Abstract

Copper slags produced in vast quantities in smelting operations could be considered as secondary material sources instead of stockpiling them in landfills. This study investigates the recovery of valuable metals from copper slag and the valorisation of the leach residue as construction material in line with the principles of a circular economy. By taking into account that the environmental characterization of the as-received copper slag did not allow its disposal in landfills without prior treatment, chemical and biological leaching were tested for the recovery of metals. Pre-treatment with acids, namely HNO3 and H2SO4, resulted in the extraction of several target metals and the production of an almost inert waste. Despite the clearly better oxidative conditions prevailing in the bioleaching reactors, chemical leaching resulted in the higher dissolution of Cu (71% vs. 51%), Co (70% vs. 36%), and Zn (65% vs. 44%). The acid consumption was much lower during the bioleaching experiments compared to the chemical leaching. The bioleach residue was suitable for its use as supplementary cementitious material, showing a better performance than the reference sample without causing any detrimental effects to the calcium aluminate cement (CAC) quality. The complete valorisation of copper slags is expected to improve the economics of the process, by avoiding landfill costs and producing saleable products with high added value.

1. Introduction

In smelting, copper-rich matte containing sulphides and copper slag as by-product are formed [1]. For every ton of copper produced during smelting and refining operations, approximately 2.2–3 tons of fayalite slag is produced and the management of these significant quantities is difficult [2,3]. Copper slags contain high amounts of iron, silicon, and aluminium oxides, while the main mineralogical phases are fayalite and magnetite [4]. Copper and zinc occur as impurities in silicates, while sulphides and the intermetallic phases occur as minor components containing metals in high concentrations [5]. The chemical composition of copper slag depends on the treatment process and furnace type, and is typically 30–40% Fe, 35–40% SiO2, ≤10% Al2O3, ≤10% CaO, and 0.5–2.1% Cu [2].

A significant portion of the produced slag is stockpiled [1], an option that may result in environmental and space challenges [2]. It is therefore necessary to carry out a complete environmental characterization prior to selecting the most appropriate management option [6]. It is known that many wastes contain hazardous substances and treatment is often required prior to safe disposal [4]. On the other hand, metallurgical slags can be considered as secondary material sources, since they are produced in large quantities and contain relatively large amounts of residual metals [5]. Metal recovery from slags has been tested with the use of pyrometallurgical, hydrometallurgical, and pyro-hydrometallurgical routes [2], while sulphuric acid has been the most commonly used leaching agent. In chemical leaching, one of the main challenges is silica dissolution, which results in filtration difficulties and metal losses and can be overcome only when operations are carried out under high pressure and temperature. On the other hand, the presence of iron in a high concentration in pregnant leach solution (PLS) makes the recovery of copper more challenging and costly. The pH is a crucial parameter that needs to be carefully monitored during slag leaching, since the formation of iron precipitates takes place at higher pH values, while operation at a lower pH may increase acid consumption and result in the formation of unfilterable gels [7]. Bioleaching has been studied as a cheaper and environmentally friendly alternative for the extraction of metals from copper slags [8,9,10,11,12,13]. No standardized leaching protocols exist for slags, since their characteristics that affect leaching vary widely [5]. The dissolution of copper sulphides and the extraction of metallic copper can be accelerated by the presence of ferric iron, which is generated by iron-oxidizing microorganisms and is a strong oxidation agent. Therefore, biohydrometallurgy may offer a simple and robust alternative for the leaching of slags and the recovery of metals.

Copper slag can also be used in several products, such as aggregates, fills, granules, tiles, and abrasives [2], while its use in cement and concrete production is considered as one of the most promising options [1,4]. Supplementary cementitious materials (SCMs) are usually incorporated in a binder as a replacement of one part of ordinary Portland cement (OPC). In blended cements, the SCM particles are expected to contribute to their final performances due to a chemical role and/or a physical filler role. The partial replacement of cement by copper slag results in considerable energy savings and reduced CO2 emissions [1]. However, if leaching of metals takes place, utilization of slag in construction engineering applications is unsuitable.

The aim of this study is to evaluate the environmental characteristics of a copper slag, define the degree of dissolution of metals during chemical and biological leaching, and investigate the potential use of the bioleach residue as SCMs in order to valorise the whole material value chain following the principles of a circular economy. Copper slag was bioleached in the presence of autotrophic bacteria in order to mobilize copper and at the same time minimize dissolution of the main iron-bearing matrix. The leach residue was tested as SCMs in mortars whose binder was a ternary system composed of Portland cement (OPC) as the main component and a calcium aluminate cement (CAC) associated with a calcium sulphate. In the ternary binder, the leach residue partially replaced the CAC as SCMs. Typically, slags exhibiting high leachability potential may be tested for metal recovery while others with low leachability may be used in civil engineering applications [5]. The novelty of this study is justified by the complete valorisation of the copper slag, first for the recovery of valuable metals followed by the use of the leach residue as SCMs. The recovery of metals and the valorisation of the leach residues in the construction sector will substantially minimize the mining of virgin raw materials, including ores and aggregates, as well as reduce the carbon footprint of metal production and improve the sustainability of the mining and cement industry.

2. Materials and Methods

2.1. Copper Slag

A 200 kg fresh copper slag sample was obtained from an operating copper plant. The dried material was comminuted with an Eirich mixer to break the agglomerates and produce a fine powder (d80 < 54 µm; d50 < 29 µm) by Outotec. The ground sample was dried to a final moisture content of 0.037% (w/w) and divided into approximately 16 kg batches that were shipped for testing. The X-ray diffraction (XRD) analysis of the slag was performed using a Bruker AXS (D8 Advance type) diffractometer with a Cu tube, scanning range from 4° to 70° 2θ, step of 0.02°, and measuring time 0.2 s/step. The qualitative analysis was assessed with the use of the DIFFRACplus EVA v. 2006 software and the Powder Diffraction File (PDF-2) database. The X-ray fluorescence (XRF) analysis was carried out using an X-ray fluorescence energy dispersive spectrometer (XRF–EDS) Bruker-AXS S2 Range type (Bruker, Karlsruhe, Germany). The loss on ignition (LOI) was determined by heating the slag at 1050 °C for 4 h. Chemical and mineralogical analyses were carried out using 2 discrete samples, obtained after grinding, homogenization, and appropriate splitting; the results obtained were almost identical (differences were within ±1%).

2.2. Environmental Tests

The toxicity of the copper slag was assessed with the use of the TCLP toxicity test [14], the EN 12457-3 test [15,16,17,18], and the NEN 7341 test [19]. In the TCLP test, a 20:1 liquid-to-solid (L/S) ratio was used and the mixture was magnetically stirred for 18 h in a conical flask at room temperature prior to filtration (0.45 µm). The concentrations of Fe, Zn, Pb, Cu, Cd, Mo, As, Sn, Ni, Ti, Co, Sb, Mn, and Sr in the extract were determined using an inductively coupled plasma mass spectrometry (ICP-MS) analyser (Agilent Technologies 7500c x, Santa Clara, CA, USA).

