Abstract

Membrane technologies have been widely applied in surface water treatment for drinking water purification. The main obstacles to the large scale application of membranes include membrane fouling, energy consumption and high investment. This study systematically investigated the performance of a hybrid system including in-situ coagulation and membrane module. The key parameters of a membrane system, including initial flux, operation mode (intermediate or continuous, time intervals, backwashing and aeration) was comprehensively investigated. In addition, the treatment performance in terms of turbidity, organic matter removal, membrane fouling and cleaning, and the effect of coagulants, were also studied. It was found that flat ceramic membranes with in-situ coagulation for surface water treatment performed much better without aeration and frequent backwashing, which gave interesting and important implications for future applications of a flat ceramic membrane, especially in drinking water purification. The hybrid system can achieve a high-water flux of 150 L/m2·h (LMH) for 8 h operation without aeration and backwash. The removal of turbidity, UV254 and COD can achieve 99%, 85% and 81%, respectively. The cake layer on the membrane surface formed from the coagulation flocs turned out to prevent the membrane to be exposed to organic pollutant immediately which minimized the fouling problem. In addition, the fouling layer on the membrane surface can be easily cleaned by air scouring and backwash at the end of experiments, with a water flux recovery of higher than 90%. These results in this study provided an alternative strategy for membrane fouling control and energy conservation.

1. Introduction

Water safety, which is mainly threatened by pathogens and micropollutants, is highlighted by U.S. National Academies in 2012, promoting the application of advanced membrane technology for portable water production. There have been significant improvements in membrane technology over the last few decades, including membrane development, new membrane processes and the hybrid membrane process. However, energy consumption and membrane fouling are still the challenges in large scale application [1,2,3].

Among various membrane technologies, ultrafiltration (UF) is a promising and the most widely applied technology for producing drinking water from surface water with a lower cost than nanofiltration (NF) and reverse osmosis (RO) [4,5]. Particularly, the ceramic membrane (characterized as microfiltration or ultrafiltration according to its pore size and molecular cut off) has the advantages of high surface hydrophilicity, good mechanical and chemical stability, longer lifespan, being easier to be cleaned by mechanical washing and integrating with other treatment processes compared with conventional polymeric membranes [6]. It has been widely applied in drinking water purification [7], wastewater treatment processes [8,9,10,11,12] and microalgae production [13,14,15,16].

However, membrane fouling, which leads to a membrane flux decline, high transmembrane pressure (TMP) and high maintenance cost, should also be carefully controlled. Either for the polymeric or ceramic membrane, the membrane fouling is strongly dependent on the operation conditions including the hydrodynamic conditions, system recovery, influent water properties and membrane properties. Membrane fouling in a low pressure driven membrane process was mainly dominated by the pore narrowing and blocking by organic foulant and small particles followed by cake layer formation on the membrane surface [17]. There are numerous research papers studying the control strategy of membrane fouling. Pretreatment, including coagulation [18,19], adsorption [20], oxidation [21,22,23], flocculation [24] and the integrating pretreatments between them [25], are key solutions for the reduction of membrane fouling and the increasing of permeate quality [26]. Among these pretreatment procedures, coagulation is widely and successfully used due to its low cost and relatively easy operation. It has a very high removal efficiency for virus and macro-organic molecules during drinking water production [27].

In this study, a flat-ceramic membrane was applied to investigate the performance of a hybrid membrane and coagulation system, membrane fouling and the optimum operation conditions. The flat-ceramic membrane was normally operated in a submerged membrane tank and produced water through pump suction resulting in lower energy consumption compared with the tubular-ceramic membrane [28]. It is worth noting that most of the flat ceramic membranes were operated similarly with the flat-sheet polymeric membranes where the on/off interval was normally 8 min: 1 or 2 min, obtaining a water production efficiency of 90% or lower [29]. Considering the high investment cost of the ceramic membrane, efforts should be down to increase its competence by tailoring a high-efficient system operation. It is meaningful to discover the optimal operation parameters regarding flat-ceramic applications, especially in surface water purification where a higher water flux should be obtained. For this purpose, the operation conditions of the system were systematically investigated to minimize membrane fouling, lower the operation energy consumption and meanwhile maintain water permeability and permeate quality.

2. Materials and Methodology

2.1. Experimental Setup and Testing Procedure

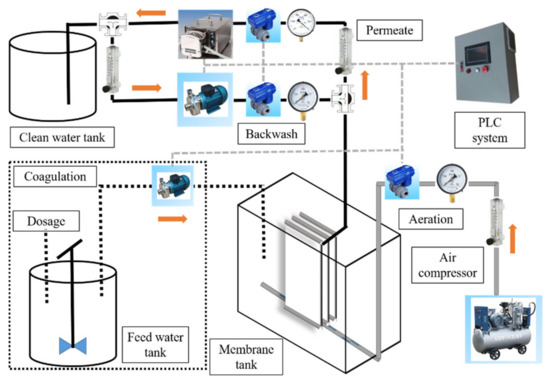

The experiments were conducted using a pilot scale, submerged, flat-ceramic membrane system which included the hybrid of coagulation-membrane module as showed in Figure 1. In order to optimize the dosage of coagulant, a series of concentrations of coagulants were applied at 10 ppm, 20 ppm and 40 ppm of PACl (1.1 mg/L, 2.2 mg/L and 4.4 mg/L coagulants as Al). The hybrid coagulation and flat-ceramic membrane system was conducted for a range of conditions, including filtration with in-situ coagulation, filtration of supernatant (pre-coagulation) and filtration with no coagulation. Three different operation modes for the membrane process, including filtration with or without periodical backwash (w/backwash or w/o backwash), filtration with or without the periodical relaxation (w/relaxation or w/o relaxation) and the continuous mode of filtration (continuous), were investigated. In this study, two operation cycles where the on/off ratio were selected: 60:1 (running 60 min stop 1 min) and 20:1 (running 20 min stop 1 min) were investigated. 30 s backwashing was applied for each operation cycle with a backwash pressure of 0.4 bar if backwashing was introduced. Otherwise, backwashing was performed after finishing all the experiments. The effect of aeration on membrane performance was also studied.

Figure 1.

The schematic diagram of the hybrid in-situ coagulation and flat-ceramic membrane testing system.

