Abstract

Many studies have been published in recent years focusing on the recovery of rare earth elements (REEs) from coal-related materials, including coal, coal refuse, coal mine drainage, and coal combustion byproducts particularly fly ash. The scientific basis and technology development have been supported by coal geologists and extractive metallurgists, and through these efforts, the concept has progressed from feasibility assessment to pilot-scale production over the last five years. Physical beneficiation, acid leaching, ion-exchange leaching, bio-leaching, thermal treatment, alkali treatment, solvent extraction, and other recovery technologies have been evaluated with varying degrees of success depending on the feedstock properties. In general, physical beneficiation can be a suitable low-cost option for preliminary upgrading; however, most studies showed exceedingly low recovery values unless ultrafine grinding was first performed. This finding is largely attributed to the combination of small RE-bearing mineral particle size and complex REE mineralogy in coal-based resources. Alternatively, direct chemical extraction by acid was able to produce moderate recovery values, and the inclusion of leaching additives, alkaline pretreatment, and/or thermal pretreatment considerably improved the process performance. The studies reviewed in this article revealed two major pilot plants where these processes have been successfully deployed along with suitable solution purification technologies to continuously produce high-grade mixed rare earth products (as high as +95%) from coal-based resources. This article presents a systematic review of the recovery methods, testing outcomes, and separation mechanisms that are involved in REE extraction from coal-related materials. The most recent findings regarding the modes of occurrence of REEs in coal-related materials are also included.

1. Introduction

Rare earth elements (REEs) including the 15 lanthanides plus yttrium and scandium have been identified as critical commodities by several international agencies and national governments due to their crucial roles in clean energy, high tech, and national defense industries [1,2,3]. REEs scarcely form natural ore depositsthat are economically recoverable. As a result, only a few commercial deposits are currently being extracted worldwide. This combination of restricted supply and critical need has prompted many public and private entities to evaluate alternative REE sources. Coal-related materials, including coal refuse, coal fly ash, and coal mine drainage have been identified as a potentially promising resource. The average REE contents in lignite and bituminous coals as well as lignite and bituminous coal ashes worldwide have been estimated to be around 69, 72, 378, and 469 ppm, respectively [4]. Many coal deposits with elevated REE contents have been found and reported in the literature [5,6,7,8]. REE concentration in coal mine drainage varies from site-to-site, ranging from several ppb to ppm levels [9,10].

Recovering REEs from coal-related materials has several advantages over commercial rare earth ores: (1) coal-related materials contain more heavy and critical REEs (HREEs and CREEs) relative to the light REEs (LREEs) [5,10]; (2) the mining costs are negligible since REEs can be produced as byproducts from the coal production and utilization processes [11]; (3) coal-based materials, particularly coal mine drainage, tend to have lower concentrations of radionuclide (e.g., U and Th) when compared to traditional ore deposits [12]; and (4) REE recovery from coal materials has the potential to mitigate or eliminate legacy environmental issues [13]. The concept has been discussed in several review articles [5,14,15,16]; however, these articles have primarily addressed geologic considerations, such as depositional settings and resource characteristics.

To this end, the U.S. Department of Energy initiated research and development efforts in 2014 to evaluate the technical and economicviability of extracting REEs from coal-related materials with a particular focus on technology maturation and process development [17]. During the last five years, the extraction of REEs from coal-related materials has progressed through feasibility assessment, field sampling and characterization, bench-scale REE separation, and pilot-scale REE production stages. During this period, many innovative findings concerning the recovery of REEs from coal-related materials have been published, which significantly contributed to the scientific knowledge in this area [11,12,18,19,20,21,22,23,24,25,26]. A review article focused on promising methods for REE recovery from coal and coal byproducts was published by the authors of [27] in 2015. However, experimental results and findings were limited at that time. Considerable developments in this area since 2015 led to a need for another review in order to cover the latest findings.

This review article summarizes technical information regarding process flowsheets, metallurgical performance, and economical metrics of the various methods that have been developed for REE extraction from coal-related materials. This review will provide comparative data to prompt further study and analysis in this area. The review is divided into three sections based on the types of the coal-related materials that were investigated as reported in the literature, i.e., coal and coal refuse, coal combustion ash, and acid mine drainage. Recent findings regarding the modes of occurrence of REEs in coal-related materials and how these findings inform process design are also covered.

2. REEs in Coal and Coal Refuse

The geological aspects such as accumulation mechanisms and modes of occurrence of REEs in coal and coal refuse have been extensively investigated by coal geologists, and these topics have been systematically reviewed in several prior publications [5,14,15,28,29]. Therefore, this article only focuses on the recovery aspect of REEs from coal and coal refuse.

2.1. Physical Beneficiation of REEs from Coal and Coal Refuse

Several studies have been performed to concentrate rare earth (RE)-bearing mineral particles from coal and coal refuse using physical beneficiation techniques such as gravity, magnetic, and flotation separations [11,20,30,31,32,33,34]. Table 1 summarizes some of the beneficiation performances. It is worth noting that decarbonization is normally conducted prior to REE beneficiation, which enables the production of clean coal. A systematic study was performed by Honaker et al. [35] to evaluate the viability of using physical separation methods (riffle table, multi-gravity, and wet high intensity magnetic separations as well as froth flotation) to concentrate rare earth minerals from coal and coal refuse, and representative test results are shown in Table 1. With respect to gravity-based separations, the REEs were only enriched by a factor of 1.1 using a riffle table, and the separation performance was still unsatisfactory when using a multi-gravity separator. This finding has been corroborated by a separate study performed by another group of researchers [24]. Physical separations (size, density, and magnetic) performed on a clean coal sample collected from Kentucky, USA showed that a maximum enrichment ratio of 1.21 was obtained. As such, a high degree of enrichment of rare earth minerals from coal and coal refuse is difficult using physical separation methods.

Table 1.

A summary of physical beneficiation of rare earth minerals from coal and coal refuse.

Froth flotation is normally utilized to treat fine particles based on their varying degrees of surface hydrophobicity. Rare earth mineral particles present in decarbonized thickener underflows of coal preparation plants can be selectivily recovered by froth flotation. As shown in Table 1, concentrates containing 2300 and 4700 ppm of REEs were obtained by using multiple treatment stages involving conventional flotation cells and column flotation, respectively. A limited concentration was also obtained when using a single-stage of flotation. For example, REEs in the decarbonized thickener underflow derived from treating Eagle seam coal was concentated by nearly two times with the flotation product containing 367 ppm of REEs on a dry whole sample basis (see Table 1). Oleic acid was used as the collector for the flotation test results shown in Table 1, which has been widely used to recover rare earth minerals (e.g., monazite and xenotime) from heavy mineral sands [36,37].

As an alternative to flotation, the hydrophobic–hydrophilic separation (HHS) process is a novel ultrafine particle concentrator that provides improved recovery of micron-size material while also providing a dewatered product [38]. The process uses hydrocarbon oils to agglomerate hydrophobic particles and recover the particles through a phase separation. As shown in Table 1, a concentrate containing 17,428 ppm of REEs was obtained from the Fire Clay decarbonized thickener underflow using HHS. Octylhydroxamate was used as the collector, which is another commonly used reagent for rare earth mineral beneficiation [39,40]. The enrichment ratio of the HHS test reached as high as 53:1. In addition to the aforementioned gravity separation and flotation studies, a concentrate containing 7,000 ppm of REEs was also obtained from the decarbonzied Fire Clay middlings using high-intensity magnetic separation [20].

Overall, rare earth minerals in the decarbonized materials can be concentrated by using flotation, HHS, and magnetic separations. However, the recovery values obtained using these technologies are often too low to be economically viable. One explanation for this consistent finding is that RE-bearing particles in coal and coal refuse are extremely fine and often interlocked within the host-particles. SEM characterizations showed that RE-enriched particles occurring in coal refuse and middlings normally have a particle size of <10 µm [20,33]. In this case, extensive grinding is required to liberate the encapsulated rare earth particles, thereby making the operating process cost prohibitive [23]. However, physical separations without significant size reduction can be employed to generate a higher-grade feedstock for downstream recovery and purification processes.

2.2. Chemical Extraction

Given the low recovery and subsequent high production costs associated with physical beneficiation, direct chemical extraction of REEs from coal refuse has been evaluated by a number of researchers [11,20,21,25,41,42,43]. Moreover, thermal and alkaline treatments prior to acid leaching have also been used to improve the REE leachability [21,44,45,46,47]. These technologies have included acid leaching, salt/ion exchange leaching, and leaching with pretreatment, which are reviewed in the following sections.

2.2.1. Salt and Acid Leaching

In the commerical production of REEs from ion-adsorbed clays, ammonium sulfate is commonly used as a salt lixiviant due to the relatively low hydration energy of ammonium ions. Rozelle et al. [48] collected two high-ash content samples from the overlying strata of the Upper Kittanning bed. The samples were crushed and screened to obtain the 595 μm × 150 μm fraction for salt leaching tests. It was found that around 80% of the total REEs were extracted from the solid, which provided promise as an economically viable option. However, in subsequent investigations performed by other researchers, only a small fraction (e.g., 10%) of the total REEs were determined to be ion-exchangeable in the components of the other coal deposits [41,49]. Given these disparate findings, successful extraction of REEs from coal and coal refuse using salt leaching largely depends on the nature of coal deposit.

REEs can be efficiently extracted using acid solutions of relatively low concentration from some coal sources. Laudal et al. successfully extracted nearly 90% of total REEs from a lignite using 0.5 M H2SO4 [25]. The high recovery was explained by the fact that the REEs in the lignite are primarily complexed with organic acids, and the complexation can be destroyed under mild acidic conditions. For bituminous coals, sytematic acid leaching studies have been condcuted on decarbonized middlings, fine refuse, and coarse refuse produced from the treatment of coals originating from different seams [11,20,43,50,51]. It was found that REEs in the mineral matter of coal middlings obtained by grinding and flotation were more leachable than those in coal refuse. For example, nearly 83% of REEs were leached from the decarbonized Fire Clay middlings using a nitric acid solution of pH 0 at 75 °C, whereas less than 30% of REEs were extracted under the same conditions from the decarbonized thickener underflow [11]. However, liberation of the mineral matter from coal middlings consumes a significant amount of energy, which requires consideration for determining economic viability [23].

