Abstract

The aircraft power supply system plays a crucial role in maintaining the stability and safety of airborne avionics. With the evolution toward more electric and all-electric aircraft, its architecture increasingly adopts symmetrical configurations, such as dual-redundant paths and three-phase balanced outputs. However, these symmetry-based designs are often disrupted by diverse fault mechanisms encountered in complex operational environments. This review contributes a comprehensive and structured analysis of how such fault events lead to symmetry-breaking phenomena across different subsystems, including generators, converters, controllers, and distribution networks. Unlike previous reviews that treat faults in isolation, this study emphasizes the underlying physical mechanisms and hierarchical fault propagation characteristics, revealing how structural coupling and multi-physics interactions give rise to failure modes. The paper concludes by outlining future research directions in symmetry-aware fault modeling and intelligent maintenance strategies, aiming to address the growing complexity and reliability demands of next-generation aircraft.

1. Introduction

With the continuous advancement of modern aviation technology, aircraft onboard electronic systems have become increasingly complex, placing higher demands on the reliability, stability, and intelligence of power supply systems. As the core of the electrical infrastructure, aircraft power supply systems not only ensure the operation of critical avionics equipment but also directly impact flight safety and mission capability. In recent years, driven by the concepts of multi-electric aircraft (MEA) and all-electric aircraft (AEA), traditional hydraulic and pneumatic energy systems are gradually being replaced by electrical systems, leading to increasing complexity in terms of capacity, structure, and control for power supply systems [1]. To address this complexity and meet high reliability requirements, power supply system architectures are increasingly adopting symmetrical configurations, such as dual redundant paths and three-phase balanced outputs. However, in complex operating environments, these symmetry-based designs are often subject to symmetry breaking due to various fault mechanisms, mainly including electrical imbalance and destruction of the circuit symmetry structure. This poses new challenges to the stable operation of power supply systems.

Recent research has explored various modeling and simulation techniques to better understand fault mechanisms. For instance, finite element analysis (FEA) has been applied to simulate electromagnetic performance and thermal distribution in power components [2,3], while numerical simulation methods have aided in evaluating fault propagation under dynamic loading conditions [4]. In parallel, the selection of experimental parameters for fault analysis has been increasingly standardized through hardware-in-the-loop (HIL) and real-time test platforms [5]. Furthermore, dynamic parameter modeling has received attention for capturing transient behaviors in generators and converters under fault conditions [6].

In addition, artificial intelligence (AI) techniques, such as neural networks, support vector machines, and deep learning models are being integrated into fault detection and predictive maintenance frameworks, significantly improving the accuracy and real-time capability of diagnosis systems [7,8,9].

Despite the increasing body of work in these areas, most existing studies focus on isolated components or fault phenomena. There remains a lack of a systematic, symmetry-oriented review that captures the interactions between physical faults and the structural symmetry of the power supply system. This paper seeks to fill this gap by providing a comprehensive overview of the aircraft power supply system’s structure, typical field failure types, and underlying physical mechanisms while emphasizing the critical role of symmetry in fault formation, propagation, and detection.

From the existing operation data and maintenance reports, the failures of aircraft power supply systems under off-field conditions are characterized by strong suddenness, diverse types, and difficult diagnosis. Among them, power interruption, bus voltage abnormality, distribution unit failure and other problems may trigger a chain reaction, posing a great threat to the safety of the aircraft. In this regard, in-depth study of typical fault types and their mechanisms in the field of the power supply system and establishment of a systematic fault knowledge base are of great significance to improve the fault prediction and warning capability, optimize the maintenance and guarantee strategy, and enhance the engineering practicability of the power supply system. Although there have been a number of fault reviews in the existing literature for aircraft power supply systems [10], flight control systems [11], rotating rectifiers [12], and cables [13], there is still a lack of a comprehensive compendium of power supply system faults, which is not conducive to recognizing the full picture of the types of faults in aircraft power supply systems. Therefore, it is of practical significance to statistically and comprehensively discuss the faults of existing aircraft power supply systems in order to provide clear ideas for industry and academic research.

Aiming at the above problems, this paper firstly introduces the composition structure of aircraft power supply systems, their respective functions, and the development history of a typical aircraft power supply systems; then from the typical outfield faults, combs and summarizes the common fault types of aircraft power supply systems and their performance characteristics; and finally summarizes the formation mechanism of various types of faults in combination with the system structure. The structure of this paper is arranged as follows: Section 2 briefly introduces the composition structure, functional partition, and working principle of the aircraft power supply system, which provides the basic background for the subsequent fault analysis; Section 3 systematically combs through the typical outfield fault types and classifies them according to the fault parts and manifestations; Section 4 deeply analyzes the formation mechanism of various types of faults, the triggering conditions, and their potential impacts; and Section 5 sums up the full text of this paper and puts forward a prospect of the subsequent research direction.

The terms and abbreviations in this paper are shown in Table 1.

Table 1.

Nomenclature.

2. Aircraft Power Supply System Overview

With the development needs of high efficiency and low cost in the aircraft manufacturing industry, modern aircraft airborne systems are tending to use electric energy to replace traditional secondary energy sources such as hydraulic energy and pneumatic energy, i.e., relying more on fuel cells, supercapacitors, and electric motors to provide the prime mover [2]. At the same time, with the development of power electronics technology and motor drive system technology, the aviation industry is vigorously promoting the research and development and application of multi-electric and all-electric aircraft technology to effectively reduce carbon emissions.

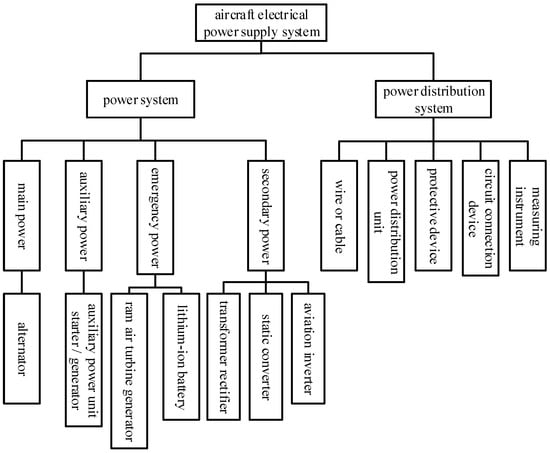

The aircraft power supply system mainly consists of two parts: the power supply system and the power distribution system. Figure 1 below shows the common components of the aircraft power supply system.

Figure 1.

Aircraft power supply system components.

A complete aircraft power system consists of primary power, secondary power, emergency power, and auxiliary power. The main power supply system is the source of electrical energy for all electrical equipment on the aircraft, such as action devices, communication and navigation, lighting facilities, etc. It usually refers to the main generator device driven by the aviation engine; the secondary power supply is a power supply device used to change the voltage, current, and frequency of the main power supply, such as a variable voltage rectifier, a static converter, etc., which converts the main power supply into another form of power to meet the needs of different electrical equipment; the emergency power supply is a power supply system independent of the main power supply system for when the main power supply fails to supply power to the important electrical equipment on board, such as aviation batteries, etc.; medium and large aircraft are usually equipped with auxiliary power systems, such as auxiliary power unit (APU)-driven generators, aviation batteries, etc., which can be used to take over from the main power supply of the aircraft in the process of service failure, and is also commonly used in ground inspection. The auxiliary power supply can replace the failed main power supply during the service of the airplane, and is also commonly used for ground inspection.

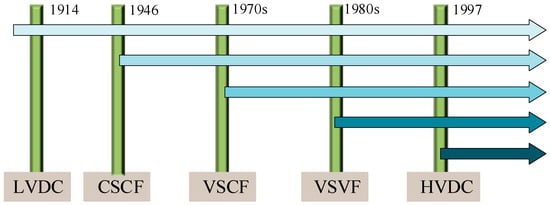

The type and structure of aircraft power systems vary according to the type of aircraft, the use of the long aircraft, and the type of engine. From the perspective of the development history of aircraft power systems, there are five typical types of power systems that have been used in aircraft: the low-voltage direct current (LVDC) power system, the constant speed and constant frequency (CSCF) AC power system, the variable speed and constant frequency (VSCF) AC power system, the variable speed and variable frequency (VSVF) AC power system, and the high-voltage direct current (HVDC) power system [14], and their development history [15] is shown in Figure 2 shown.

