From Agricultural Residues to Sustainable Boards: Complex Network Analysis of Binderless Composites

Abstract

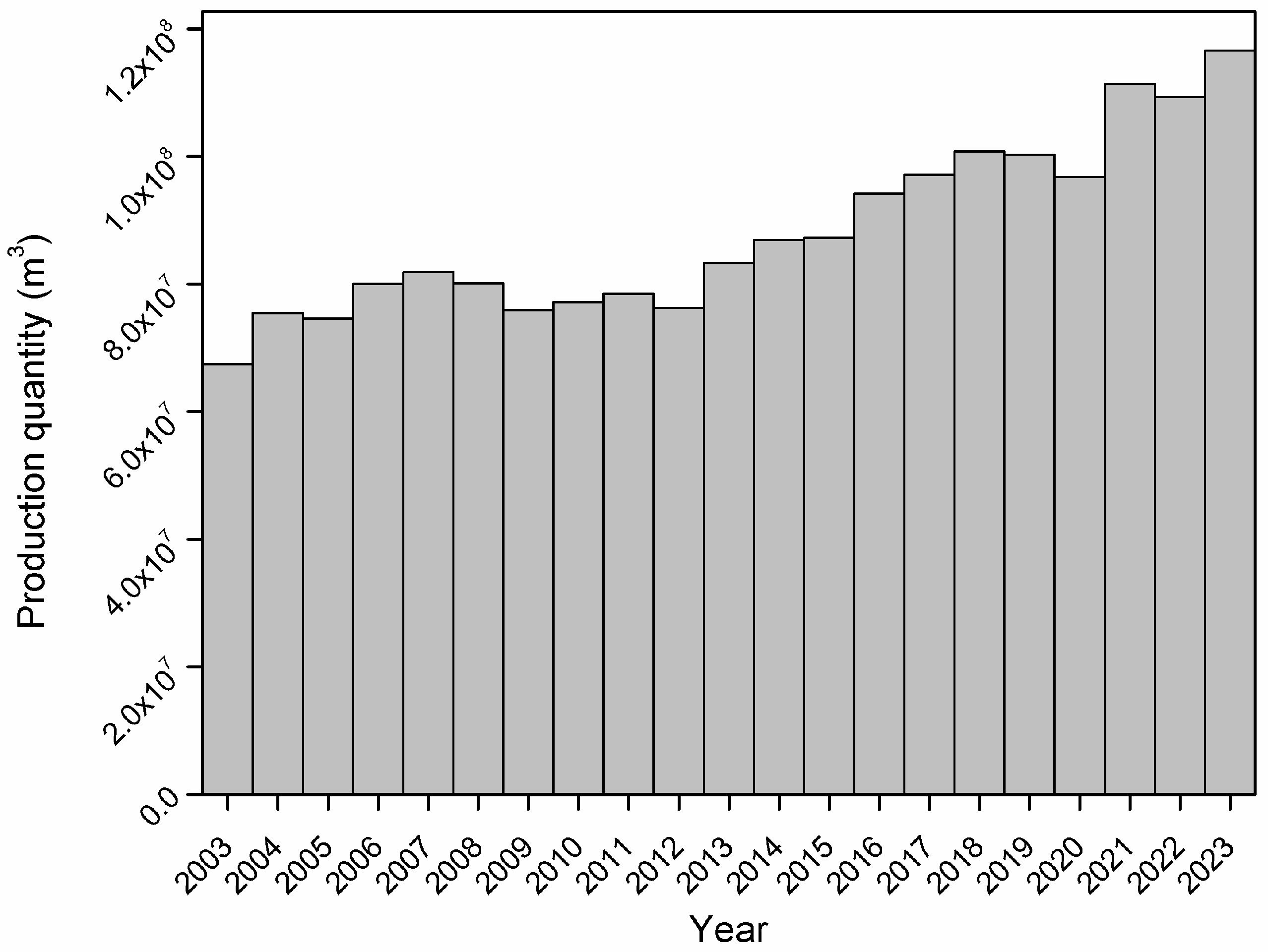

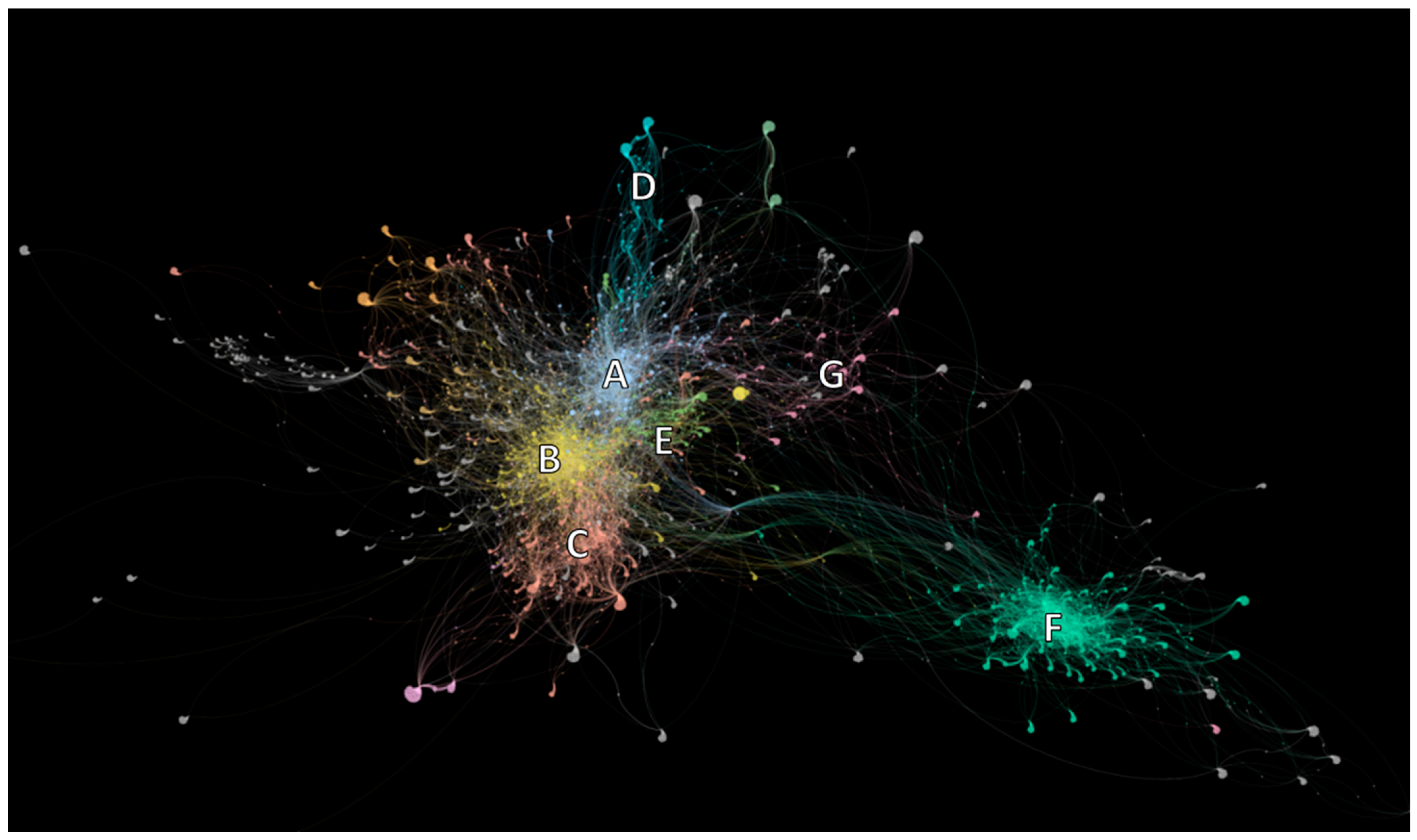

1. Introduction

2. Methods

3. Chemical Composition of Lignocellulosic Raw Materials

| Raw Material | wt% Dry Sample | |||

|---|---|---|---|---|

| Cellulose | Hemicellulose | Lignin | Ash | |

| Arundo donax [76] | 29.2–43.1 | 14.5–32 | 19.2–24.3 | 4.2–6.1 |

| Bagasse pith [38,39,69,77,78,79] | 30.9–56.9 | 28.4–29.2 | 16.6–21.7 | 2.4–5.1 |

