Abstract

In recent years, agricultural production activities have been advancing towards mechanization and intelligence to bridge the growing gap between the high labor intensity and time sensitivity of harvesting operations and the limited labor resources. As the component that directly interacts with target crops, the end-effector is a crucial part of agricultural harvesting robots. This paper first reviews their materials, number of fingers, actuation methods, and detachment techniques. Analysis reveals that three-fingered end-effectors, known for their stability and ease of control, are the most prevalent. Soft materials have gained significant attention due to their flexibility and low-damage characteristics, while the emergence of variable stiffness technology holds promise for addressing their issues of poor stability and fragility. The introduction of bionics and composite concepts offers potential for enhancing the performance of end-effectors. Subsequently, starting from an analysis of the biomechanical properties of fruits and vegetables, the relationship between mechanical damage and the intrinsic parameters of produce is elucidated. On the other hand, practical and efficient finite element analysis has been applied to various stages of end-effector research, such as structural design and grasping force estimation. Given the importance of compliance control, this paper explores the current research status of various control methods. It emphasizes that while hybrid force–position control often suffers from frequent controller switching, which directly affects real-time performance, active admittance control and impedance control directly convert external forces or torques into the robot’s reference position and velocity, resulting in more stable and flexible external control. To enable a unified comparison of end-effector performance, this review proposes a progressive comparison framework centered on control philosophy, comprising the ontological characteristic layer, physical interaction layer, feedback optimization layer, and task layer. Additionally, in response to the current lack of scientific rigor and systematization in performance evaluation systems for end-effectors, performance evaluation criteria (harvest success rate, harvest time, and damage rate) are defined to standardize the characterization of end-effector performance. Finally, this paper summarizes the challenges faced in the development of end-effectors and analyzes their causes. It highlights how emerging technologies, such as digital twin technology, can improve the control accuracy and flexibility of end-effectors.

1. Introduction

Agriculture is fundamental to human survival, providing food, feed, and raw materials for industrial production, while also playing a crucial role in global trade. According to United Nations projections, the global population is expected to reach 9.7 billion by 2050 and peak at around 10.3 billion in the mid-2080s. This growth will inevitably drive a significant increase in global food demand, with estimates suggesting a necessary rise of approximately 60% in agricultural production to meet future needs [1,2]. Simultaneously, climate change poses an increasing threat to agricultural systems by intensifying the frequency of extreme weather events such as heatwaves, droughts, floods, and cold spells, thereby escalating pressure on already scarce resources. According to United Nations reports, the global population aged over 60 has demonstrated a consistent upward trend and attained a substantially elevated proportion as of 2023 [3]. According to official statistics released by the National Bureau of Statistics of China, by the end of 2024, the population aged 60 and above had exceeded 300 million for the first time, indicating that China has now formally entered the stage of an aging society. The harvesting of fruits and vegetables is a labor-intensive task characterized by high physical demands and complex environments. Given its time-sensitive nature, any failure to promptly harvest mature crops due to labor shortages will result in reduced product quality, lower harvesting rates, and consequently, substantial financial losses for farmers. As a result, significant attention is being paid to the trajectory of agricultural development in the coming decades.

Driving agricultural production through digital technology and enhancing farm scale and efficiency have become one of the key strategic solutions. From the late 19th to the early 20th century, the Third Industrial Revolution (Industry 3.0) was shaped by the widespread adoption of digital computers. This marked the initial phase of digital agriculture, giving rise to Agriculture 3.0 or precision agriculture. By leveraging transformative technologies such as Global Positioning Systems (GPSs), Geographic Information Systems (GISs), yield monitors, and other data-generating tools, farmers gained critical insights into soil conditions, moisture levels, nutrient content, and crop health. With the rapid advancement of Industry 4.0, which began in the automotive sector and gradually influenced various fields, highly digitalized and personalized production methods were established, enabling real-time interaction between people and production equipment [4]. Against the backdrop of Industry 4.0 development, digital technologies are being utilized in agricultural production to monitor and collect operational data from robots, transmitting it to the cloud. Simultaneously, technologies such as the Internet of Things (IoT), Big Data Analytics (BDA), and Artificial Intelligence (AI) are employed to enhance intelligent decision-making and adaptability, achieving unattended, automated, and intelligent management [5,6,7]. This improves agricultural production efficiency, reduces crop damage and waste, and promotes sustainable utilization of natural resources to address the impacts of extreme climate change, global population growth, and aging on agriculture [8]. The United Nations Food and Agriculture Organization (FAO) has termed this the “Digital Agriculture Revolution,” or Agriculture 4.0. Under the influence of Agriculture 4.0, agricultural robots have become ubiquitous across all agricultural production activities, including plowing [9], transplanting [10], fertilizing [11], harvesting [12,13,14], and sorting [15,16].

The principal methods for harvesting fruits and vegetables are broadly classified into two categories: bulk harvesting and selective harvesting. Bulk harvesting is typically accomplished by applying mechanical vibration to the fruit trees to facilitate fruit detachment. Despite its high efficiency, bulk harvesting comes at the cost of significant damage to both fruits and trees, with a fruit breakage rate of approximately 5–10% and a potential yield reduction of up to 30% in the subsequent season [17]. On the other hand, fruits harvested through bulk methods often exhibit inconsistent quality, as produce at various stages of maturity is collected simultaneously. This results in lower market acceptance, and such harvests are typically destined for use as raw material in processing industries, such as winemaking. In contrast, selective harvesting involves collecting fruits differentiated by their maturity levels [18]. This method causes significantly lower damage—with a fruit breakage rate of about 3.1% and virtually no harm to tree branches, as evidenced in Table 1. In traditional selective harvesting, workers detach fruits from branches by hand or with simple tools, a process whose efficiency is highly dependent on individual experience, physical condition, and the working environment. In contrast, robotic systems can maintain consistent, efficient, and stable operation regardless of external conditions. Inspired by the biological features and harvesting motions of the human hand, researchers have developed sophisticated multisensor end-effectors for agricultural robots [19,20]. The handling of fresh-market fruits demands exceptional care, which has led to increasingly sophisticated end-effector designs. Consequently, specific technical measures are implemented: trimming the stem to a precise length prevents damage during transit and enhances shelf life, while optimal control of clamping force, picking sequence, and detachment angle is critical for minimizing mechanical injury to the fruit.

Table 1.

Inclusion Criteria for the Data Collection Phase in the Survey of End-Effectors for Fruit and Vegetable Harvesting Robots.

The end-effector is a critical component that directly interacts with target crops. The flexibility and adaptability of its structure significantly influence the overall operational performance of fruit and vegetable harvesting robots. Given the irregular shapes and variable sizes of the objects being handled, a wide variety of end-effectors have been designed to minimize fruit damage and enhance robot operational efficiency [21].

To enhance the systematicity and rigor of this review, it will adopt both quantitative and qualitative methods, drawing on the approach of Ricardo Silva Peres [22]. The research methodology is as follows:

- Review Principles

Quantitative methods include the use of semi-automated natural language processing (NLP)-based techniques to analyze the selected literature. The specific criteria for collection are shown in Table 1. For qualitative analysis, in order to understand the development status of end-effectors based on the data collected in the previous step, priority is given to literature published in earlier years.

- 2.

- Search Strings

Based on the databases listed in Table 1, a semi-automatic approach was adopted for preliminary searches. The search keywords included: “end effector,” “grippers,” “harvesting robots,” and “agriculture,” along with related terms such as “agricultural.” Additionally, technology- and design-related phrases like “soft end-effectors,” “bionic harvesting,” and “precision agriculture” were incorporated.

- 3.

- Methodology

Step 1: Data Collection

Searches were conducted in the databases according to the scope defined in Table 1 and the specified keywords. Literature outside this scope was excluded.

Step 2: Data Processing

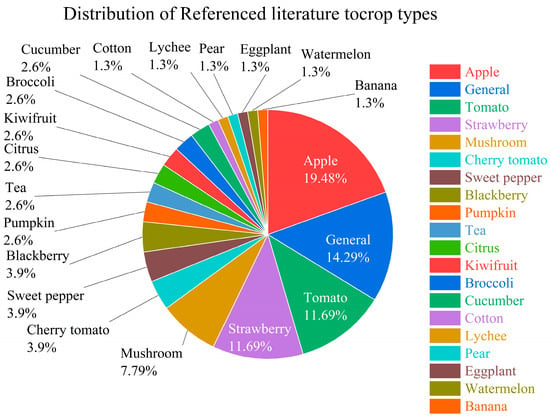

All papers were reviewed to determine their relevance to the topic. Papers that did not provide information on end-effectors were excluded. Ultimately, 77 papers related to end-effector design were identified, and the summarized data are presented in Appendix A.

Through our analysis, we found that previous reviews on end-effectors have primarily concentrated on specific types, such as rigid end-effectors [23], end-effectors for berry harvesting [24], and biomimetic harvesting end-effectors [25]. By adopting a broader perspective, this review aims to provide a more comprehensive and systematic examination of fruit and vegetable harvesting end-effectors by focusing on the following aspects:

(1) Conduct a comparative evaluation of end-effector performance through data collection, summarize the challenges faced by end-effectors, and propose improvements using emerging technologies. (2) Starting from fruit and vegetable biomechanics and mechanical damage simulation technologies, delve into the research status of real-time control technologies for end-effectors. (3) Previous studies independently compared end-effector design, perception technologies, and control algorithms, leading to significant disparities in overall performance evaluation. A unified performance comparison framework for end-effectors is proposed. (4) Define performance evaluation criteria for end-effectors, including harvesting success rate, harvesting time, and damage rate.

