Abstract

This paper provides an overview of the significance of precise thermal analysis in the context of lithium-ion battery systems. It underscores the requirement for additional research to create efficient methodologies for modeling and controlling thermal properties, with the ultimate goal of enhancing both the safety and performance of Li-ion batteries. The interaction between temperature regulation and lithium-ion batteries is pivotal due to the intrinsic heat generation within these energy storage systems. A profound understanding of the thermal behaviors exhibited by lithium-ion batteries, along with the implementation of advanced temperature control strategies for battery packs, remains a critical pursuit. Utilizing tailored models to dissect the thermal dynamics of lithium-ion batteries significantly enhances our comprehension of their thermal management across a wide range of operational scenarios. This comprehensive review systematically explores diverse research endeavors that employ simulations and models to unravel intricate thermal characteristics, behavioral nuances, and potential runaway incidents associated with lithium-ion batteries. The primary objective of this review is to underscore the effectiveness of employed characterization methodologies and emphasize the pivotal roles that key parameters—specifically, current rate and temperature—play in shaping thermal dynamics. Notably, the enhancement of thermal design systems is often more feasible than direct alterations to the lithium-ion battery designs themselves. As a result, this thermal review primarily focuses on the realm of thermal systems. The synthesized insights offer a panoramic overview of research findings, with a deeper understanding requiring consultation of specific published studies and their corresponding modeling endeavors.

1. Introduction

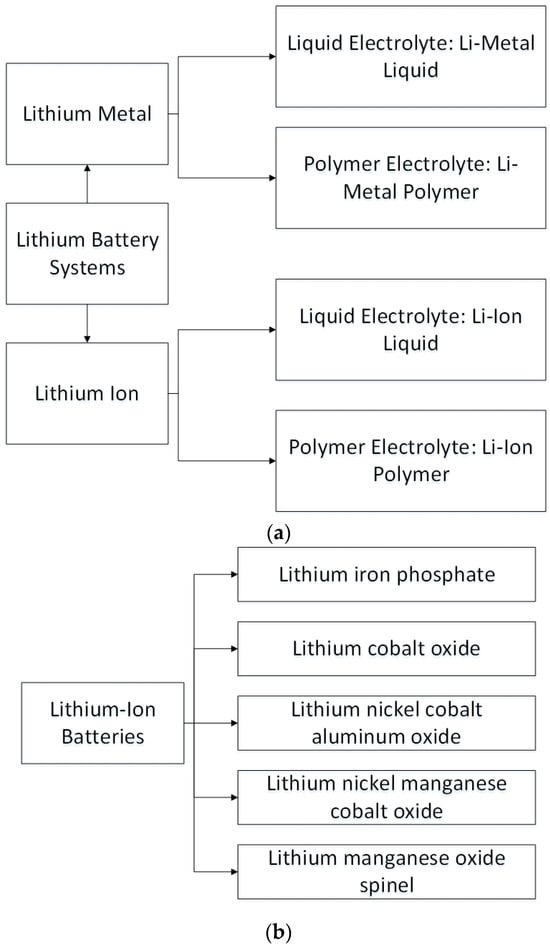

Lithium battery systems encompass a diverse array of configurations, as illustrated in Figure 1. Among these configurations, lithium-ion batteries emerge as a highly promising storage technology for reducing greenhouse gas emissions within the transportation sector. With their exceptional power and energy densities, lithium-ion batteries offer a well-suited solution for an extensive range of renewable energy storage applications. The inherent versatility of lithium-ion battery technology makes it adaptable to various usage scenarios, each with distinct specifications. In addition to their role in the renewable energy sector, lithium-ion batteries have gained significant traction in military, aerospace, and residential domains due to their exceptional safety profile, unwavering reliability, substantial power capacities, and extended operational lifespans [1,2,3]. The intricate interplay depicted in Figure 1 sheds light on the diverse technologies and applications seamlessly accommodated by lithium-ion batteries.

Figure 1.

Categorization of lithium battery systems according to (a) The nature of their electrolyte, (b) Their cathode chemistry, and (c) The construction configuration of lithium-ion battery manufacturing [4,5,6,7,8].

Dafen Chen et al. conducted an extensive comparative investigation encompassing various cooling methodologies for lithium-ion batteries [9]. These methodologies included direct liquid cooling, indirect liquid cooling, and active air-cooling mechanisms. By combining numerical simulations with experimental data obtained from laboratory tests, the study yielded significant insights. The results highlighted the limited effectiveness of air-cooling due to its relatively lower thermal conductivity and heat capacity, leading to only a modest reduction in maximum temperature. While air-based systems required less power for circulation, they were less efficient at rapidly dissipating heat during quick discharges. Indirect liquid cooling, while effective, introduced added weight due to the higher density of aluminum compared to mineral oil. Notably, the investigation also explored fin cooling, utilizing water/glycol as the coolant fluid. The analysis extended to the characterization of temperature distributions across the battery surface, contingent on varying velocities and flow directions for air-cooling and direct liquid cooling. Importantly, integrating experimental data from battery calorimeters assumes paramount importance in the thermal analysis of lithium-ion batteries. This necessity arises from the pronounced temperature elevation and heat dissipation gradients experienced by these batteries during charging and discharging, arising from both irreversible and reversible heat generation. A potential solution involves developing a dynamic, time-dependent heat generation model for lithium-ion batteries, incorporating data from battery calorimeters. This model could effectively address the challenge of non-uniform temperature distribution and heat generation on battery cell surfaces. Strategies involving modifications to the battery cell’s geometry, such as spatially separating negative and positive tabs or increasing tab size to enhance contact between electrode current collectors and external tabs, emerge as potential measures. Furthermore, exploring the configuration of current collectors within lithium-ion battery cells can lead to the selection of an optimal design if direct alterations by manufacturers prove unfeasible [10,11,12,13,14,15,16].

Another significant study by M. Shadman Rad et al. focused on the thermal modeling of lithium-ion batteries [17]. The researchers developed thermal models based on heat generation data derived from various experiments. Using an experimental setup consistent with contemporary simulation laboratories, the thermal model analyzed heat generation and temperature changes within a lithium-ion battery cell. The resulting model-calculated heat generation and temperature values were meticulously compared against experimental data to validate the model’s accuracy. In a similar vein, Cong Zhu et al. developed a customized thermal model specifically tailored to the complex configuration and geometry of lithium-ion batteries [18]. Validating the model through comparisons with laboratory measurements, the study confirmed the model’s ability to predict the batteries’ thermal behavior. Panchal et al. [19] delved into a thermal analysis of lithium-ion batteries, revealing temperature fluctuations along the battery cell’s surface, particularly under high current rates. This phenomenon originated from significant heat dissipation driven by notable temperature gradients. Collectively, previous investigations have aimed to elucidate diverse strategies for managing and evaluating the thermal characteristics of lithium-ion batteries across various cycling and operational scenarios. Literature has explored numerous configurations and assemblies to unravel the thermal intricacies of these batteries. Effective thermal management is crucial to mitigate temperature escalation, preempt further exothermic reactions, regulate heat generation, and prevent thermal runaway. While numerous simulations have attempted to predict the thermal properties of lithium-ion batteries and propose enhancements to their thermal behavior, comprehensive comparative analyses and investigations into diverse thermal configurations remain limited. This study serves as a valuable resource for both researchers and manufacturers, providing insights into the multifaceted thermal behavior of lithium-ion batteries across diverse conditions. It underscores the urgency for more extensive research into thermal characteristics, paralleling the substantial progress made in understanding the mechanics and mechanisms of these batteries. Consequently, a thorough assessment of the current state and recent advancements in thermal modeling research for lithium-ion batteries emerges as a critical undertaking.

2. Purpose of the Battery Materials

The primary aim of battery components is to facilitate the effective and dependable storage and discharge of electrical energy within batteries. Batteries are indispensable elements in a broad array of devices and applications, ranging from compact consumer gadgets like smartphones and laptops to larger systems such as electric vehicles and grid energy storage. Battery materials assume a pivotal role in determining the performance, capacity, and lifespan of batteries. The following are the key objectives of battery materials:

Energy Retention: Battery materials store electrical energy in a chemical state, enabling its controlled release when needed. This capacity for energy storage is crucial for powering portable electronic devices and electric vehicles.

Power Generation and Backup: Batteries have the capability to store energy generated from renewable sources like solar panels and wind turbines, ensuring a consistent power supply even during periods of insufficient sunlight or wind. They also serve as backup power sources in the event of grid failures.

