1. Introduction

The orthotropic steel deck (OSD) system, developed in Germany in the 1930s, was an innovative solution for long-span bridge structures. It typically employs continuous trapezoidal ribs with spans ranging from 3 to 6 m, allowing them to pass through the webs of the floor beams [

1,

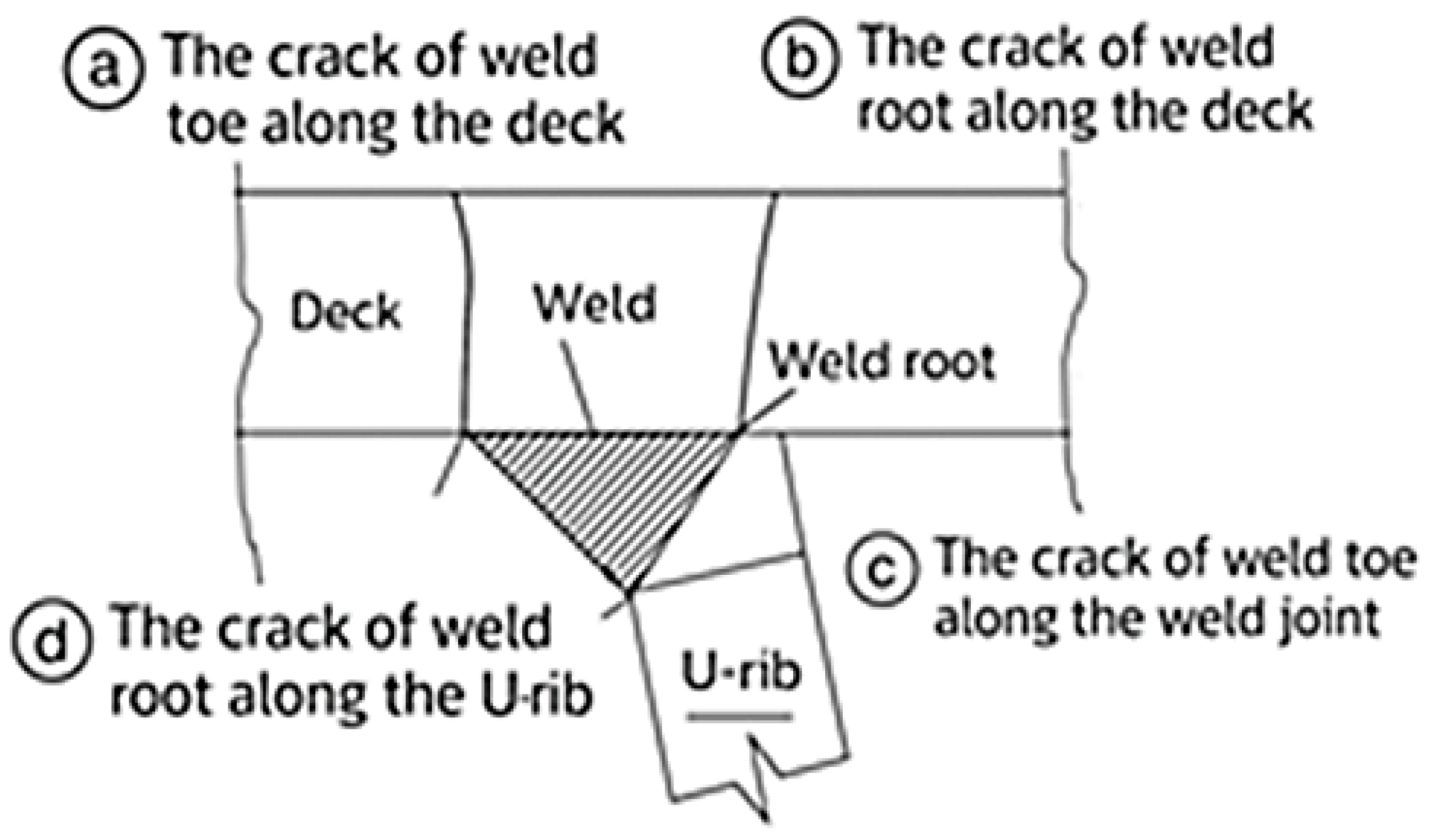

2]. This configuration places the rib–deck section in the region of negative bending moments, where the rib plate experiences compressive forces, as illustrated in

Figure 1. These compressive load impulses across the rib plate thickness generate vertical bending stresses (σ

y), which are particularly pronounced at the rib-to-deck welds (RDW) and within the rib plate itself. Symmetry in the geometry of the rib–deck section plays a crucial role in stress distribution. The trapezoidal configuration exhibits bilateral symmetry, which affects the balance between compressive and tensile stresses across the weld and plate.

The rationale for employing the rib–deck section is detailed in

Appendix A. The significance of this research lies in identifying the relationship between the stress states in both the rib plate and the root of the rib-to-deck weld (RDW). The primary objective is to develop predictive equations capable of estimating stress values in these critical regions. A key parameter influencing local buckling behavior in the rib plate is the slenderness ratio

h′/tr, where

h′ represents the inclined length of the trapezoidal rib web and

tr denotes the rib plate thickness.

Previous research on this topic has primarily focused on weld performance, often overlooking the stress state in the rib plate, local buckling criteria, and the influence of plate geometry. This study aims to address these gaps. Conversely, other investigations have examined the structural behavior of the plates without considering weld performance. For example, an experimental study on the compressive behavior of OSD plates was conducted based on American and Japanese design recommendations, but it did not analyze the stress state in the welds [

3].

Numerous rib–deck sections with identical plate dimensions and thicknesses were tested to determine the minimum compatible dimensions for the rib-to-deck welds (RDW). This included evaluating parameters such as weld toe size on the plates, weld penetration depth, percentage of weld intrusion into the rib plate, weld throat size, and overall weld area—particularly in relation to fatigue-induced stresses in the welds. However, the stress state and local buckling criteria of the plates were not considered in the mentioned study. Two types of welds were used in the study: butt welds and filet welds. A multiple linear regression (MLR) analysis was conducted to determine the minimum compatible weld dimensions, based on stress values obtained from both experimental and analytical investigations [

4]. Field observations revealed fatigue cracks originating either from the weld root or propagating through the deck plate [

5].

The effects of stress concentration due to imperfections at the RDW root were analytically studied using an OSD model based on IIW recommendations. However, the influence of plate geometry was not considered in that analysis [

6]. Although this study focuses on macro-scale mechanical behavior, microstructural investigations using techniques such as scanning electron microscopy (SEM) or optical microscopy have proven effective in identifying weld zone inhomogeneities and crack initiation mechanisms. Including such methods in future work would enrich the understanding of RDW fatigue behavior and complement the mechanical analysis.

Experimental tests involving static tension and compression loads were applied to the rib plate of a trapezoidal rib–deck section to evaluate RDW shear performance under varying values of the rib’s major base width (b). Tension loads led to RDW shear failure, whereas compression loads caused deformation in the rib plate without significantly affecting the RDW. Consequently, the results from compression loading were excluded from the study. Additionally, variations in the rib plate slenderness ratio (

h′/tr) were not considered, and no analytical study was conducted on the compressed section with full penetration butt welds [

7]. Fatigue tests were conducted using models simulating the diaphragm zone in the OSD system, which incorporates U-ribs with double-sided welds. The results revealed that the interior weld toe of the U-rib-to-top-plate joint is the region most affected by fatigue. The study identified cracks initiating at the rib-to-diaphragm welds and propagating through the diaphragm plate [

8].