Improvements in the REE leaching efficiency from coal refuse have been achieved by optimizing the operation parameters such as particle size, temperature, and leaching duration. REE recovery values were relatively low (<30%) for most of the investigated sources [11]. A summary of salt and acid leaching of REEs from coal and coal refuse is shown in Table 2. Overall, direct leaching with salt or acid failed to provide satisfactory recovery from high-rank coal and coal refuse, whereas, direct leaching is a promising choice for recovering REEs from low-rank coal. Therefore, thermal and/or alkaline pretreatment has been utilized in subsequent studies to improve the leaching performance.

Table 2.

A summary of salt and acid leaching of rare earth elements (REEs) from coal and coal refuse.

2.2.2. Alkali and Thermal Pretreatment

Alkali and thermal pretreatments of coal and coal refuse have been applied to enhance the acid leaching recoveries of REEs from coal and coal refuse [21,41,44,47,52,53]. A summary of the relevant studies reported in the literature is provided in Table 3. Yang et al. used an 8 M NaOH solution to treat decarbonized fine refuse at 75 °C for two hours prior to acid leaching [41]. It was found that the recovery of REEs was significantly increased from 22% to 75% due to the positive impact on the leachability of the light REEs. Under the same experimental conditions, a small incremental increase in recovery was achieved for the HREEs (38% to 48%). Kuppusamy et al. conducted a study of simultaneous production of clean coal and REEs by alkali-acid leaching of a coal fine refuse material [52]. The ash content of the material was reduced from 46.21% to 14.17% after treatment with a NaOH solution (30 wt.%) at 190 °C for 30 min followed by an HCl solution (7.5 wt.%) at 50 °C for 30 min. Simultaneously, 97% of the LREEs and 76% of the HREEs occurring in the material were extracted.

Table 3.

Summary of the thermal and alkaline pretreatment effects on the leaching recoveries of REEs from coal and coal refuse.

The enhanced leaching efficiency of REEs resulting from alkali treatment was explained by two mechanisms: (1) Difficult-to-leach rare earth minerals such as monazite were converted to more leachable forms [27,41] and (2) Crystal structures of the dominant minerals such as clays were destroyed resulting in liberation of the encapsulated rare earth minerals [52]. The reactions are as follows:

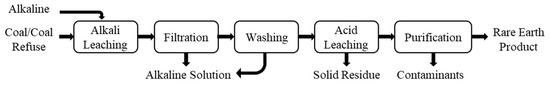

A schematic diagram incorporating the use of the alkali-acid leaching process to extract REEs from coal and coal refuse is shown in Figure 1. A negative aspect of the alkali leaching step is the considerable amount of contaminants dissolved into solution along with the REEs, which complicates the downstream purification process. Another negative aspect is the chemical cost, which will likely be prohibitively high given the relatively low content of REEs in coal-based feedstock. Additional studies need to be performed to investigate the possibility of selectively increasing the REE leachability using diluted alkaline solutions and/or weak alkalis.

Figure 1.

Schematic diagram of the alkaline-acid leaching process to extract REEs from coal and coal refuse [52].

Another scenario to enhance the REE leachability from coal and coal refuse is thermal activation, also known as calcination or roasting [21,41,44,46,47,54]. As reported by Zhang et al., after thermal activation of a coal gangue material at 700 °C for 30 min, 88.6% of the total REEs were leached using 25% HCl at room temperature [46]. The impact of thermal activation on REE leachability has been systematically studied [21,47,54]. As shown in Table 3, for both the clean coal and coal refuse, calcination under 600 °C in static atmosphere without adding any additives significantly improved the REE leaching recovery. For example, the total REE recovery from Pocahontas No. 3 coarse refuse was increased from 14% to 81% by thermal activation using 1.2 M HCl as a lixiviant. In addition, moderate recovery values were also obtained when using mildly acidic conditions. Reducing the acidity by twenty times, i.e., 1.2 M HCl to 0.06 M HCl, resulted in a relatively small drop in REE recovery for thermally activated Pocahontas No. 3 coarse refuse to around 60% [21]. As such, acid consumption is significantly reduced, which is typically the highest cost component of a rare earth extraction process.

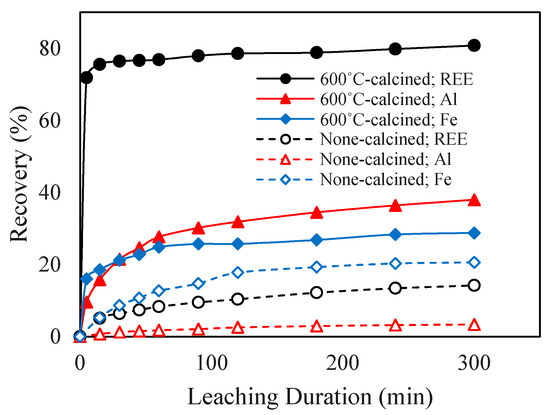

Another advantage of thermal activation is that fewer contaminants are dissolved relative to the REEs. During the calcination process, pyrite began to decompose and was converted to iron oxide (primarily hematite) in the temperature range of 400–500 °C. The crystallinity of hematite increased with the elevation in calcination temperature [21,55,56]. When calcined under high temperature, inter-layered structures of clay minerals, especially kaolinite, were destroyed due to dehydration, resulting in disintegration into thin slices and an increase in surface area [21,57,58]. The overall impact of the mineralogical changes was that Al leachability was noticeably increased, while Fe leachability was slightly increased (see Figure 2). However, as shown in Figure 2 the leaching duration can be shortened to less than 15 min, within which the REE leaching reaction is nearly completed while leaching of Al and Fe is minimal. Therefore, a pregnant leaching solution (PLS) containing relatively higher concentrations of REEs can be produced using the thermal activation-mild acid leaching process.

Figure 2.

Effects of calcination on the leaching kinetics of REEs, Al, and Fe from Pocahontas No. 3 coarse refuse. (Data were extracted from [21]).

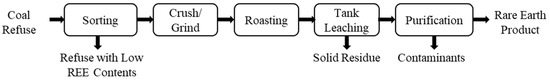

The aforementioned process has been installed and is currently under testing in a rare earth pilot plant funded by the U.S. Department of Energy [59]. A schematic diagram of the process used in the plant is shown in Figure 3. During the testing process, it was found that organic matter associated with the coal refuse helped maintain a constant temperature in the roaster, thus, significantly reducing the energy costs associated with the roaster. In addition to REEs, recent studies [54,60] showed that leaching recovery of other critical metals such as lithium from coal refuse was also positively impacted by calcination. Therefore, given the aforementioned benefits, pre-leach calcination combined with mild acid leaching is one of the most promising approaches for recovering REEs from coal-related materials.

Figure 3.

A simplified block diagram of the REE recovery process used in a REE pilot plant located in west Kentucky.

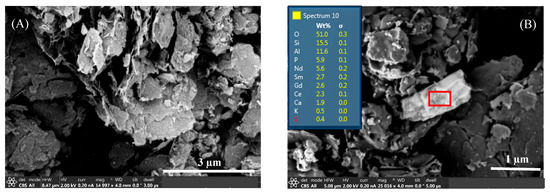

Several mechanisms have been proposed for the positive impacts of thermal activation on REE extraction from coal, i.e.,: (1) Surface area increase resulting from clay dehydration, which liberates some rare earth minerals; (2) Decomposition of the difficult-to-leach rare earth minerals; and (3) Release of a portion of the REEs that were originally associated with the organic matter, which was removed after calcination [21,42,53]. Figure 4 shows the disintegrated kaolinite particles and a REE-enriched particle present in a thermally activated coal refuse sample. Sequential chemical extraction tests have been performed on the calcination products of clean coals of West Kentucky No. 13, Fire Clay, and Illinois No. 6 [47]. It was found that a significant fraction of REEs (50% for the West Kentucky No. 13 material) existed as metal oxides, which originated from the removal of the organic matter present in the clean coals and the decomposition of the difficult-to-leach rare earth minerals.

Figure 4.

SEM-EDX images of a coal coarse refuse sample after thermal activation: (A) Disintegrated kaolinite particles; (B) A REE-enriched particle. [21].

Despite the aforementioned advantages, a few technical and fundamental problems must be resolved to fully validate the approach. As shown in Table 3, the improvements in the HREE recoveries are much smaller than those of the LREEs and elevating the calcination temperature did not enhance the recovery due to the sintering of aluminum silicates [21]. In addition, mineralogical changes of the REEs during calcination is still unclear. Previous studies only listed some possible mechanisms, whereas the direct evidence in supporting the conclusions has not been obtained to date.

3. REE Recovery from Coal Combustion Byproducts

3.1. Modes of Occurrence of REEs in Coal Combustion Ash

Coal combustion fly ash is composed of both amorphous and crystalline phases. The amorphous phases account for 60–90% of bulk fly ash composition, while crystalline material accounts for the remainder [61]. The crystalline phases mainly include quartz, mullite, hematite, magnetite, ferrite spinels, anhydrite, melilite, merwinite, periclase, tricalcium aluminate, and lime [62,63,64]. Until recently, researchers have found limited success in characterizing the amorphous phases of fly ash due to its disordered nature and heterogeneity [61]. This characteristic along with the low concentration and dispersed nature of REEs have caused difficulties in characterizing the modes of occurrence of REEs in fly ash using traditional approaches. However, many recent studies have addressed this challenge using advanced characterization tools, such as X-ray Absorption Near Edge Structure (XANES), micro-X-Ray Absorption Near Edge Structure (μ-XANES), laser ablation inductively coupled plasma mass spectroscopy (LA-ICP-MS), multimodal image analysis, and sensitive high resolution ion microprobe–reverse geometry SHRIMP-RG [65,66,67,68,69,70]. In addition, systematic SEM-EDX, TEM-EDX, and sequential chemical extraction (SCE) studies have been performed on coal combustion ashes, which also provided valuable information regarding the REE occurrence modes and potential processing routes [71,72,73,74,75,76,77,78].

