Insights for the Impacts of Inclined Magnetohydrodynamics, Multiple Slips, and the Weissenberg Number on Micro-Motile Organism Flow: Carreau Hybrid Nanofluid Model

Abstract

1. Introduction

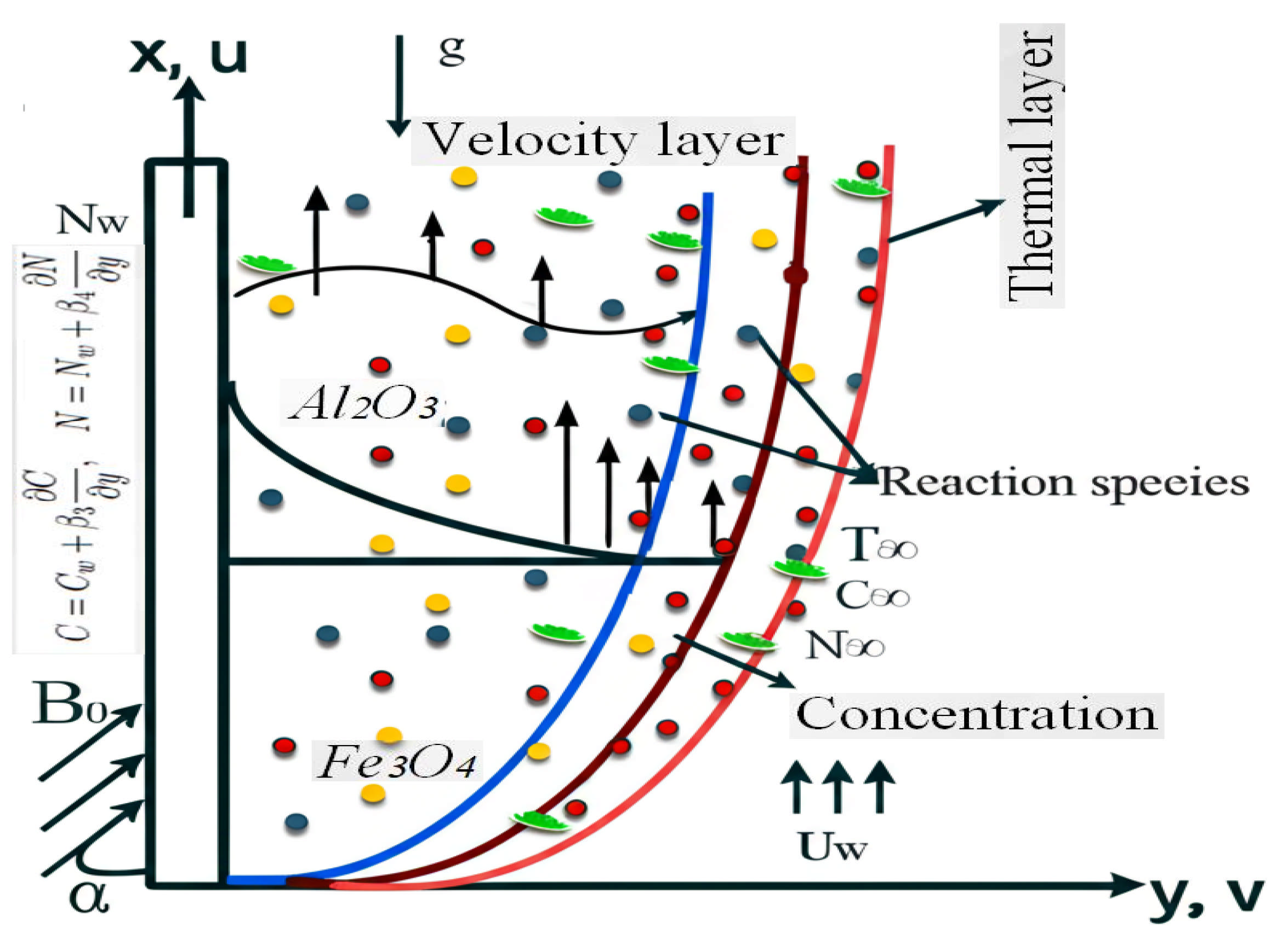

2. Physical Pattern and Interpretation

3. Physical Quantities

4. Engineering Quantities

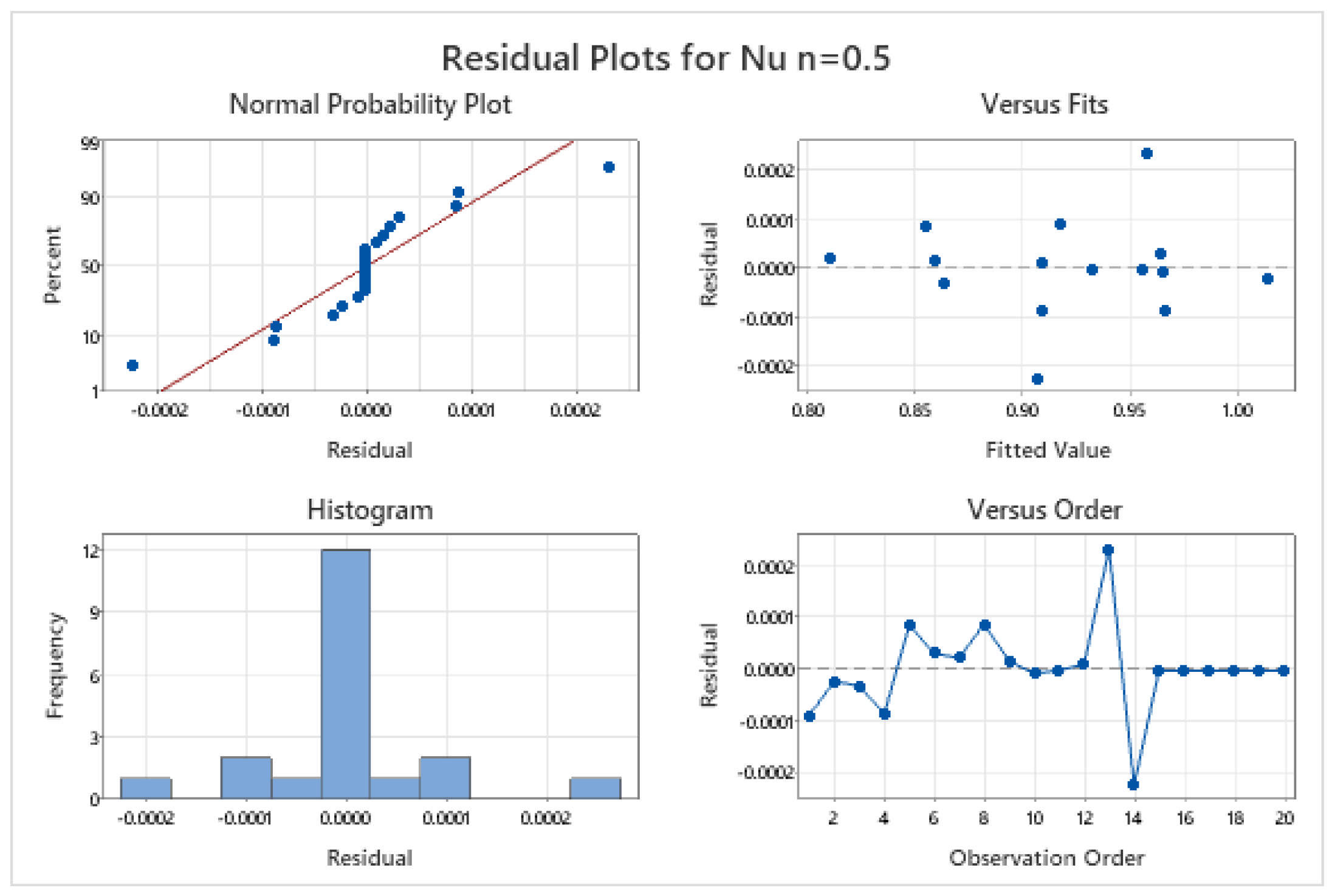

