Abstract

Titanium alloy Ti-6Al-4V possesses excellent mechanical and corrosion-resistant properties; therefore, it is widely employed in aerospace, automotive, and biomedical fields. However, its poor machinability restricts traditional processing methods. To overcome this limitation, the current work presents a symmetry analysis approach to evaluate the effects of tool coating on the micro-electric discharge machining (micro-EDM) characteristics of Ti-6Al-4V. Tungsten carbide (WC) microelectrodes were fabricated in three forms: uncoated, copper-coated, and carbon-coated. The chemical vapor deposition (CVD) method was used to coat the carbon layer, and the integrity of the coating was confirmed by Energy-Dispersive X-ray Spectroscopy/Analysis (EDS/EDX). The effect of input variables—namely, voltage, capacitance, and spindle rotational speed—on two responses was studied—the machining depth (Z-axis displacement) and tool wear rate (TWR)—using a Taguchi L9 orthogonal array. Analysis conducted using Minitab statistical software 17 revealed that both voltage and capacitance contributed to the response parameters as optimized variables. The comparative study showed that the copper- and carbon-coated WC microtool could obtain a better Z coordinate and lower tool wear ratio compared with those of the uncoated tool. The findings confirm that applying thin conductive coatings to WC tools can significantly improve the stability, precision, and overall symmetry of the micro-EDM process when machining difficult-to-cut titanium alloys.

Keywords:

carbon/copper coating; Taguchi L9; Ti-6Al-4V; micro-EDM; Z coordinate; TWR; EDM; CVD; ANOVA 1. Introduction

The thermal erosion technique known as electro-discharge machining (EDM) removes material by melting or vaporizing tiny portions of the workpiece’s surface. Through controlled erosion of the workpiece caused by recurrent electrical sparks between the work and tool electrodes immersed in a dielectric medium, the EDM process eliminates material.

Since Ti-6Al-4V alloy is known for its exceptional strength-to-weight ratio, resistance to corrosion, and mechanical dependability, it is difficult to process using traditional machining techniques. Because of these inherent challenges, EDM has become a very appealing alternative, especially for fabricating complex and micro-scale components. In the field of micro-EDM, increasing machining accuracy and productivity are crucial, having led to continuous research to improve these performance indicators. To get around the drawbacks of micro-EDM, a number of technological innovations have been investigated, including the use of coated electrodes, the addition of dielectric solutions containing conductive powders, and the introduction of controlled vibrations in the workpiece or electrode. The use of coated electrodes shows the most promise among these in terms of enhancing the quality of machining. Choosing the right coating materials becomes crucial because the electrical, thermal, and physicochemical characteristics of the coating are crucial in determining the accuracy and efficiency of micro-EDM. Furthermore, the intricate relationship between the micro-EDM process parameters and the material properties of the workpiece highlights the necessity of careful optimization to obtain the intended machining results [1]. The performance of artificial graphite, copper, and tungsten carbide electrodes in the micro-EDM of Ti-6Al-4V alloy was compared, and according to experimental results, no single electrode material can offer a high material removal rate (MRR) and a favorable tool wear rate (TWR) at the same time. Tungsten carbide electrodes, in particular, showed difficulties in striking a balance between these two performance metrics. While both tungsten carbide and graphite electrodes performed better at a discharge voltage of 240 V with a capacitance of 100 pF, copper electrodes showed the best machining behavior at a discharge voltage of 180 V with a capacitance of 1000 pF. These findings highlight the potential of copper electrodes to achieve improved machining quality under particular micro-EDM conditions and demonstrate the dependent nature of electrode suitability [2].

An AlSi-10Mg coating and micro-textures dramatically increased tool life and machinability by reducing flank wear and surface roughness. This research highlights the effectiveness of this dual approach in improving heat transfer and providing a damping effect, thereby improving machining performance [3]. This study investigates the material removal rate (MRR), tool wear rate (TWR), and surface roughness with cryogenically treated tungsten carbide tools and nano-graphene powder-mixed dielectrics at varying discharge energy levels/streams. This paper is not focused on tool coatings but on the behavior of μ-ED milling utilized in conjunction with these conditions instead [4]. The findings on the effects of utilizing boron carbide powder in deionized water as a dielectric in micro-EDM demonstrate improvement in surface quality, MRR, and TWR [5]. The research explores the effect of Al and AlCrNi-coated electrodes on surface roughness in electric discharge machining (EDM) of Ti-6Al-4V while noting that coated electrodes yield better surface quality than un-coated electrodes. This study also reports the best conditions for an improved machining process, on the effects of current, voltage, and pulse-on time [6]. To enhance the functionality and longevity of machined components, protective oxide–ceramic coatings produced by micro-arc oxidation (MAO) have also been investigated, in addition to electrode coatings. Analyzing the micro-hardness and structure of the oxide–ceramic layers that form on component surfaces is the main goal of these investigations. To assess these coatings, experimental studies have made use of cutting-edge methodologies and contemporary characterization instruments. For example, a UDG-180 welding machine was used to perform the surfacing process after various wires were used to deposit an AlSi7Mg aluminum alloy. The deposited surfaces then developed hardened oxide–ceramic layers as a result of the application of micro-arc oxidation in an anode–cathode mode [7]. These results assert that the device enhances machinability, as the electrode is able to create small craters with a consistent energy distribution. A Taguchi-DEAR optimization design was used to enhance the quality measure. The best conditions were found to be a voltage of 140 V, capacitance of 10 nF, and tool spin of 200 RPM. Moderate voltage and capacitance both minimized overcutting, made material removal possible, and subsequently improved overall machining behavior [8]. The abovementioned research also describes the influence of different electrode materials (brass, copper–tungsten, and tungsten) on Ti-6Al-4V alloy’s processing characteristics during electrical discharge machining. Of the electrode materials under consideration, copper tungsten exhibited the best overall performance, achieving more material removal and the lowest tool electrode wear rates [9]. Recent studies have focused on integrating artificial intelligence and statistical optimization techniques to enhance EDM performance, in addition to coating-based developments. It has been demonstrated that creating hybrid models based on Artificial Neural Networks (ANNs) and Taguchi-based optimization is an effective method for improving the machinability of challenging-to-machine materials. For example, optimization targeted at lowering surface roughness, boosting the material removal rate, and minimizing tool wear proved to be highly beneficial when wire EDM was applied to SNCM8 alloy steel. The ANN-based hybrid model effectively predicted machining responses based on process parameters, while the optimized parameter settings improved machining efficiency, reduced tool wear by 25%, and enhanced surface quality—contributing to more sustainable manufacturing practices [10]. Similar to this, attempts to use a rotating electrode to enhance micro-EDM performance in Ti-6Al-4V during micro-through-hole machining have produced encouraging outcomes. Important machining properties like the material removal rate, overcut, tool wear rate, and taper angle were found to be positively impacted by tool rotation. These enhancements collectively resulted in a 13.07% improvement in machining quality, highlighting the potential of process innovation to advance micro-EDM applications [11]. Its main goal is to optimize micro-EDM parameters like peak current and pulse-on time and their impact on performance metrics like overcut, taper, tool wear rate, and metal removal rate. Although they are not directly related to coated microtools, the impact of dielectric fluids and the creation of mathematical models for micro-EDM performance are also covered in [12].