Mobility for Electronic Devices: In consumer electronics such as smartphones, laptops, and tablets, battery materials empower these devices to be mobile and function without the constant need for a power connection.

Electric Vehicles: Battery materials, such as lithium-ion, are utilized in electric vehicle batteries to stockpile energy for propulsion. The efficiency and capacity of these materials directly impact the range and performance of electric cars.

Grid-Scale Energy Storage: Large-scale battery systems employ advanced materials to store surplus energy during periods of low demand and release it during peak demand, thereby stabilizing the electrical grid and facilitating the integration of renewable energy sources.

Energy Efficiency: Battery materials can enhance the energy efficiency of various systems by accumulating energy during periods of low demand and discharging it during peak demand, reducing the necessity for constant energy generation.

Environmental Advantages: Battery materials can play a pivotal role in diminishing greenhouse gas emissions by enabling the adoption of electric vehicles and renewable energy sources, which possess a smaller carbon footprint compared to fossil fuels.

Diminishing Dependence on Fossil Fuels: Through the provision of energy storage solutions, battery materials contribute to reducing our dependence on fossil fuels, aiding in the mitigation of climate change and the reduction of air pollution.

Augmenting Energy Accessibility: Batteries with efficient materials can extend electricity to remote or off-grid areas, improving the living conditions of underserved populations.

Research and Innovation: The continuous development of new battery materials represents an ongoing field of research and innovation, motivated by the need for more efficient, longer-lasting, and safer energy storage solutions.

Battery materials are vital for the efficient storage and release of electrical energy, enabling a diverse range of applications and promoting the transition to cleaner and more sustainable energy systems. Advances in battery materials continue to exert a profound impact on technology and the environment.

3. The Reasons for Choosing Lithium-Ion Batteries

Lithium-ion (Li-ion) batteries have gained widespread popularity in various applications due to their numerous beneficial features. Below are some compelling reasons for selecting lithium-ion batteries:

Impressive Energy Density: Li-ion batteries boast a remarkable energy density, enabling them to store substantial energy within a compact and lightweight package. This makes them particularly suitable for portable electronic devices, electric vehicles (EVs), and scenarios where size and weight are crucial factors.

Reusability: Li-ion batteries are rechargeable, allowing for multiple uses throughout their lifespan. This translates to cost-effectiveness compared to disposable single-use batteries.

Extended Cycle Life: Li-ion batteries typically endure a longer cycle life when compared to many other rechargeable battery types, capable of enduring hundreds to thousands of charge and discharge cycles before experiencing significant capacity degradation.

Low Self-Discharge Rate: Li-ion batteries exhibit a relatively low self-discharge rate, ensuring they retain their charge for extended periods when not in active use. This feature is valuable for devices that may remain idle for prolonged periods between uses.

Swift Charging: Li-ion batteries can be charged rapidly, especially when compared to certain other battery technologies. This rapid charging capability is essential for applications like smartphones and electric vehicles.

Versatility: Lithium-ion batteries come in various shapes and sizes, making them adaptable and suitable for a wide array of applications, ranging from small consumer electronics to large-scale energy storage systems.

Minimal Memory Effect: Unlike some other rechargeable battery types, Li-ion batteries exhibit a minimal memory effect. Consequently, they do not require complete discharge before recharging, making them more user-friendly.

Elevated Voltage Output: Li-ion batteries provide a relatively high nominal voltage. This elevated voltage output is advantageous for many applications, facilitating efficient device operation.

Reliability and Safety: While Li-ion batteries can present safety concerns if mishandled, they feature enhanced safety measures compared to older battery technologies. Manufacturers have integrated various safety mechanisms, including thermal protection and pressure relief valves, to mitigate the risk of thermal runaway and other safety issues.

Environmental Considerations: Li-ion batteries are considered more environmentally friendly than certain other battery chemistries, such as lead-acid batteries, due to their lower toxicity and potential for recycling. Recycling programs for Li-ion batteries are becoming increasingly widespread.

It is important to note that while Li-ion batteries offer numerous advantages, they are not without limitations, including environmental concerns, the potential for thermal runaway, and the finite lifespan of the cells. However, ongoing research and development endeavors are aimed at addressing these challenges and further enhancing Li-ion battery technology.

4. Impact of Temperature on Lithium-Ion Batteries

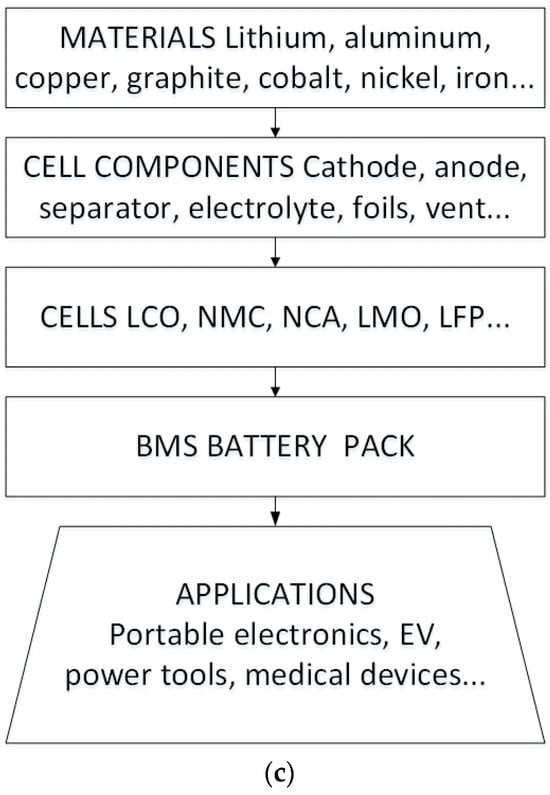

The impact of temperature on lithium-ion batteries’ performance degradation is vividly depicted in Figure 2. This deterioration primarily results from the intricate interplay of battery materials and the chemical reactions occurring within. Thermal fluctuations have the potential to induce variations in the kinetics of electrochemical reactions taking place within the battery matrix. Moreover, temperature significantly influences fundamental parameters, including the ionic conductivities of both electrolytes and electrodes. The consequences of extreme temperature conditions become even more complex when compared to milder thermal environments. The ambient temperature, influenced by variables such as seasonal changes, meteorological factors, and broader climate influences, displays location-specific fluctuations based on vehicular geography. This modulation of environmental temperature emerges as a pivotal factor determining battery longevity. Calendar life, a crucial metric representing battery lifespan, is influenced by the dynamic interplay between state of charge and temperature. Locations with elevated ambient temperatures often experience noticeable declines in battery capacity during storage conditions. Additionally, it is noteworthy that temperature also significantly affects battery cycle life, exerting a substantial influence on this critical parameter [20,21].

Figure 2.

The performance degradation of lithium-ion batteries at low temperatures [20].

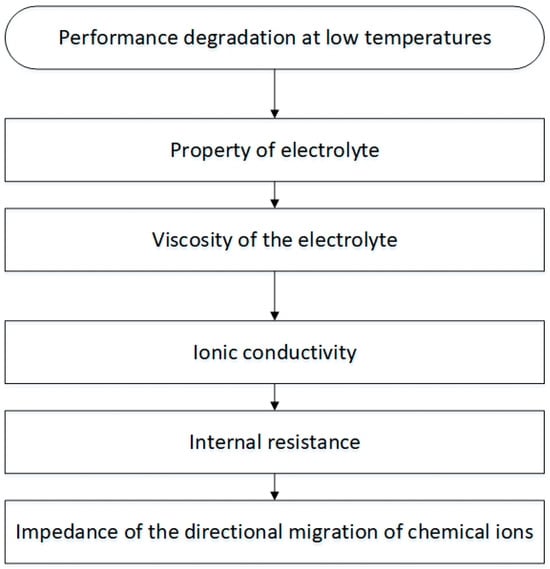

Presenting a comprehensive view of the battery’s journey, Figure 3 encapsulates the battery lifecycle. This encompassing trajectory begins with the production phase, navigates through intricate design considerations, and extends to second-life applications and the integration of electric vehicles (EVs). Thus, the profound impact of temperature fluctuations on lithium-ion batteries unravels a nuanced tapestry where diverse parameters and intricate interactions converge to shape the battery’s performance, longevity, and overall lifecycle.

Figure 3.

Battery life cycle [21].