The 2-step standard CEN EN12457-3 compliance test for granular waste materials (particle size < 4 mm) and sludges was applied to quantify the leaching potential of the slag using deionized water and predict the release pattern of elements in the long term. Leaching of 2 L/kg dry slag (20 g slag, 40 mL deionized water) was first carried out for 6 h, followed by leaching of 8 L/kg dry slag (20 g slag, 160 mL deionized water) for 18 h prior to filtration (0.45 µm). The total time of contact between the sample and the leachant was 24 h. Results were expressed using a liquid-to-solid (L/S) ratio of 2 L/kg and a combined L/S ratio of 10 L/kg, and then compared with existing limits for disposal of slags in landfills [20].

The total availability leaching test NEN 7341 is an agitated extraction test performed at two controlled pH values, pH 4 and pH 7, with the use of HNO3. The sample was extracted twice in succession at a L/S ratio of 50:1 (L/kg) using 5 g of slag in 250 mL of acid solution. In the first phase, leaching was carried out for 3 h at a constant pH 7, while in the second stage, the material was leached for 3 h at a constant pH 4. The leachates were filtered, combined, and analysed. The results of this test determine the maximum quantity of each inorganic component that can be leached and the acid neutralizing capacity of the material.

2.3. Chemical Leaching

Slag was leached using H2SO4 (0.25 and 1.5 mol/L) and HNO3 (0.5 and 3 mol/L) at 40, 60, and 80 °C for a period of 48 h, using a L/S ratio of 5% (w/v). Leaching tests were carried out in a borosilicate glass reactor with 1 L operating capacity equipped with a temperature controller (Electemp-TFT, Selecta, Barcelona, Spain), heating mantle (Fibroman-C, Selecta, Barcelona, Spain), and condenser. The pulp was stirred at 300 rpm. Samples were taken after 6, 24, and 48 h, and then analysed by ICP-MS. In addition, slag was also leached with 3 and 5 mol/L HNO3 and 1.5 and 2.5 mol/L H2SO4 for 24 h at 80 °C using a L/S ratio of 20% and 30% (w/v). The leaching tests had two objectives: (i) to determine the potential extraction and recovery of certain metals from the slag; and (ii) to valorise the obtained leaching residues for the production of alkali-activated materials that can be used as binders in the cement industry and as construction materials.

It is mentioned that the environmental, chemical, and bioleaching tests were carried out in duplicate and average values are given in the paper. However, differences noted were negligible and were within ± 2.2%.

2.4. Bioleaching

An enriched, mixed culture of iron- and sulphur-oxidizing microorganisms obtained from acidic mine waters was used in the bioleaching experiments. The enriched, mixed culture contained Marinobacter spp., Acidithiobacillus spp., Sulfurospirillum spp., Leptospirillum spp., Cuniculiplasma spp., Sulfobacillus spp., and Arcobacter spp. The culture was adapted to copper slag using an initial L/S ratio of 1% (w/v) in a total volume of 100 mL (10 mL inoculum and 90 mL of 9K medium [21]), which was increased to a 10% (w/v) pulp density. Elemental sulphur, 1% (w/v), was added since the content of the sulphides in the slag was low.

The shake flask bioleaching experiments (100 mL, 1% or 5% (w/v) pulp density, 10% inoculum, 1% (w/v) elemental sulphur, 30 °C, and 150 rpm) were run in duplicates for 21 days. The solution pH and ferrous iron concentration were measured regularly. Total elemental concentrations were measured twice by ICP: after 3–4 days and at the end of the experiment.

The reactor bioleaching experiments were conducted in batch mode using 1 L or 5 L reactors (32 °C, 10% (w/v) pulp density, and 1 L air/min). The experiments were supplemented with a 90% volume nutrient medium (150 mg/L Na2SO4.10H2O, 450 mg/L (NH4)2SO4, 50 mg/L KCl, 500 mg/L MgSO4·7H2O, 50 mg/L KH2PO4, and 14 mg/L Ca(NO3)2·4H2O) and a 10% volume of microbial culture as inoculum using a 10% (w/v) pulp density. In the chemical control test, ion-exchange water was used instead of nutrient medium and inoculum. The pH was maintained at a suitable bioleaching level by titration (pH 1.0–1.5; addition of H2SO4 or NaOH) when needed or, alternatively, there was no pH control (only the addition of 1% (w/v) elemental sulphur). The pH and redox potential were measured with a Consort multi-parameter analyser C3040 (Consort bvba, Turnhout, Belgium) equipped with an Ag/AgCl in 3M KCl electrode (Van London-pHoenix Co., Houston, TX, USA), iron speciation was determined with the phenanthroline method [22], and the elemental composition of the leachate was determined by ICP-MS in an accredited laboratory (Labtium Oy, Espoo). Different temperatures, L/S ratios, impeller types (GLS, pitch blade), and agitation speeds (300 and 400 rpm) were used in order to identify the optimal conditions and the most efficient bioleaching performance.

2.5. Leach Residue Valorisation as Supplementary Cementitious Materials

The leach residue from the bioleaching reactor (pH 1.5, redox > 600 mV) was assessed for its potential use as supplementary cementitious material (SCM) in mortars. The binder of mortars is a ternary system composed of OPC as the main component, CAC, and calcium sulphate (anhydrite µA). The CAC is used in order to obtain a higher early strength and faster setting time. In this work, CAC (Ternal RG) was replaced at 15% (w/w) and 30% (w/w) (Table 1) by the residue obtained after bioleaching of the copper slag in order to act as SCM. In contrast to Portland cement, which contains tricalcium silicate (3CaO·SiO2 or C3S), the CAC used in this study contained monocalcium aluminate (CaO·Al2O3 or CA) as the main reactive phase.

Table 1.

Recipe for producing mortars, indicating the % addition of copper slag bioleach residue as supplementary cementitious material (SCM).

The residue was manually ground using a mortar and a pestle for 5 min to produce a fine powder without any specific final particle size as a target. All ingredients were homogenized using the recipe proportions for 10 min in a glass vessel by a planetary rotating system. The final dry mixture was placed in a bowl, water was added, and the mixture stirred for 1 min with a whip blender. Standard mortar specimens were prepared in accordance to EN 196-2 [23], with the exception that the cast in the standard mortar beams was 20 mm × 20 mm × 100 mm due to the small sample size. The samples were demoulded after 24 h and stored in the air at 23 ± 2 °C and 50% relative humidity. Phase formations were identified using quantitative X-ray diffraction (QXRD) and thermogravimetric analysis (TGA) during the entire period of hydration (up to 28 days). Ultimately, the kinetics of the hydration/reaction of the mortars and microstructural development of the binding matrix were determined. The TG analysis was carried out using a NETZSCH Star System with an automatic sampler. The powder was weighted in a 40 μL Pt crucible. The temperature increased from 30 °C to 1000 °C at 10 °C/min with N2 = 60 mL/min (100% N2). Qualitative X-ray diffraction (XRD) was carried out with a D8 from Bruker with CuKα radiation and 40 kV, 45 mA, at 0.02°/14.5 s. Absolute density was measured with a pycnometer Accupyc II 1340 (Micromeritics Instrument Corporation). The overall released heat from the exothermic cement hydration reaction was determined by a calorimeter (8-channel TAM Air from TA Instruments Company).