Figure 2.

Aircraft power system development history.

The aircraft power distribution system consists of conductors or cables, power distribution devices, protection devices, circuit connection devices, and measuring instruments. Aircraft conductors are made of multiple strands of fine copper wires stranded together with an outer insulating layer for the transmission of electrical energy or circuit signals, and multiple wires are combined to form cables. There are three kinds of power distribution devices: one is manually used to connect and disconnect the circuit of the switch and button; the second is a long-distance connection of the circuit, the relay, and the contactor, where the relay is mostly used to turn on the signal circuit or small power circuits and the contactor is used to turn on and off the high-current circuits; and the third is the end of the switch or cam-type switches, commonly used in manipulation devices. Solid-state power controllers, which are contactless appliances with multiple functions of switches, relays, and circuit protectors, are beginning to be widely used in multi-electric airplanes. Power grid protectors (or fuses) and circuit breakers (automatic protection switches) are commonly used. Fuses are mainly used for short-circuit protection, and circuit breakers have both circuit protection and switching functions, and can be reused. Circuit connection devices include terminal blocks and electrical connectors. Measuring instruments are used to indicate the operating parameters in the circuit, and modern aircraft have switched to a combination of sensors and flat panel displays.

3. Summary of Typical Faults in Aircraft Power Supply Systems

A typical fault summary of the various components of aircraft power supply system that can fail are is as follows: the main power supply in the generator, constant speed drive and auxiliary power unit, and generator control unit failure; transmission lines in the cable, converging strip, and power equalization link failure; and electrical energy conversion devices such as inverters, rectifiers, and converters failure. Failure modes have various manifestations such as under-voltage, over-voltage, voltage instability, under-frequency, over-frequency, and so on. The following will sort out the common faults in each part of the aircraft power system and summarize the common characteristics among these faults.

3.1. Power System Failure

3.1.1. Main Power

The main power supply part of the aircraft power supply system mainly includes a three-stage brushless generator, generator controllers, and other parts, and if constant-speed and constant-frequency AC power supply is used, constant-speed transmission devices are also included. The generator controller is used to control the voltage and frequency of the generator output and cut off the connection between the generator and the power grid in times when the generator fails. The constant speed drive ensures that the input speed of the constant speed and constant frequency alternator is constant. Failure of any of the above three parts will lead to the failure of the main power supply, so this subsection analyzes the failure of each of the above three parts and summarizes their failure forms.

- Generators

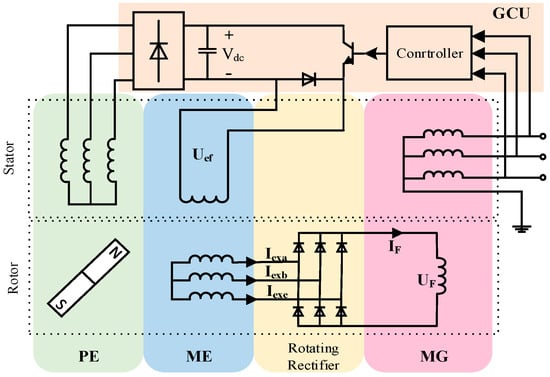

The aircraft generator is generally a three-stage brushless generator, as shown in Figure 3. The generator consists of a permanent magnet pre-exciter (PE), a main exciter (ME), a rotating rectifier, and a main generator (MG). The main generator is a rotating pole type synchronous generator, the main exciter is a rotating armature type synchronous generator, and the pre-exciter is a rotating pole type permanent magnet synchronous generator. The main exciter rotor is equipped with a rectifier (called rotating rectifier); when the generator is running, the main exciter armature generates a large alternating current through the rotary rectifier that is supplied directly to the main generator rotor excitation winding.

Figure 3.

Three-stage brushless generator.

Aircraft generator faults include over-voltage, under-voltage, over-frequency, and under-frequency faults [16]. When generator controller, excitation winding, and armature winding failures occur, it will lead to generator over-voltage or under-voltage faults; when generator speed failure occurs, over-frequency, or under-frequency faults will occur. In the following, starting from the internal structure of the generator, the specific types of faults contained in the above faults are analyzed.

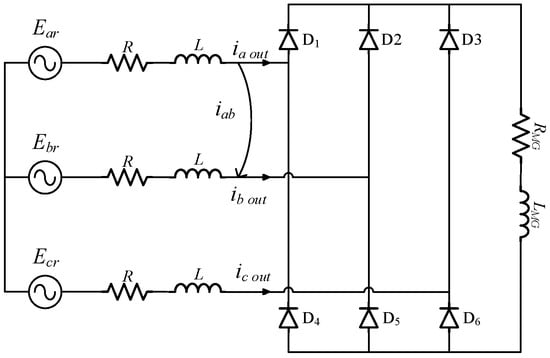

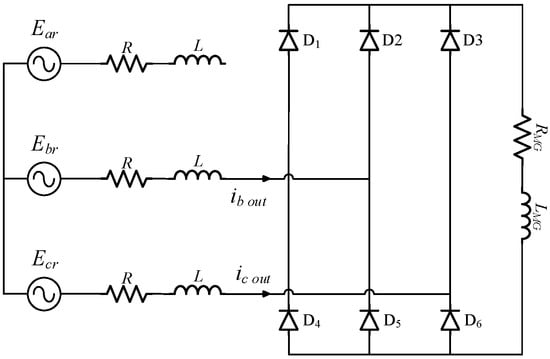

Excitation winding overheating faults and excitation winding phase short-circuit faults in the main exciter are common serious sudden faults in the excitation system [17]. As shown in Figure 4, when a phase short-circuit occurs, phase AB, taken as an example here, in this case, phase A and phase B can be regarded as a new phase AB: from the load side, the new phase AB and phase C form a special single-phase rectifier, which becomes an asymmetrical circuit, and this will cause a third harmonic to appear in the three-phase current.

Figure 4.

Phase short-circuit fault in the excitation winding of the main exciter.

Phase open-circuit faults in rotor windings are likewise a common form of fault in aircraft generators [18]. As shown in Figure 5, when a phase open-circuit fault occurs, take phase A as an example, at this time, phase B and phase C form a single-phase rectifier, making the faulty phase A current zero.

Figure 5.

Failure of the open excitation winding of the main exciter.

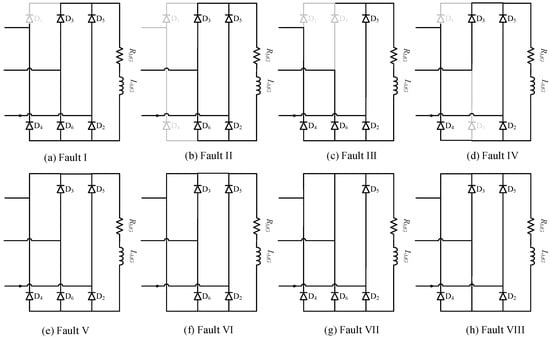

The rotating rectifier is one of the most failure prone components of a generator and has the highest failure hazard. Each diode in the rotary rectifier has the possibility of an open/short circuit, but in practice, 1 to 2 diodes fail most commonly [12]. The common failure modes are categorized, as shown in Table 2, where the typical faulty diode manifestation is shown in Figure 6.

Table 2.

Classification of rotary rectifier diode failure modes.

Figure 6.

Typical faulty diode manifestations.

- 2.

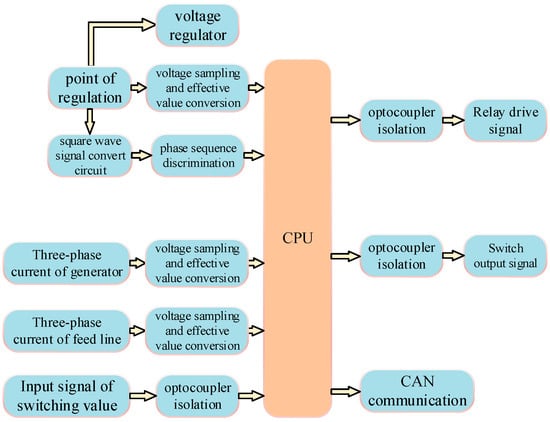

- Generator control unit

The board-level circuitry of the aircraft generator electronic controller mainly consists of ten types of typical functional circuit modules, such as the central processor, external communication interface, A/D and D/A conversion, input channels, output channels, power supply, and so on [19]. Its system hardware principle is shown in Figure 7. Failure analysis of each module will be carried out in the following.