Analytical models based on rib–deck sections were used to investigate the influence of asphalt pavement layer temperature on RDW fatigue performance. The fatigue crack growth was analyzed using the Linear Elastic Fracture Mechanics (LEFM) theory. The findings indicated a shorter fatigue life at elevated pavement temperatures [

9]. Furthermore, the critical role of residual stresses in assessing the fatigue reliability of rib-to-deck double-sided welded joints in orthotropic steel deck systems was highlighted. A Monte Carlo simulation was performed using analytical models of the OSD system, providing a framework for evaluating fatigue reliability while accounting for welding-induced residual stresses [

10]. Fatigue performance of transverse cracks initiating at the weld root and propagating through the weld throat was experimentally investigated following repair using bonded angle steel. Two groups of test specimens were considered: an unreinforced reference group and a strengthened group with bonded angle steel. Under lateral fatigue loading, the stress amplitude at the U-rib weld root was significantly reduced in the reinforced specimens [

11].

The influence of residual stresses in single-sided full-penetration RDWs in orthotropic steel decks was studied through both experimental testing and numerical simulation. Results revealed peak tensile stresses near the welds. Residual stresses on the deck surface and the U-rib surface were found to increase with greater plate thickness and higher welding speeds [

12]. Additionally, the fatigue performance of rewelded rib-to-deck weld cracks—repaired from the deck surface—was analyzed. Parameters such as local strain, crack size, fatigue life, and crack propagation behavior were examined. The results showed that rewelding restored the original stress performance; however, the crack size and its growth after secondary cracking were greater than those observed in the unrewelded specimens [

13].

The influence of residual stresses on the fatigue behavior of orthotropic steel deck (OSD) systems has also been extensively studied. Several analytical models were developed using finite element software, incorporating the rain flow counting algorithm in accordance with ASTM standards. The results demonstrated that residual stresses significantly reduce the fatigue life of OSD systems [

14]. The flexural behavior of a proposed Orthotropic Steel–Lightweight Ultra-High-Performance Concrete Composite Bridge Deck (OS-LUHPC-CBD) was investigated both experimentally and numerically. It was compared with a conventional Orthotropic Steel–Ultra-High-Performance Concrete Composite Bridge Deck (OS-UHPC-CBD), which uses high-strength Q425 steel and trapezoidal ribs. Using an OSD model, the study showed that the proposed OS-LUHPC-CBD exhibited greater ductility and flexural capacity than the OS-UHPC-CBD. Moreover, the OS-LUHPC-CBD enables the construction of long-span bridges with lower cost and weight, while maintaining similar construction feasibility to the OS-UHPC-CBD [

15]. An analytical study was conducted on the buckling behavior of orthotropic steel decks using U-ribs, employing a nonlinear finite element model of a long-span suspension bridge. The study considered key parameters such as initial geometric imperfections, residual stresses, and traffic loading. Results showed that all these factors significantly influence buckling behavior. The use of Ultra-High-Performance Concrete (UHPC) overlay was found to enhance buckling strength [

16].

The effect of multiaxial traffic loading on the fatigue performance of RDWs was investigated using the Path-Dependent Maximum Stress Range (PDMR) method within an OSD model. The PDMR method predicted high fatigue damage and was therefore recommended for fatigue assessment [

17].

Despite these contributions, none of the previous studies have explored the relationship between the mechanical behavior of the plates and welds in orthotropic steel decks. Specifically, no study has attempted to link the stress states in both the rib plate and the RDW root. It is essential to begin considering the impact of local buckling standards in the plates on the stress distribution in both the welds and the plates. Accordingly, this study investigates the influence of variations in the local buckling standard of the trapezoidal rib plate on RDW root performance, establishing a direct link between the stress states in the rib plate and the RDW root.

2. Materials and Methods

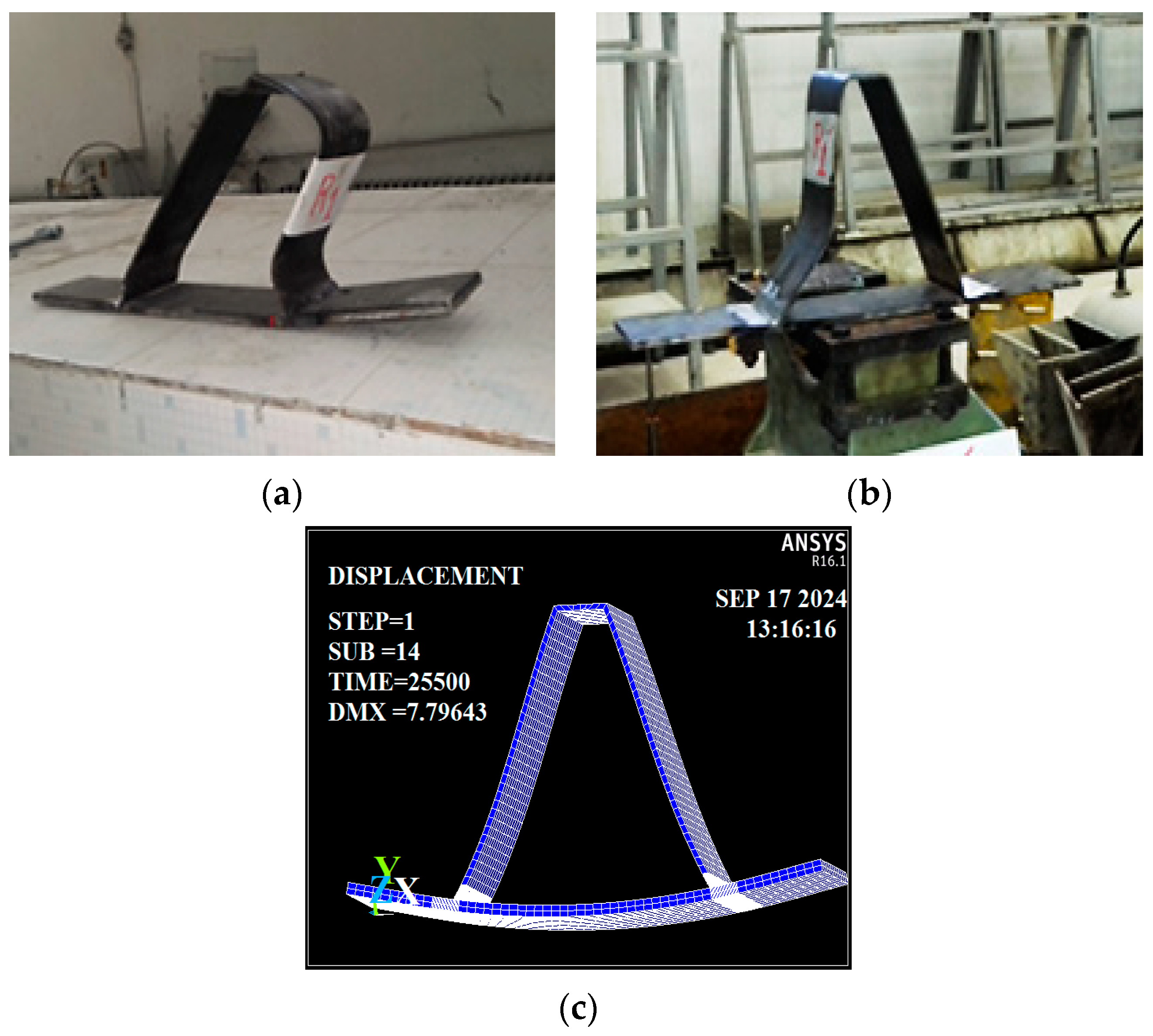

Low-carbon steel A572 Grade 50 was used in this study, with a yield strength of 345 MPa. To verify its mechanical properties, a tensile test was conducted on a sample plate with a thickness of 5 mm, as shown in

Figure 2a. The experiment was performed in the Construction Materials Laboratory at the Faculty of Civil Engineering, Aleppo University, as illustrated in

Figure 2b.