| Bagasse rind [38] | 31.1 | 22.6 | 20.8 | - |

| Bamboo [50,51,52] | 35.2–65 | 17–29.3 | 18–27.6 | - |

| Banana bunch [80] | 51.1 | 12.8 | 14.8 | 12.4 |

| Barley straw [81] | 34.8 | 27.9 | 14.6 | 5.7 |

| Brewer’s Spent Grains [41] | 9.5 | 28.7 | 11.2 | 3.3 |

| Camphor tree [64] | 43 | 25.1 | 22.7 | 0.1 |

| Castor seed [82] | 18.3 | 3.8 | 30.8 | 7.5 |

| Chestnut [83] | 51.9 (2) | - | 25.2 | - |

| Coconut coir [47,49] | 21.1–37 | 8.5–23 | 29.2–42 | 1.8–2.5 |

| Coriander [53] | 34.7 | 36.9 | 1.0 | - |

| Corn cobs–stalk biomass [34] | 43.2 | 31.8 | 14.6–16 | 2.4–3.2 |

| Empty fruit bunches [84] | 64.4–67 (2) | 20.9–24.5 | - | |

| Eucalyptus wood [85] | 43.4 | 22.3 | 31.7 | - |

| Flax fiber [86,87] | 61–71 | 16–20.6 | 1.8–5.7 | - |

| Flax shiv [86] | 39.9–41 | 25.2–26.8 | 23–30.3 | - |

| Gelam bark wood [83] | 37.6 | 41.2 | 47.7 | 1.2 |

| Hemp fiber [86] | 60–76.2 | 12.8–22.4 | 3.7–5.7 | - |

| Hemp shiv [60,86,88] | 34–60 | 15–37 | 15–30 | 1.6 |

| Kenaf powder [54] | 84 (2) | - | 25.3 | - |

| Miscanthus [40,89] | 42.6 | 21.1 | 19.9 | 0.7 |

| Oak wood [24] | 41 | 26 | 26 | - |

| Oil palm (1) [5,90] | 1.0–52.2 | 1.6–58.9 | 17.2–27.4 | 2.2–2.9 |

| Rape straw [67] | 40 | - | 19–21 | - |

| Rattan waste [91] | 34.3 | 45.6 | 21 | 5.4 |

| Rice husk [33] | 31.3 | 18.1 | 28.2 | 17.1 |

| Rice straw [34,35] | 30–36.5 | 25–30 | 8.9–12.3 | 13.3 |

| Rye straw [81] | 37.9 | 32.8 | 17.6 | 3 |

| Softwood [35] | 42–46 | 7–12 | 25–28 | 0.3–1.3 |

| Sunflower bark [24] | 43–48 | 19.5–23 | 21–32 | - |

| Wheat straw [37,52] | 39.7 | 30.6 | 17.7 | 7.7 |

| White pine [83] | 40.3 (2) | 50 | 1 | |

4. Pretreatments Strategies Applied to Lignocellulosic Raw Materials

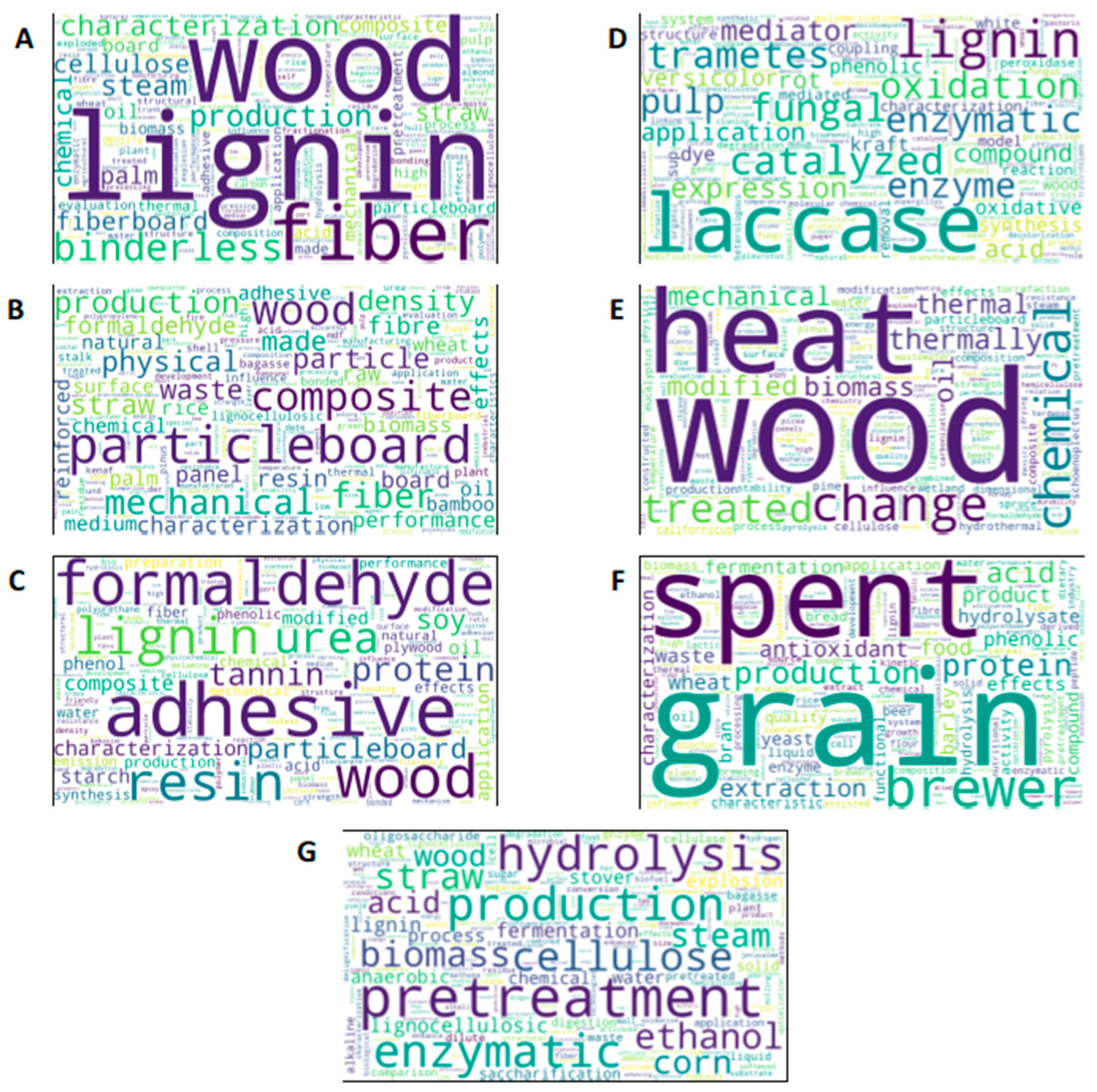

4.1. Mechanical Treatments (Milling, Grinding, Refining)

4.2. Thermal and Hydrothermal (Steam Explosion, Steam Injection)

4.3. Chemical Pre-Treatments (Acid Hydrolysis, Alkaline Treatment, Oxidation Agents)

4.4. Biological Pre-Treatments (Fungal and Enzymatic Laccase)

5. Effects of Processing Parameters on Board Properties

6. Selected Lignocellulosic Raw Materials for Binderless Board Production

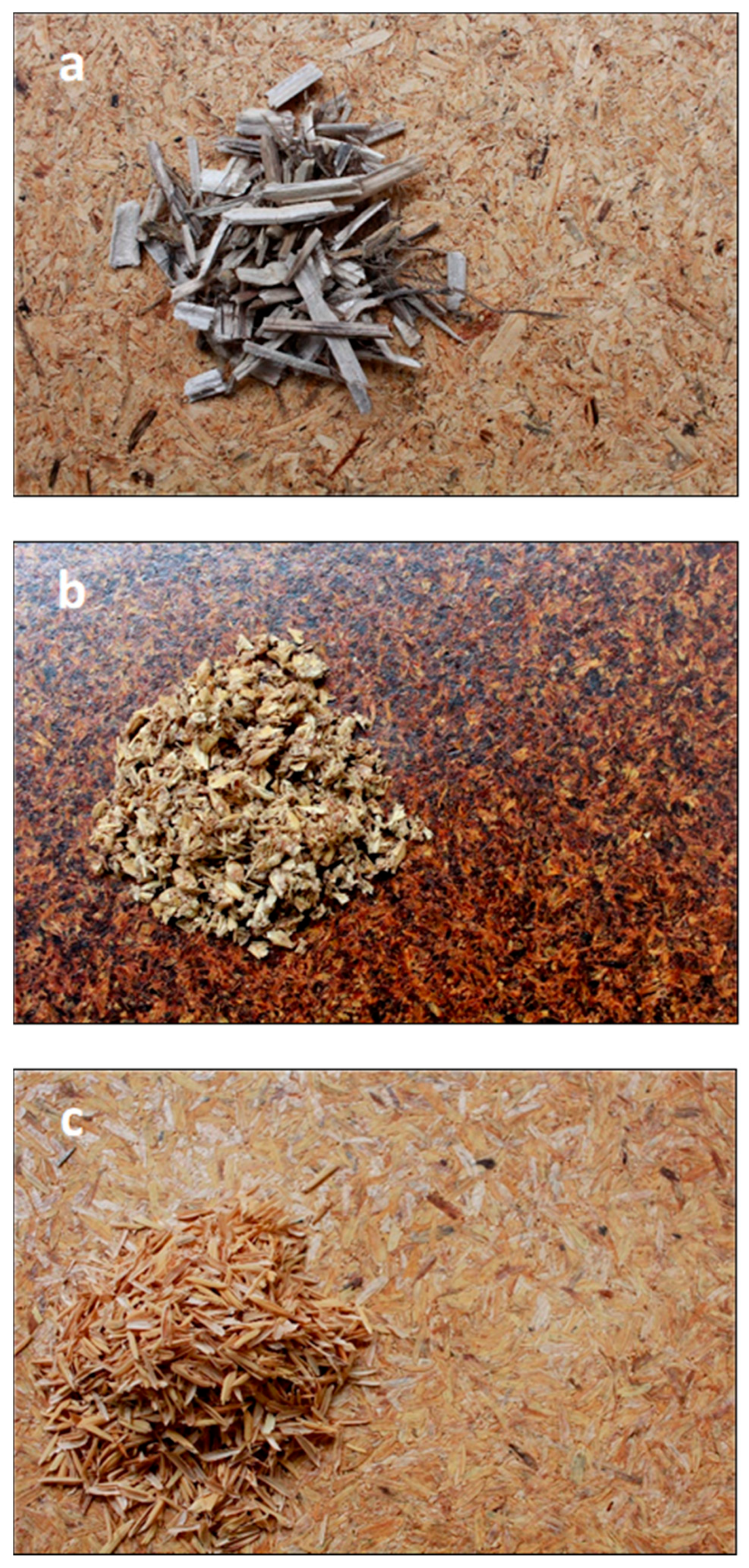

6.1. Rice Straw and Husk

6.2. Sugarcane Bagasse

6.3. Coconut Coir and Husk

6.4. Wheat Straw

6.5. Oil Palm Trunk

6.6. BSG

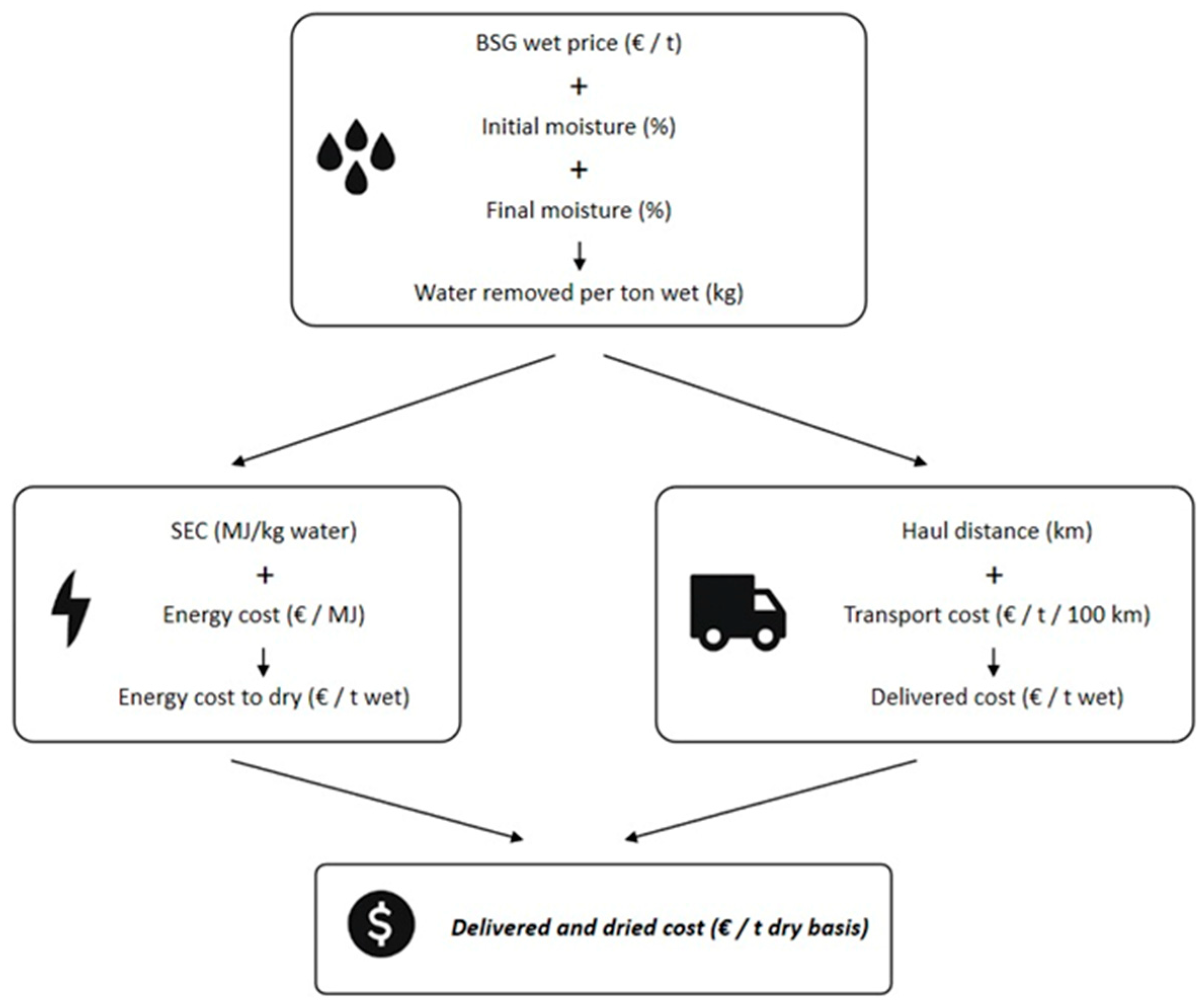

7. Costs Analysis and Future Perspectives: BSG Case

Future Perspectives for BSG Valorization

8. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TP | Pressing Temperature |

