Abstract

Tailings from the Osor fluorite mines release large amounts of potentially toxic elements into the environment. This work is a proposal to remove these waste materials and use them as a raw material in the manufacture of glass. The chemical composition of the tailings was determined by X-ray fluorescence and the mineralogy by X-ray diffraction. Waste materials have SiO2, Al2O3 and CaO contents suitable for a glass production, but Na as NaCO3 has to be added. Two glass formulations, with 80–90% of the residue and 10–20% Na2CO3, have been produced. The crystallization temperatures, obtained by differential thermal analysis, were 875 and 901 °C, and the melting temperatures were 1220 and 1215 °C for the G80-20 and G90-10 glasses, respectively. The transition temperatures of glass were 637 and 628 °C. The crystalline phases formed in the thermal treatment to produce devitrification were nepheline, plagioclase and diopside in the G80-20 glass, and plagioclase and akermanite-gehlenite in the G90-10 glass. The temperatures for the fixed viscosity points, the working temperatures and the coefficient of expansion were obtained. The chemical stability of the glass was tested and results indicate that the potentially toxic elements of the tailings were incorporated into the glass structure.

1. Introduction

Tailings produce a large number of environmental impacts [1]. Especially dangerous are the problems that occur when the tailings result from the processing of sulphide ores. In these cases the interaction of meteoric water with the sulphides remaining in the tailings drives the generation of acid drainage, which can carry large amounts of potentially toxic elements [2,3,4]. These elements are liberated into the environment and produce pollution in water, which cannot be used for other applications. Special care must be taken in those tailings with small particles, since this enlarges the reactive surface, thus promoting the development of acid-generation reactions [5].

The world consumption of mineral resources is very large and produces a large amount of waste, which has been reported as at least 5 to 7 billion tons of mine tailings per year [6], and up to 14 billion tons per year [7]. It is expected this will increase throughout the 21st century due to the need to exploit ores with lower grade [8]. Thus, management strategies that contribute new solutions for sustainable development need to be adopted. The recycling of these tailings is an attractive proposal for tailings management. This has a double benefit since the volume of new exploitations can be reduced, which is one of the principles of the circular economy [9]. On the other hand, materials from tailings frequently have high homogeneity and a fine particle size, which is useful for many applications and important energy savings can be obtained.

Moreover, the recycling of tailings for use as raw materials for the manufacture of glass and glass-ceramics removes the hazardous elements from the environment. Vitrification is a stabilization technology for hazardous wastes since it converts them into a stable glass or glass-ceramic that is suitable for manufacturing products for commercial purposes [10,11]. The mine wastes used in glass manufacturing have been extensively studied to produce glass [12,13,14], glass fibres [15] and glass-ceramics [16,17,18,19].

In this work, the tailings from the Osor mines (Girona, Catalonia, Spain), are characterized and their viability to be used as raw material for the production of commercial glass is evaluated. This is a proposal for using these raw materials in the manufacture of glass, thus contributing to the remediation of the old mining area. The Osor tailings are of special interest for making glass. They show two favourable characteristics in their chemical composition because they are waste materials of an old mine in which one of the ores was fluorite; thus, these residues are rich in fluorine and calcium. These elements favour the manufacture of glass, so the addition of CaF2 decreases melting and sintering temperatures [20]. CaF2 can play an important role in the properties of glass and glass-ceramics [21,22]. Fluorine replaces bridging oxygens in the glass network by nonbridging fluorine, which disrupts and weakens the glass network [21]. Calcium can act as a network modifier and as charge compensator for the deficiency in positive charges produced by the Al-Si substitution in the tetrahedral sites [23,24] in silicate glasses, which depolymerizes the glass network following the formation of nonbridging oxygen.

The Osor mines became one of the most important mines in Catalonia, and were exploited from Roman times until the 1980s. The volume of production was especially high between 1942 and 1980, with a daily production during the last period of activity of 80 to 90 tons of fluorite, 10 to 12 tons of zinc, and 6 to 7 tons of lead [25]. Although the mine water has a neutral pH due to the high content of neutralising minerals, it is rich in metals, especially Cd, Co, Pb, Zn, As, Ba and Sb [26], leached from the breakage of the sulphide minerals. Part of these pollutants come directly from the mine adits but also from the tailings. The small particle size of the tailings, less than 200 µm, contributes to the high pollution in soils, sediments and surface waters of the area. The tailings containing potentially toxic elements are leached and end up in the river that is a few meters from the dump [27,28].

2. Materials and Methods

2.1. Materials

The Osor mines are located in the Montseny massif, Prelitoral Catalan coastal range, 30 km west of the city of Girona. The mine exploited Ba-F-Pb-Zn veins hosted in metapelitic rocks of Paleozoic age. Such veins are abundant in the Catalonian coastal ranges with other exploited deposits, such as the Berta mine [29]. The exploited minerals were mainly fluorite, galena and sphalerite, hosted in quartz, with a minor amount of calcite, barite and pyrite.

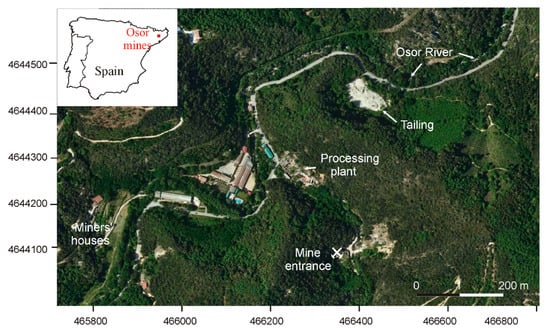

The tailings sample used in the present study came from the flotation process in the mineral processing plant of Osor, Girona, Spain (Figure 1). This is located close to the Osor River and a local road, 400 m east of the plant, occupying an area of approximately 3150 m2 and containing 60,000 m3 of homogeneous-looking material. The particle-size of the tailing material is less than 200 µm; 80% of this material is smaller than 70 µm.