The results of the tensile test showed a yield stress of 335 MPa, an ultimate tensile strength of 447 MPa, and a strain at failure of 24% [

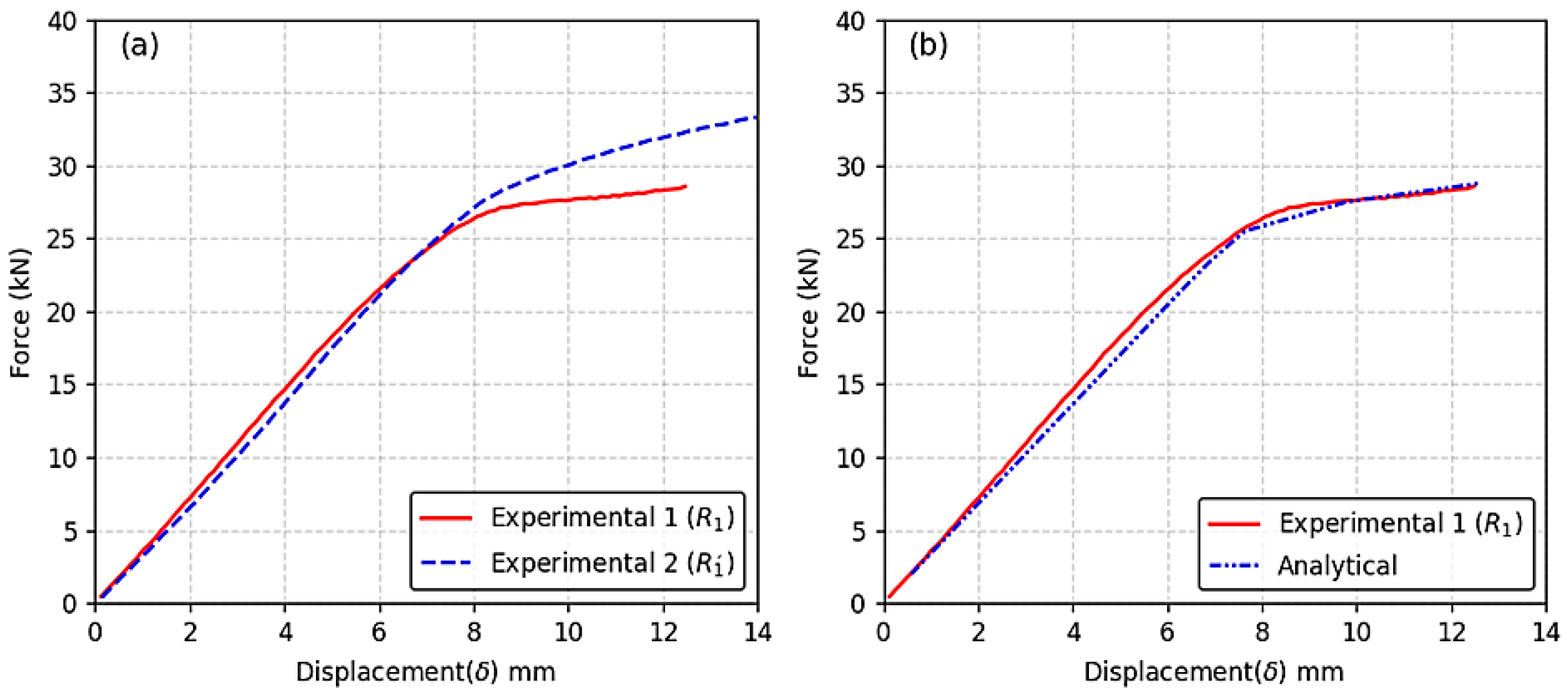

7]. Two models, R

1 and R′

1, were constructed as shown in

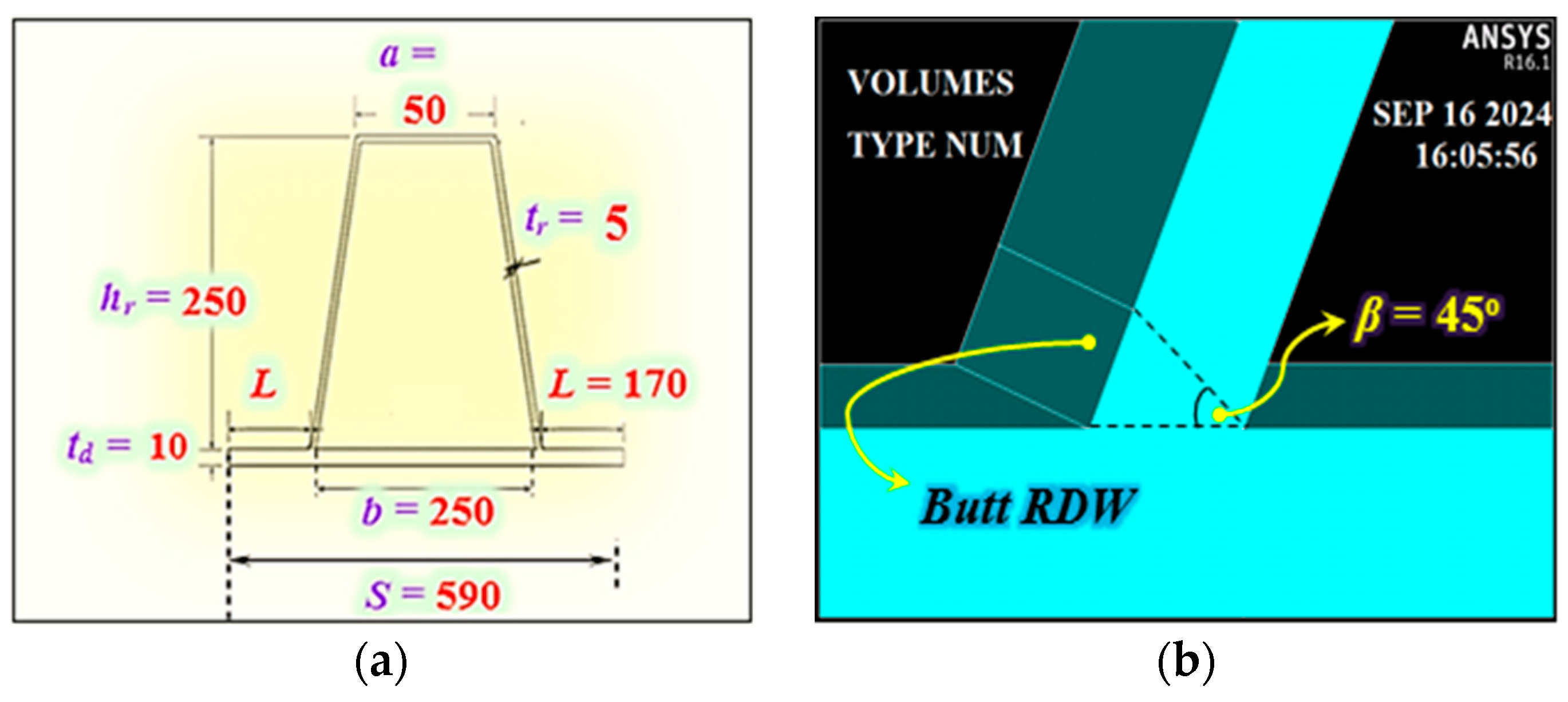

Figure 3a, using identical plate dimensions listed in

Table 1. Each model incorporated a 100% penetration butt weld for the RDW, executed with an E

6013 electrode (yield strength 410 MPa) [

18], and a minimum weld thickness equal to t

r [

19], as illustrated in

Figure 3b.

The mechanical properties of the weld metal were not experimentally tested in this study. Instead, the yield stress of 410 MPa was adopted from manufacturer specifications [

18], consistent with its widespread use in orthotropic steel deck systems. Also, this approach aligns those taken in other studies [

19].

A monotonically increasing static compression load (F) was applied to the top of the rib plate until deformation-induced failure occurred as shown in

Figure 4. This loading condition was selected to simulate the compressive stress state in the negative bending moment region of orthotropic steel bridge decks, where the rib plate is primarily subjected to quasi-static compressive forces. While in-service decks experience cyclic loading, the static loading test enables clearer identification of stress zones and yielding behavior, which are essential for calibrating the finite element model and understanding fatigue initiation.

The model was simply supported over a span of 380 mm, consistent with the laboratory configuration. This boundary condition was selected to replicate the experimental setup and ensure accurate calibration of the analytical model. While it does not fully represent the complex restraint conditions of orthotropic bridge decks in situ, where panels are typically supported by transverse beams and diaphragms, it provides a simplified framework for isolating local stress behavior near RDW.