| tP | Pressing time |

| PP | Pressing Pressure |

| MOE | Modulus of Elasticity |

| MOR | Modulus of Rupture |

| IB | Internal Bond strength |

| TS | Thickness Swelling |

| WA | Water Absorption |

| BSG | Brewer Spent Grain |

| VOCs | Volatile Organic Compounds |

| FAO | Food and Agriculture Organization |

References

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Dukarska, D.; Kawalerczyk, J.; Sedliačik, J.; Antov, P.; Unisa, M. Alternative Wood Raw Material Sources in Particleboard and OSB Production—Challenges and Perspectives. Polymers 2025, 17, 1760. [Google Scholar] [CrossRef]

- Arias, A.; González-García, S.; Feijoo, G.; Moreira, M.T. Tannin-Based Bio-Adhesives for the Wood Panel Industry as Sustainable Alternatives to Petrochemical Resins. J. Ind. Ecol. 2022, 26, 627–642. [Google Scholar] [CrossRef]

- Food and Agriculture Organization (FAO). FAOSTAT Forestry Production and Trade. Available online: https://www.fao.org/faostat/en/#data/FO (accessed on 11 November 2025).

- Nuryawan, A.; Sutiawan, J.; Rahmawaty; Masruchin, N.; Bekhta, P. Panel Products Made of Oil Palm Trunk: A Review of Potency, Environmental Aspect, and Comparison with Wood-Based Composites. Polymers 2022, 14, 1758. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Chemical and Multi-Physical Characterization of Agro-Resources’ by-Product as a Possible Raw Building Material. Ind. Crops Prod. 2018, 120, 214–237. [Google Scholar] [CrossRef]

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative Lignocellulosic Raw Materials in Particleboard Production: A Review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Kariuki, S.W.; Wachira, J.; Kawira, M.; Murithi, G. Formaldehyde Use and Alternative Biobased Binders for Particleboard Formulation: A Review. J. Chem. 2019, 2019, 5256897. [Google Scholar] [CrossRef]

- Phiri, R.; Mavinkere Rangappa, S.; Siengchin, S. Agro-Waste for Renewable and Sustainable Green Production: A Review. J. Clean. Prod. 2024, 434, 139989. [Google Scholar] [CrossRef]

- Amato, C.N.; González, R.; Dolores González, S.; Agustín Pérez, S.; Florencia Peretti, M.; Buraschi, M.; Ferro Moreno, S.; Mariano, R.C. Mapeo de Residuos Agroindustriales y Oportunidades de Negocio Biocirculares En Cadenas de Valor Argentinas. FACE Rev. Fac. Cienc. Econ. Empres. 2024, 24, 39–61. [Google Scholar] [CrossRef]

- Penna, J.; Cristeche, E. La Valoración de Servicios Ambientales: Diferentes Paradigmas; Instituto Nacional de Tecnología Agropecuaria: Buenos Aires, Argentina, 2008.