The geometry of micro-holes achieved by micro-EDM with different dielectrics, pure kerosene, pure deionized water, and mixed dielectrics of boron carbide is controlled very accurately. The research does not concentrate on the effect of the tool coating but, rather, investigates the impact of these dielectrics on the taper and circularity of micro-holes [13]. Concurrently, research has looked into using semiconductor electrodes in place of traditional copper electrodes in multi-channel EDM. These electrodes have shown significant benefits in terms of preserving high rates of material removal and enhancing surface finish at the same time. According to the findings, semiconductor-based electrodes perform better than conventional materials in terms of improving surface quality and machining efficiency, providing a promising avenue for the development of EDM technology [14]. A successful method for improving the surface integrity of Ti-6Al-4V components while reducing heat-affected zones and surface roughness is the sequential integration of micro-electrochemical machining (µ-ECM) with micro-EDM. The potential of µ-ECM to supplement micro-EDM for precision applications is demonstrated by this method, which mainly concentrates on enhancing surface quality rather than assessing particular tool coatings [15].

Furthermore, the effects of nano-powder mixed dielectrics, such as silicon carbide and carbon nanotubes, on surface finish, MRR, and micro crack formation have been examined in the context of micro-ED milling of Ti-6Al-4V. The findings emphasize that dielectric conductivity plays a crucial role in machining performance and that the selection and characteristics of dielectric additives can have a big impact on micro-EDM results [16]. The creation of an ANN-based hybrid model and Taguchi-based optimization of difficult-to-machine materials are also the main objectives of the current effort. The goal of wire-EDM for SNCM8 alloy steel is to reduce surface roughness, increase the material removal rate, and decrease tool wear. According to sustainable manufacturing practices, the model predicts machining responses based on process parameters. Optimizing the parameter settings is thought to be advantageous because it was found to improve machining efficiency and reduced tool wear by 25% while also improving surface quality [16]. The use of nano-fluid-based coolants to enhance machining performance in terms of MRR, flank wear, and surface finish has also been investigated in recent studies. The machining process was optimized using 18 experimental runs designed using the Taguchi method, with Grey Relational Analysis (GRA) used for multi-response evaluation. The study showed that cutting speed is the most important factor affecting overall machining performance and that combining the Taguchi methodology with Grey Relational Analysis for multi-response optimization offers a systematic approach to improving industrial production quality and process efficiency [17].

High-temperature rotary EDM has been studied recently for biomedical applications—specifically, in the machining of SiN4–TiN ceramic composites. Dielectric pressure, current, spark-gap voltage, machining speed, pulse-on time, and other key performance metrics were all methodically assessed. To get the best machining results, several combinations of these parameters were experimentally tested, and multi-objective Jaya optimization was used. In addition to improvements in surface roughness, top radial overcut, circularity, perpendicularity, and runout, the results showed a 10.6% increase in MRR and a 6.6% decrease in electrode TWR [18]. For medical implants, magnesium (Mg), a type of biodegradable substance, offers an excellent biocompatibility and stress-shielding function. Its limited lifespan and poor resistance to corrosion are disadvantages, though. To address this issue, magnesium has been doped with titanium to improve its mechanical and corrosion-resistance properties. Spark plasma sintering and mechanical alloying are used to create Mg-Ti alloys with improved corrosion resistance. Pre-osteoblasts are not cytotoxically affected by magnesium–titanium alloys either. They can manage the pH of stability and degradation by creating composites with polymers like PLGA. Such alloys are appropriate as temporary orthopedic implants because of their anti-corrosive and biocompatible qualities, which allow them to support weight while a fracture heals [19]. In electrical discharge drilling (EDD) in Si3N4-TiN ceramic composites using 25 trials, multiple regression analysis and integrated teaching–learning-based optimization were used to develop predictive models with 90% accuracy. The results showed improved machining precision, geometrical tolerances, micro-void frequency, and surface quality [20]. The performance of coated and WC electrodes, such as WC–Ag, TiN, and ZrN, has been reported, with emphasis on optimizing micro-EDM milling parameters for Ti-6Al-4V using WC tool electrodes. The results show that TiN-coated WC electrodes improve precision and surface integrity in micro-EDM operations by lowering the electrode wear rate and overcut, which, in turn, greatly improves machining quality [21]. Numerous investigations have looked into ways to improve the tribological performance of Ti-6Al-4V, an alloy that is used in aerospace applications because of its high weight-to-strength ratio. Techniques for surface modification, like plasma nitriding and magnetron sputtering for TiN deposition, have been extensively studied. When compared to untreated surfaces, reports show that these coatings greatly increase surface hardness and decrease roughness. TiN-coated surfaces show narrower wear tracks and lower friction coefficients than uncoated specimens according to tribological evaluations conducted under various sliding velocities and normal loads. These findings imply that TiN surface treatments successfully improve the overall durability and wear resistance of Ti-6Al-4V alloys, underscoring their potential to prolong component service life under demanding operating conditions [22]. A notable improvement in the composite attractiveness ratings for the various sparking process performance factors was reported. The data showed considerable improvements in MRR, EWR, CIRY, CYLY, and PERY. Based on the correlation between the expected and actual performance measure values, the optimal neural network was identified using regression analysis and the response surface approach. The resulting machined surface showed tiny globules that were 3.511 μm long and 1.113 μm2 in area for the center hole. Surface morphology was also analyzed to determine the best and worst holes [23]. Electro spark deposition (ESD) method, which involves applying hard alloyed coatings, is a useful method for improving the surface characteristics of nickel and titanium alloys. Research has shown that the electrode material, deposition energy, and initial substrate roughness all have a major impact on the topology and roughness of ESD coatings. Parameters such as Ra, Rt, Rq, Rz, Rmax, Wt, Rsk, Rku, Rk, and Rpk are commonly used to assess surface characteristics. It has been demonstrated that selecting the appropriate ESD parameters improves substrate surfaces by mitigating the effects of earlier treatments and casting irregularities. Research on hard alloy coatings, such as TiB2-based electrodes with nano-dimensional additives, shows that controlled ESD processes can create coatings with improved durability, functional performance, and surface quality. These advancements set standards for deposition strategy optimization across a range of materials [24]. Many studies have compared traditional EDM processes for the milling of Ti-6Al-4V ELI using different electrode materials, such as copper and graphite, with a focus on key performance indicators like surface roughness, TWR, and MRR. Statistical analyses, such as ANOVA, have been used to evaluate the effects of pulse-on current and pulse duration on machining results [25]. Silicon electrodes, which have benefits over traditional copper electrodes in terms of discharge stability, MRR, surface quality, and fewer heat-affected zones, have also been investigated for multi-channel EDM. It has been demonstrated that silicon’s higher bulk resistance makes multi-channel discharges more effective, which improves machining performance and process reliability [26]. In an increasing number of commercial applications, nanocomposites have, so far, started to replace traditional composite materials. From complex materials for the automotive and aerospace industries to computer components, data storage devices, membranes, and filters, they are used in a wide range of industries. They are available from numerous manufacturers and come in a wide variety of shapes and sizes. Because their properties may be adjusted to meet specific end-user requirements, nanocomposites provide very appealing and innovative technical solutions, even if they may be more expensive than conventional materials. Standards for the safe use, disposal, and recycling of nano trash are being prepared by international scientific groups such as the International Standards Organization (ISO). As the market for metal matrix nanocomposites expands, standardization will become increasingly important [27,28].