Figure 7.

Hardware principle of the GCU system.

- (1)

- CPU fault modes

Generally, the CPU of the generator controller is divided into five modules, such as register decoding, data storage, data transmission, data processing, and instruction sequence, etc., and the following failure analysis is carried out for each of the above modules respectively.

Registers are functional components in the CPU that have temporary storage functions or record the CPU’s operating status, and there are mainly fault forms such as incorrect access to registers, inaccessible registers, and multi-register access. Data storage faults refer to faults of the RAM and ROM modules of the CPU, where the failure modes of the RAM include fixed-type faults of the stored values of its memory cells, skip faults, combination faults, open-circuit faults, address decoding faults, etc., and the faults of the ROM mainly include faults related to missing and redundant cross-points in the arrays.

Data transmission faults are faults that occur on the various transmission signal lines within the CPU, including signal-line fixed-value faults and signal-line coupling-effect faults.

Data processing module fault modes include arithmetic operation faults, flag bit reset faults, logic operation faults, bit operation faults, and decoding faults; instruction sequence fault modes include instruction completion error, instruction not completed, and instruction completion redundancy.

- (2)

- A/D, D/A fault modes

An A/D, D/A converter acts as a conversion interface between digital and analog circuits; generator electronic controllers need to realize the input detection and output control functions, so it occupies an important position in the controller. A/D, D/A failure modes include the following faults: fixed open input line, fixed level input line, fixed open output line, fixed output line, output line coupled, and the A/D and D/A conversion signals are out of normal range.

- (3)

- Communication interface function circuit failure modes

The serial communication interface circuit is selected as a representative of external communication circuits to summarize its common failure modes. The failure modes are fixed transmit/receive signal values and fixed open circuits on the transmit/receive signal lines.

- (4)

- Sensor and signal conditioning circuit failure modes

The test information obtained from each test point goes through the signal conditioning circuit and is then sent to the CPU for acquisition and processing. Possible failure modes are: output voltage is 0 or no output, unstable output voltage or current, large difference between the measured value and the real value of the test point, no signal, signal offset or exceeding the threshold value, no frequency signal or incorrect frequency signal, and fixed high or low signal.

- 3.

- Constant speed drive

A constant-speed drive is fitted to certain models fitted with a constant-frequency three-stage generator. The device is a complex mechanical–hydraulic servo system. Its function is to convert the variable-speed power output from the aircraft engine accessory drive magazine into constant-speed power in order to produce constant-frequency alternating current from the driven generator. Its failure modes are mainly under-speed, over-speed, and disengagement, and its specific manifestations are diversified.

The previous research in [20] has analyzed the problem of oil leakage from the intake valve of a constant speed drive and pointed out that the key influencing factor of this problem is the defective design of the relevant dimensions of the torsion springs and valve seats in the assembly.

The authors of [21] studied the “delayed start” fault of the constant speed drive, which is characterized by the time from the engine ignition to the power generation of the combined power generating unit (including the constant speed drive and alternator) exceeding the specified requirements, and explained the fault mechanism as the thickening of the viscosity of the oil in the unit caused by low temperature.

In study [22], the fault causes of the aircraft warning system printing ‘left (right) generator fault‘ and ‘disconnected constant assembly‘ were analyzed in detail. It is explained that the fault may be caused by the failure of the warning system, the internal fault of the pressure signal, the poor insulation performance of the pressure signal cable or the constant assembly joint, the pollution of the constant assembly lubricating oil system, serious pollution of the filter, assembly error, a change in aircraft attitude, and so on, and the preventive measures are given.

In [23] the mechanism of bearing disintegration failure within the turbine centrifugal electric gate assembly of an engine constant speed drive unit was analyzed, and it was determined that the essence of this bearing disintegration was the circumferential fracture of the bearing’s outer sleeve ring and the shattering of the steel balls, which was a one-time overload damage caused by an abnormal axial shock load during the assembly of the bearing.

A study on the system failure caused by unstable working pressure in the main power system constant speed transmission device of a certain type of aircraft in the course of its use was carried out in [24]. The effects of operating pressure and the oil inlet filter on various components are analyzed in depth.

The previous literature has studied the phenomenon of ball head chuck burn failure during the test of a certain type of aircraft constant speed transmission device, analyzed the cause of the failure, and proposed effective solutions [25].

3.1.2. Aircraft Secondary Power Faults

In recent years, there has been a rapid development of multi-electric aircraft. Compared with the traditional aircraft, the multi-electric aircraft eliminates part of the aircraft’s pneumatic, mechanical, and hydraulic control systems and adopts electric energy for driving. In the multi-electric aircraft, the single-phase/three-phase constant-frequency 115 VAC, low-voltage 28 VDC, high-voltage 270 VDC, and other specifications or types of power supply voltages required by on-board equipment are obtained through secondary power supplies with different functions, which include AC/DC/AC, AC/DC, DC/DC converters, etc. [26]. The following summarizes the failures of power electronic converter equipment in aircraft secondary power supplies.

The secondary power supply mainly includes a variable voltage rectifier, static converter, inverter, etc. and is mainly used to transform the electrical energy from the main power supply into other kinds of power supply.

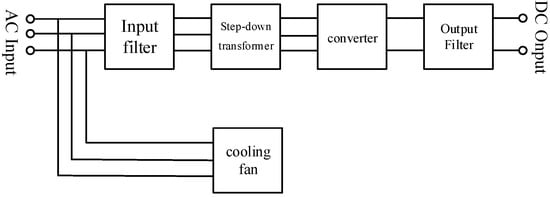

- Aircraft Transformer Rectifiers

Transformer rectifiers are used to convert 115/200 V, 400 Hz, or inverter alternating current to 28 VDC to supply DC power equipment. The transformer rectifiers used on aircraft typically consist of an input filter, a step-down transformer, a diode rectifier circuit, an output filter, and a cooling fan. Some transformer rectifiers also have balancing reactors for system current balancing. The block diagram of the transformer rectifier for a certain type of aircraft is shown in Figure 8.

Figure 8.

The block diagram of the transformer rectifier.

The faults of aircraft transformer rectifiers mainly include three categories: transformer fault, rectifier bridge module fault, and balance reactor fault. Among them, transformer faults include open circuit, short circuit, parameter drift, magnetic core aging, and other fault forms; the rectifier bridge module fault includes diode open circuit, short circuit, parameter drift, and other modes; and the reactor has common faults such as poor welding quality and poor contact between the winding and lead wires [27]. In view of the above faults, most of the existing literature starts from the specific fault phenomena, focuses on the fault mechanism, and explores preventive measures.

In [28], the fault diagnosis problem of an aircraft transformer rectifier unit is studied, and the fault mode determination framework is established, which provides a standardized basis for the subsequent fault diagnosis research of transformer rectifiers.

Reference [29] pointed out three specific fault phenomena of a certain type of transformer rectifier (forward current fault, reverse current fault, voltage out-of-tolerance fault), and analyzed the fault mechanisms and causes.

- 2.

- Static converter

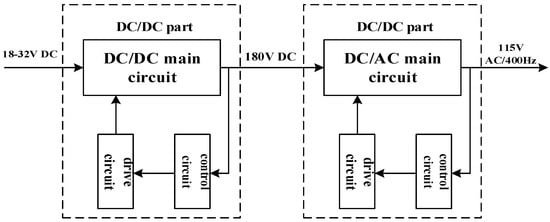

A static converter is one of the secondary power sources of aircraft, which can be used as emergency AC power supply for airborne equipment. Its main function is to convert the DC power of aircraft generator or battery into 115 V/400 Hz AC power. Generally, aDC/DC-DC/AC two-stage conversion scheme is adopted. The structure diagram is shown in Figure 9. Based on the phenomena in the actual working conditions, the existing literature studied faults such as abnormal output voltage fluctuation and abnormal output voltage amplitude and found that the causes of the faults are generally control chip faults or component faults.