Coagulant PACl was dosed into the membrane tank by a dosing pump after rapid mixing with feed water. Then the mixture solution was stirred by the aeration system installed at the bottom of the membrane tank, containing a holey tube (hole diameter was 2 mm) for 20 min prior to running the system. Five pieces of membranes with a dimension of 1000 mm (Height) × 250 mm (Width) × 6 mm (Thickness) were vertically placed in the 200 L membrane tank with a gap of 12 mm between two of them. The flat-ceramic membrane was fabricated with alumina (Al2O3), providing an average pore size of 0.1 μm, active membrane area of 0.5 m2 and pure water permeability of 800 L/m2·h·bar (supplied by Suntar International CO., Ltd., Xiamen, China). During the filtration, the permeate flow was controlled by the peristaltic pump, and another centrifugal pump was used for backwashing. A pressure gauge was placed between the membrane reactor and the suction pump to track the trans-membrane pressure (TMP). All the tests were operated in a recycling mode with clean water overflowing from the permeate water tank back into the membrane tank. The operation mode of pumps and valves were adjusted by changing their setting through a programmable logic controller (PLC) system. In addition, the filtration duration, backwash interval and backwash flowrate can be controlled by the PLC system. The TMP and water flux will be recorded for further processing.

2.2. Feed Solution Properties and Chemicals

In order to examine the performance of this system in purifying polluted surface water and to further optimize the operation parameters, the feed water was collected from a membrane bioreactor (MBR) plant for domestic wastewater treatment in Suntar Technological Park, Xiamen, China. The water sources of this plant were collected from the downstream of Kengnei Reservoir (Fujian Province), which was seriously polluted by domestic sewage drained by the residents. In order to keep the consistency in our tests, the quality of water samples collected from this MBR plant was examined, and corresponding adjustments were made to ensure that all the feed water used in this study had the same quality. The detailed property of the prepared feed water was presented in Table 1. At present, one of the most popular traditional coagulants was polyaluminum chloride (PACl). This PACl, an Al-species coagulant used in this study, had a very high removal efficiency regarding humic acid (HA), large organic molecular and turbidity [30]. It was purchased from Sino pharm Chemical Reagent Co., Ltd., Shanghai 200002, China.

Table 1.

The properties of feed solution.

2.3. Water Quality and Membrane Fouling Characterization

The water quality parameters including turbidity, UV254 and chemical oxygen demand (COD) were measured for both the feed solution and permeate water. The turbidity was detected by a turbidity meter (HACH2001Q, HACH Company, Loveland, CO, USA). The water samples were filtered through 0.45 um membrane filters before measuring UV254 and COD. COD was measured by HACH DRB200 (For digesting) and DR900 (For measuring). UV254 adsorption was measured by a double beam UV-visible spectroscopy (TU-1901) at a wavelength of 254 nm. The surface morphology and element components of the virgin and fouled ceramic membranes were analyzed by scanning electron microscopy (SEM) and energy-dispersive X-ray (EDX) spectroscopy (SU-70, HITACHI, Tokyo, Japan), respectively. The membrane samples were dried in a vacuum oven for 10 h and then coated before SEM analysis.

2.4. Membrane Fouling Analysis and Cleaning Strategy

After finishing each experiment, physical cleaning was applied as follows. The hydraulic reversible resistance and irreversible resistance could be calculated from TMP and flux data using Darcy’s Law:

where J is the permeate flux accordingly; μ is the viscosity of water at 25 °C (0.8949 × 10−2 Ns/m2). Rt is the total ceramic membrane resistance at end of the experiment, Rm is the intrinsic membrane resistance, Rr is the resistance of hydraulic reversible resistance after physical cleaning and Rir is the resistance that cannot be recovered by physical cleaning.

The fouled membrane was cleaned by the following steps: First of all, after stopping its running, the system aeration with concentrated air was injected into a pipe with holes to generate air bubbles. Membrane fouling caused by cake layer on the membrane surface can be partially cleaned through air scouring for 30 min. Then, clean tap water pre-filtered using a filtration cartridge was used for membrane backwash with a pressure of 2 bar for 30 min. Consequently, the fouling resistance Rr caused by cake layer Rcake and pore blocking Rpore that can be removed by physical cleaning was determined by measuring the pure water flux and TMP of the membrane. The fouling that can be removed in the first two steps is hydraulic reversible fouling. After physical cleaning, the final pure water flux and TMP was observed to calculate irreversible fouling Rir based on Equations (1)–(3).

3. Results and Discussion

3.1. Investigation on the Operation of the Hybrid System

3.1.1. Effect of Coagulation

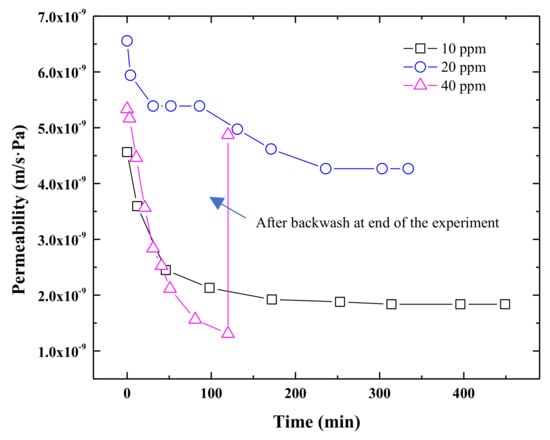

In this study, different dosages of coagulant were applied to investigate the effect of PACl dosing concentration on the performance of this hybrid system. The permeability changes at three levels of coagulant concentration were shown in Figure 2. With 10 ppm dosage, a rapid flux decline was observed and the permeability reduced to 2 × 10−9 m/s·Pa after ~100-min filtration.

Figure 2.

The effect of coagulation dosing concentration on membrane system performance. Other experimental conditions: Coagulation method: In-situ coagulation; Operation mode: periodical relaxation, w/o backwashing, w/o aeration; Operation cycle: on/off ratio 60:1; Initial flux: ~120 LMH.