The impacts of electrode materials and coatings, including copper, silver, nickel, zinc, and epoxy, on key micro-EDM performance metrics, such as TWR and MRR, have been the subject of numerous studies [29]. Through these studies, process parameters have been optimized for the depth of machining (Z coordinate) and minimum TWR.

The TWR of copper-coated tools is generally higher, mainly because copper has a lower melting point and very high thermal conductivity. Therefore, it wears more rapidly than tungsten copper (WCu) and WC. A low MRR is obtained for copper tools, while WCu electrodes can provide a good MRR and the material removal rate of a WCu tool is higher as compared to that of a copper tool because of better thermal conduction (and, thus, cooling) and electrical conductivity. Carbon coatings significantly decrease TWR, increasing the wear resistance of the tool. This is due to the enhanced corrosion resistance and thermal stability of carbon coatings. Carbon-coated electrodes have been shown to improve the depth of cut (Z), achieving optimal machining conditions with specific parameter settings (e.g., V = 160 V, C = 10,000 pF, and RPM = 600) [30].

Prior studies suggest that carbon-coated (C-coated) WC tools will have a lower TWR from high discharge voltage during micro-EDM of Ti-6Al-4V due to their superior durability at elevated temperature as a result of their hardness while maintaining a high depth of machining (Z). Conversely, copper-coated (Cu-coated) WC tools should show a somewhat higher TWR but with better spark stability and greater uniformity of surface finish based on their more efficient electrical and thermal conductivity. Accordingly, this study examines how variations in voltage, capacitance, and pulse-on time (L9 design) affect the TWR and depth of machining for uncoated, C-coated, and Cu-coated tools.

Matching the electric conductance, copper coatings exhibit superiority over carbon coatings, but their wear rate is high and their corrosion surface quality is low, requiring further improvement. At the same time, carbon coatings hold excellent potential to enhance the performance of micro-EDM, particularly in terms of depth of machining and tool life. To benefit both types of coatings, future studies could focus on optimizing process parameters. In this research the strategic assessment of microtools coated in copper and carbon in micro-EDM on Ti-6Al-4V using an L9 orthogonal array, focusing on tungsten carbide electrodes and examining how input parameters like voltage, current, pulse frequency, and pulse width affect output properties like the depth of machining (Z coordinate) and TWR.

2. Materials and Methods

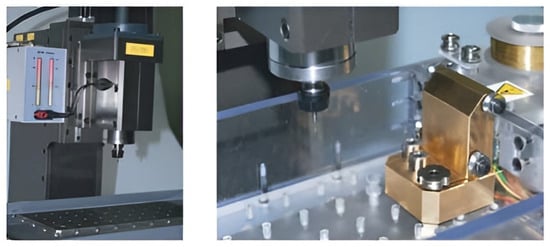

Experiments were performed at VJTI, Matunga (Mumbai), Maharashtra, India. The Hyper-10 EDM’s spindle and machine (make: Synergy Nano Systems; model: Hyper-10) is shown in Figure 1. The Hyper-10 is a tabletop-style miniature machine tool that can be used with various accessories and supports a range of machining operations, including micro milling, micro EDM, micro drilling, and micro wire EDM. The Hyper-10 machine’s versatility makes it perfect for developing an integrated hybrid process involving traditional mechanical means and non-traditional means such as EDM and ECM.

Figure 1.

Spindle of Hyper-10 EDM.

2.1. Coating of Tool Electrode

2.1.1. Coating of Copper Material on Microtool Electrode

Tungsten carbide was coated with copper using an electroplating process. The process of electrolytically applying a layer of copper to a substrate’s surface is known as copper plating. It occurs in an electrolytic cell, where copper ions are transported to the substrate via electrolysis, which dissolves a copper rod using a directed electric current. A copper rod and a tungsten carbide substrate are put into a container of water. A direct electric current can flow from the copper rod to the substrate due to the ionic solution in the water. The copper is ionized and oxidized by this current flow, which results in the loss of an electron and a positive charge on each atom. Together with the salts already present, the copper ions create a coordination complex when they dissolve in the water. After that, the copper physically moves to the object, where it gains electrons and is reduced to the metallic state. As a result, the substrate’s surface develops a thin, solid, metallic layer of copper. Figure 2 shows a copper-coated tool electrode.

Figure 2.

Coated copper electrode.

A descriptive explanation of the copper coating, with key parameters, is given below: CuSO4 · 5H2O (Copper sulfate pentahydrate): 200–250 g/L. pH: The bath is typically maintained in the range of 0.5 to 2.0, which prevents the formation of copper hydroxides and maintains a uniform deposition. Temperature: The process is usually performed at 25–40 °C. Higher temperatures increase ion mobility and the deposition rate but may affect surface morphology. Current Density: Generally maintained between 1–5 A/dm2. Deposition Duration: Typically, 5–30 min.

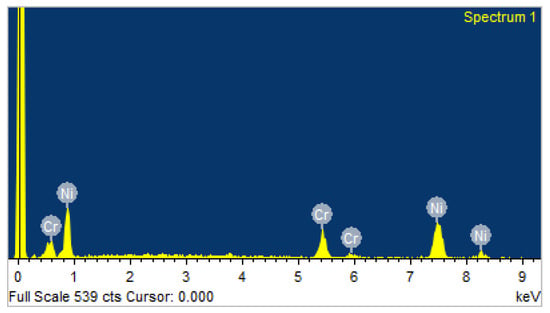

Table 1 and Figure 3 show the EDAX report of the copper coating; the presence of copper material in the coating was evident. The presence of copper Cu was also observed in the L shell.