Sequential chemical extraction (SCE) tests performed on several class F-type fly ash [79] samples (SiO2% + Al2O3% + Fe2O3% > 70%) showed that the majority of REEs were associated with silicates and aluminosilicates (quartz, glass, mullite, zircon, etc.), indicating that REEs are dispersed in the glassy phases and/or associated with the Al–Si–oxide phases [76,77,78]. Chemical composition analysis of the different size fractions of a class F-type fly ash showed that a strong positive correlation existed between the REEs and the Al plus Si contents [77], which corroborates the above conclusion. In class F fly ashes, REEs associating with carbonates and metal oxides, such as CaCO3 and CaO, accounted for less than 10% of the total REEs, whereas, 50–60% of the total REEs present in class C-type fly ashes produces from Powder River basin coal occurred as carbonates and metal oxides [66,76,77,78]. Liu et al. combined acid leaching results and solution chemistry modelling findings to predict the percentage of the total REEs that occurred as monazite and hematite in a fly ash sample [66]. It was found that 10–20% of REEs were leached in the pH range of 0–1.5, which corresponds to the range where monazite and hematite dissolve based on solution chemistry modelling. Therefore, 10–20% of the total REEs were reported to exist as monazite and hematite forms. However, many studies have shown that monazite is thermally and chemically stable, and acid cracking or roasting is required to efficiently dissolve monazite [80,81]. Therefore, the solution chemistry modelling findings indicating that monazite and hematite dissolve in solutions having a pH in the range of 0–1.5 is questionable. Furthermore, the conclusion that 10–20% of the total REEs occur as monazite and hematite needs to be re-assessed in further investigations.

The association of REEs with silicates and aluminosilicates has been further proven by SEM-EDX, TEM-EDX, and LA-ICP-MS analyses. Thompson et al. found that, during laser ablation of a REE-enriched fly ash grain, the ion intensities of Al and Si were consistent, whereas the intensities of REEs changed in different ablation periods [70]. This finding indicated that REEs tend to be localized in small grains within fly ash. Using SEM-EDX, some monazite grains within Al–Si cenospheres and aluminosilicate glass particles were found, and particle size of the grains was less than 10 µm [70]. Moreover, several other SEM-EDX studies also showed the dispersion of REE enriched grains within aluminosilicates [66,67,71,72,73,75,78]. Associations of REEs with the other phases present in fly ash such as iron oxide, zircon, Ca/Fe-rich aluminosilicates, and lime have also been reported [65,66,82]. In addition to associations with the major phases, discrete REE enriched grains such as apatite (Ca, LREE, and P) and monazite (LREE and P) were also found in fly ash [66,70].

Overall, many RE-bearing minerals such as monazite, xenotime, rhabdophane, zircon, ilmenite, lime, and calcite have been found in fly ash, and those minerals have complex association characteristics with the major phases [66,67,70,73,75]. Taggart et al. tested both the bulk and micro speciation of yttrium (Y) in fly ashes using bulk and micro XANES [69]. Bulk XANES analysis indicated that Y coordination states in the fly ashes resembled a combination of Y-oxide, Y-carbonate, and Y-doped glass. However, using micro XANES, some “hotspots” of Y were observed including different mineral forms (e.g., Y-phosphate), which were not observed in the bulk measurements. This result indicated the heterogeneity of REEs in fly ash, and microscale analysis may be unable to represent the REEs in bulk fly ash. Hower et al. reported that the distribution of REEs in a coal ash sample seemed to be in the form of nanoscale crystalline minerals with additional distributions corresponding to overlapping ultra-fine minerals as well as atomic dispersion within the fly ash glass [71]. Therefore, the heterogeneity of REEs in fly ash occurs in nano- and atomic-scales.

3.2. Physical Beneficiation of REEs from Coal Combustion Ash

Coal fly ash particles can be separated into different fractions based on their contrasts in physical characteristics such as density, particle size, magnetism, and surface hydrophobicity [19,24,83,84,85,86,87]. Rather than processing the bulk ash material, REE extraction from certain fractions that are relatively more enriched in REEs will make the overall recovery more economically viable. REEs in fly ash are more concentrated in the finer fractions relative to the entire bulk material [19,24,74,83,84,85,86]. Size fractionation analyses of REEs in fly ashes collected from power plants of various countries (China, USA, United Kingdom, Poland) showed that REE contents gradually increased with a decrease in particle size [19,74,83,85]. For example, the minus 500 mesh fraction of a fly ash sample that was collected from the Jungar power plant [74] contained 648 ppm of total REEs, which is more than two times higher than the plus 120 mesh fraction (277 ppm). Several explanations have been suggested for this phenomenon: (1) The finer fractions in fly ash usually contain more glass phase relative to the coarser fractions, while REEs are preferentially associated with the glass phase in fly ash [85]; (2) The organic-bound REEs partially volatize and deposit on the fine particles of fly ash [84,88]; and (3) REEs associated with organic matter may form extremely small particles when the organic matter is combusted and such small particles tend to enrich in the finer fractions of fly ash [84].

Fly ash particles can also be partitioned into different fractions using magnetic separation. Dai et al. analyzed the magnetic, non-magnetic, and glassy fractions of a fly ash and discovered that the magnetic fraction contained less REEs relative to the bulk fly ash (202 ppm versus 261 ppm) [84]. Blissett et al. obtained a magnetic fraction containing 270 ppm of rare earth oxide from a fly ash with 505 ppm of rare earth oxide [83]. Lin et al. separated a fly ash into five fractions by using different magnetic field intensities [24]. It was found that REEs were more enriched in the weak- and non-magnetic fractions. For example, the non-magnetic fraction of a fly ash sample contained more than 600 ppm of REEs, whereas the strongest magnetic fraction only contained around 200 ppm of REEs. Therefore, based on these studies, it can be concluded that REEs are preferentially enriched in the non-magnetic fraction of fly ash.

Fractionation of REEs was also observed in gravity and flotation separations [24,27,83]. In one of our prior studies [19], a float-sink test was performed on a fly ash sample at a density cut point of 1.8 specific gravity (SG). It was found that the 1.8 SG sink fraction contained more REEs than the 1.8 SG float fraction (521 ppm versus 376 ppm). Flotation tests using different collectors and collector dosages also produced a series of products with different REE contents varying from 400 to 650 ppm. Lin et al. performed density fractionation tests on two fly ash samples and it was found that maximum REE contents occurred in the medium density fractions (2.71–2.95 SG and 2.45–2.71 SG) [24].

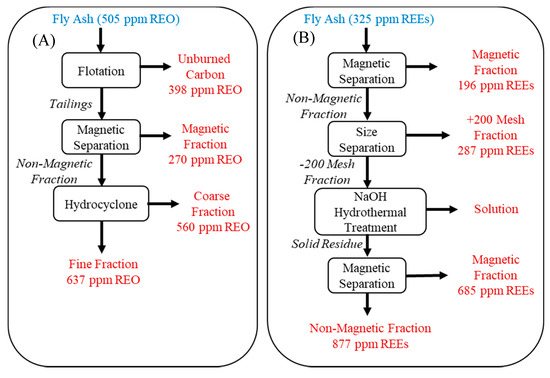

Given these results, physical separation can be used to pre-concentrate REEs from coal combustion ash, thereby providing a higher-grade feed material to the downstream extraction processes (e.g., acid leaching), resulting in a reduction in the overall recovery cost ($/kg of rare earth oxide). In the patents [89,90], magnetic separation was used to produce a feed material for the subsequent acid leaching process. Two physical beneficiation processes are shown in Figure 5. In both circuits, magnetic separation is performed prior to size fractionation, whereas in another study by Pan et al. [87], the sequence is reversed. Therefore, no fixed strategy has been proposed for the physical beneficiation process. The selection of pre-concentration strategy for a specific ash sample should be based on a comprehensive laboratory evaluation of the REE partitioning characteristics.

Figure 5.

Flowsheet reported in the literature for REE pre-concentration using physical methods: (A) reported by [83] and (B) reported by [76].

3.3. Chemical Extraction of REEs from Coal Combustion Ash

Many studies have been published in recent years focused on the chemical extraction of REEs from coal combustion ashes [26,53,76,88,89,91,92,93,94,95,96,97,98,99,100,101]. As shown in Table 4, acid leaching has been extensively exploited to extract REEs from coal combustion ash, and often the ash materials must be chemically and/or thermally treated prior to acid leaching to achieve better extraction performance. Chemical and physical characteristics of coal combustion ash change significantly relative to the raw materials after pretreatment [26,96,98]. Therefore, the leaching mechanisms are distinct.

Table 4.

Summary of REE extraction from coal combustion ash using chemical methods.

3.3.1. Acid Leaching of REEs from Coal Combustion Ashes

Satisfactory recoveries of REEs from some coal combustion ash produced from conventional boilers has been achieved by using acid leaching alone. For example, Taggart et al. extracted more than 70% of the total REEs from fly ashes of the Powder River basin using 15 M HNO3 at 85–90 °C [102]. Nearly 100% recovery was obtained from the samples using 12 M HCl at 85 °C, and a considerable amount of REEs (71%) were extracted from a fly ash sample of the same source even under much weaker acidity (1 M HCl). Cao et al. conducted a parametric study to optimize the leaching recovery of REEs from a fly ash sample that was collected from a power plant located in Guizhou, China [91]. It was found that 71.9% of La, 66.0% of Ce, and 61.9% of Nd were leached using 3 M HCl at 60 °C. However, due to the fact that most of the REEs are encapsulated in the amorphous structures of fly ash generated by combusting pulverized coal under high temperature (~1400 °C), relatively low recoveries were usually achieved using acid leaching alone. As shown in Table 4, 35–43% and 40–57% of total REEs were extracted from fly ashes of Illinois and Appalachian basins, respectively, using strong acidity at high temperature (12 M HCl at 85 °C; [96]).

Several studies prepared coal ash samples by combusting coals in muffle furnaces, which were used to simulate fly ash and bottom ash produced from pulverized coal-fired boilers [97,103]. Relatively high leaching recoveries were achieved from artificially prepared coal ashes. However, the temperatures used were much lower than the typical temperatures used in conventional pulverized coal boilers. For example, Kumari et al. burned a coal at 450 °C for 8 h and treated the material as coal bottom ash [97]. Acid leaching optimization showed that 90% of Ce and Nd as well as 35% of Y were extracted using 4 M HCl at 90 °C. It has been realized that mineral matter in coal may oxidize, decompose, fuse, disintegrate, or agglomerate under temperatures as high as 1400 °C, and rapid cooling in the post-combustion zone in boilers results in the formation of spherical, amorphous particles [104,105]. However, when combusting in a muffle furnace at a temperature lower than 900 °C, no glassy phases were detected [21,47,53,57]. Therefore, REEs in the laboratory prepared ash material are more readily leached compared with the REEs in ashes produced in pulverized coal-fired boilers.