- Menéndez, J.E.; Hilbert, J.A. Cuantificación y Uso de Biomasa de Residuos de Cultivos en Argentina para Bioenergía; INTA, Ed.; Ediciones INTA Publicaciones Periódicas: Castelar, Argentina, 2013; ISBN 9789875214484. [Google Scholar]

- Mahieu, A.; Vivet, A.; Poilane, C.; Leblanc, N. Performance of Particleboards Based on Annual Plant Byproducts Bound with Bio-Adhesives. Int. J. Adhes. Adhes. 2021, 107, 102847. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Geng, B.J.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from Agricultural Biomass and Recycled Wood Waste: A Review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Oktay, S.; Kızılcan, N.; Bengu, B. Oxidized Cornstarch–Urea Wood Adhesive for Interior Particleboard Production. Int. J. Adhes. Adhes. 2021, 110, 102947. [Google Scholar] [CrossRef]

- Farag, E.; Alshebani, M.; Elhrari, W.; Klash, A.; Shebani, A. Production of Particleboard Using Olive Stone Waste for Interior Design. J. Build. Eng. 2020, 29, 101119. [Google Scholar] [CrossRef]

- Syamani, F.A.; Ramatia, D.; Sudarmanto; Akbar, F.; Kusumah, S.S.; Hermawan, D. Combination of Citric Acid and Maltodextrin as Bonding Agent in Sorghum Bagasse Particleboard. IOP Conf. Ser. Mater. Sci. Eng. 2020, 935, 012058. [Google Scholar] [CrossRef]

- Mawardi, I.; Aprilia, S.; Faisal, M.; Ikramullah; Rizal, S. An Investigation of Thermal Conductivity and Sound Absorption from Binderless Panels Made of Oil Palm Wood as Bio-Insulation Materials. Results Eng. 2022, 13, 100319. [Google Scholar] [CrossRef]

- Chalapud, M.C.; Ciannamea, E.M.; Martucci, J.F.; Ruseckaite, R.A.; Stefani, P.M. Biobased Particleboards from Rice Husk and Soy Protein Concentrate: Evaluation of Flexural Properties and Dimensional Stability under Indoor Environmental Conditions. DYNA 2023, 90, 156–162. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Rizhikovs, J.; Andzs, M.; Bikovens, O. Influence of Manufacturing Conditions on Binder-Less Boards from Steam-Exploded Hemp Shives and Wheat Straw. Materials 2022, 15, 3141. [Google Scholar] [CrossRef] [PubMed]

- Auria, R.; Borysiuk, P.; Misiura, Z. Evaluation of the Physical and Mechanical Properties of Particle Boards Manufactured Containing Plum Pruning Waste. Biul. Inf. OB-RPPD 2021, 1, 5–11. [Google Scholar] [CrossRef]

- Amilia, W.; Rusdianto, A.S.; Sofiana, W. Characteristics of Tobacco Stem Particleboard in Printing Load Variations and Storage Time. J. Lifesci. 2020, 1, 8–14. [Google Scholar] [CrossRef]

- Wahane, A.; Sahu, A.; Verma, A.; Dewangan, T. Evaluation of the Physical and Mechanical Properties of Composite Board by Utilizing Agricultural Waste. Mater. Today Proc. 2023, 84, 16–23. [Google Scholar] [CrossRef]

- Mahieu, A.; Alix, S.; Leblanc, N. Properties of Particleboards Made of Agricultural By-Products with a Classical Binder or Self-Bound. Ind. Crops Prod. 2019, 130, 371–379. [Google Scholar] [CrossRef]

- Klímek, P.; Wimmer, R.; Kumar Mishra, P.; Kúdela, J. Utilizing Brewer’s-Spent-Grain in Wood-Based Particleboard Manufacturing. J. Clean. Prod. 2017, 141, 812–817. [Google Scholar] [CrossRef]

- Brito, F.M.S.; Bortoletto, G., Jr.; Paes, J.B.; Belini, U.L.; Tomazello-Filho, M. Technological Characterization of Particleboards Made with Sugarcane Bagasse and Bamboo Culm Particles. Constr. Build. Mater. 2020, 262, 120501. [Google Scholar] [CrossRef]

- Hussin, M.H.; Abd Latif, N.H.; Hamidon, T.S.; Idris, N.N.; Hashim, R.; Appaturi, J.N.; Brosse, N.; Ziegler-Devin, I.; Chrusiel, L.; Fatriasari, W.; et al. Latest Advancements in High-Performance Bio-Based Wood Adhesives: A Critical Review. J. Mater. Res. Technol. 2022, 21, 3909–3946. [Google Scholar] [CrossRef]

- EEA European Commission Regulation. Part 3 of Annex VI of the EC Regulation 1272/2008; EEA European Commission Regulation: Copenhagen, Denmark, 2014; Volume 58, pp. 7250–7257. [Google Scholar]

- Zhang, D.; Zhang, A.; Xue, L. A Review of Preparation of Binderless Fiberboards and Its Self-Bonding Mechanism. Wood Sci. Technol. 2015, 49, 661–679. [Google Scholar] [CrossRef]

- Ferreira, A.M.; Pereira, J.; Almeida, M.; Ferra, J.; Paiva, N.; Martins, J.; Magalhães, F.D.; Carvalho, L.H. Low-Cost Natural Binder for Particleboards Production: Study of Manufacture Conditions and Stability. Int. J. Adhes. Adhes. 2019, 93, 102325. [Google Scholar] [CrossRef]

- Vitrone, F.; Ramos, D.; Ferrando, F.; Salvadó, J. Binderless Fiberboards for Sustainable Construction. Materials, Production Methods and Applications. J. Build. Eng. 2021, 44, 102625. [Google Scholar] [CrossRef]

- Nasir, M.; Khali, D.P.; Jawaid, M.; Tahir, P.M.; Siakeng, R.; Asim, M.; Khan, T.A. Recent Development in Binderless Fiber-Board Fabrication from Agricultural Residues: A Review. Constr. Build. Mater. 2019, 211, 502–516. [Google Scholar] [CrossRef]

- Wang, Q.; Kudo, S.; Asano, S.; Hayashi, J.I. Hot-Compressed Water Treatment and Subsequent Binderless Hot Pressing for High-Strength Plate Preparation from Rice Husk. ACS Sustain. Chem. Eng. 2022, 10, 1932–1942. [Google Scholar] [CrossRef]

- Theng, D.; Arbat, G.; Delgado-Aguilar, M.; Ngo, B.; Labonne, L.; Mutjé, P.; Evon, P. Production of Fiberboard from Rice Straw Thermomechanical Extrudates by Thermopressing: Influence of Fiber Morphology, Water and Lignin Content. Eur. J. Wood Wood Prod. 2019, 77, 15–32. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, C.C.; Garcia-Ortuño, T.; Ferrandez-Garcia, M.T.; Ferrandez-Villena, M.; Ferrandez-Garcia, C.E. Fire-Resistance, Physical, and Mechanical Characterization of Binderless Rice Straw Particleboards. BioResources 2017, 12, 8539–8549. [Google Scholar] [CrossRef]

- Halvarsson, S.; Edlund, H.; Norgren, M. Manufacture of Non-Resin Wheat Straw Fibreboards. Ind. Crops Prod. 2009, 29, 437–445. [Google Scholar] [CrossRef]

- Domínguez-Robles, J.; Tarrés, Q.; Alcalà, M.; El Mansouri, N.E.; Rodríguez, A.; Mutjé, P.; Delgado-Aguilar, M. Development of High-Performance Binderless Fiberboards from Wheat Straw Residue. Constr. Build. Mater. 2020, 232, 117247. [Google Scholar] [CrossRef]

- Widyorini, R.; Xu, J.; Umemura, K.; Kawai, S. Manufacture and Properties of Binderless Particleboard from Bagasse I: Effects of Raw Material Type, Storage Methods, and Manufacturing Process. J. Wood Sci. 2005, 51, 648–654. [Google Scholar] [CrossRef]

- Nonaka, S.; Umemura, K.; Kawai, S. Characterization of Bagasse Binderless Particleboard Manufactured in High-Temperature Range. J. Wood Sci. 2013, 59, 50–56. [Google Scholar] [CrossRef]

- Velásquez, J.A.; Ferrando, F.; Farriol, X.; Salvadó, J. Binderless Fiberboard from Steam Exploded Miscanthus Sinensis. Wood Sci. Technol. 2003, 37, 269–278. [Google Scholar] [CrossRef]

- Rossi, L.; Wechsler, L.; Peltzer, M.A.; Ciannamea, E.M.; Ruseckaite, R.A.; Stefani, P.M. Sustainable Particleboards Based on Brewer’s Spent Grains. Polymers 2024, 16, 59. [Google Scholar] [CrossRef]

- Ferrández-Villena, M.; Ferrández-García, A.; García-Ortuño, T.; Ferrández-García, M.T. Evaluation of the Use of Vineyard Pruning Biomass (Bobal Variety) in Constructive Bioproducts. BioResources 2022, 17, 6542–6555. [Google Scholar] [CrossRef]

- Trobiani Di Canto, J.A.; Malfait, W.J.; Wernery, J. Turning Waste into Insulation—A New Sustainable Thermal Insulation Board Based on Wheat Bran and Banana Peels. Build. Environ. 2023, 244, 110740. [Google Scholar] [CrossRef]