Table 1.

Elements in copper coating.

Figure 3.

EDAX report of copper coating of the tool electrode.

2.1.2. Coating of Carbon Material on Microtool Electrode

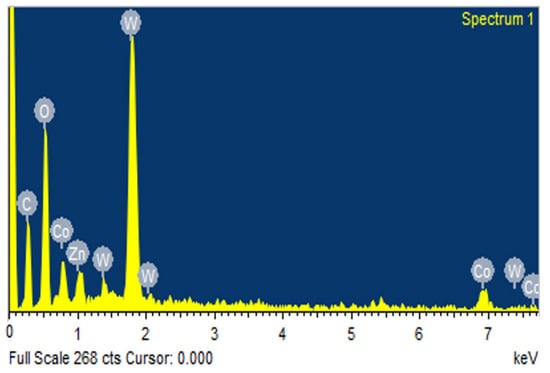

The coating was applied to a tungsten carbide substrate by chemical vapor deposition (CVD) to a thickness of up to 10 μm. Ferrocene and camphor were used. The melting points of ferrocene and camphor are 186 °C and 180 °C, respectively. Ferrocene and camphor powder were used in amounts of 0.89 and 0.11 grams, respectively. Table 2 shows the elements present in the carbon coating. The presence of C, O, and Co was observed in the K shell, whereas Zn and W are observed in the L and M shells, respectively.

Table 2.

Elements in carbon coating.

On the tungsten carbide microtool electrode, CVD created a consistent coating. Figure 4 displays the carbon coating EDAX report.

Figure 4.

EDAX report of the carbon coating on the tool electrode.

2.1.3. Tungsten Carbide Electrode

The most durable EDM tools are made of tungsten carbide electrodes, which can penetrate strong target materials and are produced in smaller quantities than those made of copper or brass. In contrast to copper and brass electrodes, which can only drill holes as small as 0.1 mm, they are utilized when the target material is robust. Table 3 lists the specific characteristics of tungsten carbide electrodes.

Table 3.

Properties of Ti-6Al-4V.

It is likely that the C layer contained Co and W only because of the diffusion of parent-material substrate (WC–Co) during coating, while Zn is likely present because it was an impurity or contamination from the chamber. These elements can only slightly improve the electrical conductivity of the coating to help stabilize the discharge in the case of using a Plasma-Controlled Coating System (PCCS). These impurities can slightly affect the thermal uniformity of the coating or the integrity of the coating, leading to a modest increase in TWR.

3. Results and Discussion

A Micro Electro Discharge Machine (make: Synergy Nano Systems; model: Hyper-10) was used for the studies. Before and after every experiment, the weight of every tool was recorded using a weight balance. Three levels of capacitance (100 pF, 1000 pF, and 10 nF) were considered in the study, Table 4. The voltage variance ranges from 120 to 160 V. For TWR, the initial and final weights of the tool and workpiece were also noted. Table 5 presents the experimental findings for the tool wear rate and depth of machining (Z-axis) as the values of voltage, capacitance, and RPM are altered.

Table 4.

Range of input parameters.

Table 5.

Electrodes for experimentation.

3.1. Experimental Results Using Tungsten Carbide Microtool Electrodes

The depth of machining (Z coordinate) and TWR were investigated via experimental scanning using the L9 orthogonal array (three input parameters and three levels). Table 6 presents experimental results for uncoated WC microtool electrodes. It shows that the TWR and depth of machining were maximum in the ninth trial. Table 6 shows the TWR and the lowest depth of machining (Z) measured in the first experiment. We will delve deeper into the TWR and conduct a detailed analysis of the machining depth.

Table 6.

Tungsten carbide electrode experimental results.

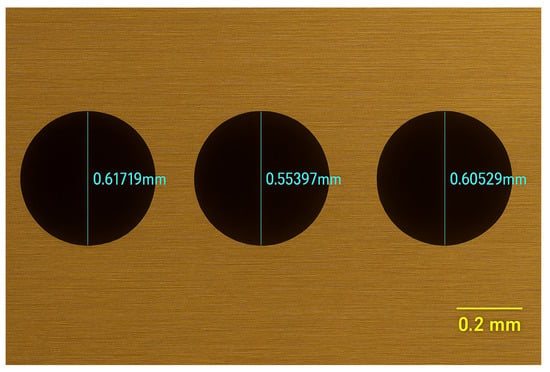

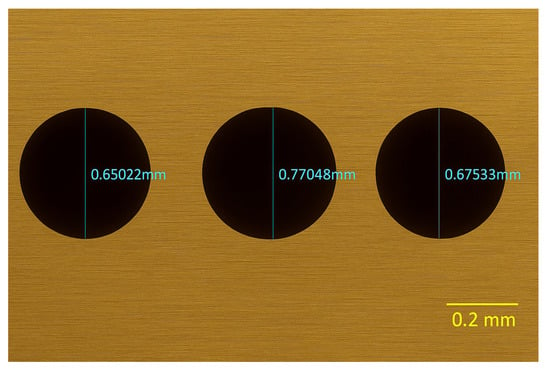

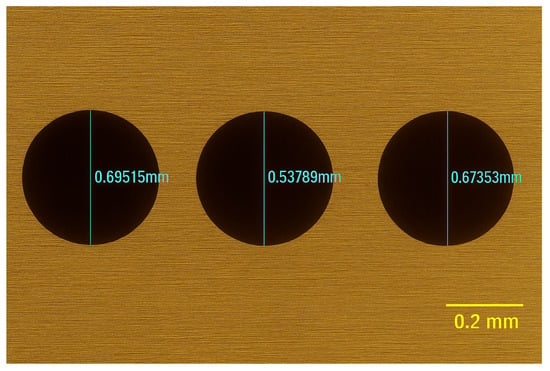

Figure 5 shows the machined surface on Ti-6Al-4V produced using the micro EDM technique. Because voltage and capacitance are energy-related properties, higher values result in a larger machining surface diameter.

Figure 5.

Microscopic images of machined surface with WC micro electrode.

3.1.1. ANOVA for Tool Wear Rate

The tungsten carbide electrode study was performed using Minitab 17. The results at the TWR are listed in Table 7. The TWR in weight loss was computed after each experiment. Table 7 shows that capacitance is the primary source of electrode wear, as the F value for capacitance is the largest and the p value is less than 0.05, whereas neither voltage nor RPM had a significant impact on the TWR of the tungsten carbide electrode. The tool wear rate of each electrode demonstrates that the two conflicting phenomena that comprise tool wear behavior are material deposition onto the electrode and erosion of the electrode material. More material is deposited on the tool, and a lot of debris is generated under high spark energy conditions.