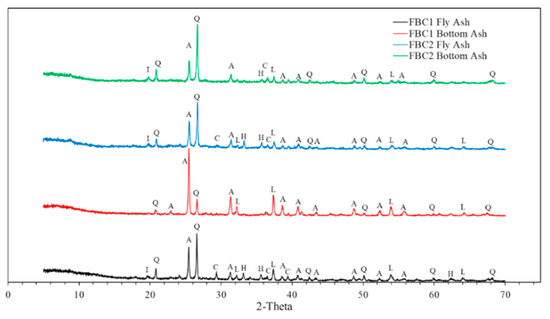

Leachabilities of REEs from fly ash produced in fluidized bed combustion (FBC) systems have also been evaluated [53,101]. REEs present in FBC ash are more leachable than ashes produced from pulverized coal-fired boilers. Tuan et al. extracted 62.1% Y, 55.5% Nd, and 65.2% Dy from a FBC bottom ash using 2 M HCl at 80 °C [101]. Honaker et al. achieved around 80% of total REE recovery from an FBC bottom ash using 1.2 M HCl at 75 °C [53]. Relatively low burning temperatures (750–900 °C) are typically utilized in FBC units [106]. Therefore, glassy phases are less likely formed during the combustion and cooling processes in FBC, which contribute to the higher REE leaching efficiency. As shown in Figure 6, the FBC ash samples maintained good crystallization and no noticeable glassy phases were found. Furthermore, similar to the thermal activation of REEs present in coal and coal refuse (Section 3.3.2), combustion in a FBC system may enhance the REE leaching efficiency due to dehydration of the clays, decomposition of the hard-to-leach rare earth minerals, and removal of the organic matters [21,47,53].

Figure 6.

XRD patterns of the fluidized bed combustion (FBC) ash samples: A, anhydrite; C, calcite; H, hematite; I, illite; L, Lime; and Q, Quartz [53].

Parametric studies have been performed to optimize the leaching recovery of REEs from coal combustion ash. Kumari et al. performed leaching tests on a coal ash using three different types of acids, i.e., hydrochloric acid, nitric acid, and sulfuric acid, under the same conditions [97]. It was found that the leaching recoveries follow the order of HCl > HNO3 > H2SO4. However, to the authors’ knowledge, sulfuric acid is less volatile and more cost-effective compared with the other two acids. Tuan et al. did not observe a significant difference among the three mineral acids in terms of REE extraction from FBC bottom ashes [101]. Despite the inconsistent findings, hydrochloric acid is the most commonly used lixiviant per literature (see Table 4). Sulfuric acid is expected to provide the worst efficiency since the large amount of calcium present in coal combustion ash will complex with sulfate to form gypsum, and some REEs will be incorporated into the gypsum structure and lost to the precipitate [107]. Leaching recovery of REEs is sensitive to liquid/solid ratio, acid concentration, temperature, and leaching duration [91,97,100]. Leaching recoveries of La, Ce, and Nd from a coal fly ash were nearly doubled when increasing the liquid/solid ratio from 5/1 to 20/1 or prolonging the reaction time from 30 to 180 min [91].

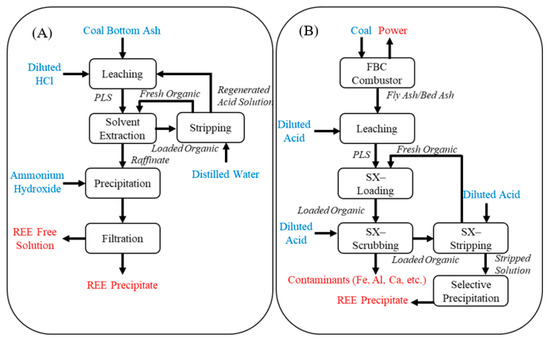

Two flowsheets that were reported in the literature for recovering REEs from coal combustion ash using acid leaching are shown in Figure 7. Solvent extraction was used in both circuits. In the first circuit (Figure 7A), tris-2-ethylhexyl amine (TEHA) was used to complex hydrogen ions in the solvent extraction step, and acid regenerated in the stripping step, which reduced the chemical cost. REEs were recovered from the raffinate of solvent extraction using precipitation. In the second circuit (Figure 7B), fly ash and bed ash produced from FBC combustors are leached using diluted acid (e.g., 1.2 M hydrochloric acid). REEs in the pregnant leach solution are extracted using a three-stage counter-current solvent extraction (SX) system. Finally, a concentrated solution of REEs containing minimal contaminants is produced from the SX-stripping stage. High-purity REE concentrates are produced by selective precipitation using oxalic acid as the precipitant.

Figure 7.

Flowsheets reported in the literature for recovering REEs from coal combustion ash using acid leaching: (A) reported by [97] and (B) reported by [53].

Overall, REE recovery from coal combustion ashes using direct acid leaching is inefficient. Harsh leaching conditions with concentrated acid solutions at higher temperatures are normally required to achieve satisfactory recovery. In addition to the direct acid leaching, REE extraction from fly ash using bioleaching was also reported [108]. Three microbial strains, Candida bombicola, Phanerochaete chrysosporium, and Cryptococcus curvatus, were tested by Park and Liang in terms of REE extraction from fly ash. Candida bombicola provided the optimal results with 63% Sc, 62.2% Y, 67.7% Yb, 64.4% Er, 60% Dy, and 51.9% Gd being extracted at 28 °C for 6 h [108].

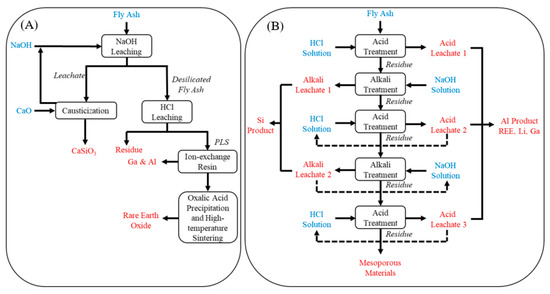

3.3.2. Chemical/Thermal Pretreatment

Coal combustion ash was chemically and/or thermally pretreated prior to acid leaching to achieve high REE recoveries [18,26,76,98,100,109]. Lin et al. performed hydrothermal treatment on a coal fly ash and found that 21.3% of the material was dissolved by using 5 M NaOH with a solid/liquid ratio of 1/20 at 100 °C for 120 min [76]. REE content in the solid material was increased from 366 to 803 ppm after hydrothermal treatment, which indicates that REEs present in coal combustion ash remain with the solid residue after the hydrothermal treatment. Wang et al. used an 8 M HCl solution to leach a hydrothermally treated fly ash and achieved a total REE recovery of 88.15% [18]. As shown in Figure 8A, Si, Ga, and Al were also recovered from the fly ash alongside REEs. Ma et al. proposed an alternative NaOH–HCl leaching process, which extracted 55% of REEs, 63% of Si, 72% of Ga, and 78% of Al from the fly ash (see Figure 8B) [98]. Unfortunately, none of the studies produced high-grade final rare earth products.

Figure 8.

Flowsheets reported in the literature for recovering REEs from coal combustion ash using NaOH hydrothermal treatment followed by acid leaching: (A) reported by [18] and (B) reported by [98].

In the hydrothermal treatment process, NaOH reacts with the major components of fly ash according to the following reactions [110,111]:

The above reactions destroy the amorphous glassy structure of fly ash and liberate the RE-bearing particles, which are dissolved in the acid leaching step. In addition, hydrothermal treatment using NaOH is also able to convert hard-to-dissolve rare earth minerals into soluble forms (Equation (1)). All of the above reactions contribute to the extraction of REEs from coal combustion ash.

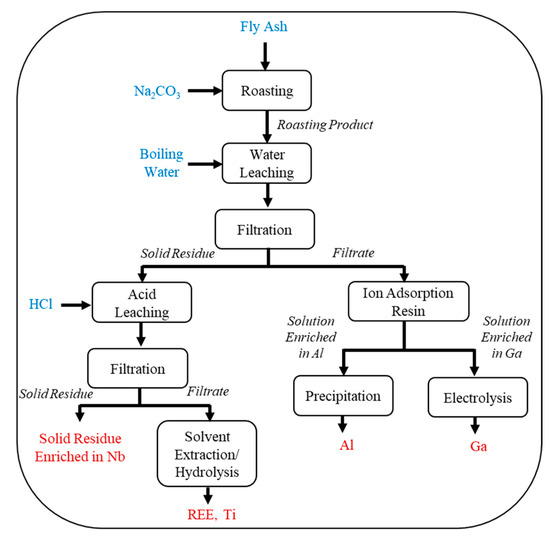

Several studies have reported that REE recovery from fly ash was improved by alkali roasting treatment prior to acid leaching [26,100,112]. Taggart et al. compared the performance of various roasting additives, including Na2O2, NaOH, CaO, Na2CO3, CaSO4, and (NH4)2SO4, by performing roasting tests at 450 °C on fly ash samples originating from power stations in the Appalachian, Illinois, and Powder River basins followed by leaching with 1 M HNO3 [26]. It was found that NaOH roasting often recovered more than 90% of the total REEs, which is more efficient than the other additives. Tang et al. optimized Na2CO3 roasting on a coal fly ash collected from Guizhou China [100]. Mass ratio of 1/1 (fly ash/ Na2CO3) and roasting temperature of 860 °C provided the maximum total REE recovery (~90%) when leaching with 2 M HCl. Liu et al. proposed a flowsheet to achieve the simultaneous extraction of REEs, Ga, and Nb from a coal fly ash of the Songzao coalfield, which is famous for its significant enrichment in trace elements [84,112,113]. As shown in Figure 9, water leaching was used to extract Ga and Al from the roasting product, and REEs were recovered from the water leaching solid residue by acid leaching. Ion adsorption resin was used to separate Ga and Al. Laboratory test results showed that 68.62% Al, 76.11% Ti, and 80.07% REEs were extracted from the fly ash using the alkali roasting–water leaching–acid leaching method. The reactions between sodium carbonate and fly ash during roasting are as follows:

Figure 9.

A flowsheet for recovering REEs, Ga, Nb, and Al from a fly ash using alkali roasting [112].

4. REE Recovery from Acid Mine Drainage and Sludge

4.1. REEs in Acid Mine Drainage

The occurrence of REEs in acid coal mine drainage (AMD) is mainly due to the dissolution of RE-bearing species under acidic conditions created by the natural oxidization of sulfide minerals, primarily pyrite. When exposed to the natural environment, pyrite is oxidized as described by the following reactions [114,115,116]:

As shown in the above equations, both ferric ions and oxygen serve as oxidants for pyrite. Moreover, it has been well realized that Fe3+/S0-oxidizing microorganisms can significantly accelerate the reaction [116,117].