The influence of global deck constraints on local stress fields is expected to be limited in this context, as the stress concentration and yielding behavior are primarily governed by the geometry of the rib plate and weld configuration. Therefore, the simply supported condition is considered sufficient for evaluating the mechanical response and validating the influence of the h′/tr ratio.

This loading configuration was chosen to simulate the stress state in the negative bending region of orthotropic steel decks, particularly in the cross-region near the floor beam, where the rib plate is subjected to compressive forces. Although real bridge decks experience bending along the rib direction due to traffic loads, applying direct compression in the experiment allows controlled investigation of local stress distribution and weld root behavior under compressive conditions. This simplification is consistent with previous studies and helps isolate the influence of geometric parameters such as the h′/tr ratio.

The simply supported boundary condition was selected to replicate the structural behavior of the rib–deck section in the negative bending region of orthotropic steel bridge decks, particularly near the floor beam intersection. In real bridge service conditions, this region experiences compressive stresses due to bending, and the support configuration allows for a realistic simulation of load transfer and deformation. This setup also facilitates controlled observation of stress distribution and failure mechanisms in the RDW root and rib plate.

An analytical model replicating the experimental setup was developed using ANSYS 16.1, incorporating the same material properties: yield stress (f

y) = 335 MPa for the plates and (f

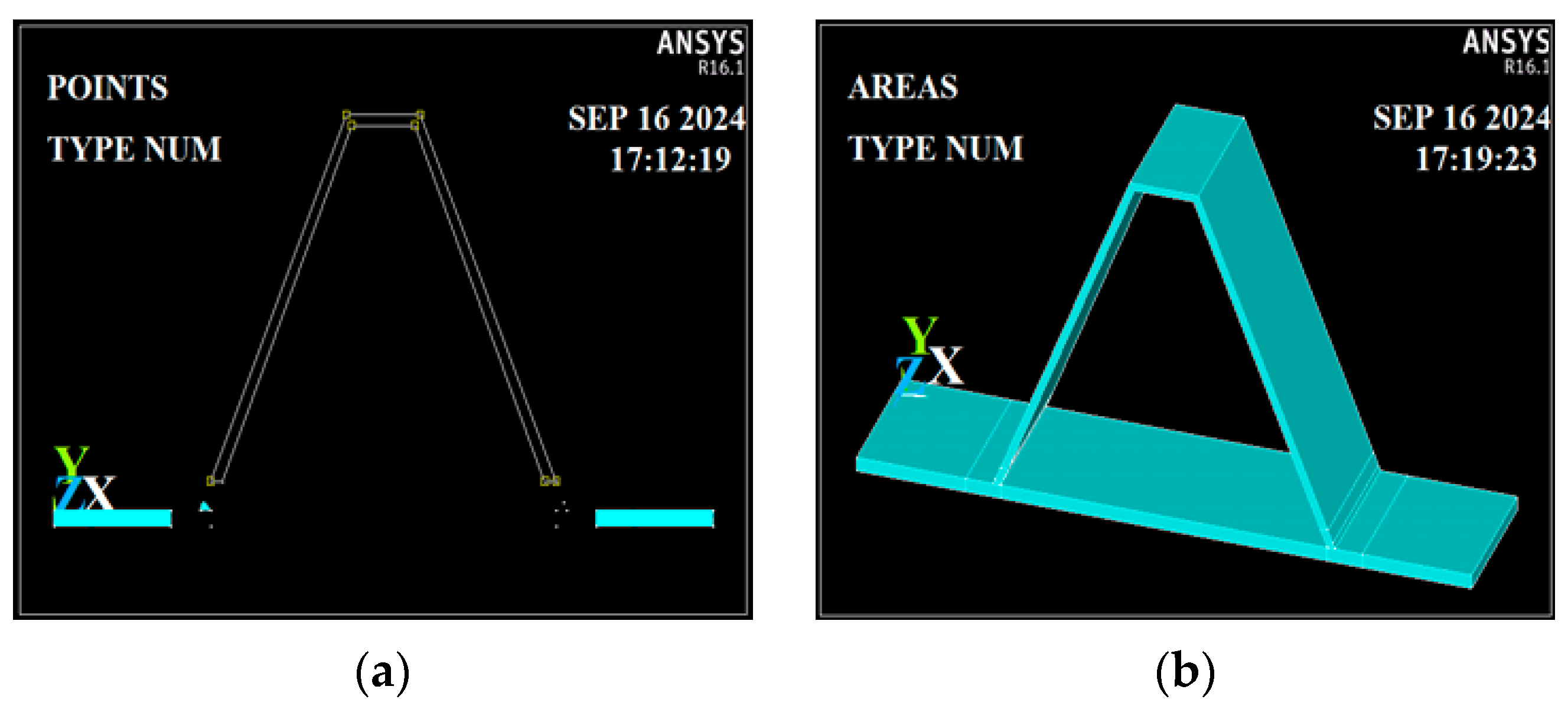

y) = 410 MPa for the welds, with Young’s modulus (E) = 200,000 MPa and Poisson’s ratio (ν) = 0.3. The modeling process began by defining key points at specific distances based on the plate and RDW dimensions, as illustrated in

Figure 5a. The butt welds were modeled with a minimum thickness equal to t

r, and a weld angle β = 45°, following the specifications in [

19], as shown in

Figure 5b.

