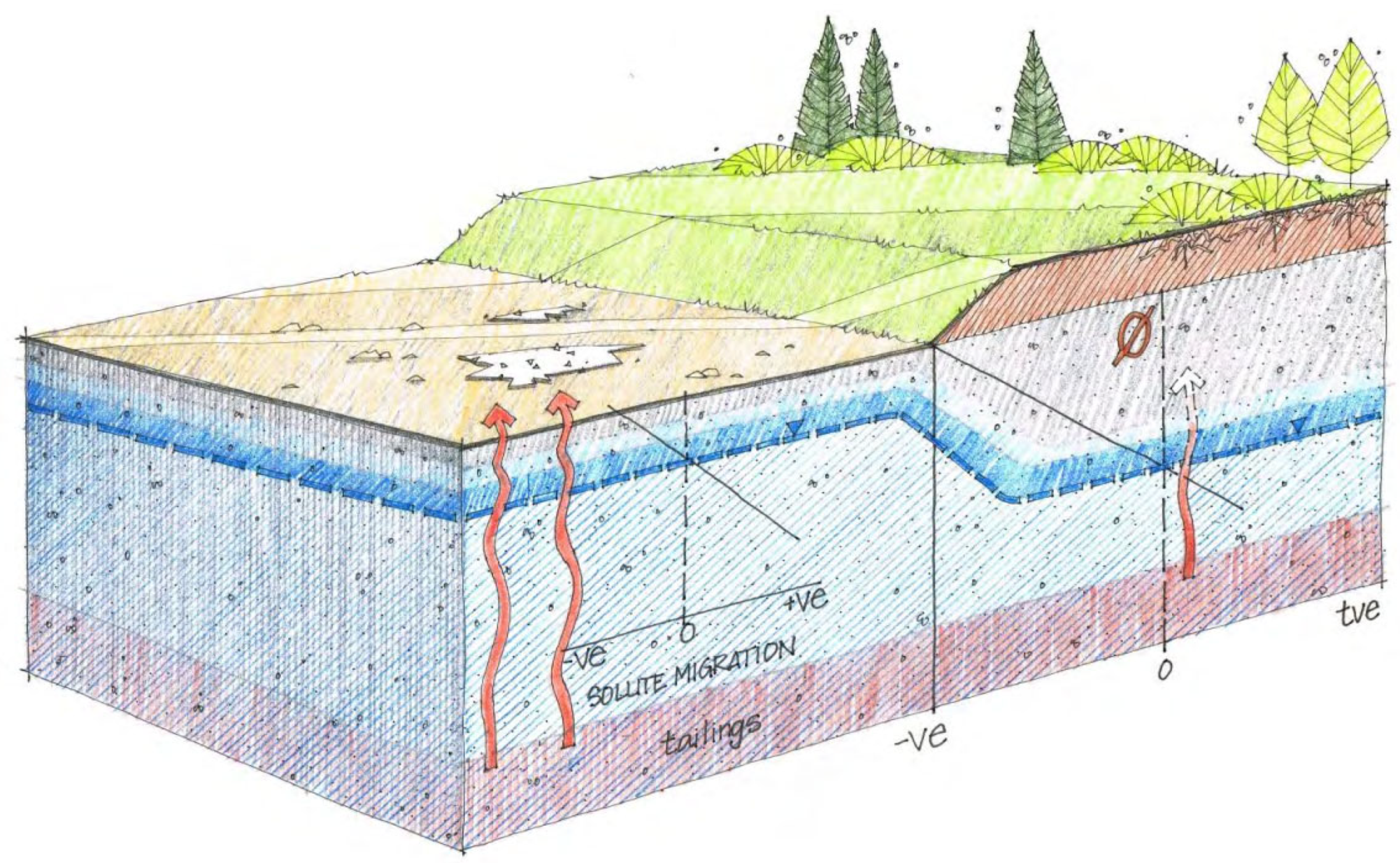

2.3.2. Hydrogeologic System

2.3.3. Geologic System

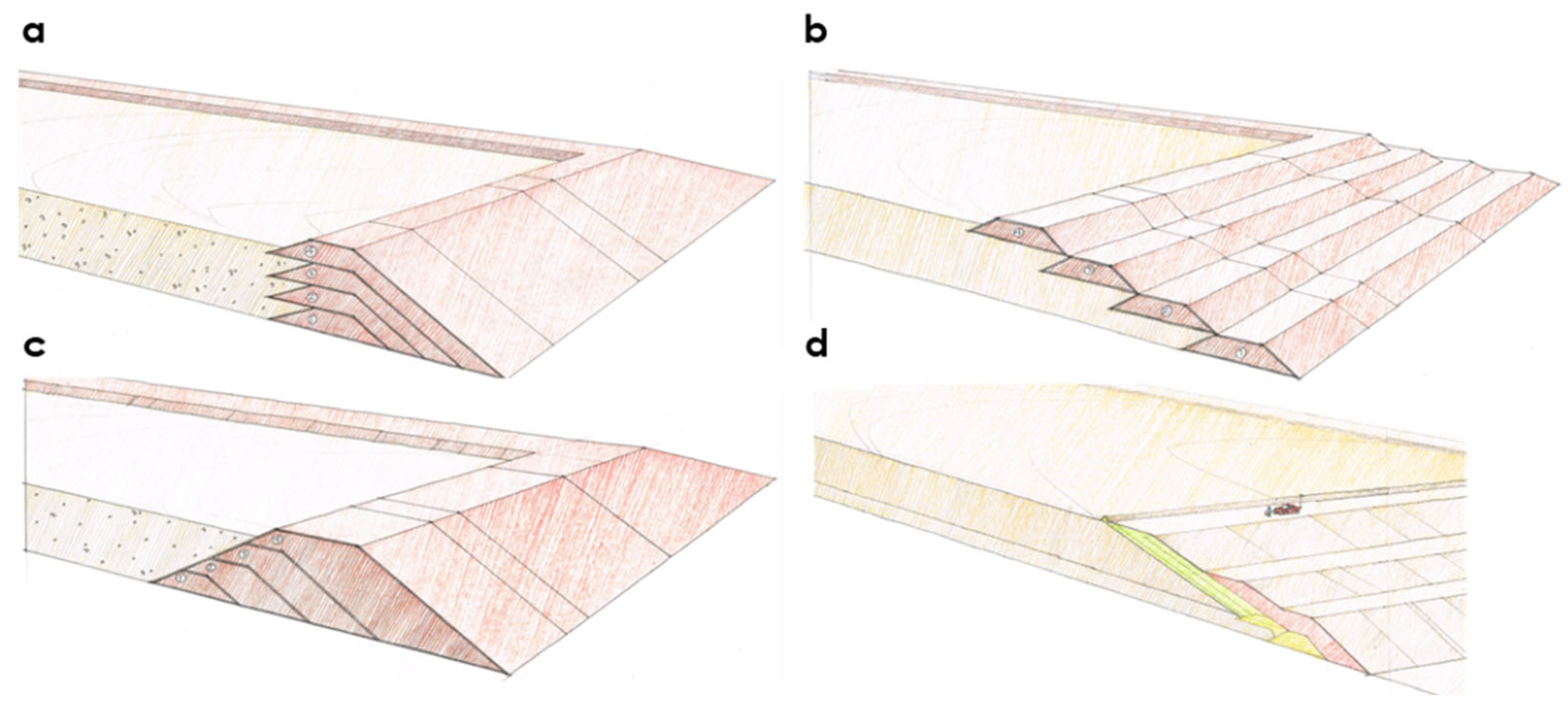

2.4. How Is It Built?

2.4.1. Tailings Deposition Method

2.4.2. Tailings Dam Construction Method

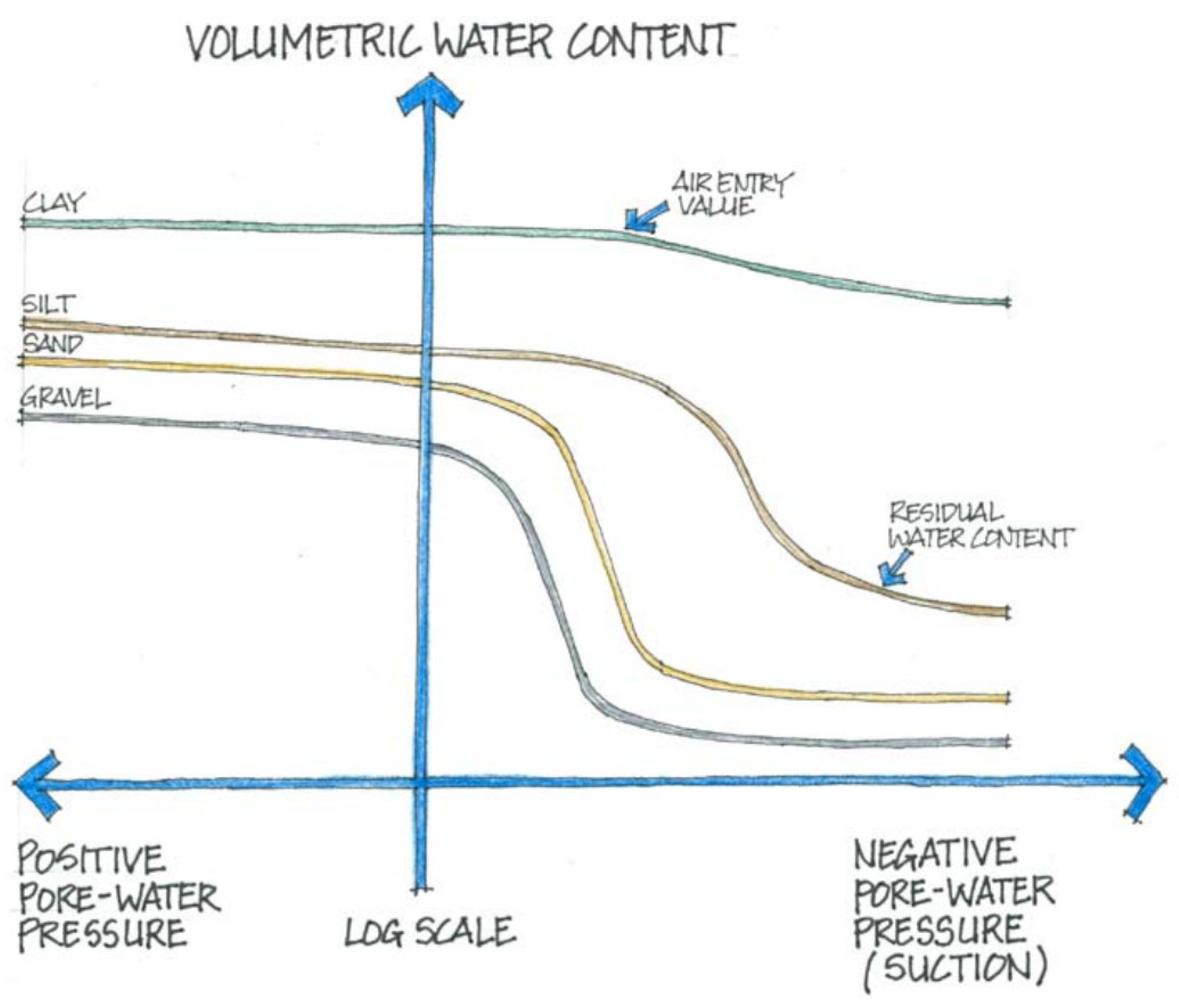

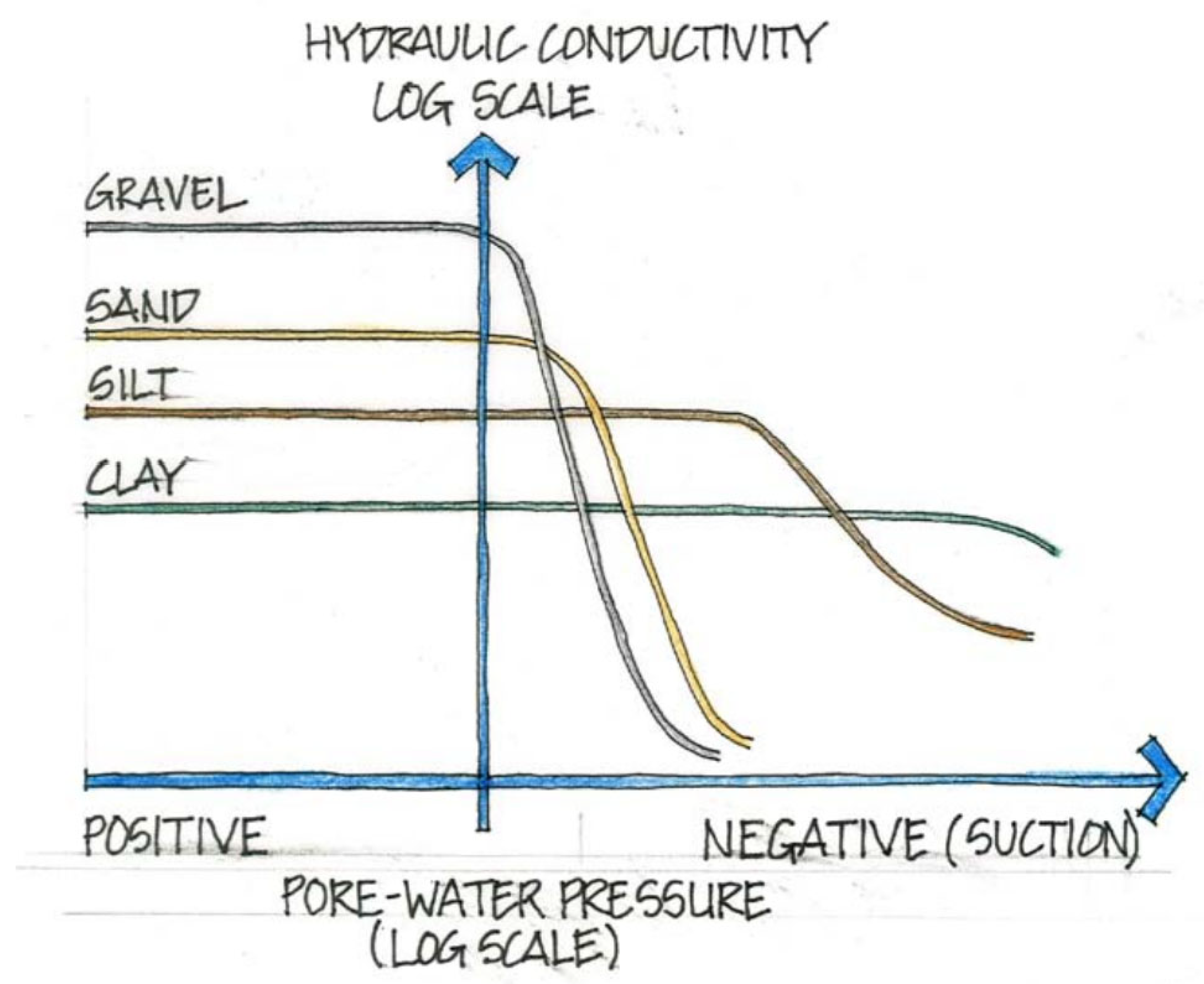

2.5. Water Balance

2.5.1. Coupled Surface-Atmosphere Water Balance(s)

2.5.2. Operational Versus Closure Water Balance(s)

2.5.3. Landform Based Water Balance(s)

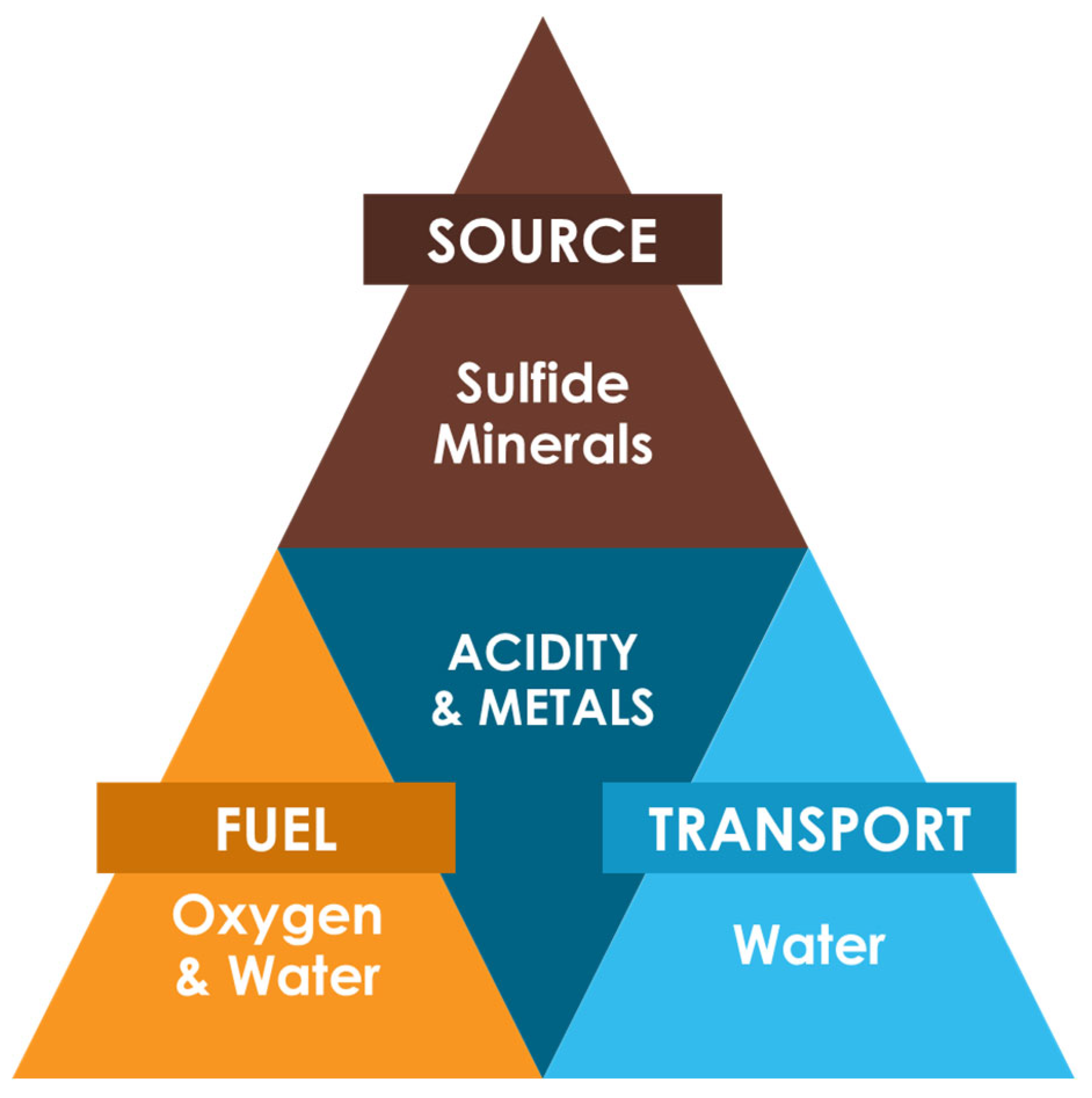

