The Impact of CO2 Laser Treatment on Kevlar® KM2+ Fibres Fabric Surface Morphology and Yarn Pull-Out Resistance

Abstract

1. Introduction

- Yarn stretch—the elongation of the high-performance yarns, including para-aramid yarns approximately are linear and rate independent.

- Uncrimping—the initially crimped fabric yarns straighten via two different modes of deformation (a) uniaxial tension parallel to a yarn direction causes crimp interchange. In result the loaded yarns straighten while the yarns of the other system become more crimped, (b) biaxial tension parallel to the yarn directions causes uncrimping in both yarn systems via transverse compression of the yarns at the cross-over points.

- Relative yarn rotation (trellising)—is related to the change in in-plane angle between both yarn systems. Frequently named “shear” trellising has both an elastic component, due to rotation between cross-over points, and a dissipative component, due to the frictional resistance to rotation at these points. It is the primary mode by which large deformations are accommodated in woven fabrics.

- Locking—the resistance to trellising increases as yarns of opposite system shear-lock against one another in the plane of the fabric. When crimp interchange cross-locking occurs causing lateral contraction of the fabric to an extent that the loaded yarns jam against one another.

- Yarn slip—occurs as the relative displacement of one yarn system with respect to the other at the cross-over points. Yarn slips permanently alters the mesostructure of the fabric and occurs with little resistance under impact.