5. Electrochemical-Thermal Behavior of Lithium-Ion Batteries

The comprehensive spectrum of electrochemical and thermal models developed to elucidate the intricate behaviors of lithium-ion batteries is represented in Table 1. This compilation underscores the diversity inherent in these models, all crafted with the overarching goal of simulating and understanding the multifaceted thermal and electrochemical dynamics exhibited by lithium-ion batteries across various environmental temperatures and current profiles. The crux of lithium-ion battery modeling lies in the formulation of complex sets of equations meticulously designed to capture the battery’s dynamic response and performance. These efforts have primarily aimed to foster the development and deployment of electrochemical-thermal battery simulation models, often involving the integration of heat transfer experiments and simulations, further enhanced by techniques like computational fluid dynamics and a range of battery-centric experiments.

Table 1.

Compilation of Electrochemical and Thermal Models for Lithium-ion Batteries.

In a significant contribution, Baghdadi et al. [22] introduced a precisely tailored, dynamic electro-thermal model calibrated specifically for high-power utilization of lithium batteries. The model’s parameters were derived from empirical insights obtained through experimental investigations, with many parameters dependent on current magnitude, temperature, and battery state of charge (SOC). Validation across a variety of operational conditions, including static and dynamic current profiles, demonstrated the model’s accuracy. Impressively, simulation results showed close agreement with extensive test data spanning twenty hours. Another noteworthy effort by Song et al. [23] involved the development of a mathematical model for the comprehensive exploration of heat transfer and thermal management aspects inherent to lithium polymer batteries. Building upon an existing electrochemical model, this enhanced version incorporated temperature-dependent parameters such as the diffusion coefficient of lithium ions, ionic conductivity of lithium ions, and transference number of lithium ions to provide a deeper understanding of thermal intricacies within the lithium polymer framework. Experimental validation, coupled with analyses of discharge behaviors and heat generation rates within lithium polymer cells, enabled a thorough comparison of experimental observations with model-derived outcomes, accompanied by a detailed discussion of diverse thermal management strategies. Similarly, Choi S.S. et al. [25] conducted a comprehensive investigation into the factors influencing the cycle life of lithium-ion cells. The insights gained emphasized the substantial impact of charge conditions on cycle life, with discharge conditions exhibiting relatively lesser sensitivity. Charging cells at rates exceeding the 1C rate, prolonged float-charge periods above 4.2 V, and high charge cut-off voltages were identified as factors negatively affecting cycle life. Interestingly, unlike other battery types, the depth of discharge displayed a limited correlation with cycle life enhancement. The association between degradation rate and charge voltage, along with the duration of exposure to high charge voltage, implicated electrochemical oxidation as a fundamental degradation mechanism.

Conversely, Thomas E.V. et al. [26] embarked on a meticulously designed accelerated aging study, thoroughly exploring the interplay between aging duration, temperature, and state-of-charge (SOC) in shaping lithium-ion cell performance. Through an extended monitoring process involving a hybrid pulse power characterization test at low current regimes over a 44-week period, a notable empirical model of power fade was established. This model comprehensively encapsulated two simultaneous degradation processes—one rapid and temperature-accelerated, and the other proceeding at a slower pace influenced by temperature and SOC. Addressing temperature-related challenges, Smart M.C. et al. [27] systematically explored the profound impact of electrolyte composition on low-temperature lithium-ion cell performance. By carefully selecting ester solvents for incorporation into multi-component electrolyte formulations, the study leveraged favorable physicochemical attributes such as low viscosity, high permittivity, and low melting points. The compatibility of these formulations with diverse electrode compositions, including LiCoO2 and LiNiCoAlO2, was demonstrated. The study also delved into lithium intercalation and deintercalation ease within Li-carbon cells at varying temperatures, employing conventional electrochemical techniques to uncover insights into surface film attributes.

Expanding into the realm of abuse testing, Spotnitz R. et al. [28] conducted a comprehensive synthesis of published studies investigating abuse testing involving lithium-ion cells and their components, complemented by the application of modeling techniques. These studies meticulously identified specific exothermic reactions and estimated heats of reaction for each, subsequently leading to model development. These models, enriched with estimated kinetic parameters and designed to address high-rate batteries, comprehensively captured cell behavior under diverse abuse conditions such as high temperatures, short-circuits, overcharging, nail penetration, and physical crushing. Notably, these models shed light on the role of fluorinated binders in thermal runaway, revealing the binder’s minimal contribution to this phenomenon. In summary, the orchestrated symphony of electrochemical and thermal models, exemplified in the table, aligns with a collective effort to decipher the intricate dynamics inherent to lithium-ion batteries. These models span a wide landscape, encompassing diverse perspectives and insights, thereby contributing to a deeper understanding of these pivotal energy storage systems.

In a distinct exploration, Rao L., Newman J. et al. [29] introduced an innovative energy balance framework for insertion battery systems, built upon enthalpy potentials as a foundational cornerstone. This pioneering approach facilitated the calculation of heat-generation rates through an inventive methodology. Additionally, an alternate model based on localized heat generation within an electrochemical cell was formulated, yielding consistent outcomes. The authors also introduced the concept of the effective open-circuit potential of an insertion battery, enhancing characterization during the open-circuit state of galvanostatic discharge. Specific simulation efforts focused on heat generation within a lithium cell during galvanostatic discharge, analyzing the interplay between the shape of the open-circuit potential and ohmic losses within the porous cathode. Remarkably, this study revealed that a single reaction could give the illusion of two reactions due to the presence of twin plateaus within the open-circuit potential. The cessation of current within electrochemical systems triggers heat generation, a consequence of the relaxation of concentration gradients. This phenomenon, referred to as the heat of mixing, results from this relaxation.

Thomas K.E. et al. [30] delved into this inquiry, providing two methodologies—a computational approach and an analytical approximation—to quantify the heat of mixing. While typically negligible within materials with robust transport properties ensuring satisfactory battery performance, exceptions arise, particularly with materials like lithium insertion electrodes engaged in insertion reactions. In such contexts, the entropy of reaction undergoes significant variations depending on the state of charge, introducing an entropy of reaction that manifests as a reversible heat effect comparable in magnitude to resistive heating. In a separate investigation, Kim U.S. et al. [31] conducted a comprehensive thermal analysis to examine the thermal performance of a lithium-polymer battery. This study delved into how electrode arrangement influences thermal behavior, considering factors such as electrode aspect ratio, positioning of current-collecting tabs, and discharge rates. Utilizing the finite element method, the study predicted potential and current density distribution across the battery’s electrodes during discharge, subsequently enabling calculations of temperature distribution within the lithium-polymer battery. Impressively, the temperature distributions derived from the model closely matched experimental measurements from batteries with different electrode types under various discharge rates. Expanding their horizons, Kim U.S. et al. [32] introduced a modeling approach to upscale a lithium-ion polymer battery (LIPB). Validation, confirmed by comparing experimental discharge curves with modeling results, demonstrated that parameters used for modeling small-scale LIPBs could be extended to larger scales, contingent on the consistency of electrode materials, composition, and manufacturing processes. Using the finite element method, the distribution of potential and current density across the LIPB electrodes during discharge was predicted and then utilized for calculations of temperature distributions within the LIPB. Notably, the temperature distributions derived from the model exhibited commendable agreement with corresponding experimental measurements.

Furthermore, Smith K.A. et al. [33] employed empirical correlations to examine the influence of temperature-dependent electrode film impedance growth (thermal stress) and cycling-dependent capacity fade (mechanical stress) on cell degradation and performance decline. This study aimed to quantify the non-uniform imbalance and performance deterioration that traverse the cell’s lifespan as degradation evolves. The results were compared with those from a 1D electrochemical/lumped thermal model. Simulations spanned varying temperatures, cycling intensities, and states-of-life, providing insight into diverse scenarios where the internal reaction field was influenced by temperature, potential, and degradation state. Shifting the focus, Yang F. et al. [34] centered their investigation on the interplay between long-term coulombic efficiency (CE) and battery degradation—an area still shrouded in mystery. This study, driven by cycle life tests on commercially available lithium-ion batteries, explored the behavior of long-term CE and its connection with capacity degradation. Through incremental capacity (IC) analysis, the study uncovered the underlying mechanisms of battery aging. The paper offered not only experimental observations but also profound discussions on battery degradation, aging mechanisms, and the evolution of CE. This inquiry unveiled two distinct degradation patterns, highlighting the link between active material loss and battery degradation and emphasizing the electrochemical interplay between the evolution of CE and capacity degradation.

