Abstract

Light-duty trucks (LDTs) are often used to tow trailers. Towing increases the load on the engine, and this additional load can affect exhaust emissions. Although heavy-duty towing impacts are widely studied, data on LDT towing impacts is sparse. In this study, portable emissions measurement systems (PEMSs) were used to measure in-use emissions from three common LDTs during towing and non-towing operations. Emission rates were characterized by operating modes defined in the Environmental Protection Agency’s (EPA’s) MOVES (MOtor Vehicle Emissions Simulator) model. The measured emission rates were compared to the default rates used by MOVES, revealing similar overall trends. However, discrepancies between measured rates and MOVES predictions, especially at high speed and high operating modes, indicate a need for refinement in emissions modeling for LDTs under towing operations. Results highlight a general trend of increased CO2, CO, HC, and NOx when towing a trailer compared to non-towing operations across nearly all operating modes, with distinct CO and HC increases in the higher operating modes. Although emissions were observed to be notably higher in a handful of scenarios, results also indicate that three similar LDTs can have distinctly different emission profiles.

1. Introduction

1.1. Background and Scope

Light-duty vehicles encompass a broad range of vehicle types typically used for personal and passenger transport, including sedans, sport utility vehicles (SUVs), and pickup trucks. The market trends for these vehicles have shown considerable shifts in recent years. In 2022, nearly 80% of new U.S. light-duty vehicle sales were a light truck [1]. Moreover, there has been an observable increase in the market share of both pickup trucks and SUVs, reflecting a growing consumer preference for larger, more powerful vehicles.

LDTs are of particular interest because they have a large load range, capable of varying by thousands of pounds between empty and fully loaded states. While specific statistics on how often LDTs operate in towing capacity are needed to clarify their usage patterns further, it is clear that this variability has the potential to affect emissions significantly. Precise estimations of emissions from LDTs are critical for crafting effective management strategies, regulations, and control technologies to curb their environmental footprint. Notably, current emission estimation methods do not fully capture the emissions from LDTs due, in part, to their highly variable payload conditions. Consequently, the conventional approaches may not represent the emissions from these vehicles in real-world scenarios, leading to potential inaccuracies in our overall understanding and management of vehicular emissions. Further, trailer-towing emissions can contribute to concerns related to elevated near-roadway exposures.

Given this context, the primary goal of this research is to provide a more nuanced examination of the impact of towing load on emission estimations from LDTs. The first objective of this study was to measure and compare LDT emission rates for off-cycle operation, specifically for trailer-towing operation. A secondary objective was to compare these LDT emission rates with those generated by an existing emissions model using the U.S. Environmental Protection Agency’s (EPA’s) MOtor Vehicle Emissions Simulator (MOVES) base emission rate table (“emissionRateByAge” table found in the MOVES4 movesdb20240104 database) [2]. Emission factors for LDTs are currently developed based on the assumption that the trucks are used similarly to passenger cars, i.e., without consideration of hauling operation. The work presented here takes steps to evaluate this assumption by measuring tailpipe emissions under light-duty towing operation, and investigates a potential need to broaden the application of conventional approaches to light-duty emissions modeling.

1.2. Literature Review

Measuring vehicle emissions is a critical aspect of environmental research. Common methods for assessing emissions include laboratory chassis dynamometer testing, tunnel studies, near-road air-quality measurements, remote sensing, and the use of portable emissions measurement systems (PEMSs) [3,4,5]. Each method has advantages and limitations, which must be thoroughly understood and carefully considered when using the emissions data in further analyses.

Dynamometer testing is a traditional method in emissions laboratory testing that replicates typical driving conditions through standardized and repeatable driving test cycles, providing precise spatial and temporal resolution. However, the high cost of this method limits the number of vehicles and driving cycles that can be tested, posing challenges for model validation to accurately reflect real-world emission variability. Concerns also include potential sampling bias in laboratory programs and questions about how well laboratory conditions mimic on-road conditions [3,6,7].

Tunnel studies utilize in-tunnel instrumentation to calculate emission factors based on pollutant concentration differences at a tunnel’s entrance and exit, considering tunnel characteristics, traffic flow, and conditions. This method captures emissions from a diverse on-road fleet under controlled conditions, offering detailed insights into inter-vehicle emission variability. However, it relies on indirect estimations, potentially introducing errors and biases due to limited operational conditions and the tunnel’s physical effects on vehicle emissions, such as the smooth driving range, gradients, and piston effect, which may significantly reduce certain emissions [3,8,9,10].

Near-road air-quality measurements involve either directly comparing measured ambient pollutant concentrations with combined emission and dispersion modeling outcomes or inversely calculating emission factors by modeling dispersion and considering local traffic conditions (e.g., multivariate regression modeling). It accounts for various driving conditions and a broad vehicle sample. However, combining emission and dispersion models through indirect measurements introduces potential errors due to simplified assumptions such as perfect mixing or meteorological conditions in estimating non-traffic emission sources, notably household and industrial emissions. The method’s effectiveness is further limited by its focus on specific locations, such as junctions where pollutant levels are higher, leading to potential errors. Reliable validation would benefit from averaging data from multiple sites, though this approach is seldom employed [3,11,12,13].

Remote sensing methods measure emissions by directing an IR/UV beam across roads to assess pollutant ratios to carbon dioxide (CO2), facilitating the calculation of mean emission factors for comparison with model predictions. This method allows for the direct measurement of emissions from a broad vehicle sample, offering a distinct advantage for data collection. However, its application in model validation faces challenges, including the need for several assumptions to convert measured values into emission factors, differences in measurement principles compared to laboratory equipment, and the specificity of measurements to particular pollutants or conditions. Remote sensing captures location-specific emissions data influenced by vehicle speed and acceleration, making the derived emission factors not directly comparable to those averaged over various driving conditions. Additionally, potential deceleration by drivers near the equipment may bias the results, suggesting that remote sensing data is most appropriately used for high-resolution emissions modeling [3,14,15]. Specifically, in studies on trucks, it has been observed that remote sensing efficiently captured emissions from in-use heavy-duty diesel trucks (HDDTs). However, it cannot represent the full operational cycle of these vehicles [16].

Vehicle onboard emissions measurements are used as an alternative to laboratory testing, allowing for the validation of emission factors under real-world driving conditions. Emission factors are determined by comparing total emissions, recorded via onboard devices over a certain distance, for one or several vehicles, offering control over variables such as cold starts and vehicle load. However, challenges such as detection limits, data quality, and the physical constraints of onboard systems have been noted despite advancements in technology and increased usage (e.g., PEMSs). Nonetheless, testing a wide range of vehicles remains limited due to the labor intensity and costs involved, especially with older vehicles that require more setup time due to the lack of easily accessible operational data from the engine management system [3,17,18].