2.6. Geochemistry

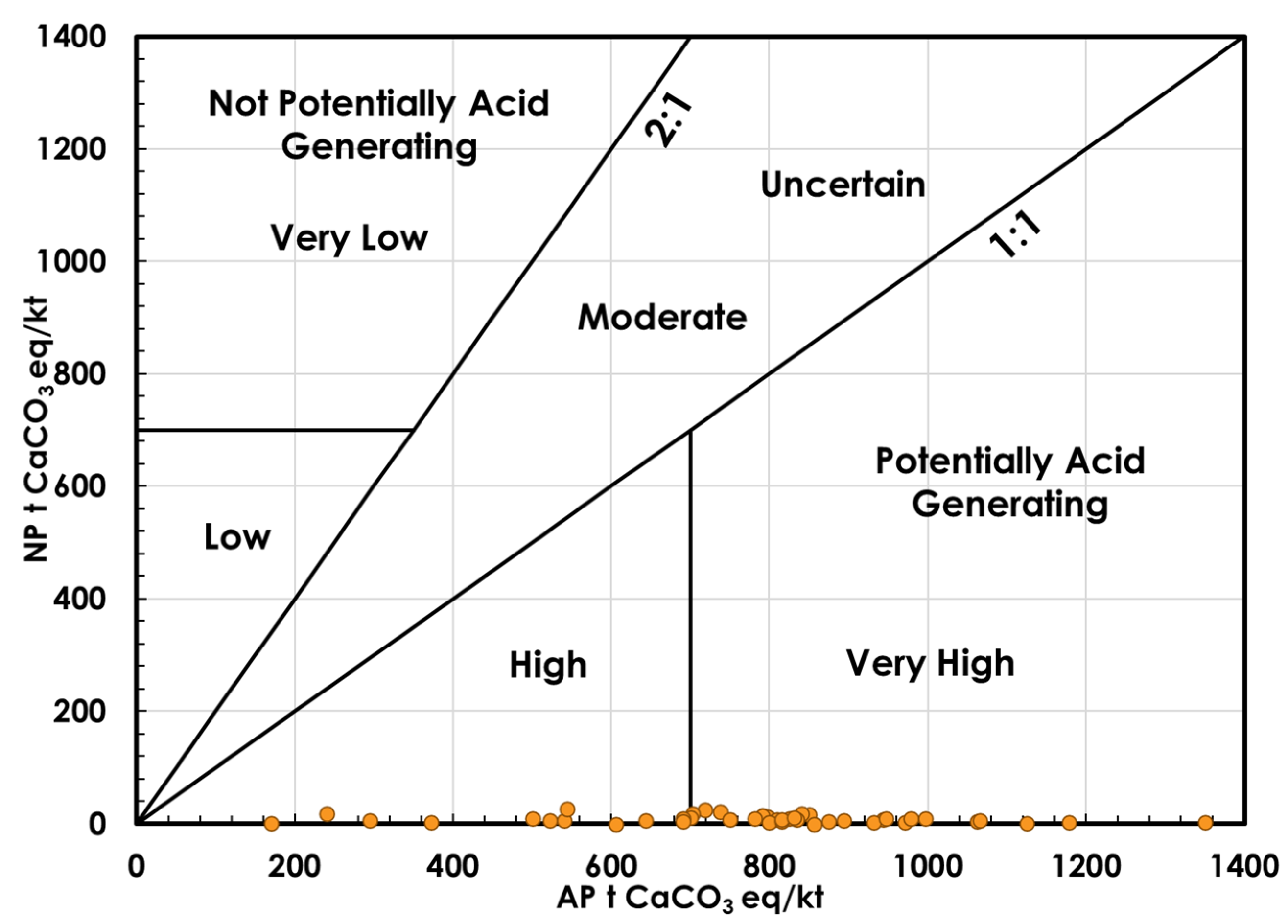

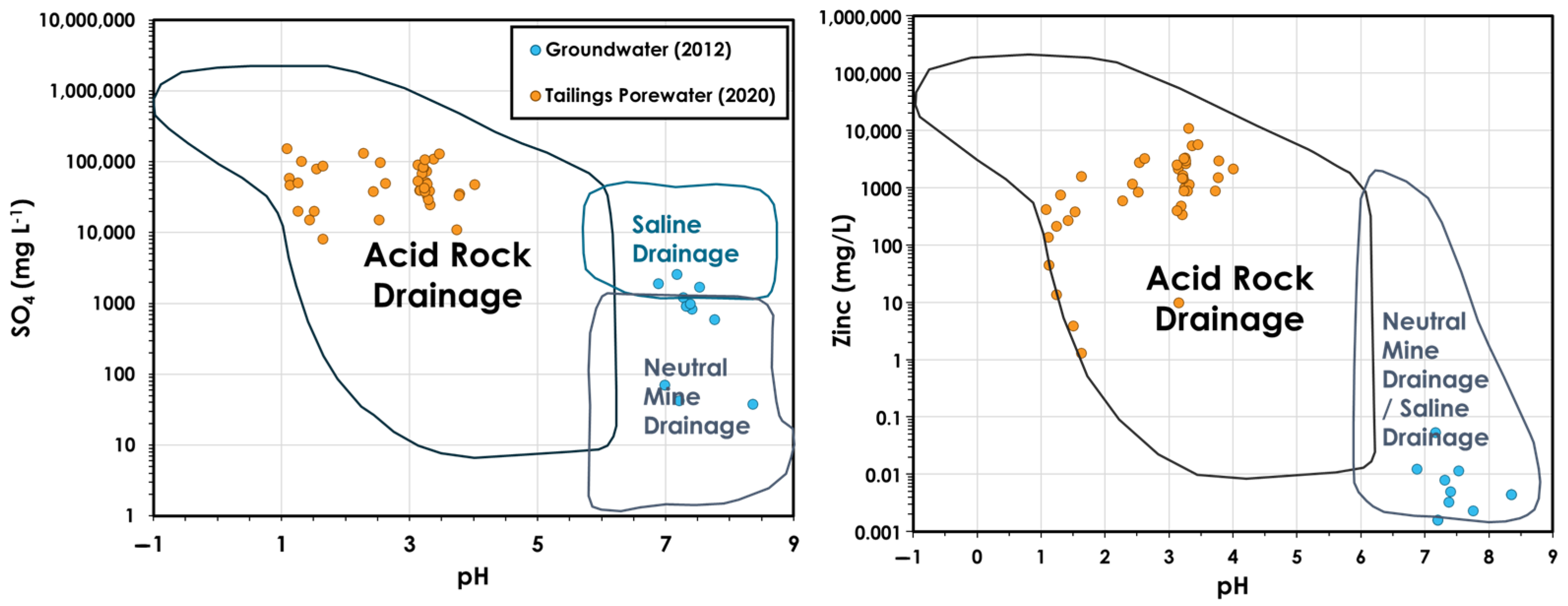

2.6.1. Oxidation Potential

2.6.2. Attenuation Along Flow Paths

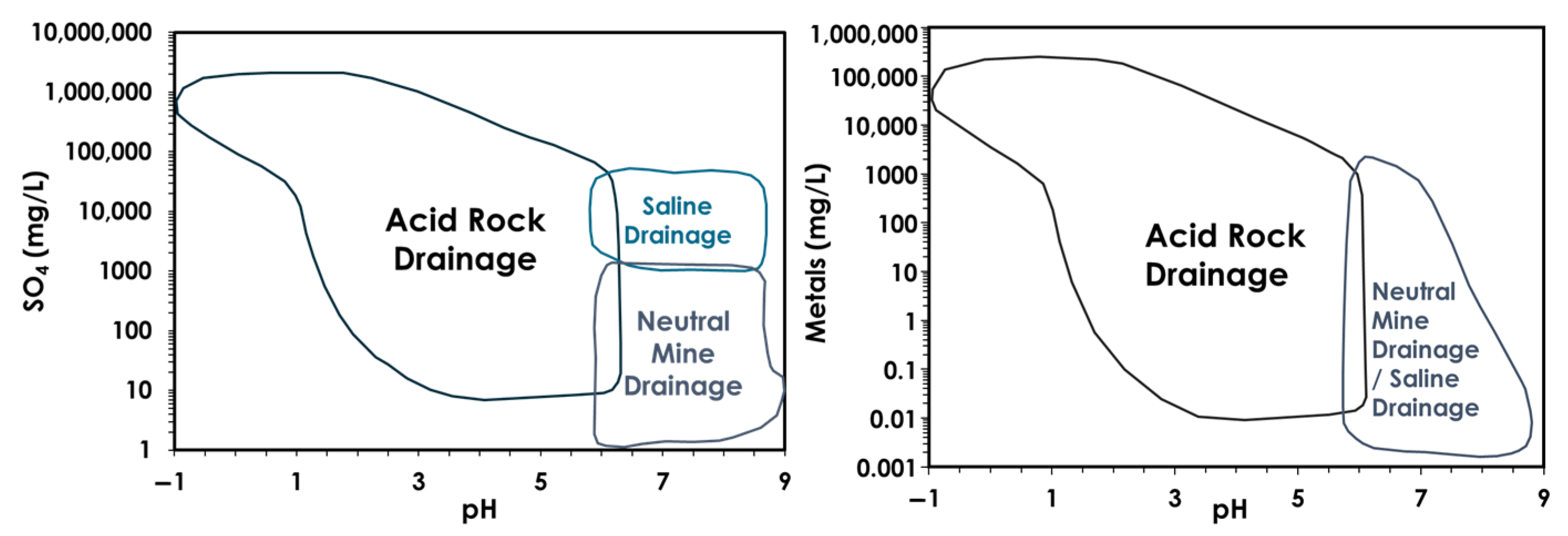

2.6.3. Net Acidity and Metal Release

3. Case Studies

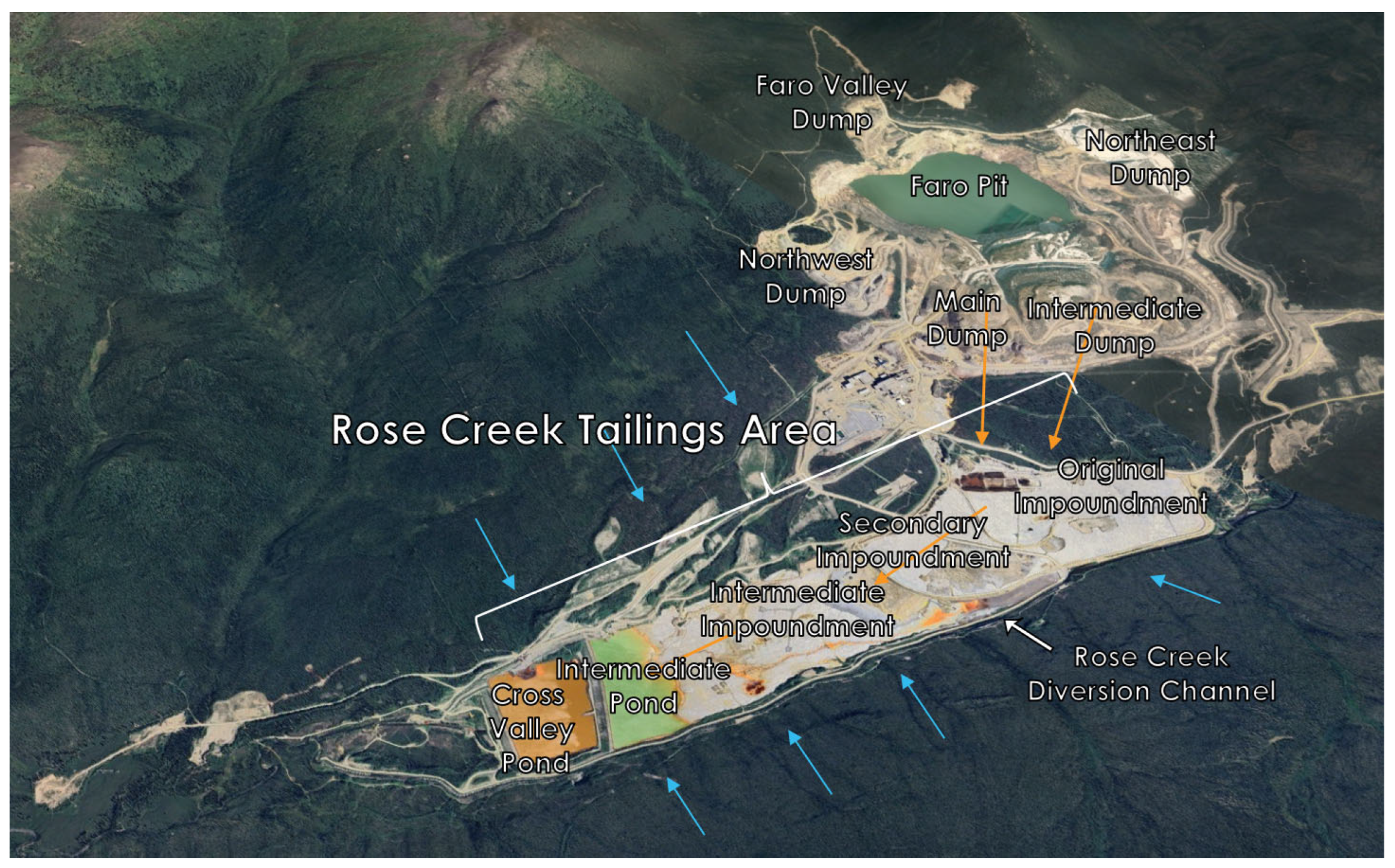

3.1. Faro Mine

3.1.1. Regional Considerations

3.1.2. How Is It Built?

3.1.3. Water Balance

3.1.4. Geochemistry

3.2. Additional Mine Site TSFs