Figure 1.

Satellite image showing UTM coordinates and the location of the Osor tailings.

Three composite samples of about 10 kg each were collected from profiles along different levels of height of the tailing. Samples OS-1 and OS-3 represent the lower and uppermost parts of the tailing and OS-2 was obtained at the intermediate height of the tailing. Samples were dried, sieved and quartered to determine their chemical and mineralogical compositions.

Sample OS-2 was selected for experiments because it represents most of the tailing material. This material was powdered and quartered to obtain homogeneous samples. According to the chemical composition of the raw tailing, two glasses were prepared, taking into account that the composition should be equilibrated with respect to the content of former, stabilizer, and refining oxides to produce a commercial quality glass [17]. To this end, the tailing sample was mixed with Na2CO3 (PANREAC, Barcelona, Spain cod.131648). Two glasses were obtained in order to establish their industrial behaviour by using 80 wt.% tailing and 20 wt.% Na2CO3 (sample G90-10), and 90 wt.% tailing and 10 wt.% Na2CO3 (sample G80-20). In order to obtain a homogeneous sample, each mixture was homogenized in a ball mill for 48 h.

2.2. Analytical Methods

The particle size distribution of the tailing samples was determined by means of an LS 13 320. Coulter particle size analyser (Beckman, Brea, CA, USA). The chemical composition of tailing samples was determined by X-ray fluorescence (XRF) using a Thermo Scientific ARL ADVANT’XP series instrument (ThermoFisher Scientific, Waltan, MA, USA). The mineralogical composition of the tailings and the phases formed during the thermal treatment of the glasses were determined by X-ray powder diffraction (XRD) using a Bragg-Brentano PANAnalyticalX’Pert Diffractometer. The system has graphite monochromator, an automatic gap, Cu Kα-radiation at λ = 1.54061 Å, powered at 45 kV-40 mA, a scanning range of 4–100° with a 0.017° 2θ step scan and a 50 s measuring time. Identification and semiquantitative evaluation of the phases was performed by using PANanalytical X’Pert HighScore software (Malvern PANanalytical, Malvern, UK). XRD and scanning electron microscopy (SEM) were used to demonstrate the amorphous structure of the glasses. The equipment used was a compact Phenom XL Desktop SEM (ThermoFisher Scientific, Waltan, MA, USA).

The density of the glass was measured by the Archimedes method using toluene as the immersion liquid following the Spanish standard UNE-EN 993-2:1996 [30].

Thermal analysis of samples was obtained by simultaneous differential thermal analysis and thermogravimetry (DTA-TG), using a Netzsch instrument (STA 409C model NETZSCH-Gerätebau GmbH, Selb, Bavaria, Germany). Analyses were carried out in the temperature range 25–1300 °C under an air atmosphere, at a constant flow rate of 80 mL/min, in a platinum crucible and at a heating rate of 10 °C/min. The amount of sample analysed was ~75 mg. The aluminium oxide Perkin Elmer 0419–0197 was taken as reference.

Glass transition temperature analysis (Tg), the dilatometric softening point (Td) and the expansion coefficient were measured with a Linseis horizontal dilatometer L76/1550 (Linseis Messgeräte GmbH, Selb, Bavaria, Germany) using a 2 cm annealing bar. The experiment was carried out from room temperature to 1300 °C at a heating rate of 10 °C/min. Viscosity at Tg had a constant value, independent of composition, of 1012.3 Pa·s [31].

The experimental viscosity–temperature curves (η–T) were drawn using the fixed points defined by Scholze [32] for hot-stage microscopy (HSM) according to rule DIN 51730 [33] and Tg (obtained with dilatometry). In this case, a quenching glass sample, with 3-mm-high test cylinders, was conformed with raw materials powdered under 45 µm and bound using a 1/20 solution of Elvacite® in acetone, and conformed in a uniaxial press. Test cylinders were heated at a 5 °C/min rate from room temperature to 1500 °C in an air atmosphere. This process was recorded in pictures with ProgRes Capture Pro software (Jenoptik AG, Jena, Germany). Analysis was performed with Hot-Stage software, developed by the Departament de Llenguatges i Sistemes Informàtics, ETSEIB, UPC [34]. The output points were plotted in a graph and then fitted to the Vögel-Fulcher-Tammann (VFT) equation. The theoretical viscosity–temperature curves were obtained using the model defined by Fluegel [35].