Despite the mentioned limitations, PEMSs are still one of the premier tools used for vehicle onboard emissions measurements. PEMSs are widely adopted in on-road emission testing and stand out for their effectiveness in capturing real-world emissions data and adapting to variable traffic and real-world scenarios [19,20,21]. Their applications in studying emission characteristics of vehicles, particularly LDTs, have been explored in various research efforts [19,22,23,24].

However, there are not many PEMS studies that examine how LDTs’ towing loads impact emissions. A study from India addressed the emission rate differences with varying payloads [25]. In the study, carbon monoxide (CO), CO2, hydrocarbon (HC), and nitrogen oxides (NOx) were addressed based on VSP. The study found that the CO emission rate doubled with load in all VSP modes; however, all the other pollutants were not affected. Another study in China tested on-road emissions from six liquefied natural gas and diesel semi-trailer towing vehicles using a PEMS unit. It found significant discrepancies in emission levels between liquified natural gas and diesel vehicles, and between vehicles meeting different emission standards, with real driving conditions leading to higher emission factors due to frequent acceleration, deceleration, and start–stop activities. Notably, NOx emissions in this study were found to be substantially high compared to the results from dynamometer testing, and total HC emissions from liquified natural gas vehicles far exceeded those from diesel vehicles in the study [26].

The research on HDDTs has been more extensive. Frey et al. (2008) conducted a similar analysis on tandem HDDTs, identifying substantial differences in emissions (44% for CO2, 78% for NOx, 23% for PM, 30% for hydrocarbon (HC), and 22% for CO) between loaded and unloaded states [23]. Song et al. (2019) extended this analysis to HDDTs with varying load levels, observing increased nitrogen oxides, carbon monoxide, and total hydrocarbon emissions (18% to 41% higher) under half and full-load conditions [27]. Wang et al. (2021) used a PEMS unit to analyze on-road HDDTs at different loads, noting significant increases in nitrogen oxides (43% and 59% higher when half-filled than when empty) and in particulate matter (62% and 44% higher when completely loaded) [28]. An important aspect to consider regarding all on-road studies is that traffic variability can present a challenge in maintaining consistent conditions for PEMS testing.

Another approach to analyzing PEMS data involves using vehicle specific power (VSP), as proposed by Jiménez [29]. VSP quantifies the engine power required to overcome forces from rolling and rotational resistances as well as from aerodynamic drag effects. VSP is also a key metric for evaluating emissions used in the EPA’s MOVES model [30]. In addition to MOVES, VSP has been utilized to develop emissions models that consider variable operational characteristics for light-duty vehicles [31,32,33,34,35], transit buses [36,37,38], and HDDTs [39,40,41].

In this study, VSP-based emission rates for LDTs were developed using data from onboard diagnostic devices and PEMSs. The study examines the impact of towing on light-duty truck emissions, both with and without trailers, utilizing operating mode bins from the MOVES model. This approach challenges the assumption in the MOVES model that emission rates for specific operating mode bins remain constant regardless of vehicle load, offering insights on how load conditions affect LDTs’ emissions.

2. Materials and Methods

On-road test runs were performed by three light-duty trucks, with and without a trailer. Tested light-duty trucks were popular and prevalent models that included both gasoline direct injection (GDI) and port fuel injection (PFI) engines. Specifications on selected trucks are listed in Table 1, including vehicle make and model, engine size, engine technology, horsepower, torque, gross vehicle weight rating (GVWR), gross combined weight rating (GCWR), and vehicle weights with and without trailers.

Table 1.

The three tested trucks (abbreviated C13, F11, F14) and their specifications are listed.

All vehicles were made to haul the same trailer weight, and towing capacity was not exceeded for any vehicle. Vehicle and trailer weights were measured using certified CAT scales at a local truck stop (see Figure 1, righthand photo). On-road measurements were collected using 3 PEMS units: 2× SEMTECH DS and 1× SEMTECH ECOSTAR (Sensors Inc., Saline, MI, USA). Figure 1 (lefthand photo) shows a test vehicle with a PEMS unit attached. All PEMS units were calibrated and zeroed before and after every driving route. Specifically, the PEMS equipment used in this study complies with standard operating procedures and is certified and maintained in accordance with the 40 CFR 1065 Subpart J PEMS protocols [42]. In addition, the PEMS post-process software (SEMTECH data processor, version 2.018) has built-in QA/QC protocols to ensure proper sample flows, temperatures, and subsystem components were operating properly during the test and within the tolerances specified in accordance with 40 CFR 1065 Subpart J protocols.

Figure 1.

Test vehicle with PEMS unit attached (photo on left). Same truck in queue to be weighed is shown with trailer attached (photo on right).

Three local on-road routes were selected to maximize the amount of time driven in one of three speed ranges: low-speed range (0–25 mph), mid-speed range (25–50 mph), and high-speed range (>50 mph). Selected routes also included significant grades: the low-speed route hit a max of about 8 degrees of incline, the mid-speed route went to about 5 degrees, and the high-speed route went as high as 6 degrees. On-road testing took place in February 2015. Each vehicle completed at least 6 test runs with a trailer and at least 5 test runs without a trailer (see Table 2). The fuel used was a single batch with approximately 7.2% ethanol, a Reid vapor pressure of 13.1, and roughly 0.5% benzene by volume. (see supplement for additional detail on fuel specs).

Table 2.

Test runs driven per speed route by each truck with and without trailer towing.

2.1. Data Processing

The raw data from each run were saved as individual files following a consistent format. As part of the PEMS data collection process, each dataset was time-aligned using the PEMS proprietary software (SEMTECH data processor, version 2.018) before being analyzed [43]. The process of time aligning the emissions (and other) datasets ensures that all data is temporally matched before analyzing it. Since the exhaust takes a different amount of time to travel through the flow meter (where the flow is measured) to the PEMS sensors (where the concentrations are measured), the data will not be recorded at the correct time in reference to when it came out of the vehicle. All equipment collected data at a 1 s frequency, and the final time-aligned data matched the timestamps from the light-duty truck test runs.