The mechanical strength of the hardened mortars was determined with the implementation of flexion and compression tests at different curing times. The specimen with dimensions 20 mm × 20 mm × 100 mm was submitted to a 3-point flexion test giving two half-blocks, which were then crushed in the compression test. For each curing time, two specimens were crushed to determine the flexion strength giving then four blocks for the compression test using a press device (3R Company). The loading rate was at 0.05 kN/s for the flexion test and at 2.4 kN/s for the compression test.

3. Results

3.1. Material Characterization

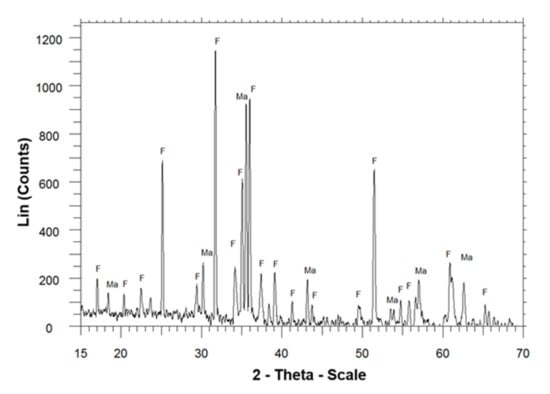

The chemical composition of the copper slag in the form of oxides is shown in Table 2, while its mineralogical analysis is shown in Figure 1. Based on the analysis of the XRD pattern, it is deduced that the main phases present in the slag were fayalite and magnetite. It is mentioned that the slag may also contain some metal sulphides, namely Cu2S, CuFeS2 and FeS, which may be of environmental concern if these phases are oxidized [10,24,25]. However, as the results of several environmental tests confirm (details are given in the following sections), no noticeable impacts are anticipated in case of improper disposal due to its low content of residual copper and sulphur.

Table 2.

Chemical composition (% w/w) of the copper slag.

Figure 1.

XRD pattern of the copper slag.

3.2. Environmental Characterization

The TCLP results for the original copper slag (Table 3) show that especially Cu as well as Zn and Fe exhibit increased solubilisation, so elevated concentrations are present in the leachant; however, no TCLP toxicity limits are available for these elements. Other elements showing higher solubilisation are Ni and Sb, but also no toxicity limits exist for these elements. As, Cd, Cr and Pb showed very limited solubilisation, far below the TCLP limits. Based on these results, it is deduced that the slag is characterized as non-toxic.

Table 3.

TCLP results for the original copper slag and its residue obtained after leaching with 3 mol/L HNO3 (DL: detection limit).

Results of the EN 12457-3 test (Table 4) show that at higher L/S ratios, elements with a higher content in slag, such as Fe, Cu, and Zn, were more easily leached and therefore their concentration in the leachant was higher. On the other hand, elements with a lower content in the slag, such as As, Mo, Sn, and Pb, were present in lower concentrations in the leachant after leaching at higher L/S ratios. All elements except As, Mo, Sb, and Pb showed higher leaching rates (mg/kg) when higher L/S ratios were used; this was anticipated since in these conditions the reaction kinetics are faster.

Table 4.

EN 12457-3 results (L/S of 2 L/kg and 10 L/kg) for the original copper slag and its residue after leaching with HNO3.

By taking into account the EN 12457-3 results, it is deduced that the slag cannot be accepted in landfills for inert wastes since several elements (Ni, Cu, Zn, As, Mo, Sb, and Pb) exceeded the limits for both L/S ratios. Slag cannot also be accepted in landfills for non-hazardous wastes, since several elements (Zn, As, Sb, and Pb with an L/S of 2; and Cu, Zn, As, and Sb with an L/S of 10) exceeded the respective limits. In addition, the slag cannot be accepted in landfills for hazardous wastes, since As and Sb with an L/S of 2 (only marginally though) and Zn with an L/S of 10 exceeded the limits.

The NEN test (Table 5) results indicated that only three elements, Cu, Zn, and Pb, showed higher solubilisation. However, their concentration in the leachant is not considered very high, but it has to be taken into account that this test was carried out with a high L/S ratio, 50:1, which favours faster kinetics.

Table 5.

NEN 7341 results for its original copper slag and its residue after 3 mol/L HNO3 leaching.

Based on the combined and extensive environmental characterization results, it is deduced that copper slag needs to be pre-treated prior to disposal. Therefore, chemical and biological leaching of the copper slag was investigated for the extraction of valuable metals and the production of an inert residue that can be used as raw material in cement production.

3.3. Chemical Leaching

Leaching of the copper slag with 0.25 or 1.5 mol/L H2SO4, and 0.5 or 3 mol/L HNO3 at 40, 60, and 80 °C for a period of 48 h using an L/S ratio of 5% (w/v), shows that at the higher acid molarity increased the leaching yields and concentrations of all metals reported in the solution. In addition, leaching at a higher temperature (80 °C) resulted in higher leaching yields. More specifically, leaching with 3 mol/L HNO3 at 80 °C for 24 h resulted in the highest extraction yields for Fe (100%), Zn (97%), and Cu (82%), elements which have the highest content in the slag. For most elements, HNO3 proved to be a slightly better leaching medium compared to H2SO4. Regarding other minor elements, with a low content varying between 0.05 and 0.4% (w/w) in the copper slag, leaching under these conditions resulted in 20% Pb, 38% Mo, 60% Ti, 70% Ni, 98% Co, 27% Sr, 35% Cd, 100% As, and 6.8% Mn extractions. Leaching of Sn and Sb did not follow a good trend, probably due to interferences during measurement with other ions present in the solution. No clear differences were shown during leaching between 24 and 48 h.

In order to improve the economics of the process, additional reactor tests with higher L/S ratios (20% and 30% (w/v)) using 3 and 5 mol/L HNO3 or 1.5 and 2.5 mol/L H2SO4 were carried out for 24 h at 80 °C. Samples were taken after 3, 6, and 24 h and analysed by ICP-MS. Leaching with 3 mol/L HNO3 (L/S of 20% and 30%) resulted in high solubilisation of metals, more specifically 80% Fe, 60% Zn, 90% As, 80% Co, 60% Ni, and 70% Cu. Lower solubilisation was noticed for the minor elements (15% Mo, 13% Ti, 10% Pb, and 10% Cr). The L/S ratio did not have any significant effect on leaching with HNO3. Leaching with 1.5 mol/L H2SO4 and an L/S ratio of 30% (w/v) resulted in the formation of a gelatinous phase, such as orthosilicic acid (H4SiO4), which prevented good stirring of the pulp as well as liquid–solid separation by filtration. Leaching with 2.5 mol/L H2SO4 and 5 mol/L HNO3 under the same experimental conditions was also performed, but after 1 h a gelatinous phase was formed, and the experiments were abandoned.