2. Key Technologies of End-Effectors

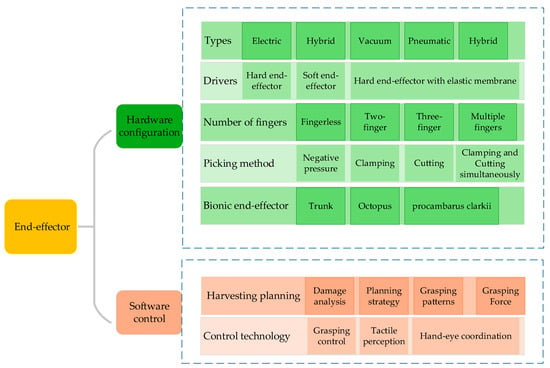

This section will elaborate on the key technologies of end-effectors from both hardware composition and software control perspectives. On the hardware side, the focus is on how the hardware components of end-effectors influence harvesting performance. On the software side, the latest research advancements in grasp planning and grasp control are highlighted. As shown in Figure 1, end-effectors can be broadly categorized into grippers, separation device, driver, and other components based on their hardware composition. Regarding software control, the subsection on harvesting planning techniques begins with an analysis of the biomechanical properties and damage mechanisms of fruits and vegetables. It further delves into the impact of end-effector picking obstacle-avoidance strategies, grasp position planning, and grasp force output on harvesting operations. In the subsection on control techniques, the study explores research on control methods, contact sensing technologies, and hand–eye coordination in end-effectors, aiming to meet operational control precision and enhance harvesting efficiency.

Figure 1.

Architectural Diagram of the End-Effector’s Hardware and Software. The green area presents the classification and introduction of the hardware components of the end effector, while the brown area provides an introduction to the software control technology of the end effector.

2.1. End-Effector Configuration Design

After the harvesting robot positions its end-effector at the target fruit through detection and planning, the subsequent harvesting phase begins. This subsection details the key hardware components of the end-effector: the gripper, separation device, and driver.

2.1.1. The Number of Fingers on an End-Effector

The number of fingers on an end-effector directly affects the stability of the fruit gripping process. Based on the number of fingers, end-effectors can be classified into fingerless, two-finger, three-finger, and multi-finger types.

Fingerless end-effectors typically grasp objects using principles such as suction or enveloping [24,26]. Fingerless end-effectors feature relatively simple structures and ease of control, they exhibit poor grasping stability. To simultaneously ensure grasping stability and avoid epidermal damage, the end-effector’s gripping suction cup utilizes an origami-inspired design, allowing it to adjust its shape and surface parameters based on the surface and morphological characteristics of cucumbers. This enhances the adsorption success rate and adsorption radius [27]. Meanwhile, the grasping performance of fingerless end-effectors is highly dependent on the smoothness of the crop surface, resulting in limited applicability. Table 2 provides a comparative analysis of the advantages, disadvantages, and performance of end-effectors with different numbers of fingers. The following section will analyze the impact of finger count on end-effector performance with reference to Table 2.

Table 2.

Analysis of Characteristics and Performance of Different Fingers.

Simulating the stem-breaking action of manual harvesting, two-finger grippers typically consist of two symmetrical fingers that employ parallel or angular opening/closing mechanisms for grasping control [36,54]. Specially designed fingertips enable simultaneous gripping and cutting operations, effectively reducing harvesting time and saving manufacturing costs for additional cutting devices. The fin-inspired finger employs a specialized structural design that enables adaptive stem cutting after grasping the fruit [37]. Simulating human finger movements during tea picking (pinching, bending, pulling), a tendon-driven soft gripper with two identical fingers was designed to generate effective force during harvesting and achieve damage-free plucking of tea buds [38]. Data from Table 2 indicates that while two-finger end-effectors offer structural simplicity and simplified control, their gripping stability remains limited. Effective stem grasping requires high precision in machine vision and control systems. To enhance grasping stability, future end-effector finger designs should focus on increasing the contact area between the fruit and the gripper.

Three-finger end-effectors commonly employ a triangular symmetric configuration with 120° inter-finger spacing, establishing three-point contact with the target object [46]. Furthermore, to accommodate the varying shapes and sizes of crops, specialized curvature designs can be applied to the finger-bending sections. This optimization maximizes the contact area during picking, ensuring stable gripping throughout the harvesting process [33]. As shown in Table 2, while the three-finger design significantly enhances harvesting performance, its structural complexity increases control challenges. Reducing the structural complexity of three-finger end-effectors to achieve simpler and more flexible control could further advance the development of end-effector technology.

Multiple finger end-effectors typically consist of four or more fingers. In general, a higher number of fingers improves dexterity in manipulation tasks, while the increased contact area enhances grasping stability [53]. However, analysis of Table 2 reveals that the harvesting performance of multi-finger end-effectors is significantly lower than other types, largely due to the increased control complexity associated with multiple fingers. To elucidate the impact of finger count on harvesting performance, Rafael Goulart et al. conducted a comparative analysis of the relationship between the number of gripper fingers and key performance metrics (including harvesting area, harvesting volume, separation success rate, harvesting success rate, peel damage, and pulp damage) [54]. Factors such as orchard standardization, canopy shape, fruit distribution, and foliage significantly affect harvesting performance. Future improvements in harvesting robot efficiency could be achieved through standardized orchard management practices, including flower thinning, fruit thinning, and branch pruning, to optimize the operational environment.

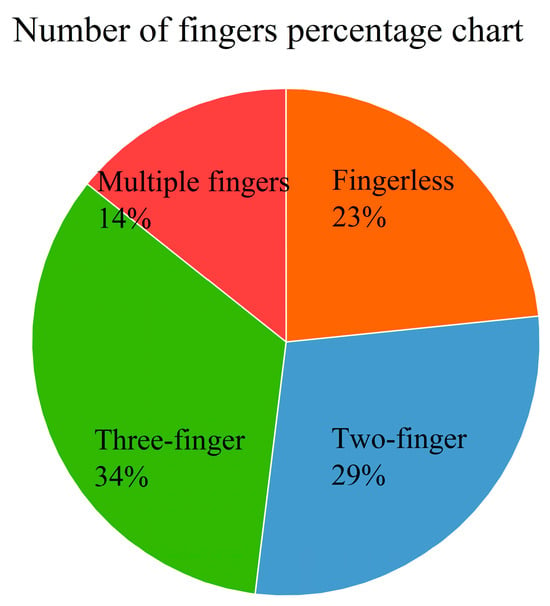

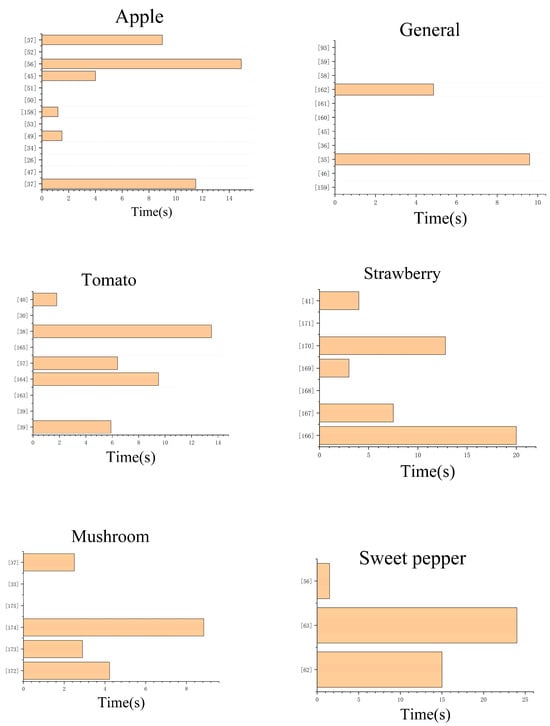

Figure 2 illustrates the proportional distribution of end-effectors by number of fingers, while Table 2 summarizes the average performance metrics—success rate, cycle time, and damage rate—associated with each configuration, based on data from Appendix A. The following analysis correlates the data in Table 1 with structural characteristics of different finger designs to explain the distribution trends shown in Figure 2.

Figure 2.

Distribution of different finger quantities.

As shown in Figure 2, fingerless end-effectors account for only 23.4% of the designs, despite their relatively high success rate and short harvesting time, due to their limited adaptability. In contrast, fingered grippers (76.6%) are more widely adopted. Among these, two- and three-fingered designs are the most prevalent, comprising 28.6% and 33.8% of the total, respectively. This prevalence can be attributed to their structurally simple and controllably stable designs, which contribute to shorter harvesting times (7.8 s and 6.5 s, respectively) and higher success rates (82.3% and 84.2%). In comparison, multi-fingered designs, while offering better envelope contact and higher adaptability, involve more complex control strategies and are more difficult to implement. These factors result in a longer harvesting time (9.2 s) and a significantly lower success rate (68.9%), explaining their relatively low adoption (14.3%).