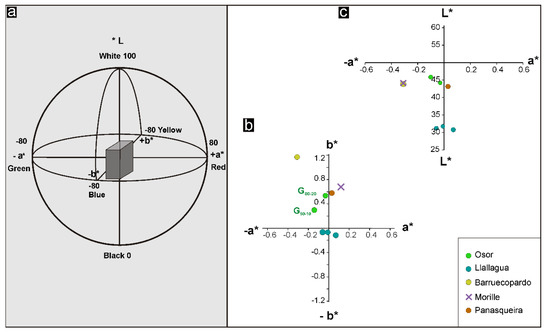

Glass colour was measured with a Spectrophotometer CM-700d Konica-Minolta Investment Ltd. (Sensing Business Division, Shanghai, China) and calibrated according to international standards [36]. The spectrophotometer was fitted with a barium sulphate-coated integrating sphere, and a standard illuminant C was used as a light source. The description of the colour was based on three parameters: lightness, saturation and intensity [37], which were based on the use of three coordinates, L*, a* and b*. L* indicates lightness, 100 being white colour and 0 black. The variables a* and b* are the chromatic coordinates: +a* is the red axis, −a* is the green axis, +b* is the yellow axis and −b* is the blue axis. Low L* values indicate that the glasses are dark and the a* and b* parameters correspond to yellowish green glasses. The colour purity was measured by the Chroma (C) parameter, which is defined by the equation:

The intensity of colour is defined by the hue angle (h), which can be determined by Equation (2). Measurement range is 360°, counted clockwise from 0° for the red colour (a*).

The refractive index was obtained using a Shibuya MC-601 refractometer (Shibuya Kogyo CO., Ltd., Tokyo, Japan).

The chemical stability of the glasses was determined by leaching tests in an acidic solution according to the DIN38414-S4 standard [38]. Leachates were analysed using inductively coupled plasma optical emission spectrometry (ICP–OES, Optima 3100, PerkinElmer, Waltham, MA, USA) and ICP–mass spectrometry (ICP-MS, Elan 6000, PerkinElmer, Waltham, MA, USA).

2.3. Glass Production

The raw mixtures were introduced in an alumina-mullite crucible and heated using a globular alumina furnace equipped with molybdenum disilicide Super Kanthal® and a Eurotherm® 902 programmer. Heating started at 2 °C min−1 up to 800 °C, followed by a holding time of 2 h, and a second step of heating at 1 °C min−1 up to 900 °C, in order to control the Na2CO3 decomposition, and a rate of 2 °C min−1 up to 1450 °C, where it remained for 4 h. After this, the components were molten. Part of this melt was cast into a metallic mould preheated at 350 °C and annealed near the glass transition temperature (Tg) at 450 °C for 30 min, followed by free cooling inside the kiln until room temperature was reached. Another part of the melt was quenched via casting on a Cu plate.

3. Results and Discussion

3.1. Characterization of the Tailing Materials

The chemical composition of tailing materials from Osor has small variations, as shown in the analyses of the three samples from different heights of the tailing (Table 1). The differences were not important for preventing their use in a glass-making plant, but the composition needs to be periodically controlled to adjust the additives. The more significant variation was in the SiO2 content, which varied from 61.76 to 66.11 wt.%. The high calcium content of the tailings, about 12 wt.%, rendered the addition of this component unnecessary. However, the low content in alkaline oxides, 1.33–1.54 wt.% of Na2O and 2.46–2.66 wt.% of K2O, rendered the addition of them necessary.

Table 1.

Chemical composition, in wt.%, of the raw Osor tailings.

The content of potentially toxic elements was significant; the experimental sample had As 12.6, Bi 0.212, Sb 3.1, Hg 0.064, Cr 35.5, Pb 4930, Zn 4500 and Cu 264 ppm.

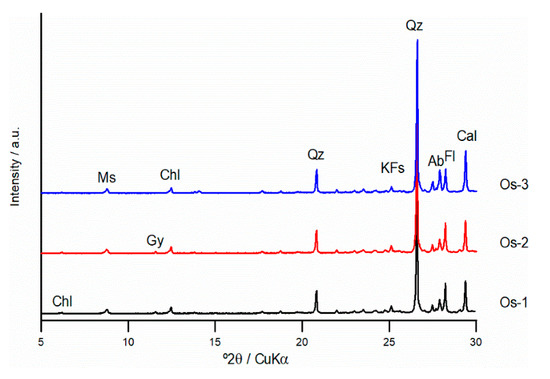

The mineralogical composition of the Osor tailing showed small variations in different areas. The most abundant minerals were quartz, albite, K-feldspar, muscovite, chlorite and calcite (Figure 2). Locally, gypsum and sphalerite occurred in relatively significant amounts (Table 2).

Figure 2.

X-ray diffraction patterns of the Osor tailing. Qz: quartz, Kfs: K-feldspar, Pl: plagioclase, Ms: muscovite, Chl: chlorite, Cal: calcite, Fl: fluorite, Gy: gypsum.

Table 2.

Semiquantitative mineralogical composition of the Osor tailings in wt.%. Mineral acronyms are the same as those used in Figure 2 (Sp: sphalerite).

3.2. Characterization of Glasses

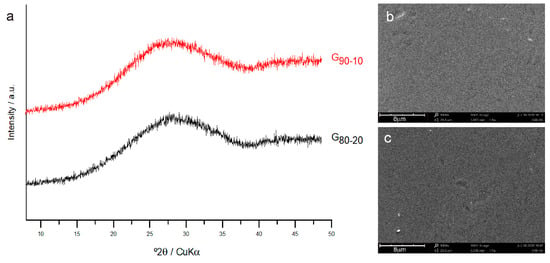

The XRD diagrams (Figure 3a) show no peaks, indicating the amorphous structure of the glasses produced. The absence of crystalline phases was also tested by SEM observations, which show uniform composition (Figure 3b,c).

Figure 3.

(a) X-ray diffraction patterns for the synthesized glasses, (b) SEM image of glass G90-10, (c) SEM image of glass G80-20.