Using the defined key points, areas were created as shown in

Figure 6a. These areas were then extruded by 100 mm along the Z-direction, resulting in solid volumes representing the rib plate, deck plate, and butt RDWs, as illustrated in

Figure 6b. The volumes were glued together, as the analysis was conducted within the elastic range. This approach was chosen to identify stress distributions and concentration zones prior to yielding, particularly near the RDW root. While the experimental failure criterion corresponds to yielding, the elastic model provides a sufficiently accurate approximation of the mechanical behavior, as confirmed by the close agreement (within 3%) between the experimental and analytical results. We acknowledge that excluding plasticity may slightly affect stress redistribution near yield zones, but for the studied loading range and geometric variations, the elastic assumption remains valid. Failure was defined as the onset of yielding, in accordance with [

6,

7,

20]. Further details are provided in

Appendix B.

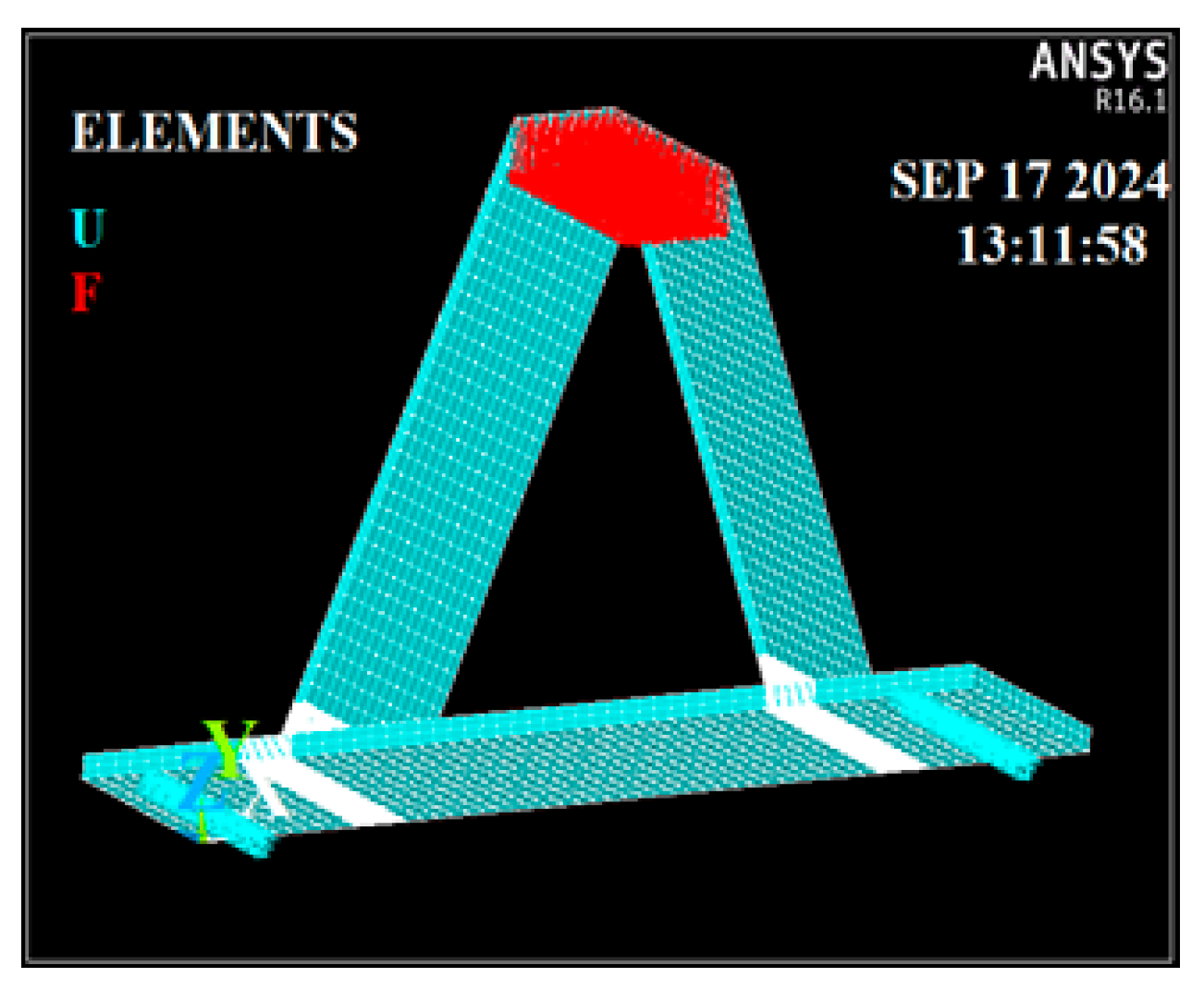

The volumes were meshed using Solid186 elements [

20], as shown in

Figure 7. These are quadratic 20-node elements, which provide higher accuracy in stress and deformation analysis. A mesh size of 8 mm was applied to the plates to ensure sufficient resolution for capturing stress gradients.

Regions located at a distance of 2 t from the weld toes were meshed with a 0.1 t element size, where (t) is the thickness of the plate containing the RDW toe. For the butt RDWs, a finer mesh size of tr/30 was applied. A mesh sensitivity study was performed to validate these choices, confirming that further refinement resulted in stress variations below 3%. This ensures numerical stability and that the reported results are independent of discretization effects. The model was simply supported over a span of 380 mm, consistent with the experimental setup. A monotonically increasing static compression load (F) was applied to the top of the rib plate, replicating the experimental conditions.