The selection of an appropriate number of fingers is also closely related to the physical properties of the crop. Characteristics such as fruit shape, size, and skin hardness directly influence the optimal gripper configuration. For example, apples and tomatoes, which are approximately spherical, are often harvested using fingerless suction or three-fingered grippers to ensure stability during picking. In contrast, delicate crops such as strawberries and grapes [61] are commonly handled with two-fingered designs that grip the fruit by the stem. This approach enables indirect contact with the fruit itself, thereby minimizing potential damage.

2.1.2. End-Effector Finger Materials

Based on the material of the end-effector, it can be further classified into hard end-effector, soft end-effector, and hard end-effector with an elastic membrane. As shown in Table 3, which presents the classification of different end-effectors based on material characteristics, the following section will analyze the impact of finger materials on end-effector performance with reference to this table.

Table 3.

Classification information of different end-effectors based on material properties.

When harvesting large-sized fruits with hard rinds, such as pumpkins and watermelons, their inherent resistance to damage places greater demands on the structural strength and gripping performance of the end-effector. In agricultural robotics applications, hard end-effectors offer superior performance in meeting the specific design requirements for such tasks [63]. Hard end-effectors are typically manufactured from materials with high structural rigidity, such as metals or engineering-grade plastics. Their inherent stiffness and resistance to deformation ensure consistent and reliable grasping performance in agricultural robotic applications [23]. The rigid five-fingered agricultural robot for pumpkin harvesting features multi-link mechanisms in its finger design, with joints that enhance finger flexibility [55]. Analysis of Table 3 indicates that Hard end-effectors, due to their substantial mass and lack of flexibility, cannot perceive operational forces, resulting in lower harvesting success rates, higher damage rates, and limited adaptability. By mimicking the spongy honeycomb structure of bird bones, it is possible to maintain excellent mechanical properties while significantly reducing the weight of the gripper, thereby improving the flexibility of rigid end-effectors. Furthermore, future research on rigid end-effectors could focus on simplifying mechanical structures and enhancing kinematic coordination to broaden their applicability.

When handling fruits with delicate and easily damaged epidermis, such as strawberries, raspberries, apples, and mulberries, hard end-effectors are highly likely to cause irreversible compression or puncture damage [28]. To ensure the quality of harvested fruits and enhance their market acceptability, soft end-effectors have increasingly emerged as a more viable technical solution. soft end-effectors are primarily fabricated using soft materials such as rubber and polymers. To mitigate potential damage to target fruits during harvesting, soft end-effectors are typically designed with enveloping mechanisms or multi-fingered architectures, which effectively distribute grasping pressure and minimize mechanical stress on the fruit surface [24]. For soft end-effectors designed for the delicate harvesting of small fruits, the contact components can consist of two semicircular structures made from flexible materials such as specialized polymer resins. These semicircular elements are embedded with sensors to provide real-time force feedback, thereby reducing compression damage on strawberries [64]. Additionally, flexible materials are suitable for finger manufacturing. The hollow folded structure of conical soft fingers ensures sufficient contact area between the fingers and the target fruit while minimizing finger size and enhancing finger flexibility [56].

It should be noted, however, that despite the low damage characteristics of soft end-effectors, challenges related to their material properties and control complexity warrant careful consideration. The inherent limitations of flexible materials—including poor durability, susceptibility to oxidation, and low temperature resistance—often restrict their load-bearing capacity and can lead to permanent deformation or tearing. These factors, coupled with their inability to operate for extended periods in high-temperature environments, result in higher maintenance and replacement costs. Furthermore, as indicated in Table 1, the frequent pairing of flexible fingers with pneumatic actuation introduces additional control difficulties. The highly nonlinear behavior of these grippers during operation complicates accurate modeling and impedes the control system’s ability to reliably predict harvesting actions [21]. To address the issues of poor stability and fragility in soft end-effectors, the application of variable stiffness technology enables effective improvement through adjustable rigidity in soft grippers. By leveraging the easily deformable characteristics of soft materials combined with the bellows concept, the adaptability of soft grippers can be enhanced to accommodate fruits of varying dimensions and sizes. Drawing design inspiration from bionics and integrating it with the flexible nature of soft grippers holds the potential to unlock more efficient and sophisticated gripper systems.

For fruits exhibiting intermediate skin firmness, including citrus, kiwifruit, and pears, the end-effector must be designed to simultaneously ensure grasping stability and damage-free harvesting performance [57]. A hard end-effector with an elastic membrane combines structural rigidity with compliant surface contact, improving grip reliability while minimizing mechanical damage to the fruit, making it particularly suitable for handling produce with moderate skin firmness. The linkage gripper of a rigid–soft composite end-effector can be constructed from rigid materials to provide robust support capacity, while the gripper tips are equipped with soft materials such as silicone elastic pads to enhance stability during grasping and prevent clamping damage [58]. Furthermore, rigid components can be tailored according to crop morphology to improve conformity between the fingers and the produce, thereby minimizing mechanical damage [65].

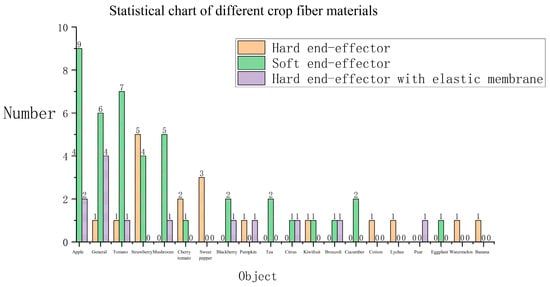

Figure 3 presents the statistical distribution of finger materials used for different crops. Based on the data from Appendix A, Table 3 summarizes the average success rate, harvesting cycle time, and damage rate associated with each type of finger material. The following analysis integrates the data in Table 3 with the advantages and disadvantages of each material to explain the proportional distribution observed in Figure 3.

Figure 3.

Statistical chart of finger materials used in different crops.

As shown in Figure 3, flexible finger materials are widely used in crop harvesting due to their low damage rate (3%), relatively high success rate (80.6%), and relatively short harvesting time (9.6 s). This is particularly evident in the harvesting of highly delicate crops such as mushrooms. In contrast, although rigid end-effectors offer stable grasping performance, they are associated with a significantly higher damage rate (9%). Their inherent weight also increases the harvesting time (13.4 s), resulting in a lower overall success rate compared to other materials. Consequently, rigid end-effectors are more suitable for handling firm-skinned, heavy produce such as pumpkins and watermelons.

Rigid end-effectors with elastic membranes, while not as widely used as their fully flexible counterparts, combine stable grasping with effective damage prevention. This hybrid design achieves the highest success rate (82.3%) and the shortest harvesting time (5.9 s) among all the materials studied. Furthermore, given the susceptibility of flexible materials to oxidation and poor durability, rigid end-effectors equipped with elastic membranes represent a promising future direction for material application in end-effector design.

2.1.3. Picking Methods of End-Effectors

Picking methods significantly influence the success rate, damage rate, and harvesting time of fruit picking, and substantially affect fruit quality. To provide a comprehensive overview of picking methods in harvesting robots, this section categorizes them into three types: Negative pressure, Clamping, and Cutting. As shown in Table 4, it presents a comparison table of the performance and advantages/disadvantages of different separation methods.

Table 4.

Comparison Table of Performance and Advantages/Disadvantages of Different Separation Methods.

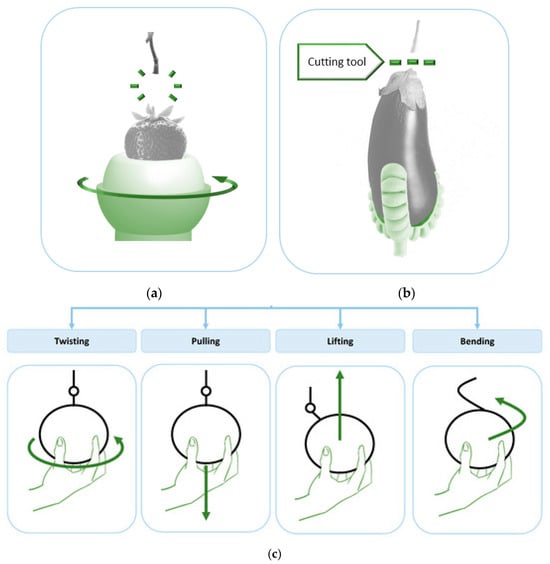

As shown in Figure 4a, a vacuum generator is typically used in the negative pressure adsorption and separation mechanism to generate negative pressure for adsorbing the target fruit, whereby the fruit stem is severed under the suction force to accomplish fruit picking [36]. As evidenced by the analysis in Table 4, negative pressure adsorption is widely applied to near-spherical or hemispherical fruits due to its rapid separation speed and minimal damage to the produce. When employing vacuum adsorption in end-effectors, the structural design of the vacuum suction nozzle ensures crop protection during harvesting while enhancing stable suction force [30]. Additionally, the stability of pressure control deserves focused attention [65].

Figure 4.

Schematic Diagram of Different Picking Methods. (a) Negative pressure; (b) Cutting; (c) Clamping [65] (open access).