WAAS-capable GPS data (WAAS = Wide Area Augmentation System; GPS = Global Positioning System) was used to calculate ground speed and grade at each point (h_calcvelocity and h_calcgrade). However, the grade calculation was limited by the GPS’s spatial resolution, which often yielded somewhat inaccurate readings. Thus, an improved approach using Light Detection and Ranging (LiDAR) data was utilized to calculate elevation for grade. LiDAR is a technology used to create high-resolution models of ground elevation with a vertical accuracy of 10 cm (4 inches) [44]. LiDAR data is collected as a “point cloud” of individual points reflected from everything on the surface. After the processing, LiDAR data is divided into objects such as road surfaces, bridge decks, vegetation, buildings, etc. LiDAR data for the testing route was collected in 2016 and 2017, and can be acquired from the North Carolina Emergency Management GIS Selection database [45]. This study captured the closest road or bridge deck LiDAR elevation to make improved grade calculations. The study also adopted a simple moving average for every five seconds for smoothing elevation changes.

Data cleaning steps were performed to generate the final compiled emission rate dataset. For LiDAR, data was removed due to known impossibilities such as sharp changes in road grade over a short interval, or instances of erroneously high elevation data that exceeded the known peak grade on the driven routes. A road grade of 15% or higher was set as the safe removal threshold since it was well above the peak grade on driven routes. For PEMSs, missing data and two files with erroneous extreme values attributed to instrument fault were removed. Thus, data was cleaned under the following removal criteria: (1) no emission measurements, (2) extreme emission measurements due to faulty device, (3) no elevation data, (4) instantaneous grade change greater than 5 percentage points, and (5) absolute value of grade greater than or equal to 15%. From the data cleaning process, the dataset was filtered from 267,620 vehicle-seconds to 139,558 vehicle-seconds. The final cleaned and time-aligned data include per-second data from the parameters listed in Table 3.

Table 3.

The final combined dataset is compiled from the data fields listed in the table below. Data fields include PEMS instrument data, vehicle parameters from onboard diagnostics (OBD), GPS data, LiDAR elevation data, test run identifiers (such as which truck, speed route, towing condition), and two calculated fields for ground speed and grade.

2.2. Analytical Approach

An overview of the analysis approach is as follows. First, the analysis focused on assessing differences in engine operation and emissions between towing and non-towing conditions. The first step is to calculate the vehicle specific power (VSP) and operating modes (opmodes) defined by MOVES. Then, the distribution of instantaneous emission rates (in units of grams per second; g/s) is evaluated for statistical significance between runs with a trailer and without a trailer for each opmode bin used in MOVES. Finally, the instantaneous emission rates of the three light-duty trucks are compared with the base MOVES emission rates.

2.3. Calculating MOVES Operating Modes

The U.S. EPA’s MOVES model can be used to estimate vehicle emission rates by analyzing a vehicle’s speed and acceleration, along with other key factors like vehicle weight, categorized by regulatory class and source type. MOVES generates emission rates by determining the amount of time spent in different vehicle operating modes. A key factor in this determination is VSP, which estimates the engine’s power demand according to Equation (1) [46].

where

represents the vehicle’s instantaneous speed (m/s) at time (from GPS ground speed);

a represents the vehicle’s instantaneous acceleration (m/s²), defined as (m/s2);

represents fractional road grade at time ;

represents the acceleration due to gravity (9.8 m/s2);

represents effects of rolling resistance (kW-s/m);

represents effects of rotational resistance (kW-s2/m2);

represents aerodynamic drag effects (kW-s3/m3);

represents the mass of the vehicle (metric tons).

Target road-load coefficients were determined experimentally by performing split coastdowns on each test vehicle with and without trailers. Coastdowns are typically completed by operating a vehicle on a flat, straight road at speeds above 70 mph and then coasting the vehicle down to speeds of 15 mph or below (40 CFR 1066.310). Split coastdown runs are performed in two segments as high-speed coastdowns and low-speed coastdowns. Due to concerns about safely performing the full coastdown on a single route, the high-speed coastdown runs took place on US 70 between Kinston and New Bern, NC, while the lower-speed coastdown runs were located on Hwy 55 between Morrisville and Research Triangle Park, NC. Methodology for road-load procedures and corresponding data collection and calculations are outlined in SAE J2263. The coefficients A, B, and C from the on-road coastdowns for the three test vehicles are shown in Table 4.

Table 4.

Road-load coefficients per vehicle, determined by on-road coastdown testing (with and without trailer in tow).

After calculating VSP, MOVES operating modes are determined according to braking, idling, and three speed ranges described in Table 5. Opmode 0 represents deceleration/braking, which is defined by instant acceleration. Opmode 1 represents idling behavior. All other opmodes are categorized according to VSP and the specified speed range, with opmodes 11 and 21 representing coasting (where VSP is less than 0) and the remaining opmodes representing cruising or acceleration (where VSP can range from 0 to over 30 kW per metric ton).

Table 5.

MOVES opmode definitions (source: U.S. EPA [46]).

2.4. Comparing Instantaneous Emission Rates

Calculated instantaneous emission rates were compared between the three trucks across opmode bins. The methodology for comparison is summarized in the following steps.

- Instantaneous VSP values of three light-duty trucks under different hauling operations (i.e., “with trailer” or “without trailer”) were calculated using Equation (1), where variables A, B, C, and M were input according to each load state.

- VSP values were clustered to generate the opmode bins based on MOVES opmode definitions.

- Opmode distributions were calculated by calculating the percent of time spent per bin for each truck with and without trailers in tow.

- Shapiro–Wilk tests were used to assess the normality of the data at different operating modes to determine the appropriate way to compare the distributions between the towing operations of the trucks.

- As data was found to be nonparametric, Mann–Whitney U tests were used to evaluate significant distinctions between “with trailer” vs. “without trailer” groups per opmode bin at the 0.05 significance level (p < 0.05).

- Finally, the instantaneous emission rate distributions were plotted by opmode bin, with significant distinctions (between with vs. without trailer groups) denoted by “*” to permit visual comparison of towing operations between the three trucks.

These calculated instantaneous emission rates were also compared to MOVES default rates. The MOVES emission rates were obtained by extracting base emission rates (the model does not adjust the rates for local temperature, humidity, and fuels) from the MOVES 4.0.1 model database emissionRateByAge table for the parameters listed in Table 6. The base MOVES emission rates are compared to the on-road emission rates derived from the PEMS data.

Table 6.

Parameters to determine MOVES base rates.

3. Results and Discussion

The results of this work are discussed in two sections. Section 3.1, “Comparison of With vs. Without Trailer Towing,” examines the three tested light-duty trucks and compares data collected from on-road test runs for towing (“with trailer”) and non-towing operations (“without trailer”); time spent per opmode, engine loads, and calculated emission rates are highlighted in sub-sections. In Section 3.2, “Comparison to MOVES Base Emission Rates,” calculated emission rates from combined on-road test runs from the three tested light-duty trucks (with and without trailer towing) are compared to MOVES4 base rates.