Figure 9.

Two-stage static converter.

The research in [30] focused on the single-phase 115 V/400 Hz AC output voltage amplitude low fault of the multi-output static converter and concluded that reason for the fault was a fault in the chip used to output the reference sine wave, which caused the SPWM control signal to be abnormal, making the output amplitude low.

The authors of [31] studied the high peak factor fault of a single-phase 115 V/400 Hz AC output voltage of a static converter, analyzed the working principle of a multi-output static converter, located the cause of the fault as component failure, and analyzed the product design defects.

The previous literature introduces the basic principle of an aeronautical static converter, analyzes some common faults, and summarizes the troubleshooting methods of static converter power supply network faults and static converter faults [32].

- 3.

- Inverter

The fault modes of an aircraft inverter mainly include open-circuit and short-circuit fault modes of three-phase inverters and single-phase inverters. According to the number and location of IGBT faults in three-phase inverters, the fault modes can be divided into three categories: single IGBT fault, all IGBT faults in a single bridge arm, and two IGBT faults in different bridge arms. There are two fault modes in the single-phase inverter: open-circuit fault and short-circuit fault.

The research in [33] analyzed the causes of inverter faults from two aspects, IGBT component faults and inverter overcurrent faults, and proposes a detection method and rectification measures.

In [34], a fast diagnosis method for the open-circuit fault of an inverter is proposed to solve the problem that the performance of a permanent magnet synchronous motor drive system will decrease when the open-circuit fault occurs in the power switching element.

The authors of [35] analyzed the common faults of inverters a in photovoltaic power generation system, explored the causes of faults, and has important reference significance for the study of faults of aviation inverters.

3.1.3. Auxiliary Power Supply

The auxiliary power supply of aircraft power supply system generally includes only the auxiliary power unit (APU) starter/generator. The APU is a small independent power device that does not rely on the external energy of the aircraft. It is generally composed of a small gas turbofan engine, a power output shaft, an automatic control device, and a few are modified from a small turboprop or turboshaft engine, which is located at the tail of the aircraft. The APU mainly works when the aircraft is located on the ground. During flight, the APU can be started as an emergency power device to provide emergency energy for each system of the aircraft to ensure flight safety.

The faults of the APU can be divided into four types: mechanical component faults, auxiliary system faults, sensor and control component faults, and systemic faults [36]. In the field of APU faults, the existing literature is mainly based on the analysis of the fault mechanism, the analysis of the troubleshooting process, and the solution and prevention of the fault.

The authors [37] analyzed the starting failure of an auxiliary power unit of a certain type of aircraft and identified the cause of the failure as poor design of the connection point between the APU suction line and the engine oil supply main pipe.

In [38], a simulation model in was built in simulink to simulate and diagnose faults in the APU of a Boeing 747 airplane. The results show that this diagnostic technique works well in detecting faults in the compressor, turbine, load control valves, and fuel metering valves, but is less reliable in diagnosing speed sensor and generator faults.

The research in [39] studied the main faults of the auxiliary power unit of an Airbus A320 airplane, including the main starting contactor fault, the air intake cannot be opened fault, the APU fuel control component fault, the ignition system fault, and the connection fault of the electronic control box. The causes of the various types of faults were analyzed, and the troubleshooting process is described in detail.

3.1.4. Emergency Power Supply

If the aircraft power system fails during flight, the system will automatically switch to the emergency power supply to ensure flight safety. The emergency power supply system is the last safety guarantee for the power supply system of the aircraft during flight. The emergency power source of the aircraft power supply system mainly includes ram air turbine generators and lithium-ion batteries.

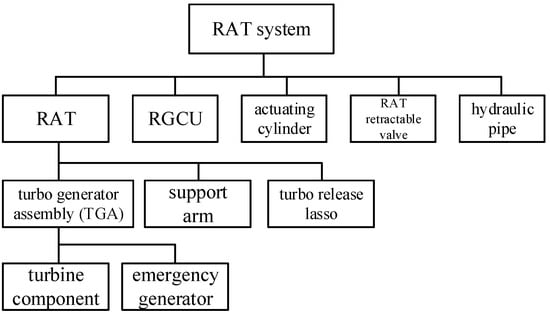

- Ram air turbine (RAT) generator

The physical architecture of the RAT system for a certain type of civil aircraft is shown in Figure 10. The RAT system mainly consists of the RAT, RAT generator control unit (RGCU), actuating cylinder, emergency generator, RAT retractable valve, hydraulic pipes, etc. Under the emergency condition of the airplane, the ram air turbine system unfolds and drives the generator to provide emergency electric power for the airplane under the action of relative airflow. Failures of the ram air turbine generator system mainly include the failure of the ram air turbine and the failure of the generator, of which the generator failure is roughly similar to the main power generator failure, so it will not be repeated here.

Figure 10.

RAT system architecture for a certain type of civil aircraft.

The faults of the ram air turbine mainly refer to the faults of the ram air turbine actuator cylinder, and there are usually two types of faults [40,41]:

① The actuator cannot be unlocked, mainly due to the failure of the locking mechanism, resulting in the unlocking process cannot be successfully achieved.

② The expansion time of the actuator is not within the range of design requirements (1–1.5 s), and there may be situations where the expansion time is too long or too short, which is related to the application of related loads and forces.

- 2.

- Lithium-ion battery

Common lithium-ion battery systems mainly include cells, battery management systems (BMSs), sensors, connecting components, and so on. Due to the complexity of their internal operation mechanisms and external use conditions, lithium-ion battery systems have multiple types of failures, as well as complex failure evolution modes. From the perspective of the control system, battery system failure modes can be mainly categorized into two types, i.e., cell failure and system failure. Cell failure is the main factor affecting the safety of the battery system, which can be further subdivided into progressive and sudden failures. System failures can be categorized into management system failures, sensor failures, and connecting component failures.

Among the cell failures, progressive failures are mainly caused by battery aging, and their nature is the superposition of a series of internal battery side reactions and is influenced by the internal and external environment of the battery. Sudden failures are failures that lead to sudden failure or serious performance degradation of the battery system without obvious signs or within a short period of time, including internal short circuits, thermal runaway, capacity diving, and liquid leakage [42,43].

3.2. Distribution System Faults

The existing literature for distribution system fault analysis mainly includes two aspects: cable faults and arc faults.

3.2.1. Cable Fault

Aircraft cable faults can be mainly categorized into soft faults and hard faults. Soft faults include wear and tear faults and intermittent faults, and ultimately are still manifested as hard faults, namely, short-circuit and disconnection faults; disconnection of hard faults is the main reason for the interruption of signal transmission and incorrect transmission.

Combined with the current situation of aircraft high-voltage DC power supply system lines, [44] uses part of the principle of longitudinal impedance phase protection to analyze and summarize the technical points of high-voltage DC power supply system line fault diagnosis.

In [45], starting from an air power failure of the aircraft power supply system, combined with the analysis of flight parameter data, it was finally found that the failure was caused by the loosening of the feeder riveting.

The authors of [46] focused on the short-circuit fault of aircraft cables and analyzed the influence of an insulation layer, the thermal effect, contact resistance, overload, and load short-circuit on the short-circuit characteristics of cables. The correctness of the proposed theoretical analysis was further verified by transient analysis and Matlab simulation results.

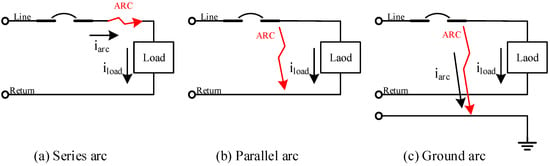

3.2.2. Arc Fault of Distribution System

Arc faults are considered to be the most dangerous events for aircraft, and many air accidents and aircraft failures have been directly or indirectly related to sustained arcs generated on the surface of the power supply lines of electrical systems [47].

Arc faults often occur in relation to the quality of the insulation of the power cables. They occur when the insulation is aged, damaged, or worn. Arc faults can be categorized as parallel arc faults, grounded arc faults, and series arc faults from the cause of arcing, as shown in Figure 11 [48].

Figure 11.

