Abstract

A two-stage exhaust air treatment system installed at a broiler fattening facility with 40,000 animals was investigated. The facility’s exhaust air was treated first by use of a chemo-scrubber (stage 1) and afterwards by a vertical biofilter (stage 2). The biofilter was equipped with root wood and honeycombed paper pad layers (half/half) to enable a direct comparison of both filter materials’ suitability. Odour samples were taken on site and afterwards analysed at an olfactometry laboratory. Ammonia concentration values were collected continuously using a photoacoustic multi-gas monitor. High mitigation performance was achieved with both filter materials, with the honeycombed paper pad layer being less susceptible to fungal growth than the root wood filter. Cellulose seems to be a proper alternative for use in biofilters, but further research is needed to estimate the long-term stability of this material.

1. Introduction

Livestock facilities contribute considerably to anthropogenic ammonia emissions. In addition, odorous emissions affect the surroundings, especially of poultry housing facilities, so that farmers are challenged not only by environmental issues concerning their farms’ emissions, but are also faced with negative attitudes of residents towards their farms. Residents often feel bothered by odours which originate from agriculture. According to the European Union emission inventory report 1990–2017 [1], 92% of the EU ammonia emissions in 2017 originated from agriculture. The main contributors were Germany, France and Spain. Besides ammonia, odorous emissions also play a major role, especially those originating from poultry housing: research undertaken by Valli et al. [2] showed that compared to pigs and cattle, laying hens and broilers have the highest odorous emissions per animal live weight unit.

As a consequence, an increasing number of farms need to be equipped with exhaust air treatment systems for environmental or politic reasons. Mitigation techniques are often linked with additional workloads and, most importantly, costs for farmers [3,4]. The exhaust air treatment system to be installed should therefore be able to deliver satisfactory results while being low maintenance. In addition, the efficiency of each system needs to be verified in a comparable way; for this reason, the Verification of Environmental Technologies for Agricultural Production (VERA) test protocol, a multinational collaboration between Denmark, The Netherlands and Germany, was established [5]. For the mitigation of odorous emissions from livestock buildings, biofilter systems have notably proven their worth [4,6,7].

Different filter materials are used for stuffing biofilters; the most popular materials are different kinds of wood chips. Chen et al. [8] tested two types of wood-chips as filter materials: western cedar and hardwood. They noted the importance of an appropriate moisture content of 60%, at which both tested chip materials led to odour reduction efficiencies of 48% to 93%. Nicolai and Janni [9] used a mixture of 50% brush wood chips and 50% sandy loam soil at a laying hen facility (caged). High amounts of dust made a correct measurement impossible. The authors recommend against the use biofilters at poultry facilities without upstream dust filters. An upstream treatment of the exhaust air, especially for the removal of dust, is also recommended by Harmon et al. [10] to help prevent the clogging of biofilters. Melse and Hol [7] also observed a high pressure drop in a biofilter downstream from a poultry manure dryer (laying hens) that was caused by dust, among other factors.

Exhaust air treatment systems used at broiler fattening facilities are faced with circumstances that can change quickly. Exhaust air, which feeds microorganisms and maintains the climatic conditions that are appropriate for these microorganisms, is ensured only during fattening periods. These periods often last no longer than about four weeks, followed by the transient vacancy of the facility in combination with intensive hygienic action. Even during a fattening period, conditions keep changing: Ogink et al. [11] noted that increasing ammonia emissions correlated with the increased size of the broilers, while Huang [12] identified the influence of outdoor climate conditions on emissions, such as temperature (outside temperatures as well as exhaust air temperatures, with the latter ranging from ca. 32 °C to 20 °C, depending on animal age and size). In correlation with outdoor temperatures, air ventilation rates need to be adjusted to keep inside temperatures at an optimum level [13]. Another unstable parameter correlated with temperatures and air ventilation rates is the relative humidity inside the facility (ranging from ca. 55% to 80% [14]).