In both the glasses produced (Table 3), only the Na2O content varied: 7.55 wt.% in the glass made with 90 wt.% of tailing and 14.1 wt.% Na2O in that made with 80% of tailing. When the Al/Na and 2Al/Ca ratios are ≤1, Al plays a role of former element and is located in a tetrahedral site [39]. In the glasses produced, Al/Na was 0.52 and 0.27, and 2Al/Ca was 0.69. In this case, at least part of the alkaline and alkaline earth elements acted as charge compensators [23]. This composition is suitable for producing durable glass and also for obtaining glass-ceramics; thus, the SiO2 + Al2O3 content was between 60 and 70 wt.% [40]. On the other hand, the high fluorine content made it possible to reach a melting state at a moderate temperature.

Table 3.

Chemical composition of the two glasses made with different waste ratios, in wt.%.

The density values of the produced glasses were 2.54 g/cm3 for the G80-20 glass and 2.61 g/cm3 for the G90-10 glass, which are slightly higher values than those of a soda-lime glass (2.44 g/cm3).

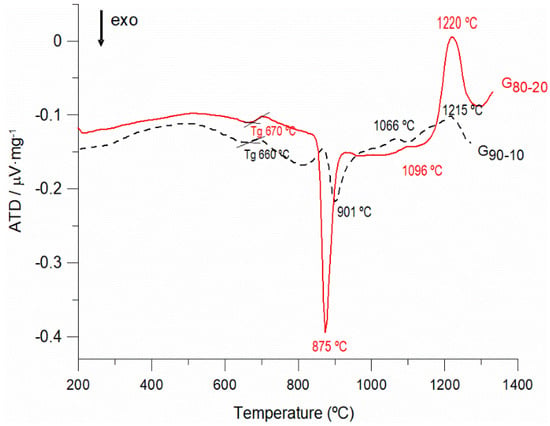

3.3. Thermal Behaviour

The DTA of the two samples show glass-transition temperatures (Tg) of 670 and 660 °C for G80-20 and G90-10, respectively (Figure 4). The exothermic peak corresponds to the formation of crystalline phases. This event occurred at a slightly lower temperature, 875 °C, and was more pronounced in the G80-20 glass, whereas in the G90-10 glass it occurred at 901 °C. Two endothermic peaks correspond to the melting temperature (Tm) of the two crystalline phases formed during the thermal treatment of the glasses. Tm was differed considerably for the glasses: 1066 and 1096 °C in the G90-10 glass and 1215 and 1220 °C in the G80-20 glass.

Figure 4.

DTA curves of glasses produced from the Osor tailings.

The Hrubý coefficient, Hr, [41] provides a useful criterion to evaluate the stability of glasses [42]. This coefficient is defined by Equation (3):

where Tc is the crystallization temperature, Tg is the glass transition temperature determined by the DTA, Tc is the main temperature of crystallization and Tm is the beginning of the melting. Hr inversely correlates with the tendency to crystallize the glass. The Hr of the G90-10 and G80-20 glasses is 1.35 and 0.85, respectively, which is indicative of high stability with respect to crystallization, especially in the glass obtained with 90 wt.% of tailing.

The stability of glasses is important when they contain potentially toxic elements that must be immobilized. Thus, poor stability may lead to the formation of crystals either during annealing of the glass, or afterwards, and lead to cracking of the glass, which increases the leaching rates in such glasses [43]. The higher soda content of the G80-20 glass significantly decreases working temperatures (forming, conditioning and melting).

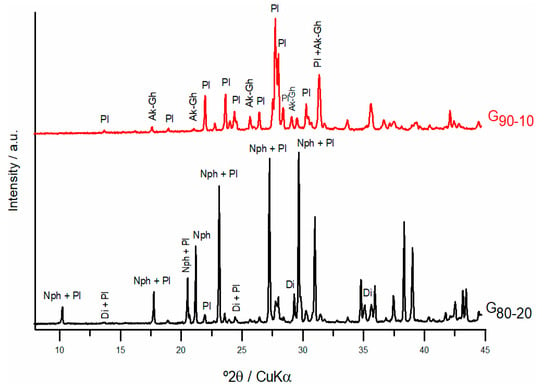

The crystalline phases formed during the crystallization of glasses at 1000 °C were different in both glasses, as suspected by the difference between their Tc, which was determined from the DTA (Figure 5).

Figure 5.

XRD pattern of the Osor glass treated at 1000 °C.

The G90-10 glass crystallized at higher temperature and the phases formed were richer in Ca, being 88 wt.% of intermediate plagioclase and 12 wt.% of crystals from the akermanite–gehlenite (Ca2Al(AlSiO7)–Ca2Mg(Si2O7)) solid solution. In the G80-20 glass, crystalline phases were 66 wt.% nepheline, 25 wt.% plagioclase and 9 wt.% diopside. The type of plagioclase formed depends on the Ca/Na ratio; with a high content of Na, the crystallization of an intermediate or a Na-rich plagioclase is expected. Therefore, this occurred at a lower temperature than in the Ca-predominant composition, where plagioclase with a composition near the anorthite end member of the plagioclase solid solution (NaCaAlSi3O8–Ca2Al2Si2O8) crystallized.

