Abstract

The purpose of this study is to explore how corn varieties and moisture content affect the mechanical properties of corn with high moisture content (26.0~36.4%). The mechanical properties of corn that affect corn threshing quality are determined by establishing the contact mechanical model of the threshing elements and corn kernels. These mechanical properties of corn include the size characteristics of corn (corn ear weight and corn kernel triaxial size) in addition to the mechanical characteristics of corn (corn elastic modulus, corn kernel breaking force, and corn stalk breaking force). The effects of corn varieties and moisture content on the mechanical properties of corn were tested. The results showed that the corn varieties and moisture content had significant effects on the mechanical properties of corn. Among them, the different levels of moisture content levels have significant differences in the mechanical properties of corn, while corn varieties have different significant differences in the mechanical properties of corn. The ear weight, corn kernel triaxial size, and the axial and radial breaking force of corn pedicels all increased significantly as the moisture content increased. Corn’s elastic modulus, kernel breaking force, and the normal breaking force of corn pedicels all decreased significantly as moisture content increased. The breaking force of corn kernels at different positions is in the order of ventral, lateral, and top surface, and the breaking force of corn pedicels in different directions is in the order of normal, axial, and radial. When the moisture content is between 26.0% and 36.4%, the maximum breaking force of a corn kernel is 401.62 N, and the minimum is 35.47 N. The maximum breaking force of corn pedicels is 32.72 N, and the minimum is 5.37 N. Understanding the influences of these relationships is very important for applications related to the threshing process, such as selecting the threshing mode, designing the threshing mechanism, and setting the threshing parameters.

1. Introduction

Corn is the world’s most widely distributed food crop and is widely planted from 53° N to 40° S [1,2,3]. Corn is not only an important food crop but it also has important economic value [4,5]. With the continuous improvement of corn planting areas and industrial value, increased quality requirements are specified for corn threshing quality.

The mechanical properties of corn have important reference significance for the selection of the threshing mode, the design of the threshing mechanism, the setting of threshing parameters, and other applications related to the corn threshing process [6]. In recent years, researchers have studied the mechanical properties and moisture content of different varieties of corn [7,8,9,10]. At the same time, the mechanical properties of corn (the breaking force of the corn kernel and pedicel) also impact the threshing quality. Jie et al. studied the best force application mode for mechanical threshing of corn seeds and pointed out that the greatest force application mode for seed corn threshing is the longitudinal bending force [11]. Cai et al. studied the relationship between the mechanical properties of corn and threshing quality and pointed out that the breaking rate is greatly affected by the minimum breaking force of corn kernels, and the minimum breaking force of corn pedicel has a great influence on the unthreshing rate [12].

Moisture content is the key factor affecting the mechanical properties of corn [13,14]. In Europe, America, and other countries, the moisture content of corn is generally 18~25% when corn is harvested [15]. Existing studies also focus on low-moisture content corn (below 25%). However, the planting mode (spring wheat and summer corn in most areas) and climatic conditions in most parts of China cause the moisture content to be high in corn harvest (25~35%) [16,17,18]. The high losses of high moisture content corn during the harvest is still one of the unsolved problems [19,20,21,22]. Therefore, to solve the problem of poor harvest quality of high moisture content corn, it is necessary to understand the mechanical properties of corn under high moisture content.

This study is based on the corn threshing process. The contact mechanics model of threshing elements and corn kernels was established to analyze the mechanical properties of corn that affect the corn threshing quality. The effects of corn varieties and moisture content on the mechanical properties of corn were studied through tests. The breaking force of corn kernels and pedicels under different corn varieties, moisture content, and loading conditions were measured, and how to improve the corn threshing quality was analyzed. This study can provide a reference for the selection of high moisture content corn threshing mode, the design of the threshing mechanism, and the setting of threshing parameters in the threshing process.

2. Theory

In the theory part, the mechanical properties of corn that affect the forces of threshing elements of the corn kernels are analyzed by establishing the contact mechanical model between threshing elements and corn kernels. Reasonable assumptions can reduce the difficulty of modeling, so this paper makes the following assumptions:

- (a)

- The contact between the threshing element and the corn kernel conforms to the application conditions of Hertz’s theory.

- (b)

- The ear of corn is considered as a whole, which means that the ear of corn moves as a whole after being hit by threshing elements, regardless of the movement of a single corn kernel.

2.1. Contact Mechanics Model of Threshing Element and Corn Kernel

Based on Hertz’s theory, the contact force caused by the contact collision between two elastic bodies is expressed as Equation (1).

Among,

where, , and stand for the maximum and minimum equivalent curvature radius of the threshing element, respectively, mm; and refer to the maximum and minimum equivalent curvature radius of corn kernel, respectively, mm; indicates the equivalent curvature radius of the contact surface, mm; denotes the comprehensive elastic modulus, ; is the elastic modulus of the threshing element,; is the elastic modulus of corn,; is the correction coefficient; and denote Poisson’s ratio of threshing element and corn;

When the corn grain is broken, according to the document [23], the maximum compression displacement of the threshing element is

where, is the critical compression value of the broken corn kernel, mm; is the relative speed between the threshing element and the corn kernel when contacting, m/s; is the comprehensive weight of the threshing element and corn, , kg; refers to the weight of the threshing element, kg; refers the weight of the corn ear, kg.

The maximum impact force of the threshing element and corn kernel during collision is expressed as:

where is the max impact force of the threshing element on corn ear, N.