2. Materials and Methods

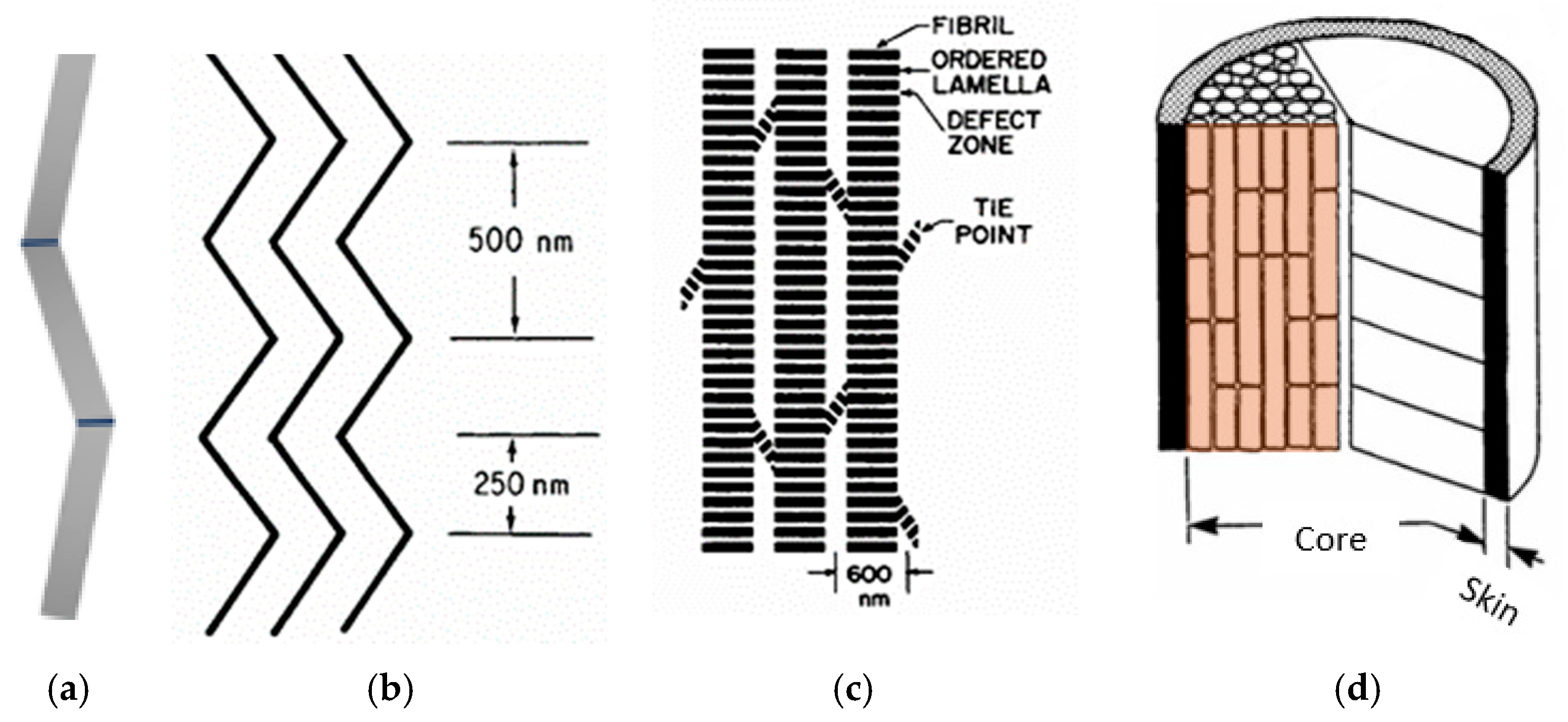

2.1. The Specific of Kevlar® Fibre Architecture

2.2. Materials

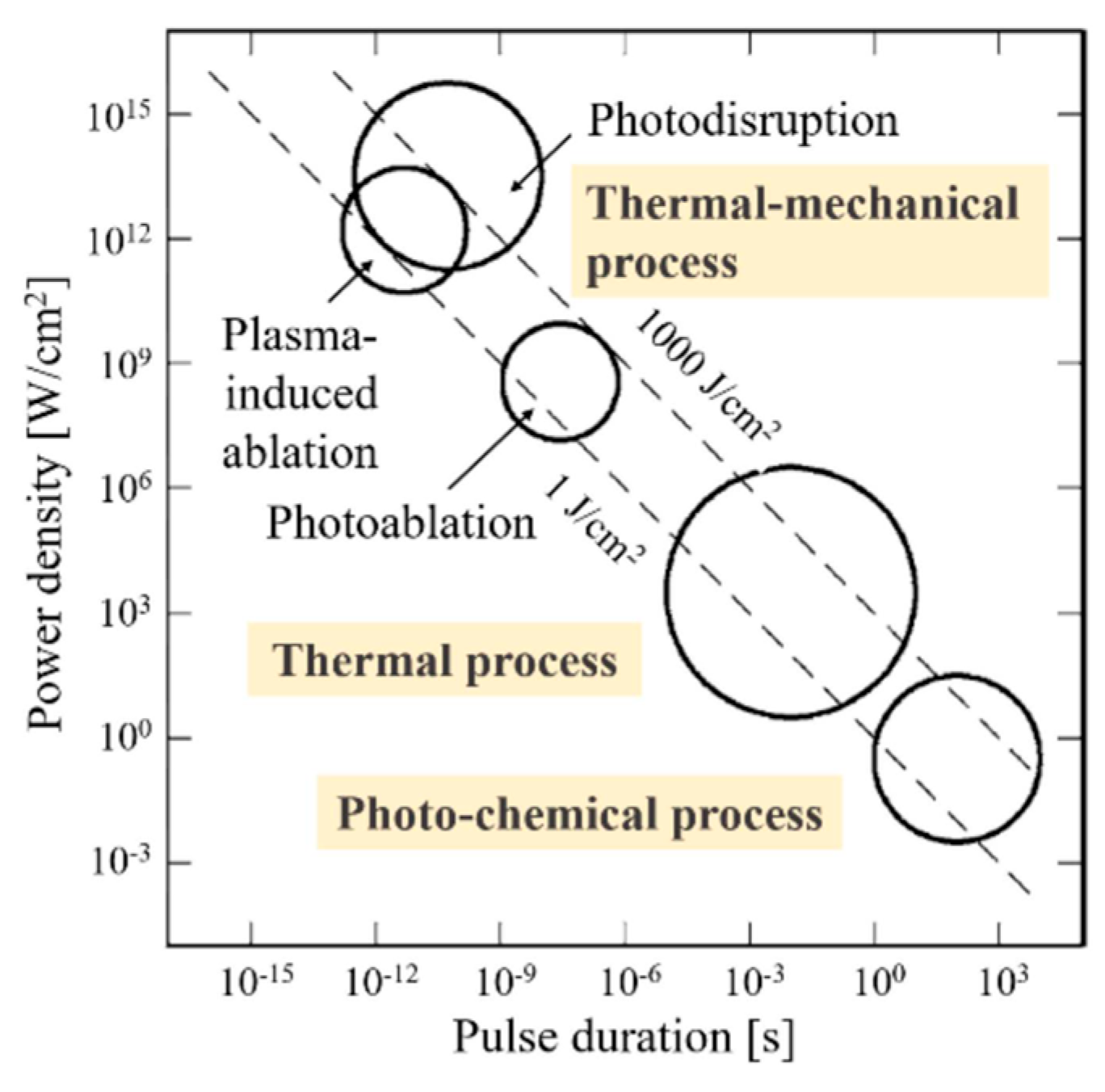

2.3. Laser Processing

2.4. Surface Morphology Investigation

2.5. Quasi-Static Yarn Pull-Out Setup and Test Methodology

2.6. Experiment Design

3. Results

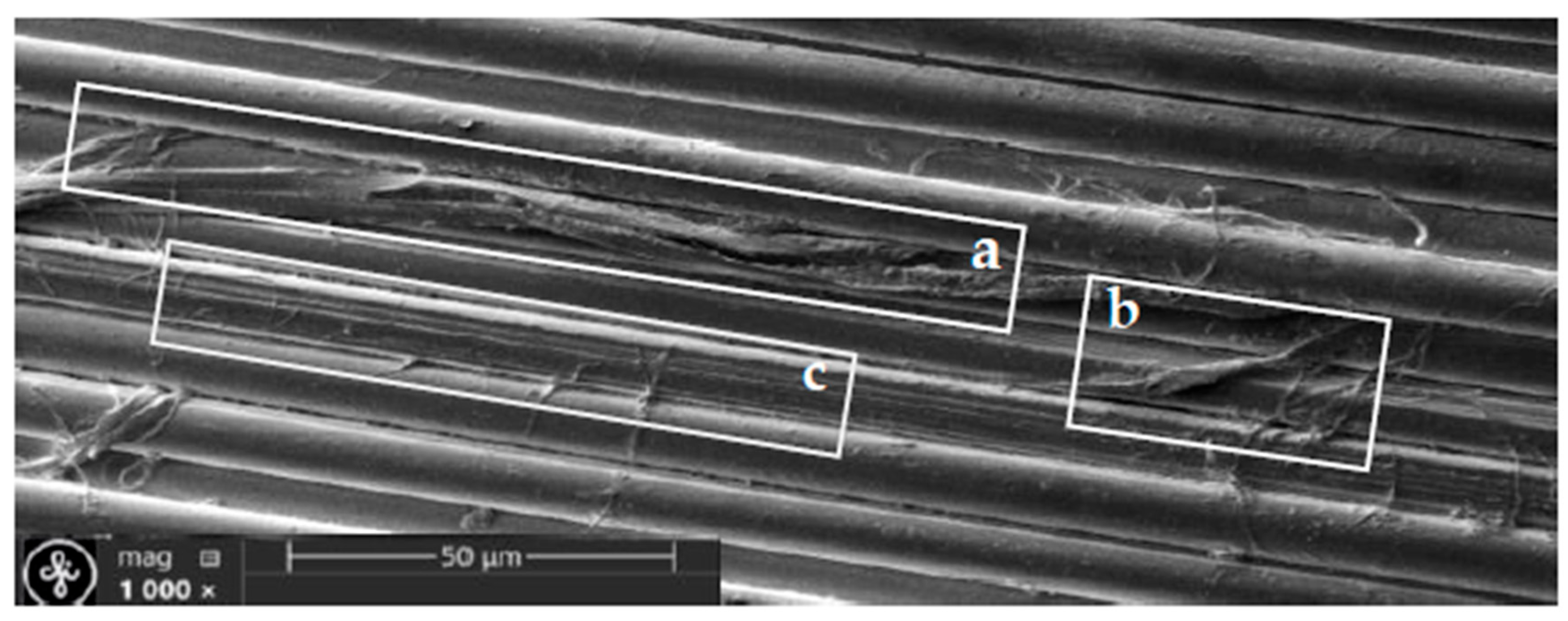

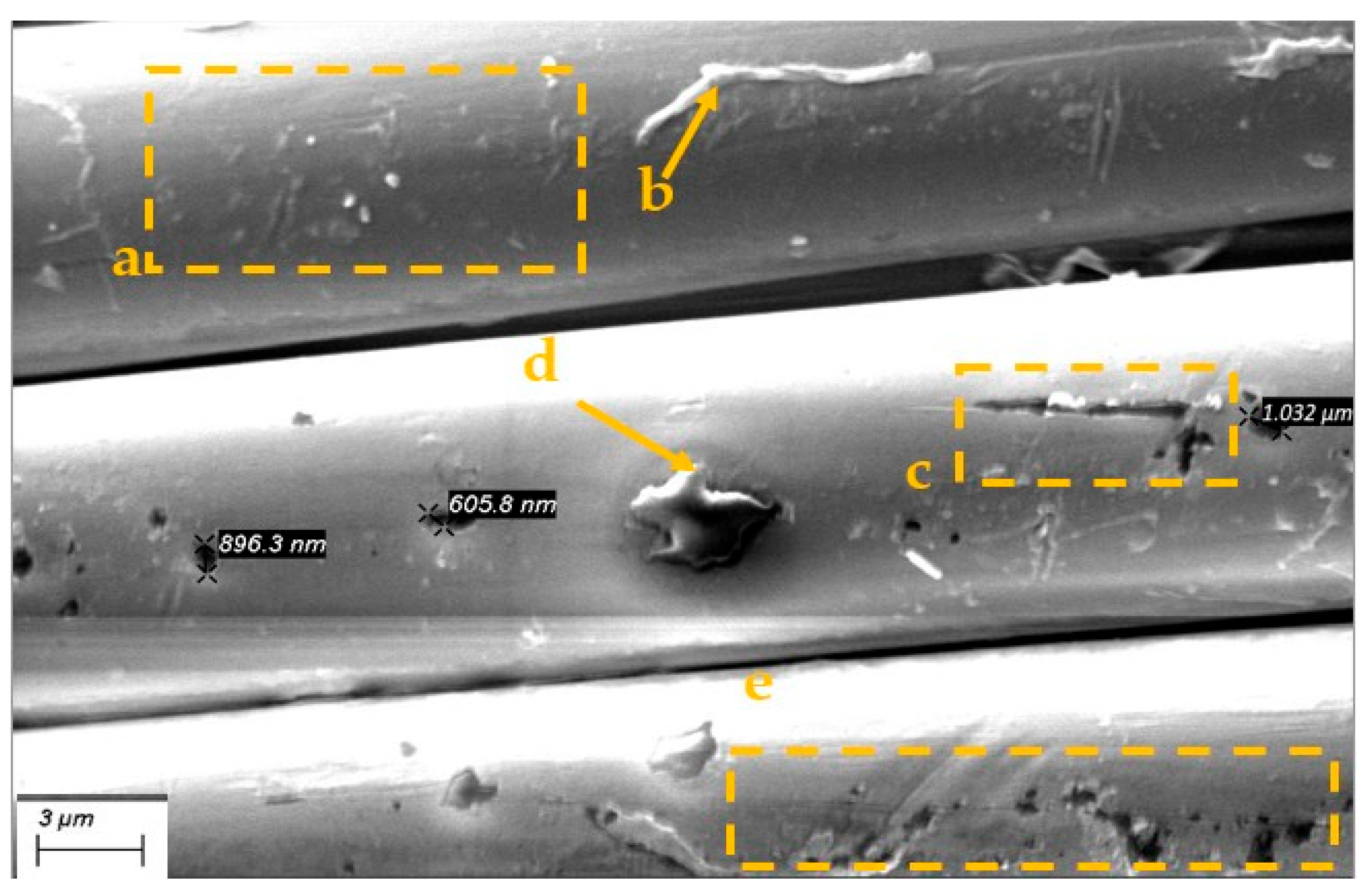