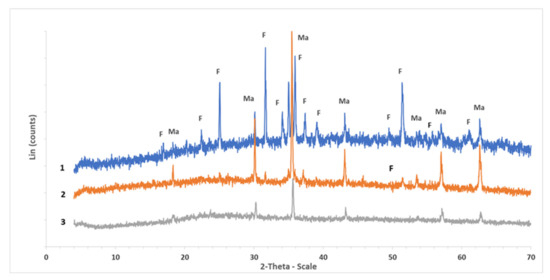

After leaching with HNO3, the residue was subjected to chemical and mineralogical analyses, while its toxicity was also assessed. The XRD patterns (Figure 2) indicate that the leach residue contained mainly magnetite, whereas most fayalite peaks diminished or disappeared. The copper slag residue after leaching with 3 mol/L HNO3 showed a much lower content of all the elements compared to the as-received sample and, based on the TCLP test, it is characterized as non-toxic (Table 3). The EN 12457-3 test results using an L/S ratio of 2 (Table 4) show that copper slag cannot be accepted in any landfill except in those accommodating inert wastes, since the content of Zn, Ni and Sb exceeded the respective limits. However, based on the EN 12457-3 L/S 10 results, most of the elements, except Sr and Sn, which had a slightly increased content in the leachate, exhibited lower solubilisation from the residue compared to the as-received slag. Slag leach residues cannot be accepted in landfills for inert or non-hazardous wastes since several elements, namely Ni, Cu, Zn, As, Mo, Sb, and Pb, exceed the respective limits. Slag leach residues cannot be accepted in landfills for non-hazardous wastes, since Ni (slightly), Zn, and Sb exceeded the limits. However, they can be accepted in landfills for hazardous wastes. The NEN test results indicated that the solubility of most elements has been markedly reduced and only Cu and Zn showed elevated solubilisation (Table 5). Considering the results from both the chemical leaching and environmental characterization tests, it can be deduced that the copper slag leach residues exhibit a substantially decreased solubilisation of most elements. The chemical composition of the copper slag in the form of oxides is shown in Table 2, while its mineralogical analysis is shown in Figure 1.

Figure 2.

XRD patterns of (1) fayalitic slag; (2) residue obtained after leaching with 1.5 mol/L H2SO4 (80 °C, 24 h, and L/S: 0.05); and (3) residue obtained after leaching with 3 mole/L HNO3 (80 °C, 24 h, and L/S: 0.30).

3.4. Bioleaching

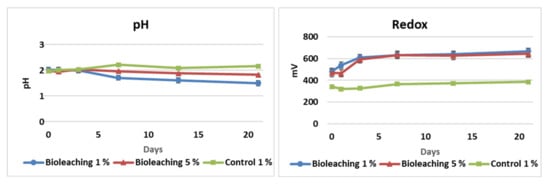

In the shake flask experiments, the pH decreased to near 1.5 and the redox potential increased to above 600 mV in the inoculated samples, whereas in the chemical control tests the pH tended to increase and the redox potential remained below 400 mV (Figure 3). Ferrous iron concentrations remained low in the inoculated samples due to biological iron oxidation, whereas in the non-inoculated tests, the ferrous iron concentration exceeded 1300 mg/L. The highest bioleaching yields were reported for Cu (71%), Zn (41%) and Co (49%) (Table 6). However, the leached metal concentrations were clearly higher with a pulp density of 5% compared to the pulp density of 1% (101 mg/L vs. 24 mg/L for Cu, 180 mg/L vs. 87 mg/L for Zn, and 7.8 mg/L vs. 3.4 mg/L for Co), since the higher pulp density provided five times more metals for leaching. The chemical control test resulted in slightly higher yields than the biological configurations (Table 6). However, the H2SO4 consumption to maintain a pH near 2 was 5 times higher for the chemical control test compared to the inoculated flask tests.

Figure 3.

pH and redox potential in the shake flask bioleaching experiments.

Table 6.

Metal yields in the shake flask bioleaching experiments of copper slag after 21 days.

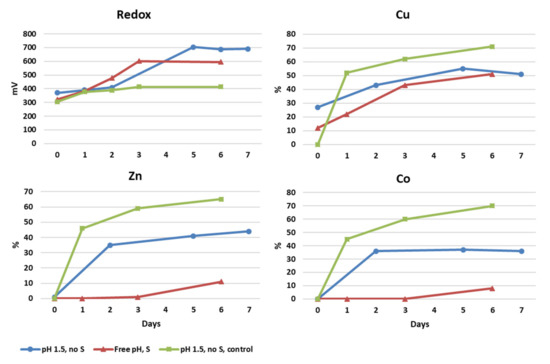

Before conducting the reactor experiments, the L/S ratio was gradually increased to 10% (w/v), level that can be considered as the lower limit for industrially relevant processes. Biological iron and sulphur oxidation remained high, when the L/S ratio was increased to 10% (w/v). The first reactor experiments showed that the friction caused by the gas liquid solid (GLS) impeller was very high for the biological system, thus a pitch blade-type impeller was used instead. The biological iron oxidation was successful, since in the bioleaching tests all iron was as Fe3+, whereas in chemical leaching the iron was present both as Fe2+ and Fe3+. The highest copper yield in the bioleaching was 51%, when the sulphur-oxidizing microorganisms produced sulphuric acid from the added sulphur or when the pH was adjusted to 1.5 with the addition of H2SO4 (Table 7; Figure 4). However, the leaching yields of the other metals were significantly higher (up to 58%) in the pH-controlled tests compared to those involving free adjustment of pH due to the microbial production of acidity (metal yields below 12%). In the pH-controlled bioleaching reactor, the redox potential increased to above +700 mV and the elemental yields for Zn, Co, and Cu reached 44%, 36%, and 51%, respectively. The selectivity index (concentration of target elements divided by concentration of undesirable elements) of the target elements (Zn, Co, and Cu) over Fe was low (selectivity index SI = 0.11); however, the filtration of the final reactor liquid was slow and is expected to be challenging at an industrial scale.

Table 7.

Metal yields (%) during bioleaching of the copper slag in the reactors (pulp density 10%, temperature 32 °C, and a blade impeller). Below detection limit (BD).

Figure 4.

Redox potential and metal yields of Cu, Zn, and Co in the 1 L reactor experiments at a 10% pulp density.

Despite the higher oxidative power prevailing in the bioleaching experiments (up to 700 mV compared to <415 mV), chemical leaching resulted in substantially higher Fe (71%), Cu (71%), Co (71%), and Zn (65%) dissolutions (Table 6 and Table 7; Figure 3 and Figure 4). The concentration of dissolved iron (23 g/L) in the chemical control tests was nearly three times higher than in the biological reactor (9 g/L) and this reduced substantially the selectivity index (SI = 0.08). In the bioleaching reactors, dissolved iron was oxidized completely from Fe2+ to Fe3+, while in the chemical leaching reactor iron remained as Fe2+. However, the increase in redox potential and oxidation degree of iron did not improve metal yields. Precipitation of iron jarosites was also noted at specific conditions and especially when the experiments were carried out at lower pulp densities and the concentration of Fe3+ was high.