Many articles have been published focusing on the characterization of REEs in AMD [9,118,119,120,121,122,123]. Based on the data drawn from 233 samples collected by the United States Geological Survey (USGS) in 1999 and 2011, Ziemkiewicz et al. found that the total REE concentration increases exponentially with a decrease in pH [124]. Other studies also observed the same phenomenon [9,121,122,123]. For example, Stewart et al. reported that the total REE concentration and solution pH in 18 AMD samples collected from the Appalachian Basin ranged from 0.29 to 1134 µg/L and 2.8–6.6, respectively, with the higher concentration occurring in low pH solutions [9]. Total REE concentration in AMD is normally less than coal and coal refuse, whereas, when reported based on total dissolved solids in AMD, the concentration is similar to or even higher than coal and coal refuse. For example, Honaker et al. obtained the dissolved solid from an AMD sample containing 6.7 mg/L total REEs by completely evaporating the liquid phase [115]. REE content in the dissolved solid was measured to be 380 ppm, which is much higher than the average content of World coals (68 ppm, [4]). Moreover, AMD samples with more than 10 mg/L REEs have been reported in the literature [125]. Therefore, AMD can be used as an alternative resource of REEs. Extremely high concentrations of REEs have been detected in some sludges generated during the passive treatment process [9,22,124]. For example, 3037 mg/kg of total REEs were estimated from sludge samples from the Saxman Run treatment plant [124]. The same group later conducted a broad survey of 141 treatment sites in the Northern and Central Appalachian coal basins and found that more that 20 of the 623 AMD sludge samples had concentrations exceeding 2000 mg/kg on a dry whole mass basis [22]. Northern Appalachian samples tended to have higher REE concentrations than those from Central Appalachia with statistically significant deviations for all REEs except Ce, Pr, and Nd.

AMD and AMD sludge typically contain more valuable REEs such as Y relative to La and Ce. For example, Y in the coarse refuse collected from the West Kentucky No. 13 and Illinois No. 6 seams represented less than 10% of the total REEs; whereas the REEs in AMD generated from the refuse piles was more than 25% Yttrium. In addition, in the basin comparison study by Vass et al., the ratio of critical REEs (defined as Y, Nd, Eu, Tb, and Dy) to total REEs was nearly 50% for the Northern Appalachian samples [22]. The enrichment of HREEs in AMD, especially the elements located in the middle of lanthanide series (Sm-Dy, middle REEs), has been well recognized by geologists, which may be explained by several mechanisms: (1) the abundance and distribution of mineral phases containing REEs, (2) the stability of RE-bearing mineral phases with respect to the aqueous fluids, (3) the chemistry of the aqueous fluids, and (4) the immobilizing capacity of minerals, precipitates, and colloidal materials to REEs [120,122,123,126,127]. Overall, AMD can be used as a potential resource of REEs due to the relatively high concentration (reported on dissolved solid basis) and the preferential enrichment in HREEs.

4.2. REE Recovery from Acid Mine Drainage

Many studies have been performed to recover valuable components such as Fe, Al, Cu, Zn, Ni, and sulfuric acid from acid mine drainage (AMD). The recovery methods can be classified as precipitation [128,129,130,131,132], adsorption [133,134], diffusion dialysis [135], and ion-exchange [129]. Seo et al. used an oxidation-sequential precipitation method to recover Fe, Al, and Mn from a coal mine drainage [131]. The laboratory test results showed that 99.2–99.3% of Fe, 70.4–82.2% of Al, and 37.8–87.5% of Mn were recovered at pH 4.5, 5.5, and 8.5, respectively. Furthermore, Cu and Zn can be selectively concentrated by collecting the precipitates formed in the pH ranges of 4.49–6.11 and 5.50–7.23, respectively [128]. Instead of artificially adding alkalis, dissolved metals in AMD can also be precipitated and recovered using OH− produced from electrochemical reactions [136]. Chockalingam and Subramanian found that rice husk is able to uptake 99% Fe3+, 98% Fe2+, 98% Zn2+, and 95% Cu2+ from an acid mine water, with a concomitant increase in the pH value by two absolute units [133]. Crane and Sapsford reported that nanoscale zerovalent iron (nZVI) selectively adsorbed Cu, Cd, and Al with more than 99.9% recovery in 1 h [137]. In addition, an acidic pH buffer enabled the formation of copper–bearing nanoparticles from AMD in presence of nZVI. Magnetite nanoparticles have also been successfully prepared from AMD [138,139,140].

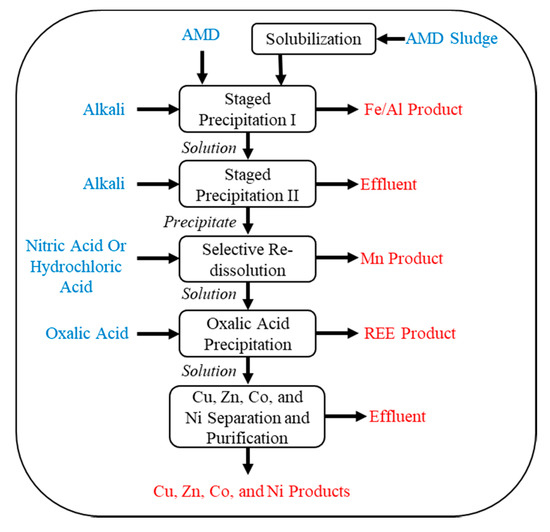

Due to the much higher economic values of REEs relative to the major metals such as iron and aluminum present in AMD, several studies regarding REE recovery from AMD have been reported recently [9,10,12,22,124,141,142,143,144]. In one of our prior studies [10], staged precipitation tests were performed on a coal mine drainage (6.14 ppm of REEs), and a REE pre-concentrate containing 1.1% of REEs was produced in the pH range of 4.85–6.11. In addition, the pre-concentrate also contained 17.1% Al, 1.7% Zn, 1.4% Cu, 1.14% Mn, 0.5% Ni, and 0.2% Co, indicating that multiple valuable components can be pre-concentrated simultaneously using staged precipitation. By using selective re-dissolution and oxalic precipitation, a product containing 94% rare earth oxides was finally obtained from the pre-concentrate. A process flowsheet has been developed in a recent study by the authors [145]. The staged precipitation results also explained the observations in the passive treatment systems of coal mine drainage, i.e., >90% REEs were sequestered in the treatment solids when pH was raised above 6.0, and REEs were preferentially retained in the basaluminite () [141,142]. Ramasamy et al. (2018) synthesized N- and O- ligand doped mesoporous silica-chitosan hybrid beads for extracting REEs from AMD and the test results showed that more than 90% of REEs were recovered in 5 min [143].

According to Vass et al., REEs in AMD treatment sludge can also be economically recovered by solubilization followed by REE extraction from the solution [22]. Further work by the same group has led to the design and construction of an acid leaching/solvent extraction mini-pilot plant for the recovery of REEs from AMD sludge. Leaching data show that high recoveries of REEs (>80%) can be achieved at a pH value of 1.0 using sulfuric acid. Moreover, the addition of a leaching modifier increased the leaching recovery from 65% to >95% at a pH of 2.0. Together with the downstream solvent extraction operation, the continuous pilot process was able to produce high-grade mixed rare earth oxide products exceeding 80% purity. Techno-economic analysis shows favorable economic outcomes; however, the authors note that the results are very sensitive to consumable costs [146].

Based on the above discussion, a flowsheet for REE recovery and comprehensive utilization of AMD is shown in Figure 10. Cost for the staged precipitation step is minimal given the fact that treatment of AMD is mandated by regulatory agencies. In addition, since only a small quantity of REE-enriched precipitate is obtained from the staged precipitation step, chemical consumptions associated with the downstream processes are low. Therefore, AMD can be considered as a promising source of REEs.

Figure 10.

A flowsheet for multiple metals recovery from acid mine drainage (AMD) and acid mine drainage sludge.

5. Summary and Conclusions

Many studies have been conducted for recovering REEs from coal-related materials, primarily coal refuse, coal combustion ash, and acid coal mine drainage. High-purity rare earth concentrates have been successfully produced from coal refuse and acid coal mine drainage. A rare earth pilot plant was constructed and tested, enabling a continuous production of REEs from coal refuse. Reasonable recovery values also have been achieved from coal combustion ash. Altogether, these findings show that significant accomplishments have been made over the past several years in this area.

A summary of the advantages and disadvantages of the methods that have been used for recovering REEs from coal-related materials is shown in Table 5. To achieve optimum recovery performance with minimum cost, process flowsheets integrating various technologies, such as physical beneficiation, acid leaching, pre-leach roasting, and hydrothermal pretreatment, need to be designed and tested. More fundamental studies are required to understand the positive impacts caused by pre-leach calcination on REE recovery from coal refuse. Moreover, this review indicates that not enough attention has been paid to the extraction behavior of other critical elements as well as major elements. This deficiency limits the development of multi-element recovery strategies from coal-related materials. In addition, downstream recovery and purification plans are also ambiguous since the extraction behavior of major elements such as Al, Fe, and Ca were rarely reported.

Table 5.

A summary of the advantages and disadvantages of the methods that have been used for REE recovery from coal-related materials.