Table 7.

Tungsten carbide electrode TWR analysis of variance.

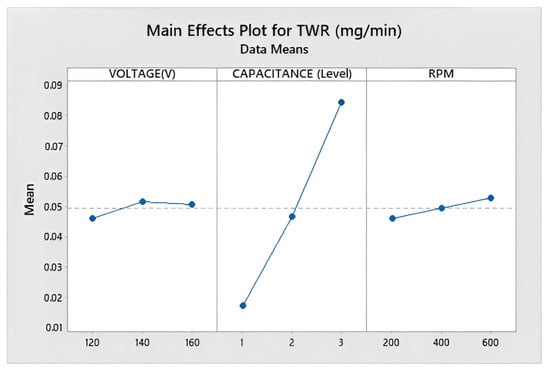

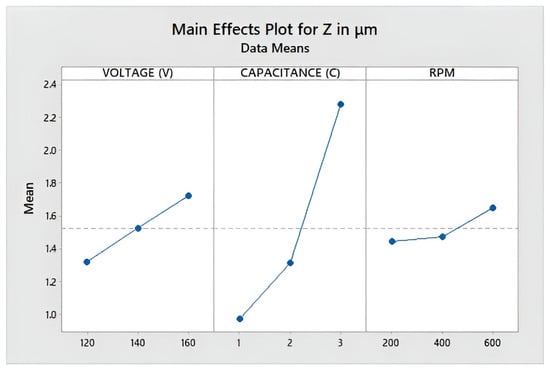

Similarly, at low spark levels, an energy-related effect results in less actual tool material being removed and less debris being deposited on the tool. Since TWR was calculated by comparing the weight of the tool before and after machining, the measured TWR included the combined effect of material removal from the tool and deposition. The constant TWR indicates that the difference between the material deposited on the tool and that removed from it remains constant, even when the process parameters are changed. The TWR principal impact graphic is shown in Figure 6.

Figure 6.

Tungsten carbide electrode main effects plot for TWR.

Three distinct voltage levels—120, 140, and 160 V—were used in this experiment. It was found that workpiece material was deposited on the tool between 140 and 160 V and that tool erosion peaked at 10 nF. It was discovered that TWR was originally higher for 140 V and 160 V but that as spark resistance increased, the TWR and Z coordinate decreased as a protective layer of carbon deposition coated the surfaces. Tool wear increases with rising voltage and capacitance, as illustrated in the principal effects graphic. Stronger sparks, produced by higher voltage and capacitance, raise the temperature, starting to melt earlier and increasing the TWR at higher values. Due to the higher spark energy, the capacitance and tool wear rate increase simultaneously. It is evident from the primary effect graphic that TWR rises in tandem with RPM. Additionally, because RPM promotes a suitable cleansing action, the TWR somewhat increases as RPM increases.

3.1.2. Analysis of Variance for Machining Depth (Z Coordinate) Tungsten Carbide Electrode

Table 8 presents the Z coordinate for the ANOVA of the uncoated tungsten carbide electrode. No other parameter appeared to be important, and capacitance was determined to be the most essential feature for the Z coordinate because the F value for capacitance is maximum, contributing 94.20%, and the p value is less than 0.05. In this case, continuous electrode feeding in the Z-axis to a predefined depth resulted in non-compensated electrode deterioration. Only an exact model can be used to calculate the volumetric wear ratio, which is the ratio of electrode wear to workpiece wear.

Table 8.

Tungsten carbide electrode Z-coordinate analysis of variance.

The primary effect charts for the depth the tool reached are displayed in Figure 7. The relationship between depth and capacitance is linear. Because the electrode gap produces less energy at lower capacitance levels, such as Level 1 (100 pF), and smaller voltage gaps, such as 120 V, there is less depth. At 160 V, less depth was attained. This is brought on by both the formation of a carbon layer, which lowers the spark energy at higher voltages, and non-compensated TWR from the bottom of the electrode. Therefore, depth increases linearly up to 140 V of power.

Figure 7.

Main effects plot of tungsten carbide electrode for Z coordinate.

Due to the tool’s rotation, RPM provides a superior flushing action. Flushing processes promote ionization and plasma channel development as tool revolutions increase.. However, one of the ongoing challenges for micro EDM researchers is the randomness of the flushing effect of the dielectric fluid. At 200 rpm, this variation in the dielectric fluid’s flushing action creates anomalies and decreases depth. Its depth grows satisfactorily above 400 rpm.

3.2. Results of an Experiment Using a Carbon-Coated Microtool Electrode

The findings of nine studies using tungsten carbide coated with carbon up to 10 μm and a standard time of 15 min are displayed in Table 9.

Table 9.

Experimental results for the carbon-coated electrode.

The minimum and maximum TWR values were displayed in the first and ninth studies. Z’s minimum and highest values were shown in the second and ninth experiments, respectively.

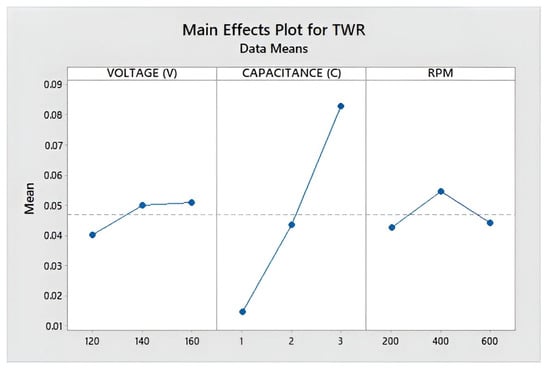

3.2.1. Analysis of Variance for TWR

Table 10 shows the electrode coated with carbon. TWR was measured using the weight reduction method. The graph demonstrates that capacitance has a significant impact on electrode wear, even though other factors, such as voltage and RPM, because the F value of capacitance is maximum, at almost 90%, and the p value is less than 0.05.

Table 10.

ANOVA for carbon-coated electrode for TWR.

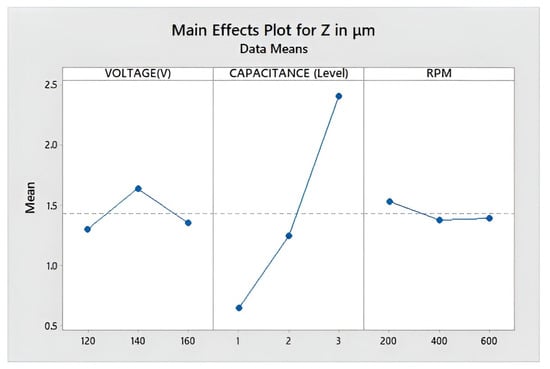

The main effect plot (Figure 8) shows that TWR increased linearly with voltage. Neither coated nor non-coated electrodes have ever shown this type of outcome. This is because there was no carbon layer deposition on the surfaces, and carbon coatings adhered better than titanium nitride coatings.