2.2. Calculation of Contact Mechanics Model Parameters

If the threshing element is the nail tooth and its diameter , then:

The weight of the threshing elements is far higher than that of the corn ear . Therefore,

According to the relative curvature ratio of the threshing element and corn kernel, [24].

The material of the nail tooth is Q235A, the elastic modulus of which is MPa. Furthermore, Poisson’s ratio , and Poisson’s ratio of corn kernel [25].

2.3. Analysis of Mechanical Properties of Corn Affecting the Threshing Quality

The threshing quality of corn is affected by the maximum impact force of the threshing element and the corn kernel, the breaking force of the corn kernel, and the breaking force of corn pedicels [16,26,27]. It can be seen from the analysis that the maximum impact force is affected by some factors, including corn ear weight, corn kernel triaxial size, and corn elastic modulus. Therefore, the mechanical properties of corn that affect threshing quality include the size characteristics of corn (corn ear weight and corn kernel triaxial size), and the mechanical characteristics of the corn kernel(elastic modulus of corn, the breaking force of the corn kernel, and corn pedicels). In this paper, the effects of corn varieties and moisture content on the mechanical properties of corn under high moisture content were studied.

3. Material and Methods

3.1. Materials

This study was conducted in the School of Engineering of China Agricultural University in Beijing, China, from 2020 to 2021. Four common corn varieties of North China (ZD958, QY187, NK815, and JN858) were selected, and the samples were collected from the Shangzhuang Experimental Station of China Agricultural University. Among them, ZD958 and QY187 are semi-horsetooth corn, JN858 is horsetooth corn, and NK815 is flint corn. Each kind of corn was planted by the grower in the optimal planting conditions for the variety. When the moisture content of corn kernels is approximately 35%, they are picked, taken back in woven bags, and placed evenly in a well-ventilated basement (25 ± 3 ℃) for further operation.

3.2. Sample Processing

The mechanical property tests on the corn were carried out three times. On the day of the sample collection, the moisture content decreased to approximately 30% and the moisture content decreased to approximately 26%. To measure the weight of the corn ears, peel the required corn ears manually and weigh them using a balance with an accuracy of 0.01 g. Manually peel off the corn kernels from the middle third of each corn ear, mix the corn kernels peeled from the same corn ear, then measure the size, the breaking force, and the elastic modulus of the corn kernels. Measure the moisture content of mixed corn kernels with a portable moisture meter (Figure 1a). Put the mixed corn kernels in a sealed bag for storage (Figure 1b) to keep the moisture content unchanged. Each test is required to be completed within 24 h.

Figure 1.

Test equipment and samples.

3.3. Size of Corn Kernels

Select 50 corn kernels randomly from the mixed kernels, and measure the triaxial size of the corn kernels with digital vernier calipers (Deli, DL3944) (Figure 1c) with an accuracy of 0.01 mm.

3.4. Breaking Force of Corn Kernels

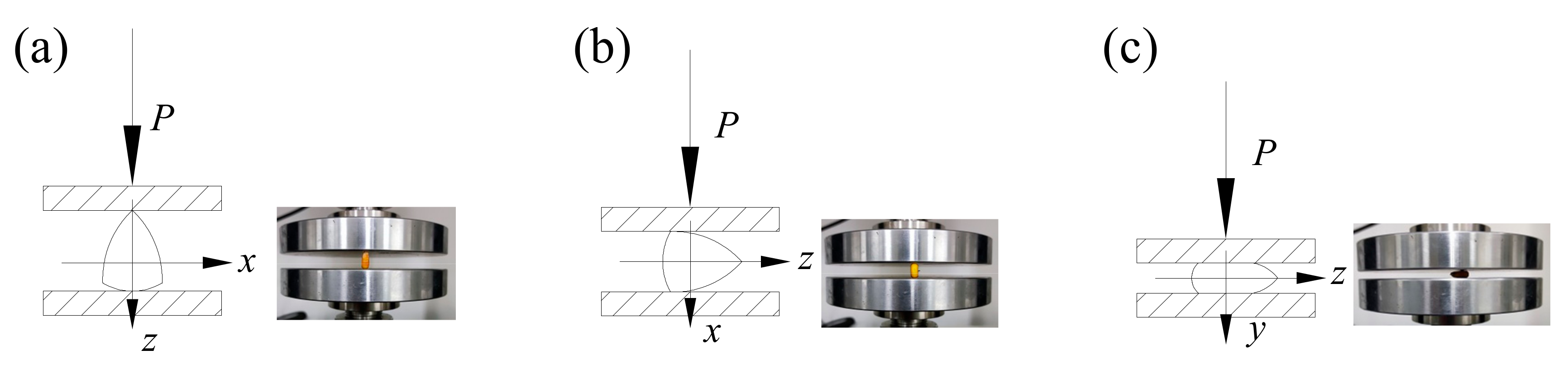

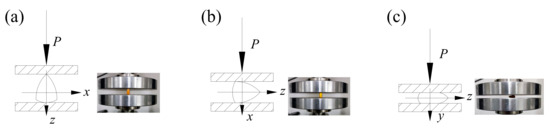

The compression testing of the corn kernels was conducted by a universal material testing machine (INSTRON (3360)) (Figure 1d). The equipment is composed of a loading module and a computer with professional software (Bluehill Universal). The loading range of the loading module is 0~50,000 N. The computer records the change curve of load with displacement in real time. Select a group of 10 corn kernels randomly from the mixed kernels and measure the breaking force on the ventral, lateral, and top surfaces according to the method shown in Figure 2. Fix the corn kernel onto the lower pressing plate with double-sided adhesive tape, set the loading speed to 2 mm/min, and repeat 3 groups of tests at each loaded position.