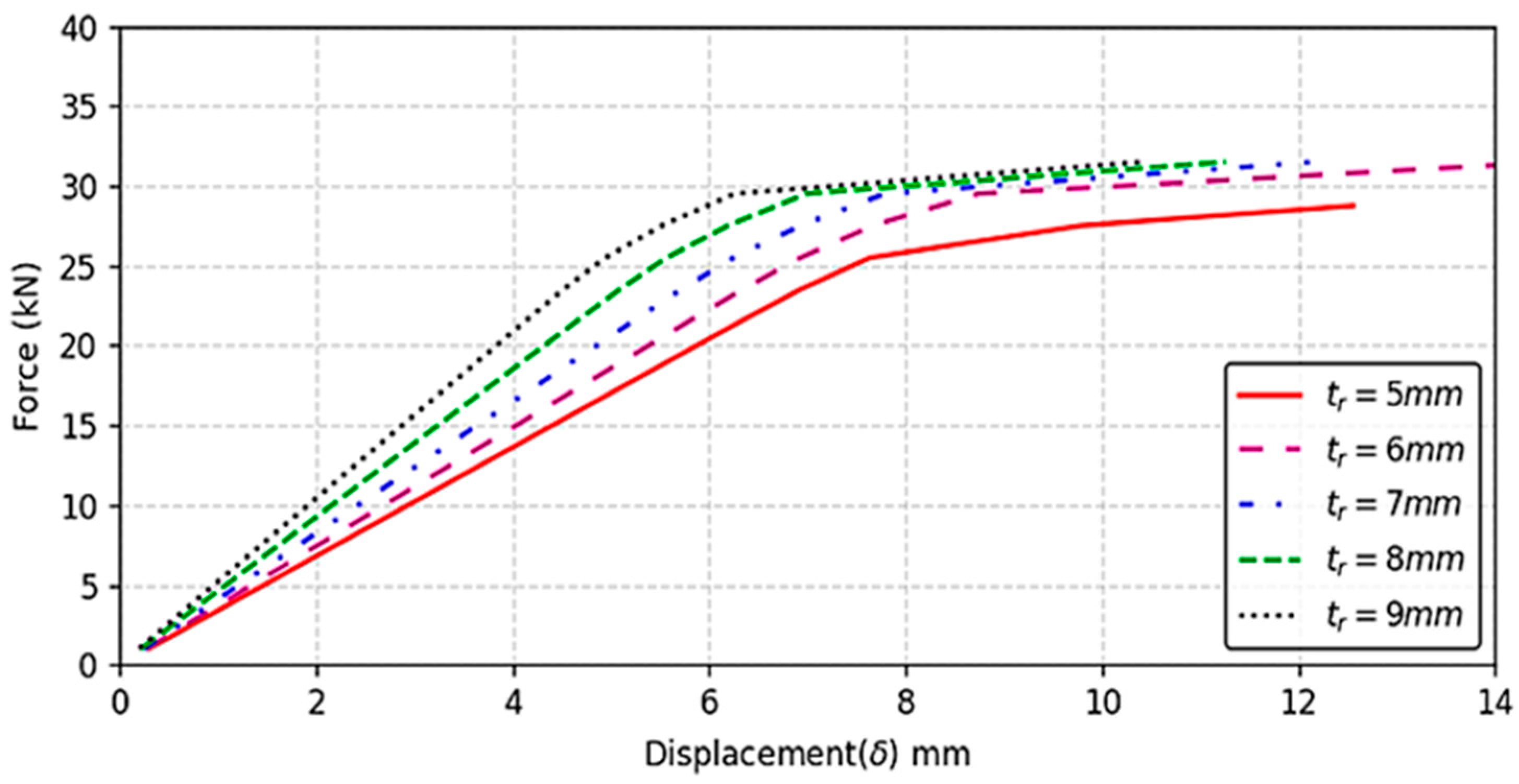

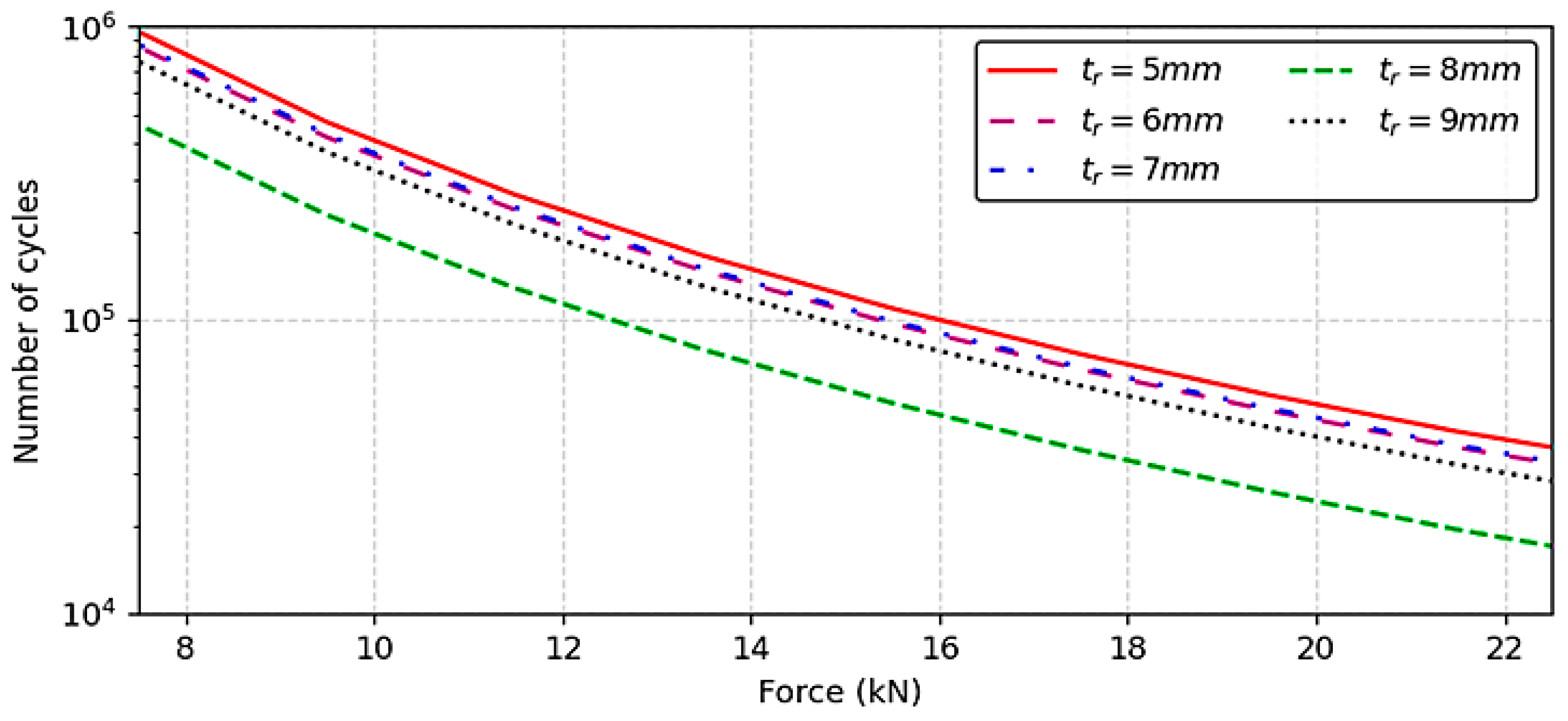

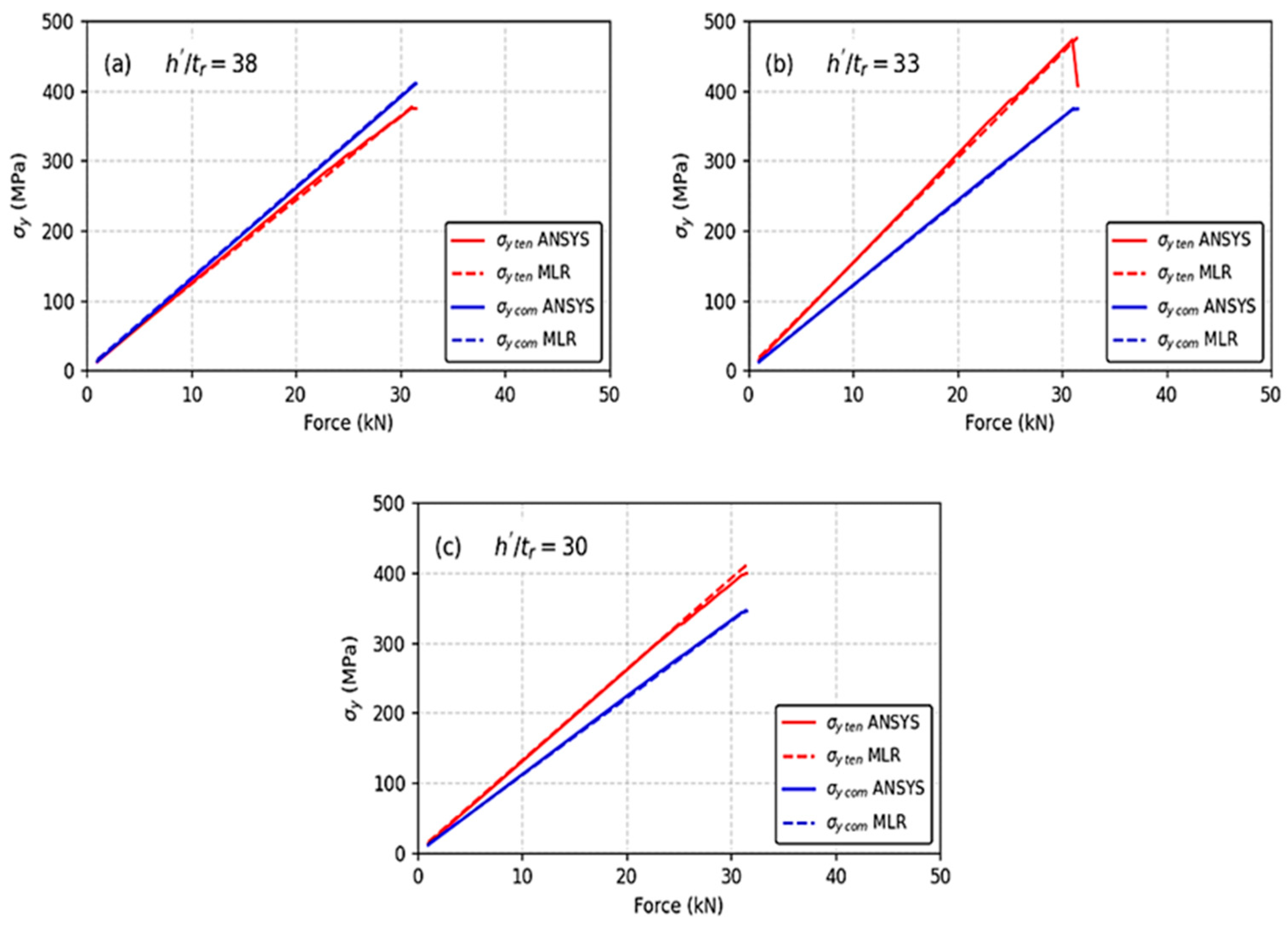

Following calibration with the experimental model, four additional analytical models were developed, each with a different rib plate thickness (tr): 6 mm, 7 mm, 8 mm, and 9 mm. These models were used to investigate the influence of the slenderness ratio (h′/tr) on the stress state in both the rib plate and the RDW root. Fatigue life was estimated using the Nominal Stress Method, where static stress amplitudes obtained from elastic simulations were treated as equivalent cyclic stresses. This approach assumes constant amplitude loading and follows IIW and Eurocode 3 guidelines. No additional scaling or cyclic calibration was applied. The method provides a conservative estimate of fatigue performance and is suitable for comparing RDW root behavior across different h′/tr ratios under elastic stress conditions. In the regression model, the compression force (F) was defined as the independent variable, while the vertical stress (σy)—either tensile or compressive—was treated as the dependent variable.