3.1. Comparison of with vs. Without Trailer Towing

3.1.1. Opmode and Engine Load Distributions

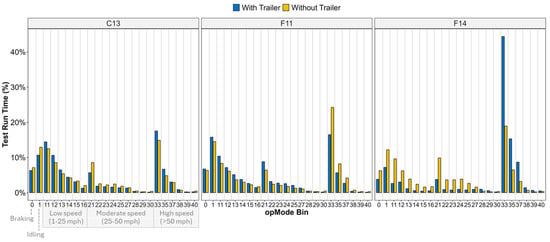

The portion of time spent in each opmode bin during the cumulative test runs is shown for the three light-duty trucks (C13, F11, F14) in Figure 2. The trucks spent the largest portion of driving time in bins 1, 11, 21, and 33. Bin 1 represents idling, while bins 11, 21, and 33 represent the lowest VSP bins per speed category: bin 11 for the low-speed (speed < 25 mph), bin 21 for the mid-speed (25 ≤ speed < 50), and bin 33 for the high-speed category (speed ≥ 50). Across all trucks and towing conditions, around 22% of test run time was spent in bin 33 and 12% of time was spent idling (bin 1), followed by 9% of time spent in low-speed coasting (bin 11). Conversely, <1% of time was spent across all trucks and towing conditions in bins 28, 29, and 30 (the highest VSP bins in the mid-speed range) and in bins 38, 39, and 40 (the highest VSP bins in the high-speed range).

Figure 2.

Percent of time spent in each opmode bin for the three tested trucks (C13, F11, F14), shown with and without trailer towing. To provide additional context, opmode bins have been labeled by speed category.

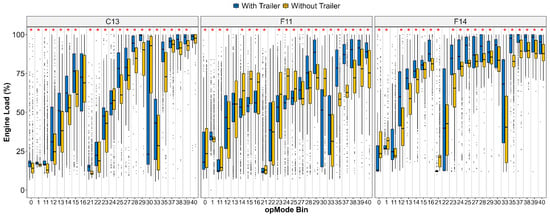

The engine load opmode distributions for the three tested light-duty vehicles are compared with and without trailer towing in Figure 3. Engine load is plotted by opmode bin for each truck, and statistical significance (between “with trailer” vs. “without trailer” groups) is denoted by an asterisk (*) at the top of each bin. When traveling at high speeds over 50 mph (i.e., bins 33–40), all three trucks suggest a trend of increased engine load for towing versus non-towing distributions. Further, these distributions are statistically distinct (p < 0.05) in all but one case (i.e., C13’s bin 40 did not indicate a distinct difference between towing and non-towing distributions). There was a handful of instances that saw higher non-towing engine load distributions that were statistically distinct, such as the large median differences observed in bin 30 for C13 and F11; this result may be attributed to the brief time spent in bin 30 when towing trailers. F11 also saw elevated non-towing distributions for other opmodes, including bins 14–16 and bins 23–25, which showed median non-towing distributions above the 75th percentile for corresponding towing distributions.

Figure 3.

Comparison of engine load (%) at different opmode bins for tested trucks (C13, F11, F14) with and without trailer towing (statistically significant differences [p < 0.05] are indicated by *).

Overall, F14 typically showed higher engine load across a wide range of opmode bins, attributed to having the least powerful engine and lowest torque rating of the three tested trucks. Compared to the other two trucks (with higher torque ratings), F14 had to work harder to pull the same trailer load.

3.1.2. Percent Differences in Emission Rates

To provide an overview of how median emission rates changed in towing and non-towing operation, the percent difference in median emission rates when hauling a trailer was calculated for each opmode bin (Table 7). For the majority of cases (i.e., for 89% of per-bin comparisons), a relative increase in emission rates is observed for trucks towing trailers compared to non-towing operations. All three trucks saw notable per-bin emission increases for towing in the higher opmodes for CO and HC emissions. Another relative increase can be observed for NOx emissions for truck F14, where each bin (other than idling) saw increased NOx rates from towing, with the largest relative increases occurring at the low-speed and mid-speed opmodes. Although towing operation was typically associated with a relative increase in emission rates, there were a few instances where towing was associated with a relative decrease in emission rates. For example, in opmode bin 30, trucks C13 and F11 saw a relative decrease while towing across all four measured pollutants. This may be related to the decreased engine load observed for C13 and F11 trailer-towing data in opmode 30 (as shown in Figure 3).

Table 7.

Emission rate impacts from towing a trailer are shown as median percent differences for the three test vehicles (C13, F11, F14) at each opmode bin. Red-shaded cells indicate trailer towing resulted in a relative increase in emission rates, while blue-shaded cells indicate a relative decrease in emission rates.

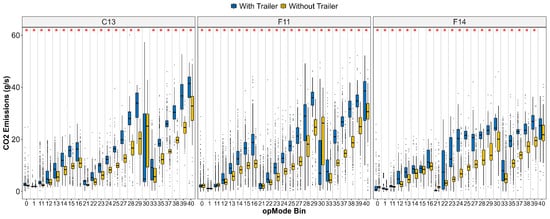

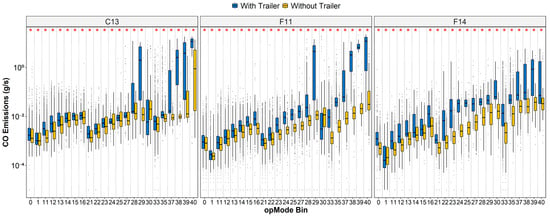

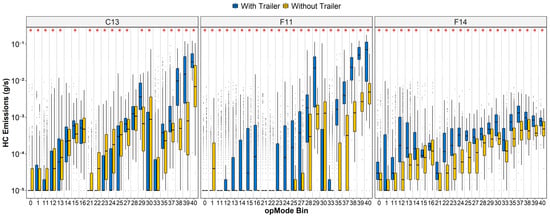

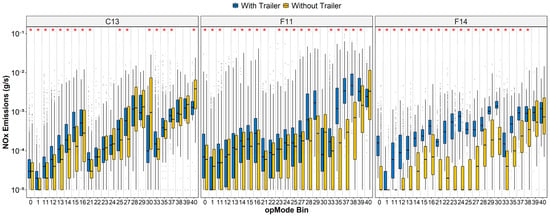

3.1.3. Instantaneous Emission Rate Distributions

To better understand how light-duty hauling may impact tailpipe emissions, the instantaneous emission rates (g/s) for CO2, CO, HC, and NOx are compared for towing vs. non-towing operations in Figure 4, Figure 5, Figure 6 and Figure 7. Emission rates are plotted by opmode bin for each truck, and statistical significance (between towing vs. non-towing groups) is denoted by an asterisk (*) at the top of each bin. Note that, unlike the plot for CO2, the emission rates for CO, NOx, and HC are plotted on a log scale.