Figure 8.

Main effect plot for carbon-coated electrode.

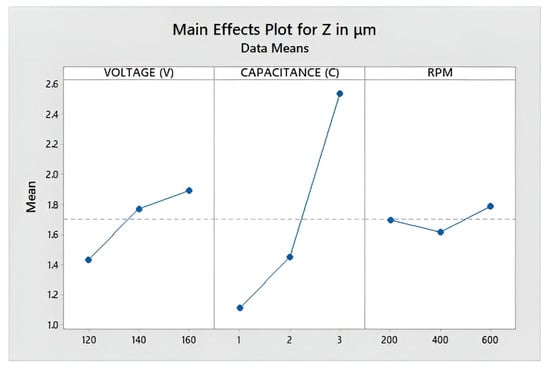

3.2.2. Analysis of Variance for Machining Depth (Z Coordinate) Carbon-Coated Electrode

While voltage and RPM had no appreciable impact on the TWR of the carbon-coated electrode, Table 11 demonstrates that capacitance dominated the Z coordinate because the F value of capacitance is maximum, at 85%, and the p value is exactly 0.05.

Table 11.

ANOVA for carbon-coated electrode for the Z coordinate.

Figure 9 and Figure 10 demonstrate comparable patterns for the two coated electrodes, for low values at 400 rpm.

Figure 9.

Main effect plot for carbon-coated electrode for the Z coordinate.

Figure 10.

Microscopic pictures of machined surfaces.

3.3. Results of an Experiment Using a Copper-Coated Microtool Electrode

An experiment was conducted using a tungsten carbide electrode coated with copperThe diameter was 496.77 μm, on an average. Table 12 displays the findings from nine tests using copper-coated electrodes.

Table 12.

Experimental findings for copper-coated microtool electrodes.

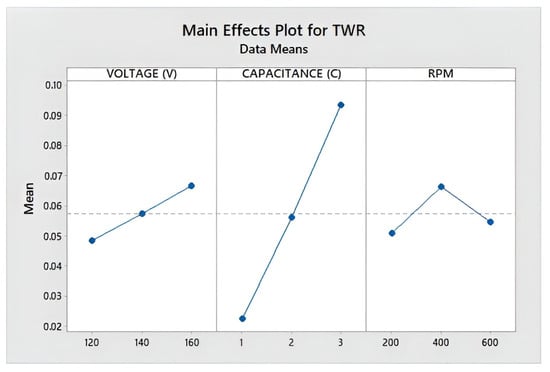

3.3.1. Analysis of Variance for TWR

Table 13 demonstrates that capacitance is the primary factor influencing the electrode’s TWR; the TWR of the carbon-coated electrode was not significantly impacted by the other parameters, such as voltage or RPM. The reason is that the capacitance (F) is at its maximum (93%) and the p value is less than 0.05.

Table 13.

Variance analysis for TWR with a copper-coated electrode.

The voltage trends in Figure 11 are comparable to those achieved when CVD was used to apply 3.385 μm of copper to a 490 μm tungsten carbide electrode. Coated electrodes are softer than non-coated tungsten carbide electrodes.

Figure 11.

Main effects plot for TWR using a microtool electrode coated with copper.

However, it is more stable at high temperatures than the titanium nitride electrode. Their surfaces were coated with a thin coating. Therefore, the thin layer exhibits reduced wear at higher voltages (160 V). As a result, TWR decreased as the carbon layer formed at 160 V. According to observations, tool motion becomes more swirling, and the thin film deteriorates as RPM increases. The machine performed better in terms of tool rotations at 400 rpm. As a result, TWR happens more frequently.

3.3.2. Analysis of Variance for Machining Depth (Z Coordinate) Copper-Coated Electrode

Table 14 makes it evident that, for aluminum chromium nitride electrodes, every input parameter was non-significant.

Table 14.

ANOVA for copper-coated electrode for the Z coordinate.

The experiments on Ti-6Al-4V titanium alloy machined with copper-coated electrodes were conducted according to the experimental design, with Minitab used to produce the significant effects plot in Figure 12. A snapshot of the 2.5 mm-thick Ti-6Al-4V plate’s machined surface, utilising the die-sinking EDM technique in accordance with the L9 orthogonal array, is shown in Figure 13.

Figure 12.

Copper-coated electrode: main effect plot for the Z coordinate.

Figure 13.

Microscopic images of a copper-coated electrode for a machined surface.

3.4. Comparative Study of Response Variables with Coated and Uncoated Tool Electrodes

Experimentation, analysis, and multi-objective optimization of uncoated and various thin-film-coated electrodes were conducted. A comparative study of uncoated and variously coated electrodes will be presented in this section.

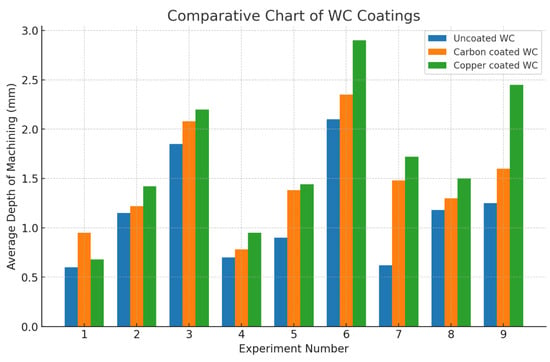

3.4.1. Comparative Study of Uncoated and Coated Electrodes for Depth of Machining (Z Coordinate)

Table 15 presents the experimental results for various thin-film-coated electrodes and an uncoated WC tool electrode. Because of its poor thermal and electrical properties, the uncoated WC microtool electrode exhibits the lowest depth of cut. The best results for depth of cut are obtained with microtool electrodes coated with copper. At higher voltages and capacitances, copper-coated electrodes exhibit a consistent depth of cut.

Table 15.

Comparison of the depth of machining with uncoated and coated electrodes.

A graphical representation of the average depth of machining is shown in Figure 14. Carbon-coated electrodes yield better results than WC electrodes, but they are not as effective as copper-coated electrodes. A copper-coated electrode enhances electrical conductivity compared to carbon-coated and uncoated electrodes, resulting in a deeper depth of machining.

Figure 14.

Comparison of the depth of machining.