- Aidawati, W.N.; Nadhari, W.; Hashim, R.; Sulaiman, O.; Sato, M.; Sugimoto, T.; Selamat, M.E. Palm Binderless Particleboard. BioResources 2013, 8, 1675–1696. [Google Scholar]

- Saari, N.; Lamaming, J.; Hashim, R.; Sulaiman, O.; Sato, M.; Arai, T.; Kosugi, A.; Wan Nadhari, W.N.A. Optimization of Binderless Compressed Veneer Panel Manufacturing Process from Oil Palm Trunk Using Response Surface Methodology. J. Clean. Prod. 2020, 265, 121757. [Google Scholar] [CrossRef]

- Araújo, C.P., Jr.; Coaquira, C.A.C.; Mattos, A.L.A.; de Souza Filho, M.d.S.M.; Feitosa, J.P.d.A.; de Morais, J.P.S.; de Freitas Rosa, M. Binderless Fiberboards Made from Unripe Coconut Husks. Waste Biomass Valorization 2018, 9, 2245–2254. [Google Scholar] [CrossRef]

- Puspaningrum, T.; Haris, Y.H.; Sailah, I.; Yani, M.; Indrasti, N.S. Physical and Mechanical Properties of Binderless Medium Density Fiberboard (MDF) from Coconut Fiber. IOP Conf. Ser. Earth Environ. Sci. 2020, 472, 012011. [Google Scholar] [CrossRef]

- Van Dam, J.E.G.; Van Den Oever, M.J.A.; Teunissen, W.; Keijsers, E.R.P.; Peralta, A.G. Process for Production of High Density/High Performance Binderless Boards from Whole Coconut Husk. Part 1: Lignin as Intrinsic Thermosetting Binder Resin. Ind. Crops Prod. 2004, 19, 207–216. [Google Scholar] [CrossRef]

- Stelte, W.; Reddy, N.; Barsberg, S.; Sanadi, A.R. Coir from Coconut Processing Waste as a Raw Material for Applications beyond Traditional Uses. BioResources 2023, 18, 2187–2212. [Google Scholar] [CrossRef]

- Wang, B.; Li, D.L.; Chen, T.Y.; Qin, Z.Y.; Peng, W.X.; Wen, J.L. Understanding the Mechanism of Self-Bonding of Bamboo Binderless Boards: Investigating the Structural Changes of Lignin Macromolecule during the Molding Pressing Process. BioResources 2017, 12, 514–532. [Google Scholar] [CrossRef]

- Guan, M.; Fu, R.; Yong, C.; Li, Y.; Xu, X. Properties of Binderless Bamboo Particleboards Derived from Biologically Fermented Bamboo Green Residues. Waste Manag. 2022, 151, 195–204. [Google Scholar] [CrossRef]

- Yang, Z.; Song, W.; Cao, Y.; Wang, C.; Hu, X.; Yang, Y.; Zhang, S. The Effect of Laccase Pretreatment Conditions on the Mechanical Properties of Binderless Fiberboards with Wheat Straw. BioResources 2017, 12, 3707–3719. [Google Scholar] [CrossRef]

- Uitterhaegen, E.; Labonne, L.; Merah, O.; Talou, T.; Ballas, S.; Véronèse, T.; Evon, P. Optimization of Thermopressing Conditions for the Production of Binderless Boards from a Coriander Twin-Screw Extrusion Cake. J. Appl. Polym. Sci. 2017, 134, 44650. [Google Scholar] [CrossRef]

- Okuda, N.; Sato, M. Manufacture and Mechanical Properties of Binderless Boards from Kenaf Core. J. Wood Sci. 2004, 50, 53–61. [Google Scholar] [CrossRef]

- Xu, J.; Han, G.; Wong, E.D.; Kawai, S. Development of Binderless Particleboard from Kenaf Core Using Steam-Injection Pressing. J. Wood Sci. 2003, 49, 327–332. [Google Scholar] [CrossRef]

- Okuda, N.; Hori, K.; Sato, M. Chemical Changes of Kenaf Core Binderless Boards during Hot Pressing (I): Influence of the Pressing Temperature Condition. J. Wood Sci. 2006, 52, 244–248. [Google Scholar] [CrossRef]

- Milawarni; Nurlaili; Sariadi; Amra, S.; Yassir. Influence of Press Temperature on the Properties of Binderless Particleboard. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2019, 536, 012066. [Google Scholar] [CrossRef]

- Milawarni; Nurlaili; Sariyadi. Characterization a Binderless Particleboard of Coffee Husk Using Hydrogen Peroxide (H2O2) and Ferrous Sulfate (FeSO4). Proc. IOP Conf. Ser. Mater. Sci. Eng. 2018, 352, 1–6. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Rizhikovs, J.; Brazdausks, P.; Fridrihsone, V.; Andzs, M. Influence of Steam Explosion Pre-Treatment Conditions on Binder-Less Boards from Hemp Shives and Wheat Straw. Ind. Crops Prod. 2021, 170, 113717. [Google Scholar] [CrossRef]

- Almusawi, A.; Lachat, R.; Atcholi, K.E.; Gomes, S. Proposal of Manufacturing and Characterization Test of Binderless Hemp Shive Composite. Int. Biodeterior. Biodegrad. 2016, 115, 302–307. [Google Scholar] [CrossRef]

- Kurokochi, Y.; Saito, Y. Heat Treatment to Increase Self-Bonding Property of Binderless Boards Manufactured from Rice Straw. IOP Conf. Ser. Earth Environ. Sci. 2022, 1063, 012002. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, A.; Ferrandez-Garcia, M.T.; Garcia-Ortuño, T.; Ferrandez-Villena, M. Influence of the Density in Binderless Particleboards Made from Sorghum. Agronomy 2022, 12, 1387. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Pizzi, A.; Zhang, H.; Halis, R. Green Hot-Pressed Board. BioResources 2018, 13, 1–67. [Google Scholar]

- Cai, Z.; Wang, X.; Song, X.; Xu, S. Performance of Binderless Board Manufactured Using Camphor Tree Residue. BioResources 2022, 17, 6692–6705. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Pizzi, A.; Zhang, H.; Halis, R. Critical Links Governing Performance of Self-Binding and Natural Binders for Hot-Pressed Reconstituted Lignocellulosic Board without Added Formaldehyde: A Review. BioResources 2018, 13, 2049–2115. [Google Scholar] [CrossRef]

- Tajuddin, M.; Ahmad, Z.; Ismail, H. A Review of Natural Fibers and Processing Operations for the Production of Binderless Boards. BioResources 2016, 11, 5600–5617. [Google Scholar] [CrossRef]

- Jerman, M.; Böhm, M.; Dušek, J.; Černý, R. Effect of Steaming Temperature on Microstructure and Mechanical, Hygric, and Thermal Properties of Binderless Rape Straw Fiberboards. Build. Environ. 2022, 223, 109474. [Google Scholar] [CrossRef]

- Domínguez-Robles, J.; Tarrés, Q.; Delgado-Aguilar, M.; Rodríguez, A.; Espinach, F.X.; Mutjé, P. Approaching a New Generation of Fiberboards Taking Advantage of Self Lignin as Green Adhesive. Int. J. Biol. Macromol. 2018, 108, 927–935. [Google Scholar] [CrossRef] [PubMed]

- Mobarak, F.; Fahmy, Y.; Augustin, H. Binderless Lignocellulose Composite from Bagasse and Mechanism of Self-Bonding. Holzforschung 1982, 36, 131–135. [Google Scholar] [CrossRef]

- Zeng, X.; Wang, G.; Liu, Y.; Zhang, X. Graphene-Based Antimicrobial Nanomaterials: Rational Design and Applications for Water Disinfection and Microbial Control. Environ. Sci. Nano 2017, 4, 2248–2266. [Google Scholar] [CrossRef]

- Casado, U.M.; Altuna, F.I.; Miccio, L.A. A Review on the Role of Crosslinked Polymers in Renewable Energy: Complex Network Analysis of Innovations in Sustainability. Sustainability 2025, 17, 4736. [Google Scholar] [CrossRef]

- Mancera, C.; Ferrando, F.; Salvadó, J. Cynara Cardunculus as Raw Material for the Production of Binderless Fiberboards: Optimization of Pretreatment and Pressing Conditions. J. Wood Chem. Technol. 2008, 28, 207–226. [Google Scholar] [CrossRef]

- Pintiaux, T.; Viet, D.; Vandenbossche, V.; Rigal, L.; Rouilly, A. Binderless Materials Obtained by Thermo-Compressive Processing of Lignocellulosic Fibers: A Comprehensive Review. BioResources 2015, 10, 1915–1963. [Google Scholar] [CrossRef]

- Chen, M.; Zheng, S.; Wu, J.; Xu, J. Study on Preparation of High-Performance Binderless Board from Broussonetia papyrifera. J. Wood Sci. 2023, 69, 17. [Google Scholar] [CrossRef]

- Alvarez, C.; Rojas, O.J.; Rojano, B.; Ganán, P. Development of Self-Bonded Fiberboards from Fiber of Leaf Plantain: Effect of Water and Organic Extractives Removal. BioResources 2015, 10, 672–683. [Google Scholar] [CrossRef]