Maintaining stable negative pressure output presents a key control challenge in vacuum adsorption systems. The development of additional suction regulation systems, combined with research on crop adsorption and detachment processes, enables adaptive pressure adjustment during harvesting. This effectively prevents fruit slippage due to insufficient suction or damage caused by excessive pressure, thereby enhancing pneumatic output stability. To address the limited applicability of vacuum adsorption—which primarily works well with smooth-surfaced, lightweight produce—hybrid suction-gripper systems offer an effective solution. These integrated systems not only resolve instability issues caused by irregular crop surfaces or environmental dust accumulation during vacuum adsorption but also overcome the spatial constraints required for reliable grip in conventional grasping methods. By combining the advantages of both suction cups and mechanical grippers, the integrated design significantly improves the flexibility and universality of end-effectors [68].

As shown in Figure 4c, clamping detachment mimics the manual harvesting process, where an end-effector grips the fruit and applies direct pulling, twisting, or bending forces to the stem. The stem is then broken by these mechanical actions, thus detaching the fruit [69]. Through the picking techniques, the typical manual fruit picking process involves the following steps: grasping the fruit, pressing the peduncle, twisting it at the abscission zone, and finally pulling straight to separate the fruit from the stem [70].

Gripping-based detachment methods demonstrate strong grasping force, superior stability, and broad applicability. However, studies reveal that single-mode detachment actions have a limited application scope. While torsional detachment causes minimal fruit damage, its prolonged separation time hinders practical implementation. Straight pulling poses significant risks to fruit trees and yields lower harvesting efficiency. Consequently, composite harvesting techniques have emerged as a research focus for enhancing gripping detachment efficiency and adaptability. The bend-pull-twist hybrid end-effector utilizes a specialized gripping mechanism to apply combined forces—bending, twisting, and stretching—to the abscission layer of the fruit. This enables stable grasping of crops with varying sizes and packaging levels [40].

For cutting and separation, as shown in Figure 4b, in the early stage of the development of the fruit-picking robot, additional cutting tools were mainly added to cut the fruit stems to separate the fruits [38]. Scissor-type detachment methods demonstrate broader applicability and relatively low operational complexity. However, the requirement for additional separation mechanisms leads to increased manufacturing costs and extended harvesting time. To improve cutting efficiency, the concept of multi-arm collaborative harvesting has been introduced. For instance, Yang Yu et al. developed a dual-arm collaborative harvesting robot for ridge-cultivated strawberries. By integrating hand–eye coordination technology, a “palm” camera was mounted beneath the fingers to detect target fruits and guide the end-effector for precise positioning and movement [41]. In recent years, the design of specialized end-effectors tailored to the growth characteristics of specific crops has gained significant attention. For example, lychee fruits typically grow in dense, multi-branched clusters. To align with this growth pattern, a comb-cutting-based approach has been proposed to significantly enhance picking efficiency. Zhaoshen Yao et al. designed a lychee comb-cutting end-effector that employs multiple parallel blades to simultaneously sever fruit stems [71]. Furthermore, to improve real-time state feedback, tactile temporal updating mechanisms have been integrated with machine vision, strengthening the end-effector’s real-time perception and adaptive control capabilities during operation.

During practical harvesting operations, the dense and irregular agricultural environment poses significant challenges. The inclusion of additional cutting mechanisms increases the volume of end-effectors, thereby raising the probability of collisions with branches and fruits, which substantially impacts operational efficiency. To address this issue, integrating cutting devices directly into grippers enables simultaneous grasping and stem cutting, effectively minimizing such complications. A broccoli harvesting robot integrating gripping and cutting functions divides its fingers into cutting fingers and gripping fingers. During the separation process, the cutting and gripping fingers close simultaneously to complete harvesting [42]. Azamat Yeshmukhametov et al. further enhanced this approach by adding blades to the edges of a hemispherical gripper, enabling synchronous stem cutting during the gripper’s closure, thereby reducing harvesting time [72].

Observations of manual harvesting practices reveal that repeated disinfection of cutting blades is necessary to prevent viral infections in plants, which significantly impairs cutting efficiency. Thermal cutting methods utilizing high-temperature electrodes or lasers offer effective solutions to this problem. The application of electrode discharge cutting for thermal incision helps inhibit the transmission of fungi or bacteria, thereby contributing to an extended shelf life of fruits [67]. However, the high maintenance costs associated with electrical cutting methods remain a major limitation. Most conventional end-effectors consist of separate mechanical grippers and cutting devices, resulting in bulky systems incapable of performing precise harvesting tasks in complex environments. Laser cutting technology presents a promising alternative by significantly reducing the volume of harvesting devices and enhancing operational flexibility [73]. Additionally, laser cutting systems require minimal maintenance, offer wider adaptability, and effectively improve the operational efficiency of end-effectors.

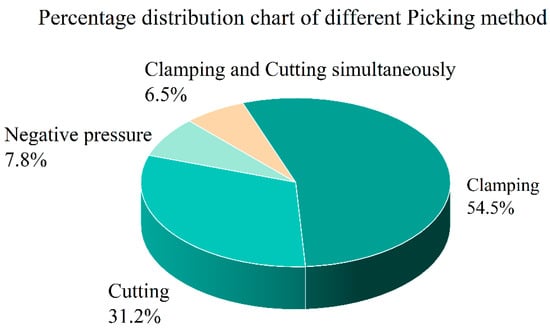

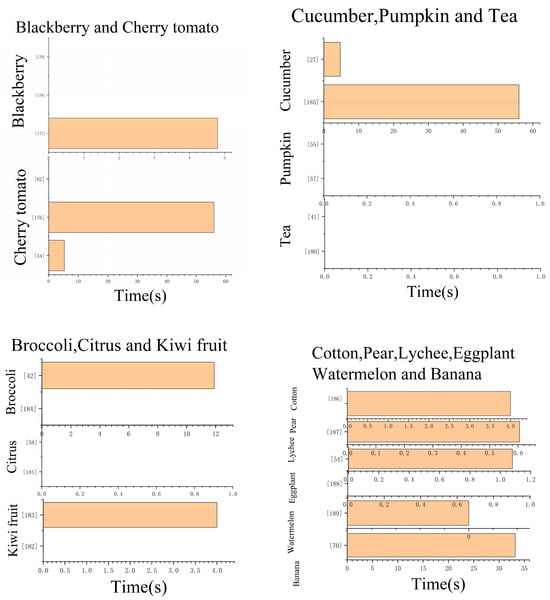

Figure 5 illustrates the proportional distribution of four fruit-picking methods: gripping, cutting, negative pressure adsorption, and combined gripping-cutting. Based on data from Appendix A, Table 4 summarizes the average success rate, harvesting cycle time, and damage rate for each method. The following analysis integrates the data in Table 4 with the inherent advantages and disadvantages of each method to explain their respective distribution patterns.

Figure 5.

Percentage distribution chart of the picking method.

As indicated in Figure 5, the gripping method accounts for the highest proportion (54.5%). This prevalence is attributed to its direct application of pulling, twisting, or bending forces via fingers to detach the fruit, eliminating the need for a separate detachment mechanism. This not only reduces design complexity and cost but also simplifies control, resulting in a shorter harvesting time (5.9 s) and contributing to its high success rate (82.6%). In contrast, despite its high success rate (81.8%) and short cycle time (6.5 s), negative pressure adsorption accounts for a relatively small share (7.8%) due to its susceptibility to interference from branches, leaves, and dust during operation, which leads to a significantly higher damage rate (5%).

The cutting method, despite a lower success rate (77.43%) and longer harvesting time (12 s), holds a considerable share (31.2%) owing to its broad adaptability and low cost. Furthermore, integrating the cutting mechanism into the fingertips of the gripper enables simultaneous gripping and cutting. This combined approach significantly enhances the success rate (86.77%). However, the need for the end-effector to adapt to variations in fruit shape and size during this process results in a substantially longer harvesting time (33.2 s).

2.1.4. Driver Mechanism of the End-Effector

A drive mechanism is a device that converts electrical signals into mechanical force to ensure the end-effector provides sufficient gripping force for successful harvesting tasks. Based on the type of drive mechanism, end-effector can be classified into the following categories: Electric, Pneumatic, Vacuum, Magnetic, Hydraulic, and Hybrid drives. As shown in Table 5, it provides an introduction to the main components driven by different driving methods and their characteristics.

Table 5.

Introduction to the Main Components Driven by Different Driving Methods and Their Characteristics.

In an electric end-effector, the drive system utilizes motors to generate force and torque, which are transmitted through gear mechanisms or other transmission systems to open or close the gripper, thereby enabling the harvesting of target fruits [74]. The electric end-effector utilizes a rotating motor to drive a gear system, enabling the gripper to close. Through the rotation of the end-effector, the fruit is separated from the branch. Simultaneously, the motor output torque ensures stable grasping of the fruit, preventing damage [32]. As indicated in Table 5, electric drives are characterized by flexibility, stability, and strong adaptability. For precision operations in mushroom harvesting, Haonan Shi et al. designed an electric mushroom harvesting end-effector. Its lifting module employs a screw mechanism to achieve vertical movement of the gripper, providing precise control to prevent harvesting damage. The rotation module twists the clamped mushroom for accurate detachment [62]. However, compared to other driving methods, electric drives entail higher costs (approximately $700–$2000) and more complex control systems. Future research should focus on reducing the operational costs of motor systems, which would facilitate the commercialization of harvesting robots.