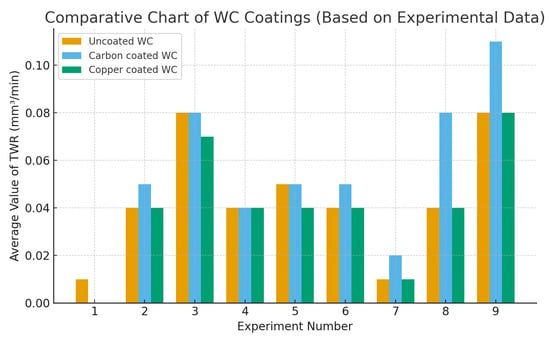

3.4.2. Comparison of Coated and Uncoated Electrodes for TWR

Table 16 presents the experimental findings for different thin-film-coated electrodes and uncoated WC tool electrodes, expressed as TWR. Because CVD method is used for coating, the carbon-coated WC microtool electrode exhibits the maximum TWR. The best TWR results are obtained using copper-coated microtool electrodes, which are nearly identical to WC tools. Electrodes coated with copper exhibit stability, even at greater capacitance and voltage levels, as shown in Figure 15.

Table 16.

Comparison of TWR using coated and uncoated electrodes.

Figure 15.

Comparison of TWR.

4. Conclusions

The performance of thin-film-coated tungsten carbide microtools in the micro EDM process was studied, with special emphasis on evaluating the tool wear rate and machining depth using Minitab software 17 and the Taguchi method of experimental design. An L9 orthogonal array was used to investigate the effects of process factors (spindle speed (RPM), voltage, and capacitance) on a workpiece (titanium alloy Ti-6Al-4V (grade 5)). The experimental tests utilized WC tool electrodes coated with carbon and copper, as well as electrodes with no coating. The carbon coatings were deposited by CVD, and the copper coatings were deposited by electroplating.

The results indicated that although carbon-coated WC tools had a higher TWR level, copper-coated WC electrodes exhibited the lowest TWR, indicating better wear resistance and prolonged electrode life. Both carbon- and copper-coated electrodes showed a reduction in depth of machining compared to the uncoated WC tool, which offers the possibility of improving machining accuracy. Nevertheless, under specific discharge conditions, carbon-coated electrodes showed greater depth of machining at higher capacitances, suggesting limitations.

Overall, carbon-coated electrodes may be a suitable substitute for thin-film copper coatings on WC microtool electrodes, which are the most effective for micro EDM applications. Both coatings show notable benefits over uncoated WC electrodes.

Author Contributions

Conceptualization, S.S. and P.B.G.; methodology, V.G. and A.S.; investigation, P.B.G.; resources, S.S., M.V., and A.S.; data curation, S.S. and A.A.; writing—original draft preparation, P.B.G.; writing—review and editing, S.S., M.V., N.H.-P., and AA; visualization, S.S.; supervision, N.H.-P. and A.A.; project administration, V.G. and A.A.; funding acquisition, M.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding authors.

Conflicts of Interest

Author Marko Vulović was employed by the Public Company for Water Supply and for the Production and Distribution of Electricity “Ibar”, Zubin Potok, Serbia. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ANNs | Artificial Neural Networks |

| CVD | Chemical Vapor Deposition |

| EDS/EDX | Energy-Dispersive X-ray Spectroscopy/Analysis |

| GRA | Grey Relational Analysis |

| EDD | Electrical Discharge Drilling |

| Z coordinate | Depth of Machining |

| Z | Depth of Cut |

| EDM | Electrical Discharge Machining |

| ESD | Electro Spark Deposition |

| WC | Tungsten Carbide |

| TWR | Tool Wear Rate |

| MAO | Micro-Arc Oxidation |

| MRR | Material Removal Rate |

| MWCNT | Multi-Wall Carbon Nanotube |

| micro-EDM | Micro-Electric Discharge Machining |

| µ-ECM | Micro-Electrochemical Machining |

| EDAX | Energy-Dispersive Analysis of X-rays |

| ANNOVA | Analysis of Variance |

| PCCS | Plasma-Controlled Coating System |

References

- Pham, H.-V.; Nguyen, H.-P.; Shailesh, S.; Nguyen, D.-T.; Bui, N.-T. Improving Micro-EDM Machining Efficiency for Titanium Alloy Fabrication with Advanced Coated Electrodes. Micromachines 2024, 15, 692. [Google Scholar] [CrossRef]

- Pal, M.R.; Debnath, K.; Rao, G.S.; Mahapatra, R.N. Micro-EDM of Ti-6Al-4V using various tool materials: Multi-response optimization and surface characterization. Surf. Rev. Lett. 2024, 31, 2450080. [Google Scholar] [CrossRef]

- George, A.; Sahu, S.S.; Dhanish, P.B.; Mathew, J.; Kuriachen, B. Tool surface modification methodology to improve the machinability of Ti6Al4V through combination of micro-EDM texturing and AlSi-10Mg soft coating techniques in dry turning. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2023, 237, 5330–5351. [Google Scholar] [CrossRef]

- Pillai, K.V.A.; Hariharan, P.; Jafferson, J.M. μED milling of Ti-6Al-4V using cryogenic-treated Wc tool and nano-graphene powder-mixed dielectric at different discharge energy regimes. Int. J. Adv. Manuf. Technol. 2019, 102, 2721–2743. [Google Scholar] [CrossRef]

- Kibria, G.; Shivakoti, I.; Bhattacharyya, B. Experimentation and Analysis into Micro-Hole Machining of Ti-6Al-4V by Micro-EDM Using Boron Carbide Powder Mixed De-Ionized Water. Int. J. Manuf. Mater. Mech. Eng. 2014, 4, 22–41. [Google Scholar] [CrossRef]

- Phan, N.H.; Dong, P.V.; Muthuramalingam, T.; Thien, N.V.; Dung, H.T.; Hung, T.Q.; Duc, N.V.; Ly, N.T. Experimental Investigation of Uncoated Electrode and PVD AlCrNi Coating on Surface Roughness in Electrical Discharge Machining of Ti-6Al-4V. Int. J. Eng. 2021, 34, 928–934. [Google Scholar] [CrossRef]

- Kuznetsov, Y.; Gribakin, A.; Kravchenko, I.; Goncharenko, V.; Feryabkov, A.; Panov, A.; Kalashnikova, L. Study of Structure and Microhardness of Protective Oxide-Ceramic Coatings Obtained by Micro-Arc Oxidation on Deposited Surfaces. Adv. Eng. Lett. 2024, 3, 164–172. [Google Scholar] [CrossRef]

- Phan, H.N.; Muthuramalingam, T.; Dong, P.V.; Shailesh, S.; Dung, H.T.; Thien, N.V.; Ly, N.T. Multi-objects Optimization in Μ -Edm Using Alcrni Coated Tungsten Carbide Electrode for Ti-6AL-4V. Int. J. Adv. Manuf. Technol. 2022, 122, 2267–2276. [Google Scholar] [CrossRef]