To ensure accurate estimation of cell thermal characteristics, Bernardi D. et al. [35] devised a comprehensive energy balance equation for battery systems. Critical for battery system design and thermal management, this equation incorporates a range of factors driving temperature changes within cells, encompassing electrochemical reactions, phase transitions, mixing effects, and Joule heating. This versatile framework addresses multifaceted effects comprehensively while considering simplifications and practical scenarios. Demonstrating the equation’s practical utility, mathematical models of cell discharge with varying reaction mechanisms were analyzed. These examples illustrated how the energy equation facilitates the analysis of diverse term contributions, highlighting the intricate nature of heat generation processes within cells while emphasizing the benefits of adopting such a comprehensive energy equation for such analyses.

6. Thermal Characteristics of Lithium-Ion Batteries

Lithium-ion batteries, known for their nonhomogeneous composition, exhibit diverse heating patterns on the surface of battery cells. This intricate interplay poses significant challenges for effective thermal modeling and the design of efficient thermal management systems tailored to various lithium-ion battery applications. As illustrated in Table 2, researchers have employed a plethora of methods to scrutinize the thermal attributes of lithium-ion batteries. Furthermore, extensive laboratory-based experimental characterizations have been conducted on diverse lithium-ion batteries operating under varied conditions. This line of inquiry predominantly seeks to unravel the relationship between surface temperature gradients and the thermal dynamics of lithium-ion battery cells. Parameters including power, open-circuit voltage, capacity, entropic heat coefficient, heat capacity, internal resistance, temperature, and battery heat generation have been meticulously determined across diverse load currents and an expansive temperature range. The insights garnered from these experimental results are pivotal for refining thermal modeling approaches for these batteries.

Table 2.

Different methods for thermal analysis and characteristics of lithium-ion batteries.

The intricacies embedded in the thermal modeling of lithium-ion batteries necessitate a nuanced approach, as the solution varies depending on pack topologies, battery cell designs, and specific application contexts. In essence, a tailored thermal modeling system is indispensable for each unique lithium-ion battery instance. Key aspects such as the entropic heat coefficient, internal resistance, battery heat generation, and thermal models serve as foundational elements enabling the simulation of diverse lithium-ion batteries, unlocking insights into their thermal dynamics.

In a parallel pursuit, Bazinski, S.J. et al. [37] meticulously explored the influence of reversible (entropic) heat sources on the thermal behavior of lithium-ion batteries, particularly during the initial charge and discharge stages. The entropic coefficient (EC) emerged as a pivotal factor shaping the magnitude and direction of this reversible heat. The researchers identified varying EC values for a lithium-iron phosphate battery, revealing the significant impact of cell temperature on EC, particularly at extreme state-of-charge (SOC) levels. Employing curve fitting of experimental data, a correlation emerged linking EC to temperature and SOC. To validate this, calorimetric data from test cells were integrated to demonstrate the impact of reversible heating on the overall heat generation rate within the cell. This synergistic fusion of calorimetric data and EC measurement facilitated the assessment of irreversible heat generation within the cell. This exploration not only offers insights into the relationship between temperature, SOC, and EC but also sheds light on the processes of reversible and irreversible heat generation inherent to lithium-ion batteries.

In a different vein, Kumaresan, K. et al. [38] developed a thermal model to predict the discharge performance of a lithium-ion cell across varying operating temperatures. The model’s predictions were validated with experimental data from lithium-ion pouch cells. This thermal model incorporated a parameter set tailored to the lithium-ion cell, accounting for concentration and temperature dependencies. These parameters were determined through a comparative analysis of model predictions and experimental discharge profiles encompassing diverse temperatures and discharge rates. The concentration and temperature dependencies of these parameters were subsequently correlated using empirical formulations. The study also examined the implications of incorporating the temperature dependencies of various parameters within the model into simulated discharge profiles. The integration of temperature-dependent parameters enhanced the model’s predictive accuracy for the discharge performance of lithium-ion cells operating across different temperatures.

Taking a different approach, Botte, G.G. et al. [39] used a mathematical model integrating an anode (carbon) decomposition reaction to predict the temperature trajectory of a lithium-ion cell under medium- and high-rate discharge conditions. The investigation explored the influence of distinct design parameters and the activation energy associated with the anode (carbon) decomposition reaction on the projected temperature within a LixC6/LiyNiO2 cell. Model predictions highlighted the critical role of particle size in the negative electrode as a crucial parameter for accurately predicting the cell’s temperature. On a similar trajectory, Srinivasan, V. et al. [40] aimed to enhance the understanding of Li-ion cell thermal behavior through a two-dimensional, first principles-based thermal-electrochemical modeling approach. The model encompassed reversible, irreversible, and ohmic heats within matrix and solution phases, incorporating temperature-dependent transport, kinetic, and mass-transfer parameters based on Arrhenius expressions. Experimental data on the entropic contribution of manganese oxide spinal and carbon electrodes were integrated to assess the significance of this term in overall heat generation. Through simulations, the study estimated thermal and electrical energy, along with active material utilization, at distinct rates, providing a comprehensive exploration of the interplay between temperature and electrochemistry. Moreover, the paper explored the prospect of using experimental data instead of an electrochemical model to deduce heat generation rates. Discrepancies between local and lumped thermal models were analyzed, and the feasibility of using a heat generation rate established under specific thermal conditions for other scenarios was evaluated. Model simulations offered valuable insights into the appropriateness of various approximations when developing comprehensive thermal models for Li-ion cells.

In a distinct study, Al Hallaj, S. et al. [42] utilized a simplified one-dimensional thermal mathematical model with lumped parameters to simulate temperature profiles within lithium-ion cells. The model seamlessly integrated experimentally derived heat-generation parameters specific to the Sony (US18650) cell. Simulation outcomes were impeccably aligned with temperature measurements for discharge rates spanning C/2, C/3, and C/6, although slight deviations were noted for the C/1 discharge rate. The model’s capabilities extended to simulating temperature profiles under diverse operational scenarios and cooling rates for scaled-up cylindrical lithium-ion cells with capacities of 10 and 100 Ah. Profound insights emerged—cooling rate had a substantial impact on cell temperature across all discharge rates. Notably, a noticeable temperature gradient within the cell occurred only at higher cooling rates, where the Biot number exceeded 0.1. Conversely, at lower cooling rates, the cell’s behavior resembled that of a lumped system with a uniform temperature distribution. Pioneering the establishment of temperature thresholds for scale-up using the simplified model, commercial lithium-ion cells with various open circuit potentials (OCV) were tested in an accelerated rate calorimeter (ARC) to determine onset-of-thermal-runaway (OTR) temperatures. Specifically, Sony (US18650) cells with OCVs of 4.06, 3.0, and 2.8 V were examined, yielding measured OTR temperatures of 104 °C, 109 °C, and 144 °C, respectively. A significant finding emerged—a sharp OCV decrease, indicative of an internal short circuit, occurred at temperatures near the separator material’s melting point across all OCV values.

In a parallel endeavor, Smith, K. et al. [43] employed a thermal model to dissect the limitations of pulse power and thermal dynamics in a Li-ion hybrid-electric vehicle (HEV) battery pack. The pack, housing 72 cells with a nominal voltage of 276 V and a capacity of 6 Ah, underwent scrutiny. High-rate pulse discharges, operational at approximately 25 °C, consistently reached their minimum voltage threshold of 2.7 V per cell due to active material Li depletion or saturation on electrode surfaces, highlighting solid-state diffusion as the limiting factor. In contrast, the maximum voltage threshold of 3.9 V per cell, designed to prevent lithium deposition on the negative electrode during charging, was considered overly conservative for high-rate pulses initiated from states-of-charge (SOCs) below 100%. The investigation revealed an intriguing insight—the maximum pulse charge rate, originating from a 50% SOC, could increase by up to 50% without risking lithium deposition, challenging the necessity for an excessively cautious maximum voltage threshold. While adhering to minimum and maximum voltage limits, the battery pack aligned with the power assist mode pulse power requirements of the Partnership for a New Generation of Vehicles (PNGV) at temperatures exceeding 16 °C. However, it fell short of achieving the desired energy output target.

In another venture, Verbrugge, M.W. et al. [44] proposed a technique to address current and temperature distributions in large-scale battery modules with three-dimensional configurations. Simulations focused on a specific module comprising cells with a lithium metal anode, polymer electrolyte, and vanadium oxide cathode. The findings highlighted the nonlinear correlation between power output and system temperature, primarily influenced by temperature’s impact on electrochemical reaction rates and ionic conductivity. The study also explored the estimation of physicochemical parameters, some of which were not readily available in existing literature but played a pivotal role as model inputs.