For each h′/t

r value, 60 data points were input, consisting of F values ranging from 5500 N to 31,500 N in increments of 500 N, along with their corresponding σ

y values. The Enter Method was used for regression analysis. The resulting regression coefficients were evaluated for statistical significance using the T-test, ensuring the reliability of the predictive models. Further details and explanations are provided in

Appendix C.

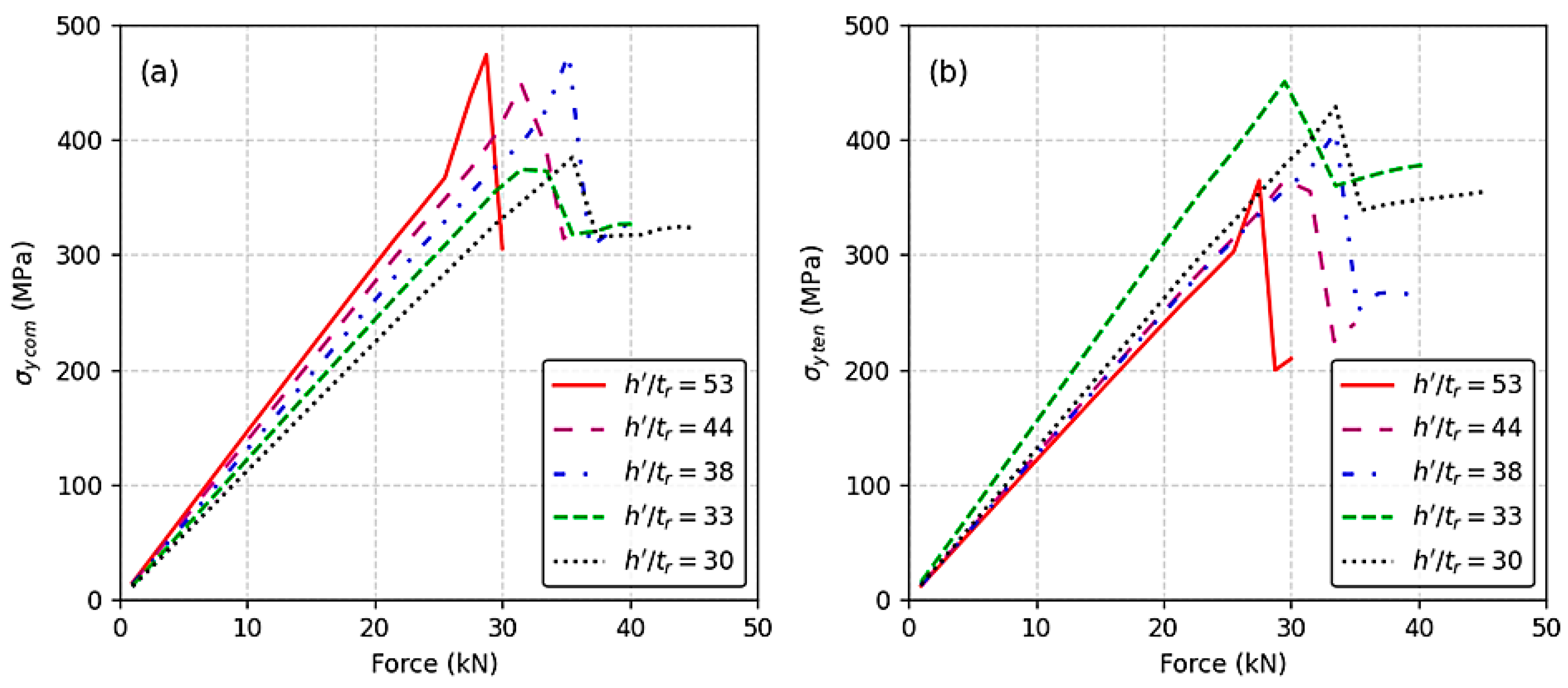

4. Discussion

When a compressive force is applied to the rib plate—similar to the stress state in the negative bending region of an orthotropic steel deck—it was observed from both the experimental and analytical models in this study that the compressive stress region is located in the rib plate above the toes of the rib-to-deck welds (RDWs). Conversely, the tensile stress region is concentrated in the root of the RDW. These stress distributions were clearly identified through the deformation shapes obtained from the models.