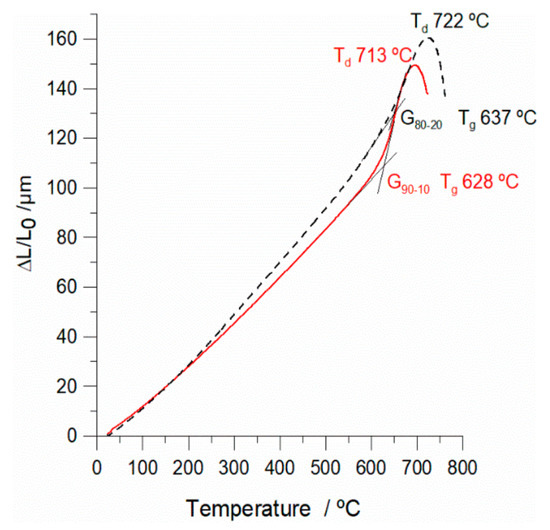

3.4. Rheological Properties

The dilatometric analysis of the two glasses (Figure 6) yielded a Tg of 637 °C in the G80-20 glass and 628 °C in the G90-10 glass. The comparison of these values with those obtained by DTA-TG shows a difference of about 30 °C between both.

Figure 6.

Thermal expansion plot as a function of temperature used to determine Tg and Td.

The dilatometric softening point, Td, was 713 and 722 °C (Figure 6), and the calculated thermal expansion coefficient, in the range 25–450 °C, was 10.84 × 10−6 and 9.00 × 10−6 °C−1 for G80-20 and G90-10, respectively (Table 6). These values are similar to those of other glasses produced from waste materials, such as slags [44].

Both rheological properties described above were slightly higher in the Osor glasses than in a typical soda-lime glasses. These commercial glasses have a Tg from 550 to 580 °C and an expansion coefficient between 8 × 10−6 and 9.00 × 10−6 °C−1 [45].

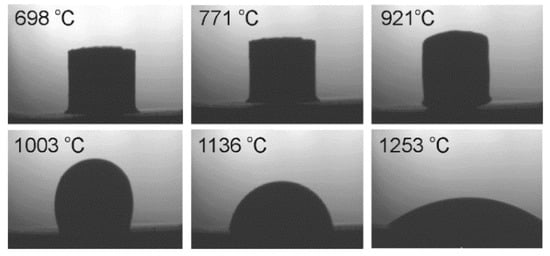

Viscosity is an important property of the raw glass melt for glass making. The control of this parameter is essential in commercial production for achieving a high efficiency and quality of products [46]. The experimental fixed viscosity points obtained by the automatic image analysis provided by HSM are given in Table 4. Figure 7 shows the images corresponding to the thermal geometrical evolution of the G80-20 glass.

Table 4.

Experimental temperatures for the fixed viscosity points [33,49] and workability calculated temperatures.

Figure 7.

Hot-stage photomicrographs of the G80-20 glass with the temperatures of fixed viscosity points: first shrinkage, maximum shrinkage, softening, ball, half ball and flow.

According to the working range, glasses can be classified as short glasses and long glasses. The working range of the temperature has been established on viscosity values between 106 and 103 Pa·s [46] or between 104 and 108 Pa·s [47]. Long glasses present a working range of than 400 °C [47]. The forming and shaping of long glasses is easier and allows for working at lower temperatures, while the short glasses become rigid more quickly, enabling automatized production processes [47,48]. The viscosity range between 106 and 103 Pa·s in the case of G90-10 was 293 °C and in G80-20 was 479 °C. Therefore, the manufacture of glasses can only be carried out automatically in the case of raw tailing with a higher soda addition.

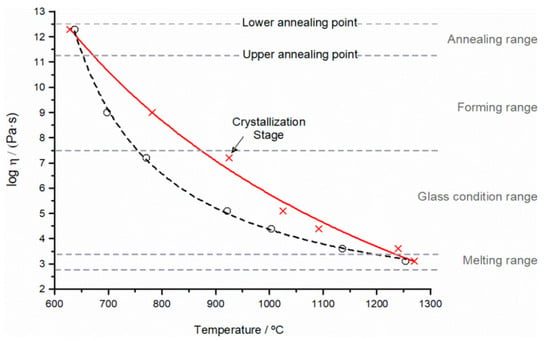

The viscosity-temperature curves for the glasses produced (Figure 8) were obtained using HSM results and by determining the correlation between the fixed points of the known viscosity, the Tg obtained by a dilatometer corresponding to a viscosity of 1012.3 Pa·s and the Vogel-Fulcher-Tammann (VFT) equation [32]. The G80-20 curve has a relatively low fitting in the intermediate region of viscosity, which can be attributed to the crystallization stage [50].

Figure 8.

Viscosity–temperature curves and workability intervals of the glasses studied using fixed viscosity points. G90-10 = dashed black line (R-squared = 0.9991, Vogel-Fulcher-Tammann (VFT) equation and G80-20 = red line (R-squared = 0.9921, VFT).

3.5. Optical Properties

The CIEL AB space [36] provides an objective measure of the colour. In Table 5, the colour parameters for the glasses from the Osor tailings are shown. The low values of C* indicate that the glasses plotted near the centre of the colour sphere and thus, present low purity. Hue values of the Osor glasses were 93.18 and 110.32°; values between 90 and 180° indicate yellow-green tonality. In Figure 9, these parameters are shown together with others obtained from glasses produced using tailings from different origins, whose characteristics were previously published [13,19,51]. Comparison of the colour parameters from these glasses indicates that tailing glasses usually show medium or dark colour and a low purity. These results are due to the abundant metals content, or the chromophore elements, which usually occurs in tailings from metallic deposits. Yellow-green glasses are common when tailings contain high iron levels and low Mn/Fe ratios [52].