In a parallel investigation, Chen, Y. M.W. et al. [45] embarked on the mathematical modeling of heat generation and transport within lithium/polymer-electrolyte batteries, with a focus on their deployment in electric vehicles. Findings revealed that thermal management remains inconsequential for batteries operating at low discharge rates. However, at high discharge rates, battery temperature can rise significantly, particularly if the cell stack’s thickness exceeds a specific threshold. Interestingly, it was found that enhancing cooling conditions does not have a significant impact on increasing heat dissipation within large-scale battery systems due to the limited thermal conductivity of the polymer material. Model predictions can guide the design of appropriate battery structures and the selection of suitable cooling strategies to achieve the desired operational temperature range for a given discharge rate.

In another comprehensive overview, Gomadam, P.M. et al. [46] reviewed the mathematical models developed at the University of South Carolina for lithium and nickel battery systems. This encompassing survey covered models tailored for Li/Li-ion batteries, including simulations of single electrode particles, individual electrodes, full cells, and battery sets operating across diverse scenarios such as constant current discharge, pulse discharge, impedance, and cyclic voltammetry. Additionally, the review included models designed for nickel battery systems, elucidating complete cell performance and the behavior of nickel hydroxide as an active material. The robustness of these models, substantiated through recurrent comparisons with experimental data, showcased their accuracy in predicting real-world outcomes.

Shen et.al [47] introduced a modified air cooling system featuring a non-vertical, Z-shaped structure. They investigated how this innovative design affected the thermal properties of lithium iron phosphate power batteries. This system departs from the traditional Z-shaped cooling arrangement by tilting battery packs at different angles, resulting in a non-vertical airflow channel structure. When compared to the conventional Z-shaped air cooling system, the highest temperature within the battery pack decreased from an initial 38.15 °C to 34.14 °C, representing a 10.5% reduction. Moreover, the temperature variation decreased from an initial 2.59 °C to 1.97 °C, marking a 23.9% decrease. This modified air-cooled battery thermal management system improves the heat exchange rate between the battery pack and the surrounding air, leading to enhanced cooling performance and temperature uniformity. The outcomes of this study serve as a foundation for the development of a modified Z-shaped air cooling system, contributing to the safety improvements in electric vehicles and providing valuable insights for the further advancement of Battery Thermal Management Systems (BTMS).

Wu et.al [48] introduced an electrochemical-thermal model (ETM) designed to evaluate the heat generation characteristics of cylindrical Lithium-ion Batteries (LIBs). This model considers various discharge rates and the ratio of negative to positive electrode capacity (N/P ratio). To provide a comprehensive assessment of LIB thermal properties, the proposed ETM was validated using experimental data acquired at ambient temperatures of 25 °C and 35 °C. Subsequently, the study examined the distribution patterns of heat generation characteristics in LIBs under various conditions through numerical analysis. A notable aspect of this investigation was the thorough exploration of how different discharge rates and N/P ratios affect the heat generation in batteries. The results highlighted the significant role of heat generation in the negative electrode and emphasized the importance of considering the impact of the reversible term on the overall heat generation in LIB cells, particularly at lower discharge rates. Additionally, the research suggested that selecting the appropriate N/P ratio can improve the total heat generation of LIBs, offering advantages for optimizing performance in the early stages of battery design and thermal management.

Chen, S.C. et al. [49] developed a comprehensive three-dimensional thermal model to understand the thermal behavior of a lithium-ion battery. The model ingeniously incorporated the layered structure of cell stacks, battery pack casing, and the space between these elements to provide a detailed analysis of heat dissipation. It included location-dependent convection and radiation at boundaries to accurately represent distinct heat dissipation characteristics across all surfaces. The study also proposed a simplified thermal model that achieved comparable calculation speed to a one-dimensional model, with a maximum error of less than 0.54 K. Both models effectively captured the asymmetric temperature distribution within the battery and even predicted temperature anomalies on the surface when a metal case was used. Insights gained emphasized the importance of factors such as the metal battery case, contact layer, and heat-spreader effects in battery system design.

In the study conducted by Zhu and their team [50], a series of experiments were carried out using a cone calorimeter to investigate Lithium-ion Battery (LIB) packs of varying sizes (1 × 1, 1 × 2, 2 × 2, 2 × 3, 3 × 3) and at different states of charge (SOC) levels (100%, 50%, and 0%). The research examined several fire-related parameters, such as the heat release rate (HRR), mass loss, and concentrations of CO, CO2, and O2. Interestingly, the study observed similar combustion patterns characterized by intermittent jets for LIB packs at both 50% SOC and 100% SOC. The findings revealed a consistent positive correlation between the total mass loss (TML) and the peak value of HRR (pHRR), described by a power function, in relation to the surface area of the exposed heat source. Notably, for battery packs with a 100% SOC, the pHRR of the 3 × 3 cell module increased significantly, approximately by a factor of 8, reaching 12 kW. The study also assessed the presence of the toxic gas carbon monoxide (CO) by determining the fractional effective dose (FED). It was found that for battery packs with sizes smaller than 2 × 3, the FED remained below 1 for packs at both 50% SOC and 100% SOC. This research offers valuable insights into predicting the progression and fire risk associated with larger-scale battery fires and provides potential strategies for mitigating thermal runaway (TR) hazards in accident scenarios.

Chen, S.-C. et al. [51] developed a two-dimensional thermal model specifically tailored for spirally wound cells, aiming to establish a standardized simulation methodology for these battery configurations. The model carefully considered the geometric attributes and boundary conditions of the spiral architecture to avoid distorted results caused by improper approximations of the spiral geometry. While this versatile model architecture offered precision, it came at the expense of computational time. Simulations performed on lithium batteries exposed to natural convection revealed that peak temperatures clustered in a circular region near the liquid-filled hollow core rather than at its exact center. Additionally, radiation emerged as a significant contributor to heat dissipation, accounting for up to 53.6% of the total when surface emissivity approached unity. Introducing airflow parallel to the cylinder axis proved effective in maintaining surface temperatures, although internal temperatures remained elevated for batteries with a larger radius. Airflow perpendicular to the cylinder axis, while slightly less effective than parallel flow, still contributed to reduced heat dissipation. Ensuring temperature uniformity required a battery case with high thermal conductivity. Chen, Y. et al. [52] developed a three-dimensional model to simulate and compare heat generation and transport in a lithium polymer electrolyte battery during galvanostatic discharges and under a dynamic power profile, such as the Simplified Federal Urban Driving Schedule (SFUDS). The study aimed to achieve and maintain operational temperature and temperature uniformity within the battery through well-designed thermal management. The findings highlighted the crucial role of anisotropic thermal conductivity and emphasized its importance in battery design. The study offered insights into designing laminated cell stacks to achieve uniform operational temperatures, especially when cooling channels or electric heaters were applied to the stack’s extremities. Under the SFUDS power profile, the time-averaged heat generation rate was low, necessitating high-performance insulation materials to maintain desired operational temperatures. The thermal model served as a toolkit for evaluating different configurations of cooling channels and electric heaters, optimizing heating intensities, and selecting insulating materials. Chen, Y. et al. [53] conducted a thermal analysis of lithium polymer electrolyte batteries, aiming to understand the relationship between battery thermal behavior and various design parameters. The study aimed to guide the preservation of operational temperature by designing appropriate cell stack structures and selecting suitable cooling and insulating systems. The analysis explored the effects of stack size and different cooling/insulating conditions on battery temperature across a range of discharge rates. These investigations provided valuable insights for maintaining desired operational temperatures. The study also calculated temperature distributions within cell stacks for different cell designs, including variations in component thicknesses and current collector materials. This analysis not only identified optimal cell structures from a heat transfer perspective but also discussed the thermal properties of lithium polymer electrolyte batteries with different positive electrode materials, such as V6O13, TiS2, and redox polymers. The study shed light on the thermal conductivity of batteries influenced by varying electrode compositions. Lastly, Du, S. et al. [54] conducted a study focusing on irreversible heat generation in lithium-ion batteries and its implications for electronic device development. The primary factors contributing to internal irreversible heat generation in Li-ion batteries are polarization and ohmic heat generation. The study developed a thermo-electrochemical coupling model that integrated dynamic parameters and the electric double layer to uncover the mechanisms behind this phenomenon. Results revealed a key insight—irreversible heat production increases significantly with discharge rate, with polarization heat production being the dominant factor. Ohmic heat production primarily contributes to electrolyte heating, while heating at the negative active material is much smaller compared to the positive active material. Calculations demonstrated that the ratio of ohmic heat production to total irreversible heat production rises as the discharge rate increases, helping to balance the influence of polarization heating. The study further investigated the role of particle size in irreversible heat production and polarization heat production at the positive and negative electrodes. The findings underscored the greater impact of particle size at the negative electrode on these factors within the battery. In summary, this study highlighted the crucial role of irreversible heat generation in li-ion batteries, revealing polarization heat production’s dominance and the relatively smaller contribution of ohmic heat production from negative active materials. It also emphasized the influence of electrode particle size on irreversible heat production and polarization heat production, shedding light on an often overlooked but essential aspect of li-ion battery dynamics.