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Network for Acid Prevention. Rock Placement Strategies to Enhance Operational and Closure Performance of Mine Rock Stockpiles. Phase 1 Work Program—Review, Assessment & Summary of Improved Construction Methods. 2020. Available online: https://www.inap.com.au/wp-content/uploads/2020-Jan-INAP-Improving-Stockpile-Construction-Phase-1-Final-Report.pdf (accessed on 13 December 2024).

- ISO 14044:2006+A2:2020; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2020.

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Moutik, B.; Summerscales, J.; Graham-Jones, J.; Pemberton, R. Life Cycle Assessment Research Trends and Implications: A Bibliometric Analysis. Sustainability 2023, 15, 13408. [Google Scholar] [CrossRef]

- Doka, G. A Model for Waste-Specific and Climate-Specific Life Cycle Inventories of Tailings Impoundments; Version 2; Doka Life Cycle Assessments: Zurich, Switzerland, 2018; Available online: https://www.doka.ch/04_TailingsDoka2018.pdf (accessed on 2 April 2024).

- Rader, K.; Dwyer, R.; Turner, D.; Drielsma, J.; Dumaresq, C.; Barabash, S.; Skruch, D.; Greig, A.L.; Assem, L.; Bayliss, C.; et al. Workshop on Improving Estimates of Releases from Mine Tailings in Life Cycle Assessment. Available online: https://bc-mlard.ca/files/presentations/2019-17-RADER-ETAL-improving-estimates-releases-mine-tailings.pdf (accessed on 14 July 2025).

- Turner, D.; Hischier, R.; Doka, G. Life Cycle Inventories of Sulfidic Tailings Disposal; Doka Life Cycle Assessments: Zurich, Switzerland, 2019; Available online: https://www.doka.ch/SulfidicTailingsLCITurner2019.pdf (accessed on 2 April 2024).