Figure 4.

Comparison of CO2 emission rates at different opmode bins for tested trucks (C13, F11, F14) with and without trailer towing (statistically significant differences [p < 0.05] are indicated by *).

Figure 5.

Comparison of CO emission rates (in log scale) at different opmode bins for tested trucks (C13, F11, F14) with and without trailer towing (statistically significant differences [p < 0.05] are indicated by *).

Figure 6.

Comparison of HC emission rates (in log scale) at different opmode bins for tested trucks (C13, F11, F14) with and without trailer towing (statistically significant differences [p < 0.05] are indicated by *).

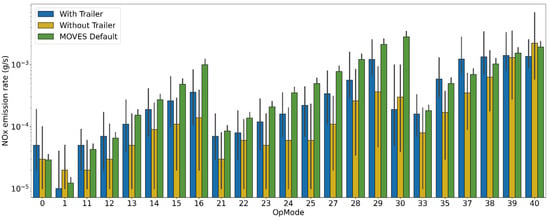

Figure 7.

Comparison of NOx emission rates (in log scale) at different opmode bins for tested trucks (C13, F11, F14) with and without trailer towing (statistically significant differences [p < 0.05] are indicated by *).

CO2 emission rates showed roughly similar trends for the three tested trucks, with higher distributions across nearly all operating modes when hauling a trailer (Figure 4). Towing and non-towing CO2 distributions were low and similar during deceleration/braking (bin 0), idling (bin 1), and coasting (bins 11 and 21) for all three test vehicles. There were two instances, both in opmode 30 for vehicles C13 and F11, where the non-towing data indicated higher median emission rates than the corresponding trailer-towing data; however, only F11’s bin 30 was found to be statistically distinct at the 0.05 significance level. There were only two additional opmode bins across the tested trucks that did not observe statistically significant differences between towing and non-towing groups: F14 bins 15 and 40. All remaining opmode bins across all tested trucks showed significantly distinct per-bin CO2 distributions between “with trailer” and “without trailer” emission rates.

For CO emission rates, the three trucks showed statistically distinct increases from trailer towing in nearly all cases (Figure 5). F14 generally saw clearer distinction between per-bin towing and non-towing distributions across opmodes compared to C13 and F11. However, at higher VSP, C13 and F11 saw some bins in the higher opmodes with more dramatic towing-related CO increases compared to those observed for F14. Similar to aforementioned trends in CO2, there were two instances, in opmode 30 for C13 and F11, where non-towing CO data indicated higher median emission rates, but only F11 showed statistically distinct distributions (p < 0.05).

HC emission rates for towing operations showed higher median distributions than non-towing operations at the higher opmode bins for all three trucks, and towing distributions were higher across all opmode bins for F14 in particular (Figure 6). In vehicles C13 and F11, there were several instances where HC emission rates were too low to be detected by the PEMS and, therefore, showed near-zero median HC emission rates. The research team investigated these near-zero observations second by second and found that the low values are not associated with a measurement error and are correctly reported as below-detection observations (HC detection shown at 10−5 g per second in Figure 6). As with other measured pollutants, HC emission rates for C13 and F11’s bin 30 showed higher non-towing median distributions, which were both found to have statistically distinct distributions at the 0.05 significance level.

Lastly, NOx emission rates were typically slightly elevated under towing operation across opmodes, with more apparent towing increases occurring at some of the higher opmode bins for vehicle F11, and also occurring across nearly all opmode bins for vehicle F14 (Figure 7). C13 and F11 showed higher non-towing NOx rates in bins 30 and 40, but only C13 showed statistically distinct distributions (p < 0.05). In some opmode bins, NOx emission rates were below the detectable level of the PEMS; this was especially prevalent in the non-towing data.

In summary, CO2 and CO emission rates exhibited noticeable distinction between towing and non-towing data for the three test vehicles across opmodes, while HC and NOx trends varied by vehicle and by opmode. Generally, towing a trailer and driving with a higher VSP resulted in higher emission rates.

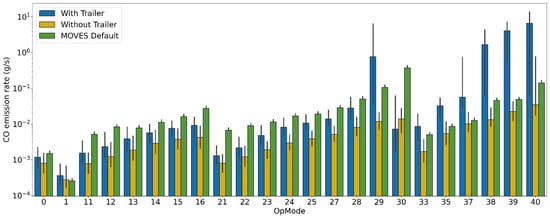

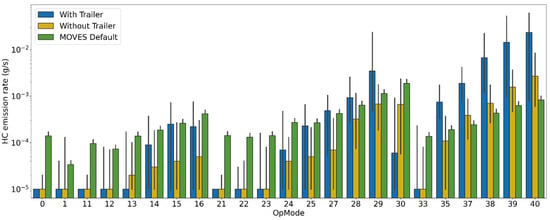

3.2. Comparison to MOVES Base Emission Rates

To gain insight on potential emissions impacts caused by light-duty towing operations that may not be fully captured by MOVES, the calculated emission rates from the tested trucks were compared to MOVES base emission rates. Median emission rates for the three light-duty trucks (shown with 25th percentile and 75th percentile intervals) were compared to MOVES base rates for CO, HC, and NOx in Figure 8, Figure 9, and Figure 10, respectively. These plots are also shown with means and 95% confidence intervals in the Supplementary Material (Figures S1–S3), but keep in mind that test data was not found to be normally distributed and that very little time was spent in some of the opmode bins, resulting in small sample sizes where individual extreme data points can drive the mean.

Figure 8.

Median CO emission rates at different opmode bins for combined trucks with and without trailer towing (shown with 25th and 75th percentile intervals) compared to MOVES base emission rates.

Figure 9.

Median HC emission rates at different opmode bins for combined trucks with and without trailer towing (shown with 25th and 75th percentile intervals) compared to MOVES base emission rates.

Figure 10.

Median NOx emission rates at different opmode bins for combined trucks with and without trailer towing (shown with 25th and 75th percentile intervals) compared to MOVES base emission rates.

Combined CO emission rates (medians with 25th and 75th percentiles) for the tested trucks were compared to MOVES base rates in Figure 8 (see also Figure S1 for plot with CO means and 95% confidence intervals). Towing and non-towing test run data was typically similar or slightly lower than MOVES for the lower opmodes. However, at the higher speed bins, there were noteworthy CO increases associated with trailer towing (showing, roughly, an order of magnitude increase in CO emission rates compared to MOVES).