In a pneumatic end-effector, a control system is typically used to regulate the pneumatic actuator’s compressed air, enabling the fingers to move and perform grasping tasks [66,75]. Compared to electric actuators, pneumatic grippers exhibit limitations in output force and torque, resulting in relatively lower stability and control precision. However, pneumatic systems offer distinct advantages through continuous force regulation by adjusting system pressure. Furthermore, the inherent compressibility of gases enhances the buffering and protective capabilities of end-effectors. The pneumatic finger-type end-effector operates during harvesting by using telescopic cylinders to tighten the gripper around the fruit. Subsequently, the drive gear and rotary cylinder rotate to separate the fruit from the cluster [43]. Despite these advantages, pneumatic systems face challenges in adaptability and limited grasping force output. To address these limitations, soft grippers with variable stiffness characteristics present a promising solution for effectively enhancing grasping capability. Concurrently, the development of novel soft materials with improved durability will significantly expand the applicability of pneumatic drive systems.

In a vacuum end-effector, harvesting robots typically utilize suction devices to securely grip target fruits. This method is generally suitable for fruits with smooth surfaces and low weight [59]. Although pneumatic grippers also rely on air pumps for pressure generation, vacuum-driven systems employ “octopus-tentacle” inspired suction mechanisms to adhere to target fruits. The adsorption force can be precisely regulated by adjusting the pump pressure, thereby minimizing potential damage to the produce. A representative implementation is demonstrated by Chris Lehnert et al., who developed a vacuum-based sweet pepper harvesting robot. When the end-effector aligns with the target pepper, the suction cup extends to establish optimal contact with the fruit surface. Subsequently, an integrated cutting blade activates to precisely sever the peduncle, achieving clean separation from the plant [76].

Although vacuum-driven systems generally cause less damage to target fruits compared to electric drives, their suction-based end-effectors require high surface quality of the produce. They are susceptible to interference from foliage, dust, and other surface contaminants, while fruits with irregular shapes or delicate skins often experience unstable adsorption. Furthermore, precise regulation of suction force remains challenging: insufficient vacuum pressure compromises gripping capability, whereas excessive pressure may cause internal fruit damage. These limitations represent major obstacles to the advancement of vacuum-driven technology. To address these issues, Wanjia Hua et al. developed a vacuum-based end-effector for apple harvesting. They systematically evaluated its adsorption performance, fruit separation efficiency, and potential compression damage, analyzing the effects of suction cup diameter, separation methods (rotation and pulling), and air pressure levels on practical field applications [77].

In the field of magnetic end-effector, magnetic drive is attracting growing attention due to its advantages such as non-contact operation and high responsiveness. Magnetic-driven end-effectors primarily control the magnetic field strength by adjusting the electric current, inducing deformation of the gripper to achieve grasping functionality. Zheng Zhang et al. developed a magnetic-driven bionic robotic gripper with a bistable morphing structure. The compliant fingers of this end-effector consist of two cylindrical shells fabricated from carbon fiber-reinforced polymer. When the electromagnet generates a magnetic field acting on the neodymium magnets, repulsive magnetic forces along the curved edges induce deformation. This causes the two fixed asymmetric shells to transition from a flat state to a concave configuration, thereby achieving the gripping motion [44]. However, magnetic actuation requires indirect control of grippers through electromagnetic effects, resulting in relatively complex control systems. If this challenge can be effectively addressed, magnetically driven grippers are expected to become an emerging research focus.

In hydraulic drive systems, the opening and closing of the end-effector are primarily controlled by regulating hydraulic pressure and flow. A typical system includes a hydraulic pump, hydraulic cylinder, hydraulic oil tank, and control valves. Capable of delivering high torque and power, these systems exhibit strong load-bearing capacity and smooth motion, making them particularly suitable for heavy-duty agricultural tasks performed by robotic arms [78]. To address the limited load-bearing capacity of electrically driven robotic arms, which struggle to securely handle heavy banana bunches, Tianci Chen et al. developed an autonomous banana harvesting robot that integrates clamping and cutting functions for banana stems. The clamping mechanism is powered by a hydraulic cylinder, which drives a linkage system via push-pull rods. This design enables self-adjusting jaws that deliver consistent clamping force throughout the cutting process [79]. While hydraulic systems offer superior stability and high load capacity, their large size compromises operational flexibility, resulting in reduced cutting efficiency and limited applicability. Furthermore, hydraulic drives entail significantly higher costs compared to alternative actuation methods, constraining their widespread adoption.

In electric–pneumatic hybrid drive systems, end-effectors typically employ pneumatic actuators to generate gripping force. However, due to the large stroke requirement of electric actuators, they are difficult to integrate into lightweight and compact manipulator designs. To achieve both powerful grasping and dexterous manipulation with the end-effector, Shotaro Mori et al. proposed a novel hybrid pneumatic-electric robotic end-effector. This design utilizes lightweight pneumatic artificial muscles and a passive clutch mechanism to address these requirements, while also incorporating an electric motor for precise finger control [80].

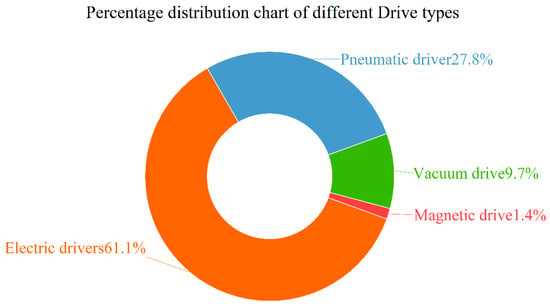

Figure 6 categorizes references by drive method, with Table 6 providing a comparative analysis. Electric drives dominate end-effector applications (57.1%) due to their high precision, adaptability and low maintenance, despite higher initial costs. Pneumatic systems rank second (26%) with advantages in cost control and low damage potential. Vacuum drives (9.1%) offer low-cost operation but require specific fruit surface properties. While magnetic drives currently represent only 1.3%, they show promise for their controllability and minimal maintenance. Hydraulic systems (1.3%) are limited by high costs and maintenance demands. Electro-pneumatic hybrid drives (5.2%) balance wide applicability with higher equipment costs.

Figure 6.

Proportion of Different Drive Methods.

Table 6.

Comparative Analysis of Drive Methods: Cost, Maintenance, Response Speed, and Precision.

2.1.5. Bionic End-Effector

Animals and plants have inhabited the Earth for tens of millions of years. Throughout this extensive period of natural evolution, they have adapted to diverse and dynamic environmental conditions, developing unparalleled biological structures to acquire nutrients and sustain growth. By closely observing these adaptations, researchers have integrated biological structures and behavioral mechanisms into the design of robotic grippers. This bio-inspired design enhances the end-effector’s effectiveness in complex harvesting environments and improves overall picking efficiency [81,82].

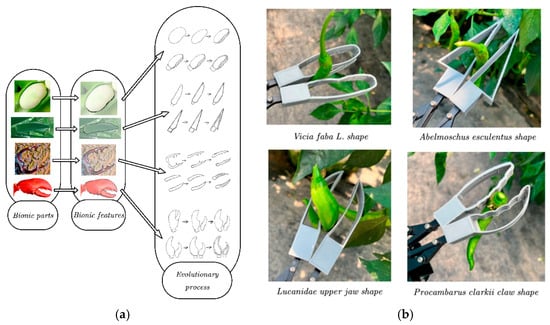

Drawing inspiration from coordinated multi-finger arrangement and collaborative movement, Chuanxing Du et al. developed a bionic finger mechanism by simulating the finger configurations and postures of human workers during pepper harvesting. Through biomimetic design with an angled multi-finger arrangement, this innovation effectively addresses the challenge of ground loss during mechanical pepper harvesting, significantly improving the net recovery rate [83]. To meet the high-energy impact requirements for Gentiana root-soil separation, Hongguang Cui et al. designed a soil removal device for Gentiana root-soil complexes, mimicking the woodpecker’s pecking behavior. The system’s optimal operational parameters have been systematically determined [84]. Inspired by the Asian elephant’s feeding mechanism—where the distal tip of the trunk performs tactile sensing while the enveloping structure facilitates grasping—Qingyu Wang et al. developed a bionic pneumatic soft-hand end-effector. This system incorporates multi-modal grasping strategies to enable damage-free harvesting of delicate apples [60]. Hongyi Chen designed an underwater bionic octopus gripper by mimicking the octopus’s ability to perceive environmental information through its tentacles and dorsal membrane, along with its use of suction cups for precise object capture. The gripper features suction-cup-like structures and embedded friction sensors [85]. Leveraging biological principles, Lexing Deng et al. designed a flexible pepper harvesting end-effector that mimics the morphological characteristics of broad bean pods. Using finite element analysis, the team validated the feasibility of four gripper configurations and analyzed their deformation behavior under various harvesting scenarios. In practical experiments (Figure 7b), the broad bean-inspired flexible end-effector demonstrated the best overall performance, achieving high picking efficiency along with the lowest rates of fruit breakage and fruit drop. Its performance significantly surpassed that of manual and traditional mechanical harvesting methods, effectively meeting the requirements for pepper harvesting in facility agriculture [86].