3.5. Bioleach Residue as Supplementary Cementitious Material

The potential of the bioleach residue, obtained from tests with the highest leaching yield (pH control 1.5), for its use as SCM was investigated in order to enable full valorisation of the slag and decrease the environmental footprint of the entire process. The contribution of copper slag as SCM to the mortar performance was compared to the reference sample (without filler or SCM) and to the “filler” sample containing fine sand as 15% (w/w) or 30% (w/w) replacement of CAC. Although the role of SCM in early hydration is assumed limited because they are generally inert or slightly hydraulic, latent hydraulic, or pozzolanic materials, they may have a higher contribution after longer ageing periods. As the particle size of the bioleach residue is larger (d90: 526 µm) than that of the CAC, this should not act as filler.

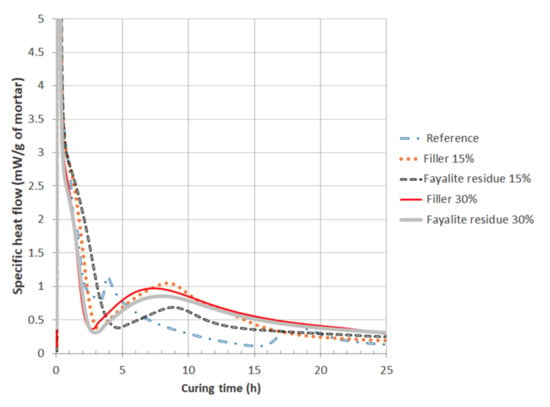

In terms of heat flow indicating the thermal events during the hydration process, the copper slag bioleach residue showed a similar profile to that of the filler sample; however, a slight delay in the second hydration peak after approximately 9 h of curing instead of 8 h, with a lower magnitude as well, was also noticed (Figure 5). Compared to the reference sample, which did not contain any SCM, the copper slag leach residue clearly exhibited an accelerating effect on the hydration kinetics for both the substitution rates examined, namely, 15% and 30%.

Figure 5.

Specific hydration heat flow for mortars containing copper slag leach residue as 15% or 30% replacement of CAC in comparison to reference mortars and mortars containing a filler.

Table 8 shows the results pertinent to the mechanical performance of the mortars containing copper slag bioleach residue, in terms of flexural and compressive strength. It is seen from this data that the mortars containing copper slag bioleach residue were at least equivalent or even better in terms of performance than the reference or filler sample at both the replacement rates of CAC used (15% and 30%).

Table 8.

Mechanical strength of mortars containing copper slag bioleach residue as SCM. Each value is an average of 2 values for the flexural strength and of 4 values for the compressive strength.

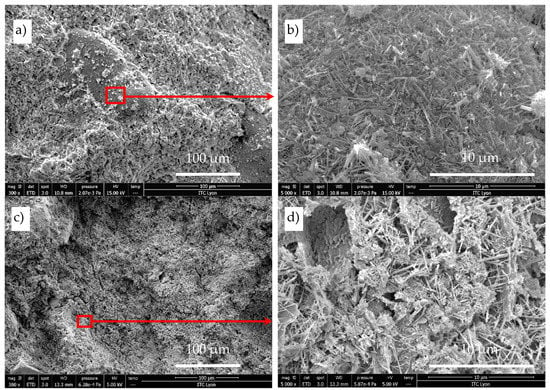

As the hydration process and hydration products are important factors for the final mechanical performance, the hydration of mortars in terms of content of bound water and type of hydration products was assessed after various periods of curing. The total percentage of bound water determined by TGA after 1 day (24 h) and 28 days of curing was 7.1% (w/w) and 8.6% (w/w) for the copper slag leach residue at a 15% replacement rate of CAC and 7.1% (w/w) and 7.5% (w/w) for the filler, respectively. Based on the XRD results, C3S was consumed from the copper slag residue, potentially resulting in the formation of a C–S–H binding gel that contributed substantially to the increase in the mechanical strength. However, this result was not expected, since the residue did not contain any element potentially involved in the formation of hydration products, such as ettringite and C–S–H in such systems. There was also no Ca present in the material but only a small quantity of soluble Si and Al. Yet, this sample contained the same type of hydrates, ettringite, and portlandite (CH) as the filler sample according to the XRD analysis. The TG results were consistent with the respective XRD data in terms of the presence of hydrated crystalline phases. Besides, Figure 6a–d shows the microstructure of the hardened samples of two mortars after 28 days of hydration. It is seen that the microstructure appears dense for both samples with a homogeneous and continuous matrix showing many hydrates, such as needle-like ettringite and probably portlandite and C–S–H (Figure 6a–d). In the case of the filler sample, the picture shows a quartz grain (Figure 6a) with a strong hydrate development on its surface (Figure 6b), suggesting a potential site of nucleation at the filler grains. Regarding the copper slag bioleach residues (Figure 6c,d), it is seen that in the prints of the particles left after sample breakage, hydrates develop intimately around the solid particles, suggesting numerous mechanical bonds between the aggregate grains and the matrix. Since the hydration process is ceased after a specific curing time by acetone, which is used to remove the residual free water, this type of water is not expected to participate in the weight loss calculated between 30 and 400 °C in the TG studies. The difficulty in assessing the total weight loss is due to the overlap of the TG/derivative thermogravimetry (DTG) signals of ettringite (Ett.), C–S–H and Ms (Monosulfate), whereas in the XRD patterns the types of crystalline hydrates, except the amorphous C–S–H phases, can be identified.

Figure 6.

Microstructure by SEM on surface fractures of filler 15% (a,b) and copper slag bioleach residue 15% (c,d) after 28 days of hydration.

4. Discussion

Based on the assessment that the slag is not suitable for disposal in landfills without prior treatment, chemical and biological leaching were carried out for the recovery of valuable metals. Leaching of copper slag with 2.5 mol/L H2SO4 and 5 mol/L HNO3 resulted in the formation of a gelatinous phase. The formation of a gelatinous phase causing problems during leaching and filtration was also reported in earlier studies investigating leaching of various types of slags with H2SO4 [26,27,28].

The highest bioleaching yields in the shake flasks were reported for Cu (71%), Zn (41%), and Co (49%) (Table 6), and are at a similar level compared to previous bioleaching shake flask studies. The existing literature has shown that the leaching yields of copper slags depend on the slag type and the experimental conditions used. In the study of Kaksonen et al. [11], bioleaching (10% (w/v) pulp density, pH 2.1–2.2, and 25 days) resulted in 70–83% Cu and 4–14% Zn extraction. Bioleaching with Acidithiobacillus thiooxidans (1% (w/v) pulp density, pH 2.5, 1–2 mm particle size, and 21 days) resulted in 81% Cu, 79% Zn, and 22% Fe dissolution [12]. The metal yields for Zn, Fe, Cu, and Ni were 30–80% on average, depending on the conditions [8]. In the study of Mikoda et al. [24], the metal yields after 28 days bioleaching of various copper slags (1% (w/v) pulp density, and 28 °C) were 88–100% Co, 40–44% Mo, 70–99% rare earth elements (REE), and 55–93% V. The results of Potysz and Kierczak [13] demonstrated that bioleaching of two different copper slags at a 1% pulp density over 21 days resulted in 99% and 52% Cu extraction, respectively.