5. Execution of Methodology

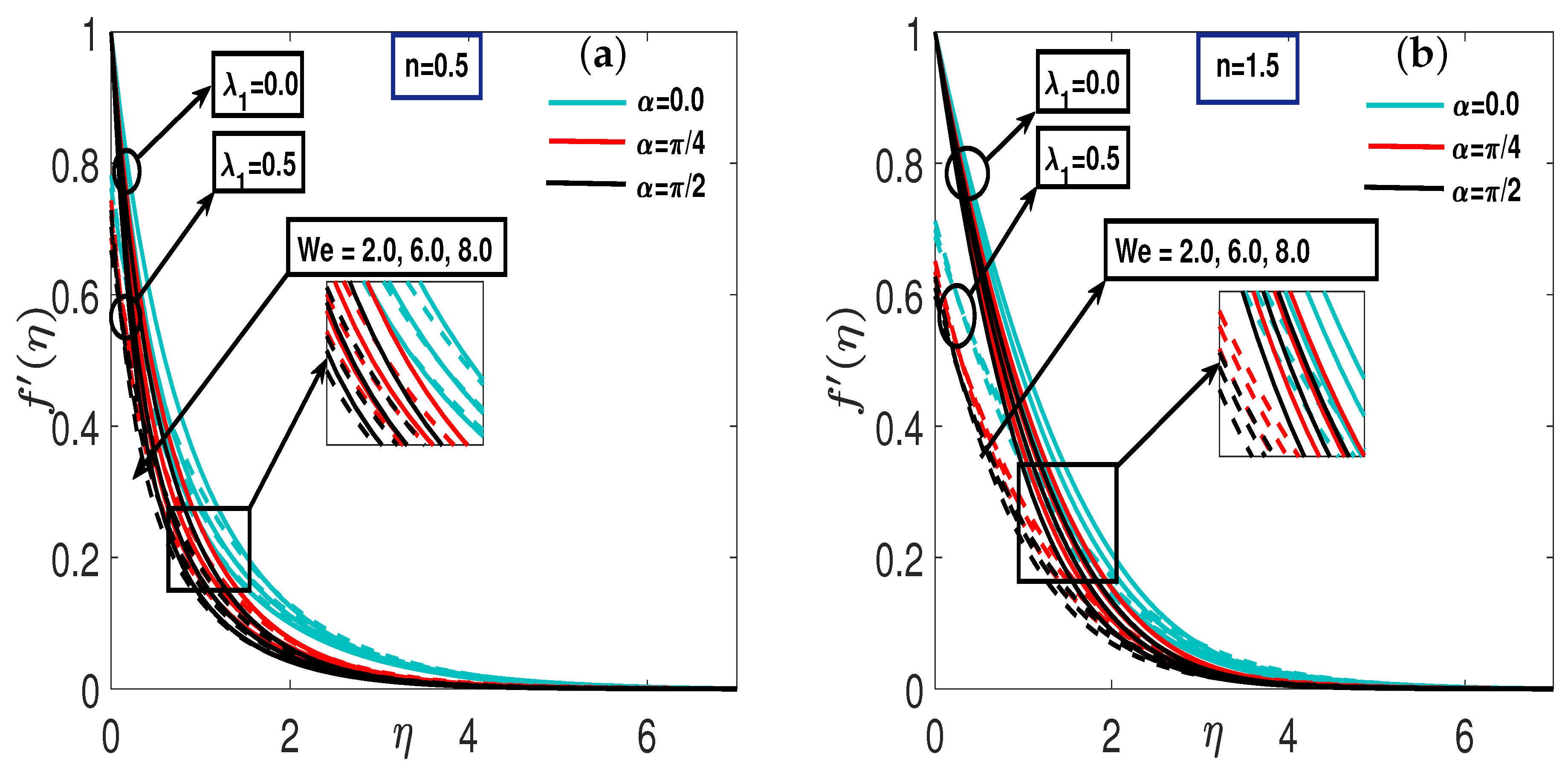

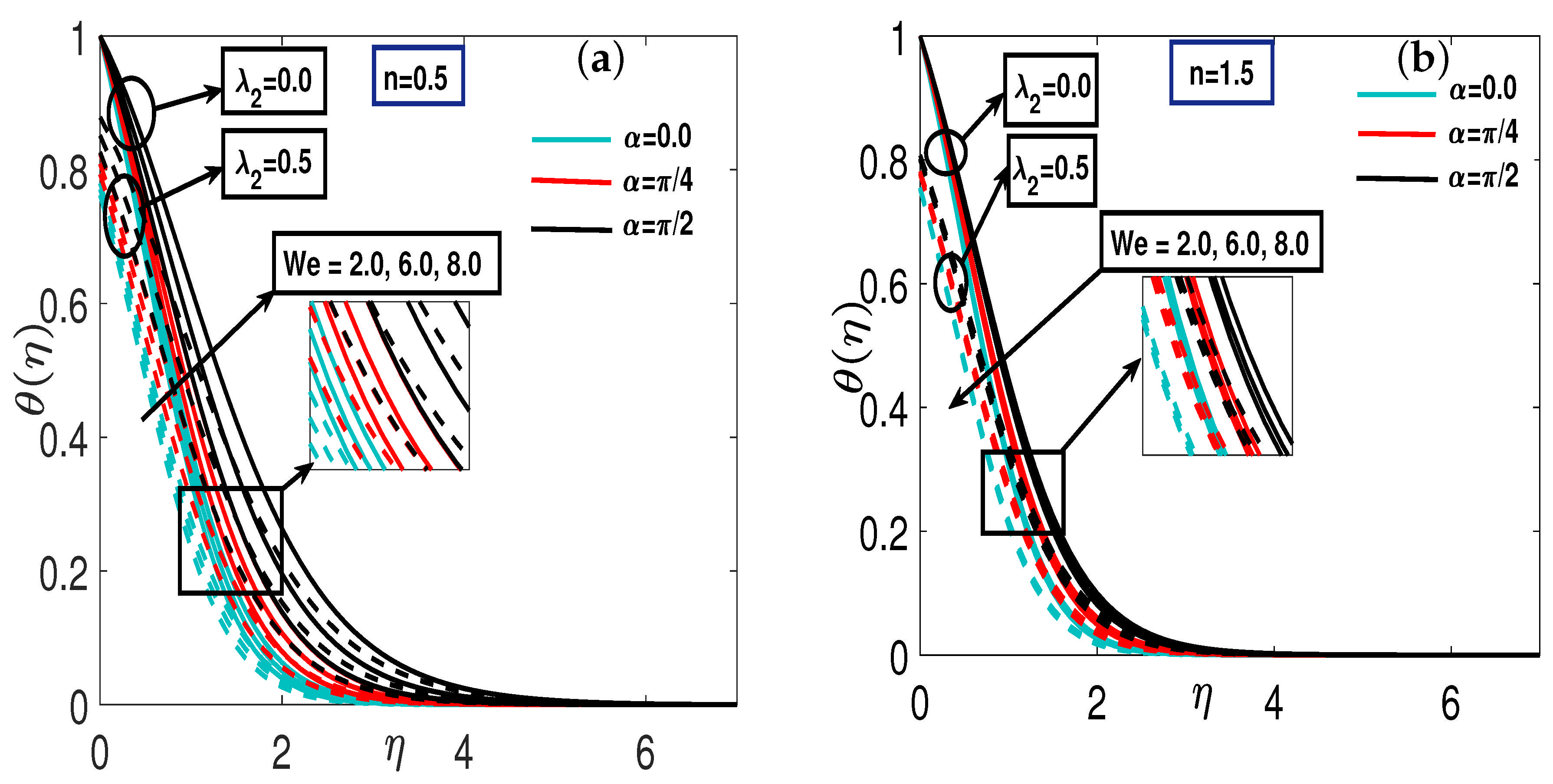

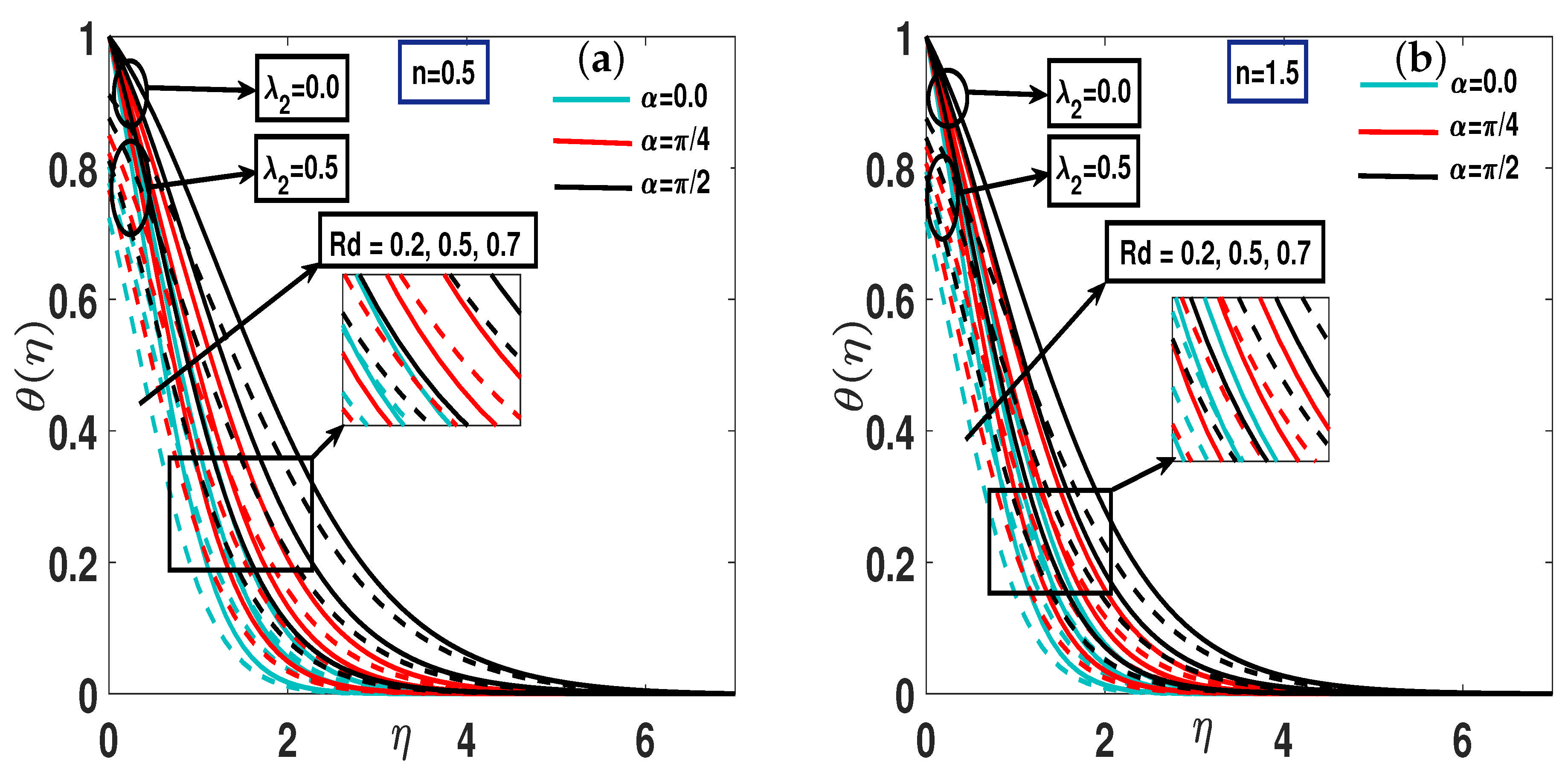

6. Results and Discussion

7. Concluding Remarks

- A magnetic field promotes higher temperature and elevates the motile concentration profiles. However, it induces a reversing character in the velocity and concentration profiles