- Chen, S.; Lian, M.; Wu, X.; Lei, J.; Hang, Z.; Peng, T.; Luo, F.; Yang, J.; Xu, B. Study on the micro-EDM processing characteristics of Ti-6Al-4V alloy with different electrode materials. Int. J. Adv. Manuf. Technol. 2021, 116, 3369–3376. [Google Scholar] [CrossRef]

- Chaudhari, S.; Sunheriya, N.; Giri, J.; Kanan, M.; Chadge, R.; Sathish, T. Qualitative Enhancement In Machining Efficiency of SNCM8 Alloy Through Hybrid ANN-Taguchi Optimization Approach. Appl. Eng. Lett. 2025, 10, 48–61. [Google Scholar] [CrossRef]

- Tiwary, A.P.; Chakraborty, S.; Pradhan, B.B.; Bhattacharyya, B. Improvement in micro-EDM characteristics using rotational electrode during micro through hole machining on Ti-6Al-4V. In Proceedings of the 2nd International Conference on Mechanical Materials and Renewable Energy (ICMMRE 2019), East Sikkim, India, 6–7 December 2019; Volume 2273, p. 050067. [Google Scholar] [CrossRef]

- Pradhan, B.B.; Masanta, M.; Sarkar, B.R.; Bhattacharyya, B. Investigation of electro-discharge micro-machining of titanium super alloy. Int. J. Adv. Manuf. Technol. 2009, 41, 1094–1106. [Google Scholar] [CrossRef]

- Kibria, G.B. Investigation into micro-hole geometrical accuracy during micro-EDM of Ti-6Al-4V employing different dielectrics. Int. J. Mach. Machin. Mater. 2011, 10, 310–325. [Google Scholar] [CrossRef]

- Zhu, X.; Li, G.; Mo, J.P.T.; Ding, S. Multi-channel electrical discharge machining of titanium alloy Ti-6Al-4V with semiconductor electrodes. J. Phys. Conf. Ser. 2023, 2612, 012011. [Google Scholar] [CrossRef]

- Ramver; Dvivedi, A.; Kumar, P. On Improvement in Surface Integrity of µ-EDMed Ti-6Al-4V Alloy by µ-ECM Process. In TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2019; pp. 745–753. [Google Scholar] [CrossRef]

- Hasan, W.N.; Aljashaami, D.H.J. Optimization of machining parameters in turning to steel using grey relational analysis. Appl. Eng. Lett. 2025, 10, 90–99. [Google Scholar] [CrossRef]

- Selvarajan, L.; Venkataramanan, K.; Nair, A.; Choudhury, B. Si3N4-TiN rotary EDM optimization by Mo-Jaya algorithm with Pareto optimal solution, analysis of micro-structural and geometrical tolerances. J. Mech. Behav. Biomed. Mater. 2023, 145, 105995. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, N.; Anwar, S.; Ishfaq, K.; Rafaqat, M.; Saleh, M.; Ahmad, S. The potentiality of sinking EDM for micro-impressions on Ti-6Al-4V: Keeping the geometrical errors (axial and radial) and other machining measures (tool erosion and work roughness) at minimum. Sci. Rep. 2019, 9, 17218. [Google Scholar] [CrossRef]

- Selvarajan, L.; Venkataramanan, K.; Choudhury, B.; Chandrasekaran, M. Evaluating of surface morphology on EDD machining parameters for Si3N4-TiN using TLBO-MRA. Mater. Manuf. Process. 2023, 39, 465–479. [Google Scholar] [CrossRef]

- Huang, C.H.; Yang, A.B.; Hsu, C.Y. The optimization of micro EDM milling of Ti-6Al-4V using a grey Taguchi method and its improvement by electrode coating. Int. J. Adv. Manuf. Technol. 2018, 96, 3851–3859. [Google Scholar] [CrossRef]

- Danişman, Ş.; Ersoy, E.; Doğan, C. Investigation of the Surface Properties of Tin-Coated Ti6Al4v Alloy. Appl. Eng. Lett. J. Eng. Appl. Sci. 2021, 6, 175–183. [Google Scholar] [CrossRef]

- Selvarajan, L.; Venkataramanan, K.; Devaraj, S.; Jesudas, T. The effect of rotary EDM parameters on the surface integrity and geometric parameters of holes in Si3N4-TiN electro conductive ceramics using DFA-RSM-ANN method. Tribol. Int. 2024, 200, 110050. [Google Scholar] [CrossRef]

- Kostadinov, G.; Danailov, P.; Dimitrova, R.; Kandeva, M.; Penyashki, T.; Kamburov, V.; Nikolov, A.; Elenov, B. Surface Topography and Roughness Parameters of Electrospark Coatings on Titanium and Nickel Alloys. Appl. Eng. Lett. J. Eng. Appl. Sci. 2021, 6, 89–98. [Google Scholar] [CrossRef]

- Karmiris-Obratański, P.; Zagórski, K.; Papazoglou, E.L.; Karkalos, N.E.; Markopoulos, A.P. On machining Ti6Al4V ELI with EDM by using copper and graphite electrodes: A comparison study. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1037, 012003. [Google Scholar] [CrossRef]

- Zhu, X.; Wei, T.; Li, S.; Li, G.; Ding, S. Multi-Channel Electrical Discharge Machining of Ti-6Al-4V Enabled by Semiconductor Potential Differences. Micromachines 2025, 16, 147. [Google Scholar] [CrossRef]

- Krstić, J.; Jovanović, J.; Gajević, S.; Miladinović, S.; Vaxevanidis, N.M.; Kiss, I.; Stojanović, B. Application of Metal Matrix Nanocomposites in Engineering. Adv. Eng. Lett. 2024, 3, 180–190. [Google Scholar] [CrossRef]

- Anthuvan, R.N.; Krishnaraj, V. Effect of coated and treated electrodes on Micro-EDM characteristics of Ti-6Al-4V. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–16. [Google Scholar] [CrossRef]

- Meena, V.K.; Azad, M.S. Grey Relational Analysis of Micro-EDM Machining of Ti-6Al-4V Alloy. Mater. Manuf. Process. 2012, 27, 973–977. [Google Scholar] [CrossRef]

- Shanmugam, R.; Thangaraj, M.; Thangamani, G.; Ramoni, M. Enhancing the Performance Measures of Electrical Discharge Machining Using Additive Manufactured Copper Tool Electrode on Drilling Titanium Alloy Specimens. In Proceedings of the ASME 2023 International Mechanical Engineering Congress and Exposition, New Orleans, LO, USA, 29 October–2 November 2023; Volume 4. [Google Scholar] [CrossRef]

- Sawant, S.N.; Patil, S.K.; Unune, D.R.; Wojciechowski, S. Effect of copper, tungsten copper and tungsten carbide tools on micro-electric discharge drilling of Ti-6Al-4V alloy. J. Mater. Res. Technol. 2024, 24, 4242–4257. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).