Before conducting the bioleaching reactor experiments, the L/S ratio was gradually increased to 10% (w/v), a level that can be considered as the lower limit for industrially relevant processes. An increase in pulp density from 1% to 2% and 10% (w/v) significantly decreased the metal dissolution in the studies of Mikoda et al. [24] and Vestola et al. [8], respectively. Panda et al. [29] noted that the range of pulp densities from 15% to 25% resulted in a similar Cu extraction (~70%) from copper slag, whereas a lower pulp density (<15%) enables an almost 100% Cu extraction. In this study, biological iron and sulphur oxidation remained high, when the L/S ratio was increased to 10% (w/v).

The reactor bioleaching results, both in terms of yield and leaching kinetics (51% Cu, 36% Co, and 44% Zn in 7 days), compare favourably with previous stirred tank reactor bioleaching studies for copper slag. Stirred tank bioleaching at 10% (w/v) pulp density resulted in 44% Cu and 14% Zn leaching yields at pH 2.3–2.5, values which were clearly reduced after 37 days of contact time during operation at pH 2.5–3.0 [10]. In an earlier study [9], metal yields in a stirred tank reactor operating at 20–25 °C, a pH below 1 and 5% (w/v) pulp density were 41% for Fe, 62% for Cu, 35% for Zn, and 44% for Ni after 29 days of bioleaching.

Despite the higher oxidative power prevailing in the bioleaching experiments (up to 700 mV compared to <415 mV), chemical leaching resulted in substantially higher Fe (71%), Cu (71%), Co (71%), and Zn (65%) dissolutions (Table 6 and Table 7). The bioleaching results of the present study are very different compared to those mentioned in previous slag bioleaching studies [5], where the biotic conditions have always resulted in significantly higher metal recovery compared to abiotic conditions. The concentration of dissolved iron (23 g/L) in the chemical control tests was nearly three times higher than in the biological reactor (9 g/L) and this reduced substantially the selectivity index (SI = 0.08). In the bioleaching reactors, dissolved iron was oxidized completely from Fe2+ to Fe3+, while in the chemical leaching reactor iron remained as Fe2+. The beneficial effect of the biologically produced Fe3+ is well known and has been underlined in earlier studies investigating bioleaching of refractory arsenical gold sulphide concentrates [30]. Carranza et al. [31] and Muravyov et al. [7] used biologically produced ferric iron to accelerate copper leaching from copper slag. However, the increase in redox potential and oxidation degree of iron did not improve the metal yields, since leaching was not based on redox reactions or part of the leached metals precipitated. The generation of Fe3+ in bioleaching reactors most likely results in iron precipitation as jarosite or schwertmannite at low pH [32]; this confirmed by the fact that the concentration of iron decreased rapidly in the last days of the experiments. Precipitation of iron jarosites was also noted at specific conditions and especially when experiments carried out at lower pulp densities and the concentration of Fe3+ was high. Iron precipitation generates acid, which significantly decreases the acid consumption in bioleaching compared to chemical leaching tests. The decreased iron concentration also decreases the cost of chemical reagents and the volume of the waste generated in the subsequent PLS purification steps. However, useful elements may co-precipitate alongside with iron in the bioleaching experiments, resulting in lower metal yields.

Sulphur-oxidizing microorganisms produce acidity from the added sulphur, which results in decreased acid consumption. In the study of Vestola et al. [8], metal yields during bioleaching and chemical leaching of slag were comparable, but the acid consumption decreased in bioleaching, where the microorganisms produced sulphuric acid from elemental sulphur. Another alternative for future studies is the use of only sulphur-oxidizing microorganisms in bioleaching, since iron oxidation may result in decreased metal yields. The use of thermophilic bioleaching cultures can be justified only if the benefits overcome the cost of heating [5].

The results show that the bioleach residue can be used as SCM. So far, a rather limited number of studies are available in the literature regarding utilization of copper slags as SCM. Moura et al. [33] investigated the potential of copper slag as SCM in concrete. More recently, most of the available studies in the literature deal with the assessment of copper slags as SCM partially replacing OPC or as fine aggregate in concrete or mortars. In these studies, the advantageous contribution of copper slag to the performance of cement or concrete was generally attributed to either the filler effect or the pozzolanic activity, inducing a reduction of porosity [34,35] or an enhanced microstructure with a uniformly distributed and compact C–S–H gel [36], a higher consumption of Ca2+ ions for finer slags [37], or a higher durability [38]. However, none of those systems involved CAC addition to OPC, as in this study. Astoveza et al. [39] assessed the valorisation potential of the novel industrial by-products as SCM in CAC-based formulated binding systems, showing a significant interest for long-term performances. In a very recent study, it was also mentioned that the copper slag investigated in this paper, as such or after plasma treatment for the recovery of Fe- and Zn-rich products, exhibited a poor alkali activation potential, which was substantially increased after mixing with FeNi slag, a material that exhibits a higher pozzolanic activity [40]. Compared to the reference sample, which did not contain any SCM, the copper slag leach residue clearly exhibited an accelerating effect on the hydration kinetics for both substitution rates examined, namely, 15% and 30%. As a result, the residue did not affect the action of the CAC as an accelerator of the ordinary Portland cement (OPC) set [41]. The evaluation of abiotic leach residues as SCMs is also suggested for future studies.

5. Conclusions

The detailed environmental characterization of the as-received copper slag indicated that the slag (a) cannot be characterized as toxic according to the TCLP test; (b) based on the EN 12457-3 results, the slag cannot be disposed of in landfills unless prior treatment is carried out; and (c) based on the NEN test results, only three elements, namely Cu, Zn, and Pb, showed noticeable solubilisation. An additional issue that needs to be considered in similar studies is the harmonization of various environmental protocols, since their results cannot always be accurately interpreted to clearly assess the toxicity and the most appropriate disposal or management options of a specific material.

Based on the assessment that the slag is not suitable for disposal in landfills without prior treatment, chemical and biological leaching were carried out for the recovery of valuable metals. Chemical leaching with HNO3 resulted in higher solubilisation of several elements and prevented the formation of a gelatinous phase, unlike leaching with H2SO4. Chemical leaching was also more efficient at an increased temperature and higher acidity. Despite the clearly higher oxidative power in the bioleaching experiments, chemical leaching resulted in substantially higher Cu (71% vs. 51%), Co (70% vs. 36%), and Zn (65% vs. 44%) dissolution. However, the acid consumption was clearly lower in bioleaching compared to chemical control tests, thus decreasing the operating costs, while the leaching yields and kinetics were comparable to previous studies. The reason for lower leaching yields in the bioleaching tests is mainly related to the reduced iron dissolution or later co-precipitation of valuable metals alongside with iron. A new process option could combine chemical leaching and biological iron control, which could clearly decrease the consumption of chemical reagents, both in the extraction and recovery steps compared to the traditional leaching–precipitation process. In addition, the bioleach residue can be used as SCM, and the mortars produced exhibited a better compressive strength after 28 days (25.5–28.1 MPa) than the reference sample (13.8 MPa), while no detrimental effects to the CAC were noticed.