Figure 7.

Bionic end-effector: (a) Extraction and evolution of bionic features. (b) Harvesting experiments with various end-effector configurations [86]. (open access).

2.2. End-Effector Harvesting Planning Technology

Agricultural production activities are highly diverse and complex, and harvesting robots often operate in unstructured environments. Therefore, the end-effector must exhibit strong adaptability and high control accuracy to ensure successful picking. However, crop tissues are soft and susceptible to damage, with significant variations in size, weight, and maturity. If the end-effector lacks sufficient stability, incomplete envelopment of the fruit may occur, leading to slippage during handling and failure to achieve clean cutting. Moreover, due to the variability among individual fruits, the system often lacks precise grip force control, resulting in fruit damage.

To enhance the stability and reliability of the gripping system and minimize grasping damage to fruits and vegetables, this chapter will begin with an analysis of their biomechanical properties. It further delves into the effects of end-effector harvesting obstacle-avoidance planning strategies, grasping patterns, and grasping force on harvesting performance.

2.2.1. Analysis of Mechanical Damage in Fruit and Vegetable Grasping by End-Effectors

Fruits and vegetables are prone to mechanical damage such as compression, abrasion, and puncture during harvesting, processing, and transportation, which significantly reduces their market value. Determining the biomechanical properties of produce—including elasticity, hardness, sugar content, soluble solids content, and viscoelasticity—is crucial for improving quality and reducing mechanical damage. Fabrice Vaudelle et al. utilized visible/near-infrared spectroscopy and the Monte Carlo Method (MCM) to investigate texture-related parameters—such as size, firmness, and soluble solid content—of different apple varieties [87]. Research on the binding forces and physical morphology of immature fruit stems, mature fruit stems, flowers, and leaves provides theoretical foundations and detailed data for the design of harvesting robots [88]. By evaluating the physical and mechanical properties of crops, the impact of different maturity stages on the stress–strain behavior of jujubes can be revealed, offering new insights into mechanical resistance, deformability, and structural stability [89].

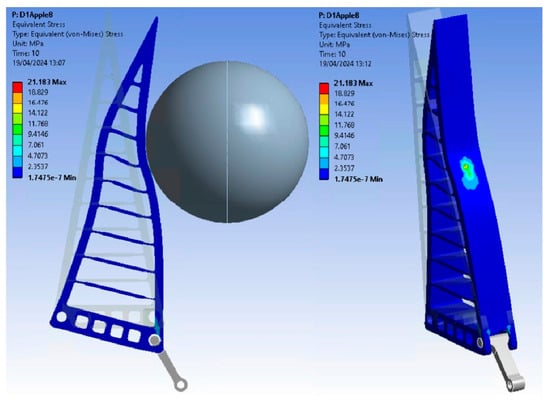

In the field of mechanical damage simulation, finite element analysis (FEA) is commonly employed to investigate the mechanisms of fruit and vegetable damage during harvesting. This approach facilitates the identification of optimal operational parameters for harvesting robots and provides a theoretical basis for adjusting their working conditions. Wei Ji et al. utilized a viscoelastic Burgers model to calculate the deformation resistance and stage-specific dynamic characteristics of apples during grasping. Based on this, they established a viscoelastic finite element complex model of the apple and conducted simulations to analyze the stress variations during contact and collision between the gripper and the apple under different constant velocities [90]. To investigate the impact of compression damage on fruit quality, Haobin Chen et al. developed a multi-scale finite element model of the fruit’s skin and flesh. Through this model, they analyzed the effects of compression distance and storage duration on internal stress distribution, revealing the relationship between the mechanical properties of apples and resulting damage. Their study provides critical insights for predicting internal bruising and supports the development of new systems aimed at preventing fruit damage [91]. Rui Song et al. employed reverse engineering technology to reconstruct a three-dimensional model of blood oranges. Using this model, they simulated both uniaxial compression tests and contact processes on variable-curvature surfaces, thereby elucidating the mechanical characteristics of a contact-based picking method for citrus fruits [92].

2.2.2. End-Effector Harvesting Obstacle-Avoidance Path Planning Strategy

As a core technology of fruit-picking robots, the sophistication of the planning strategy directly influences both harvesting efficiency and fruit quality. During operation, formulating an appropriate picking strategy based on the geometric and physical characteristics of the target fruit, the working environment, and the type of end-effector gripper can effectively mitigate issues such as friction and compression between adjacent fruits, thereby enhancing harvesting performance [93,94,95,96,97]. When harvesting crops with densely clustered fruit patterns—such as tomatoes, kiwis, and lychees—the close proximity of individual fruits makes them highly susceptible to abrasion and impact damage during picking operations. To achieve collision-free harvesting of clustered tomatoes, Nianzu Dai et al. addressed the complex operational environment through YOLOv5-based multi-tomato detection and localization. By integrating density clustering and shortest-path optimization principles, they automatically grouped adjacent tomatoes into picking clusters and proposed an optimal sequential harvesting strategy [98]. For lychee harvesting robots, Lei Ye et al. developed a rapid collision-free posture planning method utilizing binocular stereo vision. They introduced an improved Adaptive Particle Swarm Optimization (APSO) algorithm to solve inverse kinematics problems, incorporating the concept of target gravity and adaptive parameter adjustment into the Bi-RRT algorithm [99]. Rui Suo et al. proposed an enhanced multi-category kiwifruit detection method, classifying fruits into four or five types based on robotic harvesting strategies and field occlusion conditions. Through transfer learning for multi-class kiwifruit recognition, they significantly improved the real-time performance of the fruit detection system [100]. Additionally, multi-arm motion planning has gradually emerged as a research focus in this field [101].

Visual uncertainty remains a critical constraint for deploying end-effectors in heterogeneous crop canopies. In a recent study, Rana et al. proposed a soft classification-based mapping framework that employs a Modified Possibilistic C-Means (MPCM) clustering algorithm combined with vegetation indices (SAVI, MSAVI, MCARI) to model spectral overlap and intra-class variability in agricultural imagery. This fuzzy logic approach offers valuable insights for compliant control and adaptive perception in harvesting robots—effectively addressing spectral uncertainties when fruits, leaves, and occluded structures exhibit mixed reflectance characteristics [102].

2.2.3. End-Effector Grasping Patterns Design

Currently, research on end-effectors predominantly focuses on structural design and grasping control strategies, while the grasping principles and working mechanisms of picking patterns remain relatively understudied. Therefore, it is essential to improve the planning of end-effector grasping positions on the fruit surface during harvesting. By designing separation modes based on these pre-planned grasping points, compliant and effective fruit picking can be ensured.

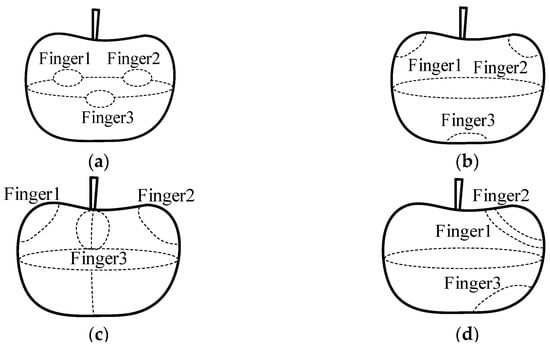

Focusing on grasping stability, Pan Fan et al. systematically planned gripping positions for a three-finger end-effector in two configurations: vertical grasping (parallel to the stem-calyx axis) and horizontal grasping (centered toward the equatorial plane), as depicted in Figure 8a,b. The team designed four harvesting motions—vertical pulling, horizontal pulling, vertical rotation, and rotational-horizontal pulling—to determine the optimal three-finger grasping posture [48]. Wei Ji et al. enhanced existing gripping positions by proposing two novel configurations: inward-finger horizontal centripetal grasping and inward-finger grasping parallel to the sepals axis (Figure 8c,d). Additionally, they introduced an innovative stem-separation method utilizing a circumferential downward motion of the end-effector. Experimental results identified the optimal picking angle for this method as 15–20°, with the combination of vertical inward-finger posture and circumferential downward motion proving to be the most effective harvesting strategy [103].

Figure 8.

Apple grasping patterns: (a) Vertical, (b) Horizontal. (c) Medial-finger horizontal centripetal grasping; (d) Medial-finger grasping parallel to the calyx axis [103]. (open access).

2.2.4. Modeling and Analysis of Grasping Force in End-Effector

When the grasping force exerted by the end-effector exceeds the damage threshold of the fruit or vegetable tissue, it causes clamping damage; conversely, if the force is too small, the fruit may slip from the end-effector, leading to impact damage. To achieve appropriate grasping force control, this section will examine the interaction between the end-effector and the fruit through three key aspects: end-effector model simulation, grasping force analysis and optimization, and dynamic simulation of the grasping process. The objective is to enhance grasping stability and compliance, minimize damage, and improve overall fruit quality [104].