Classification of distribution system arc faults.

A parallel arc fault occurs between the power line and the return line, also known as a short circuit, and is defined as a fault caused by aging or damage to the power cable and a defect in the insulation through to the core. Grounded arc faults are defined between the power line and the chassis of the structure. In parallel and grounded arc faults, power is transferred directly from the source to the loop or chassis through a faulted connection with very low impedance. As a result, the arc current is significantly higher than the nominal load current, which makes parallel and grounded arc faults easy to detect. Conventional protective devices can easily respond to these faults.

The series arc fault is a different phenomenon. It occurs on the transmission line and does not produce high current as a short circuit. Series arc faults are caused by partial disconnection and loose connection, which can occur between wires and terminals or between jacks and plugs. Any of these conditions may lead to series arc faults, resulting in an increase in total impedance. Since this is a high impedance fault, the amplitude of the series arc fault current is lower than the rated load current and much lower than the trip curve. Conventional over-current protection and current differential protection methods cannot respond to series arc faults.

3.3. Fault Characterization Summary

The faults in each part of the aircraft power supply system have been discussed in detail above, and the fault forms of each of its systems are now summarized, as shown in Table 3. The table also summarizes the fault characteristic parameters corresponding to each fault, which facilitates the subsequent study of fault identification and fault diagnosis.

Table 3.

Summary of aircraft power supply system failure forms.

The aircraft power supply system is highly integrated in the development of modern aviation technology. With the in-depth application of high-power semiconductor devices, intelligent control strategies, and digital technologies, the system has evolved into a complex system integrating multi-physical field coupling, dynamic hierarchical architecture, and highly redundant design. The multi-parameter interactions of energy conversion, medium property changes, mechanical stress fluctuations, and thermodynamic state migration accompanying the operation process have posed significant challenges for system condition monitoring and fault diagnosis. The evolution patterns of these physicochemical parameters show significant differences between normal and abnormal operating conditions, constituting the explicit/implicit characterization of the system operating state. It is worth noting that the system fault characterization has significant spatio-temporal ambiguity, which is further exacerbated by unpredictable disturbances and signal noise in the operating environment. The complexity of the fault mechanism of the system is mainly reflected in the following multidimensional characteristics:

- Hierarchical correlation characteristics

The system architecture follows the modular design principle of “system–subsystem–component”, which makes the fault characterization and diagnosis process have a hierarchical correspondence. Based on this characteristic, it is necessary to construct differentiated diagnostic models and formulate corresponding hierarchical diagnostic strategies.

- 2.

- Fault conduction characteristics

There are two propagation mechanisms: horizontal and vertical. The horizontal level shows a chain reaction between components at the same level, and the vertical level shows a cross-level progressive effect, that is, component-level failures may cause functional abnormalities of subsystems up to the system level.

- 3.

- Nonlinear mapping characteristics

There exists a complex many-to-many mapping relationship between system faults and characterization signals, and this nonlinear diagnostic feature matrix is the core factor leading to difficulties in fault localization. Specifically, a single fault source may trigger multiple characterization signals, while the same characterization signal may correspond to multiple potential fault modes

- 4.

- Time-varying cumulative characteristics

The fault evolution process has significant time dimension characteristics, including three stages of fault initiation, propagation, and diffusion to significant characterization. By analyzing the fault propagation delay and characterization signal evolution law, early warning and trend prediction of faults can be realized.

Aiming at the above multi-dimensional complexity characteristics, the modern diagnostic system needs to integrate multi-source sensing technology to implement full-dimensional monitoring of key state parameters. Combined with intelligent data analysis algorithms, it realizes the diagnostic goals of fault source localization, mechanism analysis, and development prediction, and then builds an intelligent maintenance decision-making system based on condition assessment.

4. Fault Mechanism Analysis of Aircraft Power Supply Systems

Based on the physical mechanism of electrical system faults, this chapter analyzes the formation process of typical faults. Combined with the failure or aging of electronic devices, temperature change, mechanical vibration, mechanical wear, and other factors, the influence of the external field environment on the reliability of the power supply system is discussed.

4.1. Failure or Aging of Electronic Devices

There are a large number of electronic components in the aircraft power supply system. The working state of these devices directly affects the function of the system. Most of the functional faults can be located as the faults of a single device. Therefore, the failure or aging of the device is an important cause of the failure of the aircraft power supply system. The failure modes of semiconductor devices can be roughly divided into six categories, namely, open circuit, short circuit, no function, characteristic degradation, low qualification rate of retest, and poor structure [49]. Failure mechanisms can be classified into the following six types according to their causes:

- Degradation caused by design issues refers to design defects in layout, circuitry, and structure.

- The internal degradation mechanism refers to the secondary breakdown, CMOS blocking effect, neutron radiation damage, structural performance degradation caused by heavy metal contamination and material defects, instantaneous power overload, etc.

- The surface degradation mechanism refers to the channel leakage caused by sodium ion smearing, γ radiation damage, surface breakdown (creep), and small current gain reduction caused by surface recombination.

- The deterioration mechanism of the metallization system refers to aluminum electromigration, aluminum corrosion, aluminization damage, aluminum notch, step breaking aluminum, over-electric stress burning, etc.

- The packaging deterioration mechanism refers to tube leg corrosion, leakage, and leakage or short circuit caused by foreign objects in the shell.

- The damage caused by the use of the problem refers to electrostatic damage, surge damage, mechanical damage, damage caused by excessive temperature, failure caused by interference signals, corrosion of solder pins, etc.

4.2. Temperature Variation

During the operation of the aircraft power supply system, temperature change is one of the important external environmental factors that affect the stability and reliability of the system [50]. Especially in the field operation conditions, the aircraft is often in the extreme environment of high temperature or low temperature, coupled with the thermal effect of the equipment itself, it is easy for thermal fluctuations to lead to the occurrence and development of a variety of faults. The temperature change may mainly cause typical faults such as poor contact of electrical connectors, degradation of electronic module performance, aging of cable insulation, and misoperation of thermal protection devices.

Temperature increases can lead to higher contact resistance at electrical connectors. The thermal expansion of metals caused by temperature increases may cause originally tightly fitted connectors to loosen, resulting in poor contact. The rise in contact resistance further leads to localized heating, accelerating oxidation, and erosion of the contact surfaces. Under cyclic thermal stress, this ultimately results in connection failure. Additionally, in low-temperature environments, differences in thermal expansion coefficients between the connector housing and internal elastic contact components may cause a reduction in contact pressure, leading to intermittent contact issues [51].

Semiconductor devices in electronic control modules are extremely sensitive to temperature changes. High temperatures accelerate the decline in carrier mobility, increase leakage current, and reduce breakdown voltage in semiconductor devices, leading to unstable circuit performance and even device failure. In low-temperature environments, some devices exhibit poor startup characteristics, such as crystal oscillator frequency drift and reduced capacitance, which may also cause the control system to malfunction [52].

The insulation layer of cables can undergo thermal aging when exposed to high temperatures for long periods of time or frequent temperature fluctuations, resulting in problems such as decreased insulation resistance, reduced dielectric strength, and deterioration of mechanical strength. The accumulation of such problems can ultimately lead to faults such as breakdown discharge, leakage, or short circuits [13].

In power supply systems, some thermosensitive components (such as thermal relays and thermal fuses) may malfunction when there are drastic changes in temperature or when the ambient temperature deviates from the design value. For example, at hot high-altitude airports, some protective components on board may disconnect prematurely because the ambient temperature itself is close to the operating temperature, causing abnormal power interruptions [53].

In summary, temperature changes have a significant impact on many key components of aircraft power supply systems. Not only can they directly cause faults, but they can also indirectly reduce system reliability by accelerating material aging and performance degradation.

4.3. Mechanical Vibration

Mechanical vibration is a dynamic environmental stress that is common during aircraft flight, taxiing, takeoff, landing, and engine operation and has a significant impact on the structural safety and electrical connection reliability of the power supply system. Under long-term or intense vibration, multiple components in the aircraft power supply system are prone to structural loosening, fatigue damage, poor electrical connections, and other faults, which in severe cases can lead to power interruptions, arc discharges, and other safety hazards.