Drake, S.J. et al. [55] introduced an innovative method for measuring the heat generation rate of Li-ion cells at high discharge rates, reaching up to 9.6C. This approach involves simultaneous measurements of cell temperature and surface heat flux, providing insights into heat stored and lost from the cell. Unlike calorimetry-based methods, this in-situ approach allows measurements in laboratory or field settings. Prior to heat generation measurements, a preliminary test measures the temperature gradient within the cell under identical ambient conditions. This data is used to correct temperature discrepancies within the cell during subsequent heat generation measurements. The paper also introduces a method to measure the internal cell temperature, providing more precise temperature data for heat generation analysis. By comparing heat generation measurements with established theoretical models, the study demonstrates the agreement between experimental data and theoretical projections. This validation confirms the effectiveness of the proposed measurement method and reinforces trust in the theoretical models used to understand heat generation in Li-ion cells. The paper also briefly discusses the potential benefits of actively cooling the cell, highlighting the advantages of cooling in managing heat generation and improving cell performance. Active cooling strategies are identified as valuable tools for mitigating excessive heat generation and enhancing the comprehensive thermal management of Li-ion cells. Gümüşsu, E. et al. [56] introduced a three-dimensional computational fluid dynamics (CFD) model to investigate the thermal performance of lithium-ion batteries under natural convection. This model encompasses the entire flow field surrounding the battery and internal conduction, to predict the battery’s temperature during discharge. The model relies solely on electrical performance parameters, granting it predictive power in thermal analysis. By comparing macro-scale thermophysical properties such as specific heat and thermal conductivity, the study reveals the significant role of specific heat in moderating the battery’s temperature, while the influence of thermal conductivity remains comparatively limited. Interestingly, the study finds that experimental data can be closely predicted even without considering the entropic term in heat generation calculations. The discrepancy between experimental and predicted battery surface temperatures remains within 3 °C across all discharge rates, regardless of the battery’s operational history. This developed CFD model serves as a versatile platform for exploring the thermal behavior of lithium-ion batteries across various packaging configurations, encompassing both natural and forced convection conditions. It facilitates a nuanced exploration of battery thermal management and optimization strategies, ultimately resulting in improved performance and safety for lithium-ion batteries. Xiao, M. et al. [57] conducted an experimental investigation using a calorimeter to enhance an electrochemical thermal model with additional terms. Calorimetric measurements were compared with model predictions to assess the model’s accuracy and reliability. The inclusion of these supplementary heat source terms, validated through experimental measurements, enhances the electrochemical thermal model’s ability to provide a comprehensive understanding of heat generation in batteries. This augmentation enhances battery thermal management and elevates safety considerations in practical applications. Abdul-Quadir, Y. et al. [58] introduced a method for discerning heat generation in individual battery cells during charge and discharge, a crucial element in effective battery thermal management. This method accounts for overpotential resistances through four distinct measurement techniques, incorporating the contribution of entropic heat generation within the cell. The authors conducted calorimeter tests to directly quantify heat generation within the battery cell, and the accuracy of the proposed method was validated through a comparison of calculated and measured heat generation values. The study highlights a strong agreement between overpotential resistances obtained from various techniques, except for direct current resistance measured using impedance spectroscopy. These findings instill confidence in the proposed method’s capability to accurately estimate heat generation, making it an essential tool for precise heat generation estimation. Eddahech, A. et al. [59] conducted a series of tests using an accelerating rate calorimeter to explore the thermal behavior of high-power lithium-ion cells during charge and discharge cycles at various current rates. The study focused on characterizing cell heat capacity, quantifying cell entropy, and understanding the impact of state-of-charge fluctuations and charge-discharge current rates on battery heat generation. These insights provide a deeper understanding of the cells’ heat generation and thermal characteristics, contributing to a more comprehensive grasp of their thermal behavior. Nieto, N. et al. [60] developed a thermal model tailored for a large Li-ion pouch cell with a capacity of 10.5 Ah. This model was based on experimental measurements of internal resistance and the entropic heat coefficient. Adiabatic calorimetry data were used to validate the thermal model’s accuracy. The study covered higher discharge rates and broader temperature operation ranges compared to previous research. The results demonstrated the thermal model’s reasonable prediction error for discharge processes conducted at moderate and elevated rates. The paper also discussed the strengths and limitations of the thermal model, offering insights into its practical applicability and key considerations for designing thermal management systems. Overall, the thermal model proved to be an effective predictor of heat generation behavior in large-format Li-ion pouch cells. Vertiz et al. [61] conducted a combined approach of calculated and experimental methods to explore the fundamental thermal characteristics of a commercially available high-capacity (14 Ah) pouch cell using LiFePO4/graphite chemistry. This investigation involved dual comparative analyses. Firstly, it compared heat generation predictions from Newman’s model with experimental heat measurements. Secondly, it established a correlation between empirical thermal behavior and the response of a 1D electro-thermal model. This research methodology allowed for a comprehensive assessment of the cell’s thermal behavior and validated the accuracy of theoretical predictions against experimental data.

7. Thermal Runaway of Lithium-Ion Batteries

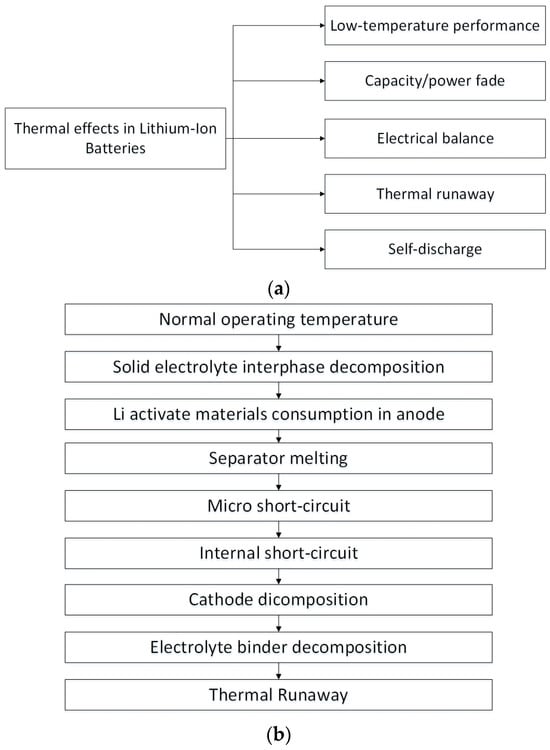

Figure 4 provides a comprehensive illustration of the thermal effects observed in lithium-ion batteries, accompanied by an informative portrayal of the conventional thermal runaway process inherent in these batteries [62,63]. Inadequate thermal management of lithium-ion batteries can lead to a phenomenon known as thermal runaway. Figure 4b offers a detailed depiction, elucidating the typical progression of thermal runaway in lithium-ion batteries. This process unfolds in distinct stages. During the initial phase, the solid electrolyte interface layer undergoes decomposition, triggering self-heating within the cell. This self-heating serves as a catalyst for subsequent reactions, ultimately resulting in the melting of the separator. Initially, this leads to a minor micro-short circuit, which then escalates into a more significant internal short circuit, intensifying self-heating and progressing to the second stage. In the second phase, exothermic reactions between the electrolyte and the cathode begin. The culmination of this escalating sequence occurs in the final stage, characterized by the decomposition of both the electrode and the electrolyte, resulting in a full-fledged thermal runaway [63].

Figure 4.

(a) Thermal effects in lithium-ion batteries [62], (b) Illustrative drawing of a conventional thermal runaway process [63].