A similar trend is observed for HC emission rates, where test run data was below or similar to MOVES across the lower opmodes, but the higher-speed bins showed instances with noteworthy HC increases associated with trailer towing (roughly an order of magnitude increase compared to MOVES base rates), as shown in Figure 9 (see also Figure S2 for plot with HC means and 95% confidence intervals). There is also some indication that non-towing HC emissions were higher than MOVES base rates at the high-speed opmode bins, although to a lesser degree than towing emissions. This may indicate that MOVES default emission rates are more optimistic than the rates measured from the three tested vehicles. Also, as previously discussed, HC emissions data was often so low that it fell beneath the PEMS detection threshold (HC rates are shown as below detectable limit under 10−5 g/s).

NOx emission rates showed less distinct trends compared to CO and HC, but still showed indications of elevated emissions compared to MOVES at the higher opmodes (bins 35–38), as shown in Figure 10 (see also Figure S3 for plot with NOx means and 95% confidence intervals). Overall, this study suggests that trailer-towing operations may result in higher emission rates (especially for CO and HC) when operating at higher opmodes. However, comparing to emission rates in MOVES may require further refinement to accurately reflect real-world conditions.

4. Conclusions

There is limited research examining the impacts of towing operations on light-duty truck emissions. Opmode-specific emission rates for pollutants are crucial factors that can be used to help investigate how light-duty truck emissions are affected by hauling operations. This field study utilized OBD and PEMS data to generate emission rates for three light-duty trucks operating with and without trailers in tow. For each of the three tested trucks, emission rate comparisons were made between towing and non-towing operations across operating modes. In nearly all opmode bins, CO2 emission rates for the tested trucks were observed to be higher when towing trailers compared to non-towing operations. For CO and HC emission rates, the largest towing increases (relative to non-towing emissions) were observed in the latter half of the opmode bins for all tested trucks. It is possible that these increases in CO and HC emissions were caused by the vehicle engines burning a richer fuel air mixture under heavy load, resulting in a larger portion of incomplete combustion gases in the exhaust. One limitation of this study is that it explains vehicle emissions through opmode, which is modeled by the vehicle’s speed, acceleration, weight, and road-load coefficients, as well as the vehicle’s characteristics and road grade. Opmode-specific rates were designed to represent fleet average emissions for the purposes of emission inventory modeling. Analyzing these individual vehicle rates in terms of opmode allows us to compare the emissions of these vehicles to our best understanding of the national fleet of light-duty trucks. However, opmode does not directly represent the load on the powertrain. Likewise, the method averages transient loads over one-second intervals. As such, opmode rates provide less insight into the specific mechanisms that may cause the emissions of these vehicles to deviate from the fleet average.

These results indicate that some light-duty emissions are notably higher while towing trailers in a handful of scenarios compared to corresponding non-towing data and also compared to base MOVES emission rates. However, results also indicate that this was not always the case and that, in a handful of scenarios, three similar light-duty trucks can have very different emission profiles. There are several limitations to comparing this study’s data to MOVES, and more research would be needed to determine whether the MOVES model may require adjustment to incorporate light-duty hauling operations. The comparison to MOVES base rates is limited given that MOVES represents the full fleet of passenger trucks operating in the U.S. and includes SUVs and some classes of vans (i.e., not limited to light-duty trucks), which may not directly compare to the three trucks assessed in this study. A direct comparison to MOVES would require obtaining data describing the portion of time that trucks in the U.S. operate with and without towing loads to generate appropriately weighted emission rates. Additional limitations include the limited sample size for some opmode bins as well as the unknowns associated with the proprietary software algorithms that manage vehicle emissions controls. It is unclear whether the differences from MOVES base rates can be predominately attributed to trailer-towing operation or to other confounding factors that may not be fully captured by the tested trucks and tested scenarios. Future research could work to identify rich/lean operations and other conditions that may lead to peak emissions generation while towing. Investigating emissions impacts from additional, newer light-duty trucks would also aid in better understanding towing-related emissions burdens that may be missed by current estimates. Ultimately, off-cycle emissions from light-duty towing and steep road grades may result in notably higher emission rates in certain cases. More research is needed to investigate the prevalence and causes of these higher-emission scenarios before these effects can be accurately modeled in MOVES.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/atmos16060749/s1, Table S1: Specs for test fuel; Figure S1: Mean CO emission rates at different opmode bins for combined trucks with and without trailers compared to MOVES base emission rates; Figure S2: Mean HC emission rates at different opmode bins for combined trucks with and without trailers compared to MOVES base emission rates; Figure S3: Mean NOx emission rates at different opmode bins for combined trucks with and without trailers compared to MOVES base emission rates.

Author Contributions

B.K.: data curation, formal analysis, methodology, validation, visualization, writing—review and editing. R.J.: conceptualization, data curation, formal analysis, methodology, validation, visualization, writing—original draft. R.S. (Rodolfo Souza): data curation, formal analysis (LiDAR analysis), methodology, validation. M.X.: writing—review and editing. J.J.: data curation, formal analysis, visualization. C.R.F.: conceptualization, data curation, methodology, resources, software, validation, writing—review and editing. J.F.: conceptualization, investigation, methodology, resources, writing—review and editing. M.V.: data curation, formal analysis, writing—review and editing. C.G.: methodology, formal analysis. T.R.: supervision, validation, writing—review and editing. R.W.B.: resources, supervision, writing—review and editing. M.A.: methodology, validation, writing—review and editing. A.F.: conceptualization, methodology, resources. T.L.: conceptualization, investigation, data curation, methodology, resources, project administration. R.S. (Richard Snow): conceptualization, investigation, data curation, formal analysis, methodology, resources, software. C.W.: supervision. R.L.: investigation. H.V.: supervision, validation, visualization, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

Funding was provided by the U.S. Environmental Protection Agency’s Air, Climate & Energy National Research Program.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be publicly available on EPA’s Science Hub database soon after publication.

Acknowledgments

The authors are grateful for the research support provided by the following EPA staff in the Office of Transportation and Air Quality: Rich Cook, Angela Cullen, and James Warila.

Conflicts of Interest

Author Craig Williams was employed by the company Consolidated Safety Services Inc. Author Russell Logan was employed by the company Jacobs Technology Inc. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Disclaimer Statement

This document has been reviewed in accordance with U.S. Environmental Protection Agency policy and approved for publication. Any mention of trade names or commercial products does not constitute endorsement or recommendation for use. The views expressed in this journal article are those of the authors and do not necessarily represent the views or policies of the U.S. Environmental Protection Agency.