- Adrianto, L.R.; Pfister, S.; Hellweg, S. Regionalized Life Cycle Inventories of Global Sulfidic Copper Tailings. Environ. Sci. Technol. 2022, 56, 4553–4564. [Google Scholar] [CrossRef] [PubMed]

- Muller, S.; Lassin, A.; Lai, F.; Thiéry, D.; Guignot, S. Modelling releases from tailings in life cycle assessments of the mining sector: From generic models to reactive transport modelling. Miner. Eng. 2022, 180, 107481. [Google Scholar] [CrossRef]

- Moncur, M.C.; Ptacek, C.J.; Lindsay, M.B.J.; Blowes, D.W.; Jambor, J.L. Long-term mineralogical and geochemical evolution of sulfide mine tailings under a shallow water cover. Appl. Geochem. 2015, 57, 178–193. [Google Scholar] [CrossRef]

- Power, C. An Integrated Strategy to Treat and Control Acid Mine Drainage from Waste Rock and Underground Workings at the Former Franklin Mine in Nova Scotia, Canada: Field Performance Monitoring. Pollutants 2025, 5, 1. [Google Scholar] [CrossRef]

- Price, W.A.; Errington, J.C. Guidelines for Metal Leaching and Acid Rock Drainage at Minesites in British Columbia; British Columbia Ministry of Energy and Mines: Victoria, BC, Canada, 1998; 88p. [Google Scholar]

- Tremblay, G.A.; Hogan, C.M. Mine Environment Neutral Drainage (MEND) Manual 5.4.2d: Prevention and Control, Report 5.4.2. 2001. 352p. Available online: https://mend-nedem.org/wp-content/uploads/5-4-2dVolume4_PreventionControlL.pdf (accessed on 13 December 2024).

- Haug, M.D. A Review of a Non-Traditional Dry Cover. MEND Report 2.21.3b. 2002. 142p. Available online: https://mend-nedem.org/wp-content/uploads/2013/01/2.21.3b.pdf (accessed on 13 December 2024).

- Johnson, D.B.; Hallberg, K.B. Acid mine drainage remediation options: A review. Sci. Total Environ. 2005, 338, 3–14. [Google Scholar] [CrossRef] [PubMed]

- Bussière, B.; Guittonny, M. Hard Rock Mine Reclamation: From Prediction to Management of Acid Mine Drainage; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Bussière, B.; Plante, B.; Broda, S.; Aubertin, M.; Chen, D.; Medina, F. Water infiltration control in waste rock piles with capillary barrier effects: Design, construction and instrumentation of the experimental waste rock pile in the Lac Tio mine (in French). In Proceedings of the Symposium on Environment and Mines, Rouyn-Noranda, QC, Canada, 14–17 June 2015. [Google Scholar]

- Zhang, A.; Bain, J.G.; Schmall, A.; Ptacek, C.J.; Blowes David, W. Geochemistry and mineralogy of legacy tailings under a composite cover. Appl. Geochem. 2023, 159, 105819. [Google Scholar] [CrossRef]

- International Network for Acid Prevention. Global Cover System Design Technical Guidance Document. 2017. Available online: https://www.inap.com.au/wp-content/uploads/global-cover-system-design.pdf (accessed on 7 February 2025).

- Rahimdel, M.J.; Ghodrati, B. Risk Prioritization for Failure Modes in Mining Railcars. Sustainability 2021, 13, 6195. [Google Scholar] [CrossRef]

- Robertson, A.; Shaw, S. Failure Modes & Effects Analysis (FMEA); Infomine: Vancouver, BC, Canada, 2003. [Google Scholar]

- Barbour, L.S.; Krahn, J. Numerical Modelling—Prediction or Process? Geotech. News 2004, 22, 44–52. [Google Scholar]

- Maher, K.; Mayer, K.U. The Art of Reactive Transport Model Building. Elements 2019, 15, 117–118. [Google Scholar] [CrossRef]

- Blowes, D.W.; Ptacek, C.J.; Jambor, J.L.; Weisener, C.G. The Geochemistry of Acid Mine Drainage. In Environmental Geochemistry, Treatise on Geochemistry, Vol.9 ed B.; Elsevier Inc.: Toronto, ON, Canada, 2003; pp. 149–204. [Google Scholar]

- Dockrey, J.W.; Lindsay, M.B.J.; Mayer, K.U.; Beckie, R.D.; Norlund, K.L.I.; Warren, L.A.; Southam, G. Acidic microenvironments in waste rock characterized by neutral drainage: Bacteria–mineral interactions at sulfide surfaces. Minerals 2014, 4, 170–190. [Google Scholar] [CrossRef]

- Plante, B.; Bussière, B.; Benzaazoua, M. Lab to field scale effects on contaminated neutral drainage prediction from the Tio mine waste rocks. J. Geochem. Explor. 2014, 137, 37–47. [Google Scholar] [CrossRef]

- Hendry, J.M.; Biswas, A.; Essilfie-Dughan, J.; Day, S.J.; Barbour, L.S. Reservoirs of Selenium in Coal Waste Rock: Elk Valley, British Columbia, Canada. Environ. Sci. Technol. 2015, 49, 8228–8236. [Google Scholar] [CrossRef] [PubMed]

- Vriens, B.; Peterson, H.; Laurenzi, L.; Smith, L.; Aranda, C.; Mayer, K.U.; Beckie, R.D. Long-term monitoring of waste-rock weathering at the Antamina mine, Peru. Chemosphere 2019, 215, 858–869. [Google Scholar] [CrossRef] [PubMed]

- Mayer, K.; Amos, R.; Molins, S.; Gérard, F. Reactive transport modeling in variably saturated media with MIN3P: Basic model formulation and model enhancements. In Groundwater Reactive Transport Models; Bentham Science Publishers Ltd.: Sharjah, United Arab Emirates, 2012; pp. 187–212. [Google Scholar]

- Smith, L.J.; Lopez, D.L.; Beckie, R.D.; Morin, K.A.; Dawson, R.F.; Price, W.A. Hydrogeology of Waste Rock Dumps. MEND Associate Project PA-1. 1995. Available online: http://mend-nedem.org/wp-content/uploads/2013/01/1.Associate-Project-PA-1.pdf (accessed on 13 December 2024).

- Mayer, K.U.; Alt-Epping, P.; Jacques, D.; Arora, B.; Steefel, C.I. Benchmark problems for reactive transport modeling of the generation and attenuation of acid rock drainage. Comput. Geosci. 2015, 19, 599–611. [Google Scholar] [CrossRef]

- Okane Consultants. Conceptual Model Framework Development for Tailings; Prepared for International Copper Association and ICMM. In Proceedings of the Society of Environmental Toxicology and Chemistry (SETAC) Europe 34 Annual Meeting, Seville, Spain, 7 May 2024; 7 May 2024. [Google Scholar]

- Peel, M.C.; Finlayson, B.L.; McMahon, T.A. Updated world map of the Köppen Geiger climate classification. Hydrol. Earth Syst. Sci. Discuss. 2007, 11, 1633–1644. [Google Scholar] [CrossRef]

- Freeze, A.; Cherry, J. Groundwater; Prentice-Hall: Hoboken, NJ, USA, 1979. [Google Scholar]

- Villeneuve, S.A.; Barbour, L.S.; Hendry MJim Carey, S.K. Estimates of water and solute release from a coal waste rock dump in the Elk Valley, British Columbia, Canada. Sci. Total Environ. 2017, 601–602, 543–555. [Google Scholar] [CrossRef] [PubMed]

- McKeown, M.; Christensen, D.; Mueller, S.; O’Kane, M.; Weber, P. Forecasting long term water quality after closure: Boliden Aitik Cu mine. In Proceedings of the 13 International Mine Water Association Congress, Lappeenranta, Finland, 25–30 June 2017; Available online: https://www.imwa.info/docs/imwa_2017/IMWA2017_Christensen_761.pdf (accessed on 12 December 2024).