Author Contributions

Conceptualization, W.Z.; methodology, A.N. and X.Y.; resources, R.H.; writing—original draft preparation, W.Z. and X.Y.; writing—review and editing, R.H., A.N., and X.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chu, S. Critical Materials Strategy; DIANE Publishing: Darby, PA, USA, 2011. [Google Scholar]

- Trump, D. A federal strategy to ensure secure and reliable supplies of critical minerals. Donald Trump Washington DC Accessed April 2018, 3, 2018. [Google Scholar]

- Blengini, G.A.; Nuss, P.; Dewulf, J.; Nita, V.; Talens Peiró, L.; Vidal-Legaz, B.; Latunussa, C.; Mancini, L.; Blagoeva, D.; Pennington, D.; et al. EU methodology for critical raw materials assessment: Policy needs and proposed solutions for incremental improvements. Resour. Policy 2017, 53, 12–19. [Google Scholar] [CrossRef]

- Ketris, M.P.; Yudovich, Y.E. Estimations of clarkes for carbonaceous biolithes: World averages for trace element contents in black shales and coals. Int. J. Coal Geol. 2009, 78, 135–148. [Google Scholar] [CrossRef]

- Seredin, V.V.; Dai, S. Coal deposits as potential alternative sources for lanthanides and yttrium. Int. J. Coal Geol. 2012, 94, 67–93. [Google Scholar] [CrossRef]

- Dai, S.; Xie, P.; Jia, S.; Ward, C.R.; Hower, J.C.; Yan, X.; French, D. Enrichment of U-Re-V-Cr-Se and rare earth elements in the Late Permian coals of the Moxinpo Coalfield, Chongqing, China: Genetic implications from geochemical and mineralogical data. Ore Geol. Rev. 2017, 80, 1–17. [Google Scholar] [CrossRef]

- Seredin, V.V. Rare earth element-bearing coals from the Russian Far East deposits. Int. J. Coal Geol. 1996, 30, 101–129. [Google Scholar] [CrossRef]

- Hower, J.C.; Ruppert, L.F.; Eble, C.F. Lanthanide, yttrium, and zirconium anomalies in the Fire Clay coal bed, Eastern Kentucky. Int. J. Coal Geol. 1999, 39, 141–153. [Google Scholar] [CrossRef]

- Stewart, B.W.; Capo, R.C.; Hedin, B.C.; Hedin, R.S. Rare earth element resources in coal mine drainage and treatment precipitates in the Appalachian Basin, USA. Int. J. Coal Geol. 2017, 169, 28–39. [Google Scholar] [CrossRef]

- Zhang, W.; Honaker, R.Q. Rare earth elements recovery using staged precipitation from a leachate generated from coarse coal refuse. Int. J. Coal Geol. 2018, 195, 189–199. [Google Scholar] [CrossRef]

- Honaker, R.Q.; Groppo, J.; Yoon, R.-H.; Luttrell, G.H.; Noble, A.; Herbst, J. Process evaluation and flowsheet development for the recovery of rare earth elements from coal and associated byproducts. Miner. Metall. Process. 2017, 34, 107–115. [Google Scholar] [CrossRef]

- Vass, C.R.; Noble, A.; Ziemkiewicz, P.F. The occurrence and concentration of rare earth elements in acid mine drainage and treatment by-products: Part 1—Initial survey of the Northern Appalachian Coal Basin. Min. Metall. Explor. 2019, 917–929. [Google Scholar] [CrossRef]

- Sarswat, P.K.; Leake, M.; Allen, L.; Free, M.L.; Hu, X.; Kim, D.; Noble, A.; Luttrell, G.H. Efficient recovery of rare earth elements from coal based resources: A bioleaching approach. Mater. Today Chem. 2020, 16. [Google Scholar] [CrossRef]

- Seredin, V.V.; Dai, S.; Sun, Y.; Chekryzhov, I.Y. Coal deposits as promising sources of rare metals for alternative power and energy-efficient technologies. Appl. Geochem. 2013, 31, 1–11. [Google Scholar] [CrossRef]

- Dai, S.; Yan, X.; Ward, C.R.; Hower, J.C.; Zhao, L.; Wang, X.; Zhao, L.; Ren, D.; Finkelman, R.B. Valuable elements in Chinese coals: A review. Int. Geol. Rev. 2018, 60, 590–620. [Google Scholar] [CrossRef]

- Dai, S.; Xie, P.; Ward, C.R.; Yan, X.; Guo, W.; French, D.; Graham, I.T. Anomalies of rare metals in Lopingian super-high-organic-sulfur coals from the Yishan Coalfield, Guangxi, China. Ore Geol. Rev. 2017, 88, 235–250. [Google Scholar] [CrossRef]

- Alvin, M.A. The rarity of rare earth elements (PowerPoint slides). Presentated at National Assocation Regulatorgy Utility Commissioners (NARUC) Winter Policy Summit, Washington, DC, USA, 12 February 2018. [Google Scholar]

- Wang, Z.; Dai, S.; Zou, J.; French, D.; Graham, I.T. Rare earth elements and yttrium in coal ash from the Luzhou power plant in Sichuan, Southwest China: Concentration, characterization and optimized extraction. Int. J. Coal Geol. 2019, 203, 1–14. [Google Scholar] [CrossRef]

- Zhang, W.; Groppo, J.; Honaker, R. Ash beneficiation for REE recovery. In Proceedings of the 2015 World Coal Ash Conference, Nashville, TN, USA, 5–7 May 2015. [Google Scholar]

- Zhang, W.; Yang, X.; Honaker, R.Q. Association characteristic study and preliminary recovery investigation of rare earth elements from Fire Clay seam coal middlings. Fuel 2018, 215, 551–560. [Google Scholar] [CrossRef]

- Zhang, W.; Honaker, R. Calcination pretreatment effects on acid leaching characteristics of rare earth elements from middlings and coarse refuse material associated with a bituminous coal source. Fuel 2019, 249, 130–145. [Google Scholar] [CrossRef]

- Vass, C.R.; Noble, A.; Ziemkiewicz, P.F. The occurrence and concentration of rare earth elements in acid mine drainage and treatment byproducts. Part 2: Regional survey of Northern and Central Appalachian Coal Basins. Min. Metall. Explor. 2019, 36, 917–929. [Google Scholar] [CrossRef]

- Huang, Q.; Noble, A.; Herbst, J.; Honaker, R. Liberation and release of rare earth minerals from Middle Kittanning, Fire Clay, and West Kentucky No. 13 coal sources. Powder Technol. 2018, 332, 242–252. [Google Scholar] [CrossRef]

- Lin, R.; Howard, B.H.; Roth, E.A.; Bank, T.L.; Granite, E.J.; Soong, Y. Enrichment of rare earth elements from coal and coal by-products by physical separations. Fuel 2017, 200, 506–520. [Google Scholar] [CrossRef]

- Laudal, D.A.; Benson, S.A.; Addleman, R.S.; Palo, D. Leaching behavior of rare earth elements in Fort Union lignite coals of North America. Int. J. Coal Geol. 2018, 191, 112–124. [Google Scholar] [CrossRef]

- Taggart, R.K.; Hower, J.C.; Hsu-Kim, H. Effects of roasting additives and leaching parameters on the extraction of rare earth elements from coal fly ash. Int. J. Coal Geol. 2018, 196, 106–114. [Google Scholar] [CrossRef]

- Zhang, W.; Rezaee, M.; Bhagavatula, A.; Li, Y.; Groppo, J.; Honaker, R. A review of the occurrence and promising recovery methods of rare earth elements from coal and coal by-products. Int. J. Coal Prep. Util. 2015, 35, 281–294. [Google Scholar] [CrossRef]

- Dai, S.; Ren, D.; Chou, C.L.; Finkelman, R.B.; Seredin, V.V.; Zhou, Y. Geochemistry of trace elements in Chinese coals: A review of abundances, genetic types, impacts on human health, and industrial utilization. Int. J. Coal Geol. 2012, 94, 3–21. [Google Scholar] [CrossRef]

- Dai, S.; Finkelman, R.B. Coal as a promising source of critical elements: Progress and future prospects. Int. J. Coal Geol. 2018, 186, 155–164. [Google Scholar] [CrossRef]

- Gupta, T.; Ghosh, T.; Akdogan, G.; Bandopadhyay, S. Maximizing REE enrichment by froth flotation using Box-Behnken design in Alaskan coal. In Proceedings of the 2017 SME Annual Conference & Expo, Denver, CO, USA, 19–22 February 2017; pp. 408–412. [Google Scholar]

- Gupta, T.; Ghosh, T.; Akdogan, G.; Srivastava, V.K. Characterizing rare earth elements in Alaskan coal and ash. Miner. Metall. Process. 2017, 34, 138–145. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, X.; Zheng, X.; Lin, X.; Cao, H.; Zhang, Y.; Sun, Z. Lithium carbonate recovery from cathode scrap of spent lithium-ion battery: A closed-loop process. Environ. Sci. Technol. 2017, 51, 1662–1669. [Google Scholar] [CrossRef]

- Zhang, W.; Honaker, R.; Groppo, J. Concentration of rare earth minerals from coal by froth flotation. Miner. Metall. Process. 2017, 34, 132–137. [Google Scholar] [CrossRef]

- Honaker, R.; Groppo, J.; Bhagavatula, A.; Rezaee, M.; Zhang, W. Recovery of rare earth minerals and elements from coal and coal byproducts. In Proceedings of the International Coal Preparation Conference, Lousiville, KY, USA, 25–27 April 2016; pp. 25–27. [Google Scholar]

- Honaker, R.; Hower, J.; Eble, C.; Weisenfluh, J.; Groppo, J.; Rezaee, M.; Bhagavatula, A.; Luttrell, G.H.; Bratton, R.C.; Kiser, M.; et al. Laboratory and bench-scale testing for rare earth elements. Cell 2014, 724, 554–3652. [Google Scholar]

- Cheng, T.-W.; Holtham, P.N.; Tran, T. Froth flotation of monazite and xenotime. Miner. Eng. 1993, 6, 341–351. [Google Scholar] [CrossRef]

- Pavez, O.; Peres, A.E.C. Effect of sodium metasilicate and sodium sulphide on the floatability of monazite-zircon-rutile with oleate and hydroxamates. Miner. Eng. 1993, 6, 69–78. [Google Scholar] [CrossRef]

- Gupta, N.; Li, B.; Luttrell, G.; Yoon, R.H.; Bratton, R.; Reyher, J. Hydrophobic-hydrophilic separation (HHS) process for the recovery and dewatering of ultrafine coal. In Proceedings of the 2016 SME Annual Conference and Expo, Phoenix, AZ, USA, 21–24 February 2016; pp. 706–709. [Google Scholar]

- Pradip, P.; Fuerstenau, D.W. Design and development of novel flotation reagents for the beneficiation of Mountain Pass rare-earth ore. Miner. Metall. Process. 2013, 30, 1–9. [Google Scholar] [CrossRef]

- Pradip; Fuerstenau, D.W. The adsorption of hydroxamate on semi-soluble minerals. Part I: Adsorption on barite, Calcite and Bastnaesite. Colloids Surf. 1983, 8, 103–119. [Google Scholar] [CrossRef]

- Yang, X.; Werner, J.; Honaker, R.Q. Leaching of rare earth elements from an Illinois basin coal source. J. Rare Earths 2019, 37, 312–321. [Google Scholar] [CrossRef]

- Wei, G.; Bo, F.; Jinxiu, P.; Wenpu, Z.; Xianwen, Z. Depressant behavior of tragacanth gum and its role in the flotation separation of chalcopyrite from talc. J. Mater. Res. Technol. 2019, 8, 697–702. [Google Scholar] [CrossRef]