References

- Bureau of Transportation Statistics. New and Used Passenger Car and Light Truck Sales and Leases 2023. Available online: https://www.bts.gov/content/new-and-used-passenger-car-sales-and-leases-thousands-vehicles (accessed on 16 June 2025).

- U.S. Environmental Protection Agency MOVES4. Latest Version of Motor Vehicle Emission Simulator. Available online: https://www.epa.gov/moves/latest-version-motor-vehicle-emission-simulator-moves (accessed on 16 June 2025).

- Smit, R.; Ntziachristos, L.; Boulter, P. Validation of Road Vehicle and Traffic Emission Models—A Review and Meta-Analysis. Atmos. Environ. 2010, 44, 2943–2953. [Google Scholar] [CrossRef]

- Ropkins, K.; Ibarra-Espinosa, S.; Bernard, Y. Vehicle Emissions Measurement and Modeling. In Traffic-Related Air Pollution; Elsevier: Amsterdam, The Netherlands, 2020; pp. 75–109. [Google Scholar]

- Lyu, P.; Wang, P.S.; Liu, Y.; Wang, Y. Review of the Studies on Emission Evaluation Approaches for Operating Vehicles. J. Traffic Transp. Eng. Engl. Ed. 2021, 8, 493–509. [Google Scholar] [CrossRef]

- National Research Council. Modeling Mobile-Source Emissions; National Academies Press: Washington DC, USA, 2020. [Google Scholar]

- Smit, R.; Dia, H.; Morawska, L. Road Traffic Emission and Fuel Consumption Modelling: Trends, New Developments and Future Challenges. In Traffic Related Air Pollution and Internal Combustion Engines; Nova Publishers: New York, NY, USA, 2009; pp. 29–68. ISBN 978-1-60741-145-1. [Google Scholar]

- Bishop, G.A.; Holubowitch, N.E.; Stedman, D.H. Remote Measurements of On-Road Emissions from Heavy-Duty Diesel Vehicles in California; Year 1, 2008; National Renewable Energy Laboratory: Denver, CO, USA, 2009. [Google Scholar]

- John, C.; Friedrich, R.; Staehelin, J.; Schläpfer, K.; Stahel, W.A. Comparison of Emission Factors for Road Traffic from a Tunnel Study (Gubrist Tunnel, Switzerland) and from Emission Modeling. Atmos. Environ. 1999, 33, 3367–3376. [Google Scholar] [CrossRef]

- Geller, M.D.; Sardar, S.B.; Phuleria, H.; Fine, P.M.; Sioutas, C. Measurements of Particle Number and Mass Concentrations and Size Distributions in a Tunnel Environment. Environ. Sci. Technol. 2005, 39, 8653–8663. [Google Scholar] [CrossRef]

- Baldauf, R.; Thoma, E.; Hays, M.; Shores, R.; Kinsey, J.; Gullett, B.; Kimbrough, S.; Isakov, V.; Long, T.; Snow, R.; et al. Traffic and Meteorological Impacts on Near-Road Air Quality: Summary of Methods and Trends from the Raleigh near-Road Study. J. Air Waste Manag. Assoc. 2008, 58, 865–878. [Google Scholar] [CrossRef] [PubMed]

- Moutinho, J.L.; Liang, D.; Golan, R.; Sarnat, S.E.; Weber, R.; Sarnat, J.A.; Russell, A.G. Near-Road Vehicle Emissions Air Quality Monitoring for Exposure Modeling. Atmos. Environ. 2020, 224, 117318. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.M.; Jeong, C.-H.; Hilker, N.; Shairsingh, K.K.; Healy, R.M.; Sofowote, U.; Debosz, J.; Su, Y.; McGaughey, M.; Doerksen, G.; et al. Near-Road Air Pollutant Measurements: Accounting for Inter-Site Variability Using Emission Factors. Environ. Sci. Technol. 2018, 52, 9495–9504. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, Q.; Shi, Y.; Wang, D. On-Road Remote Sensing Measurements and Fuel-Based Motor Vehicle Emission Inventory in Hangzhou, China. Atmos. Environ. 2007, 41, 3095–3107. [Google Scholar] [CrossRef]

- Carslaw, D.C. Evidence of an Increasing NO2/NOx Emissions Ratio from Road Traffic Emissions. Atmos. Environ. 2005, 39, 4793–4802. [Google Scholar] [CrossRef]

- Burgard, D.A.; Bishop, G.A.; Stedman, D.H.; Gessner, V.H.; Daeschlein, C. Remote Sensing of In-Use Heavy-Duty Diesel Trucks. Environ. Sci. Technol. 2006, 40, 6938–6942. [Google Scholar] [CrossRef]

- North, R.J.; Noland, R.B.; Ochieng, W.Y.; Polak, J.W. Modelling of Particulate Matter Mass Emissions from a Light-Duty Diesel Vehicle. Transp. Res. Part Transp. Environ. 2006, 11, 344–357. [Google Scholar] [CrossRef]

- Silva, C.; Farias, T.; Frey, H.C.; Rouphail, N.M. Evaluation of Numerical Models for Simulation of Real-World Hot-Stabilized Fuel Consumption and Emissions of Gasoline Light-Duty Vehicles. Transp. Res. Part Transp. Environ. 2006, 11, 377–385. [Google Scholar] [CrossRef]

- Gallus, J.; Kirchner, U.; Vogt, R.; Börensen, C.; Benter, T. On-Road Particle Number Measurements Using a Portable Emission Measurement System (PEMS). Atmos. Environ. 2016, 124, 37–45. [Google Scholar] [CrossRef]

- Kousoulidou, M.; Fontaras, G.; Ntziachristos, L.; Bonnel, P.; Samaras, Z.; Dilara, P. Use of Portable Emissions Measurement System (PEMS) for the Development and Validation of Passenger Car Emission Factors. Atmos. Environ. 2013, 64, 329–338. [Google Scholar] [CrossRef]

- Meena, S.; Singh, S.K. Assessment of Real Driving Emissions from Vehicles Using Portable Emission Measurement Systems: A Systematic Review. Appl. Ecol. Environ. Sci. 2022, 10, 273–280. [Google Scholar]

- Brodrick, C.-J.; Laca, E.A.; Burke, A.F.; Farshchi, M.; Li, L.; Deaton, M. Effect of Vehicle Operation, Weight, and Accessory Use on Emissions from a Modern Heavy-Duty Diesel Truck. Transp. Res. Rec. 2004, 1880, 119–125. [Google Scholar] [CrossRef]