Conventionally, slags with high leachability can be valorised through leaching for metal recovery while those with low leachability for civil engineering applications. The results of this study prove that a complete valorisation of copper slags is feasible. They can be leached for the recovery of valuable metals, while the leach residues can be used as construction materials, thus improving the economics of the process and substantially reducing the footprint of the metallurgical and construction sectors, in line with the principles of a circular economy.

Author Contributions

Conceptualization, P.K.; writing—original draft preparation, P.K., J.M., M.S., R.S. and K.K.; writing—review and editing, P.K. and K.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by European Union’s Horizon 2020 Research and Innovation program, grant number 690088 METGROW PLUS, metgrowplus.eu.

Acknowledgments

We thank E. Kolehmainen from Outotec for the comminution of the copper slag, and R-M. Mineau, J-M. Bertino, and L. Saez from Imerys for the SCM laboratory work.

Conflicts of Interest

The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Shi, C.; Meyer, C.; Behnood, A. Utilization of copper slag in cement and concrete. Resour. Conserv. Recycl. 2008, 52, 1115–1120. [Google Scholar] [CrossRef]

- Gorai, B.; Jana, R.K. Characteristics and utilisation of copper slag-A review. Resour. Conserv. Recycl. 2003, 39, 299–313. [Google Scholar] [CrossRef]

- Marangoni, M.; Arnout, L.; Machiels, L.; Pandelaers, L.; Bernardo, E.; Colombo, P.; Pontikes, Y. Porous, sintered glass-ceramics from inorganic polymers based on fayalite slag. J. Am. Ceram. Soc. 2016, 99, 1985–1991. [Google Scholar] [CrossRef]

- Murari, K.; Siddique, R.; Jain, K.K. Use of waste copper slag, a sustainable material. J. Mater. Cycles Waste Manag. 2015, 17, 13–26. [Google Scholar] [CrossRef]

- Potysz, A.; van Hullebusch, E.D.; Kierczak, J. Perspectives regarding the use of metallurgical slags as secondary metal resources-A review of bioleaching approaches. J. Environ. Manag. 2018, 219, 138–152. [Google Scholar] [CrossRef]

- Tsiridis, V.; Petala, M.; Samaras, P.; Kungolos, A.; Sakellaropoulos, G.P. Environmental hazard assessment of coal fly ashes using leaching and ecotoxicity tests. Ecotoxicol. Environ. Saf. 2012, 84, 212–220. [Google Scholar] [CrossRef]

- Muravyov, M.I.; Fomchenko, N.V.; Usoltsev, A.V.; Vasilyev, E.A.; Kondrat’eva, T.F. Leaching of copper and zinc from copper converter slag flotation tailings using H2SO4 and biologically generated Fe2(SO4)3. Hydrometallurgy 2012, 119–120, 40–46. [Google Scholar] [CrossRef]

- Vestola, E.A.; Kuusenaho, M.K.; Närhi, H.M.; Tuovinen, O.H.; Puhakka, J.A.; Plumb, J.J.; Kaksonen, A.H. Acid bioleaching of solid waste materials from copper, steel and recycling industries. Hydrometallurgy 2010, 103, 74–79. [Google Scholar] [CrossRef]

- Kaksonen, A.H.; Lavonen, L.; Kuusenaho, M.; Kolli, A.; Närhi, H.; Vestola, E.; Puhakka, J.A.; Tuovinen, O.H. Bioleaching and recovery of metals from final slag waste of the copper smelting industry. Miner. Eng. 2011, 24, 1113–1121. [Google Scholar] [CrossRef]

- Kaksonen, A.H.; Särkijärvi, S.; Puhakka, J.A.; Peuraniemi, E.; Junnikkala, S.; Tuovinen, O.H. Chemical and bacterial leaching of metals from a smelter slag in acid solutions. Hydrometallurgy 2016, 159, 46–53. [Google Scholar] [CrossRef]

- Kaksonen, A.H.; Särkijärvi, S.; Peuraniemi, E.; Junnikkala, S.; Puhakka, J.A.; Tuovinen, O.H. Metal biorecovery in acid solutions from a copper smelter slag. Hydrometallurgy 2017, 168, 135–140. [Google Scholar] [CrossRef]

- Potysz, A.; Lens, P.N.L.; van de Vossenberg, J.; Rene, E.R.; Grybos, M.; Guibaud, G.; Kierczak, J.; van Hullebusch, E.D. Comparison of Cu, Zn and Fe bioleaching from Cu-metallurgical slags in the presence of Pseudomonas fluorescens and Acidithiobacillus thiooxidans. Appl. Geochem. 2016, 68, 39–52. [Google Scholar] [CrossRef]

- Potysz, A.; Kierczak, J. Prospective (bio)leaching of historical copper slags as an alternative to their disposal. Minerals 2019, 9, 542. [Google Scholar] [CrossRef]

- US EPA. TCLP (Toxicity Characteristics Leaching Procedure), Method 1311, Revision 2, July 1992. Available online: https://www.epa.gov/sites/production/files/2015-12/documents/1311.pdf (accessed on 11 May 2020).

- CEN. Characterization of Waste – Compliance Test for Leaching of Granular Waste Materials and Sludges-Part 3: Two Stage Batch Test at a Liquid to Solid Ratio of 2 l/kg and 8 l/kg for Materials with High Solid Content and with Particle Size below 4 mm; EN12457-3:2002; CEN: Brussels, Belgium, 2002. [Google Scholar]

- Centioli, D.; Rob, N.J.; Comans, R.N.J.; Gaudino, S.; Galas, C.; Belli, M. Leaching tests: Useful tools for the risk assessment of contaminated sediments. Ann. Ist. Super. Sanità 2008, 44, 252–257. [Google Scholar]

- Van der Sloot, H.A.; Hjelmar, O.; Bjerre Hansen, J.; Woitke, P.; Lepom, P.; Leschber, R.; Bartet, B.; Debrucker, N. Validation of CEN/TC 292 Leaching Tests and Eluate Analysis Methods prEN 12457 1-4, ENV 13370 and ENV 12506 in co-operation with CEN/TC 308, Energy Research Centre of the Netherlands (ECN), Report Number ECN-C--01-117, Petten, The Netherlands. 2001. Available online: https://publicaties.ecn.nl/PdfFetch.aspx?nr=ECN-C--01-117 (accessed on 18 May 2020).