Table 5.

Colour parameters for glasses synthesized from tailings.

Figure 9.

CIE LAB chromatic diagram of the Osor glasses. Data of Llallagua glass from [51]. (a) CIE LAB colour sphere, (b) a*, b* colour coordinates, (c) L*, a* coordiunates.

The refractive index, n, of both glasses produced was 1.54, which is similar than that of typical soda-lime-silica commercial glasses, with an n of 1.51 to 1.52, and slightly higher than in vitreous glasses because cations fill the interstices in the network [45].

3.6. Leaching Behaviour

The test for leachability of potentially toxic elements from the glasses of the Osor tailings, determined using the DIN 38414-S4 standard [36], showed that the concentrations of metals in the leachates were always under the threshold limits established in the standard [36]. These results suggest that the metals were fixed in the structure of the glasses. Metal retention was similar in both glasses, although the G80-10 glasses better retained metals. The Pb content in the G90-10 glass was 4437 ppm, from this, 0.230 ppm was removed during the leaching test, which represents 0.0005 wt.% of the total amount of Pb in this glass (Table 6). These results indicate the high stability of the toxic elements in the glassy structure, as has been reported in other glasses made from tailings [13,19,51] and in industrial waste products [53].

Table 6.

Chemical composition of glasses, their leachates and threshold limits (TL) according to the DIN 38414-S4 standard. Results are expressed in ppm.

4. Conclusions

Tailings from the Osor mines are rich in calcium and only soda needs to be added to make commercial glass.

Two different doses of Na2CO3 were used for the experimental glasses. The transition and melting temperatures were higher in the case glasses with less soda content. The Hr of G90-10 was higher than that of G80-20, suggesting that glass with less soda content was more stable with respect to crystallization. However, G80-20 displayed a wider range of workability temperatures. Therefore, glasses were more stable, but more difficult to produce in the compositions with 10% Na2CO3 compared to those with 20% Na2O3.

The composition of the tailings from the Osor mines is suitable for the manufacture of commercial glass. The glasses obtained from the tailings retain potentially toxic elements in their structure and prevent environmental contamination. Although both compositions retain these potentially toxic elements, glass with 20% Na2CO3 is more efficient.

The tailing and Na2O3 dosages are suitable for making commercial glass. Although the higher Na2O3 content resulted in greater efficiency, the cost of production should also be taken into account before a final decision is made.

Author Contributions

Conceptualization, M.G.-V. and P.A.; methodology, M.G.-V., S.M. and P.A.; software, M.G.-V., O.T. and P.A.; validation, S.M. and M.G.-V.; formal analysis, O.T., P.A. and M.G.-V.; investigation, O.T., N.R. and L.M.D.; resources, M.G.-V. and S.M.; data curation, O.T.; writing—original draft preparation, P.A. and M.G.-V.; writing—review, all authors; visualization, M.G.-V. and P.A.; supervision, M.G.-V., P.A. and S.M.; project administration and funding acquisition, M.G.-V. and P.A. All authors have read and agreed to the published version of the manuscript.

Funding

This study benefitted from the budget granted by the Generalitat de Catalunya (Autonomous Government of Catalonia) to the Consolidated Research Group SGR-2017SGR1687 and 2017SGR0707.

Acknowledgments

The authors thank the staff of the Scientific-Technical Service Unit of the University of Barcelona (CCiTUB) for their technical support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Grangeia, C.; Ávila, P.; Matias, M.; Da Silva, E.F. Mine tailings integrated investigations: The case of Rio tailings (Panasqueira Mine. Central Portugal). Eng. Geol. 2011, 123, 359–372. [Google Scholar] [CrossRef]

- Ritcey, G. Tailings Management: Problems and Solutions in the Mining Industry; Elsevier: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Dold, B. Evolution of Acid Mine Drainage Formation in Sulphidic Mine Tailings. Minerals 2014, 4, 621–641. [Google Scholar] [CrossRef]

- Chen, T.; Yan, Z.A.; Xu, D.; Wang, M.; Huang, J.; Yan, B.; Xiao, X.; Ning, X. Current situation and forecast of environmental risks of a typical lead-zinc sulfide tailings impoundment based on its geochemical characteristics. J. Environ. Sci. 2020, 93, 120–128. [Google Scholar] [CrossRef] [PubMed]

- Jamieson, H.E.; Walker, S.R.; Parsons, M.B. Mineralogical characterization of mine waste. Appl. Geochem. 2015, 57, 85–105. [Google Scholar] [CrossRef]

- Mudd, G.M.; Boger, D.V. The Ever Growing Case for Paste and Thickened Tailings-towards More Sustainable Mine Waste Management. J. Aust. Inst. Min. Metall. 2013, 2, 56–59. [Google Scholar]

- Schoenberger, E. Environmentally sustainable mining: The case of tailings storage facilities. Resource. Policy 2016, 49, 119–128. [Google Scholar] [CrossRef]

- Tayebi-Khorami, M.; Edraki, M.; Corder, G.; Golev, A. Re-Thinking Mining Waste through an Integrative Approach Led by Circular Economy Aspirations. Minerals 2019, 9, 286. [Google Scholar] [CrossRef]

- Lèbre, É.; Corder, G.; Golev, A. The role of the mining industry in a circular economy: A framework for resource management at the mine site level. J. Ind. Ecol. 2017, 21, 662–672. [Google Scholar] [CrossRef]