Figure 2.

The experimental method of the force required for broken corn (a) top surface, (b) lateral surface, and (c) ventral surface.

3.5. Elastic Modulus of Corn Kernels

The elastic modulus of the corn kernel is calculated according to the displacement pressure curve of the corn kernel compressed on the ventral surface (Figure 2c). The calculation formula for the elastic modulus is Equation (7) [28].

among

where is the displacement of the corn kernel, mm; stands for the coefficient as determined by interpolation in Table 1 through the interpolation method; and is the breaking force of the corn kernel on the ventral surface.

Table 1.

Different values corresponding to the value.

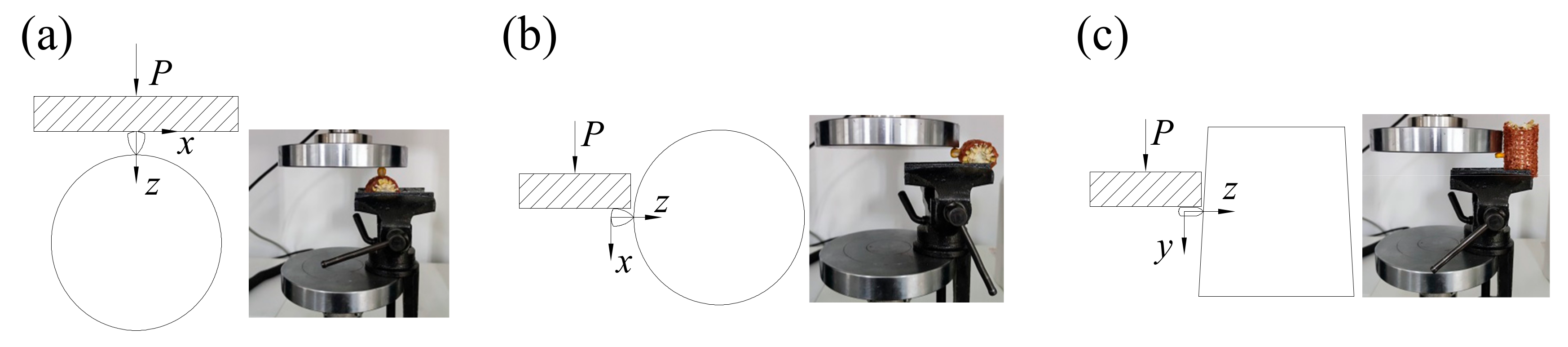

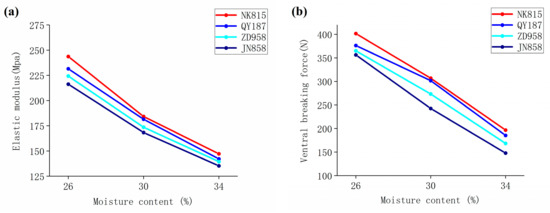

3.6. Breaking Force of Corn Pedicel

The directions of force acting on the corn pedicel in the threshing space includes normal compression, axial shear, and radial shear. Keeping only the middle third of the corn ear, manually peel off the surplus corn kernels around the corn kernels being measured, and measure the breaking force of the corn pedicel, as shown in Figure 3. Set the loading speed at 2 mm/min, and conduct 20 tests in each loading direction.

Figure 3.

The testing method for the breaking force of corn pedicel; (a) normal, (b) radial shear, and (c) axial shear.

3.7. Statistical Analysis

The repeatability of the experimental methods in this study was carried out according to standard procedures. SPSS 22 statistical software (version 22.0, Statistical Package for the Social Sciences Inc., Chicago, IL, USA) was used to calculate the mean and standard deviation of the measured data. The significant differences were analyzed by factor analysis of variance (ANOVA), and Duncan correction at p < 0.05.

4. Results and Discussion

Table 2 shows the variance analysis of corn varieties and moisture content on ear weight; corn kernel length, width, and thickness; the elastic modulus of corn; breaking force of corn kernel (ventral, lateral, and top); and the breaking force of the corn pedicel (normal, axial shear, and radial shear). The results showed that, except for the significant effects of corn varieties on the corn kernel length, thickness, and breaking force of axial shear direction in p < 0.05, the significant effects of corn varieties and moisture content on other indexes were p < 0.01. This suggests that the mechanical properties of corn change more significantly with changes in moisture content. In contrast, the different varieties of corn have slightly less significant effects on corn kernel length, thickness, and pedicel breaking force in the axial direction, which may be due to the association of genotypes among different corn varieties, and environmental factors during growth.

Table 2.

Variance analysis of varieties and moisture content on mechanical properties of corn.

4.1. Size Characteristics of Corn

The ear weight and triaxial size of corn kernels under different varieties and moisture content are shown in Table 3. It can be seen from the table that the corn ear weights of ZD958, NK815, JN858, and QY187 are, respectively, 283.16~336.42 g, 296.31~342.17 g, 301.24~352.16 g, and 288.27~335.26 g; the length of the corn kernels are 10.32~12.33 mm, 10.83~12.18 mm, 11.13~13.31 mm, and 11.03~12.35 mm; the width of the corn kernels are 8.63~10.78 mm, 9.55~10.69 mm, 7.42~9.86 mm, and 9.53~10.87 mm; and the thickness of the corn kernels are4.39~5.41 mm, 4.57~5.18 mm, 4.78~5.41 mm, and 4.24~5.23 mm.

Table 3.

Ear weight and triaxial size of corn kernels with different varieties and moisture content.