All the circumstances mentioned above were taken into account in the experimental design to generate a suitable exhaust air treatment system for the mitigation of dust, ammonia and mainly, odour at a broiler fattening facility.

2. Experiments

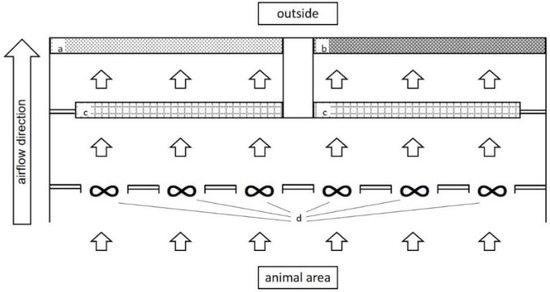

The field experiments took place at a broiler fattening facility in Lower Saxony, Germany. The facility housed 40,000 broilers. Broilers were kept on the floor, which was covered with saw dust. Manure was not removed during the fattening period. The facility had six frequency-controlled ventilation fans at the gable end. Supply air inlets were located at the eave’s sides. The exhaust air treatment system comprised two stages: first a chemo-scrubber, and then a biofilter downstream. Figure 1 shows a schematic representation of the system. The chemo-scrubber was equipped with sulfuric acid-enriched water. The pH of this cleaning fluid was kept below 2.7. The biofilter was equipped with two different filter materials at the same time: half of the biofilter stage was filled with root wood (variant 1), while the other half was equipped with honeycombed paper pads made of impregnated cellulose (variant 2). Each biofilter layer measured 7.5 m (width) × 0.6 m (length) × 2.5 m (height). The experimental setup enabled a direct comparison of the two filter materials’ efficiency under identical conditions. As a consequence, the data for the raw gas of both filter materials tested at the broiler fattening facility is the same.

Figure 1.

Schematic representation of the examined filter (a: root wood biofilter layer; b: honeycombed paper pads biofilter layer; c: chemo-scrubber; d: fans).

Ammonia concentration values were measured using a photoacoustic multi-gas monitor (INNOVA 1412 in combination with multiplexer 1309, LumaSense Technologies A/S, Ballerup, DK; cf. [15]. Odour samples taken on site were analysed at the olfactometry laboratory (n = 4 samples per day) according to DIN EN 13725:2003–07 [16] test scheme using an olfactometer (TO 8, ECOMA, Weyhe-Dreye, Germany).

Samples were taken on three days during different production cycles throughout the year in 2017, each time during the fourth week of fattening, as emissions rise with the age and size of the animals. Three odour samples were taken at each measuring point in clean gas and one in raw gas at the end of each 24 h interval. Samples were taken with a low-pressure sampling device connected to a hood. A hood was attached to each of the clean gas sampling points on the outside of the biofilter to avoid cross-influences, as for example, from wind. The bags were made of NalophanTM. The material was chosen as it helps to avoid the contamination of the examined air. Additionally, ammonia was measured at an interval of 3 minutes over a period of 24 h. This sums up to 480 measured values for each measured spot (raw gas, honeycomb paper filter and root wood filter) per day, and to a total of 1440 values for the whole trial. The results are presented as arithmetic means. For statistical analyses, IBM SPSS statistics version 24 (IBM Corporation, USA, 2016) was used.

3. Results and Discussion

Table 1 shows the mean values of all three days for ammonia and odour in raw and clean gas. Low ammonia concentration values ( 3.99 ppm) were measured in raw gas. Despite these already low initial values, a further reduction of 71% (chemo-scrubber combined with root wood filter, variant 1) and 68% (chemo-scrubber combined with honeycombed paper pad filter, variant 2) was achieved through the use of the exhaust air treatment system. The odour concentration measured in raw gas had an average of 256OUE m−3. This initial value could be reduced in variant 1 by 97OUE m−3 to 159OUE m−3 and in variant 2 by 131 OUE m−3 to 125OUE m−3. No specific odour of the raw gas was detected in a clean gas sample at any time.