In end-effector design, virtual prototyping and simulation help ensure structural rationality and reliability, thereby reducing fruit damage during operation. By simulating the expansion behavior of fingers with different shapes through finite element analysis, and integrating adaptability and modularity into the design concept, the end-effector can be freely configured to accommodate crops of varying diameters [105]. Through advanced control algorithms, the grasping force of end-effectors can be analyzed and optimized to minimize damage to target fruits. Yuan Fahui et al. combined kinematic analysis of an asparagus end-effector with a backpropagation neural network to develop a real-time viscoelastic parameter prediction framework. This approach effectively estimates deformation behavior and guides the determination of the optimal gripping force range [106]. To optimize contact force between the end-effector and apples, Hongwei Zhang et al. applied force-closure theory, considering constraints related to force closure, nonlinear friction cones, and torque. Experimental results demonstrated that this model achieves a grasping success rate of over 90% [107].

Utilizing finite element-based dynamic simulation to model the grasping and contact process of end-effectors has emerged as a new research direction for determining the optimal characteristics of grippers. This approach aims to enhance the adaptability and harvesting efficiency of end-effectors in real-world environments. Finny Varghese et al. designed a flexible fin-ray-based soft end-effector, as illustrated in Figure 9. To determine the optimal gripper characteristics, they simulated the interaction between the gripper and the fruit, conducted force analysis on the fingers during the grasping process, and examined the stress and strain distribution on the gripper to minimize potential damage to the fruit during manipulation [108]. Using finite element analysis and reverse engineering methods, finite element models of various crop components were established. Through finite element simulations of pure pulling harvesting modes, the pure bending harvesting method that minimizes damage to specific crops [109] and the optimal inflation pressure [110] can be identified.

Figure 9.

Finite element simulation of the end-effector gripping process [108] (open access).

2.3. End-Effector Harvesting Control Technology

2.3.1. End-Effector Grasping Control

Efficient control methods directly impact the precision, stability, and efficiency of end-effector operations during harvesting. Dedicated control methods for end-effectors primarily include trajectory optimization, force control, and impedance control [111].

During the operation of fruit-picking robots, the smooth motion of the end-effector is crucial. To prevent vibrations or oscillations from compromising harvesting performance, the end-effector must reach the target position with minimal oscillation during trajectory tracking, thereby ensuring grasping stability. By incorporating target bias, adaptive step size, and pruning strategies, the optimized Informed-RRT* algorithm enables shorter and smoother motion paths for robotic arms, with angular velocity and angular acceleration exhibiting smooth and continuous trends [112]. The vision-based semantic-inspired bionic grasping algorithm for robotic arms improves the DeepLabV3+ model and GR-ConNet, leveraging model predictive control to enhance control robustness and achieve better trajectory tracking and compliance [113].

With the rapid advancement of artificial intelligence, the integration of human creativity, learning capabilities, and machine technologies has led to increasingly flexible, highly adaptive, and autonomous robotic systems. In the context of human–robot collaboration, numerous AI-based grasping planning algorithms have been proposed. Learning-based adaptive harvesting strategies have become a research focus for improving the planning efficiency of robotic arms. The introduction of reinforcement learning algorithms has continuously enhanced robots’ ability to operate independently in complex environments, while optimizing the planning paths of robotic arms. Truong Nhut Huynh et al. combined the contextual reasoning capability of large language models with the real-time decision-making of reinforcement learning to enhance robotic robustness and continuously optimize task strategies. This integration enables robots to adjust their actions in response to real-time environmental changes, making them suitable for unstructured and dynamically evolving scenarios [114]. Despite advancements in artificial intelligence-based motion planning for robots, gaps remain in real-time adaptability and integrated resource optimization. Existing systems often rely on predefined models and lack the capability to adjust planning strategies in real time, thereby limiting their performance in dynamically changing environments. Furthermore, motion planning and grasping control are typically treated as separate processes, leading to inefficiencies in the coordination of resources across operations [115].

The end-effector’s gripper directly interacts with fruits, and effective control of the contact force not only enhances grasping stability during harvesting but also reduces potential fruit damage. Jingwei Sun et al. developed a fully actuated adaptive apple harvesting end-effector based on triboelectric force feedback. By integrating biomechanical modeling, structural optimization, sensor integration, and force feedback control, the end-effector achieves high grasping stability and a low damage rate, effectively addressing the challenge of balancing gripping reliability and non-destructive harvesting in unstructured orchard environments [116].

Compliant control strategies can be broadly categorized into passive hybrid force–position control and active admittance control or impedance control. In force–position control, the machine’s position is adjusted based on force feedback, and frequent switching of controllers directly affects the real-time performance of robotic control. Passive compliant control methods often suffer from insufficient control precision and performance tracking in complex working conditions. In contrast, admittance control and impedance control eliminate the need for external sensors by directly converting external forces or torques into the robot’s reference position or velocity, resulting in more stable external control, enhanced flexibility and compliance, and improved real-time performance in mechanical control. Impedance control can improve the response relationship between the manipulator and its environment. It regulates dynamic interactions during robotic operations to accomplish specific tasks, such as tracking a desired trajectory while maintaining contact forces within an appropriate or allowable range to ensure grasping stability [117,118].

To achieve precise control in kiwifruit harvesting, Zixu Li et al. proposed a flexible grasping strategy utilizing impedance control. They integrated a fuzzy PID controller into the impedance-based kiwifruit picking system and optimized the fuzzy PID control strategy, reducing the system’s settling time from 1.91 s to 1.08 s. This enables accurate control of the fruit grasping process [119]. To achieve compliant grasping for apple harvesting robots and reduce mechanical damage during the grasping process, Wei Ji et al. proposed a variable damping impedance control strategy for tracking the grasping force of the end-effector, based on the establishment of a contact force model. This approach results in smoother tracking of the grasping force and significantly improves dynamic performance [120]. Based on impedance control theory, Zongbin Wang et al. established a contact force model between the robot and the orchard environment and improved the adaptive variable impedance control algorithm. The contact force was used as feedback for the adaptive variable impedance control, with the damping parameters adjusted adaptively to regulate the interaction force between the robot and the orchard environment. Experimental results for fruit picking demonstrated that, under adaptive variable impedance control, the robot exhibited an overshoot of 4.53% and a settling time of 3.54 s, representing reductions of 3.83% and 0.77 s, respectively, compared to traditional impedance control [121].

Robot admittance control typically models human–robot interaction as a mass-damping-stiffness system. The admittance parameters, particularly damping, determine the performance of compliant control. Studies have found that constant admittance parameters cannot adapt to the dynamic changes in the robot, whereas variable admittance control not only maintains accuracy but also reduces execution time, enhancing the robot’s real-time control capability. The adaptive admittance control technology developed by Tao Sun et al. enables human–robot collaborative assembly of large parts without the use of external sensors [122]. While active motion control can effectively predict human intent to achieve flexible manipulation, its stability is often compromised by environmental variations. To address the degradation of grasping stability and compliance caused by environmental changes, Qi Zhou et al. integrated multimodal reinforcement learning with adaptive compliance control, significantly improving the system’s performance and achieving a grasping success rate of 99.8% [123].

Traditional vision-based grasping methods often suffer from limited stability and adaptability due to environmental factors such as illumination variations and shadows. With advancements in deep learning and reinforcement learning, robots can now acquire complex manipulation strategies from large-scale data, effectively addressing challenges faced by conventional grasping approaches. Confronted with unstructured orchard environments, fluctuating light conditions, and leaf occlusion issues, Dong Woon Choi et al. developed an AI-driven robotic system for adaptive grasping and precise detachment. The system employs an AI-powered hand–eye module that estimates the 6D pose of target fruits, effectively compensating for positional errors during pose estimation and grasping in citrus harvesting [58]. To overcome limitations of traditional grasping in dynamic and uncertain environments—particularly in achieving precise interaction between estimated grasping poses and objects—Xiao Hu et al. proposed a tactile-based reinforcement learning framework for adaptive grasping under observational uncertainty. This approach enables real-time grasp adjustment through tactile feedback, significantly improving grasping stability and robustness while mitigating inherent constraints of traditional grasping planning methods [124]. Despite these advancements, reinforcement learning still faces challenges in complex tasks due to high state-action dimensionality and reward design complexity. Xiaofan Yang et al. introduced a novel learning framework for complex robotic tasks: Goal-Based Arm-Grasp Coordination RL (GBAGC-RL). This method integrates task representation, subgoal extraction, and goal-based hierarchical reinforcement learning to develop efficient and transferable robotic manipulation skills, while substantially simplifying reward function design [125].

2.3.2. Tactile Perception for End-Effectors

Tactile perception technology typically employs integrated sensors to acquire real-time data on the grasping status of the end-effector during operation. This enables stable control of the grasping process, ensuring that fruits remain undamaged during manipulation. Common types of contact sensors include pressure sensors, tactile sensors, force sensors, and others. These sensors are generally installed on the joints of the end-effector, the surface of the fingers, or other critical areas to detect and measure various parameters related to motion, position, force, torque, and temperature [126].

Addressing the issue of slip during end-effector grasping, detecting initial slip in the grasping process and optimizing the applied force are key to preventing slippage and achieving secure grasping. A tactile information acquisition system was developed to monitor and record contact forces and shape changes in the fingers during grasping in real time. By employing machine learning to detect sliding motions, it ensures non-destructive grasping with the most appropriate force levels [127]. To prevent slipping between the fruit and the fingers, a soft gripper for apple harvesting with force feedback and slip detection was designed, effectively reducing fruit slippage during grasping [128]. Utilizing deep neural networks and machine learning-based techniques, the system enables simultaneous measurement of hardness and monitoring of contact forces during a single contact with peaches, achieving non-destructive assessment of fruit hardness and contact forces [129].