This study confirmed the inverse relationship between the geometric ratio h′/t

r and the location of yielding. When the value of h′/t

r exceeds a certain threshold, the maximum compressive stress σ

y com in the rib plate becomes greater than the maximum tensile stress σ

y ten in the RDW root. In this case, yielding—and thus failure—is governed by σ

y com, which is attributed to the higher deformation capacity of the rib plate. These findings warrant a re-examination of previous studies [

4,

6,

9,

11,

13], which have primarily focused on RDW performance using plate models with fixed dimensions. The observed stress patterns suggest that symmetric geometric configurations, particularly those with balanced h′/t

r ratios, contribute to uniform stress distribution. This symmetry enhances fatigue resistance and structural resilience by minimizing localized stress concentrations. Future research could build upon those studies, integrating the present results to refine the understanding of RDW behavior under varying geometric configurations.

When h′/t

r reaches the threshold value, the maximum compressive stress in the rib plate and the maximum tensile stress in the RDW root are nearly equal. This indicates that both regions operate within a similar elastic field. Conversely, when h′/t

r falls below the threshold, the maximum tensile stress σ

y ten in the RDW root exceeds the compressive stress in the rib plate. In this scenario, yielding is governed by σ

y ten, and failure initiates at the RDW root. This observation supports and reinforces the findings of Li et al. [

8], which demonstrated that the interior weld toe of the U-rib-to-top plate joint within the diaphragm zone is the region most susceptible to fatigue. Similarly, Zhang et al. [

5] reported field observations of fatigue cracks originating from the RDW root. It is essential to note that neither of the two studies [

5,

8] accounted for geometric variations or slenderness criteria, which may significantly influence stress distribution and failure mechanisms.

This study demonstrated the inverse relationship between the geometric ratio h′/tr and the performance of the RDW root. When the h′/tr ratio falls below the threshold value, the performance of the RDW root decreases significantly—by nearly half—compared to the initial condition. This reduction is attributed to the diminished deformation capacity of the rib plate, which causes stress to concentrate more intensely in the RDW root.

For values of h′/tr slightly below the threshold, the maximum tensile stress σy ten in the RDW root may be somewhat reduced due to the increased resistance of the plate section in the RDW root region. However, σy ten still exceeds the maximum compressive stress σy com in the rib plate, indicating that failure is governed by tensile stress in the RDW root.

The multiple linear regression (MLR) equations presented in

Table 3, developed specifically for the trapezoidal rib–deck section studied here, are effective for predicting both σ

y com and σ

y ten. These equations enable the identification of the stress state in the rib plate and RDW root for each acceptable h′/t

r value, thereby allowing assessment of RDW performance. As such, they can serve as a comparative standard across different models.

Residual stresses and heat-affected zone (HAZ) effects are known to influence fatigue performance, especially under tensile loading. In this study, the rib–deck section was subjected to compression loads in the rib plate, simulating the stress state in the cross-region with the floor beam. Since the RDW root was not directly exposed to tensile fatigue loading, residual stress and HAZ effects were not considered. Their omission may lead to higher stress concentrations in the RDW root, and this limitation will be acknowledged in future research.

The h′/tr ratio physically represents the slenderness of the inclined rib web. A higher ratio indicates a slenderer rib, which is more flexible and capable of distributing compressive stresses over a wider area. This results in dominant compressive behavior in the rib plate. Conversely, a lower h′/tr ratio corresponds to a stiffer rib section, which restricts deformation and causes stress concentration at the RDW root. This shift increases tensile stress and reduces fatigue resistance. Therefore, h′/tr governs the balance between structural flexibility and stress localization, making it a crucial parameter in welded joint performance.

For future research, it is recommended to re-examine trapezoidal rib–deck sections with varying dimensions to assess their influence on the stress distribution in the rib plate and RDW root. Additionally, studies should explore alternative closed rib geometries, such as U-shaped or V-shaped ribs, and investigate the use of different weld types, such as filet welds.

5. Conclusions

This study investigated the intricate relationship between the elastic–plastic behavior of the rib plate and the fatigue performance of the rib-to-deck weld (RDW) root in orthotropic steel bridge decks. Through a combined experimental and analytical approach, the following key conclusions were drawn:

Stress Distribution: under compressive loading simulating the negative bending moment region, maximum compressive stress (σy com) concentrates in the rib plate above the weld toes. In contrast, maximum tensile stress (σy ten) localizes at the critical RDW root.

Critical Role of h′/tr Ratio: the geometric slenderness ratio h′/tr is a pivotal parameter governing the failure mode and fatigue life.

When h′/tr exceeds the limit value of 38, compressive stress in the rib plate dominates, and failure is governed by the rib plate yield.

At the limit value of h′/tr = 38, a balanced state is achieved where compressive and tensile stresses are nearly equal, optimizing structural performance.

When h′/tr falls below the limit, tensile stress at the RDW root becomes dominant, leading to a significant reduction in fatigue performance. A decrease from h′/tr = 38 to 33 resulted in a 47% drop in the number of load cycles to failure.

Symmetry and Structural Performance: the observed stress patterns suggest that symmetric geometric configurations, particularly those with balanced h′/tr ratios, contribute to uniform stress distribution. This symmetry enhances fatigue resistance and structural resilience by minimizing localized stress concentrations. The trapezoidal rib geometry, with its bilateral symmetry, plays a key role in balancing stress fields across the weld and plate.

Predictive Modeling: the developed multiple linear regression (MLR) equations provide a highly accurate and practical tool for predicting stress values in both the rib plate and the RDW root, eliminating the need for extensive finite element simulations in preliminary design stages.

However, this study is subject to certain limitations. The analysis was confined to static loading and an elastic material model, which was used to identify stress concentration zones; the effects of low-cycle fatigue and plastic stress redistribution were not captured. Furthermore, the influence of welding-induced residual stresses and the microstructural properties of the heat-affected zone (HAZ), which are known to impact fatigue crack initiation significantly, was not considered. The simplified supported boundary condition and the focus on a single trapezoidal rib geometry with full-penetration butt welds also define the scope of the current findings.

Despite these limitations, the results unequivocally demonstrate that optimizing the h′/tr ratio is essential for achieving a balanced stress distribution and enhancing the fatigue resistance of orthotropic steel bridge decks. The findings provide designers with clear guidance for selecting rib plate geometries to improve the resilience of these critical connections. Future work should address the present limitations by incorporating cyclic plasticity and residual stresses, and extending the analysis to other rib geometries and weld types to generalize these findings further.