- Vitrone, F.; Ramos, D.; Ferrando, F.; Salvadó, J. The Influence of Thickness and Final Heat Treatment on Mechanical Properties and Dimensional Stability of Binderless Fiberboards from Steam Exploded Arundo donax L. Mater. Today Proc. 2022, 58, 999–1004. [Google Scholar] [CrossRef]

- Jamaludin, M.A.; Bahari, S.A.; Zakaria, M.N.; Saipolbahri, N.S. Influence of Rice Straw, Bagasse, and Their Combination on the Properties of Binderless Particleboard. J. Korean Wood Sci. Technol. 2020, 48, 22–31. [Google Scholar] [CrossRef]

- Panyakaew, S.; Fotios, S. New Thermal Insulation Boards Made from Coconut Husk and Bagasse. Energy Build. 2011, 43, 1732–1739. [Google Scholar] [CrossRef]

- Nadhari, W.N.A.W.; Karim, N.A.; Boon, J.G.; Salleh, K.M.; Mustapha, A.; Hashim, R.; Sulaiman, O.; Azni, M.E. Sugarcane (Saccharum officinarium L.) Bagasse Binderless Particleboard: Effect of Hot Pressing Time Study. Mater. Today Proc. 2020, 31, 313–317. [Google Scholar] [CrossRef]

- Quintana, G.; Velásquez, J.; Betancourt, S.; Gañán, P. Binderless Fiberboard from Steam Exploded Banana Bunch. Ind. Crops Prod. 2009, 29, 60–66. [Google Scholar] [CrossRef]

- Sun, R.-C.; Tomkinson, J. Appendix 1. Essential Guides for Isolation/Purification of Polysaccharides. In Encyclopedia of Separation Science; Wilson, I.D., Ed.; Academic Press: Cambridge, MA, USA, 2000; pp. 4568–4574. ISBN 9780122267703. [Google Scholar]

- Kurniati, M.; Fahma, F.; Amalia Kartika, I.; Sunarti, T.C.; Syamsu, K.; Hermawan, D.; Saito, Y.; Sato, M. Binderless Particleboard from Castor Seed Cake: Effect of Pressing Temperature on Physical and Mechanical Properties. Asian J. Agric. Res. 2015, 9, 180–188. [Google Scholar] [CrossRef][Green Version]

- Christy, E.O.; Soemarno; Sumarlan, S.H.; Soehardjono, A. Binderless Bark Particleboard Made from Gelam (Melaleuca viridiflora Sol. Ex Gaertn.) Bark Waste: The Effect of the Pressing Temperature on Its Mechanical and Physical Properties. BioResources 2021, 16, 4171–4199. [Google Scholar] [CrossRef]

- Mejía, E.H.; Quintana, G.C.; Ogunsile, B.O. Development of Binderless Fiberboards from Steam-Exploded and Oxidized Oil Palm Wastes. BioResources 2014, 9, 2922–2936. [Google Scholar] [CrossRef]

- Xiao, L.-P.; Lin, Z.; Peng, W.-X.; Yuan, T.-Q.; Xu, F.; Li, N.-C.; Tao, Q.-S.; Xiang, H.; Sun, R.-C. Unraveling the Structural Characteristics of Lignin in Hydrothermal Pretreated Fibers and Manufactured Binderless Boards from Eucalyptus grandis. Sustain. Chem. Process. 2014, 2, 9. [Google Scholar] [CrossRef]

- Jiang, Y.; Lawrence, M.; Hussain, A.; Ansell, M.; Walker, P. Comparative Moisture and Heat Sorption Properties of Fibre and Shiv Derived from Hemp and Flax. Cellulose 2019, 26, 823–843. [Google Scholar] [CrossRef]

- Arévalo, R.; Peijs, T. Binderless All-Cellulose Fibreboard from Microfibrillated Lignocellulosic Natural Fibres. Compos. Part A Appl. Sci. Manuf. 2016, 83, 38–46. [Google Scholar] [CrossRef]

- Brazdausks, P.; Tupciauskas, R.; Andzs, M.; Rizhikovs, J.; Puke, M.; Paze, A.; Meile, K.; Vedernikovs, N. Preliminary Study of the Biorefinery Concept to Obtain Furfural and Binder-Less Panels from Hemp (Cannabis sativa L.) Shives. Energy Procedia 2015, 72, 34–41. [Google Scholar] [CrossRef]

- Klímek, P.; Wimmer, R.; Meinlschmidt, P.; Kúdela, J. Utilizing Miscanthus Stalks as Raw Material for Particleboards. Ind. Crops Prod. 2018, 111, 270–276. [Google Scholar] [CrossRef]

- Boon, J.G.; Hashim, R.; Danish, M.; Nadhari, W.N.A.W. Physical and Mechanical Properties of Binderless Particleboard Made from Steam-Pretreated Oil Palm Trunk Particles. J. Compos. Sci. 2019, 3, 46. [Google Scholar] [CrossRef]

- Ahmad, Z.; Tajuddin, M.; Salim, N.F.F.; Halim, Z. Effect of Alkaline Treatment on Properties of Rattan Waste and Fabricated Binderless Particleboard. IIUM Eng. J. 2018, 19, 185–196. [Google Scholar] [CrossRef]

- Ciannamea, E.M.; Stefani, P.M.; Ruseckaite, R.A. Medium-Density Particleboards from Modified Rice Husks and Soybean Protein Concentrate-Based Adhesives. Bioresour. Technol. 2010, 101, 818–825. [Google Scholar] [CrossRef]

- Nasir, M.; Gupta, A.; Beg, M.D.H.; Chua, G.K.; Jawaid, M.; Kumar, A.; Khan, T.A. Fabricating Eco-Friendly Binderless Fiberboard from Laccase-Treated Rubber Wood Fiber. BioResources 2013, 8, 3599–3608. [Google Scholar] [CrossRef]

- Sun, W.; Tajvidi, M.; Hunt, C.G.; Cole, B.J.W.; Howell, C.; Gardner, D.J.; Wang, J. Fungal and Enzymatic Pretreatments in Hot-Pressed Lignocellulosic Bio-Composites: A Critical Review. J. Clean. Prod. 2022, 353, 131659. [Google Scholar] [CrossRef]

- Ahmad, Z.; Tajuddin, M.; Maleque, M.A.; Halim, Z. Effects of Particle Sizes on the Properties of Binderless Boards Made from Rattan Furniture Waste. J. Eng. Sci. 2019, 15, 49–61. [Google Scholar] [CrossRef]

- Lamaming, S.Z.; Lamaming, J.; Rawi, N.F.M.; Hashim, R.; Kassim, M.H.M.; Hussin, M.H.; Bustami, Y.; Sulaiman, O.; Amini, M.H.M.; Hiziroglu, S. Improvements and Limitation of Soy Protein-Based Adhesive: A Review. Polym. Eng. Sci. 2021, 61, 2393–2405. [Google Scholar] [CrossRef]

- Lee, S.; Shupe, T.F.; Hse, C.Y. Mechanical and Physical Properties of Agro-Based Fiberboard. Eur. J. Wood Wood Prod. 2006, 64, 74–79. [Google Scholar] [CrossRef]

- Laemsak, N.; Okuma, M. Development of Boards Made from Oil Palm Frond II: Properties of Binderless Boards from Steam-Exploded Fibers of Oil Palm Frond. J. Wood Sci. 2000, 46, 322–326. [Google Scholar] [CrossRef]

- Anglès, M.N.; Ferrando, F.; Farriol, X.; Salvadó, J. Suitability of Steam Exploded Residual Softwood for the Production of Binderless Panels. Effect of the Pre-Treatment Severity and Lignin Addition. Biomass Bioenergy 2001, 21, 211–224. [Google Scholar] [CrossRef]

- Audibert, E.; Ducceschi, L.; Quintero, A.; Martel, F.; Paës, G.; Rémond, C. Binderless Particleboards from Steam Exploded Woody Biomass: Chemical and Morphological Properties Relate to Their Mechanical and Physical Behavior. Ind. Crops Prod. 2025, 229, 120983. [Google Scholar] [CrossRef]

- Ramos, D.; El Mansouri, N.E.; Ferrando, F.; Salvadó, J. All-Lignocellulosic Fiberboard from Steam Exploded Arundo donax L. Molecules 2018, 23, 88. [Google Scholar] [CrossRef] [PubMed]

- Van Dam, J.E.G.; Van Den Oever, M.J.A.; Keijsers, E.R.P. Production Process for High Density High Performance Binderless Boards from Whole Coconut Husk. Ind. Crops Prod. 2004, 20, 97–101. [Google Scholar] [CrossRef]

- Kurokochi, Y.; Sato, M. Steam Treatment to Enhance Rice Straw Binderless Board Focusing Hemicellulose and Cellulose Decomposition Products. J. Wood Sci. 2020, 66, 7. [Google Scholar] [CrossRef]

- JIS A 5905:2003; Fiberboards. Japanese Standards Association: Tokyo, Japan, 2003.