This serious membrane fouling may be attributed to the residual organic foulants which were left over with an insufficient coagulant. Further increasing the concentration of coagulant to 20 ppm, the permeability of this system was successfully enhanced for the whole operation period, suggesting an optimum dosage of coagulant of 20 ppm for this system. With further addition of coagulant of 40 ppm, surprisingly a dramatic flux decline was recorded. At this condition, there may be lots of excess coagulant left over in the feed solution, which in turn acted as foulants, and led to a serious fouling problem. To further examine the fouling mechanism at 40 ppm coagulant, backwashing was applied, and the result shown in Figure 2 revealed that the flux was almost fully recovered. Fortunately, the fouling caused by the excess coagulant was easy to be removed by backwashing, while it suggested that excess amount of coagulants would increase the hydraulic reversible fouling. Accordingly, the different filtration behaviors may be due to the coagulation efficiency and the size of formed floc at different coagulant dosages. The size of floc highly depended upon the dosage concentration where the largest floc size can be obtained with proper coagulant dosage [29].

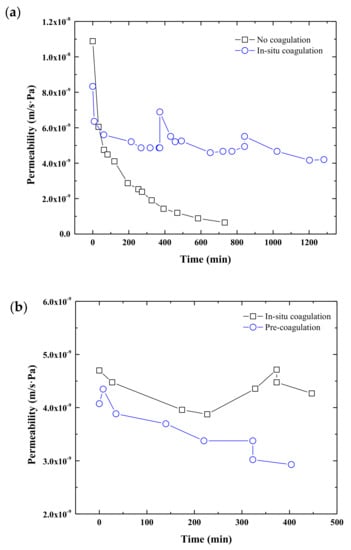

As showed above, the optimal coagulation dosage in this system was 20 ppm. Unless otherwise specified, all the following tests were conducted with 20 ppm dosage and operated at periodical relaxation mode without aeration or interval backwashing. The filtration behaviors of in-situ coagulation, pre-coagulation and no coagulation were compared and demonstrated in Figure 3. As can be seen in Figure 3a, mitigation of fouling by addition of coagulant was prominent. Much higher permeability was observed compared to the filtration without coagulant. Furthermore, it showed that at the same initial operation flux pre-coagulation induced much more severe fouling of membrane. As can be found in Figure 3b, the higher permeability was recorded in the in-situ coagulation. All these results suggested that the in-situ coagulation greatly improved membrane performance. The possible reason was that the cake layer formed by coagulation flocs may work as pre-filters which retained the small foulants thus helped to reduce fouling in the internal pores and membrane surface. Consequently, the in-situ coagulation was better than pre-coagulation. It suggested that the optimal in-situ coagulation would result with good performance of membrane system via efficiently controlling membrane fouling control in a hybrid membrane process.

Figure 3.

The effect of coagulation method on the performance of the hybrid membrane system: (a) A comparison between No coagulation and In-situ coagulation; (b) A comparison between In-situ coagulation and Pre-coagulation; Other experimental conditions: Coagulant concentration: 20 ppm; Operation mode: periodical relaxation, w/o backwashing, w/o aeration; Operation cycle: on/off ratio 60:1.

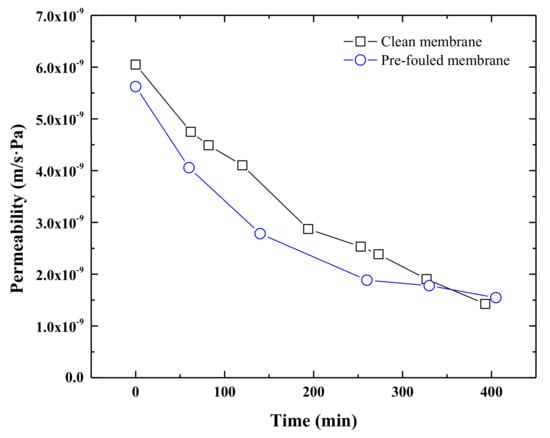

In order to characterize the effect of coagulation flocs deposited on the membrane surface, a pre-fouled membrane was used to test the performance compared with a virgin membrane. The results were shown in Figure 4. It can be found that the cake layer formed on the membrane surface does not affect the membrane performance. By comparing the permeability of these membranes, there was no obvious difference between the two conditions. Pre-deposition process in which adsorbent layers are pre-deposited onto the membrane surface before filtration was also applied to eliminate membrane fouling. This phenomenon also help to illustrate the better behavior for in-situ coagulation than pre-coagulation. These adsorbent layers could be powdered activated carbon (PAC), Al hydrolytic flocs [31], heated iron particles, nano particles and so on.

Figure 4.

The comparison of membrane performance between a clean membrane and a pre-fouled membrane. Other experimental conditions: Coagulant concentration: 20 ppm; Coagulation method: In-situ coagulation; Operation mode: periodical relaxation, w/o backwashing, w/o aeration; Operation cycle: on/off ratio 60:1; Initial flux: ~120 L/m2·h (LMH).

3.1.2. Effect of Initial Flux

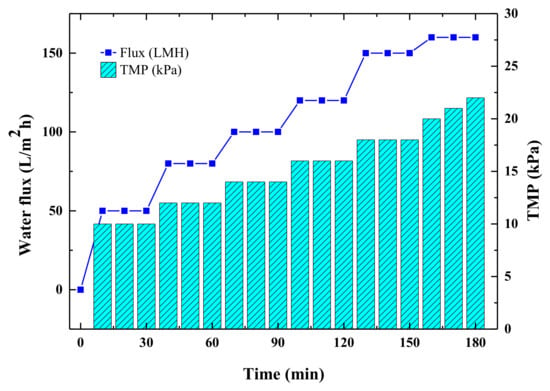

Critical flux is an important parameter for membrane system operation, since the number of membrane modules utilized and footprints will be reduced if the system can operate at a relative lager flux for a long time. According to Field et al. who introduced the concept of critical flux [32], the critical flux hypothesis for microfiltration (MF) is that the decline of flux will not occur along with operation time if the initial flux is below the critical flux. More severe flux decline and membrane fouling would take place when the operation flux is higher than it [15]. Wu et al. found that the productivity for harvesting microalgae cells under super-critical flux conditions was three times higher than the sub-critical flux condition [15], and the super-critical flux condition induced more severe membrane fouling. Thus, it is essential to set up proper operation parameters including initial flux, operation mode and aeration for the application of a membrane system. To alleviate membrane fouling, the hybrid membrane system is better operated at low or near the critical flux. In this study, the critical flux under the condition that in-situ coagulation with ceramic membrane by adding 20 ppm PAC was determined. The result was shown in Figure 5. Each period of operation lasted for 30 min for the setting of water flux. The change in TMP was recorded. The critical flux for the test condition was determined to be around 150 LMH.

Figure 5.