The effects of mechanical vibration are most pronounced at cable and connector connection points. Due to the relative displacement between cables and connectors, prolonged vibration can cause contact surface wear, contact pressure drop, or even pin misalignment, leading to increased contact resistance, signal interruption, or intermittent connection, which may trigger system false alarms or functional loss. The study [54] mentions that an under-voltage fault in an aircraft generator was caused by a mechanical failure of the engine. The specific cause was that after the engine started, the generator terminal plate continuously closed and disconnected under high vibration, which was equivalent to adding a variable resistance between the generator and the ground, causing an under-voltage fault in the aircraft generator.

Vibration can also induce microcracks, solder joint fatigue, and cause component detachment on printed circuit boards (PCBs). A typical example is the interior of certain static converters or inverters, where power devices are fixed to the heat sink substrate by screws or soldering. High-frequency vibration can accumulate microscopic fatigue damage at the solder joints, gradually evolving into open-circuit or short-circuit faults.

Mechanical vibrations can also affect the normal operation of mechatronic systems such as constant-speed transmission devices. For example, mechanical components like torsion springs, gears, and bearings within constant-speed systems may become loose, worn, or misaligned due to prolonged vibration impacts, leading to unstable output speeds and abnormal generator frequencies (under-frequency or over-frequency), which can impair power supply quality.

Emergency power supply units such as RAT systems may also fail to deploy in a timely manner due to vibration-induced jamming of the deployment mechanism or locking mechanism faults, thereby affecting the timeliness and reliability of the emergency power supply.

In summary, the influence of mechanical vibration on the aircraft power supply system presents the dual characteristics of structural damage and electrical performance degradation. The faults caused by mechanical vibration have the characteristics of strong concealment, cumulative development, and sudden performance.

4.4. Mechanical Wear

Mechanical wear is one of the key factors causing long-term performance degradation of aircraft power supply systems. Especially under external conditions such as high loads, high-frequency operation, and complex environmental vibrations, the continuous physical wear generated by the relative motion of mechanical components can cause key components to deteriorate or even fail. Typical faults include abnormal constant speed transmission output, auxiliary power unit start failure, and contactor malfunction, all of which are directly related to wear.

In the main power system, the constant-speed transmission device is a critical mechanical component connecting the engine to the alternator. This device relies on the high-precision meshing and sliding of internal gears, bearings, ball-head clamps, and other transmission pairs to achieve constant-speed output. Mechanical wear can cause pitting on gear surfaces, bearing fatigue spalling [24], or ball head wear [26], which can destroy the stability of the transmission chain, cause output speed fluctuations, and lead to power supply faults such as unstable generator frequency, under-frequency, or over-frequency.

APUs are also susceptible to mechanical wear. As a critical device for ground power supply or emergency power during flight, the gas turbine, turbine bearings, and gear mechanisms inside the APU often fail to start or generate power stably due to increased bearing clearance or turbine rotor imbalance after prolonged operation [55].

In addition, the mechanical contacts and elastic structures of the electromagnetic switching components, such as relays and contactors in the power distribution system, are also subject to wear during repeated switching [56]. Contact wear can lead to increased contact resistance, contact erosion, and even jamming, resulting in contactor failure, malfunction, or arcing. In severe cases, this can cause local overheating and arc faults, affecting the stability and safety of power distribution.

In summary, mechanical wear mainly affects the operating status of multiple pieces key equipment in the power supply system through increased structural gaps and degraded friction pair performance. The faults it causes are characterized by gradual development, difficult diagnosis, and sudden harmful consequences.

4.5. Electromagnetic Interference (EMI)

EMI is one of the important non-contact interference factors facing modern aircraft power supply systems. With the continuous improvement of aircraft electrification, the density of onboard equipment has increased, the current intensity has risen, and power electronic conversion equipment has been widely used, making the electromagnetic environment increasingly complex. Electromagnetic interference can cause control signal errors, power device malfunctions, communication interface failures, and even the overall paralysis of power supply modules in aircraft power supply systems, becoming an important mechanism for inducing system abnormalities and potential faults.

In generator control units, critical circuits such as central processors, A/D and D/A converters, and communication interfaces are highly sensitive to electromagnetic interference. EMI can enter the control system through cables, gaps in the aircraft fuselage, or power lines, causing logic circuit misfires, signal sampling distortion, or abnormal voltage levels. For example, when external electromagnetic wave radiation is superimposed on the analog signal line, the A/D converter output may jump or saturate, causing control command errors, which in turn trigger faults such as generator misregulation or mis-switching. The research in [57] points out that the internal voltage regulation circuit of the generator controller is a sensitive circuit, which manifests itself in the form of unstable output voltage and high-frequency noise after the reference voltage source is affected by electromagnetic interference.

Power electronic devices such as static converters, DC/DC converters, and inverters are themselves sources of interference due to frequent high-frequency switching operations, and they are also susceptible to interference. If electromagnetic compatibility is not adequately considered in the design, external electromagnetic interference can induce drive signal distortion, dead-zone control errors, or IGBT misfiring through switching device coupling paths, ultimately leading to output voltage fluctuations, harmonic distortion, or direct damage to power devices. For example, improper grounding design of multiple channels in a multi-output static converter can easily cause crosstalk between channels under electromagnetic interference conditions, leading to abnormal phenomena in the multi-output system [58].

Additionally, digital communication lines such as serial interfaces and CAN buses in communication systems may experience data packet loss, command errors, or complete loss of connection under electromagnetic interference, thereby affecting the coordinated control between various components of the power system, resulting in system response delays or functional loss. Reference [59] reviews the experimental research results on electromagnetic interference in aircraft wires and cables and proposes a method for testing the electromagnetic immunity of wires and cables within aircraft. The research in [60] indicates that in a certain type of aircraft, the communication system frequently experiences signal interference in strong electromagnetic environments due to inadequate shielding design, severely affecting the coordination between ground-to-air communication and power supply system scheduling.

Therefore, electromagnetic interference has a wide and far-reaching impact on aircraft power supply systems, with characteristics such as multiple propagation paths and difficult fault location. To reduce the risks it poses, it is necessary to fully implement electromagnetic interference resistance design principles at the design stage, such as using metal shielding, filters, ground separation, optical isolation, and other suppression measures, and to conduct electromagnetic sensitivity testing and immunity verification at the system level to ensure the stability and safety of the aircraft’s power supply system in complex electromagnetic environments.

5. Summary and Future Prospects

5.1. Summary

Based on a large number of references and engineering practice, this review systematically investigates the fault types and failure mechanisms in modern aircraft power supply systems, emphasizing the concept of symmetry disruption across subsystems. The key findings are as follows:

- A comprehensive overview of the aircraft power supply system architecture was presented to provide a structural foundation for fault analysis.

- Common types of faults were classified based on actual occurrence and subsystem structure, covering various parts of the aircraft power supply system.

- Failure mechanisms were analyzed from a physical perspective, involving multi-physics coupling factors such as temperature variation, EMI, mechanical vibration, and component aging.

- A symmetry-based framework was introduced to interpret fault propagation paths and hierarchical relationships among fault sources and symptoms.

These findings provide a holistic understanding of the fault behavior in complex aircraft power systems and highlight the need for integrated diagnostic and prognostic strategies.

5.2. Technical Challenges

Although significant advancements have been made in the analysis of aircraft power supply system faults, several technical challenges persist that hinder further development of robust diagnostic and maintenance strategies.

- Multi-Physical Coupling Complexity

Aircraft power systems operate under the influence of electrical, thermal, mechanical, and electromagnetic domains simultaneously. The interactions among these fields lead to high-dimensional dynamic behavior, where faults can no longer be analyzed in isolation. This complexity challenges the development of unified fault modeling frameworks.

- 2.

- Hierarchical Fault Propagation

Modern aircraft power systems follow a layered architecture from components to subsystems and the system level. Faults tend to propagate across these layers in both vertical and lateral directions. Accurately capturing the interdependencies and causal relationships remains difficult due to the nonlinear, time-dependent system behavior.

- 3.

- Signal Ambiguity and Uncertainty

Fault-related signals often lack distinctiveness, as different fault types may produce similar observable characteristics. In addition, interference, noise, and insufficient sampling rates further obscure the fault signatures. These issues reduce the reliability and sensitivity of conventional diagnosis techniques.