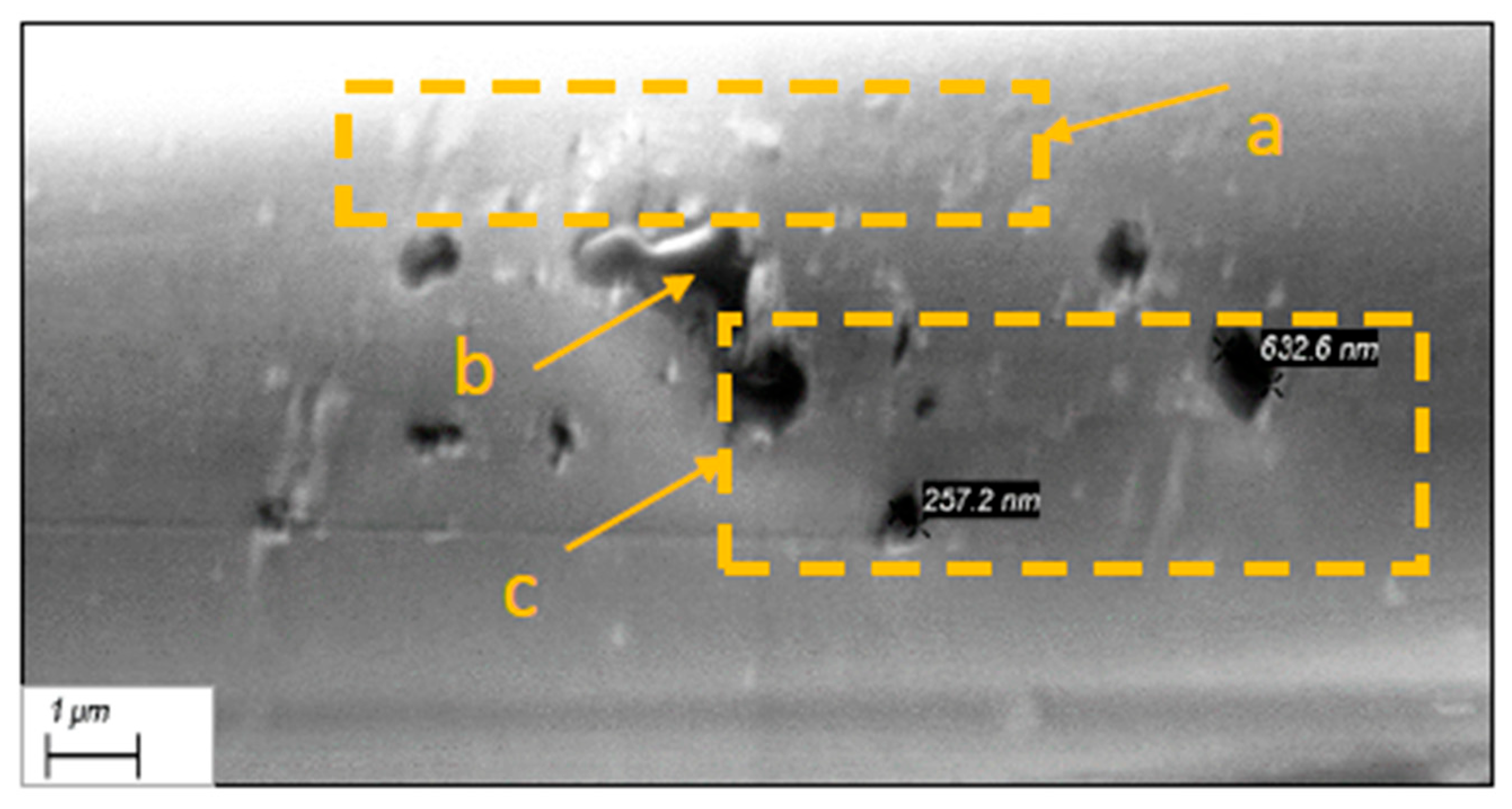

3.1. Laser Unprocessed Kevlar® Fabric Surface Morphology

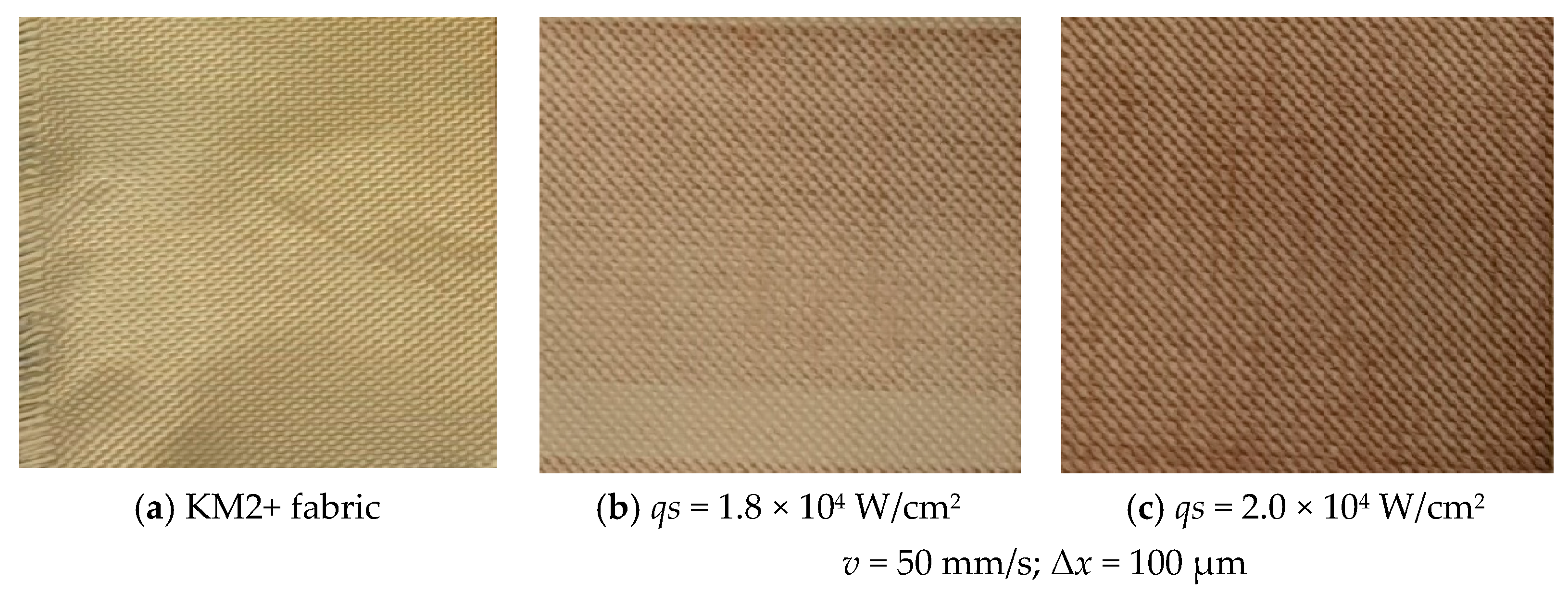

3.2. Laser Irradiated-Surface Structures

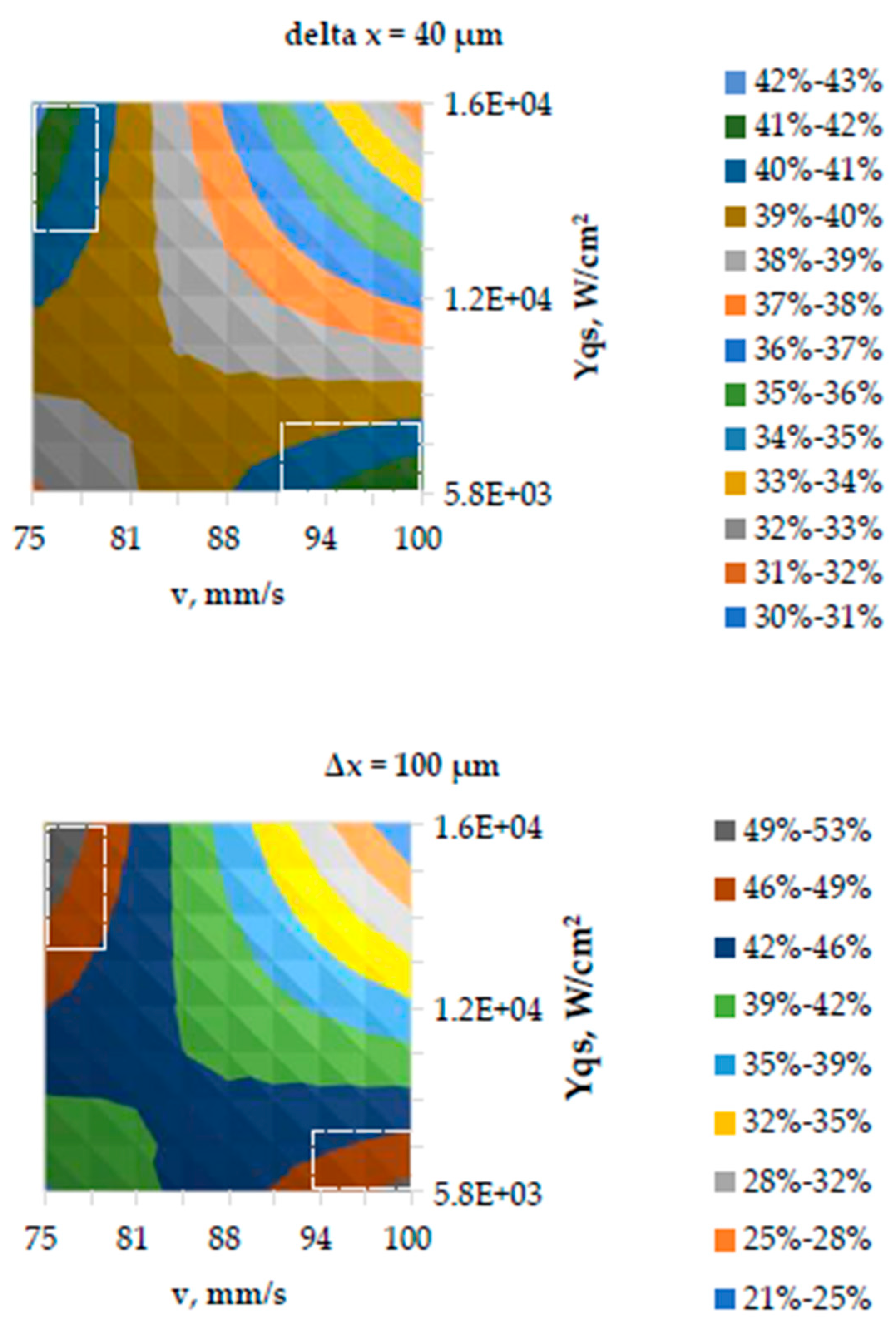

3.3. Influence of Laser Parameters Interaction on Kevlar® Fabric Surface Roughness

| Faktors | Designation | Coded xi Values | |||

|---|---|---|---|---|---|

| −1 | 0 | 1 | Interval | ||