The water flux and transmembrane pressure (TMP) change during limiting flux tests. Other experimental conditions: Coagulant concentration: 20 ppm; Coagulation method: In-situ coagulation; Operation mode: periodical relaxation, w/o backwashing, w/o aeration; Operation cycle: on/off ratio 60:1.

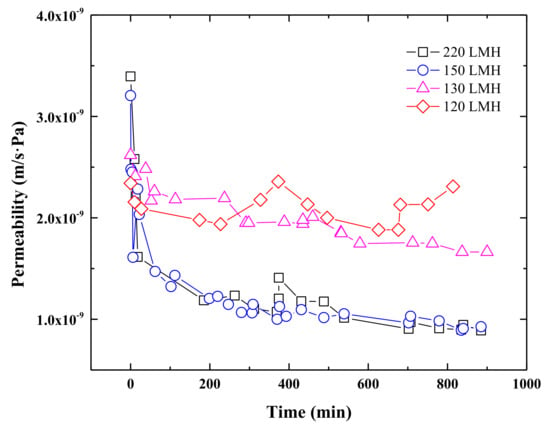

The effect of different initial flux was also investigated and the results were shown in Figure 6. At the high operation fluxes of 220 LMH and 150 LMH, there were much rapider flux declines compared with the other two initial fluxes (130 LMH and 120 LMH respectively). This may be attributed to the accumulation of foulants in membrane pores and the tighter attachment of coagulation flocs on the membrane surface, resulting from a higher permeate drag force induced by the high operation frequency of the pump, large permeate volume and more severe concentration polarization [33]. The colloidal particles and coagulation flocs attached on the membrane surface through more frequent colliding between them and the membrane surface at high initial flux. The cake layer was further compressed by the higher TMP at a higher initial flux [34]. As shown in Figure 6, the membrane flux decreased dramatically in about 5 min at high initial flux. For the initial flux at 130 and 120 LMH, the permeability can be successfully maintained at a stable status along with the whole operation time. This phenomenon can be illustrated by the attachment coefficient, which is a function, as permeate flux diminished to zero at flux lower than critical flux [35]. Consequently, the optimal initial flux for this hybrid system was around 120 LMH, consistent with the result obtained in Figure 5.

Figure 6.

The effect of initial flux on the hybrid membrane system performance. Other experimental conditions: Coagulant concentration: 20 ppm; Coagulation method: In-situ coagulation; Operation mode: periodical relaxation, w/o backwashing, w/o aeration; Operation cycle: on/off ratio 60:1.

3.1.3. Effect of Operation Mode

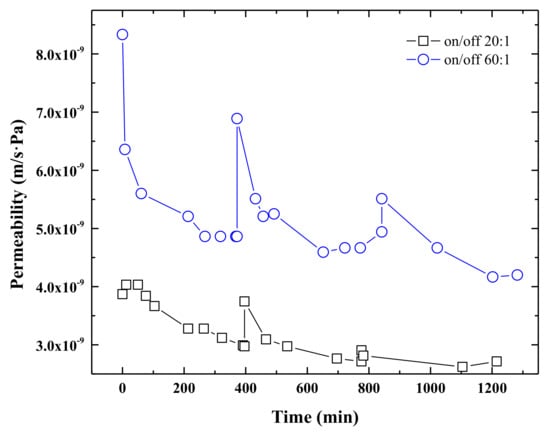

There are three different operation modes for the membrane process, including filtration with periodical backwash, filtration with the periodical relaxation and the continuous mode of filtration. Filtration with periodical backwash and periodical relaxation are effective membrane fouling control strategies for long-term sustainability of flux. Figure 7 compared the membrane performance with an operation mode of filtration with periodical relaxation: the on/off ratios were 20:1 and 60:1, respectively. It showed that the on/off ratio of 60:1 provided a much higher permeability of this system. At every operation recycle, the periodical relaxation for both conditions helped to increase membrane flux. While after a running of 20 h, the on/off ratio of 60:1 seemed to be much better at maintaining the permeate flux for a long-term operation. However, the permeability of on/off ratio of 60:1 decreased to a remarkably low level. Thus, in this study, for the operation of in-situ coagulation hybrid with flat-ceramic membrane, the on/off ratio of 60:1 was applicable for the current feed solution.

Figure 7.

The effect of operation cycle on the hybrid membrane system performance. Other experimental conditions: Coagulant concentration: 20 ppm; Coagulation method: In-situ coagulation; Operation mode: periodical relaxation, w/o backwashing, w/o aeration.

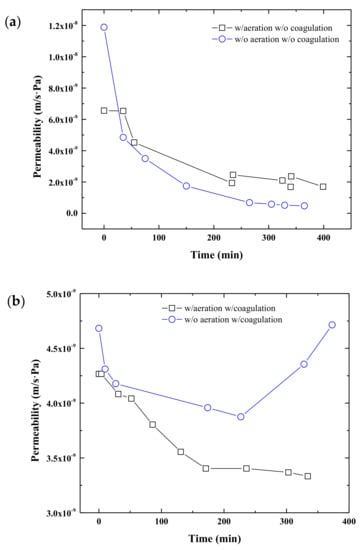

Aeration is an important hydrodynamic parameter that needs to be carefully controlled to avoid excessive membrane fouling. It is normally coupled with backwashing for fouling control in the industry by losing or removing cake layer on the membrane surface. It can be seen from Figure 8a that when purifying water using a flat-ceramic membrane only, aeration in the membrane tank can help to reduce membrane fouling. Figure 8b showed the membrane performance during the operation of the hybrid membrane system with in-situ coagulation. It turned out that the membrane system performed better without aeration viewed from the permeability. It is interesting to note the phenomena that aeration did not contribute to the improvement of the efficiency in this particular membrane system. It had been reported that aeration did not necessarily improve the membrane performance at some circumstances, and even induced more severe fouling [36], especially in hybrid coagulation and the membrane system. The process of coagulation started with the collision between positively-charged coagulants and negatively-charged colloidal particles, and then flocs in small size formed. The flocs grow rapidly and joined together to form larger flocs [37]. The floc size would be reduced due to the introduced shear forces by aeration. It also had been found that the critical flux can be enhanced efficiently in a coagulation and membrane system by applying lower frequent vibration other than higher frequencies, as the flocs were broken down with the increasing of turbulent conditions [38].

Figure 8.