- 4.

- Limited Generalization of Diagnostic Models

Existing diagnostic methods are often tailored to specific system configurations and rely on fixed rules or thresholds. Their ability to adapt to new architectures or emerging fault patterns is limited. This lack of scalability hinders their application to evolving platforms such as more-electric and all-electric aircraft.

Addressing these challenges requires a shift toward more flexible, data-driven, and system-aware approaches to fault detection and characterization.

5.3. Future Prospects

With the continuous advancement of aviation electrification technology, all-electric aircraft (MEA) are becoming an important direction for the future development of aircraft. All-electric aircraft exhibit significant differences from traditional aircraft in terms of design concepts, power supply structures, and system functions. They feature more concentrated power loads, higher power ratings, and more complex system coupling, placing stricter demands on the stability and reliability of power supply systems.

In the context of all-electric aircraft, the types of faults in the power supply system will be more diverse, and the fault propagation paths will be more complex. Research on fault analysis for all-electric aircraft can be conducted in depth from the following aspects:

- Fault modeling mechanism for all-electric architecture

All-electric aircraft eliminate many traditional hydraulic and pneumatic systems, and electric actuators become critical loads, resulting in more complex and coupled power supply systems. Future research needs to focus on this new system architecture and construct a unified multi-energy flow (electricity, heat, control) coupling modeling system to study the evolution and impact chain of faults from a system-level perspective.

- 2.

- Data-driven fault identification mechanism based on air–ground integration

In the future, advanced sensor layout and flight data recording systems will be used to collect and compress key electrical parameters, fault signs, and alarm information in real time during flight, which will then be transmitted to the ground processing center via high-speed air–ground links. The ground system can diagnose and predict fault conditions based on big data analysis and intelligent algorithms, thereby realizing “remote health monitoring” and “preventive maintenance” of aircraft in service, significantly improving the efficiency and accuracy of field support.

Author Contributions

Conceptualization, Z.Z. and Q.Z.; methodology, J.W. and C.Q.; validation, Z.Z. and J.W. formal analysis, C.Q.; investigation, Z.Z. and J.W.; resources, Z.Z. and X.F.; writing—original draft preparation, Z.Z. and J.W.; writing—review and editing, C.Q. and Q.Z.; visualization, Z.Z. and J.W.; supervision, Z.Z. and X.F.; project administration, Z.Z.; and funding acquisition, Z.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

Authors Z.Z., Q.Z. and C.Q. were employed by the company Avic China Aero-Polytechnology Establishment. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Cano, T.C.; Castro, I.; Rodríguez, A.; Lamar, D.G.; Khalil, Y.F.; Albiol-Tendillo, L.; Kshirsagar, P. Future of Electrical Aircraft Energy Power Systems: An Architecture Review. IEEE Trans. Transp. Electrif. 2021, 7, 1915–1929. [Google Scholar] [CrossRef]

- Lyu, G.; Terao, Y.; Ohsaki, H. HTS Cable Design for Aircraft Application Considering Fault Conditions. IEEE Trans. Appl. Supercond. 2024, 34, 1–5. [Google Scholar] [CrossRef]

- Du, H.; Liu, Y.; Li, T.; Zhu, P. A High-Fidelity and Computationally Efficient Model for an Electrically Excited Synchronous Generator Based on Current–Flux Linkage Neural Networks. J. Electr. Eng. Technol. 2024, 19, 2903–2918. [Google Scholar] [CrossRef]

- Grigore-Muler, O. Modeling and Simulation of an Aircraft Electrical Power System. RRST-EE 2023, 68, 224–231. [Google Scholar] [CrossRef]

- Wang, M.; Xu, L.; Wang, K.; Zheng, Z.; Li, Y.; Grada, C.; Zhang, H. Hardware-in-the-loop real-time platform for more electric aircraft. J. Eng. 2018, 2018, 446–452. [Google Scholar] [CrossRef]

- El-Kishky, H.; Ebrahimi, H. On modeling and control of advanced aircraft electric power systems: System stability and bifurcation analysis. Int. J. Electr. Power Energy Syst. 2014, 63, 246–259. [Google Scholar] [CrossRef]

- Guzman, I.; Babiceanu, R.F. Fault Diagnosis of Aircraft Power Systems Based on Transients and Artificial Intelligence. In Proceedings of the 2024 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Naples, Italy,, 26–29 November 2024; pp. 1–7. [Google Scholar]

- Laib, A.; Terriche, Y.; Boudjefdjouf, H. Enhanced artificial intelligence technique for soft fault localization and identification in complex aircraft microgrids. Eng. Appl. Artif. Intell. 2024, 127 Pt B, 107289. [Google Scholar] [CrossRef]

- Wang, X.; Cui, J.; Tang, J.; Ye, J. Fault Diagnosis Technology Research of Aircraft Generator Rotating Rectifier Based on Extreme Learning Machine. Mach. Build. Autom. 2017, 46, 219–222. [Google Scholar]

- Lai, S.; Chen, G.; Yan, J.; Qing, X. Review and development trend of fault diagnosis methods for aircraft power supply system. Adv. Aeronaut. Sci. Eng. 2024, 15, 27–44. [Google Scholar]

- Wang, Y.; Gao, Y.; Shi, T. A review of flight control system fault research based on QAR data. China Saf. Sci. J. 2024, 34, 1–9. [Google Scholar]

- Wang, T.; Zhou, H.; Zhang, X.; Li, W.; Cao, W. A review of fault analysis and diagnosis methods for rotating rectifier in aircraft starter/generator. Acta Aeronaut. Astronaut. Sin. 2024, 45, 030405. (In Chinese) [Google Scholar]

- Liu, C.; Zhou, Y.; Wang, K. Summary of cable fault on a certain type of aircraft. Technol. Mark. 2019, 26, 164. [Google Scholar]

- Li, Y.; Zhang, X.; Xv, L. A Survey on Stability Analysis for HVDC Power System in MEA. J. Power Supply 2017, 15, 2–11. [Google Scholar]

- Wan, W.; Yan, Y. Modern Aircraft Power System and Its Development. Sci. Technol. Innov. 2011, 3, 47–48. [Google Scholar]

- Yan, S.; Ma, S.; Li, H. Modeling and Simulation of Aircraft Automatic Distribution System. J. Nanjing Univ. Aeronaut. Astronaut. 2006, 38, 519–523. [Google Scholar]

- He, L.; Liang, L.; Huang, X.; Ma, C. Aeronautical Generator Fault diagnosis Based on Particle Swarm Optimization SVM. Comput. Meas. Control. 2013, 21, 3237–3239. [Google Scholar]

- Pang, J.; Liu, W.; Han, X.; Wei, Z.; Fan, Y. Fault Detection and Location in Exciter Rotor Windings of the Brushless Synchronous Starter/Generator. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 1, pp. 3193–3198. [Google Scholar]

- Wong, C. Aircraft GCU Build-in-Test Function Research and Fault Analysis; Civil Aviation University of China: Tianjin, China, 2012. [Google Scholar]

- Wang, L.; Ma, Z. Leakage Problem Analysis of a Constant Speed Transmission Type Intake Valve. Hydraul. Pneum. Seals 2014, 34, 59–62. [Google Scholar]

- Wang, L.; Gao, F. Study on “Start Delay” Phenomenon for a Certain Type Constant Speed Drive. Hydraul. Pneum. Seals 2016, 36, 64–66. [Google Scholar]

- Xiao, H. Fault analysis of airborne alarm system of an aircraft. Sci. Technol. Vis. 2018, 33–35. [Google Scholar]

- Fu, G.; Lv, F. Bearing Failure Analysis of Engine Constant-speed Driving Turbine Centrifugal Swift Module. In Proceedings of the 2013 National Conference on Failure Analysis, Dalian, China, 1 September 2013. [Google Scholar]

- Ma, H. Failure Analysis Of Constant Speed Transmission Device of Aircraft Main Power Supply System. Mech. Eng. 2011, 1, 141–142. [Google Scholar]

- Ma, H. Burn Failure Analysis Of Ball-Head Chuck of Constant Speed Transmission Device Of Aircraft. Mech. Eng. 2010, 12, 102–103. [Google Scholar]