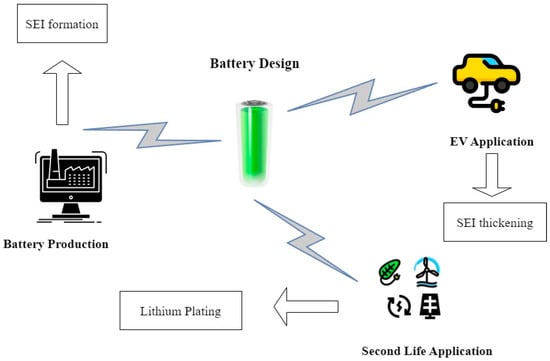

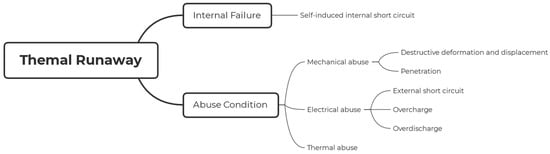

Thermal runaway occurs as a result of internal reactions within a battery, causing a rapid increase in internal temperature. This temperature rise, in a cyclic manner, accelerates reactions, creating a loop that further intensifies the temperature increase. This unchecked cycle of reactions and rising temperatures can lead to the generation of smoke, the ignition of fires, and, in extreme cases, even explosions. Table 3 provides an inclusive overview of various studies that delve into the complexities of the thermal runaway mechanism in lithium-ion batteries. The rise in pressure and temperature within the battery is driven by exothermic reactions occurring across the cathode, anode, and electrolyte. In a bid to ensure safety in commercial applications such as electric vehicles, many countries have established mandatory standards that batteries must meet before entering the market. However, it is important to emphasize that despite the existence of these standards, incidents related to thermal runaway still occur. These incidents do not arise due to a lack of standards but rather stem from inherent malfunctions and adverse conditions that batteries might encounter throughout their lifecycle in specific applications (as illustrated in Figure 5). It is vital to acknowledge that while internal malfunctions are possible, their likelihood is typically low [64,65].

Table 3.

Different studies about the thermal runaway mechanism of lithium-ion batteries.

Figure 5.

Thermal runaway mechanism.

Abuse conditions, encompassing mechanical, electrical, and thermal abuse, pose a higher likelihood of occurrence and can lead to hazardous situations in lithium-ion batteries.

- Mechanical Abuse: Mechanical abuse transpires when batteries undergo displacement, deformation, or penetration, resulting in separator destruction. Such events can give rise to internal short circuits, electrolyte leakage, and eventual fires. The simulation of mechanical abuse and the evaluation of thermal runaway risks for large-format Li-ion batteries have been emphasized, underscoring the necessity to assess battery safety under mechanical abuse scenarios.

- Electrical Abuse: Electrical abuse comprises external short circuits, overcharging, and over-discharging conditions, each of which can lead to detrimental consequences if not managed effectively.

Researchers like S. Santhanagopalan et al. [66] have developed thermal models grounded in electrochemical principles to study internal short circuits in lithium-ion cells. Such models offer insights into various experimental observations. The simulations mimic different short-circuit situations that may occur within lithium-ion cells, calculating the resulting power generation. Parameters like state of charge (SOC) and initial cell temperature are examined to understand the behavior of short-circuited cells. Experimental tests are conducted to validate the model’s predictions, aiding in the design of safer cells and enhancing safety measures. R.A. Leising et al. [68] performed extensive analysis on prismatic lithium-ion batteries under short-circuit and overcharging conditions. Internal thermocouples were used to assess thermal profiles during these extreme scenarios. Results highlighted the importance of internal temperature measurements, as differences were noted between internal and surface temperatures. The study demonstrated the significance of cathode material quantity in overcharging-induced cell rupture. T.G. Zavalis et al. [69] employed a coupled electrochemical-thermal model to examine the potential hazards of thermal runaway stemming from exothermic side reactions in short-circuited lithium-ion battery cells. This study emphasized the pivotal role of mass transport in the electrolyte and electric resistance in determining temperature increase rates under different short-circuit scenarios. H. Maleki et al. [70] investigated the thermal stability of lithium-ion cells under internal short circuit (ISCr) conditions using a combination of experimental methods and thermal modeling. They examined the influence of ISCr location, cell capacity, and state of charge on ISCr events. The study highlighted the limitations of certain experimental approaches in simulating high-risk ISCr events and emphasized the importance of ISCr location in its consequences. T. Yamauchi et al. [71] introduced a model for lithium secondary batteries that elucidates charging/discharging behavior and temperature increases during internal short circuits. Their model suggests that the cumulative generation of Joule heat due to high currents during internal short circuits contributes to thermal runaway. In essence, research endeavors focusing on abuse conditions and safety considerations offer valuable insights into the complex interactions that can lead to hazardous outcomes in lithium-ion batteries. These insights play a crucial role in enhancing battery design, manufacturing, and management strategies to ensure safety and prevent accidents.

Certainly, the information you provided highlights several studies that delve into the mechanical aspects of lithium-ion batteries, specifically focusing on the effects of external forces, mechanical failures, and their interactions with electrical and thermal responses. These studies contribute to the overall understanding of the behavior and safety of lithium-ion batteries under different mechanical abuse conditions. The research conducted by these teams sheds light on various aspects:

- Impact and Crush Testing of Battery Packs (Y. Xia et al. [72]): This study employed finite element modeling to comprehensively investigate the effects of ground impact on lithium-ion battery packs in electric vehicles. By developing global and detailed FE models, they assessed the structural response and potential failure modes of battery packs subjected to ground forces. The research provided insights for designing protective structures to withstand ground impact and highlighted the importance of evaluating battery safety under mechanical abuse conditions.

- Mechanical-Electrical-Thermal Interactions (C. Zhang et al. [73] and C. Zhang et al. [74]): These studies developed models that simultaneously consider mechanical, electrical, and thermal aspects to understand the behavior of lithium-ion batteries under external crushing. The models incorporated detailed mechanical material properties and accurately predicted mechanical deformation, separator failure, and short-circuit initiation. The studies emphasized the significance of test conditions and electrical contacts in influencing the electrical-thermal behavior of cells following a short circuit.

- Separator Failure Under Loading (Y. Xia et al. [75] and E. Sahraei et al. [76]): These studies specifically focused on separator failure under various loading conditions. Y. Xia et al. [75] investigated the influence of loading conditions on separator failure through numerical simulations and found that torsion significantly increased strain, leading to the initiation of internal short circuits. E. Sahraei et al. [76] performed tests and finite element modeling on different types of battery cells, including separator failure, validating their models’ predictions against experimental observations.

- Deformation and Failure Analysis (M.Y. Ali et al. [77] and W.-J. Lai et al. [78]): These studies analyzed the mechanical behavior of battery components and modules under different loading conditions. M.Y. Ali et al. [77] developed computational models to simulate component and cell behavior under constrained compression, capturing various phenomena observed in experiments. W.-J. Lai et al. [78] conducted comprehensive tests on module components and investigated mechanical behavior through tensile and constrained compression tests, providing insights into module behavior and validation through finite element analysis.

Overall, these studies contribute valuable insights into the mechanical responses and failure modes of lithium-ion batteries under different abuse conditions, aiding in the design of safer battery systems and enhancing the understanding of battery safety considerations.

The information you’ve provided highlights additional studies that have contributed to the understanding of the mechanical behavior and failure mechanisms of lithium-ion battery cells under different loading conditions. These studies further demonstrate the importance of accurate modeling and testing for predicting mechanical responses and enhancing battery safety. Let us discuss these studies in more detail:

- Mechanical Abuse Testing and Fracture Prediction (L. Greve et al. [79]): This study conducted a comprehensive quasi-static mechanical abuse test program on cylindrical lithium-ion battery cells with a 0% state of charge. The focus was on various load cases, and the results revealed that macroscopic jelly roll fracture is a primary cause of internal short circuits. To predict these fracture events and short circuits, a macro-mechanical finite element crash simulation model was developed using the Mohr and Coulomb criterion. The model accurately predicted punch displacement at the point of fracture and the locations of internal short circuits, emphasizing the reliability of the criterion in predicting fracture events and their effects on battery safety.

- Finite Element Modeling of Mechanical Behavior (E. Sahraei et al. [80]): This study developed a finite element model for individual battery cells, utilizing shell elements for the aluminum and copper foils and solid elements for the active material, binder, and separator. The simulations correlated well with experimental results for various loading scenarios. The presence of a thin pouch enclosure was found to significantly influence deformation and failure mechanisms. The developed model serves as a foundation for modeling battery modules and packs at different length scales, enabling better optimization of strength-to-weight ratios and safety assessments.

- Mechanical Testing and Modeling of Shell Casings (X. Zhang et al. [81]): In this study, a comprehensive test program was conducted on empty shell casings of 18,650 lithium-ion cylindrical cells. Plasticity and fracture models were developed to predict the behavior of the shell casings under various loading conditions. The models accurately predicted plastic behavior and fracture initiation and propagation within the casings. The study highlighted the importance of considering the metallic shell casing in mechanical modeling, as it significantly contributes to the mechanical resistance of the cells under different loading scenarios.