4.2. Effects of Varieties and Moisture Content on Size Characteristics of Corn

4.2.1. The Effect of Moisture Content on the Size Characteristics of Corn

It can be seen from Table 3, with an increase in moisture content, the weight of corn ears and the triaxial size of corn kernels increase significantly. Chandio et al. and Milani have also reported similar results [7,29]. Duncan’s method (p < 0.05) was used to test the effect of different levels of moisture content on the corn ear weight and triaxial size of the corn kernel. The results showed that different moisture content levels had significant differences in the corn ear weight and corn kernel triaxial size.

4.2.2. Effect of Varieties on Size Characteristics of Corn

Table 4 shows the size characteristics of the different varieties of corn. It can be seen that the different corn varieties have significant differences in corn ear weight and corn kernel size. At the same time, JN858 has the largest ear weight, corn kernel length, and corn kernel thickness; QY187 has the largest corn kernel width; while ZD958 had the lowest ear weight and corn kernel length, JN858 had the lowest corn kernel width; and QY187 had the lowest corn kernel thickness.

Table 4.

Size characteristics of different corn varieties.

4.3. Mechanical Characteristics of Corn

The mechanical properties of corn of different varieties and moisture content are shown in Table 5. It can be seen from the table that when the moisture content of corn is 26.0~36.4%, the elastic modulus of ZD958, NK815, JN858, and QY187 are respectively 139.46~224.32 Mpa, 147.18~243.76 Mpa, 135.28~216.29 Mpa, and 142.12~231.53 Mpa; the breaking force of corn kernel on the ventral surface is 168.28~364.92 N, 196.61~401.62 N, 147.82~356.31 N, and 142.12~231.53 N; the breaking force of corn kernel on the lateral surface is 69.47 N~94.73 Nmm, 87.64~102.21 N, 67.43~85.22 N, and 84.18~118.61 N; the breaking force of corn kernel on the top surface is 36.94~55.35 N, 52.61~69.34 N, 35.47~49.64 N, and 38.73~60.83 N; the breaking force of corn pedicel in the normal direction is 15.41~26.84 N, 21.57~32.72 N, 11.94~23.27 N, and 18.85~29.34 N; the breaking force of corn pedicel in the axial shear direction is 8.36 N~10.28 Nmm, 10.91~12.73 N, 6.31~9.49 N, and 8.24~11.53 N; and the breaking force of corn pedicel in the radial shear direction is 6.71~10.96 N, 5.78~9.42 N, 5.37~9.36 N, and 6.42~10.27 N.

Table 5.

Mechanical characteristics of corn with different varieties and moisture content.