- Yang, X. Leaching Characteristics of Rare Earth Elements from Bituminous Coal-Based Sources. Ph.D. Thesis, University of Kentucky, Lexington, KY, USA, 2019. [Google Scholar]

- Bo, C.; Ya, L.A.I.; Guo, X.I.A.O.; Chang, X.U. Technique for extraction and concentration of rare earth elements in gangue. Glob. Geol. 2010, 28, 257–260. [Google Scholar]

- Kuppusamy, V.K.; Holuszko, M. Rare earth elements in flotation products of coals from East Kootenay coalfields, British Columbia. J. Rare Earths 2019. [CrossRef]

- Zhang, P.; Han, Z.; Jia, J.; Wei, C.; Liu, Q.; Wang, X.; Zhou, J.; Li, F.; Miao, S. Occurrence and Distribution of Gallium, Scandium, and Rare Earth Elements in Coal Gangue Collected from Junggar Basin, China. Int. J. Coal Prep. Util. 2017, 39, 389–402. [Google Scholar] [CrossRef]

- Zhang, W.; Honaker, R. Enhanced leachability of rare earth elements from calcined products of bituminous coals. Miner. Eng. 2019, 142, 105935. [Google Scholar] [CrossRef]

- Rozelle, P.L.; Khadilkar, A.B.; Pulati, N.; Soundarrajan, N.; Klima, M.S.; Mosser, M.M.; Miller, C.E.; Pisupati, S.V. A study on removal of rare earth elements from U.S. coal byproducts by ion exchange. Metall. Mater. Trans. E 2016, 3, 6–17. [Google Scholar] [CrossRef]

- Finkelman, R.B.; Palmer, C.A.; Wang, P. Quantification of the modes of occurrence of 42 elements in coal. Int. J. Coal Geol. 2018, 185, 138–160. [Google Scholar] [CrossRef]

- Honaker, R.; Yang, X.; Chandra, A.; Zhang, W.; Werner, J. Hydrometallurgical Extraction of Rare Earth Elements from Coal; Springer International Publishing: Berlin, Germany, 2018; ISBN 978-3-319-95021-1. [Google Scholar]

- Zhang, W.; Noble, A. Mineralogy characterization and recovery of rare earth elements from the roof and floor materials of the Guxu coalfield. Fuel 2020, 270, 117533. [Google Scholar] [CrossRef]

- Kuppusamy, V.K.; Kumar, A.; Holuszko, M. Simultaneous extraction of clean coal and rare earth elements from coal tailings using alkali-acid leaching process. J. Energy Resour. Technol. Trans. ASME 2019, 141, 1–7. [Google Scholar] [CrossRef]

- Honaker, R.Q.; Zhang, W.; Werner, J. Acid leaching of rare earth elements from coal and coal ash: Implications for using fluidized bed combustion to assist in the recovery of critical materials. Energy Fuels 2019, 33, 5971–5980. [Google Scholar] [CrossRef]

- Zhang, W.; Honaker, R. Characterization and recovery of rare earth elements and other critical metals (Co, Cr, Li, Mn, Sr, and V) from the calcination products of a coal refuse sample. Fuel 2020, 267, 117236. [Google Scholar] [CrossRef]

- Hu, G.; Dam-Johansen, K.; Wedel, S.; Hansen, J.P. Decomposition and oxidation of pyrite. Prog. Energy Combust. Sci. 2006, 32, 295–314. [Google Scholar] [CrossRef]

- Music, S.; Popović, S.; Ristić, M. Thermal decomposition of pyrite. J. Radioanal. Nucl. Chem. Artic. 1992, 162, 217–226. [Google Scholar] [CrossRef]

- Cao, Z.; Cao, Y.; Dong, H.; Zhang, J.; Sun, C. Effect of calcination condition on the microstructure and pozzolanic activity of calcined coal gangue. Int. J. Miner. Process. 2016, 146, 23–28. [Google Scholar] [CrossRef]

- De la Villa, R.V.; García, R.; Martínez-Ramírez, S.; Frías, M. Effects of calcination temperature and the addition of ZnO on coal waste activation: A mineralogical and morphological evolution. Appl. Clay Sci. 2017, 150, 1–9. [Google Scholar] [CrossRef]

- Honaker, R.Q.; Zhang, W.; Werner, J.; Noble, A.; Luttrell, G.H.; Yoon, R.-H. Enhancement of a process flowsheet for recovering and concentrating critical materials from bituminous coal sources. Min. Metall. Explor. 2019. accepted. [Google Scholar] [CrossRef]

- Zhang, W.; Noble, A.; Yang, X.; Honaker, R. Lithium leaching recovery and mechanisms from density fractions of an Illinois Basin bituminous coal. Fuel 2020, 268, 117319. [Google Scholar] [CrossRef]

- Chancey, R.T.; Stutzman, P.; Juenger, M.C.G.; Fowler, D.W. Comprehensive phase characterization of crystalline and amorphous phases of a Class F fly ash. Cem. Concr. Res. 2010, 40, 146–156. [Google Scholar] [CrossRef]

- Goodarzi, F. Characteristics and composition of fly ash from Canadian coal-fired power plants. Fuel 2006, 85, 1418–1427. [Google Scholar] [CrossRef]

- Kukier, U.; Ishak, C.F.; Sumner, M.E.; Miller, W.P. Composition and element solubility of magnetic and non-magnetic fly ash fractions. Environ. Pollut. 2003, 123, 255–266. [Google Scholar] [CrossRef]

- McCarthy, G.J.; Solem, J.K.; Manz, O.E.; Hassett, D.J. Use of a database of chemical, mineralogical and physical properties of North American fly ash to study the nature of fly ashand its utilization as a mineral admixture in concrete. MRS Online Proc. Libr. Arch. 1989, 178, 3. [Google Scholar] [CrossRef]

- Kolker, A.; Scott, C.; Hower, J.C.; Vazquez, J.A.; Lopano, C.L.; Dai, S. Distribution of rare earth elements in coal combustion fly ash, determined by SHRIMP-RG ion microprobe. Int. J. Coal Geol. 2017, 184, 1–10. [Google Scholar] [CrossRef]

- Liu, P.; Huang, R.; Tang, Y. Comprehensive understandings of rare earth element (REE) speciation in coal fly ashes and implication for REE extractability. Environ. Sci. Technol. 2019, 53, 5369–5377. [Google Scholar] [CrossRef]

- Montross, S.N.; Verba, C.A.; Chan, H.L.; Lopano, C. Advanced characterization of rare earth element minerals in coal utilization byproducts using multimodal image analysis. Int. J. Coal Geol. 2018, 195, 362–372. [Google Scholar] [CrossRef]

- Stuckman, M.Y.; Lopano, C.L.; Granite, E.J. Distribution and speciation of rare earth elements in coal combustion by-products via synchrotron microscopy and spectroscopy. Int. J. Coal Geol. 2018, 195, 125–138. [Google Scholar] [CrossRef]

- Taggart, R.K.; Rivera, N.A.; Levard, C.; Ambrosi, J.P.; Borschneck, D.; Hower, J.C.; Hsu-Kim, H. Differences in bulk and microscale yttrium speciation in coal combustion fly ash. Environ. Sci. Process. Impacts 2018, 20, 1390–1403. [Google Scholar] [CrossRef] [PubMed]

- Thompson, R.L.; Bank, T.; Montross, S.; Roth, E.; Howard, B.; Verba, C.; Granite, E. Analysis of rare earth elements in coal fly ash using laser ablation inductively coupled plasma mass spectrometry and scanning electron microscopy. Spectrochim. Acta-Part B At. Spectrosc. 2018, 143, 1–11. [Google Scholar] [CrossRef]

- Hower, J.C.; Cantando, E.; Eble, C.F.; Copley, G.C. Characterization of stoker ash from the combustion of high-lanthanide coal at a Kentucky bourbon distillery. Int. J. Coal Geol. 2019, 213, 103260. [Google Scholar] [CrossRef]

- Hower, J.C.; Qian, D.; Briot, N.J.; Santillan-Jimenez, E.; Hood, M.M.; Taggart, R.K.; Hsu-Kim, H. Nano-scale rare earth distribution in fly ash derived from the combustion of the fire clay coal, Kentucky. Minerals 2019, 9, 206. [Google Scholar] [CrossRef]

- Hower, J.C.; Qian, D.; Briot, N.J.; Henke, K.R.; Hood, M.M.; Taggart, R.K.; Hsu-Kim, H. Rare earth element associations in the Kentucky State University stoker ash. Int. J. Coal Geol. 2018, 189, 75–82. [Google Scholar] [CrossRef]

- Hower, J.; Groppo, J.; Henke, K.; Hood, M.; Eble, C.; Honaker, R.; Zhang, W.; Qian, D. Notes on the Potential for the Concentration of Rare Earth Elements and Yttrium in Coal Combustion Fly Ash. Minerals 2015, 5, 356–366. [Google Scholar] [CrossRef]

- Hower, J.C.; Dai, S.; Seredin, V.V.; Zhao, L.; Kostova, I.J.; Silva, L.F.O.; Mardon, S.M.; Gurdal, G. A note on the occurrence of yttrium and rare earth elements in coal combustion byproducts. Coal Combust. Gasif. Prod. 2013, 39–47. [Google Scholar] [CrossRef]

- Lin, R.; Stuckman, M.; Howard, B.H.; Bank, T.L.; Roth, E.A.; Macala, M.K.; Lopano, C.; Soong, Y.; Granite, E.J. Application of sequential extraction and hydrothermal treatment for characterization and enrichment of rare earth elements from coal fly ash. Fuel 2018, 232, 124–133. [Google Scholar] [CrossRef]

- Pan, J.; Zhou, C.; Tang, M.; Cao, S.; Liu, C.; Zhang, N.; Wen, M.; Luo, Y.; Hu, T.; Ji, W. Study on the modes of occurrence of rare earth elements in coal fly ash by statistics and a sequential chemical extraction procedure. Fuel 2019, 237, 555–565. [Google Scholar] [CrossRef]

- Pan, J.; Zhou, C.; Liu, C.; Tang, M.; Cao, S.; Hu, T.; Ji, W.; Luo, Y.; Wen, M.; Zhang, N. Modes of occurrence of rare earth elements in coal fly ash: A case study. Energy Fuels 2018, 32, 9738–9743. [Google Scholar] [CrossRef]

- ASTM standard specification for coal fly ash and raw or calcined natural pozzolan for use. Annu. B. ASTM Stand. 2010, 3–6. [CrossRef]