The effect of aeration on the performance of this hybrid membrane system. (a) Operation mode: periodical relaxation, w/o backwashing; Operation cycle: on/off ratio: 60:1, Coagulation: w/o coagulation; (b) Operation mode: periodical relaxation, w/o backwashing; Operation cycle: on/off ratio: 20:1, Coagulation: In-situ coagulation. Other experimental conditions: Coagulant concentration: 20 ppm; Initial flux: ~120 LMH.

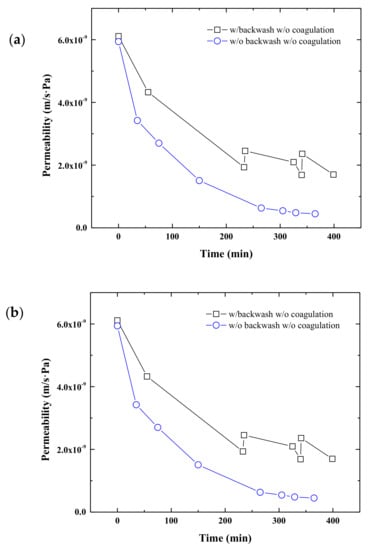

Backwashing is usually applied during the operation of a membrane system to eliminate membrane fouling. During the operation intervals, backwash can recover the reversible resistance, even that the total irreversible fouling keeps increasing within each cycle. Figure 9 compared the membrane performance with and without backwashing under different operation modes. As shown in Figure 9a, backwashing at each operation cycle minimized membrane fouling by immediately filtrating the feed solution without coagulation pretreatment. At the end of experiments, membrane flux was 15.3% and 24.3% declines with and without backwash, respectively. The TMP with backwash changed from 10 kPa to 46 kPa, and the TMP without backwash increased from 10 kPa to 63 kPa, demonstrating a more severe membrane fouling. It is surprising to note that a contrary conclusion was found for the condition of in-situ coagulation. As described in Figure 9b, without backwashing, the permeability decreased from 6.7 m/s·kPa to 4.3 m/s·kPa, and while operating with backwashing, the membrane permeability decreased from 6.4 m/s·kPa to 2.1 m/s·kPa. These results indicated that filtration without periodical backwash was a much better operation mode for the hybrid membrane system in this study. Actually, it had been discussed that backwashing was not always working properly for all membrane processes. Ma et al. found that backwashing cannot remove the pre-layered floc layer on the UF membrane surface due to the strong adhesion force caused by Al flocs and HA [31]. Ye and co-works described that although optimum backwashing time (set at 30 s) helped to reduce the increasing of TMP for each operation recycle, while excess backwash might also lead to fouling [39]. The experimental results in this study also demonstrated that backwashing was also not always efficient in removing membrane fouling. Long time backwashing or high backwash strength would aggravate membrane fouling due to the decomposing of the fouling cake layer and breaking of the lumen of the membrane.

Figure 9.

The effect of backwash on the hybrid membrane system performance. (a) Operation mode: periodical relaxation, w/o aeration; Operation cycle: on/off ratio: 60:1; Coagulation: w/o coagulation; Initial flux: ~120 LMH; (b) Operation mode: periodical relaxation, w/o aeration; Operation cycle: on/off ratio: 20:1, Coagulant concentration: 20 ppm; Coagulation method: In-situ coagulation; Initial flux: ~150 LMH. Other experimental conditions: Backwashing time for each operation cycle: 30 s.

In terms of the results obtained in this study, the backwash for an in-situ coagulation and membrane system might break the loose cake layer formed by coagulation flocs on the membrane surface and decompose the coagulation flocs to small particles. Simultaneously, the membrane fouling would be more severe.

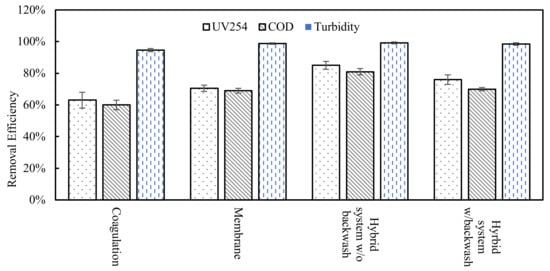

3.2. Performance of the Hybrid System

The membrane system integrating coagulation and membrane process had a significant improvement in the removal of humic acid [40]. The performance of our hybrid system was also analyzed in terms of UV254, COD and turbidity removal. As shown in Figure 10, coagulation can remove more than 60% organic fouling and the removal efficiency of UV254 and COD can be as high as 85% and 81%, respectively, using this hybrid membrane system. The permeate turbidity after membrane filtration reduced from 1.03 NTU to 0.2 NTU. For the operation mode with backwash in each operation recycle, however, the removal efficiencies of UV254 and COD were 80% and 70% respectively, which were lower than that without backwash. As it had been mentioned in Section 3.1.3, backwash did not mitigate membrane fouling during the long run. Membrane fouling during submerged ultrafiltration is mainly dominated by cake filtration and pore blocking, or their combination [41,42]. The cake layer formed on the membrane surface can improve the permeate quality of the hybrid system [43,44]. Backwash worked out to be an inefficient operation mode for this hybrid membrane system, not only for membrane fouling control, but also for the quality of permeate.

Figure 10.

The comparison of pollutants removal efficiency between coagulation, membrane filtration, hybrid system without backwash and hybrid system with backwash. Other experimental conditions: Coagulant concentration: 20 ppm; Coagulation method: In-situ coagulation; Operation mode: periodical relaxation, w/o backwashing, w/o aeration; Operation cycle: on/off ratio 60:1; Initial flux: ~120 LMH.

The energy consumption of a membrane system is dependent on factors including system design and footprint, water recovery and capacity, membrane type and configuration, and the operation strategy [45]. Bubbling through aeration is a common and efficient strategy for membrane fouling control, especially in a submerged membrane system [46]. However, the energy consumption of aeration is considerably high (approximately 50% of the total energy consumed during the water treatment process utilizing membrane technology) [47,48]. In consequence, a certain potential for energy savings can be facilitated by optimizing the operational strategy. Many efforts have been down by increasing bubbling efficiency [49] or adding mechanical strength [38,50], thus to control membrane fouling and decrease the energy consumption of the membrane systems. The improvements achieved in this study in the membrane performance and foulant removal suggested that the capital costs could be reduced by eliminating flocculation and sedimentations zones. Besides, our results suggested that the most efficient operation mode was without aeration and backwashing, which would be efficient in energy saving.