| ×1 | qs, W/cm2 | 5.8 × 103 | 1.1 × 104 | 1.6 × 104 | 5.1 × 103 |

| ×2 | v, mm/s | 75 | 88 | 100 | 130 |

| ×3 | Δx, µm | 40 | 70 | 100 | 30 |

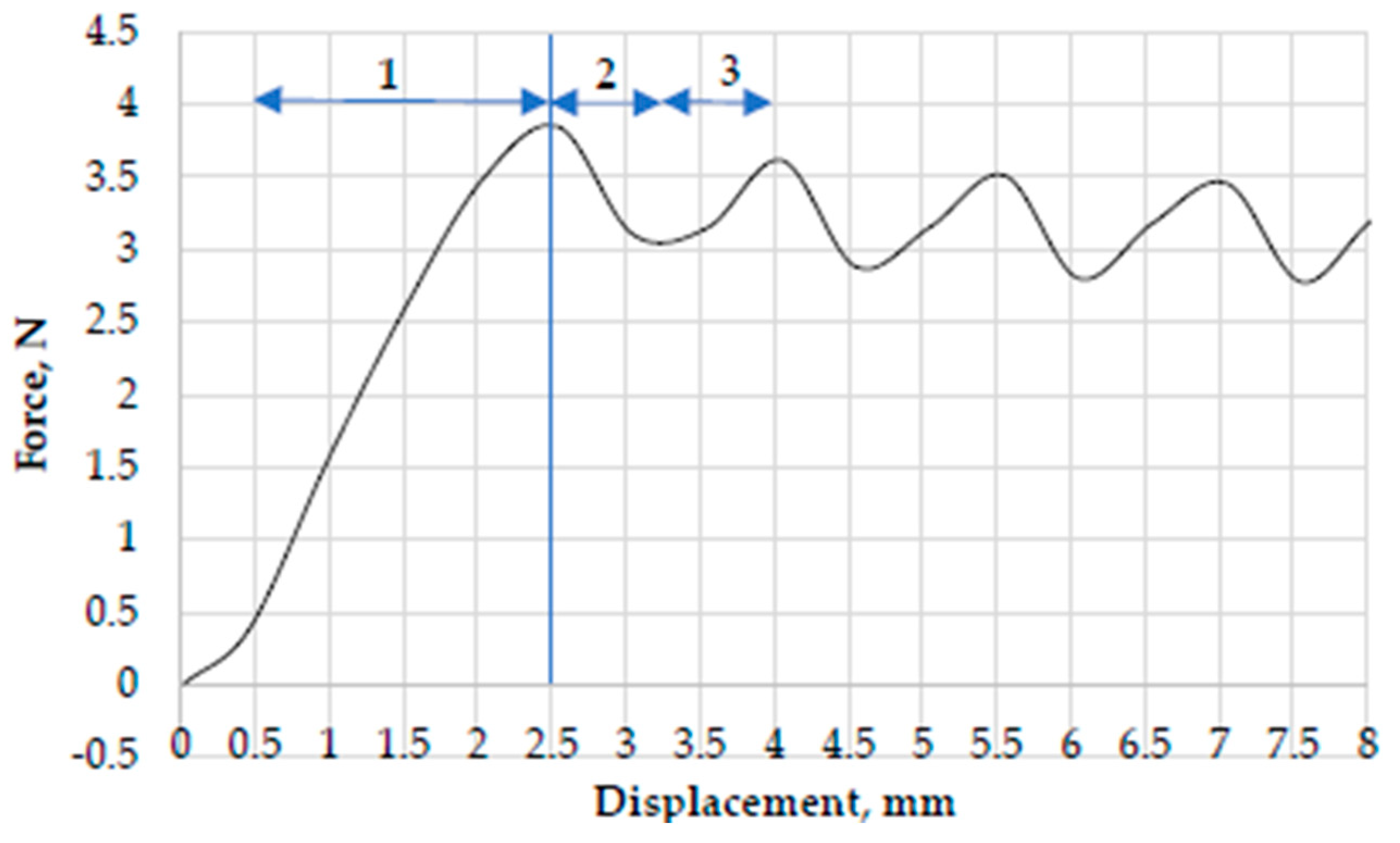

3.4. Quasi-Static Yarn Pull-Out

| Junction Rupture Force, N | Tensile Stress,% | Crimp Extension, mm | Mean JRF Increase * | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Range | Mean | ± | Range | Mean | ± | Range | Mean | ± | ||