- Baun, E.N.; Holm, J.; Hansen, J.B.; Wahlström, M. CEN EN 12457 leaching test: Comparison of test results obtained by part 1 and 2 with test results obtained by part 3. Nordtest Report TR 539, approved 2003-10, Finland. 2003. Available online: http://www.nordtest.info/index.php/technical-reports/item/cen-en-12457-leaching-test-comparison-of-test-results-obtained-by-part-1-and-2-with-test-results-obtained-by-part-3-nt-tr-539.html. (accessed on 11 May 2020).

- Nederlands Normalisatie Instituut (NNI). Leaching Characteristics of Solid Earthy and Stony Building and Waste Materials-Leaching Tests: Determination of the Availability of Inorganic Components for Leaching, 1st ed.; NEN 7341; ICS 13.030-70;91.100; Nederlands Normalisatie Instituut (NNI): Delft, The Netherlands, 1995. [Google Scholar]

- European Commission. Council Decision of 19 December 2002 Establishing Criteria and Procedures for the Acceptance of Waste at Landfills Pursuant to Article 16 of and Annex II to Directive 1999/31/EC; European Commission: Brussels, Belgium, 2003. [Google Scholar]

- Silverman, M.P.; Lundgren, D.G. Studies on the chemoautotrophic iron bacterium ferrobacillus ferrooxidans. I. An improved medium and a harvesting procedure for securing high cell yields. J. Bacteriol. 1959, 77, 642–647. [Google Scholar] [CrossRef]

- American Public Health Association. Standard Methods for the Examination of Water and Wastewater, 20th ed.; Clesceri, L.S., Greenberg, A.E., Eaton, A.D., Eds.; American Public Health Association: Washington, DC, USA, 1998. [Google Scholar]

- CEN. Method of Testing Cement-Part 2: Chemical Analysis of Cement; CEN-EN 196-2; CEN: Brussels, Belgium, 2013. [Google Scholar]

- Mikoda, B.; Potysz, A.; Kmiecik, E. Bacterial leaching of critical metal values from Polish copper metallurgical slags using Acidithiobacillus thiooxidans. J. Environ. Manag. 2019, 236, 436–445. [Google Scholar] [CrossRef]

- Piatak, N.M.; Parsons, M.B.; Seal, R.R., II. Characteristics and environmental aspects of slag: A review. Appl. Geochem. 2015, 57, 236–266. [Google Scholar] [CrossRef]

- Zhang, Y.; Hua, Y.; Gao, X.; Xu, C.; Li, J.; Li, Y.; Zhang, O.; Xiong, L.; Su, Z.; Wang, M.; et al. Recovery of zinc from a low-grade zinc oxide ore with high silicon by sulfuric acid curing and water leaching. Hydrometallurgy 2016, 166, 16–21. [Google Scholar] [CrossRef]

- Kazadi, D.M.; Groot, D.R.; Steenkamp, J.D.; Pöllmann, H. Control of silica polymerization during ferromanganese slag sulphuric acid digestion and water leaching. Hydrometallurgy 2016, 166, 214–221. [Google Scholar] [CrossRef]

- Davris, P.; Stopic, S.; Balomenos, E.; Panias, D.; Paspaliaris, I.; Friedrich, B. Leaching of rare earth elements from eudialyte concentrate by suppressing silica gel formation. Miner. Eng. 2017, 108, 115–122. [Google Scholar] [CrossRef]

- Panda, S.; Mishra, S.; Rao, D.S.; Pradhan, N.; Mohapatra, U.; Angadi, S.; Mishra, B.K. Extraction of copper from copper slag: Mineralogical insights, physical beneficiation and bioleaching studies. Korean J. Chem. Eng. 2015, 32, 667–676. [Google Scholar] [CrossRef]

- Komnitsas, C.; Pooley, F.D. Optimization of the bacterial oxidation of an arsenical gold sulphide concentrate from Olympias, Greece. Miner. Eng. 1991, 4, 1297–1303. [Google Scholar] [CrossRef]

- Carranza, F.; Romero, R.; Mazuelos, A.; Iglesias, N.; Forcat, O. Biorecovery of copper from converter slags: Slags characterization and exploratory ferric leaching tests. Hydrometallurgy 2009, 97, 39–45. [Google Scholar] [CrossRef]

- Komnitsas, K.; Bartzas, G.; Paspaliaris, I. Efficiency of limestone and red mud barriers: Laboratory column studies. Miner. Eng. 2004, 17, 183–194. [Google Scholar] [CrossRef]

- Moura, W.A.; Goncalves, J.P.; Lima, M.B.L. Copper slag waste as a supplementary cementing material to concrete. J. Mater. Sci. 2007, 42, 2226–2230. [Google Scholar] [CrossRef]

- Edwin, R.S.; Gruyaert, E.; Dils, J.; De Belie, N. Influence of vacuum mixing on the carbonation resistance and microstructure of reactive powder concrete containing secondary copper slag as Supplementary Cementitious Material (SCM). Procedia Eng. 2017, 171, 534–542. [Google Scholar] [CrossRef]

- Edwin, R.S.; Gruyaert, E.; De Belie, N. Influence of intensive vacuum mixing and heat treatment on compressive strength and microstructure of reactive powder concrete incorporating secondary copper slag as supplementary cementitious material. Constr. Build. Mater. 2017, 155, 400–412. [Google Scholar] [CrossRef]

- Sharma, R.; Khan, R.A. Sustainable use of copper slag in self compacting concrete containing supplementary cementitious materials. J. Clean. Prod. 2017, 151, 179–192. [Google Scholar] [CrossRef]

- Edwin, R.S.; De Schepper, M.; Gruyaert, E.; De Belie, N. Effect of secondary copper slag as cementitious material in ultra-high performance mortar. Constr. Build. Mater. 2016, 119, 31–44. [Google Scholar] [CrossRef]

- Gupta, N.; Siddique, R. Durability characteristics of self-compacting concrete made with copper slag. Constr. Build. Mater. 2020, 247, 118580. [Google Scholar] [CrossRef]

- Astoveza, J.; Trauchessec, R.; Soth, R.; Salminen, J.; Pontikes, Y. Assessing the reactivity of industrial by-products in calcium aluminate cement-based formulations. In Proceedings of the 6th International Slag Valorisation Symposium, Science, Innovation & Entrepreneurship in Pursuit of a Sustainable World, Mechelen, Belgium, 1–5 April 2019; Malfliet, A., Peys, A., Di Maria, A., Eds.; KU Leuven, Materials Engineering: Leuven, Belgium, 2019. [Google Scholar]

- Komnitsas, K.; Yurramendi, L.; Bartzas, G.; Karmali, V.; Petrakis, E. Factors affecting co-valorization of fayalitic and ferronickel slags for the production of alkali activated materials. Sci. Total Environ. 2020, 721, 137753. [Google Scholar] [CrossRef] [PubMed]

- Nehring, J.; Neubauer, J.; Berger, S.; Goetz-Neunhoeffer, F. Acceleration of OPC by CAC in binary and ternary systems: The role of pore solution chemistry. Cem. Concr. Res. 2018, 107, 264–274. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).