4.4. Effect of Moisture Content on Mechanical Characteristics of Corn

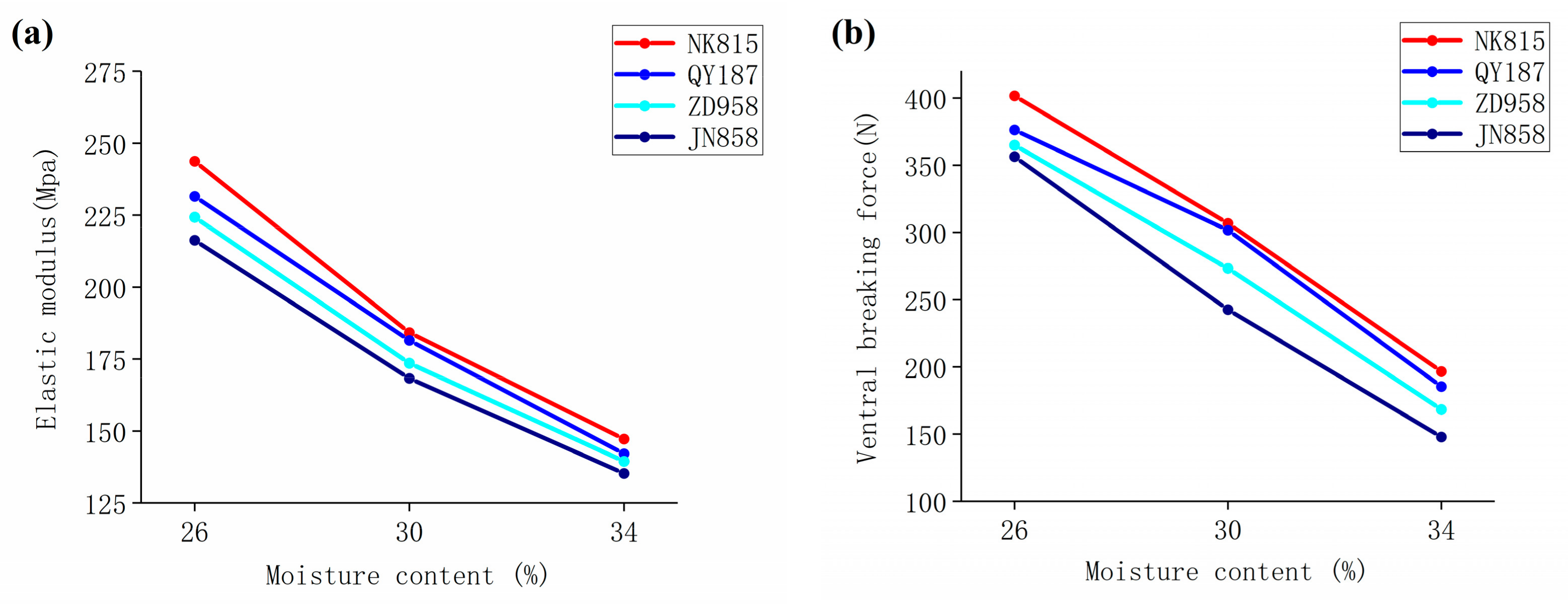

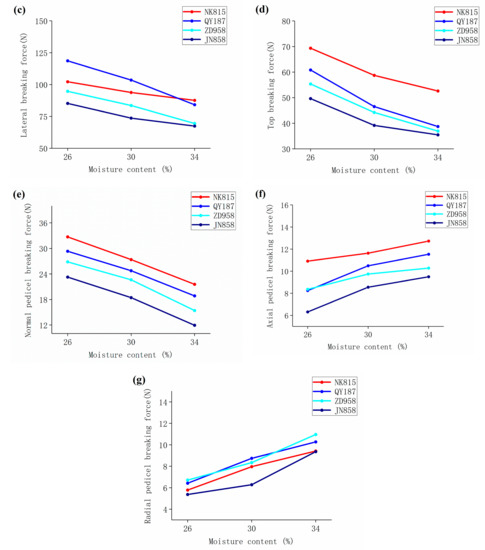

The influence of moisture content on the elastic modulus of corn is shown in Figure 4a. With the increase in moisture content, the elastic modulus of the four corn varieties decreases. Similar results were reported in the study of low-moisture corn [7,30]. This is because when the moisture content increases, the brittleness of corn kernels decreases, and the toughness increases—leading to a decrease in the elastic modulus of corn.

Figure 4.

Effect of moisture content on mechanical characteristics of corn. (a) The effect of moisture content on elastic modulus. (b) The effect of moisture content on ventral breaking force. (c) The effect of moisture content on lateral breaking force. (d) The effect of moisture content on top breaking force. (e) The effect of moisture content on normal pedicel breaking force. (f) The effect of moisture content on axial pedicel breaking force. (g) The effect of moisture content on radial pedicel breaking force.

The influence of moisture content on corn kernel breaking force is shown in Figure 4b–d. With the increase in moisture content, the corn kernel breaking force of the four corn varieties decreases. This shows that the higher the moisture content of corn kernels, the easier the corn kernels are to break. Fu et al., Zhou et al., and Zhu et al. also pointed out that high moisture content corn was more prone to kernel breakage during the harvest [30,31,32,33,34]. At the same time, the slope of the curve of the effect of moisture content on the mechanical properties of corn did not vary much and had the same trend for different varieties of maize. This indicates that the effect of moisture content on the mechanical properties of different varieties of corn is not significantly different.

The influence of moisture content on the breaking force of corn pedicels is shown in Figure 4e–g. With the increase in moisture content, the breaking force of the pedicels in the normal direction decreases, whereas it increases in the radial and axial directions. Similar results were reported in the study of low-moisture corn [35,36]. Li and Gao and Li et al. reported that the reason why the normal breaking force of the corn pedicel decreases with the increase in moisture content is that when the moisture content increases, the plasticity of the pedicel increases, and the brittleness decreases, therefore the pedicel is easy to break. However, we noticed that the breaking force of corn pedicel in the normal direction was significantly larger than that in the axial and radial shear directions. Therefore, we think that the reason why the breaking force of corn pedicels in the normal direction is greater than that in the axial and radial shear directions is that corn kernels are supported by corn cobs during the normal compression of corn pedicels. And with the increase in moisture content, the breaking force of corn pedicels decreases in the normal direction, which is because the corncob becomes soft with the increase in moisture content, and the supporting effect on corn kernels is weakened. The reason why the breaking force of corn pedicel increases with the increase of moisture content in the radial and axial shear directions is that with the increase in moisture content, the toughness of corn pedicel is enhanced, and the ability to resist fragmentation is increased, so it is not easy to break.

Duncan’s method (p < 0.05) was used to test the effect of different levels of moisture content on the mechanical characteristics of corn. The results showed that different moisture content levels had significant differences in the mechanical characteristics of corn.

4.5. Effect of Varieties on Mechanical Characteristics of Corn

Table 6 shows the mechanical characteristics of different varieties of corn. Significant differences can be seen in the mechanical characteristics of the various corn varieties. At the same time, of the four corn varieties, NK815 has the largest elastic modulus, breaking force on the ventral and top surface of the corn kernel, and breaking force of corn pedicels in normal and radial shear directions; QY187 has the largest breaking force on the lateral surface of the corn kernel; and ZD958 has the largest breaking force of corn pedicels on radial shear directions. JN858 has the lowest elastic modulus of corn, the breaking force of corn kernels, and the breaking force of corn pedicels.

Table 6.

Mechanical properties of different corn varieties.

4.6. Effect of Loading Position on the Breaking Force of Corn Kernel

In the three loading positions of the corn kernels, the breaking force is arranged in the order of ventral, lateral, and top, which is consistent with the research results of Li et al. under low moisture content [10]. This is mainly because the substances (corneous endosperm, silty endosperm, and embryo) that make up the corn kernel are more evenly distributed in the horizontal direction of the ventral side, and the loading area of the corn kernel is large, therefore making it have better pressure bearing characteristics. When the loading position is on the lateral surface, the material bearing the pressure on the corn kernel is the corneous endosperm. When the loading position is on the top surface, the material bearing the pressure on the corn kernel is the embryo and silty endosperm. The pressure-bearing capacity of the embryo and silty endosperm is significantly lower than that of the corneous endosperm [37]. Therefore, the pressure-bearing capacity of the lateral surface of the corn kernel is greater than that of the top surface. This indicates that when making the choice of threshing method, the ventral and lateral sides of the corn kernels should be forced as much as possible and the top side should be forced as little as possible to reduce the corn kernel breaking rate. [38,39].