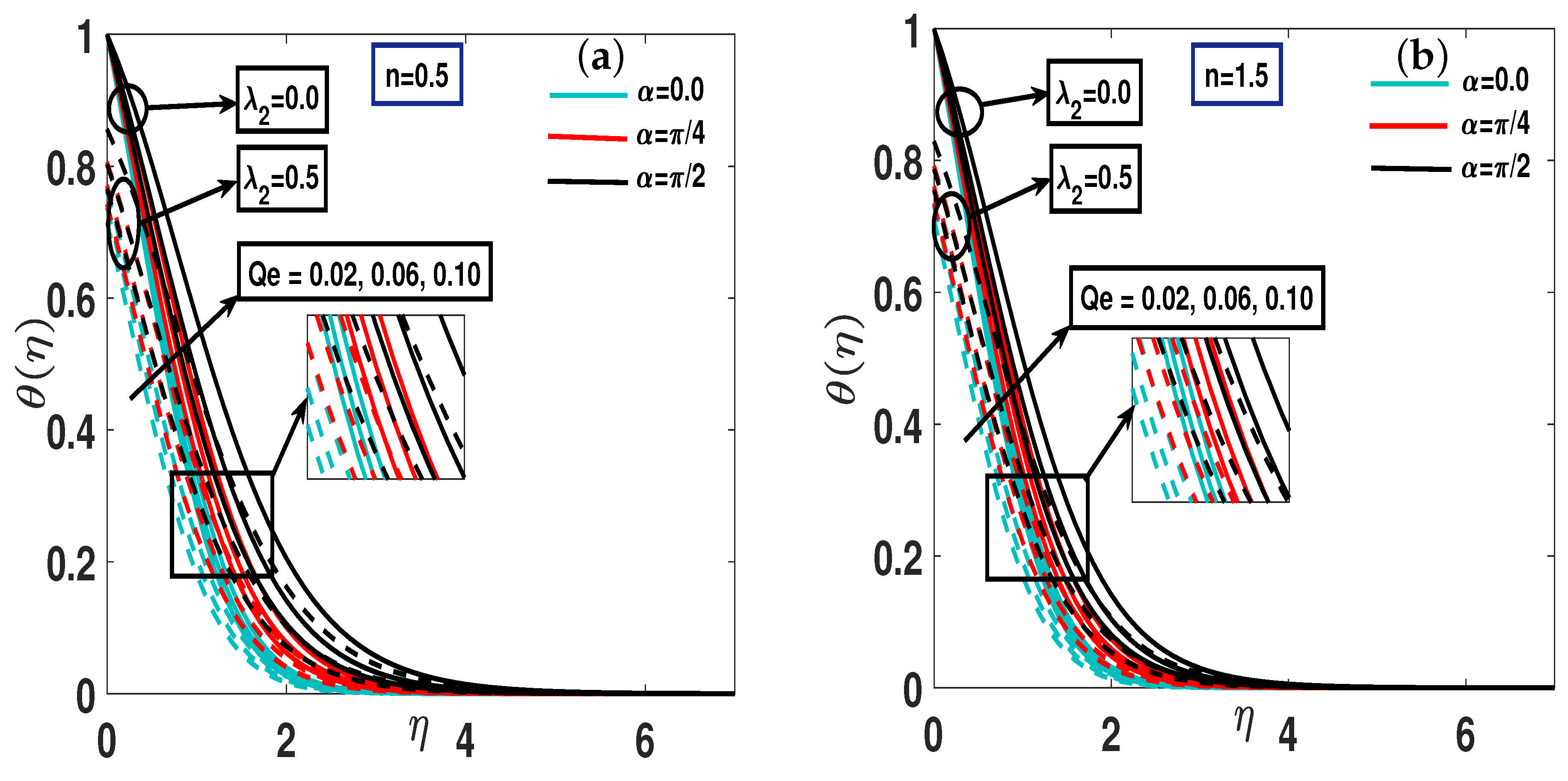

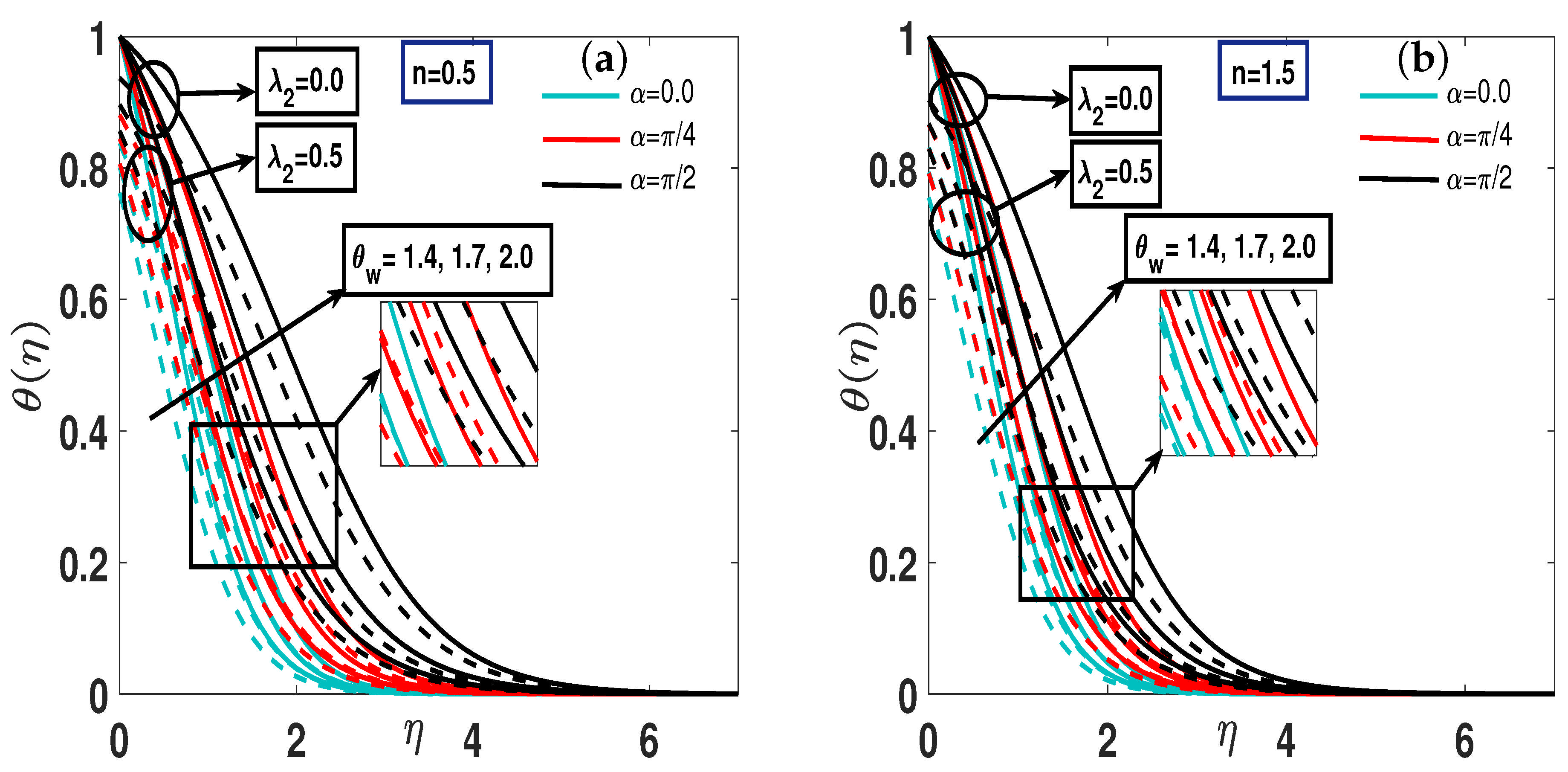

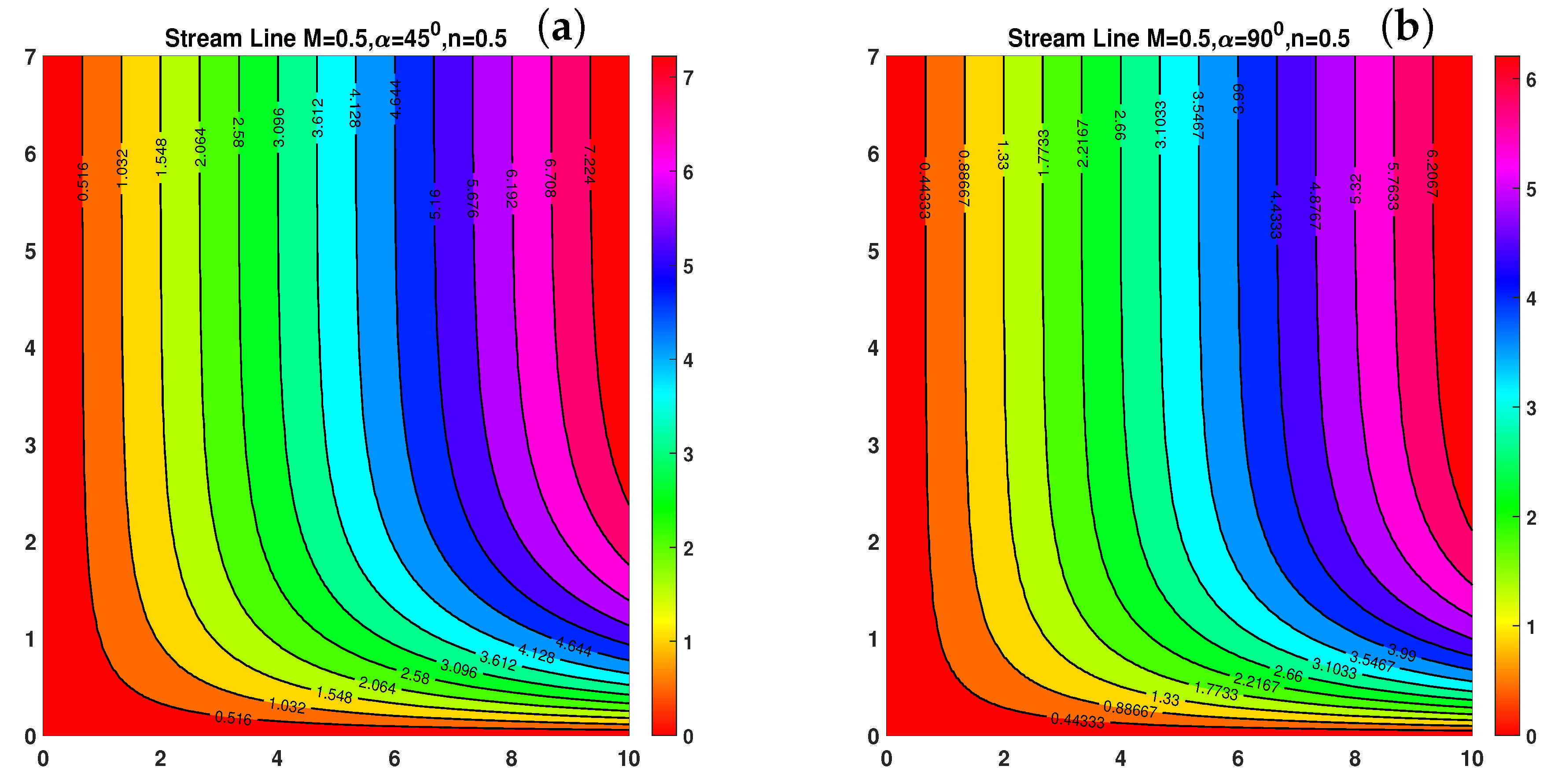

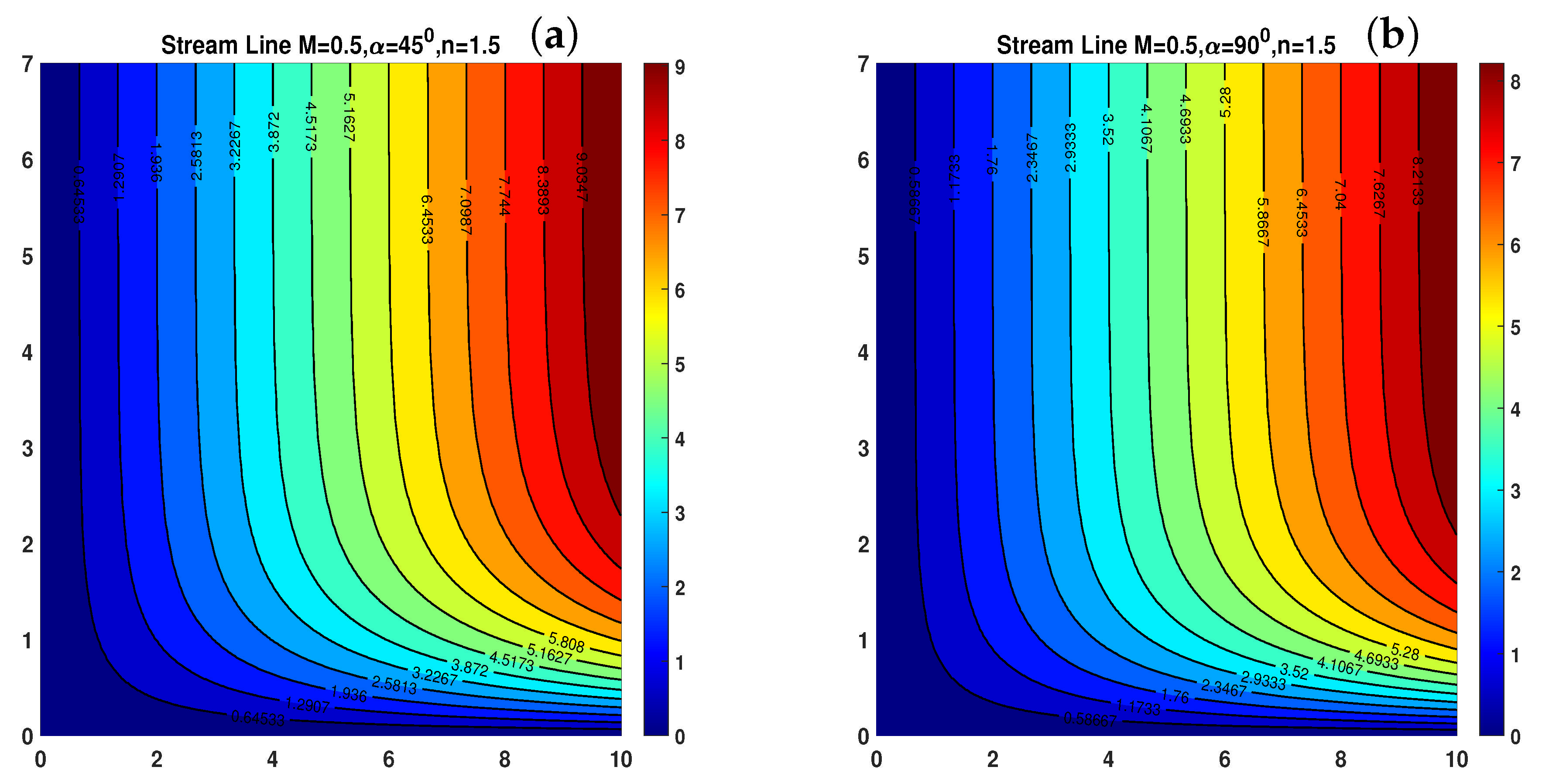

- The physical parameters of heat sources, nonlinear radiation, and the Weissenberg number intensify the temperature field, and the structure of the boundary layers exhibits symmetry as a result of parameters acting at various angles .

- The Weissenberg number affects heat transfer, skin friction, and the velocity profile differently at various angles , with effects intensifying when and weakening when .