- Kumari, A.; Panda, R.; Jha, M.K.; Kumar, J.R.; Lee, J.Y. Process development to recover rare earth metals from monazite mineral: A review. Miner. Eng. 2015, 79, 102–115. [Google Scholar] [CrossRef]

- Cetiner, Z.S.; Wood, S.A.; Gammons, C.H. The aqueous geochemistry of the rare earth elements. Part XIV. The solubility of rare earth element phosphates from 23 to 150 °C. Chem. Geol. 2005, 217, 147–169. [Google Scholar] [CrossRef]

- Hower, J.; Groppo, J.; Joshi, P.; Dai, S.; Moecher, D.; Johnston, M. Location of cerium in coal-combustion fly ashes: Implications for recovery of lanthanides. Coal Combust. Gasif. Prod. 2003, 5, 73–78. [Google Scholar] [CrossRef]

- Blissett, R.S.; Smalley, N.; Rowson, N.A. An investigation into six coal fly ashes from the United Kingdom and Poland to evaluate rare earth element content. Fuel 2014, 119, 236–239. [Google Scholar] [CrossRef]

- Dai, S.; Zhao, L.; Peng, S.; Chou, C.L.; Wang, X.; Zhang, Y.; Li, D.; Sun, Y. Abundances and distribution of minerals and elements in high-alumina coal fly ash from the Jungar Power Plant, Inner Mongolia, China. Int. J. Coal Geol. 2010, 81, 320–332. [Google Scholar] [CrossRef]

- Dai, S.; Zhao, L.; Hower, J.C.; Johnston, M.N.; Song, W.; Wang, P.; Zhang, S. Petrology, mineralogy, and chemistry of size-fractioned fly ash from the Jungar power plant, Inner Mongolia, China, with emphasis on the distribution of rare earth elements. Energy Fuels 2014, 28, 1502–1514. [Google Scholar] [CrossRef]

- Lanzerstorfer, C. Pre-processing of coal combustion fly ash by classification for enrichment of rare earth elements. Energy Rep. 2018, 4, 660–663. [Google Scholar] [CrossRef]

- Pan, J.; Nie, T.; Vaziri Hassas, B.; Rezaee, M.; Wen, Z.; Zhou, C. Recovery of rare earth elements from coal fly ash by integrated physical separation and acid leaching. Chemosphere 2020, 248, 126112. [Google Scholar] [CrossRef]

- Kashiwakura, S.; Kumagai, Y.; Kubo, H.; Wagatsuma, K. Dissolution of rare earth elements from coal fly ash particles in a dilute H2SO4 solvent. Open J. Phys. Chem. 2013, 03, 69–75. [Google Scholar] [CrossRef]

- Joshi, P.B.; Preda, D.V.; Skyler, D.A.; Tsinberg, A.; Green, B.D.; Marinelli, W.J. Recovery of Rare Earth Elements and Compounds from Coal Ash. U.S. Patent 8,968,688, 3 March 2015. [Google Scholar]

- Joshi, P.B.; Preda, D.V.; Skyler, D.A.; Scherer, A.; Green, B.D.; Marinelli, W.J. Recovery of rare earth Elements and Compounds from Coal Ash. U.S. Patent 9,394,586, 19 July 2016. [Google Scholar]

- Cao, S.; Zhou, C.; Pan, J.; Liu, C.; Tang, M.; Ji, W.; Hu, T.; Zhang, N. Study on influence factors of leaching of rare earth elements from coal fly ash. Energy Fuels 2018, 32, 8000–8005. [Google Scholar] [CrossRef]

- Das, S.; Gaustad, G.; Sekar, A.; Williams, E. Techno-economic analysis of supercritical extraction of rare earth elements from coal ash. J. Clean. Prod. 2018, 189, 539–551. [Google Scholar] [CrossRef]

- Fan, M.; Co, E.M.; Zhao, Y.; Long, Z.; Liu, W. Preprint 17–103. Recovery of valuable elements from Chinese coal by-products. In Proceedings of the Preprint 17–103, 1–6. SME Annual Meeting, Dever, CO, USA, 19–22 February 2017. [Google Scholar]

- Huang, Z.; Fan, M.; Tian, H. Rare earth elements of fly ash from Wyoming’s Powder River Basin coal. J. Rare Earths 2019. [Google Scholar] [CrossRef]

- Huang, C.; Wang, Y.; Huang, B.; Dong, Y.; Sun, X. The recovery of rare earth elements from coal combustion products by ionic liquids. Miner. Eng. 2019, 130, 142–147. [Google Scholar] [CrossRef]

- King, J.F.; Taggart, R.K.; Smith, R.C.; Hower, J.C.; Hsu-Kim, H. Aqueous acid and alkaline extraction of rare earth elements from coal combustion ash. Int. J. Coal Geol. 2018, 195, 75–83. [Google Scholar] [CrossRef]

- Kumari, A.; Parween, R.; Chakravarty, S.; Parmar, K.; Pathak, D.D.; Lee, J.; Jha, M.K. Novel approach to recover rare earth metals (REMs) from Indian coal bottom ash. Hydrometallurgy 2019, 187, 1–7. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, S.; Zhang, H.; Cheng, F. Novel extraction of valuable metals from circulating fluidized bed-derived high-alumina fly ash by acid–alkali–based alternate method. J. Clean. Prod. 2019, 230, 302–313. [Google Scholar] [CrossRef]

- Shimizu, R.; Sawada, K.; Enokida, Y.; Yamamoto, I. Supercritical fluid extraction of rare earth elements from luminescent material in waste fluorescent lamps. J. Supercrit. Fluids 2005, 33, 235–241. [Google Scholar] [CrossRef]

- Tang, M.; Zhou, C.; Pan, J.; Zhang, N.; Liu, C.; Cao, S.; Hu, T.; Ji, W. Study on extraction of rare earth elements from coal fly ash through alkali fusion–Acid leaching. Miner. Eng. 2019, 136, 36–42. [Google Scholar] [CrossRef]

- Tuan, L.Q.; Thenepalli, T.; Chilakala, R.; Vu, H.H.T.; Ahn, J.W.; Kim, J. Leaching characteristics of low concentration rare earth elements in Korean (Samcheok) CFBC bottom ash samples. Sustainability 2019, 11, 2562. [Google Scholar] [CrossRef]

- Taggart, R.K.; Hower, J.C.; Dwyer, G.S.; Hsu-Kim, H. Trends in the rare earth element content of U.S.-based coal combustion fly ashes. Environ. Sci. Technol. 2016, 50, 5919–5926. [Google Scholar] [CrossRef] [PubMed]

- Peiravi, M.; Ackah, L.; Guru, R.; Mohanty, M.; Liu, J.; Xu, B.; Zhu, X.; Chen, L. Chemical extraction of rare earth elements from coal ash. Miner. Metall. Process. 2017, 34, 170–177. [Google Scholar] [CrossRef]

- Kutchko, B.G.; Kim, A.G. Fly ash characterization by SEM-EDS. Fuel 2006, 85, 2537–2544. [Google Scholar] [CrossRef]

- Ward, C.R.; French, D. Determination of glass content and estimation of glass composition in fly ash using quantitative X-ray diffractometry. Fuel 2006, 85, 2268–2277. [Google Scholar] [CrossRef]

- Mastral, A.M.; Callén, M.S.; García, T. Fluidized bed combustion (FBC) of fossil and nonfossil fuels. A comparative study. Energy Fuels 2000, 14, 275–281. [Google Scholar] [CrossRef]

- Dutrizac, J.E. The behaviour of the rare earth elements during gypsum (CaSO4·2H2O) precipitation. Hydrometallurgy 2017, 174, 38–46. [Google Scholar] [CrossRef]

- Park, S.; Liang, Y. Bioleaching of trace elements and rare earth elements from coal fly ash. Int. J. Coal Sci. Technol. 2019, 6, 74–83. [Google Scholar] [CrossRef]

- Matyas, B.; Gerber, P.; Solymos, A.; Kaszanitzky, F.; Panto, G.; Leffler, J. Process for Recovering Rare Metals from the Combustion Residue of Coal by Digestion. U.S. Patent 4,649,031, 10 March 1987. [Google Scholar]

- Ding, J.; Ma, S.; Shen, S.; Xie, Z.; Zheng, S.; Zhang, Y. Research and industrialization progress of recovering alumina from fly ash: A concise review. Waste Manag. 2017, 60, 375–387. [Google Scholar] [CrossRef]

- Yao, Z.T.; Xia, M.S.; Sarker, P.K.; Chen, T. A review of the alumina recovery from coal fly ash, with a focus in China. Fuel 2014, 120, 74–85. [Google Scholar] [CrossRef]

- Liu, H.; Tian, H.; Zou, J. Combined extraction of rare metals Ga-Nb-REE from fly ash. Sci. Technol. Rev. 2015, 33, 39–43, (In Chinese with English Abstract). [Google Scholar]

- Dai, S.; Wang, X.; Zhou, Y.; Hower, J.C.; Li, D.; Chen, W.; Zhu, X.; Zou, J. Chemical and mineralogical compositions of silicic, mafic, and alkali tonsteins in the late Permian coals from the Songzao Coalfield, Chongqing, Southwest China. Chem. Geol. 2011, 282, 29–44. [Google Scholar] [CrossRef]

- Fernando, W.A.M.; Ilankoon, I.M.S.K.; Syed, T.H.; Yellishetty, M. Challenges and opportunities in the removal of sulphate ions in contaminated mine water: A review. Miner. Eng. 2018, 117, 74–90. [Google Scholar] [CrossRef]

- Honaker, R.Q.; Zhang, W.; Yang, X.; Rezaee, M. Conception of an integrated flowsheet for rare earth elements recovery from coal coarse refuse. Miner. Eng. 2018, 122, 233–240. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Jafari, A.; Yaghmaei, S.; Vossoughi, M.; Roostaazad, R. Bioleaching of low-grade sphalerite using a column reactor. Hydrometallurgy 2006, 82, 75–82. [Google Scholar] [CrossRef]

- Casas, J.M.; Martinez, J.; Moreno, L.; Vargas, T. Bioleaching model of a copper-sulfide ore bed in heap and dump configurations. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 1998, 29, 899–909. [Google Scholar] [CrossRef]

- Merten, D.; Geletneky, J.; Bergmann, H.; Haferburg, G.; Kothe, E.; Büchel, G. Rare earth element patterns: A tool for understanding processes in remediation of acid mine drainage. Chemie der Erde 2005, 65, 97–114. [Google Scholar] [CrossRef]