4.7. Effect of Loading Direction on the Breaking Force of Corn Pedicel

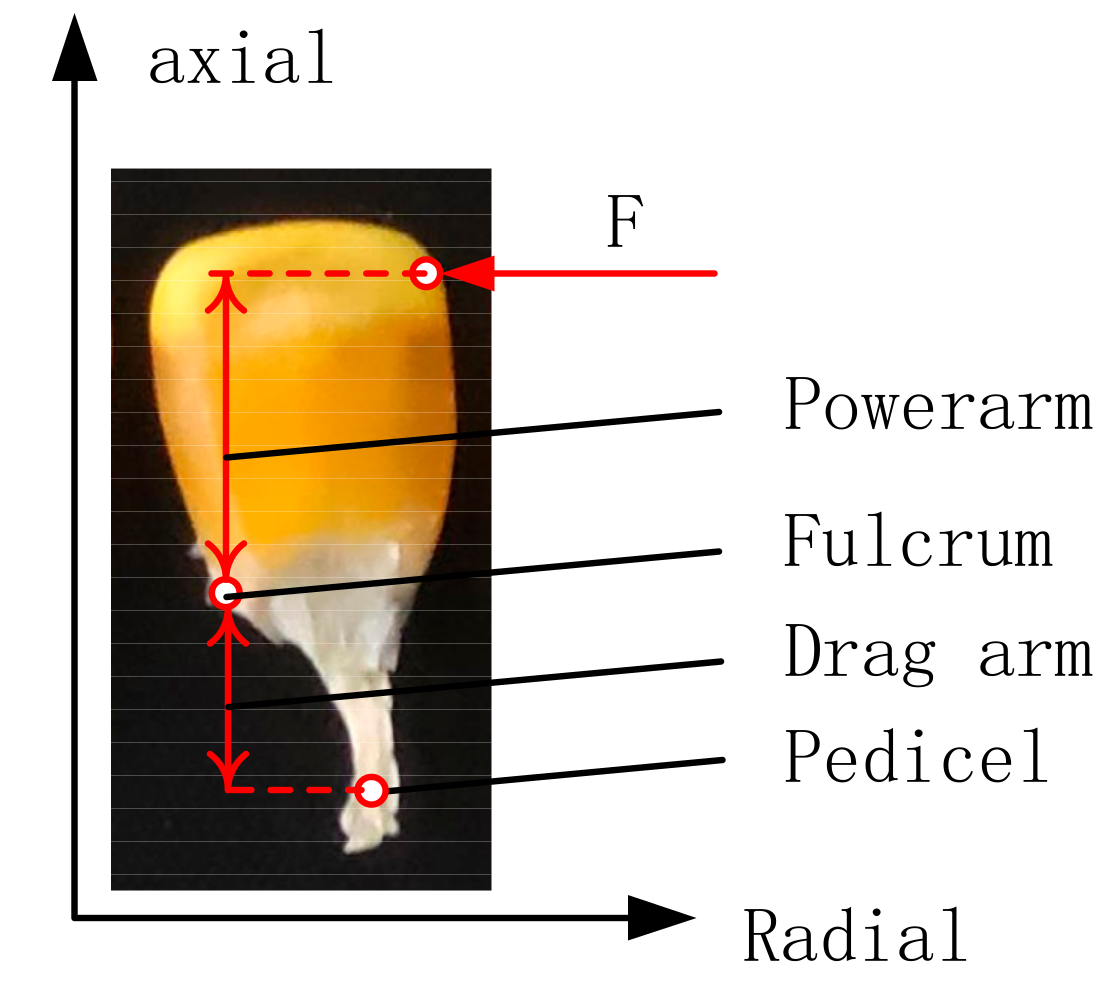

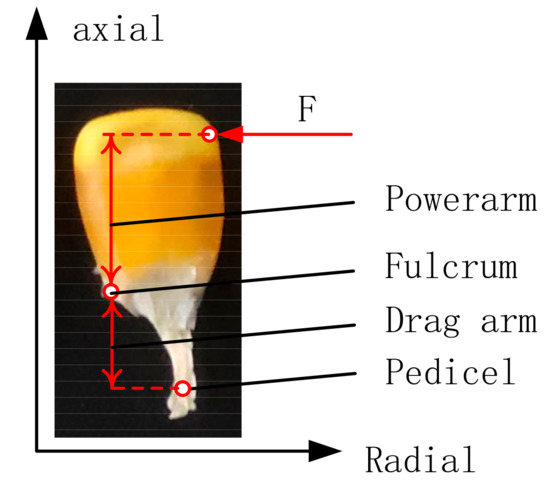

In the three loading directions of the corn pedicel, the breaking force of the corn pedicel is normal, axial, and radial shear. The reason why the breaking force of corn pedicel is the largest in the normal direction has been explained above, that is, the corn cob supports the corn kernel. The result that the breaking force of corn pedicel in the axial shear direction is greater than the radial shear direction is consistent with the research result of Su et al., and Jie et al. [9,11]. The force analysis of the corn pedicel is shown in Figure 5. The bottom of the corn kernel is wider in the radial direction than it is in the axial direction. Thus, when the corn pedicel is subjected to radial force, the force required to destroy the corn pedicel is smaller due to the lever principle.

Figure 5.

Force analysis of corn pedicel.