- Li, Y. Analysis of Aircraft Secondary Power Failure Mode and Fault Feature Extraction; Civil Aviation University of China: Tianjin, China, 2020. [Google Scholar]

- Lin, Y. Research on Fault Diagnosis Method of Aviation Auto-Transformer Rectifier Unit; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2019. [Google Scholar]

- Chen, S.; Yv, N. Research on the typical fault modes of multi-category aviation transformer rectifier units. Adv. Aeronaut. Sci. Eng. 2023, 14, 118–131. [Google Scholar]

- Zhan, X. Analysis on the Unbalance of Power Supply in the Parallel Operation of Aircraft. Value Eng. 2016, 35, 146–147. [Google Scholar]

- Li, G.; Yang, K.; Yan, J. Fault on Low Output Voltage Amplitude of the Multi-output Static Converter. Aviat. Maint. Eng. 2025, 02, 105–107. [Google Scholar]

- Li, G.; Qin, S.; Yan, K. Research on High Peak Factor Fault of Output Voltage of Multi-Output Static Converter. China Plant Eng. 2024, 21, 146–148. [Google Scholar]

- Bai, J. Analysis of the principle and common faults of a 3kVA aeronautical static converter. Aviat. Saf. Equip. Maint. Technol. Symp. 2014, 5, 551–555. [Google Scholar]

- Wang, D. Fault Analysis and Treatment of Auxiliary Inverter for Metro Vehicle. Reliab. Rep. 2025, 1, 108–109. [Google Scholar]

- Zhao, J.; Guo, K.; Xue, W. Research on Quick Diagnosis Method for Open Circuit Fault of Inverters in Permanent Magnet Synchronous Motor Drive Systems. Electr. Eng. 2024, 23, 270–273, 278. [Google Scholar]

- Lu, X. Analysis of Common Faults and Causes of Inverters in Photovoltaic Power Generation System. Nanning, Guangxi, China. 2024, Volume 10, pp. 468–477. Available online: https://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZBDL202412001052.htm (accessed on 3 August 2025).

- Ahmed, U.; Ali, F.; Jennions, I. A review of aircraft auxiliary power unit faults, diagnostics and acoustic measurements. Prog. Aerosp. Sci. 2021, 124, 100721. [Google Scholar] [CrossRef]

- Xing, D.; Xue, J.; Gao, K. Analysis on the APU Starting Fault for a Certain Type of Aircraft. Aviat. Maint. Eng. 2020, 5, 88–89. [Google Scholar]

- Skliros, C.; Ali, F.; Jennions, I. Fault simulations and diagnostics for a Boeing 747 Auxiliary Power Unit. Expert Syst. Appl. 2021, 184, 115504. [Google Scholar] [CrossRef]

- Jin, R. Research on Fault of A320 Aircraft Auxiliary Power Unit. J. Shandong Ind. Technol. 2016, 19, 183–184. [Google Scholar] [CrossRef]

- Dai, D.; Cai, J.; Huang, Y. Cause Analysis of RAT Actuator Failure Based on Modelica Simulation. J. Nanjing Univ. Aeronaut. Astronaut. 2021, 53, 136–141. [Google Scholar]

- Huang, Y.; Cai, J.; Dai, D. Fault Diagnosis of RAT Actuator Based on Bayesian Network. In Proceedings of the ICCASIT, Weihai, China, 14–16 October 2020; pp. 859–863. [Google Scholar]

- Hu, X.; Zhang, K.; Liu, K.; Lin, X.; Dey, S.; Onori, S. Advanced Fault Diagnosis for Lithium-Ion Battery Systems: A Review of Fault Mechanisms, Fault Features, and Diagnosis Procedures. IEEE Ind. Electron. Mag. 2020, 14, 65–91. [Google Scholar] [CrossRef]

- Zou, B.; Zhang, L.; Xue, X.; Tan, R.; Jiang, P.; Ma, B.; Song, Z.; Hua, W. A Review on the Fault and Defect Diagnosis of Lithium-Ion Battery for Electric Vehicles. Energies 2023, 16, 5507. [Google Scholar] [CrossRef]

- Yang, M.; Gao, B.; Yv, M.; Gao, C. A Line Fault Diagnosis Method for Aircraft High Voltage DC Power Supply System. Comput. Program. Ski. Maint. 2024, 05, 148–150. [Google Scholar]

- Chen, H.; Tan, T.; Zhao, L. Analysis and Research on the Failure of Aircraft Main Power System in the Air. Aviat. Maint. Eng. 2024, 6, 75–78. [Google Scholar]

- Li, H.; Deng, L.; Luo, Q.; Zhang, Y.; Han, Y. Analysis on Short-circuit Fault of AircraftCable and Research on Its Mechanism. Sichuan Electr. Power Technol. 2019, 42, 19–24. [Google Scholar]

- Cui, B.; Wang, Y.; Wang, C.; Li, Y.; Li, F. Series Arc Fault Identification Method in Aviation Lines Based on Multi-Information Fusion. Trans. China Electrotech. Soc. 2019, 34, 118–125. [Google Scholar]

- Calikoglu, A.; Tamyurek, B. Series DC Arc Fault in More Electric Aircraft. In Proceedings of the 2023 IEEE Applied Power Electronics Conference and Exposition, Orlando, FL, USA, 19–23 March 2023; pp. 3125–3132. [Google Scholar]

- Liu, Y. Failure Mechanism and Common Fault Analysis of Electronic Components. Digit. Commun. 2012, 39, 92–96. [Google Scholar]

- Zhu, L. Correlation Analysis of Aircraft Fault and Temperature Change. Mod. Manuf. Technol. Equip. 2021, 57, 128–129, 137. [Google Scholar]

- Yang, K.; Wang, T.; Shen, X.; Sun, Y. Research on Correlation Between Contact Resistance and Temperature of Fuel Cells. Aerosp. Shanghai 2023, 40, 111–120. [Google Scholar]

- Zhang, M. Research on Prognostics and Health Management of Semiconductor Device Under Temperature Environmental Stress; Shenyang University of Technology: Shenyang, China, 2024. [Google Scholar]

- Zhao, Q.; Xie, Y. Fault Analysis and Improvement Measures of Temperature Fuse Fault for Metro Traction Motor. Urban Mass Transit. 2019, 22, 184–187. [Google Scholar]

- Li, B. Analysis of Under-pressure Fault of 737-300 Aircraft Engine. Sci. Technol. Innov. Her. 2017, 14, 35–36. [Google Scholar]

- Zhao, H. Research on Maintenance Strategy of APU Based On Performance Degradation; Shenyang Aerospace University: Shenyang, China, 2024. [Google Scholar]

- Meng, X.; Sun, Q.; Yu, C.; Zhang, Y. Mechanism Analysis and Maintenance Research on Deterioration of Aircraft Contactor Contact. Electr. Energy Manag. Technol. 2023, 30–35. [Google Scholar] [CrossRef]

- Hu, L.; Yan, D.; Zhangli, Y. Improvement Research on Electromagnetic Compatibility of Generator ControlUnit(GCU) on System of Power Supply Aircraft. Micromotors 2011, 44, 38–40, 63. [Google Scholar]

- Xu, P.; Mei, J.; Qin, J. Research on EMI Control Techniques of Airborne Power Electronic Equipment. In Proceedings of the 2018 IEEE International Symposium on Electromagnetic Compatibility and 2018 IEEE Asia-Pacific Symposium on Electromagnetic Compatibility (EMC/APEMC), Singapore, 14–18 May 2018; pp. 837–839. [Google Scholar]

- Leuchter, J.; Dong, Q.H.; Boril, J.; Blasch, E. Electromagnetic immunity of aircraft wireless and cables from electromagnetic interferences. In Proceedings of the 2017 IEEE/AIAA 36th Digital Avionics Systems Conference (DASC), St. Petersburg, FL, USA, 17–21 September 2017; pp. 1–6. [Google Scholar]

- Cui, H.; Wang, B.; Zhang, H. Analysis and Handling of Electromagnetic Interference in Communication for a Certain Type of Aircraft. Aviat. Maint. Eng. 2023, 8, 81–83. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).