| KM2+440 | 0.38 | 2.42 | 0.04 | 1.2 | 2.37 | 2.15 | 1.5 | 2.86 | 0.16 | |

| V1_laz | 0.53 | 3.65 | 0.05 | 0.7 | 2.10 | 2.15 | 0.8 | 2.63 | 0.09 | 50.8% |

| V2_laz | 0.80 | 4.82 | 0.08 | 1.2 | 2.74 | 2.15 | 1.5 | 3.30 | 0.14 | 99.4% |

| V3_laz | 0.42 | 4.68 | 0.05 | 1.2 | 2.74 | 2.15 | 1.5 | 3.30 | 0.15 | 93.5% |

| V4_laz | 0.58 | 4.1 | 0.07 | 0.8 | 2.16 | 1.02 | 1.0 | 2.18 | 0.13 | 69.7% |

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- National Institute of Justice. Ballistic Resistance of Body Armour; NIJ Standard 0101.07; National Institute of Justice: Washington, DC, USA, 2025.

- Tapie, E.; Shim, V.P.W.; Guo, Y.B. Influence of weaving on the mechanical response of aramid yarns subjected to high-speed loading. Int. J. Impact Eng. 2015, 80, 1–12. [Google Scholar] [CrossRef]

- Parsonsa, E.M.; Weerasooriyab, Y.; Sarvac, S.; Socrate, S. Impact of woven fabric: Experiments and mesostructure-based continuum-level simulations. J. Mech. Phys. Solids 2010, 58, 1995–2021. [Google Scholar] [CrossRef]

- Nilakantan, G.; Gillespie, J.W. Yarn pull-out behaviour of plain-woven Kevlar fabrics: Effect of yarn sizing, pullout rate, and fabric pre-tension. Compos. Struct. 2013, 101, 215–224. [Google Scholar] [CrossRef]

- Rao, M.; Duan, Y.; Keefe, M.; Powers, B.; Bogetti, T. Modeling the effects of yarn material properties and friction on the ballistic impact of a plain-weave fabric. Compos. Struct. 2009, 89, 556–566. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Young, R.; Kinloch, I. Finite element analysis of effect of inter-yarn friction on ballistic impact response of woven fabrics. Compos. Struct. 2016, 135, 8–16. [Google Scholar] [CrossRef]

- Das, S.; Jagan, S.; Shaw, A.; Pal, A. Determination of inter-yarn friction and its effect on ballistic response of para-aramid woven fabric under low velocity impact. Compos. Struct. 2015, 120, 129–140. [Google Scholar] [CrossRef]

- Kirkwood, J.E.; Kirkwood, K.M.; Lee, Y.S.; Egres, R.G.; Wagner, N.J.; Wetzel, E.D. Yarn Pull-Out as a Mechanism for Dissipating Ballistic Impact Energy in Kevlar(R) KM2 Fabric: Part II: Predicting Ballistic Performance. Text. Res. J. 2004, 74, 939–948. [Google Scholar] [CrossRef]

- Moure, M.; Feito, N.; Aranda-Ruiz, J.; Loya, J.; Rodriguez-Millan, M. On the characterization and modelling of high-performance para-aramid fabrics. Compos. Struct. 2019, 212, 326–337. [Google Scholar] [CrossRef]

- Zhou, Y.; Ali, M.; Gong, X.; Yang, D. An overview of yarn pull-out behavior of woven fabrics. Text. Res. J. 2017, 89, 223–234. [Google Scholar] [CrossRef]

- Dong, Z.; Sun, C.T. Testing and modelling of yarn pull-out in plain woven Kevlar fabrics. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1863–1869. [Google Scholar] [CrossRef]

- Bilisik, K.; Korkmaz, M. Single and multiple yarn pull-outs on aramid woven fabric structures. Text. Res. J. 2011, 81, 847–864. [Google Scholar] [CrossRef]

- Bilisik, K. Properties of yarn pull-out in para-aramid fabric structure and analysis by statistical model. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1930–1942. [Google Scholar] [CrossRef]

- Thomas, F.D.; Roark, J.; Moy, P.; Sockalingam, S.; O’Brien, D.J.; Weerasooriya, T. Experiments and simulations for dynamic yarn pull-out response of Kevlar® fabrics. Compos. Part A Appl. Sci. Manuf. 2024, 181, 108147. [Google Scholar] [CrossRef]

- Javaid, M.U.; Militký, J.; Wiener, J.; Jabbar, A.; Salačová, J.; Umair, M. Effect of surface modification and knife penetration angle on the Quasi-Static Knife Penetration Resistance of para-aramid fabrics. J. Text. Inst. 2019, 110, 590–599. [Google Scholar] [CrossRef]

- Abiru, S.; Lizuka, K. Bulletproof Fabric and Process for Its Production. Patent USA 5935881, 10 August 1999. [Google Scholar]

- Yang, Y.; Chen, X. Influence of fabric architecture on energy absorption efficiency of soft armour panel under ballistic impact. Compos. Struct. 2019, 224, 111015. [Google Scholar] [CrossRef]

- Rodríguez-Millán, M.; Álvarez-Díaz, A.; Aranda-Ruiz, J.; Álvarez-Díaz, J.; Loya, J.A. Experimental analysis for stabbing resistance of different aramid composite architectures. Compos. Struct. 2019, 208, 525–534. [Google Scholar] [CrossRef]

- Lee, B.W.; Kim, I.J.; Kim, C.G. The influence of the particle size of silica on the ballistic performance of fabrics impregnated with silica colloidal suspension. J. Compos. Mater. 2009, 43, 2679–2698. [Google Scholar] [CrossRef]

- Lee, Y.S.; Wetzel, E.D.; Wagner, N.J. The ballistic impact performance of Kevlar woven fabric impregnated with a colloidal shear thickening fluid. J. Mater. Sci. 2003, 38, 2825–2833. [Google Scholar] [CrossRef]

- Decker, M.; Halbach, C.; Nam, C.; Wagner, N.; Wetzel, E. Stab resistance of shear thickening fluid (STF)–treated fabrics. Compos. Sci. Technol. 2007, 67, 565–578. [Google Scholar] [CrossRef]

- Hassan, T.A.; Rangari, V.K.; Jeelani, S. Synthesis, processing and characterization of shear thickening fluid (STF) impregnated fabric composites. Mater. Sci. Eng. A 2010, 527, 2892–2899. [Google Scholar] [CrossRef]

- Feng, X.; Li, S.; Wang, Y.; Wang, Y.; Liu, J. Effects of different silica particles on quasistatic stab resistant properties of fabrics impregnated with shear thickening fluids. Mater. Des. 2014, 64, 456–461. [Google Scholar] [CrossRef]

- Rahman, A.S.; Mathur, V.; Asmatulu, R. Effect of nanoclay and graphene inclusions on the low-velocity impact resistance of Kevlar epoxy laminated composites. Compos. Struct. 2018, 187, 481–488. [Google Scholar] [CrossRef]