With the continuous development of tactile technology, tactile perception is no longer limited to acquiring object motion states. Deep tactile perception technology, aimed at recreating the rich sensory experiences of texture, hardness, elasticity, and temperature during physical object contact in virtual or remote environments, has emerged. Nicolas Kosanovic et al. introduced a bionic real-time multi-channel tactile system and its perception technology. By measuring finger compliance and vibrations through dynamic sensors on the robotic hand, they quantified and identified material compliance and texture. This approach achieved over 80% accuracy in distinguishing between smooth and rough objects without requiring contact force/velocity control [130].

2.3.3. Hand–Eye Coordination for End-Effectors

During traditional manual harvesting, workers typically begin by visually identifying the location of ripe fruits. They then grasp the fruit firmly with one hand while using scissors with the other to cut the plant stem, thereby completing the picking process. To enhance picking control accuracy and mitigate the impact of complex environments and irregular targets on harvesting efficiency, reliable hand–eye coordination technology is crucial for the real-time control of harvesting robots [131].

To achieve continuous and uninterrupted harvesting operations, Ping Zhang et al. proposed a parallel dual-arm robotic control method of white asparagus based on moving–looking–harvesting coordination and asynchronous harvest cooperation. First, to reduce control complexity, a dual-arm parallel harvesting mode with independent harvesting areas was designed. Second, addressing the random distribution characteristics of asparagus, a coordinated moving–looking–harvesting control strategy was proposed, enabling synchronization of the robot’s movement, asparagus recognition, and harvesting operations. Finally, a selective harvesting system was constructed, and its performance was evaluated in the field. The results showed that, compared to single-arm harvesting, dual-arm harvesting saved 45.17% of the time, increased the harvesting success rate by 3.19%, while maintaining workload balance [132].

The method of using high-gain controllers to compensate for fruit motion is susceptible to measurement noise. To address this issue, S.S. Mehta et al. developed a robust image-based visual servo controller for regulating the robot’s motion toward target fruit in the presence of unknown fruit movement [133].

To address the issue of control degradation caused by dynamic fruit tracking, Tao Li et al. proposed a novel Image-Based Uncalibrated Visual Servoing (IBUVS) control method. This approach utilizes an eye-in-hand camera and an RGB-D (Red-Green-Blue Depth) camera to construct a hybrid visual servoing system incorporating multi-object detection and edge computing technologies. Furthermore, an adaptive tracking controller was implemented to ensure that the harvesting robot accurately follows a predefined trajectory when approaching target fruits [134].

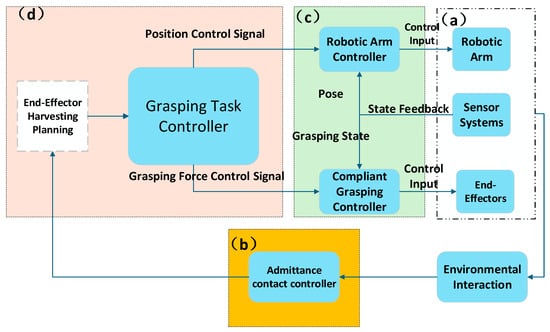

2.4. Unified Comparative Framework for End-Effectors

Through extensive research, we have observed that previous studies often evaluate end-effector design, sensing technologies, and control algorithms in isolation, leading to significant inconsistencies in overall performance assessment. To enable a unified comparison of end-effector performance, this review proposes a control-centric hierarchical framework comprising four progressive layers, as shown in Figure 10: (a) Ontological Characteristic Layer (white), (b) Physical Interaction Layer (orange), (c) Feedback Optimization Layer (light green), and (d) Task Layer (light brown).

Figure 10.

Hierarchical Comparative Framework Diagram. (a) Ontological Characteristic Layer (white), (b) Physical Interaction Layer (orange), (c) Feedback Optimization Layer (light green), and (d) Task Layer (light brown), Hardware components (blue).

The Ontological Characteristic Layer describes the configurational features and intrinsic physical parameters of the end-effector, including dimensions, power consumption, cost, and mass.

The Physical Interaction Layer represents the level at which the end-effector engages in physical interactions with the environment and objects. Key performance metrics at this layer include grasping force output range, speed and displacement output ranges, and fingertip contact surface friction coefficient.

The Feedback Optimization Layer utilizes sensor information for feedback-driven performance enhancement of the end-effector and robotic arm. Critical indicators at this level comprise closed-loop stability, grasping stability, control precision, and slip detection capability.

The Task Layer corresponds to specific operational objectives such as harvesting, with performance measures including harvest success rate, cycle time, and damage rate. This structured approach enables comprehensive cross-dimensional analysis while maintaining focus on control philosophy as the unifying thread throughout the evaluation process.

The Admittance Contact Controller is used to receive environmental signals and enable effective behavior planning for the end-effector, including grasp position, grasp angle, grasp speed, and motion trajectory. Grasping Task Controller outputs control signals to downstream controllers based on planned tasks, including pose signals, grasping force, and grasping speed. The Robotic Arm and Compliant Grasping Controller receive control signals from the Grasping Task Controller to precisely control the robotic arm’s end-effector. Simultaneously, they utilize state feedback from sensors to optimize control performance.

2.5. End-Effector Performance Evaluation Criteria

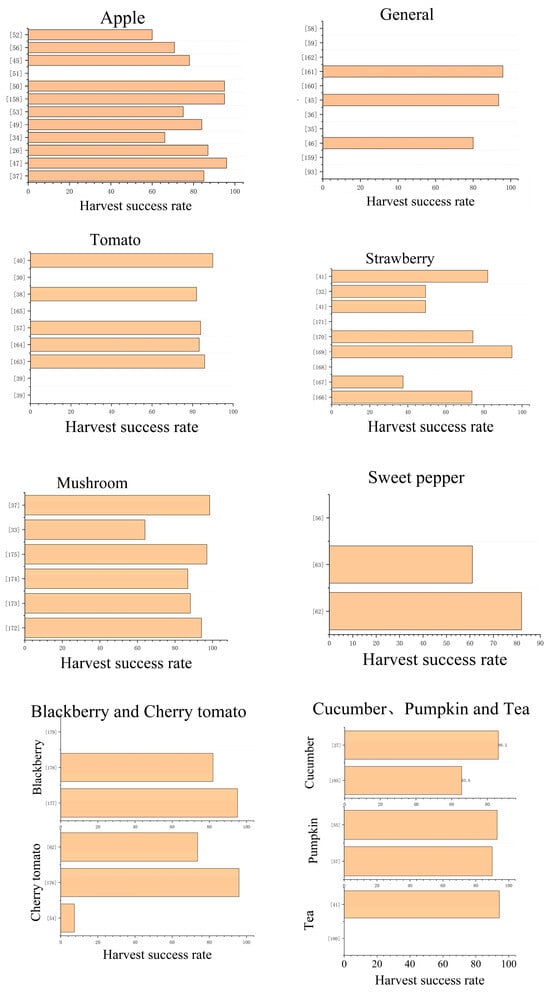

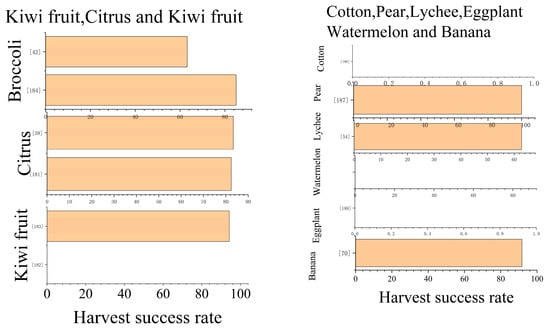

To properly evaluate the performance of end-effectors, researchers generally adopt three key criteria for comparison: harvesting success rate, harvesting cycle time, and damage rate. However, the existing performance evaluation system for end-effectors lacks scientific rigor and systematic comprehensiveness.

According to the data presented in Appendix A, out of 77 referenced studies, only 54 document the harvesting success rate, accounting for 70% of the total literature. Only 37 studies provide details on the harvesting cycle time, representing just 48% of the total literature. Notably, the maximum recorded cycle time is 33.2 s, while the minimum is 0.605 s—a striking 55-fold difference between the extremes, which suggests a lack of consistent measurement standards across different crop types. Even more remarkably, only 4 studies report the damage rate, making up a mere 5.1% of the total literature.

In light of these significant gaps and inconsistencies, this paper will provide a concise explanation and critical discussion of these three evaluation criteria.

The harvest success rate is defined as the percentage of successfully harvested mature fruits relative to the total number of mature fruits in the crop canopy, calculated as follows:

Harvest Success Rate = (Number of Successfully Harvested Mature Fruits/Total Number of Mature Fruits in the Canopy) × 100%

Here, “successfully harvested fruits” include both undamaged and damaged fruits, provided that the fruits remain stably gripped during both the separation process and subsequent transfer into the collection bin. It is important to note that the harvest success rate can be influenced by multiple factors, such as: Accuracy of computer vision-based recognition and positioning, Fruit characteristics (e.g., shape, size, and surface texture), and operational and environmental conditions.