5. Conclusions

This paper studied the effects of varieties and moisture content on the mechanical properties of corn, providing a reference for the selection of corn threshing methods, the design of the threshing mechanism, and the setting of threshing parameters. The effects of corn varieties and moisture content on the mechanical properties of corn were tested, and the following conclusions were drawn:

- (a)

- The corn varieties and moisture content had significant effects on the mechanical properties of corn. Among them, the different levels of moisture content levels have significant differences in the mechanical properties of corn, while corn varieties have different significant differences in the mechanical properties of corn

- (b)

- With the increase in moisture content, the ear weight, corn kernel triaxial size, and the axial and radial breaking force of corn pedicels increased significantly. In addition, the elastic modulus of corn, the breaking force of corn kernels, and the normal breaking force of corn pedicels decreased significantly.

- (c)

- The breaking force of corn kernels at different positions is in the order of ventral, lateral, and top surface, and the breaking force of corn pedicels in different directions is in the order of normal, axial, and radial.

Author Contributions

X.Z.: Conceptualization, Methodology, Software, Investigation, Data curation, Writing—original draft. R.C.: Resources, Writing—review & editing. Y.M.: Data curation. All authors have read and agreed to the published version of the manuscript.

Funding

National Key R&D Program Projects (2016YFD0701901) and the National Natural Science Foundation of China (52172396).

Data Availability Statement

Acknowledgments

All of the authors would like to acknowledge the financial support from the National Key R&D Program Projects (2016YFD0701901) and the National Natural Science Foundation of China (52172396).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Xu, J.; Meng, J.; Quackenbush, L.J. Use of remote sensing to predict the optimal harvest date of corn. Field Crop. Res. 2019, 236, 1–13. [Google Scholar] [CrossRef]

- Ferraretto, L.F.; Shaver, R.D.; Luck, B.D. Silage review: Recent advances and future technologies for whole-plant and fractionated corn silage harvesting. J. Dairy Sci. 2018, 101, 3937–3951. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.E.; Dai, J. Integrated Feature Selection of ARIMA with Computational Intelligence Approaches for Food Crop Price Prediction. Complexity 2018, 2018, 1910520. [Google Scholar] [CrossRef]

- Singh, V.; Stone, J.; Robert, J.P.; Vani, S.N. Industrial Biotechnology Shaping Corn Biorefineries of the Future. Cereal Food World 2019, 64. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Z.; Yang, M.; Huang, H.; Ye, C. Spatio-temporal Feature of Maize Production Efficiency in Main Producing Provinces of China. Trans. Chin. Soc. Agric. Mach. 2018, 49, 183–193. [Google Scholar]

- Li, X.; Du, Y.; Liu, L.; Mao, E.; Yang, F.; Wu, J.; Wang, L. Research on the constitutive model of low-damage corn threshing based on DEM. Comput. Electron. Agr. 2022, 194, 106722. [Google Scholar] [CrossRef]

- Chandio, F.A.; Li, Y.; Ma, Z.; Ahmad, F.; Syed, T.N.; Shaikh, S.A.; Tunio, M.H. Influences of moisture content and compressive loading speed on the mechanical properties of maize grain orientations. Int. J. Agr. Biol. Eng. 2021, 14, 41–49. [Google Scholar] [CrossRef]

- Gao, L.; Li, F.; Zhang, X.; Zhang, Y.; Liu, X.; Jiao, W. Mechanism of moisture content affect on corn seed threshing. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2011, 42, 42–92. [Google Scholar]

- Su, Y.; Cui, T.; Xia, G.; Gao, X.; Li, Y.; Qiao, M.; Xu, Y. Effects of different moisture content and varieties on physico–mechanical properties of maize kernel and pedicel. J. Food Process. Eng. 2021, 44, e13778. [Google Scholar] [CrossRef]

- Li, X.; Gao, L.; Ma, F. Experimental research of corn seed kernel on the impacting damage. J. Shenyang Agric. Univ. 2007, 38, 89–93. [Google Scholar]

- Jie, X.; Li, X.; Sun, L.; Du, X.; Gao, L. Experiment on optimal forcing method for seed-corn thresher. Trans. Chin. Soc. Agric. Mach. 2009, 40, 71–75. [Google Scholar]

- Cai, C.J.; Chen, Z.; Han, Z.D.; Liu, G.M.; Zhang, Z.L.; Hao, J.F. Study on relationship of biomechanical characteristics of corn seed and threshing performance. J. Agric. Mech. Res. 2017, 4, 192–196, (In Chinese with English abstract). [Google Scholar]

- Li, Y.M.; Chandio, F.A.; Ma, Z.; Lakhiar, I.; Sahito, A.R.; Ahmad, F.; Mari, I.; Farooq, U.; Suleman, M. Mechanical strength of wheat grain varieties influenced by moisture content and loading rate. Int. J. Agric. Biol. Eng. 2018, 11, 52–57. [Google Scholar] [CrossRef]

- Shahbazi, F.; Valizade, S.; Dowlatshah, A. Mechanical damage to green and red lentil seeds. Food Sci. Nutr. 2017, 5, 943–947. [Google Scholar] [CrossRef]

- Huang, H.; Faulkner, D.; Berger, L.; Eckhoff, S. Harvest Date Influence on Dry Matter Yield and Moisture of Corn and Stover. T Asabe 2012, 55, 593–598. [Google Scholar] [CrossRef]

- Li, L.; Lei, X.; Xie, R.; Wang, K.; Hou, P.; Zhang, F.; Li, S. Analysis of influential factors on mechanical grain harvest quality of summer maize. Sci. Agric. Sin. 2017, 50, 2044–2051. [Google Scholar]