- Marabini, A.M.; Plescia, P.; Maccari, D.; Burragato, F.; Pelino, M. New materials from industrial mining wastes: Glass–ceramic and glass and rock-wool fibre. Int. J. Miner. Process. 1998, 53, 121–134. [Google Scholar] [CrossRef]

- Bingham, P.A.; Hand, R.J.; Forder, S.D.; Lavaysierre, A. Vitrified Metal Finishing Wastes II. Thermal and Structural Characterisation. J. Hazard. Mater. 2005, 122, 129–138. [Google Scholar] [CrossRef] [PubMed]

- Park, H.S.; Park, J.H. Vitrification of red mud with mine wastes through melting and granulation process–Preparation of glass ball. Non-Cryst. Solids 2017, 475, 129–135. [Google Scholar] [CrossRef]

- Alfonso, P.; Tomasa, O.; Garcia-Valles, M.; Tarragó, M.; Martínez, S.; Esteves, H. Potential of tungsten tailings as glass raw materials. Mater. Lett. 2018, 228, 456–458. [Google Scholar] [CrossRef]

- Okereafor, U.; Makhatha, M.; Mekuto, L.; Mavumengwana, V. Gold Mine Tailings: A Potential Source of Silica Sand for Glass Making. Minerals 2020, 10, 488. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, M.; Sohn, J.; Park, H. Applicability of gold tailings, waste limestone, red mud, and ferronickel slag for producing glass fibers. J. Clean. Prod. 2018, 203, 957–965. [Google Scholar] [CrossRef]

- Shao, H.; Liang, K.; Peng, F.; Zhou, F.; Hu, A. Production and properties of cordierite-based glass-ceramics from gold tailings. Miner. Eng. 2005, 18, 635–637. [Google Scholar] [CrossRef]

- Lay, G.F.T.; Rockwell, M.C.; Wiltshire, J.C.; Ketata, C. Characteristics of silicate glasses derived from vitrification of manganese crust tailings. Ceram Int. 2009, 35, 1961–1967. [Google Scholar]

- Baowei, L.; Leibo, D.; Xuefeng, Z.; Xiaolin, J. Structure and performance of glass–ceramics obtained by Bayan Obo tailing and fly ash. J. Non-Cryst. Solids 2013, 380, 103–108. [Google Scholar] [CrossRef]

- Alfonso, P.; Castro, D.; García-Vallès, M.; Tarragó, M.; Tomasa, O.; Martínez, S. Recycling of tailings from the Barruecopardo tungsten deposit for the production of glass. J. Therm. Anal. Calorim. 2016, 125, 681–687. [Google Scholar] [CrossRef]

- Karamanov, A.; Hamzawy, E.M.; Karamanova, E.; Jordanov, N.B.; Darwish, H. Sintered glass-ceramics and foams by metallurgical slag with addition of CaF2. Ceram. Int. 2020, 46, 6507–6516. [Google Scholar] [CrossRef]

- Hill, R.; Wood, D.; Thomas, M. Trimethylsilylation analysis of the silicate structure of fluoro-alumino-silicate glasses and the structural role of fluorine. J. Mater. Sci. 1999, 34, 1767–1774. [Google Scholar] [CrossRef]

- Pei, F.; Zhu, G.; Li, P.; Guo, H.; Yang, P. Effects of CaF2 on the sintering and crystallisation of CaO–MgO–Al2O3–SiO2 glass-ceramics. Ceram. Int. 2020, 46, 17825–17835. [Google Scholar] [CrossRef]

- Cormier, L.; Neuville, D.R. Ca and Na environments in Na2O–CaO–Al2O3–SiO2 glasses: Influence of cation mixing and cation-network interactions. Chem. Geol. 2004, 213, 103–113. [Google Scholar] [CrossRef]

- Angeli, F.; Gaillard, M.; Jollivet, P.; Charpentier, T. Contribution of 43Ca MAS NMR for probing the structural configuration of calcium in glass. Chem. Phys. Lett. 2007, 440, 324–328. [Google Scholar] [CrossRef]

- Ligero, F.B. La mineria a Osor. Quad. Selva 1995, 8, 137. [Google Scholar]

- Corcoll, N.; Bonet, B.; Morin, S.; Tlili, A.; Leira, M.; Guasch, H. The effect of metals on photosynthesis processes and diatom metrics of biofilm from a metal-contaminated river: A translocation experiment. Ecol. Indic. 2012, 18, 620–631. [Google Scholar] [CrossRef]

- Navarro, A.; Font, X.; Viladevall, M. Metal Mobilization and Zinc-Rich Circumneutral Mine Drainage from the Abandoned Mining Area of Osor (Girona. NE Spain). Mine Water Environ. 2015, 34, 329–342. [Google Scholar] [CrossRef]

- Bori, J.; Vallès, B.; Navarro, A.; Riva, M.C. Ecotoxicological risks of the abandoned F–Ba–Pb–Zn mining area of Osor (Spain). Environ. Geochem. Health 2017, 39, 665–679. [Google Scholar] [CrossRef] [PubMed]

- Piqué, À.; Canals, À.; Grandia, F.; Banks, D.A. Mesozoic fluorite veins in NE Spain record regional base metal-rich brine circulation through basin and basement during extensional events. Chem. Geol. 2008, 257, 139–152. [Google Scholar] [CrossRef]