- EN 312 P3; Particleboards—Specifications. European Committee for Standardization: Brussels, Belgium, 2010.

- Chen, Y.; Yan, Z.; Liang, L.; Ran, M.; Wu, T.; Wang, B.; Zou, X.; Zhao, M.; Fang, G.; Shen, K. Comparative Evaluation of Organic Acid Pretreatment of Eucalyptus for Kraft Dissolving Pulp Production. Materials 2020, 13, 361. [Google Scholar] [CrossRef]

- Young, R.A.; Fujita, M.; River, B.H. New Approaches to Wood Bonding A Base-Activated Lignin Adhesive System. Wood Sci. Technol. 1985, 19, 363–381. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, L.; Xiao, Y.; Fan, Q.; Yang, C.; Deng, Y.; Lu, H.; Cheng, L. Preparation of Wheat Straw Hot-Pressed Board through Coupled Dilute Acid Pretreatment and Surface Modification. Materials 2024, 17, 1950. [Google Scholar] [CrossRef] [PubMed]

- Ghaffar, S.H.; Fan, M. Lignin in Straw and Its Applications as an Adhesive. Int. J. Adhes. Adhes. 2014, 48, 92–101. [Google Scholar] [CrossRef]

- Salgado-Delgado, R.; Ramirez–Navarrete, F.D.; Felix–Lerma, M.V.; Salgado–Delgado, A.M.; Olarte–Paredes, A.; Rubio–Rosas, E. Modificación Química del Aserrín de Madera para Mejorar la Interfaz en Materiales Compuestos con Matriz Termoplástica/Termofija. Available online: https://reviberpol.org/wp-content/uploads/2021/09/2021-22-4-152-164.pdf (accessed on 7 November 2025).

- Börcsök, Z.; Pásztory, Z. The Role of Lignin in Wood Working Processes Using Elevated Temperatures: An Abbreviated Literature Survey. Eur. J. Wood Wood Prod. 2021, 79, 511–526. [Google Scholar] [CrossRef]

- Abd Karim, N.; Lamaming, J.; Yusof, M.; Hashim, R.; Sulaiman, O.; Hiziroglu, S.; Wan Nadhari, W.N.A.; Salleh, K.M.; Taiwo, O.F. Properties of Native and Blended Oil Palm Starch with Nano-Silicon Dioxide as Binder for Particleboard. J. Build. Eng. 2020, 29, 101151. [Google Scholar] [CrossRef]

- Kusumah, S.S.; Umemura, K.; Guswenrivo, I.; Yoshimura, T.; Kanayama, K. Utilization of Sweet Sorghum Bagasse and Citric Acid for Manufacturing of Particleboard II: Influences of Pressing Temperature and Time on Particleboard Properties. J. Wood Sci. 2017, 63, 161–172. [Google Scholar] [CrossRef]

- Hidalgo-Cordero, J.F.; García-Ortuño, T.; García-Navarro, J. Comparison of Binderless Boards Produced with Different Tissues of Totora (Schoenoplectus californicus (C.A. Mey) Soják) Stems. J. Build. Eng. 2020, 27, 100961. [Google Scholar] [CrossRef]

- Mehrzad, S.; Taban, E.; Soltani, P.; Samaei, S.E.; Khavanin, A. Sugarcane Bagasse Waste Fibers as Novel Thermal Insulation and Sound-Absorbing Materials for Application in Sustainable Buildings. Build. Environ. 2022, 211, 108753. [Google Scholar] [CrossRef]

- Cai, W.; Zhao, Z. Exploiting Sugarcane Waste Molasses and Dephenolized Cottonseed Protein as the Promising Component for Eco-Friendly Wood-Based Panel Adhesive Formulation. Wood Mater. Sci. Eng. 2024, 19, 858–867. [Google Scholar] [CrossRef]

- Barbu, M.C.; Montecuccoli, Z.; Förg, J.; Barbeck, U.; Klímek, P.; Petutschnigg, A.; Tudor, E.M. Potential of Brewer’s Spent Grain as a Potential Replacement of Wood in Pmdi, Uf or Muf Bonded Particleboard. Polymers 2021, 13, 319. [Google Scholar] [CrossRef] [PubMed]

- Zeko-Pivač, A.; Tišma, M.; Žnidaršič-Plazl, P.; Kulisic, B.; Sakellaris, G.; Hao, J.; Planinić, M. The Potential of Brewer’s Spent Grain in the Circular Bioeconomy: State of the Art and Future Perspectives. Front. Bioeng. Biotechnol. 2022, 10, 870744. [Google Scholar] [CrossRef] [PubMed]

- Goodman, B.A. Utilization of Waste Straw and Husks from Rice Production: A Review. J. Bioresour. Bioprod. 2020, 5, 143–162. [Google Scholar] [CrossRef]

- da Silva Aires, F.I.; Freitas, I.S.; dos Santos, K.M.; da Silva Vieira, R.; Nascimento Dari, D.; de Sousa, P.G., Jr.; Serafim, L.F.; Menezes Ferreira, A.Á.; Galvão da Silva, C.; da Silva, É.D.L.; et al. Sugarcane Bagasse as a Renewable Energy Resource: A Bibliometric Analysis of Global Research Trends. ACS Sustain. Resour. Manag. 2025, 2, 1551–1561. [Google Scholar] [CrossRef]

- Luo, P.; Yang, C. Production of Binderless Particleboard Using Rice Straw Pretreated with Liquid Hot Water. Appl. Mech. Mater. 2012, 200, 331–334. [Google Scholar] [CrossRef]

- Jackowski, M.; Niedźwiecki, Ł.; Jagiełło, K.; Uchańska, O.; Trusek, A. Brewer’s Spent Grains—Valuable Beer Industry by-Product. Biomolecules 2020, 10, 1669. [Google Scholar] [CrossRef]

- El Haddaji, B.; Benzaama, M.; Quiertant, M.; Mendili, Y. El Insight into the Use of Brewers’ Spent Grain as a Low-Carbon Aggregate in Building Materials. Biomimetics 2024, 9, 781. [Google Scholar] [CrossRef]

- Ferraz, E.; Coroado, J.; Gamelas, J.A.F.; Silva, J.; Rocha, F.; Velosa, A. Spent Brewery Grains for Improvement of Thermal Insulation of Ceramic Bricks. J. Mater. Civ. Eng. 2013, 25, 1638–1646. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Dragone, G.; Roberto, I.C. Brewers’ Spent Grain: Generation, Characteristics and Potential Applications. J. Cereal Sci. 2006, 43, 1–14. [Google Scholar] [CrossRef]

- Lynch, K.M.; Steffen, E.J.; Arendt, E.K. Brewers’ Spent Grain: A Review with an Emphasis on Food and Health. J. Inst. Brew. 2016, 122, 553–568. [Google Scholar] [CrossRef]

- Kerby, C.; Vriesekoop, F. An Overview of the Utilisation of Brewery By-Products as Generated by British Craft Breweries. Beverages 2017, 3, 24. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Brewer’s Spent Grains: Possibilities of Valorization, a Review. Appl. Sci. 2020, 10, 5619. [Google Scholar] [CrossRef]

- Anh, L.D.H.; Pásztory, Z. An Overview of Factors Influencing Thermal Conductivity of Building Insulation Materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Ablaoui, E.M.; Malendowski, M.; Szymkuć, W.; Pozorski, Z. Determination of Thermal Properties of Mineral Wool Required for the Safety Analysis of Sandwich Panels Subjected to Fire Loads. Materials 2023, 16, 5852. [Google Scholar] [CrossRef] [PubMed]

- Gregg, J.S.; Jürgens, J.; Happel, M.K.; Strøm-Andersen, N.; Tanner, A.N.; Bolwig, S.; Klitkou, A. Valorization of Bio-Residuals in the Food and Forestry Sectors in Support of a Circular Bioeconomy: A Review. J. Clean. Prod. 2020, 267, 122093. [Google Scholar] [CrossRef]

- Guaygua-Amaguaña, P.; Vaca-Medina, G.; Vialle, C.; Sablayrolles, C.; Evon, P. Eco-Design of Thermopressing through Induction of 100% Coriander-Based Fiberboards: Optimization of Molding Conditions. Materials 2024, 17, 4852. [Google Scholar] [CrossRef]

- Grzegorzewska, E.; Burawska-Kupniewska, I.; Boruszewski, P. Economic Profitability of Particleboards Production with a Diversified Raw Material Structure. Maderas-Cienc. Tecnol. 2020, 22, 537–548. [Google Scholar] [CrossRef]

- Chojnacka, K.; Mikula, K.; Izydorczyk, G.; Skrzypczak, D.; Witek-Krowiak, A.; Moustakas, K.; Ludwig, W.; Kułażyński, M. Improvements in Drying Technologies—Efficient Solutions for Cleaner Production with Higher Energy Efficiency and Reduced Emission. J. Clean. Prod. 2021, 320, 128706. [Google Scholar] [CrossRef]