- Kukle, S.; Vališevskis, A.; Briedis, U.; Balgale, I.; Baķe, I. Hybrid Soft Ballistic Panel Packages with Integrated Graphene-Modified Para-Aramid Fabric Layers in Combinations with the Different Ballistic Kevlar Textiles. Polymers 2024, 16, 2106. [Google Scholar] [CrossRef]

- da Silva, A.O.; Weber, R.P.; Monteiro, S.N.; Lima, A.M.; Faria, G.S.; da Silva, W.O.; Oliveira, S.d.S.A.; Monsores, K.G.d.C.; Pinheiro, W.A. Effect of graphene oxide coating on the ballistic performance of aramid fabric. J. Mater. Res. Technol. 2020, 9, 2267–2278. [Google Scholar] [CrossRef]

- Hanif, W.Y.W.; Risby, M.S.; Noor, M.M. Influence of carbon nanotube inclusion on the fracture toughness and ballistic resistance of twaron/epoxy composite panels. Procedia Eng. 2015, 114, 118–123. [Google Scholar] [CrossRef]

- LaBarre, E.D.; Calderon-Colon, X.; Morris, M.; Tiffany, J.; Wetzel, E.; Merkle, A.; Trexler, M. Effect of a carbon nanotube coating on friction and impact performance of Kevlar. J. Mater. Sci. 2015, 50, 5431–5442. [Google Scholar] [CrossRef]

- Biradar, A.; Arulvel, S.; Kandasamy, J.; Sultan, M.T.H.; Shahar, F.S.; Najeeb, M.I.; Gaff, M.; Hui, D. Nanocoatings for ballistic applications: A review. Nanotechnol. Rev. 2023, 12, 20230574. [Google Scholar] [CrossRef]

- Chu, Y.; Chen, X.; Wang, Q.; Cui, S. An investigation on sol–gel treatment to aramid yarn to increase inter–yarn friction. Appl. Surf. Sci. 2014, 320, 710–717. [Google Scholar] [CrossRef]

- Sun, D.; Chen, X. Plasma modification of Kevlar fabrics for ballistic applications. Text. Res. J. 2012, 82, 1928–1934. [Google Scholar] [CrossRef]

- Chu, Y.; Chen, X.; Sheel, D.W.; Hodgkinson, J.L. Surface modification of aramid fibres by atmospheric pressure plasma–enhanced vapor deposition. Text. Res. J. 2014, 84, 1288–1297. [Google Scholar] [CrossRef]

- Manaee, P.; Valefi, Z.; Goodarz, M. The effect of bond coat type on the stab resistance of Al2O3–13 wt% TiO2 plasma sprayed ceramic coating on aramid fabrics. Surf. Interfaces 2020, 18, 100432. [Google Scholar] [CrossRef]

- Zlobina, I.V.; Bekrenev, N.V. Study of mechanical and protective characteristics of composite materials based on aramid fabrics modified in a microwave electromagnetic field. IOP Conf. Ser. Mater. Sci. Eng. 2019, 511, 012031. [Google Scholar] [CrossRef]

- Nayak, R.; Padhye, R. The use of laser in garment manufacturing: An overview. Fash Text 2016, 3, 1–16. [Google Scholar] [CrossRef]

- Marchant, A.L. Experimental and Theoretical Studies of Surface and Volume Changes in Dielectrics Induced by Long Pulse RFCO2 Laser Irradiation. Ph.D. Thesis, University of Hull, Hull, UK, 2012. [Google Scholar]

- Vilumsone-Nemes, I. Automated laser cutting of textile materials. In Industrial Cutting of Textile Materials, 2nd ed.; Woodhead Publishing: Sawston, UK, 2018; pp. 151–177. [Google Scholar]

- Angelova, Y.P. Factors influencing the laser treatment of textile materials: An overview. J. Eng. Fibers Fabr. 2020, 15, 1558925020952803. [Google Scholar] [CrossRef]

- Nayak, R.; Padhye, R. Garment Manufacturing Technology; Woodhead Publishing: Sawston, UK, 2015; e-Book. [Google Scholar]

- Matthews, J. Textiles in Three Dimensions: An Investigation into Processes Employing Laser Technology to form Design Led Three Dimensional Textiles. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2011. [Google Scholar]

- Wang, J.; Chen, B. Bubble Dynamics during Laser Irradiated Thermo-Mechanical Response of Pigmented Skin Phantom. Energies 2022, 15, 2019. [Google Scholar] [CrossRef]

- Lin, J.; Peng, Z.; Liu, Y.; Ruiz-Zepeda, F.; Ye, R.; Samuel, E.L.; Yacaman, M.J.; Yakobson, B.I.; Tour, J.M. Laser-Induced Porous Graphene Films from Commercial Polymers. Nat. Commun. 2014, 5, 5714. [Google Scholar] [CrossRef]

- Sun, B.; McCay, R.N.; Goswami, S.; Xu, Y.; Zhang, C.; Ling, Y.; Lin, J.; Yan, Z. Gas-Permeable, Multifunctional On-Skin Electronics Based on Laser-Induced Porous Graphene and Sugar-Templated Elastomer Sponges. Adv. Mater. 2018, 30, 1804327. [Google Scholar] [CrossRef] [PubMed]

- Zang, X.; Shen, C.; Chu, Y.; Li, B.; Wei, M.; Zhong, J.; Sanghadasa, M.; Lin, L. Laser-Induced Molybdenum Carbide Graphene Composites for 3D Foldable Paper Electronics. Adv. Mater. 2018, 30, 1800062. [Google Scholar] [CrossRef]

- Ye, R.; Chyan, Y.; Zhang, J.; Li, Y.; Han, X.; Kittrell, C.; Tour, J.M. Laser-Induced Graphene Formation on Wood. Adv. Mater. 2017, 29, 1702211. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Z.; Chen, D.; Liu, F.; Yang, Z.; Li, X.; Yu, H.; Liu, H.; Zhou, W. Laser Synthesis and Microfabrication of Micro/Nanostructured Materials Toward Energy Conversion and Storage. Nano-Micro Lett. 2021, 13, 1–48. [Google Scholar] [CrossRef]

- Wang, H.; Wang, H.; Wang, Y.; Su, X.; Wang, C.; Zhang, M.; Jian, M.; Xia, K.; Liang, X.; Lu, H.; et al. Laser Writing of Janus Graphene/Kevlar Textile for Intelligent Protective Clothing. ACS Nano 2020, 14, 3219–3226. [Google Scholar] [CrossRef]

- Kalinowski, A.; Radek, N.; Orman, Ł.; Pietraszek, J.; Szczepaniak, M.; Bronček, J. Laser Surface Texturing: Characteristics and Applications. Syst. Saf. Hum.-Tech. Facil.-Environ. 2023, 5, 240–248. [Google Scholar]

- Kumar, V.; Verma, R.; Kango, S.; Sharma, V.S. Recent Progresses and Applications in Laser-Based Surface Texturing Systems. Mater. Today Commun. 2021, 26, 101736. [Google Scholar] [CrossRef]

- Kromer, R.; Costil, S.; Cormier, J.; Berthe, L.; Peyre, P.; Courapied, D. Laser Patterning Pretreatment before Thermal Spraying: A Technique to Adapt and Control the Surface Topography to Thermomechanical Loading and Materials. J. Therm. Spray Technol. 2016, 25, 401–410. [Google Scholar] [CrossRef]

- Roenbeck, M.R.; Sandoz-Rosado, E.J.; Cline, J.; Wu, V.; Moy, P.; Afshari, M.; Reichert, D.; Lustig, S.R.; Strawhecker, K.E. Probing the internal structures of Kevlar® fibers and their impacts on mechanical performance. Polymer 2017, 128, 200–210. [Google Scholar] [CrossRef]

- Blades, H. High Modulus, High Tenacity Poly (P-Phenylene Terephthalamide) Fiber. U.S. Patent 3,869,430, 4 March 1975. [Google Scholar]