- Plumlee, G.S. The Environmental Geology of Mineral Deposits. In The Environmental Geochemistry of Mineral Deposits, Part A: Processes, Techniques, and Health Issues, Part B: Case Studies and Research Topics; Society of Economic Geologists: Littleton, CO, USA, 1997. [Google Scholar]

- Richards, D.C.; Borden, R.K.; Benneet, J.W.; Blowes, D.W.; Logsdon, M.J.; Miller, S.D.; Slater, S.; Smith, L.; Wilson, G.W. Design and Implementation of a Strategic Review of ARD Risk in Rio Tinto. In Proceedings of the 7 International Conference on Acid Rock Drainage (ICARD), St. Louis, MO, USA, 27–30 March 2006; pp. 1657–1672. [Google Scholar]

- Plumlee, G.S.; Smith, K.S.; Montour, M.R.; Ficklin, W.H.; Mosier, E.L. Geologic Controls on the Composition of Natural Waters and Mine Waters Draining Diverse Mineral-Deposit Types. In The Environmental Geochemistry of Mineral Deposits, Part A: Processes, Techniques, and Health Issues, Part B: Case Studies and Research Topics; Society of Economic Geologists: Littleton, CO, USA, 1999; Volume 6B, pp. 373–432. [Google Scholar]

- Williamson, M.A.; Rimstidt, J.D. The kinetics and electrochemical rate-determining step of aqueous pyrite oxidation. Geochim. Cosmochim. Acta 1994, 58, 5443–5454. [Google Scholar] [CrossRef]

- Singer, P.C.; Stumm, W. Acidic mine drainage: The rate-determining step. Science 1970, 167, 1121–1123. [Google Scholar] [CrossRef] [PubMed]

- Price, W.A. Prediction Manual for Drainage Chemistry from Sulphidic Geologic Materials. 2009, pp. 1–579. Available online: https://mend-nedem.org/wp-content/uploads/1.20.1_PredictionManual.pdf (accessed on 12 December 2024).

- International Network for Acid Prevention. Chapter 2: The Acid Rock Drainage Process (GARD Guide). 2012. Available online: http://www.gardguide.com/index.php/Chapter_2 (accessed on 13 December 2024).

- Napier-Munn, T.; Parbhakar, A.K.; Edraki, M.; Bradshaw, D. Managing ARD potential through mine planning and mineral processing practice. In Proceedings of the Sixth Australian Workshop on Acid and Metalliferous Drainage, Burnie, Australia, 15–18 April 2008; pp. 351–376. [Google Scholar]

- Klohn Crippen Berger. Study of Tailings Management Technologies. MEND Report 2.50.1. 2017. Available online: https://mend-nedem.org/wp-content/uploads/2.50.1Tailings_Management_TechnologiesL.pdf (accessed on 12 December 2024).

- Stantec Consulting Ltd. Review of Water Quality Issues in Neutral pH Drainage: Examples and Emerging Priorities for the Mining Industry in Canada; MEND Report 10.1; 2004; p. 58. Available online: https://mend-nedem.org/wp-content/uploads/2013/01/10.1.pdf (accessed on 12 December 2024).

- Okane Consultants. Cold Regions Cover System Design Technical Guidance Document. MEND Report 1.61.5c. 2012. Available online: https://mend-nedem.org/wp-content/uploads/2013/01/1.61.5c.pdf (accessed on 12 December 2024).

- Guymon, G.L. Unsaturated Zone Hydrology; Prentice-Hall, Inc.: Englewood Cliffs, NJ, USA, 1994. [Google Scholar]

- Devito, K.; Mendoza, C.; Clara, Q. Conceptualizing Water Movement in the Boreal Plains. Implications for Watershed Reconstruction; University of Alberta: Edmonton, AB, Canada, 2012; pp. 1–164. [Google Scholar]

- Baisley, A. Climate Change for Northern Latitudes. In Proceedings of the 2018 Northern Latitudes Mining Reclamation Workshop, Whitehorse and Carcross, Yukon, YT, Canada, 11–12 September 2018. [Google Scholar]

- Aubertin, M.; Aachib, M.; Authier, K. Evaluation of diffusive gas flux through covers with a GCL. Geotext. Geomembr. 2000, 18, 215–233. [Google Scholar] [CrossRef]

- Millington, R.J. Gas diffusion in porous media. Science 1959, 130, 100–102. [Google Scholar] [CrossRef] [PubMed]

- Wilson, W.G.; Miskolczi, J.; Dagenais, A.-M.; Levesque, I.; Smith, Q.; Lanteigne, L.; Hulett, L.; Landriault, D. The Application of Blended Waste Rock and Tailings for Cover Systems in Minewaste Management. J. Am. Soc. Min. Reclam. 2006, 2006, 2424–2438. [Google Scholar] [CrossRef]

- Wunderly, M.D.; Blowes, D.W.; Frind, E.O.; Ptacek, C.J. Sulfide Mineral Oxidation and Subsequent Reactive Transport of Oxidation Products in Mine Tailings Impoundments: A Numerical Model. Water Resour. Res. 1996, 32, 3173–3187. [Google Scholar] [CrossRef]

- Raymond, K.E.; Robertson, J.; Zettl, J.; O’Kane, M. Enhanced Conceptualization of Reactive Filtered Tailings Oxidation using a Reactive Transport Model. In Proceedings of the Tailings and Mine Waste 2024, Westminster, CO, USA, 10–13 November 2024; pp. 1391–1406. [Google Scholar]

- Hendry, M.J.; Johnson, T.M.; Schmeling, E.; Shaw, S.; Kirk, L. Application of selenium isotopes to define selenium bioreduction in coal waste rock: Elk Valley, British Columbia. Sci. Total Environ. 2024, 957, 177838. [Google Scholar] [CrossRef] [PubMed]

- Government of Canada; Crown-Indigenous Relations and Northern Affairs. Faro Mine Remediation Project: Yukon. In Faro Mine Remediation Project Yukon. 2016. Available online: https://www.rcaanc-cirnac.gc.ca/eng/1480019546952/1537554989037 (accessed on 12 December 2024).

- SRK Consulting Inc. 2020 Tailings Porewater Characterization Report; Faro Mine Remediation Project; SRK Consulting Inc.: Vancouver, BC, Canada, 2021. Available online: https://emrlibrary.gov.yk.ca/aam/2020-tailings-porewater-characterization-report-faro-mine.pdf (accessed on 12 December 2024).