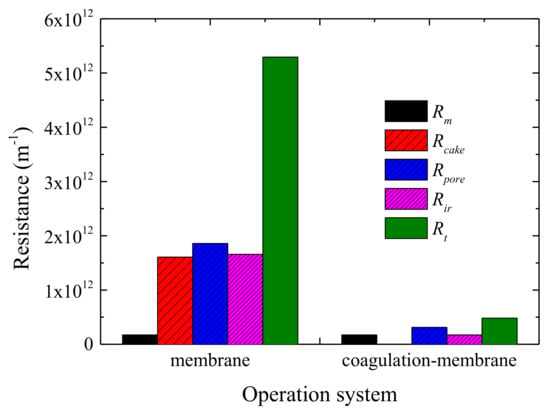

3.3. Membrane Fouling

In order to identify the contribution of different types of fouling resistance, the hydraulic filtration resistances were calculated with Equations (1) and (2) using a resistance-in-series model. The results are given in Figure 11. The comparison of with and without in-situ coagulation obviously showed that the hybrid system had a much higher efficiency in fouling control. Both hydraulic reversible and irreversible fouling were reduced dramatically with in-situ coagulation.

Figure 11.

The comparison of membrane fouling resistance between membrane filtration and hybrid membrane system.

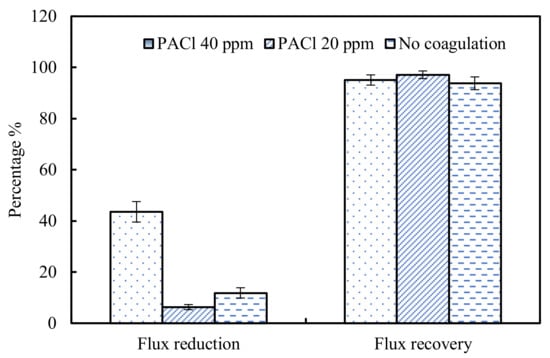

Mechanical force cleaning includes air scouring and clean water backwashing. After finishing the experiments, physical cleanings were applied. The flux reduction and flux recovery compared with the initial flux were presented in Figure 12. Obviously, it indicated that in-situ coagulation with optimum coagulant dosage demonstrated a minimized flux reduction and the highest water recovery (97.1%). The cleaning process was also captured with photos in the Supplementary Materials (Figure S1b–d). It is further found that the cake layer formed on the membrane surface during in-situ coagulation and membrane filtration can be fully removed by physical cleaning. Other remaining irreversible fouling caused by soluble organic foulant can be removed by chemical cleaning. The water flux of the fouled membrane can be fully recovered after chemical cleaning by soaking the membrane module in 0.01 mM NaClO solution for 2 h. The fouled membrane of the hybrid system was also analyzed, and more information can be found in the Supplementary Materials.

Figure 12.

The comparison of flux recovery after physical cleaning by air scouring and backwashing with in-situ coagulation and without coagulation.

4. Conclusions

In this paper, a study was conducted on a hybrid system containing in-situ coagulation and flat-ceramic membrane for drinking water purification from polluted surface water. A series of operation parameters were systematically optimized, including dosage of coagulant, type of coagulation, initial flux, operating cycle, aeration and backwash. Results suggested that running this system at an initial flux ~120 LMH with on/off ratio of 60:1 and in-situ coagulation of 20 ppm coagulant without aeration and backwash would provide a good performance. With the optimum operation, this hybrid system with in-situ coagulation and membrane had the lowest fouling propensity. The coagulant flocs attached on the membrane surface formed a loose cake layer which can prevent the immediate exposure of membrane surface to organic foulants. The in-situ coagulation not only minimized membrane fouling, but also improved the quality of permeate water. This system removed 85% UV254 and 81% COD, and resulted a permeate with the turbidity as low as 0.2 NTU, which was far below the standard of China for drinking water (1 NTU). In addition, the loose cake layer formed on membrane can be easily removed by physical cleaning, including air scouring and backwashing. The flux recovery rate can be as high as 97.1% percent. As a result of the operation without aeration and backwashing, the hybrid system was operated with minimum energy consumption. The results in this study provided important implications for the application of future flat-ceramic membranes. Further study should focus on the efficient of energy conservation and the scale up of the system.

Supplementary Materials

The following are available online at https://www.mdpi.com/2073-4441/11/12/2606/s1.

Author Contributions

S.M. and M.Z. conceived and designed the experiments; all authors participated equally in the conceptualization, methodology, software, validation, formal analysis, investigation, resources, data curation, original draft preparation, review and editing, visualization and supervision. Project administration and funding acquisition, S.M. and M.Z. All authors read and approved the final manuscript.

Funding

This research was co-funded by a grant from Suntar Membrane Technology (Xiamen) Co. Ptd and Xiamen University and a grant from the National Natural Science Foundation of China [No. 51808019].

Acknowledgments

This research was supported by the National Natural Science Foundation of China.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shannon, M.A.; Bohn, P.W.; Elimelech, M.; Georgiadis, J.G.; Mariñas, B.J.; Mayes, A.M. Science and technology for water purification in the coming decades. Nature 2008, 452, 301–310. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.Y.; Yang, Z.; Guo, H.; Wen, J.J.; Nghiem, L.D.; Cornelissen, E. Potable water reuse through advanced membrane technology. Environ. Sci. Technol. 2018, 52, 10215–10223. [Google Scholar] [CrossRef] [PubMed]

- Ibrar, I.; Naji, O.; Sharif, A.; Malekizadeh, A.; Alhawari, A.; Alanezi, A.A.; Altaee, A. A review of fouling mechanisms, control strategies and real-time fouling monitoring techniques in forward osmosis. Water 2019, 11, 695. [Google Scholar] [CrossRef]

- Gao, W.; Liang, H.; Ma, J.; Han, M.; Chen, Z.-L.; Han, Z.-S.; Li, G.-B. Membrane fouling control in ultrafiltration technology for drinking water production: A review. Desalination 2011, 272, 1–8. [Google Scholar] [CrossRef]

- Babayev, M.; Du, H.; Botlaguduru, V.S.V.; Kommalapati, R.R. Zwitterion-modified ultrafiltration membranes for permian basin produced water pretreatment. Water 2019, 11, 1710. [Google Scholar] [CrossRef]