- Wang, B.; Mao, Z.; Li, D.; Zhang, K.; Zhou, C.; Ren, M.; Li, T. Multiscale insights into the stretching behavior of Kevlar fiber. Comput. Mater. Sci. 2020, 185, 109957. [Google Scholar] [CrossRef]

- Picken, S.; Sikkema, D.; Boerstoel, H.; Dingemans, T.; van der Zwaag, S. Liquid crystal main-chain polymers for high-performance fibre applications. Liq. Cryst. 2011, 38, 1591–1605. [Google Scholar] [CrossRef]

- Dobb, M.G.; Johnson, D.J.; Saville, B.P. Structural aspects of high modulus aromatic polyamide fibres. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1980, 294, 483–485. [Google Scholar] [CrossRef]

- Morgan, R.J.; Pruneda, C.O.; Steele, W.J. The relationship between the physical structure and the microscopic deformation and failure processes of poly(p-phenylene terephthalamide) fibers. J. Polym. Sci. Polym. Phys. Ed. 1983, 21, 1757–1783. [Google Scholar] [CrossRef]

- Northolt, M.G.; Vanaarts, J. Crystal and molecular-structure of poly-(P-phenylene terephthalamide). J. Polym. Sci. Polym. Lett. 1973, 11. [Google Scholar] [CrossRef]

- Tashiro, K.; Kobayashi, M.; Tadokoro, H. Elastic Moduli and Molecular Structures of Several Crystalline Polymers, Including Aromatic Polyamides. Macromolecules 1977, 10, 413–420. [Google Scholar] [CrossRef]

- Sawyer, L.C.; Chen, R.T.; Jamieson, M.G.; Musselman, I.H.; Russell, P.E. The fibrillar hierarchy in liquid crystalline polymers. J. Mater. Sci. 1993, 28, 225–238. [Google Scholar] [CrossRef]

- Panar, M.; Avakian, P.; Blume, R.C.; Gardner, K.H.; Gierke, T.D.; Yang, H.H. Morphology of Poly (p-Phenylene Terephthalamide) Fibers. J. Polym. Sci. Polym. Phys. Ed. 1983, 21, 1955–1969. [Google Scholar] [CrossRef]

- Elliott, A.D. Confocal Microscopy: Principles and Modern Practices. Curr. Protoc. Cytom. 2019, 92, e68. [Google Scholar] [CrossRef] [PubMed]

- Roark, J.; Thomas, F.D.; Sockalingam, S.; Kempf, J.; Christy, D.; Haas, D.; O’brien, D.J.; Senecal, K.J.; Crittenden, S.R. Experimental Investigation of the Influence of Metallic Coatings on Yarn Pull-Out Behavior in Kevlar® Fabrics. Fibers 2023, 11, 7. [Google Scholar] [CrossRef]

- Kromer, R.; Costil, S.; Verdy, C.; Gojon, S.; Liao, H. Laser surface texturing to enhance adhesion bond strength of spray coatings—Cold spraying, wire-arc spraying, and atmospheric plasma spraying. Surf. Coat. Technol. 2018, 352, 642–653. [Google Scholar] [CrossRef]

- Xb, J.; Schille, F.; Ullmann, L.; Schneider, M.; Graefensteiner, S.; Schiefer, M.; Gerlach, E.; Leidich, H.; Exner, J. Laser surface texturing for high friction contacts. Laser Micro/Nanoeng. 2015, 10, 3. [Google Scholar]

- Kalpakjian, S.; Schmid, S.R. Schmid. Manufacturing Engineering and Technology, Seventh Edition. Procedia Manuf. 2016, 5, 568. [Google Scholar]

- Ahmmed, K.M.T.; Grambow, C.; Kietzig, A.-M. Fabrication of Micro/Nano Structures on Metals by Femtosecond Laser Micromachining. Micromachines 2014, 5, 1219–1253. [Google Scholar] [CrossRef]

- Stratakis, E.; Bonse, J.; Heitz, J.; Siegel, J.; Tsibidis, G.D.; Skoulas, E.; Papadopoulos, A.; Mimidis, A.; Joel, A.-C.; Comanns, P.; et al. Laser engineering of biomimetic surfaces. Rep. Mater. Sci. Eng. 2020, 141, 100562. [Google Scholar] [CrossRef]

- Obilor, A.F.; Pacella, M.; Wilson, A.; Silberschmidt, V.V. Micro-texturing of polymer surfaces using lasers: A review. Int. J. Adv. Manuf. Technol. 2022, 120, 103–135. [Google Scholar] [CrossRef]

- DuPont. Kevlar® Aramid Fiber Technical Guide. Available online: https://www.dupont.com/content/dam/dupont/amer/us/en/safety/public/documents/en/Kevlar_Technical_Guide_0319.pdf (accessed on 9 October 2025).

- Gamaly, E.G. The physics of ultra-short laser interaction with solids at non-relativistic intensities. Phys. Rep. 2011, 508, 91–243. [Google Scholar] [CrossRef]

- Pacella, M. Pulsed Laser Ablation (PLA) of Ultra-Hard Structures: Generation of Damage-Tolerant Freeform Surfaces for Advanced Machining Applications. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2014. [Google Scholar]

- Stepak, B.; Antończak, A.J.; Bartkowiak-Jowsa, M.; Filipiak, J.; Pezowicz, C.; Abramski, K.M. Fabrication of a polymer-based biodegrad able stent using a CO2 laser. Arch. Civ. Mech. Eng. 2014, 14, 317–326. [Google Scholar] [CrossRef]

- Mishra, S.; Yadava, V. Laser beam micromachining (LBMM)—A review. Opt. Lasers Eng. 2015, 73, 89–122. [Google Scholar] [CrossRef]

- Ravi-Kumar, S.; Lies, B.; Lyu, H.; Qin, H. Laser ablation of polymers: A review. Procedia Manuf. 2019, 34, 316–327. [Google Scholar] [CrossRef]

- Riveiro, A.; Maçon, A.L.B.; del Val, J.; Comesaña, R.; Pou, J. Laser surface texturing of polymers for biomedical applications. Front. Phys. 2018, 6, 16. [Google Scholar] [CrossRef]

- Nilakantan, G.; Merrill, R.L.; Keefe, M.; Gillespie, J.W.; Wetzel, E.D. Experimental investigation of the role of frictional yarn pull–out and windowing on the probabilistic response of Kevlar fabrics. Compos. Part B 2015, 68, 215–229. [Google Scholar] [CrossRef]

- Zhou, Y.; Ma, M.; Nur, A.; Zhang, R.; Xiong, Z.; Lin, Y.; Xiang, Y.; Zhang, Z. An overview on the ballistic performance of woven-fabric-based flexible protective systems: Experimental and numerical studies. Thin–Walled Struct. 2024, 205, 112394. [Google Scholar] [CrossRef]

- Kirkwood, K.M.; Kirkwood, J.E.; Lee, Y.S.; Egres, R.G.; Wagner, N.J.; Wetzel, E.D. Yarn Pull-Out as a Mechanism for Dissipating Ballistic Impact Energy in Kevlar® KM-2 Fabric: Part I: Quasi-Static Characterization of Yarn Pull-Out. Text. Res. J. 2004, 74, 920–928. [Google Scholar] [CrossRef]

- Sebastian, S.A.R.D.; Bailey, A.I.; Briscoe, B.J.; Tabor, D. Extensions, displacements and forces associated with pulling a single yarn from a fabric. J. Phys. Appl. Phys. 1987, 20, 130–139. [Google Scholar] [CrossRef]

- Sebastian, S.; Bailey, A.; Briscoe, B.; Tabor, D. Effect of a Softening Agent on Yarn Pull-out Force of a Plain Weave Fabric. Text. Res. J. 1986, 56, 604–611. [Google Scholar] [CrossRef]