- Frey, H.C.; Rouphail, N.M.; Zhai, H. Link-Based Emission Factors for Heavy-Duty Diesel Trucks Based on Real-World Data. Transp. Res. Rec. 2008, 2058, 23–32. [Google Scholar] [CrossRef]

- Yu, L.; Wang, Z.; Shi, Q. PEMS-Based Approach to Developing and Evaluating Driving Cycles for Air Quality Assessment; Center for Transportation Training and Research, Texas Southern University: Houston, TX, USA, 2010. [Google Scholar]

- Mahesh, S.; Ramadurai, G. Effect of Load on Fuel Consumption and Real-World Emissions from Light-Duty Trucks Using Portable Emission Measurement Systems (PEMS). In Proceedings of the Transportation Research Board 97th Annual Meeting, Washington, DC, USA, 7 January 2018–11 January 2018. [Google Scholar]

- Lv, L.; Ge, Y.; Ji, Z.; Tan, J.; Wang, X.; Hao, L.; Wang, Z.; Zhang, M.; Wang, C.; Liu, H. Regulated Emission Characteristics of In-Use LNG and Diesel Semi-Trailer Towing Vehicles under Real Driving Conditions Using PEMS. J. Environ. Sci. 2020, 88, 155–164. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; He, L.; Hu, J.; Hu, K.; Du, Q.; Zu, L.; Bao, X. Actual Road Emission Characteristics of China II Heavy Duty Diesel Trucks under Different Load Conditions. Environ. Pollut. Control 2019, 41, 34–40. [Google Scholar] [CrossRef]

- Wang, X.; Song, G.; Zhai, Z.; Wu, Y.; Yin, H.; Yu, L. Effects of Vehicle Load on Emissions of Heavy-Duty Diesel Trucks: A Study Based on Real-World Data. Int. J. Environ. Res. Public Health 2021, 18, 3877. [Google Scholar] [CrossRef]

- Jimenez-Palacios, J.L. Understanding and Quantifying Motor Vehicle Emissions with Vehicle Specific Power and TILDAS Remote Sensing. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1998. [Google Scholar]

- U.S. Environmental Protection Agency. What Is Vehicle Specific Power (VSP)? Available online: https://www.epa.gov/moves/what-vehicle-specific-power-vsp (accessed on 16 June 2025).

- Song, G.; Yu, L.; Tu, Z. Distribution Characteristics of Vehicle-Specific Power on Urban Restricted-Access Roadways. J. Transp. Eng. 2012, 138, 202–209. [Google Scholar] [CrossRef]

- Chong, H.S.; Kwon, S.; Lim, Y.; Lee, J. Real-World Fuel Consumption, Gaseous Pollutants, and CO2 Emission of Light-Duty Diesel Vehicles. Sustain. Cities Soc. 2020, 53, 101925. [Google Scholar] [CrossRef]

- Ng, E.C.; Huang, Y.; Hong, G.; Zhou, J.L.; Surawski, N.C. Reducing Vehicle Fuel Consumption and Exhaust Emissions from the Application of a Green-Safety Device under Real Driving. Sci. Total Environ. 2021, 793, 148602. [Google Scholar] [CrossRef]

- Zhai, Z.; Tu, R.; Xu, J.; Wang, A.; Hatzopoulou, M. Capturing the Variability in Instantaneous Vehicle Emissions Based on Field Test Data. Atmosphere 2020, 11, 765. [Google Scholar] [CrossRef]

- Zhang, L.; Lin, J.; Qiu, R. Characterizing the Toxic Gaseous Emissions of Gasoline and Diesel Vehicles Based on a Real-World on-Road Investigation. J. Clean. Prod. 2021, 286, 124957. [Google Scholar] [CrossRef]

- Lai, J.; Yu, L.; Song, G.; Guo, P.; Chen, X. Development of City-Specific Driving Cycles for Transit Buses Based on VSP Distributions: Case of Beijing. J. Transp. Eng. 2013, 139, 749–757. [Google Scholar] [CrossRef]

- Rosero, F.; Fonseca, N.; López, J.-M.; Casanova, J. Effects of Passenger Load, Road Grade, and Congestion Level on Real-World Fuel Consumption and Emissions from Compressed Natural Gas and Diesel Urban Buses. Appl. Energy 2021, 282, 116195. [Google Scholar] [CrossRef]

- Rosero, F.; Fonseca, N.; López, J.-M.; Casanova, J. Real-World Fuel Efficiency and Emissions from an Urban Diesel Bus Engine under Transient Operating Conditions. Appl. Energy 2020, 261, 114442. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, L.; Song, G. Emissions Characteristics for Heavy-Duty Diesel Trucks under Different Loads Based on Vehicle-Specific Power. Transp. Res. Rec. 2017, 2627, 77–85. [Google Scholar] [CrossRef]

- Dhital, N.B.; Wang, S.-X.; Lee, C.-H.; Su, J.; Tsai, M.-Y.; Jhou, Y.-J.; Yang, H.-H. Effects of Driving Behavior on Real-World Emissions of Particulate Matter, Gaseous Pollutants and Particle-Bound PAHs for Diesel Trucks. Environ. Pollut. 2021, 286, 117292. [Google Scholar] [CrossRef]

- He, L.; Zhang, S.; Hu, J.; Li, Z.; Zheng, X.; Cao, Y.; Xu, G.; Yan, M.; Wu, Y. On-Road Emission Measurements of Reactive Nitrogen Compounds from Heavy-Duty Diesel Trucks in China. Environ. Pollut. 2020, 262, 114280. [Google Scholar] [CrossRef] [PubMed]

- Code of Federal Regulation 40 CFR §1065 Subpart J—Field Testing and Portable Emission Measurement Systems. Available online: https://www.ecfr.gov/current/title-40/part-1065/subpart-J (accessed on 9 May 2025).

- SEMTECH SEMTECH DS+ for Light Duty—Gaseous and Exhaust Flow Analyzer. Available online: https://sensors-inc.com/Products/SEMTECH/DS_Plus_Light_Duty (accessed on 16 June 2025).

- U.S. Geological Survey. What Is Lidar Data and Where Can I Download It? Available online: https://www.usgs.gov/faqs/what-lidar-data-and-where-can-i-download-it#faq (accessed on 16 June 2025).

- North Carolina Spatial Data Download. Available online: https://sdd.nc.gov/DataDownload.aspx (accessed on 16 June 2025).

- U.S. Environmental Protection Agency. Exhaust Emission Rates for Light-Duty Onroad Vehicles in MOVES4; U.S. Environmental Protection Agency: Washington, DC, USA, 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).