Table 1.

Ammonia and Odour concentration in raw gas, clean gas and total difference for different biofilter filling materials (variant 1: root wood; variant 2: honeycombed paper pads); mean values over three days with n = 1440 for ammonia and n = 3 for raw gas odour and n = 9 for each odour of variant 1 and variant 2.

The honeycombed paper pad filter seems to be of higher efficiency than the root wood filter. A possible explanation of the higher clean gas values for variant 1 may be the inherent odour of the root wood material; shortly after the installation of the biofilter, fungal growth was observed in this filter material. Despite these differences in efficiency, both variants were suitable for achieving a substantial reduction of odour concentration. Nevertheless, even after several fattening periods, the fungal growth was considerably lower at the honeycombed paper pad filter than at the root wood filter, which makes it less susceptible to disturbances, and more suitable overall. Fungal growth accelerates the process of material degradation. Degraded material tends to settle, which increases the risk of air leaks, where air can pass the filter untreated [10]. The honeycombed paper pad filter was less susceptible to degradation during the experimental period. Furthermore, another advantage of the honeycombed paper layer compared to root wood is a steadier airflow due to the constant pore size across the whole filter.

The advantages of combining an acid scrubber with a biofilter are, amongst others, the mitigation of ammonia and moisturising of the air before entering the biofilter and thus, better conditions for the microorganisms inside the biofilter. This worked out very well for the honeycombed paper pad filter, while the chemo-scrubber stage could not prevent fungal growth inside the root wood filter. Also, clogging in the biofilter by dust was not observed, which matches the findings of Nicolai and Janni [9] and Harmon et al. [10]. Yet, there is still need for further investigation to increase the odour reduction efficiency and to clarify the impact of the inherent odour development inside biofilters.

4. Conclusions

In this preliminary study, the suitability of impregnated cellulose pads for biofilters was tested on a farm scale and simultaneously compared to root wood as a commonly-used biofilter filling material.

The main conclusions of this study are:

- Both the root wood and honeycombed paper pad material helped to mitigate odour concentrations of exhaust air by up to 51%.

- The honeycombed paper pad filter provided better results, presumably due to lower inherent odour and lower fungal growth.

- Further investigation according to the VERA protocol [5] is needed for a long-term stability evaluation of the honeycombed paper pad material, as well as for objective comparability to other systems.

Author Contributions

Conceptualization, C.S., M.S.K. and W.B.; methodology, C.S., M.S.K.; software, C.S., M.S.K.; validation, C.S., M.S.K.; formal analysis, C.S.; investigation, C.S.; resources, W.B.; data curation, C.S.; writing—original draft preparation, C.S.; writing—review and editing, C.S.; M.S.K. and W.B.; visualization, C.S.; supervision, M.S.K. and W.B.; project administration, W.B.; funding acquisition, W.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Federal Ministry of Food and Agriculture (BMEL) based on a decision of the Parliament of the Federal Republic of Germany via the Federal Office for Agriculture and Food (BLE) under the innovation support programme (founding code 28-1-72.003-13).

Acknowledgments

We thank the animal housing owner for giving us the opportunity for achieving this study in his farm as well as Peter Ebertz for his contribution to the construction of the experimental setup.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tista, M.; Gager, M.; Gaisbauer, S.; Ullrich, B. European Union Emission Inventory Report 1990–2017 under the UNECE Convention on Long-Range Transboundary Air Pollution (LRTAP); Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-9480-078-7. [Google Scholar]

- Valli, L.; Moscatelli, G.; Labartino, N. Odour emissions from livestock production facilities. Chem. Eng. Trans. 2008, 15, 239–246. [Google Scholar]