- Bilisik, K. Determination of stick-slip stage of single and multiple yarn ends pull-out in para-aramid (Kevlar®) woven fabric. J. Ind. Text. 2013, 43, 90–115. [Google Scholar] [CrossRef]

- Liu, X.; Du, D.; Mourou, G. Laser ablation and micromachining with ultrashort laser pulses. J. Quantum Electron. 1997, 33, 1706–1716. [Google Scholar] [CrossRef]

- Nemani, S.K.; Annavarapu, R.K.; Mohammadian, B.; Raiyan, A.; Heil, J.; Haque, A.; Abdelaal, A.; Sojoudi, H. Surface modification: Surface modification of polymers: Methods and applications. Adv. Mater. Interfaces 2018, 5, 1870121. [Google Scholar] [CrossRef]

- Alamri, S.; Lasagni, A.F. Development of a general model for direct laser interference patterning of polymers. Opt. Express 2017, 25, 9603. [Google Scholar] [CrossRef]

- Yang, M.; Zhu, X.L.; Liang, G. Research on Pyrolysis Process of Kevlar Fibers with Thermogravimetric Analysis coupled and Fourier Transform Infrared Spectroscopy. Guang Pu Xue Yu Guang Pu Fen Xi Guang Pu 2016, 36, 1374–1377. [Google Scholar] [PubMed]

| Kevlar® Fibre Type | Elastic Modulus (GPa) | Tensile Strength (GPa) | Ultimate Strain (mm/mm) |

|---|---|---|---|

| K119 | 66.5 + 8.6 | 3.40 + 0.49 | 0.043 + 0.003 |

| K29 | 72.8 + 6.9 | 3.30 + 0.39 | 0.042 + 0.002 |

| ** KM2 + | 84.3 + 8.1 | 2.99 + 0.33 | 0.03 + 0.004 |

| * K49 | 93.0 + 11.6 | 2.74 + 0.35 | 0.028 + 0.003 |

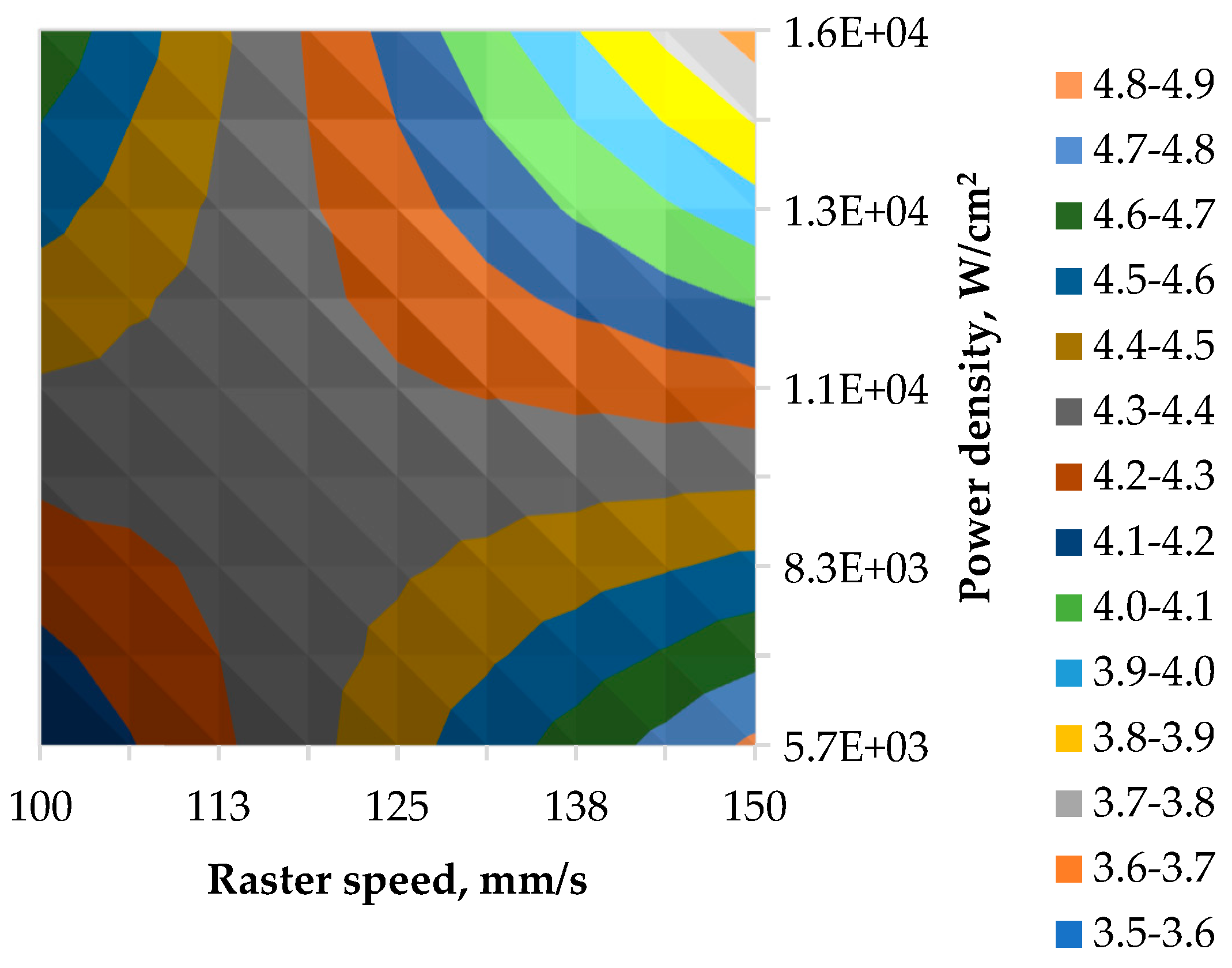

| −1 | 0 | 1 | Interval | ||

|---|---|---|---|---|---|

| Power density (W/cm2) | qs | 5.7 × 103 | 1.1 × 104 | 1.6 × 104 | 5.1 × 103 |

| Raster speed, mm/s | V | 1.0 × 102 | 1.25 × 102 | 15 × 102 | 25 |

| Raster step between lines,µm | Δx | 80 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kukle, S.; Lazov, L.; Lohmus, R.; Briedis, U.; Adijans, I.; Bake, I.; Dunchev, V.; Teirumnieka, E. The Impact of CO2 Laser Treatment on Kevlar® KM2+ Fibres Fabric Surface Morphology and Yarn Pull-Out Resistance. Polymers 2025, 17, 2931. https://doi.org/10.3390/polym17212931

Kukle S, Lazov L, Lohmus R, Briedis U, Adijans I, Bake I, Dunchev V, Teirumnieka E. The Impact of CO2 Laser Treatment on Kevlar® KM2+ Fibres Fabric Surface Morphology and Yarn Pull-Out Resistance. Polymers. 2025; 17(21):2931. https://doi.org/10.3390/polym17212931

Chicago/Turabian StyleKukle, Silvija, Lyubomir Lazov, Rynno Lohmus, Ugis Briedis, Imants Adijans, Ieva Bake, Vladimir Dunchev, and Erika Teirumnieka. 2025. "The Impact of CO2 Laser Treatment on Kevlar® KM2+ Fibres Fabric Surface Morphology and Yarn Pull-Out Resistance" Polymers 17, no. 21: 2931. https://doi.org/10.3390/polym17212931

APA StyleKukle, S., Lazov, L., Lohmus, R., Briedis, U., Adijans, I., Bake, I., Dunchev, V., & Teirumnieka, E. (2025). The Impact of CO2 Laser Treatment on Kevlar® KM2+ Fibres Fabric Surface Morphology and Yarn Pull-Out Resistance. Polymers, 17(21), 2931. https://doi.org/10.3390/polym17212931