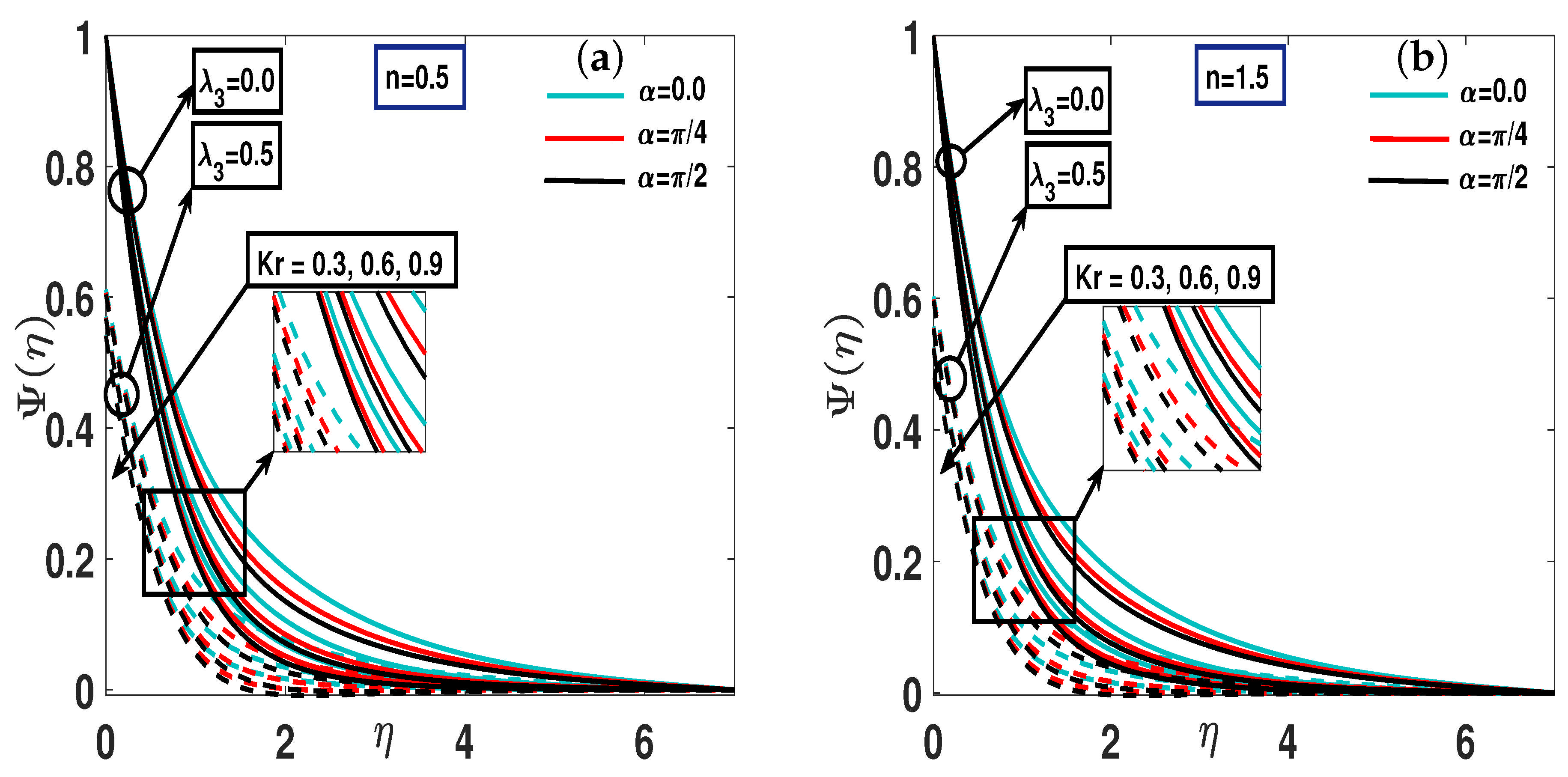

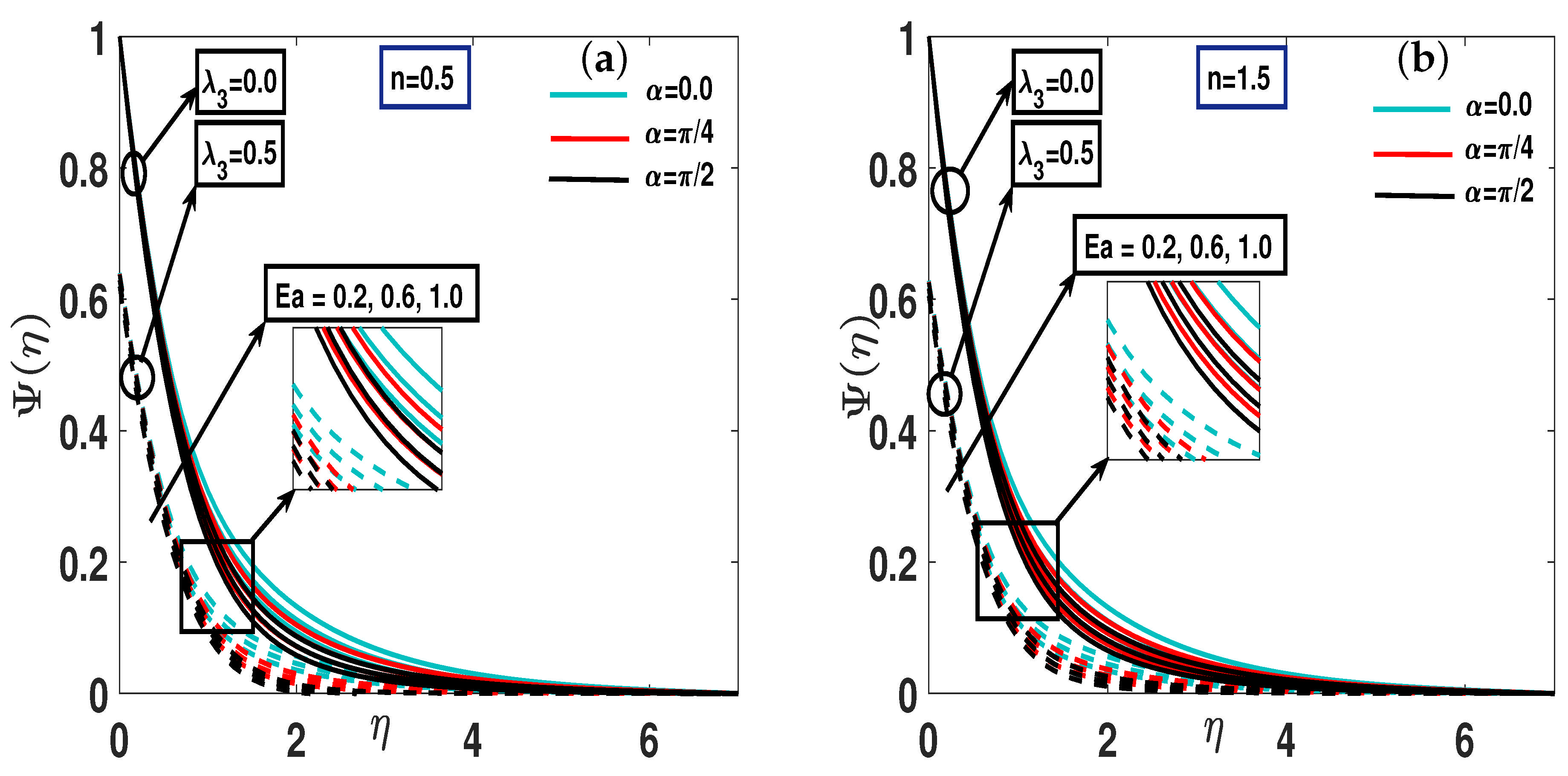

- The hybrid nanofluid concentration is effectively affected by activation energy, whereas a significant decrease is noted upon increasing the chemical reaction parameter with the simultaneous effect of concentration slip and inclined magnetohydrodynamic for shear thinning and shear thickening .