- Kulesha, O.; Maletskyi, Z.; Kvaal, K.; Ratnaweera, H. Strategy for flux enhancement in biofilm ceramic membrane bioreactor applying prepolymerized and non-prepolymerized inorganic coagulants. Water 2019, 11, 446. [Google Scholar] [CrossRef]

- Bottino, A.; Capannelli, C.; Del Borghi, A.; Colombino, M.; Conio, O. Water treatment for drinking purpose: Ceramic microfiltration application. Desalination 2001, 141, 75–79. [Google Scholar] [CrossRef]

- Jeong, Y.; Hermanowicz, S.W.; Park, C. Treatment of food waste recycling wastewater using anaerobic ceramic membrane bioreactor for biogas production in mainstream treatment process of domestic wastewater. Water Res. 2017, 123, 86–95. [Google Scholar] [CrossRef]

- Niwa, T.; Yamashita, T.; Mitsumizo, M.; Takahashi, M.; Hatamoto, M.; Yamaguchi, T.; Kekre, K.A.; Lin, L.L.; Tao, G.; Seah, H. Pilot-scale test of industrial wastewater treatment by UASB and MBR using a ceramic flat sheet membrane for water reuse. J. Water Reuse Desalin. 2017, 8, 490–496. [Google Scholar] [CrossRef]

- Mouiya, M.; Abourriche, A.; Bouazizi, A.; Benhammou, A.; El Hafiane, Y.; Abouliatim, Y.; Nibou, L.; Oumam, M.; Ouammou, M.; Smith, A.; et al. Flat ceramic microfiltration membrane based on natural clay and Moroccan phosphate for desalination and industrial wastewater treatment. Desalination 2018, 427, 42–50. [Google Scholar] [CrossRef]

- Qiu, Q.; Zhao, B.W.; Qiu, L.P. Development of flat ceramic membrane technology on municipal wastewater treatment. IOP Conf. Ser. Mater. Sci. Eng. 2018, 392, 022036. [Google Scholar] [CrossRef]

- Kulesha, O.; Maletskyi, Z.; Ratnaweera, H. Multivariate chemometric analysis of membrane fouling patterns in biofilm ceramic membrane bioreactor. Water 2018, 10, 982. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, L.; Roddick, F.A. Understanding the fouling of a ceramic microfiltration membrane caused by algal organic matter released from Microcystis aeruginosa. J. Membr. Sci. 2013, 447, 362–368. [Google Scholar] [CrossRef]

- Jana, A.; Ghosh, S.; Majumdar, S. Energy efficient harvesting of Arthrospira sp. using ceramic membranes: Analyzing the effect of membrane pore size and incorporation of flocculant as fouling control strategy. J. Chem. Technol. Biotechnol. 2018, 93, 1085–1096. [Google Scholar] [CrossRef]

- Wu, X.; Zhou, C.; Li, K.; Zhang, W.; Tao, Y. Probing the fouling process and mechanisms of submerged ceramic membrane ultrafiltration during algal harvesting under sub- and super-critical fluxes. Sep. Purif. Technol. 2018, 195, 199–207. [Google Scholar] [CrossRef]

- Nędzarek, A.; Drost, A.; Harasimiuk, F.; Tórz, A.; Bonisławska, M. Application of ceramic membranes for microalgal biomass accumulation and recovery of the permeate to be reused in algae cultivation. J. Photochem. Photobiol. B Biol. 2015, 153, 367–372. [Google Scholar] [CrossRef]

- Meng, S.; Fan, W.; Li, X.; Liu, Y.; Liang, D.; Liu, X. Intermolecular interactions of polysaccharides in membrane fouling during microfiltration. Water Res. 2018, 143, 38–46. [Google Scholar] [CrossRef]

- Matsushita, T.; Matsui, Y.; Shirasaki, N.; Kato, Y. Effect of membrane pore size, coagulation time, and coagulant dose on virus removal by a coagulation-ceramic microfiltration hybrid system. Desalination 2005, 178, 21–26. [Google Scholar] [CrossRef]

- Hakami, M.W.; Alkhudhiri, A.; Zacharof, M.-P.; Hilal, N. Towards a sustainable water supply: Humic acid removal employing coagulation and tangential cross flow microfiltration. Water 2019, 11, 2093. [Google Scholar] [CrossRef]

- Campinas, M.; Rosa, M.J. Assessing PAC contribution to the NOM fouling control in PAC/UF systems. Water Res. 2010, 44, 1636–1644. [Google Scholar] [CrossRef]

- Song, J.; Zhang, Z.; Zhang, X. A comparative study of pre-ozonation and in-situ ozonation on mitigation of ceramic UF membrane fouling caused by alginate. J. Membr. Sci. 2017, 538, 50–57. [Google Scholar] [CrossRef]

- Tang, S.; Zhang, Z.; Zhang, X. Coupling in-situ ozonation with ferric chloride addition for ceramic ultrafiltration membrane fouling mitigation in wastewater treatment: Quantitative fouling analysis. J. Membr. Sci. 2018, 555, 307–317. [Google Scholar] [CrossRef]

- Song, J.; Zhang, Z.; Tang, S.; Tan, Y.; Zhang, X. Does pre-ozonation or in-situ ozonation really mitigate the protein-based ceramic membrane fouling in the integrated process of ozonation coupled with ceramic membrane filtration? J. Membr. Sci. 2018, 548, 254–262. [Google Scholar] [CrossRef]

- Blöcher, C.; Dorda, J.; Mavrov, V.; Chmiel, H.; Lazaridis, N.K.; Matis, K.A. Hybrid flotation—Membrane filtration process for the removal of heavy metal ions from wastewater. Water Res. 2003, 37, 4018–4026. [Google Scholar] [CrossRef]

- Noguchi, M.; Aoki, M.; Kozono, H.; Kouchiwa, H.; Yoda, Y. The Study on the ceramic membrane wastewater reuse system with pre-ozonation and coagulation. Ozone Sci. Eng. 2013, 35, 243–248. [Google Scholar] [CrossRef]

- Sun, H.; Liu, H.; Wang, S.; Cheng, F.; Liu, Y. Ceramic membrane fouling by dissolved organic matter generated during on-line chemical cleaning with ozone in MBR. Water Res. 2018, 146, 328–336. [Google Scholar] [CrossRef] [PubMed]