- Sexsmith, K.; Doherty, J. Characterization of Porewater Chemistry within Weathered Sulfide Mine Tailings at the Faro Mine Site. In Proceedings of the from the 13 International Conference on Acid Rock Drainage (ICARD), Halifax, NS, Canada, 16–20 September 2024. [Google Scholar]

- Faro Mine Remediation Project. 2019 Project Proposal Submission: Appendix 7C Groundwater; Government of Canada: Faro, YT, Canada, 2019. [Google Scholar]

- Mead, S.P.; Fourie, A.B.; Tibbett, M.; Beersing, A. Faro Mine remediation project—An overview. In Proceedings of the Sixth International Conference on Mine Closure, Mine Closure 2011, Lake Louise, AB, Canada, 18–21 September 2011; pp. 433–440. [Google Scholar]

- Mackie, D.; Kuranov, P. Lessons Learned from Operation of Groundwater Collection Systems at the Faro Mine, Yukon. In Proceedings of the 30th Annual BC MEND Metal Leaching/Acid Rock Drainage Workshop, Vancouver, BC, Canada, 6–7 December 2023. [Google Scholar]

- Nahir, M. Faro Mine Rehabilitation Project. In Proceedings of the MEND Manitoba Workshop, Winnipeg, MB, Canada, 4–5 June 2008. [Google Scholar]

- Laberge Environmental Services. Summary Report: Groundwater Water Quality Monitoring Faro Mine Complex (Fmc) September 2012; Yukon Energy Mines and Resources: Whitehorse, YT, Canada, 2013. [Google Scholar]

- Robertson GeoConsultants Inc. Update to the Water & Load Balance Study for Rose Creek Tailings Storage Facility, Faro Mine, Yukon Territory; Government of Yukon: Whitehorse, YT, Canada, 2017. [Google Scholar]

- Bao, Z.; Bain, J.; Holland, S.P.; Wilson, D.; MacKenzie, P.; Ptacek, C.J.; Blowes, D.W. Faro Waste Rock Project: Characterizing geochemical heterogeneity in sulfide- and carbonate-rich waste rock. Appl. Geochem. 2020, 121, 104691. [Google Scholar] [CrossRef]

- Beylot, A.; Bodénan, F.; Guezennec, A.G.; Muller, S. LCA as a support to more sustainable tailings management: Critical review, lessons learnt and potential way forward. Resour. Conserv. Recycl. 2022, 183, 106347. [Google Scholar] [CrossRef]

| Major Climate | PPT | Temp | Sub Region Description | Threshold * |

|---|---|---|---|---|

| A | Tropical | Tcold ≥ 18 | ||

| f | Rainforest | Pdry ≥ 60 | ||

| m | Monsoon | Not (Af) and Pdry ≥ 100—MAP/25 | ||

| w | Savannah | Not (Af) and Pdry < 100—MAP/25 | ||

| B | Arid | MAP < 10 × Pthreshold | ||

| w | Desert | MAP < 5 × Pthreshold | ||

| s | Steppe | MAP ≥ 5 × Pthreshold | ||

| h | Hot | MAT ≥ 18 | ||

| k | Cold | MAT < 18 | ||

| C | Temperate | Thot > 10 and 10 < Tcold < 18 | ||

| s | Dry Summer | Psdry < 40 and Psdry < Pwwet/3 | ||

| w | Dry Winter | Pwdry < Pswet/10 | ||

| f | Without dry season | Not (Cs) or (Cw) | ||

| a | Hot Summer | Thot ≥ 22 | ||

| b | Warm Summer | Not (a) and Tmon10 ≥ 4 | ||

| c | Cold Summer | Not (a or b) and 1 ≤ Tmon10 < 4 | ||

| D | Cold | Thot > 10 and Tcold ≤ 0 | ||

| s | Dry Summer | Psdry < 40 and Psdry < Pswet/3 | ||

| w | Winter | Pwdry < Pswet/10 | ||

| f | Without dry season | Not (Ds) or (Dw) | ||

| a | Hot Summer | Thot ≥ 22 | ||

| b | Warm Summer | Not (a) and Tmon10 ≥ 4 | ||

| c | Cold Summer | Not (a, b, or d) | ||

| d | Very Cold Winter | (a or b) and Tcold < −38 | ||

| E | Polar | Thot < 10 | ||

| T | Tundra | Thot > 0 | ||

| F | Frost | Thot ≤ 0 |

| Parameter | Units | Whole Tails | Rougher Tails | 1st Cleaners Scavenger Tails | Cyclone Underflow (Untreated) | Cyclone Underflow (Desulfurized) |

|---|---|---|---|---|---|---|

| Paste pH | pH units | 7.48 | 8.51 | 6.96 | 8.15 | 8.39 |

| NP | t CaCO3 kt−1 | 4.8 | 5.0 | 7.2 | 4.0 | 3.8 |

| AP | t CaCO3 kt−1 | 125 | 1.73 | 518 | 6.55 | 1.43 |

| Net AP | t CaCO3 kt−1 | −120.69 | 3.27 | −511.04 | −2.55 | 2.37 |

| NP/AP | t CaCO3 kt−1 | 0.04 | 2.89 | 0.01 | 0.61 | 2.66 |

| S | % | 4.25 | 0.091 | 19.4 | 0.220 | 0.046 |

| SO4 | % | 0.24 | 0.04 | 2.80 | 0.01 | <0.01 |

| Bin | Sub-Bin | Faro TSF | Site A | Site B |

|---|---|---|---|---|

| Regional Considerations | Climate |

|

|

|

| Hydrogeologic Setting |

|

|

| |

| Geologic System (ore deposit) |

|

|

| |

| How is it Built | Tailings Deposition Method |

|

|

|

| Tailings Storage Facility |

|

|

| |

| Water Balance | Coupled Surface-Atmosphere Balance |

|

|

|

| Landform Based Water Balanceincluding GW-SW Interaction |

|

|

| |

| Geochemistry | ARD Potential |

|

|

|

| Attenuation Along Flow Paths |

|

|

| |

| Net Acidity and Metals Release |

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raymond, K.E.; O’Kane, M.; Logsdon, M.; Gopalapillai, Y.; Hewitt, K.; Drielsma, J.; Meili, D. Basis for a New Life Cycle Inventory for Metals from Mine Tailings Using a Conceptual Model Tool. Minerals 2025, 15, 752. https://doi.org/10.3390/min15070752

Raymond KE, O’Kane M, Logsdon M, Gopalapillai Y, Hewitt K, Drielsma J, Meili D. Basis for a New Life Cycle Inventory for Metals from Mine Tailings Using a Conceptual Model Tool. Minerals. 2025; 15(7):752. https://doi.org/10.3390/min15070752

Chicago/Turabian StyleRaymond, Katherine E., Mike O’Kane, Mark Logsdon, Yamini Gopalapillai, Kelsey Hewitt, Johannes Drielsma, and Drake Meili. 2025. "Basis for a New Life Cycle Inventory for Metals from Mine Tailings Using a Conceptual Model Tool" Minerals 15, no. 7: 752. https://doi.org/10.3390/min15070752

APA StyleRaymond, K. E., O’Kane, M., Logsdon, M., Gopalapillai, Y., Hewitt, K., Drielsma, J., & Meili, D. (2025). Basis for a New Life Cycle Inventory for Metals from Mine Tailings Using a Conceptual Model Tool. Minerals, 15(7), 752. https://doi.org/10.3390/min15070752