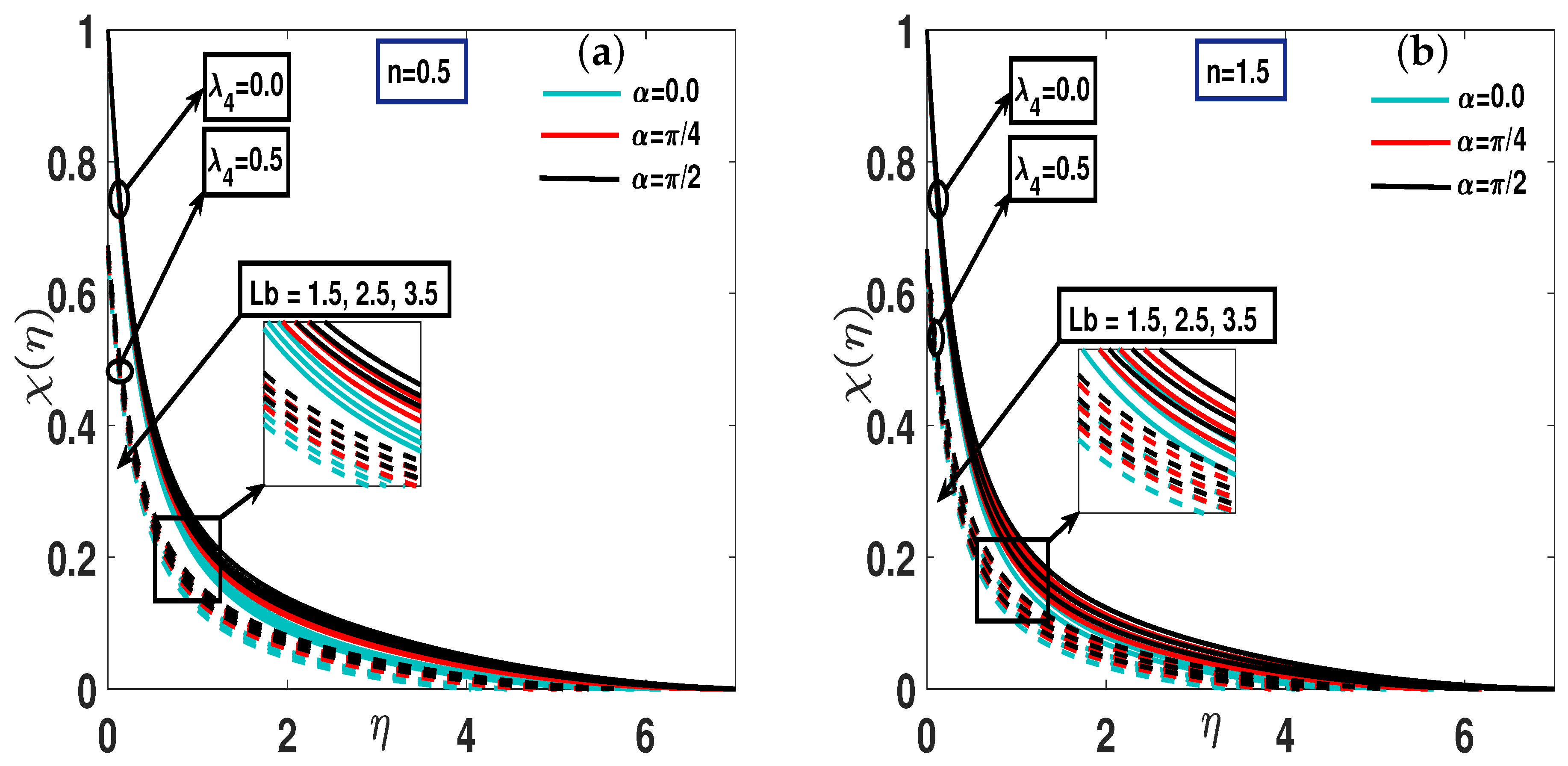

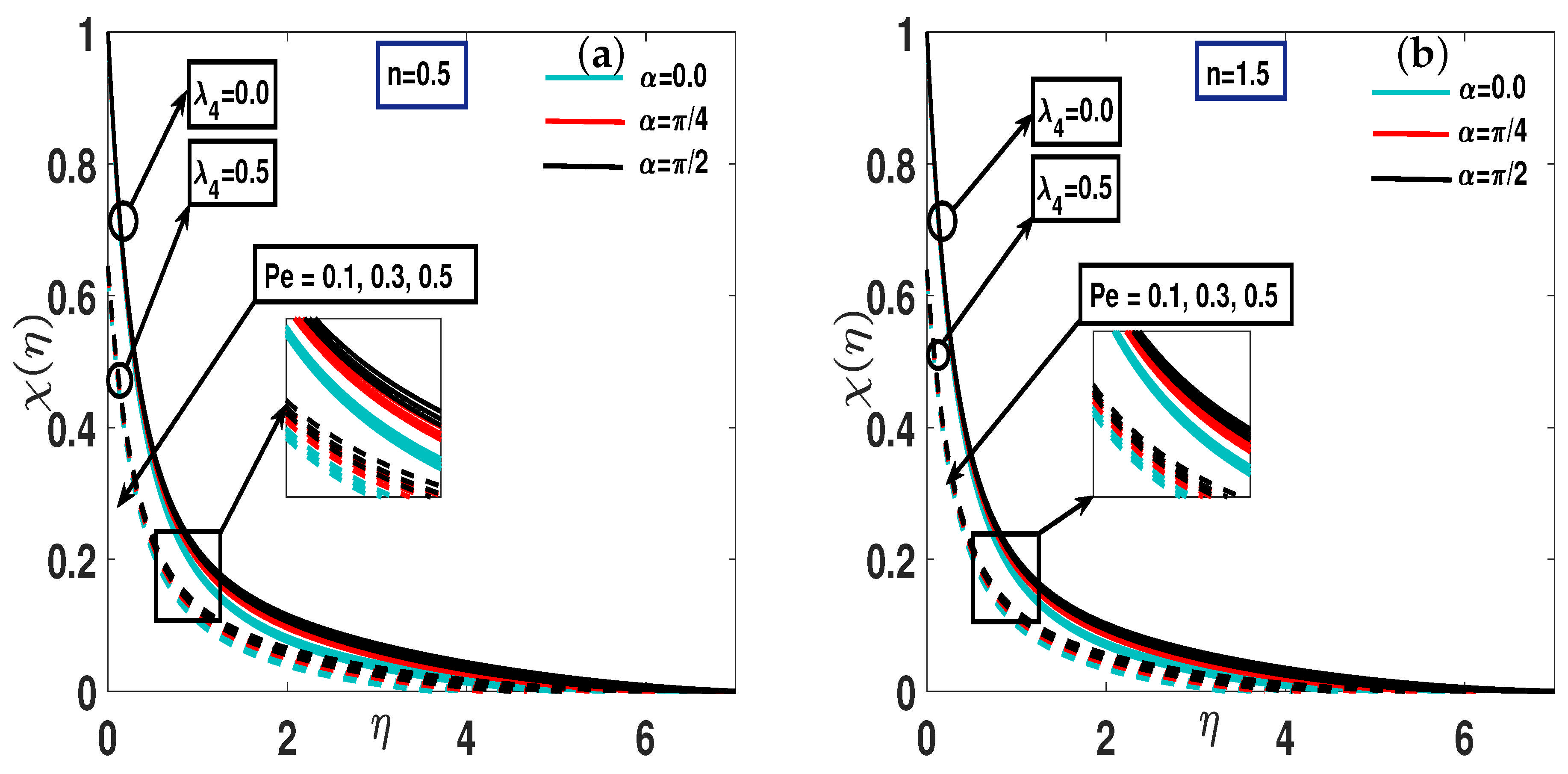

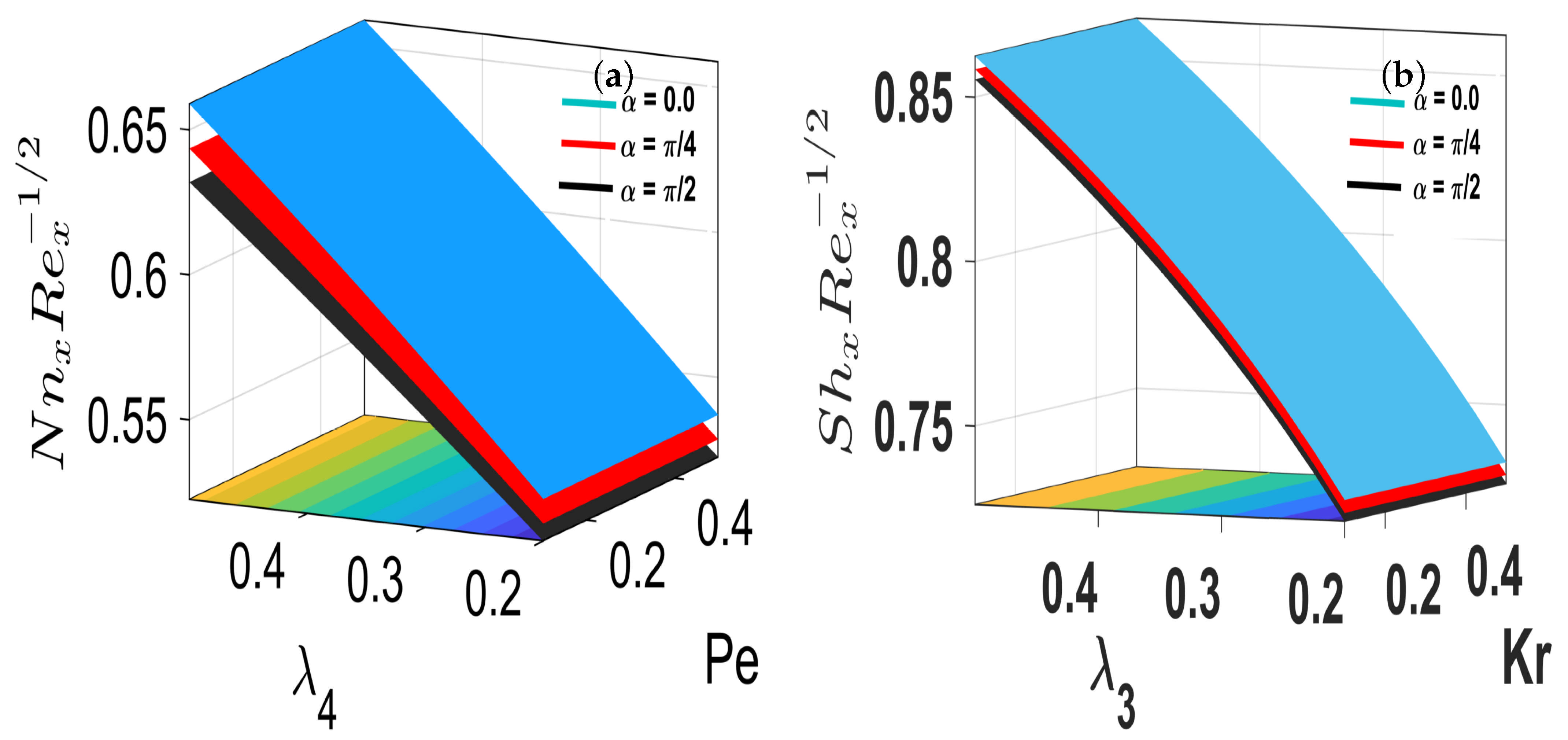

- The motile profile shrinks with increasing and in dilatant and quasi-elastic liquids, showing a parallel effect from , under the presence of the boundary slip parameter for microorganisms.

- Increasing the inclination angle () causes the skin friction