- Fiksdal, L.; Leiknes, T. The effect of coagulation with MF/UF membrane filtration for the removal of virus in drinking water. J. Membr. Sci. 2006, 279, 364–371. [Google Scholar] [CrossRef]

- Phan, D.D.; Babick, F.; Trịnh, T.H.T.; Nguyen, M.T.; Samhaber, W.; Stintz, M. Investigation of fixed-bed photocatalytic membrane reactors based on submerged ceramic membranes. Chem. Eng. Sci. 2018, 191, 332–342. [Google Scholar] [CrossRef]

- Low, S.L.; Ong, S.L.; Ng, H.Y. Characterization of membrane fouling in submerged ceramic membrane photobioreactors fed with effluent from membrane bioreactors. Chem. Eng. J. 2016, 290, 91–102. [Google Scholar] [CrossRef]

- Feng, L.; Wang, W.; Feng, R.; Zhao, S.; Dong, H.; Sun, S.; Gao, B.; Yue, Q. Coagulation performance and membrane fouling of different aluminum species during coagulation/ultrafiltration combined process. Chem. Eng. J. 2015, 262, 1161–1167. [Google Scholar] [CrossRef]

- Ma, B.; Wang, X.; Hu, C.; Jefferson, W.A.; Liu, H.; Qu, J. Antifouling by pre-deposited Al hydrolytic flocs on ultrafiltration membrane in the presence of humic acid and bovine serum albumin. J. Membr. Sci. 2017, 538, 34–40. [Google Scholar] [CrossRef]

- Field, R.W.; Wu, D.; Howell, J.A.; Gupta, B.B. Critical flux concept for microfiltration fouling. J. Membr. Sci. 1995, 100, 259–272. [Google Scholar] [CrossRef]

- Tang, C.Y.; Kwon, Y.-N.; Leckie, J.O. Fouling of reverse osmosis and nanofiltration membranes by humic acid—Effects of solution composition and hydrodynamic conditions. J. Membr. Sci. 2007, 290, 86–94. [Google Scholar] [CrossRef]

- Babel, S.; Takizawa, S. Microfiltration membrane fouling and cake behavior during algal filtration. Desalination 2010, 261, 46–51. [Google Scholar] [CrossRef]

- She, Q.; Tang, C.Y.; Wang, Y.-N.; Zhang, Z. The role of hydrodynamic conditions and solution chemistry on protein fouling during ultrafiltration. Desalination 2009, 249, 1079–1087. [Google Scholar] [CrossRef]

- Meng, F.; Yang, F.; Shi, B.; Zhang, H. A comprehensive study on membrane fouling in submerged membrane bioreactors operated under different aeration intensities. Sep. Purif. Technol. 2008, 59, 91–100. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, D.; Li, T.; Chow, C.W.K.; Huang, C. Influence of floc structure on coagulation–microfiltration performance: Effect of Al speciation characteristics of PACls. Sep. Purif. Technol. 2010, 72, 22–27. [Google Scholar] [CrossRef]

- Genkin, G.; Waite, T.D.; Fane, A.G.; Chang, S. The effect of vibration and coagulant addition on the filtration performance of submerged hollow fibre membranes. J. Membr. Sci. 2006, 281, 726–734. [Google Scholar] [CrossRef]

- Ye, Y.; Sim, L.N.; Herulah, B.; Chen, V.; Fane, A.G. Effects of operating conditions on submerged hollow fibre membrane systems used as pre-treatment for seawater reverse osmosis. J. Membr. Sci. 2010, 365, 78–88. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X. Ultrafiltration with in-line coagulation for the removal of natural humic acid and membrane fouling mechanism. J. Environ. Sci. 2006, 18, 880–884. [Google Scholar] [CrossRef]

- Iritani, E.; Katagiri, N.; Takenaka, T.; Yamashita, Y. Membrane pore blocking during cake formation in constant pressure and constant flux dead-end microfiltration of very dilute colloids. Chem. Eng. Sci. 2015, 122, 465–473. [Google Scholar] [CrossRef]

- Hou, L.; Wang, Z.; Song, P. A precise combined complete blocking and cake filtration model for describing the flux variation in membrane filtration process with BSA solution. J. Membr. Sci. 2017, 542, 186–194. [Google Scholar] [CrossRef]

- Chang, I.-S.; Bag, S.-O.; Lee, C.-H. Effects of membrane fouling on solute rejection during membrane filtration of activated sludge. Process. Biochem. 2001, 36, 855–860. [Google Scholar] [CrossRef]

- Vyrides, I.; Stuckey, D.C. Fouling cake layer in a submerged anaerobic membrane bioreactor treating saline wastewaters: Curse or a blessing? Water Sci. Technol. A J. Int. Assoc. Water Pollut. Res. 2011, 63, 2902–2908. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.; Jang, Y.S.; Jo, Y.; Choi, Y.-J.; Lee, S.; Choi, Y. Application of tubular membranes for surface water treatment: Effect of membrane properties and operation modes. Desalin. Water Treat. 2015, 57, 10077–10085. [Google Scholar] [CrossRef]

- Ndinisa, N.V.; Fane, A.G.; Wiley, D.E. Fouling control in a submerged flat sheet membrane system: Part I —Bubbling and Hydrodynamic Effects. Sep. Sci. Technol. 2006, 41, 1383–1409. [Google Scholar] [CrossRef]

- Krzeminski, P.; van der Graaf, J.H.J.M.; van Lier, J.B. Specific energy consumption of membrane bioreactor (MBR) for sewage treatment. Water Sci. Technol. 2012, 65, 380–392. [Google Scholar] [CrossRef] [PubMed]

- Al-Karaghouli, A.; Kazmerski, L.L. Energy consumption and water production cost of conventional and renewable-energy-powered desalination processes. Renew. Sustain. Energy Rev. 2013, 24, 343–356. [Google Scholar] [CrossRef]

- Howell, J.A.; Chua, H.C.; Arnot, T.C. In situ manipulation of critical flux in a submerged membrane bioreactor using variable aeration rates, and effects of membrane history. J. Membr. Sci. 2004, 242, 13–19. [Google Scholar] [CrossRef]

- Pradhan, M.; Vigneswaran, S.; Kandasamy, J.; Aim, R.B. Combined effect of air and mechanical scouring of membranes for fouling reduction in submerged membrane reactor. Desalination 2012, 288, 58–65. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).