- UNE-EN 993-2:1996. Métodos de Ensayo para Productos Refractarios Conformados Densos. Parte 2: Determinación de la Densidad Absoluta. Spanish Standard; AENOR: Madrid, Spain, 1996. [Google Scholar]

- Engels, M.; Link, S. Bubble control in ceramic glazes. Interceram 2006, 3, 152–156. [Google Scholar]

- Scholze, H. Der Einfluss von Viskosität und Oberflächenspannung auf erhitzungsmikroskopische Messungen an Gläsern. Ber. Dtsch. Keram. Ges. 1962, 39, 63–68. [Google Scholar]

- DIN 51730. Determination of ash Fusion Behaviour, German Standard; DIN Deutsches Institut für Normung, E.V.: Berlin, Germany, 1976. [Google Scholar]

- Garcia-Valles, M.; Hafez, H.; Cruz-Matías, I.; Vergés, E.; Aly, M.H.; Nogués, J.M.; Ayala, D.; Martinez, S. Calculation of viscosity–temperature curves for glass obtained from four wastewater treatment plants in Egypt. J. Therm. Anal. Calorim. 2013, 111, 107–114. [Google Scholar] [CrossRef]

- Fluegel, A. Glass viscosity calculation based on a global statistical modeling approach. Glass Technol. 2007, 48, 13–30. [Google Scholar]

- CIE. Technical Report, Colorimetry; Commission Internationale de L’Eclairage: Vienna, Austria, 1931. [Google Scholar]

- McGuire, R.G. Reporting of objective color measurements. HortScience 1992, 27, 1254–1255. [Google Scholar] [CrossRef]

- DIN 38414-S4. Schlamm und Sedimente, Bestimmung der Eluierbarkeit mit Wasser; DIN Deutsches Institut für Normung, E.V.: Berlin, Germany, 1984. [Google Scholar]

- Mysen, B.O. Structure and Properties of Silicate Melts; Elsevier: Amsterdam, The Netherlands, 1988. [Google Scholar]

- Barbieri, L.; Lancettotti, I.; Manffredini, T.; Queralt, I.; Rincon, J.M.; Romero, M. Design, obtainment and properties of glasses and glass–ceramics from coal fly ash. Fuel 1999, 78, 271–276. [Google Scholar] [CrossRef]

- Hrubý, A. Evaluation of glass-forming tendency by means of DTA. Czechoslov. J. Phys. B 1972, 22, 1187–1193. [Google Scholar] [CrossRef]

- Kozmidis-Petrovic, A.; Šesták, J. Forty years of the Hrubý glass-forming coefficient via DTA when comparing other criteria in relation to the glass stability and vitrification ability. J. Therm. Anal. Calorim. 2012, 110, 997–1004. [Google Scholar] [CrossRef]

- Donald, I.W.; Metcalfe, B.L.; Taylor, R.J. The immobilization of high level radioactive wastes using ceramics and glasses. J. Mater. Sci. 1997, 32, 5851–5887. [Google Scholar] [CrossRef]

- Wu, J.P.; Rawlings, R.D.; Boccaccini, A.R. A glass–ceramic derived from high TiO2-containing slag: Microstructural development and mechanical behaviour. J. Am. Ceram. Soc. 2006, 89, 2426–2433. [Google Scholar] [CrossRef]

- Shelby, J.E. Introduction to Glass Science and Technology; Royal Society of Chemistry: Cambridge, UK, 2005. [Google Scholar]

- Cheng, J.; Xiao, Z.; Yang, K.; Wu, H. Viscosity, fragility and structure of Na2O–CaO–Al2O3–SiO2 glasses of increasing Al/Si ratio. Ceram. Int. 2013, 39, 4055–4062. [Google Scholar] [CrossRef]

- Fernández Navarro, J.M. La Sociedad Española de Cerámica y Vidrio a lo Largo de Medio Siglo; Sociedad Española de Cerámica y Vidrio: Madrid, Spain, 1991. [Google Scholar]

- Karamanov, A.; Di Gioacchino, R.; Pisciella, P.; Pelino, M.; Hreglich, A. Viscosity of iron rich glasses obtained from industrial wastes. Glass Technol. 2002, 43, 34–38. [Google Scholar]

- Pascual, M.J.; Pascual, L.; Duran, A. Determination of the viscosity-temperature curve for glasses on the basis of fixed viscosity-temperature determined by hot stage microscopy. Phys. Chem. Glasses 2001, 42, 61–66. [Google Scholar]

- Khalil, T.K.; Boccaccini, A.R. Heating microscopy study of the sintering behaviour of glass powder compacts in the binary system SiO2–TiO2. Mater. Lett. 2002, 56, 317–321. [Google Scholar] [CrossRef]

- Arancibia, J.R.H.; Alfonso, P.; Garcia Vallès, M.; Martínez Manent, S.; Parcerisa, D.; Canet, C.; Romero, F.M. Manufacturing of glass from tin mining tailings in Bolivia. Bol. Soc. Esp. Ceram. Vidr. 2013, 52, 143–150. [Google Scholar] [CrossRef][Green Version]

- Mirti, P.; Davit, P.; Gulmini, M. Colourants and opacifiers in seventh and eighth century glass investigated by spectroscopic techniques. Anal. Bioanal. Chem. 2002, 372, 221–229. [Google Scholar] [CrossRef]

- Pisciella, P.; Crisucci, S.; Karamanov, A.; Pelino, M. Chemical durability of glasses obtained by vitrification of industrial wastes. Waste Manag. 2001, 21, 1–9. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).