surface to shift toward the base plane; conversely, the Nusselt number surface shows an opposite trend.

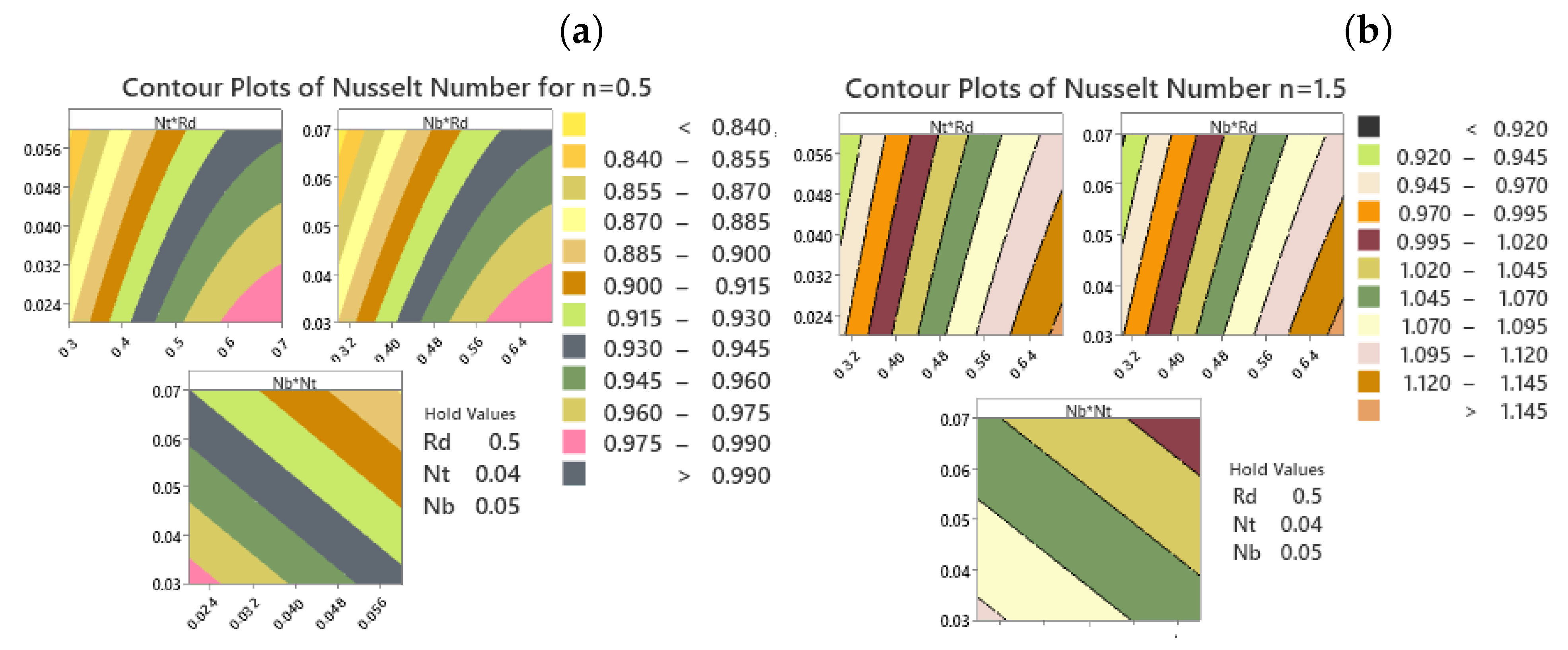

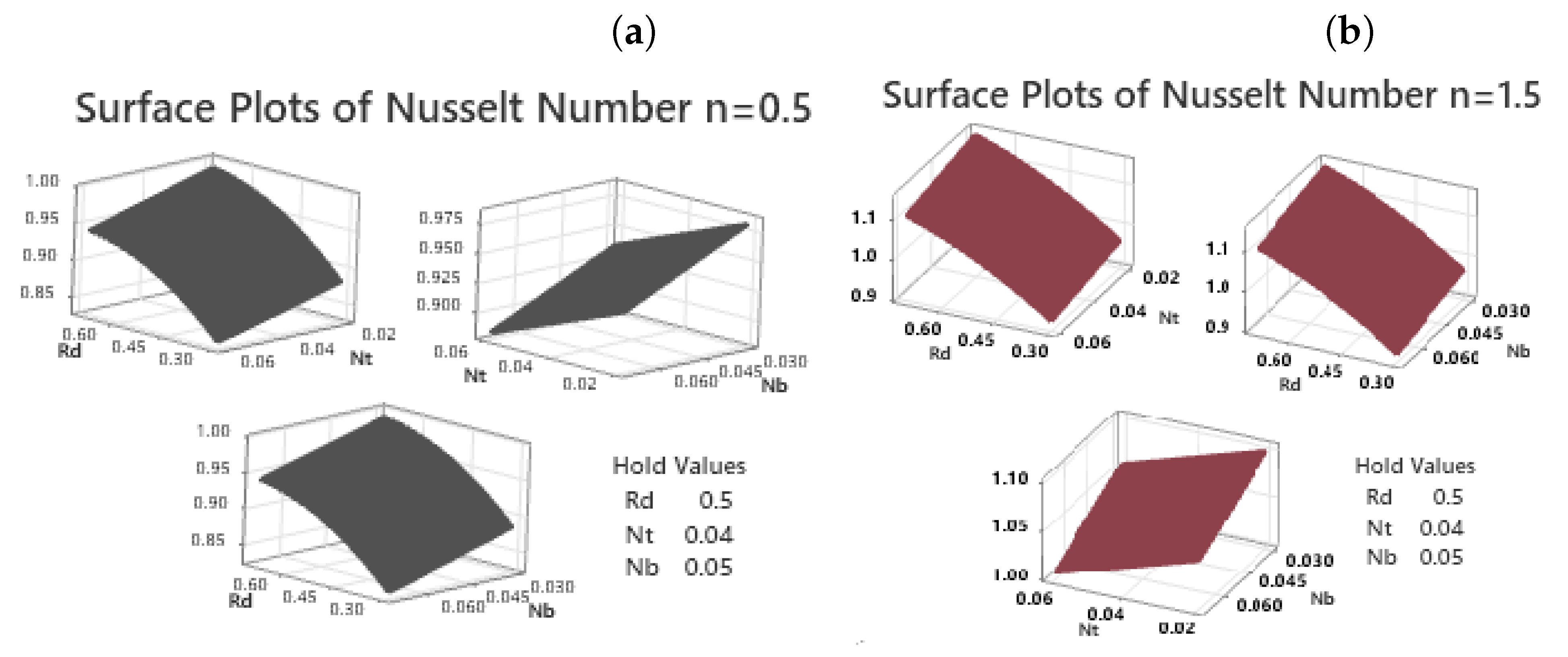

- The maximum heat transfer rate occurs at larger radiation parameter values. An increase in the inclination angle within the range of to () results in a reduction in the Nusselt number.