- Loyon, L.; Burton, C.H.; Misselbrook, T.; Webb, J.; Philippe, F.X.; Aguilar, M.; Doreau, M.; Hassouna, M.; Veldkamp, T.; Dourmad, J.Y.; et al. Best available technology for European livestock farms: Availability, effectiveness and uptake. J. Environ. Manag. 2016, 166, 1–11. [Google Scholar] [CrossRef]

- Grimm, E. (Ed.) Exhaust Air Treatment Systems for Animal Housing Facilities. Techniques-Performance-Costs; KTBL: Darmstadt, Germany, 2008; ISBN 9783939371601. [Google Scholar]

- The International VERA Secretariat. VERA TEST PROTOCOL for Livestock Housing and Management Systems. Version 3:2018-09; The International VERA Secretariat: Delft, The Netherlands, 2018. [Google Scholar]

- Van der Heyden, C.; Demeyer, P.; Volcke, E.I.P. Mitigating emissions from pig and poultry housing facilities through air scrubbers and biofilters: State-of-the-art and perspectives. Biosyst. Eng. 2015, 134, 74–93. [Google Scholar] [CrossRef]

- Melse, R.W.; Hol, J.M.G. Biofiltration of exhaust air from animal houses: Evaluation of removal efficiencies and practical experiences with biobeds at three field sites. Biosyst. Eng. 2017, 159, 59–69. [Google Scholar] [CrossRef]

- Chen, L.; Hoff, S.; Cai, L.; Koziel, J.; Zelle, B. Evaluation of Wood Chip-Based Biofilters to Reduce Odor, Hydrogen Sulfide, and Ammonia from Swine Barn Ventilation Air. J. Air Waste Manag. Assoc. 2009, 59, 520–530. [Google Scholar] [CrossRef]

- Nicolai, R.E.; Janni, K.A. Effect of Biofilter Retention Time on Emissions from Dairy, Swine and Poultry Buildings. In Proceedings of the ASAE Annual International Meeting, Toronto, ON, Canada, 18–22 July 1999. [Google Scholar]

- Harmon, J.D.; Hoff, S.J.; Rieck-Hinz, A.M. Animal Housing—Biofilters Overview. Agric. Environ. Ext. Publ. 2014, 210. Available online: http://lib.dr.iastate.edu/extension_ag_pubs/210 (accessed on 1 December 2019).

- Ogink, N.W.M.; Melse, R.W.; Mosquera, J. Multi-Pollutant and One-Stage Scrubbers for Removal of Ammonia, Odor, and Particulate Matter from Animal House Exhaust Air. Livest. Environ. VIII 2008, 701P0408, 269–276. [Google Scholar]

- Huang, D. Odour and Gas Emissions, Odour Impact Criteria, and Dispersion Modelling for Dairy and Poultry Barns. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2018. [Google Scholar]

- Pedersen, S. Forced Ventilation. In CIGR Handbook of Agricultural Engineering II. Animal Production & Aquacultural Engineering,1999; CIGR: Liège, Belgium, 1999; pp. 68–88. [Google Scholar]

- Hiller, P.; Pieper, H.; Schierhold, S.; Meyer, A. Hähnchenhaltung. Leitlinien für die gute landwirtschaftliche Praxis in der Hähnchenhaltung; Landwirtschaftskammer Niedersachsen: Lower Saxony, Germany, 2016. [Google Scholar]

- Schmithausen, A.J.; Trimborn, M.; Büscher, W. Methodological Comparison between a Novel Automatic Sampling System for Gas Chromatography versus Photoacoustic Spectroscopy for Measuring Greenhouse Gas Emissions under Field Conditions. Sensors 2016, 16, 1638. [Google Scholar] [CrossRef] [PubMed]

- Luftbeschaffenheit—Bestimmung der Geruchsstoffkonzentration mit dynamischer Olfaktometrie; Deutsche Fassung EN 13725:2003; DIN EN 13725:2003-07; Beuth Verlag GmbH: Berlin, Germany, 2003.

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).