- Puligundla, P.; Mok, C. Recent Advances in Biotechnological Valorization of Brewers’ Spent Grain. Food Sci. Biotechnol. 2021, 30, 341–353. [Google Scholar] [CrossRef]

| Raw Material | Pretreatment Method | Temperature (°C)/Time (min) | MOR (MPa) | IB (MPa) | WA (%)/TS (%) |

|---|---|---|---|---|---|

| Arundo donax L. [101] | Steam explosion | 210/9.5 | 40.4 | 1.3 | 17.6/15 |

| control | - | 40 | 0.7 | 75/65 | |

| Oil palm trunk [90] | Steam treatment | 200/60 | 18.7 | 0.75 | nd/21.8 (TS) |

| control | - | 15.4 | 0.66 | nd/26 (TS) | |

| Rice straw [103] | Steam treatment | 200/20 | 6 | 0.32 | 35/5 |

| control | - | 3 | 0.03 | 53/35 |

| Raw Material | Pretreatment | TP (°C) | tP (min) | PP (MPa) | Particle Size (mm) | Density (kg/m3) | MOR. (MPa) | MOE (GPa) | IB (MPa) |

|---|---|---|---|---|---|---|---|---|---|

| RS [77] | - | 180 | 10 | n.d. | 0.84 | 800 (1) | 13 | 1.03 | 0.3 |

| RS [61] | Heat treatment (200 °C, 1.5 MPa 40 min) | 220 | 10 | 5 | ≤1 | 800 (1) | 7.3 | 2.10 | 0.3 |

| RH [33] | Hot compressed water (160 °C) | 170–245 | 8 | n.d. | n.d. | 1400 | 21 | 2.37 | n.d. |

| RS [35] | - | 110 | 60 (3 cycles) | 2.6 | <0.25 mm | 1101.5 | 18.02 | 2.58 | 0.3 |

| RS [34] | Thermo-mechanical fractionation, twin-screw extruder; (100–110 °C) Biolignin™ | 200 | 5–1 (2 cycles) | 22.3 (2) | - | 1414 | 50.3 | 8.06 | n.d. |

| Raw Material | Pretreatment | TP (°C) | tP (min) | PP (MPa) | Density (kg/m3) | MOR (MPa) | MOE (GPa) | IB (MPa) |

|---|---|---|---|---|---|---|---|---|

| BP and residual sugar [77] | - | 180 | 10 | n.d. | 800 | 20 | 1.9 | 0.6 |

| BP, BR [39] | - | 260 | 10 | n.d. | 800 | 16.6 | 3.5 | 1.2 |

| Depithed bagasse [69] | <0.5 mm * | 175 | 5 | 25.5 | 1350 | 63 | - | - |

| BP [38] | - | 190 | 10 | n.d. | 750 | 10 | 1.4 | 0.2 |

| BR [38] | - | 190 | 10 | n.d. | 750 | 2.0 | 0.4 | 0.1 |

| BP [38] | Steam injection | 190 | 3 | 1.0 | 650 | 6.0 | 0.8 | 0.15 |

| BR [38] | Steam injection | 190 | 3 | 1.0 | 650 | 2.0 | 0.4 | 0.09 |

| Raw Material | Particle Size (mm) | TP (ᵒC) | tP (min) | PP (MPa) | Density (kg/m3) | MOR (MPa) | MOE (MPa) | IB (MPa) |

|---|---|---|---|---|---|---|---|---|

| Coconut coir [48,102] | 0.88 | 180 | 3–30 | 0.30–0.75 | 1300–1400 | 50 | 5000 | nd. |

| Coconut husk [78] | 8–10 | 200 | 13 | 14.7 | 450 | 1.94 | 365 | 0.002 |

| White coir pith and fiber 7:3 (w/w) [46] | 4 | 210 | 4 | 15.7 | 1372 | 18 | 3410 | nd. |

| Coconut coir [47] | 10–20 | 180 | 20 | 2.4 | 500 | 37 | 2800 | 0.31 |

| Pretreatment | TP (°C) | tP (min) | PP (MPa) | Density (kg/m3) | MOR (MPa) | MOE (MPa) | IB (MPa) |

|---|---|---|---|---|---|---|---|

| Fenton [36] | 200 | 1.5 | 0.5 | 1000 | 28 | 4000 | 0.5 |

| Soda pulping (7 wt% NaOH) [37] | 150/220 | 45/10 | 8/14 | 1013 | 52.8 | 1890 | 0.4 |

| Mechanical refining [37] | 150/220 | 45/10 | 8/14 | 1119 | 98.7 | 6500 | 1.6 |

| Steam explosion [59] | 175 | 16 | 6 | 1150 | 22.1 | 4482 | 0.6 |

| Steam explosion [20] | 175 | 16 | 6 | 800 | 15.5 | 2750 | 0.6 |

| Pretreatment | TP (°C) | tP (min) | PP (MPa) | Density (kg/m3) | MOR (MPa) | MOE (MPa) | IB (MPa) |

|---|---|---|---|---|---|---|---|

| Steam pretreatment (160 °C) [90] | 200 | 20 | 10 | 600 | 18.7 | n.d. | 0.75 |

| Hot water (100 °C, 30 min) [18] | 200 | 25 | 15 | 650 | 8.18 | n.d. | n.d. |

| Steam explosion and Fenton reagent oxidation [84] | 190 | 6 | 5 | 1200 | 28.5 | 3100.1 | n.d. |

| Particle Size (mm) | TP (°C) | MOR (MPa) | MOE (GPa) | IB (MPa) |

|---|---|---|---|---|

| >2.5 | 160 | 1.82 | 0.46 | 0.09 |

| >2.5 | 170 | 2.43 | 0.54 | 0.15 |

| 0.2–2.38 | 160 | 2.06 | 0.61 | 0.09 |

| 0.2–2.38 | 170 | 4.14 | 0.77 | 0.23 |

| Material | Thermal Conductivity (W/m·K) | Density (kg/m3) | Typical Applications |

|---|---|---|---|

| BSG panel | 0.10–0.13 | 350–450 | Interior insulation, furniture cores |

| BSG–hemp mix | 0.07–0.10 | 250–350 | Partition boards, eco-panels |

| Hemp shive panel | 0.05–0.08 | 220–300 | Light insulation, acoustic boards |

| Mineral wool | 0.035–0.045 | 30–100 | Thermal and acoustic insulation |

| Expanded polystyrene (EPS) | 0.031–0.038 | 15–30 | Conventional wall/roof insulation |

| Parameter | Scenario 1. High-Efficiency or Heat-Recovery System (Most Energy-Efficient Drying Scenario). No Gate Prices, Low Haul Distance, and Cheap Energy Cost. | Scenario 2. Same as 1, but Conventional Convective Dryers with Limited Heat Recovery. | Scenario 3. Same as 1, but Just Drying Up to Processing Conditions (35%). |

|---|---|---|---|

| BSG wet price (€/t) | 0 | 0 | 0 |

| Initial moisture (%) | 75 | 75 | 75 |

| Final moisture (%) | 10 | 10 | 35 |

| Water removed per ton wet (kg) | 722.2 | 722.2 | 615.4 |

| Specific energy consumption (SEC, MJ/kg water) | 4 | 8 | 4 |

| Energy cost (€/MJ) | 0.02 | 0.02 | 0.02 |

| Energy cost to dry (€/t wet) | 57.8 | 115.6 | 49.2 |

| Haul distance (km) | 20 | 20 | 20 |

| Transport cost (€/t/100 km) | 5 | 5 | 5 |

| Delivered cost (EUR/t wet, incl. transport) | 1 | 1 | 1 |

| Delivered and dried cost (EUR/t dry basis) | 235.1 | 466.2 | 200.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rossi, L.; Miccio, L.A.; Ciannamea, E.M.; Stefani, P.M. From Agricultural Residues to Sustainable Boards: Complex Network Analysis of Binderless Composites. Polymers 2025, 17, 3082. https://doi.org/10.3390/polym17223082

Rossi L, Miccio LA, Ciannamea EM, Stefani PM. From Agricultural Residues to Sustainable Boards: Complex Network Analysis of Binderless Composites. Polymers. 2025; 17(22):3082. https://doi.org/10.3390/polym17223082

Chicago/Turabian StyleRossi, Lucia, Luis A. Miccio, Emiliano M. Ciannamea, and Pablo M. Stefani. 2025. "From Agricultural Residues to Sustainable Boards: Complex Network Analysis of Binderless Composites" Polymers 17, no. 22: 3082. https://doi.org/10.3390/polym17223082

APA StyleRossi, L., Miccio, L. A., Ciannamea, E. M., & Stefani, P. M. (2025). From Agricultural Residues to Sustainable Boards: Complex Network Analysis of Binderless Composites. Polymers, 17(22), 3082. https://doi.org/10.3390/polym17223082