- The hybrid nanofluid model enhances cooling efficiency in applications like solar panels and electronic equipment. It is also highly effective in industries such as coating and polymer extrusion, where precise control of mass and heat transfer under magnetic fields is essential.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choi, S.U.S.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles; Argonne National Lab. (ANL): Argonne, IL, USA, 1995. [Google Scholar]

- Sharma, R.P.; Badak, K.; Khan, U.; Ishak, A.; Sherif, E.S.M.; Wróblewski, P. Dynamics of variable thermal conductivity and multiple slip conditions in a Carreau hybrid nanofluid flow past a stretching sheet. ZAMM—J. Appl. Math. Mech./Z. Angew. Math. Mech. 2024, e202400388. [Google Scholar] [CrossRef]

- Eid, M.R.; Mahny, K.; Dar, A.; Muhammad, T. Numerical study for Carreau nanofluid flow over a convectively heated nonlinear stretching surface with chemically reactive species. Phys. A Stat. Mech. Its Appl. 2020, 540, 123063. [Google Scholar] [CrossRef]

- Khan, M.; Shahid, A.; Malik, M.; Salahuddin, T. Chemical reaction for Carreau-Yasuda nanofluid flow past a nonlinear stretching sheet considering Joule heating. Results Phys. 2018, 8, 1124–1130. [Google Scholar] [CrossRef]

- Gopal, D.; Naik, S.H.S.; Kishan, N.; Raju, C. The impact of thermal stratification and heat generation/absorption on MHD carreau nano fluid flow over a permeable cylinder. SN Appl. Sci. 2020, 2, 639. [Google Scholar] [CrossRef]

- Reddy, R.R.; Reddy, P.B.A.; Chamkha, J. Influence of Soret and Dufour effects on unsteady 3D MHD slip flow of Carreau nanofluid over a slendering stretchable sheet with chemical reaction. Nonlinear Anal. Model. Control 2019, 24, 853. [Google Scholar] [CrossRef]

- Gautam, A.K.; Rajput, S.; Bhattacharyya, K.; Pandey, A.K.; Chamkha, A.J.; Begum, M. Comparative study of two non-Newtonian fluids with bioconvective induced MHD flow in presence of multiple slips, heat source/sink and nonlinear thermal radiation. Chem. Eng. J. Adv. 2022, 12, 100365. [Google Scholar] [CrossRef]

- Jiann, L.Y.; Isa, S.M.; Rawi, N.A.; Mohamad, A.Q.; Shafie, S. Investigating the effects of Wu’s slip and Smoluchowski’s slip on hybrid TiO2/Ag nanofluid performance. J. Adv. Res. Fluid Mech. Therm. Sci. 2023, 107, 236–252. [Google Scholar] [CrossRef]

- Shamshuddin, M.; Raizah, Z.; Akkurt, N.; Patil, V.S.; Eldin, S.M. Case study of thermal and solutal aspects on non-Newtonian Prandtl hybrid nanofluid flowing via stretchable sheet: Multiple slip solution. Case Stud. Therm. Eng. 2023, 49, 103186. [Google Scholar] [CrossRef]

- Abdeen, W.S.; Rashad, A.M.; Mahdy, A.; Elshehabey, H.M. Bio-Convection Eyring-Powell Hybrid Nanofluid Flow Over an Extended Sheet in the Existence of Chemical Reaction and Motile Microorganisms. J. Nanofluids 2024, 13, 973–984. [Google Scholar] [CrossRef]

- Rehman, S.; Hashim; Boujelbene, M.; Waqas, M. On the augmentation of heat transfer with hybrid nanofluid containing microorganisms on flat plate under thermal radiation, using mixtures models. Energy Environ. 2024, 0958305X241244487. [Google Scholar] [CrossRef]

- Yaseen, M.; Rawat, S.K.; Shah, N.A.; Kumar, M.; Eldin, S.M. Ternary hybrid nanofluid flow containing gyrotactic microorganisms over three different geometries with Cattaneo–Christov model. Mathematics 2023, 11, 1237. [Google Scholar] [CrossRef]

- Bilal, S.; Shah, I.A.; Rashid, M.; Khan, I. Impact of activation energy on carreau nanofluid flow over non-linear stretching surface. Heliyon 2024, 10, e23934. [Google Scholar] [CrossRef]

- Hayat, T.; Qayyum, S.; Alsaedi, A.; Shafiq, A. Inclined magnetic field and heat source/sink aspects in flow of nanofluid with nonlinear thermal radiation. Int. J. Heat Mass Transf. 2016, 103, 99–107. [Google Scholar] [CrossRef]

- Mabood, F.; Shafiq, A.; Khan, W.A.; Badruddin, I.A. MHD and nonlinear thermal radiation effects on hybrid nanofluid past a wedge with heat source and entropy generation. Int. J. Numer. Methods Heat Fluid Flow 2022, 32, 120–137. [Google Scholar] [CrossRef]

- Chalavadi, S.; Madde, P.; Naramgari, S.; Gangadhar Poojari, A. Effect of variable heat generation/absorption on magnetohydrodynamic Sakiadis flow of Casson/Carreau hybrid nanoliquid due to a persistently moving needle. Heat Transf. 2023, 50, 8354–8377. [Google Scholar] [CrossRef]

- Rehman, S.; Hashim, A.; Shah, S.I.; Galal, A.M. Multiple aspects of heat generation/absorption on the hydromagnetic flow of Carreau nanofluids via nonuniform channels. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 237, 1961–1975. [Google Scholar] [CrossRef]

- Bhatti, M.M.; Abbas, T.; Rashidi, M.M.; Ali, M.E.S. Numerical simulation of entropy generation with thermal radiation on MHD Carreau nanofluid towards a shrinking sheet. Entropy 2016, 18, 200. [Google Scholar] [CrossRef]

- Fatima, K.; Prasad, J. Effect of Inclined Magnetic Field and Chemical Reaction on Radiative Hybrid Nanofluid Flow Through an Exponentially Stretched Porous Surface in the Presence of Heat Source. J. Mech. Contin. Math. Sci 2025, 20, 38–53. [Google Scholar] [CrossRef]

- Kathuroju, S.K.; Prashar, P.; Ojjela, O. Asymptotic analysis of MHD chemically reacting boundary layer flow of Jeffrey hybrid nanofluid. ZAMM—J. Appl. Math. Mech./Z. Angew. Math. Mech. 2024, 104, e202300770. [Google Scholar] [CrossRef]

- Sreenivasulu, M.; Bhuvana Vijaya, R. Influence of exponential heat source, variable viscosity and shape factor on a hybrid nanofluid flow over a flat plate when thermal radiation and chemical reaction are significant. Mod. Phys. Lett. B 2024, 38, 2450102. [Google Scholar] [CrossRef]

- Jat, K.; Sharma, K.; Soni, P.; Choudhary, P. Numerical analysis of heat and mass transport of hybrid nanofluid over a nonlinear stretchable sheet with magnetic field in presence of Soret and dufour Effect. In Proceedings of the 5th National Conference on Recent Advancement in Physical Sciences, Uttarakhand, India, 19–20 December 2023; Journal of Physics: Conference Series. IOP Publishing: Bristol, UK, 2024; Volume 2844, p. 012019. [Google Scholar]

- Rafique, K.; Mahmood, Z.; Ansari, M.A.; Kumar, A.; Khan, U. Investigating Soret–Dufour effects and discharge concentration on accelerating hybrid nanofluid flow over radiative disk embedded in porous media under convective conditions. Can. J. Phys. 2025, 103, 860–878. [Google Scholar] [CrossRef]

- Kumar, S.; Prasad, P.; Raju, C.; Shehzad, S.; Bashir, M.; Varma, S. Three-dimensional magnetized slip flow of Carreau non-Newtonian fluid flow through conduction and radiative chemical reaction. Indian J. Phys. 2021, 96, 491–501. [Google Scholar]

- Khan, M.; Hashim. Effects of multiple slip on flow of magneto-Carreau fluid along wedge with chemically reactive species. Neural Comput. Appl. 2018, 30, 2191–2203. [Google Scholar] [CrossRef]

- Nanda, G.; Patel, H. Thermophoresis and brownian motion effects on inclined mhd nano-fluid flow with multi slip condition. J. Comput. Anal. Appl. 2025, 34, 795. [Google Scholar]

- Deshwal, J.; Chaudhary, S.; Kumar, R. Chemical reaction and inclined magnetic field effects on tri-hybrid Carreau nanofluid slip flow of blood past a porous inclined stenosed artery with viscous dissipation. Phys. Scr. 2025, 100, 035216. [Google Scholar] [CrossRef]

- Shah, S.Z.H.; Ayub, A.; Bhatti, S.; Khan, U.; Ishak, A.; Sherif, E.S.M.; Pop, I. Aspects of inclined magnetohydrodynamics and heat transfer in a non-Newtonian tri-hybrid bio-nanofluid flow past a wedge-shaped artery utilizing artificial neural network scheme. ZAMM—J. Appl. Math. Mech./Z. Angew. Math. Mech. 2024, 104, e202400278. [Google Scholar] [CrossRef]

- Mohamed, R.; Abo-Dahab, S.; Soliman, M. Effects of nonlinear thermal radiation and heat generation/absorption on magnetohydrodynamic (MHD) Carreau nanofluid flow on a nonlinear stretching surface through a porous medium. J. Nanofluids 2022, 11, 845–856. [Google Scholar] [CrossRef]

- Yasmin, H. Numerical investigation of heat and mass transfer study on MHD rotatory hybrid nanofluid flow over a stretching sheet with gyrotactic microorganisms. Ain Shams Eng. J. 2024, 15, 102918. [Google Scholar] [CrossRef]

- Lu, D.; Ramzan, M.; ul Huda, N.; Chung, J.D.; Farooq, U. Nonlinear radiation effect on MHD Carreau nanofluid flow over a radially stretching surface with zero mass flux at the surface. Sci. Rep. 2018, 8, 3709. [Google Scholar] [CrossRef]

- Yahaya, R.I.; Arifin, N.M.; Ali, F.M.; Isa, S. Hybrid Nanofluid Flow with multiple slips over a Permeable Stretching/Shrinking sheet embedded in a porous medium. J. Adv. Res. Fluid Mech. Therm. Sci. 2023, 106, 143–152. [Google Scholar] [CrossRef]