- Wang, K.; Li, L.; Gao, S.; Wang, Y.; Huang, Z.; Xie, R.; Ming, B.; Hou, P.; Xue, J.; Zhang, G.; et al. Analysis of main quality index of corn harvesting with combine in China. Acta Agron. Sin. 2021, 47, 2440–2449. [Google Scholar] [CrossRef]

- Xu, T.; Lu, T.; Zhao, J.; Wang, R.; Xing, J.; Zhang, Y.; Cai, W.; Liu, Y.; Liu, X.; Chen, C.; et al. The grain dehydration characteristics of the main summer maize varieties in Huang-Huai-Hai region. Sci. Agric. Sin. 2021, 54, 708–719. [Google Scholar] [CrossRef]

- Marques, O.J.; Dalpasquale, V.A.; Vidigal Filho, P.S.; Scapim, C.A.; Reche, D.L. Mechanical damages in grains of commercial corn hybrids as a function of the crop moisture content. Semin-Cienc. Agrar. 2011, 32, 565–575. [Google Scholar] [CrossRef]

- Shi, W.; Shao, H.; Sha, Y.; Shi, R.; Shi, D.; Chen, Y.; Ban, X.; Mi, G. Grain dehydration rate is related to post-silking thermal time and ear characters in different maize hybrids. J. Integr. Agric. 2022, 21, 964–976. [Google Scholar] [CrossRef]

- Wang, K.; Li, L.; Lu, Z.; Gao, S.; Wang, Y.; Huang, Z.; Xie, R.; Ming, B.; Hou, P.; Xue, J.; et al. Mechanized grain harvesting quality of summer maize and its major influencing factors in Huanghuaihai region of China. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–7. [Google Scholar]

- Xie, R.; Lei, X.; Wang, K.; Guo, Y.; Chai, Z.; Hou, P.; Li, S. Research on Corn Mechanically Harvesting Grain Quality in Huanghuaihai Plain. Crops 2014, 2, 76–79. [Google Scholar]

- Zhang, X.W.; Yi, K.C.; Gao, L.X. Contacting mechanics analysis during impact process between maize seeds and threshing component. Chin. Agric. Sci. Bull. 2015, 31, 285–290. [Google Scholar]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985; p. 110. [Google Scholar]

- Xu, L.; Li, Y.; Ding, L. Contacting mechanics analysis during impact process between rice and threshing component. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2008, 24, 146–149. [Google Scholar]

- Li, X.; Ma, F.; Gao, L. Dropping impact experiment on corn seeds. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2009, 25, 113–116. [Google Scholar]

- Yu, Y.; Fu, H.; Yu, J. DEM-based simulation of the corn threshing process. Adv. Powder Technol. 2015, 26, 1400–1409. [Google Scholar] [CrossRef]

- ASAE S368.4 DEC2000 (R2017); Compression Test of Food Materials of Convex Shape. American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2017.

- Milani, E.; Seyed, M.; Razavi, A.; Koocheki, A.; Nikzadeh, V.; Vahedi, N.; Moeinfard, M.R.; Gholamhosseinpour, A. Moisture dependent physical properties of cucurbit seeds. Int. Agrophys. 2007, 21, 157–168. [Google Scholar]

- Lupu, M.I.; Pădureanu, V.; Canja, C.M.; Măzărel, A. The Effect of Moisture Content on Grinding Process of Wheat and Maize Single Kernel; IOP Conference Series: Materials Science and Engineering, 2016; IOP Publishing: Bristol, UK, 2016; p. 22024. [Google Scholar]

- Fu, Q.; Fu, J.; Chen, Z.; Zhang, L.; Ren, L. Influence of different corn ear position and orientation and water content on fracture mechanics of corn peduncle. Trans. Chin. Soc. Agric. Eng. 2019, 35, 60–69. [Google Scholar]

- Fu, J.; Yuan, H.; Zhang, D.; Chen, Z.; Ren, L. Multi-Objective Optimization of Process Parameters of Longitudinal Axial Threshing Cylinder for Frozen Corn Using RSM and NSGA-II. Appl. Sci. 2020, 10, 1646. [Google Scholar] [CrossRef]

- Zhou, D.; Xu, C.; Xin, Y.; Hou, P.; Wu, B.; Yu, H.; Zhang, J.; Zhang, Q. Model Study on the Combination of Operating Parameters of Corn Kernel Harvesters. Appl. Sci. 2021, 11, 10328. [Google Scholar] [CrossRef]

- Zhu, X.; Chi, R.; Du, Y.; Qin, J.; Li, X. Experimental study on the key factors of low-loss threshing of high-moisture maize. Int. J. Agric. Biol. Eng. 2020, 13, 23–31. [Google Scholar] [CrossRef]

- Li, X.P.; Gao, L.X. Experimental study on breaking mechanism of kernel stem of corn seed. Trans. CSAE 2007, 23, 47–51. [Google Scholar]

- Li, X.P.; Gao, L.X.; Ma, F.L. Experimental research of seed corn on the threshing property. J. Agric. Mech. Res 2007, 2, 156–158. [Google Scholar]

- Yu, S. Corn Kernel Damage Test and Analysis of Corn Threshing Process. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2019. [Google Scholar]

- Patil, K.; Pandit, S.; Pol, G.; Kadam, S.; Jadhav, A. Design and fabrication of corn shelling and threshing machine. Int. J. Innovat. Res. Sci. Technol. 2016, 5, 13981–13986. [Google Scholar]

- Xiaopeng, H.; Chunhe, L.; Jianfang, S. Research and design on corn sheller by extruding and rubbing method. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2003, 19, 105–108. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).