These studies collectively contribute to a deeper understanding of the mechanical behavior and failure mechanisms of lithium-ion battery cells. By utilizing advanced modeling techniques and conducting comprehensive mechanical abuse testing, researchers are able to predict fracture events, understand failure mechanisms, and enhance battery safety considerations.

8. Safety of Lithium-Ion Batteries

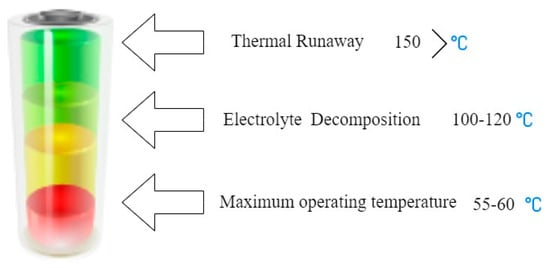

Figure 6 illustrates a diagram indicating the stages leading toward thermal runaway. Ensuring the safety of lithium-ion (Li-ion) batteries is of paramount importance, given their widespread use in various applications. Thermal safety is a critical aspect, and addressing potential issues like thermal runaway is crucial to preventing accidents and ensuring the safe operation of Li-ion batteries. Let us delve deeper into the challenges and research efforts related to the safety of Li-ion batteries:

Figure 6.

A diagram indicating the stages leading toward TR [82].

Challenges in Ensuring Safety:

- Thermal Runaway: Thermal runaway is a key safety concern for Li-ion batteries. It involves a self-accelerating process in which the battery’s internal temperature rises uncontrollably due to exothermic reactions, potentially leading to smoke, fire, or explosions. Managing and preventing thermal runaway is a critical challenge in battery design and operation.

- Predictive Modeling: Developing accurate predictive models for thermal runaway is complex due to the intricate interplay of electrochemical, thermal, and mechanical factors within the battery. Creating models that can reliably predict and simulate the onset and progression of thermal runaway is an ongoing challenge.

- Detection and Mitigation: Detecting the early signs of thermal runaway is vital for timely intervention. Developing effective methods for detecting temperature increases, gas emissions, and other indicators of thermal runaway is essential. Additionally, devising strategies to mitigate the consequences of thermal runaway is crucial for minimizing damage and ensuring safety.

Research Efforts and Strategies:

- Thermal Runaway Modeling: Researchers have been actively working on developing sophisticated models that simulate thermal runaway processes. These models integrate factors such as heat generation, heat dissipation, and internal cell behavior to predict the conditions that can lead to thermal runaway. Accurate models aid in designing safer battery chemistries and architectures.

- Thermal Management: Effective thermal management strategies are crucial to preventing excessive heat buildup within batteries. Strategies include using advanced cooling methods, optimizing electrode materials, and designing efficient pathways for heat dissipation to maintain safe operating temperatures.

- Advanced Materials: Researchers are exploring new materials that have improved thermal stability and reduced reactivity, aiming to minimize the likelihood of thermal runaway. Materials like solid-state electrolytes and advanced electrode materials can contribute to enhanced battery safety.

- State-of-Health Monitoring: Developing monitoring systems that continuously assess the battery’s health and performance can provide early warnings of potential safety issues. Monitoring parameters such as internal resistance, voltage, and temperature changes can help predict and prevent thermal runaway.

- Safety Standards and Regulations: Governments and international organizations are setting safety standards and regulations for the design, manufacture, and use of Li-ion batteries. Compliance with these standards ensures that batteries meet certain safety criteria and reduces the risk of accidents.

- Battery Design Optimization: Battery pack design and configuration play a significant role in safety. Designing robust cell enclosures, separators, and thermal management systems helps contain and dissipate heat effectively.

- Advanced Testing Techniques: Researchers are developing advanced testing methods that subject batteries to various abuse conditions, including mechanical, electrical, and thermal abuse. These tests help identify failure mechanisms and design batteries that are more resilient to abuse.

In conclusion, ensuring the safety of Li-ion batteries requires a multidisciplinary approach involving materials science, electrochemistry, thermal engineering, and more. Research efforts continue to address challenges related to thermal runaway prediction, early detection, mitigation strategies, and regulatory frameworks. By understanding the stages leading to thermal runaway and actively researching solutions, the field is moving toward safer and more reliable Li-ion batteries for a wide range of applications.

Absolutely, the safety of lithium-ion (Li-ion) batteries in electric vehicles is a critical concern, given their pivotal role in these technologies. The research efforts and studies you’ve highlighted underscore the multi-faceted nature of battery safety and the ongoing work to address various challenges. Let us further discuss these key points:

Harmonization of Battery Testing Standards:

- The rapid proliferation of Li-ion batteries in electric vehicles has led to the need for consistent safety testing standards across different markets. Variations in regulations and standards can result in inefficiencies and inconsistencies in battery testing.

- Lin et al. [83] conducted a comprehensive analysis comparing Chinese, German, United Nations, and European regulations. By identifying discrepancies and suggesting improvements, they aim to promote harmonization among these regulations. This would lead to standardized testing methodologies that can improve efficiency and reliability in battery testing.

Nonflammable Electrolytes and Safety Considerations:

- Safety concerns related to the flammability of liquid electrolytes have driven researchers to explore nonflammable alternatives. However, as demonstrated by Liu et al. [84], the complexity of battery chemistry can lead to unexpected safety outcomes.

- Liu et al.’s study emphasizes the importance of considering the interactions between different components within the battery system. Even though a nonflammable electrolyte was used, the interaction with other elements led to unforeseen exothermic reactions, highlighting the need for a comprehensive approach to safety evaluation.

Temperature Prediction and Battery Safety:

- Battery temperature management is crucial for maintaining safety and performance, particularly in electric vehicles. The study by Hong et al. [85] introduces an innovative approach for real-time temperature prediction using clustering-based data partitioning and neural networks.

- Accurate temperature prediction aids in the early detection of thermal anomalies, helping prevent thermal runaway incidents. The study’s methodology leverages real-world data to create a reliable model adaptable to various climates and operational conditions.

Fault Diagnosis and Risk Assessment:

- As Li-ion batteries age and experience various operating conditions, the potential for faults increases. Detecting and diagnosing faults is essential for maintaining battery safety and performance.

- Zhang et al. [86] provide an overview of fault diagnosis methods tailored for Li-ion batteries. These methods encompass statistical analysis, models, signal processing, knowledge-based approaches, and data-driven techniques.

- Risk assessment of thermal abuse, as presented by Xia et al. [87], is crucial for understanding the potential consequences of various internal, external, and random factors. Their approach integrates models, stochastic considerations, and risk evaluation to predict thermal safety boundaries and assess risk probabilities.

In conclusion, the safety of Li-ion batteries in electric vehicles is a multifaceted challenge that requires a holistic approach. Researchers are addressing various aspects, including harmonizing testing standards, exploring new electrolytes, predicting temperatures, diagnosing faults, and assessing risk probabilities. The ongoing efforts in research and development aim to enhance the safety, reliability, and performance of Li-ion batteries, supporting their continued adoption in electric vehicles and other applications.

9. Thermal Management of Lithium-Ion Batteries

C. Zhang et al. [88] achieved temperature control of a lithium-ion battery (TAFEL-LAE895 100 Ah ternary) in electric cars by combining heat pipes (HP) and a thermoelectric cooler (TEC). The utilization of heat pipes, with their high thermal conductivity, increased temperature loss. However, the initial design fell short of dissipating heat effectively at high rates. Consequently, a thermoelectric cooler was incorporated to enhance the battery’s heat dissipation at rates exceeding the average. Simulations indicate that this innovative approach will effectively prolong the battery’s lifespan through temperature regulation.

To reduce the temperature of lithium-ion batteries, T. Talluri et al. [89] incorporated commercial phase change materials (PCMs) with different thermal properties. The researchers examined the effect of expanded graphite on temperature loss and performed statistical analysis on single-pouch battery data. The findings indicated that the inclusion of expanded graphite enhanced heat dissipation due to its high thermal conductivity. When PCMs were used, the battery’s temperature during discharge could be lowered by approximately 11 degrees Celsius compared to cases without expanded graphite. Accurate temperature analysis was conducted through cold and warm soaking methods. The utilization of expanded graphite resulted in a reduction of approximately 4 and 2 h in the equilibrium time during cold and hot soaking, respectively, demonstrating improved temperature control performance after implementing PCMs. Consequently, based on the simulated results, expanded graphite emerged as the optimal choice for PCMs in this research.