- Das, M.; Nandi, S.; Kumbhakar, B.; Shanker Seth, G. Soret and Dufour effects on MHD nonlinear convective flow of tangent hyperbolic nanofluid over a bidirectional stretching sheet with multiple slips. J. Nanofluids 2021, 10, 200–213. [Google Scholar] [CrossRef]

- Alrehili, M. Improvement for engineering applications through a dissipative Carreau nanofluid fluid flow due to a nonlinearly stretching sheet with thermal radiation. Case Stud. Therm. Eng. 2023, 42, 102768. [Google Scholar] [CrossRef]

- Raju, S.S.K.; Babu, M.J.; Raju, C. Irreversibility analysis in hybrid nanofluid flow between two rotating disks with activation energy and cross-diffusion effects. Chin. J. Phys. 2021, 72, 499–529. [Google Scholar] [CrossRef]

- Neethu, T.S.; Areekara, S.; Mathew, A. Statistical approach on 3D hydromagnetic flow of water-based nanofluid between two vertical porous plates moving in opposite directions. Heat Transf. 2021, 50, 5170–5197. [Google Scholar] [CrossRef]

- Ghadikolaei, S.; Gholinia, M.; Hoseini, M.; Ganji, D. Natural convection MHD flow due to MoS2–Ag nanoparticles suspended in C2H6O2H2O hybrid base fluid with thermal radiation. J. Taiwan Inst. Chem. Eng. 2019, 97, 12–23. [Google Scholar] [CrossRef]

- Ghadikolaei, S.; Yassari, M.; Sadeghi, H.; Hosseinzadeh, K.; Ganji, D. Investigation on thermophysical properties of Tio2–Cu/H2O hybrid nanofluid transport dependent on shape factor in MHD stagnation point flow. Powder Technol. 2017, 322, 428–438. [Google Scholar] [CrossRef]

- Sabu, A.S.; Areekara, S.; Mathew, A. Effects of multislip and distinct heat source on MHD Carreau nanofluid flow past an elongating cylinder using the statistical method. Heat Transf. 2021, 50, 5652–5673. [Google Scholar] [CrossRef]

- Khan, W.; Pop, I. Boundary-layer flow of a nanofluid past a stretching sheet. Int. J. Heat Mass Transf. 2010, 53, 2477–2483. [Google Scholar] [CrossRef]

- Wang, C. Free convection on a vertical stretching surface. ZAMM—J. Appl. Math. Mech./Z. Angew. Math. Mech. 1989, 69, 418–420. [Google Scholar] [CrossRef]

- Kumar, P.; Poonia, H.; Ali, L.; Shah, N.A.; Chung, J.D. Significance of Weissenberg number, Soret effect and multiple slips on the dynamic of biconvective magnetohydrodynamic carreau nanofuid flow. Mathematics 2023, 11, 1685. [Google Scholar] [CrossRef]

- Kumari, P.; Poonia, H.; Kumar, P.; Aquib, M. Inclined MHD Flow of Carreau Hybrid Nanofluid over a Stretching Sheet with Nonlinear Radiation and Arrhenius Activation Energy Under a Symmetry-Inspired Modeling Perspective. Symmetry 2025, 17, 1330. [Google Scholar] [CrossRef]

| n | Bvp5c [39] | RKF45 [39] | RK4 [39] | Current Result | |

|---|---|---|---|---|---|

| 00.5 | 1.0 | 00.989702 | 00.989709 | 00.989709 | 00.989705 |

| 2.0 | 00.901331 | 00.901343 | 00.901343 | 00.901340 | |

| 3.0 | 00.830948 | 00.830972 | 00.830972 | 00.830960 | |

| 01.5 | 1.0 | 01.145708 | 01.145708 | 01.145708 | 01.145708 |

| 2.0 | 01.367059 | 01.367061 | 01.367061 | 01.367058 | |

| 3.0 | 01.611580 | 01.611585 | 01.611585 | 01.611583 |

| Khan [40] | Wang [41] | Current Results | |

|---|---|---|---|

| 00.7 | 00.4539 | 00.453932 | 00.453946 |

| 02.0 | 00.9113 | 00.911359 | 00.911364 |

| 07.0 | 01.8954 | 01.895428 | 01.895437 |

| 020 | 03.3539 | 03.354174 | 03.354172 |

| n | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 2.0 | 0.5 | 0.3 | 0.5 | 0.03 | −0.527111 | −0.601869 | −0.659435 | 1.0446460 | 0.939929 | 0.830034 |

| - | 4.0 | - | - | - | - | −0.476473 | −0.539980 | −0.588676 | 1.014796 | 0.888463 | 0.749531 |

| - | 6.0 | - | - | - | - | −0.436829 | −0.494217 | −0.538261 | 0.985187 | 0.838113 | 0.668262 |

| - | - | 0.1 | - | - | - | −0.703466 | −0.806995 | −0.890672 | 1.162428 | 1.094829 | 1.026973 |

| - | - | 0.5 | - | - | - | −0.527111 | −0.601869 | −0.659435 | 1.044646 | 0.939929 | 0.830034 |

| - | - | 0.7 | - | - | - | −0.468163 | −0.533047 | −0.581870 | 0.994626 | 0.86976285 | 0.733840 |

| - | - | - | 0.3 | - | - | −0.527111 | −0.601869 | −0.659435 | 1.044646 | 0.939929 | 0.830034 |

| - | - | - | 0.5 | - | - | −0.527111 | −0.601869 | −0.659435 | 1.197162 | 1.054621 | 0.900435 |

| - | - | - | 0.7 | - | - | −0.527111 | −0.601869 | −0.659435 | 1.324502 | 1.140270 | 0.937680 |

| - | - | - | - | 0.02 | - | −0.527111 | −0.601869 | −0.659435 | 1.027009 | 0.920977 | 0.809490 |

| - | - | - | - | 0.04 | - | −0.527111 | −0.601869 | −0.659435 | 1.009391 | 0.902054 | 0.788964 |

| - | - | - | - | 0.06 | - | −0.527111 | −0.601869 | −0.659435 | 0.991797 | 0.883165 | 0.768461 |

| - | - | - | - | - | 0.03 | −0.527111 | −0.6018699 | −0.659435 | 1.055302 | 0.950957 | 0.8413789 |

| - | - | - | - | - | 0.05 | −0.527111 | −0.6018699 | −0.659435 | 1.033974 | 0.928902 | 0.8187097 |

| - | - | - | - | - | 0.07 | −0.527111 | −0.6018699 | −0.659435 | 1.012584 | 0.906852 | 0.796126 |

| 1.5 | 2.0 | 0.5 | 0.3 | 0.5 | 0.03 | −0.577454 | −0.66744630 | −0.7383706 | 1.0663477 | 0.9788646 | 0.89124861 |

| - | 4.0 | - | - | - | - | −0.604035 | −0.6980943 | −0.7720928 | 1.0721157 | 0.9885325 | 0.9057679 |

| - | 6.0 | - | - | - | - | −0.6250351 | −0.7215622 | −0.7973422 | 1.0744292 | 0.9928002 | 0.9126137 |

| - | - | 0.1 | - | - | - | −0.8693453 | −1.0319911 | −1.1725263 | 1.216047194 | 1.178152592 | 1.1427349440 |

| - | - | 0.5 | - | - | - | −0.57745424 | −0.6674463 | −0.7383706 | 1.0663477 | 0.9788646 | 0.89124861 |

| - | - | 0.7 | - | - | - | −0.44236496 | −0.5048088 | −0.5511111 | 0.9603352 | 0.82694211 | 0.6808565 |

| - | - | - | 0.3 | - | - | −0.5774542 | −0.6674463 | −0.738370 | 1.066347 | 0.97886468 | 0.8912486 |

| - | - | - | 0.5 | - | - | −0.5774542 | −0.6674463 | −0.738370 | 1.2290514 | 1.1115718 | 0.9908486 |

| - | - | - | 0.7 | - | - | −0.5774542 | −0.6674463 | −0.738370 | 1.367745 | 1.2171891 | 1.0596390 |

| - | - | - | - | 0.02 | - | −0.5774542 | −0.6674463 | −0.738370 | 1.048988 | 0.9604717 | 0.8717179 |

| - | - | - | - | 0.04 | - | −0.5774542 | −0.6674463 | −0.738370 | 1.031643 | 0.942104 | 0.8522147 |

| - | - | - | - | 0.06 | - | −0.5774542 | −0.6674463 | −0.738370 | 1.014317 | 0.923767 | 0.8327426 |

| - | - | - | - | - | 0.03 | −0.5774542 | −0.6674463 | −0.738370 | 1.0767765 | 0.989572 | 0.9021788 |

| - | - | - | - | - | 0.05 | −0.5774542 | −0.6674463 | −0.738370 | 1.0559031 | 0.968155 | 0.8803323 |

| - | - | - | - | - | 0.07 | −0.5774542 | −0.6674463 | −0.738370 | 1.0349712 | 0.946738 | 0.858548 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sandeep; Kumar, P.; Malik, P.S.; Aquib, M. Insights for the Impacts of Inclined Magnetohydrodynamics, Multiple Slips, and the Weissenberg Number on Micro-Motile Organism Flow: Carreau Hybrid Nanofluid Model. Symmetry 2025, 17, 1601. https://doi.org/10.3390/sym17101601

Sandeep, Kumar P, Malik PS, Aquib M. Insights for the Impacts of Inclined Magnetohydrodynamics, Multiple Slips, and the Weissenberg Number on Micro-Motile Organism Flow: Carreau Hybrid Nanofluid Model. Symmetry. 2025; 17(10):1601. https://doi.org/10.3390/sym17101601

Chicago/Turabian StyleSandeep, Pardeep Kumar, Partap Singh Malik, and Md Aquib. 2025. "Insights for the Impacts of Inclined Magnetohydrodynamics, Multiple Slips, and the Weissenberg Number on Micro-Motile Organism Flow: Carreau Hybrid Nanofluid Model" Symmetry 17, no. 10: 1601. https://doi.org/10.3390/sym17101601

APA StyleSandeep, Kumar, P., Malik, P. S., & Aquib, M. (2025). Insights for the Impacts of Inclined Magnetohydrodynamics, Multiple Slips, and the Weissenberg Number on Micro-Motile Organism Flow: Carreau Hybrid Nanofluid Model. Symmetry, 17(10), 1601. https://doi.org/10.3390/sym17101601