Analysis of Mechanical Properties of Crumb Rubber Tires Mixed with Silty Sand of Various Sizes and Percentages

Abstract

1. Introduction

2. Review of the Risk of Recycling Crumb Rubber Tires

3. Materials and Methods

3.1. Materials

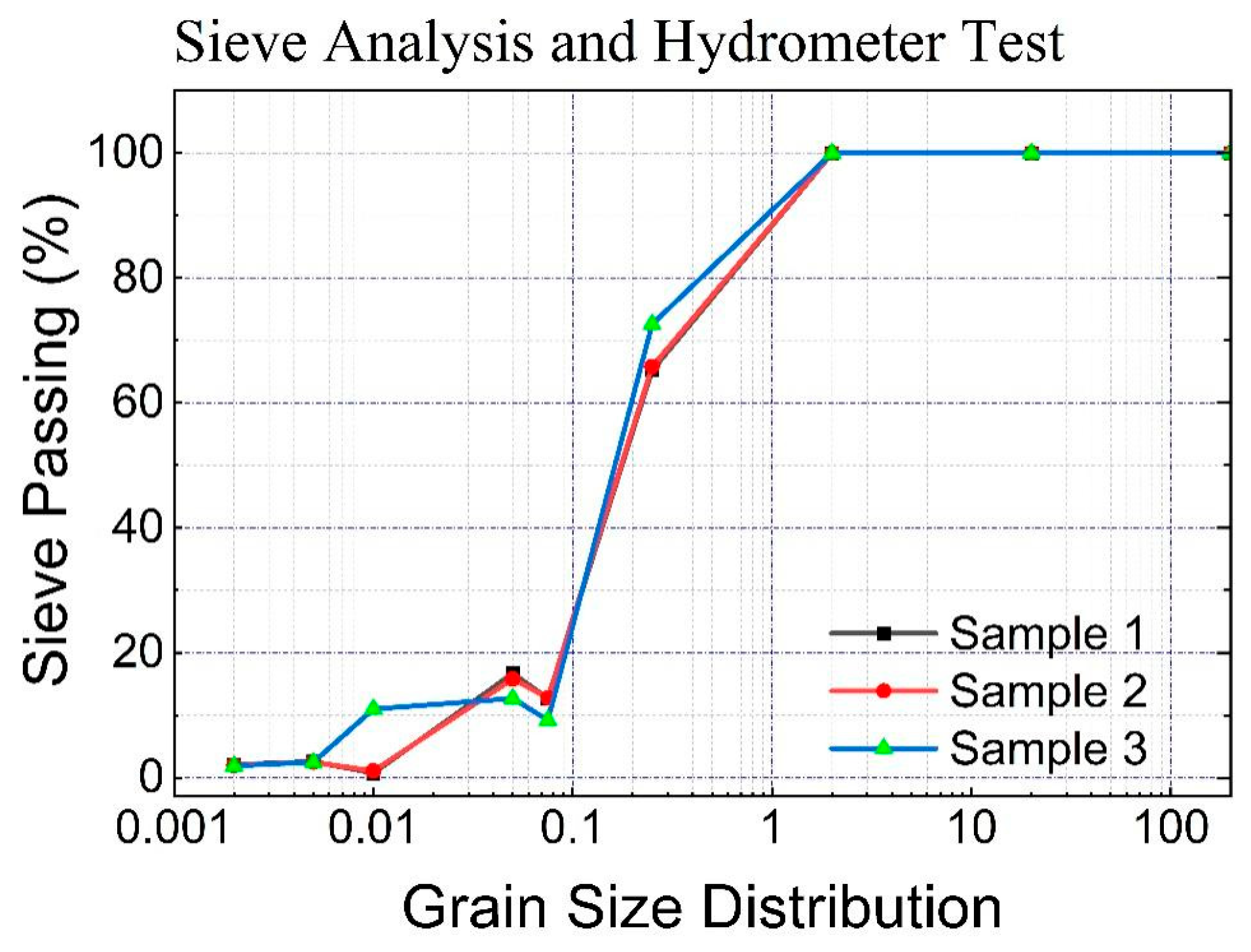

3.1.1. Sieve Test Description for Silty Sand

Composition of Silty Sand

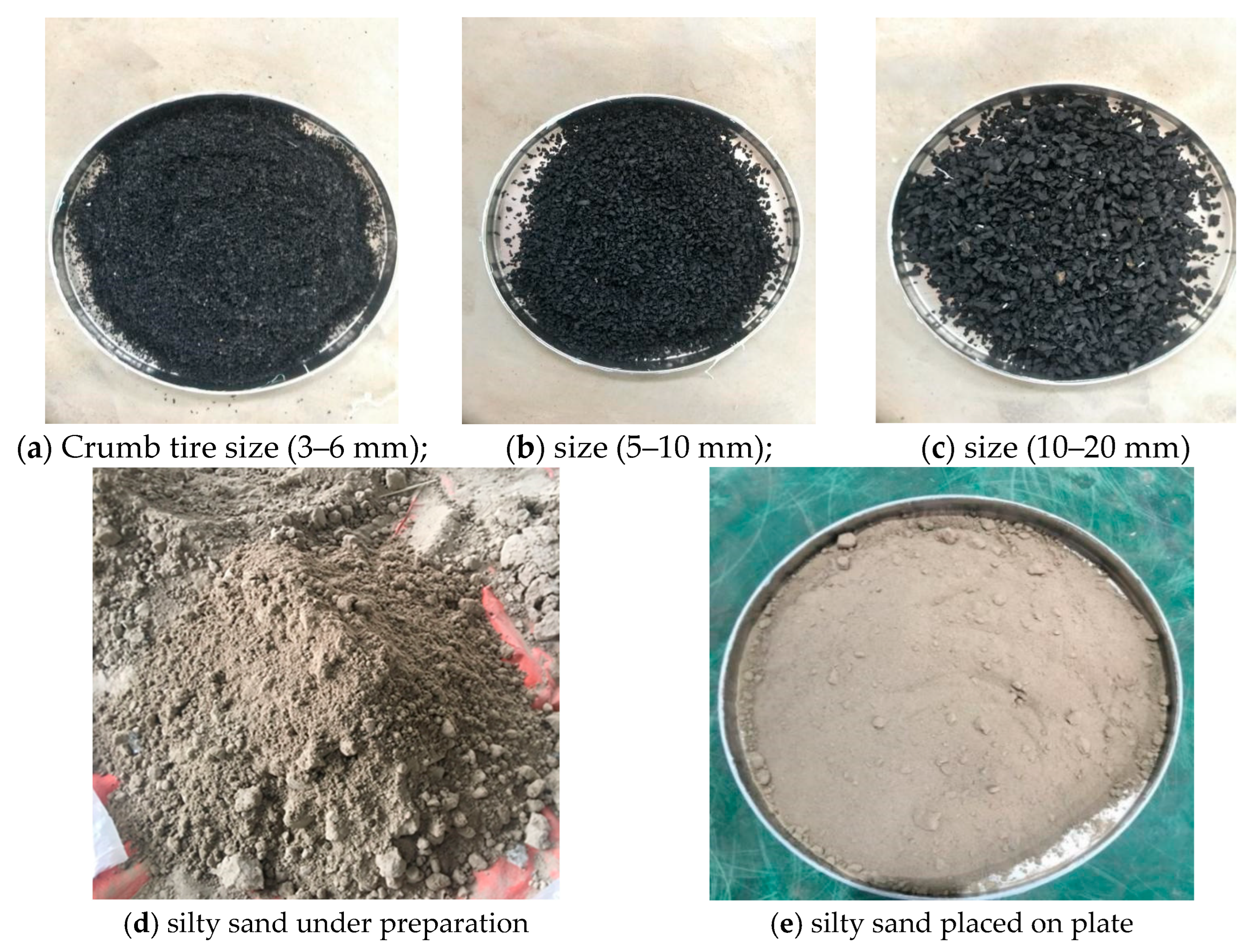

3.1.2. Crumb Rubber Tires

Composition of Crumb Rubber Tires

3.2. Methods

3.3. Sample Preparation

3.3.1. Triaxial Test Procedure and Apparatus

Apparatus

Testing Procedure

- (1)

- The triaxial cell was first thoroughly cleaned, a rubber membrane was placed on the pedestal, the cylindrical container was positioned correctly, a water pipe was connected, an air pressure pipe was placed, and a membrane filler was placed on the pedestal’s bottom to prevent the sample from entering the hole.

- (2)

- A silty sand sample mixture was weighed and compacted at three levels according to the cell height. Once all three layers had been filled and compacted, a second membrane filler was placed on top of the filled and compacted sample, and the pedestal was then positioned and secured on top. By opening valve number five, the air inside was removed. If the pressure on the monitor screen was greater than −60 kPa, it was turned off. This serves to hold the sample upright, and it works particularly well with granular materials that are not self-supporting.

- (3)

- The cylindrical device that held the sample in place during compaction was removed, the small sample that had fallen was cleaned, and any issues found during compaction were noted for correction. The samples were then prepared for placement in a vacuum, which was released and fixed on the triaxial cell base. To prevent the loss of air pressure, the chamber should be secured by tightening the bolts, and then the system should proceed to the bottom load frame.

- (4)

- The triaxial cell sample was moved on top and connected to the bottom of the loading frame via the monitor screen. The valve was open to fill the water vacuum; once it was full, the small outlet pipe connected to the top ran out of the water, and the pump and valve were closed. The sample was then subjected to pressure via a monitor screen to ensure that there was enough water and oil. The strain rate speed was set at 0.6 mm/minute at the start of the test.

- (5)

- The name was set, and pressure was applied to the sample via the proper triaxial test procedure. When the pressure exceeded 100 kPa, valves 1 and 4 were opened to release the air pressure and waited until the applied pressure was reached. The axial force on the sample was applied, the shearing stage started, and the test continued until the sample reached failure [34,35,36]. Figure 6 show the sample processed after and before the triaxial test.

4. Test Results and Discussion

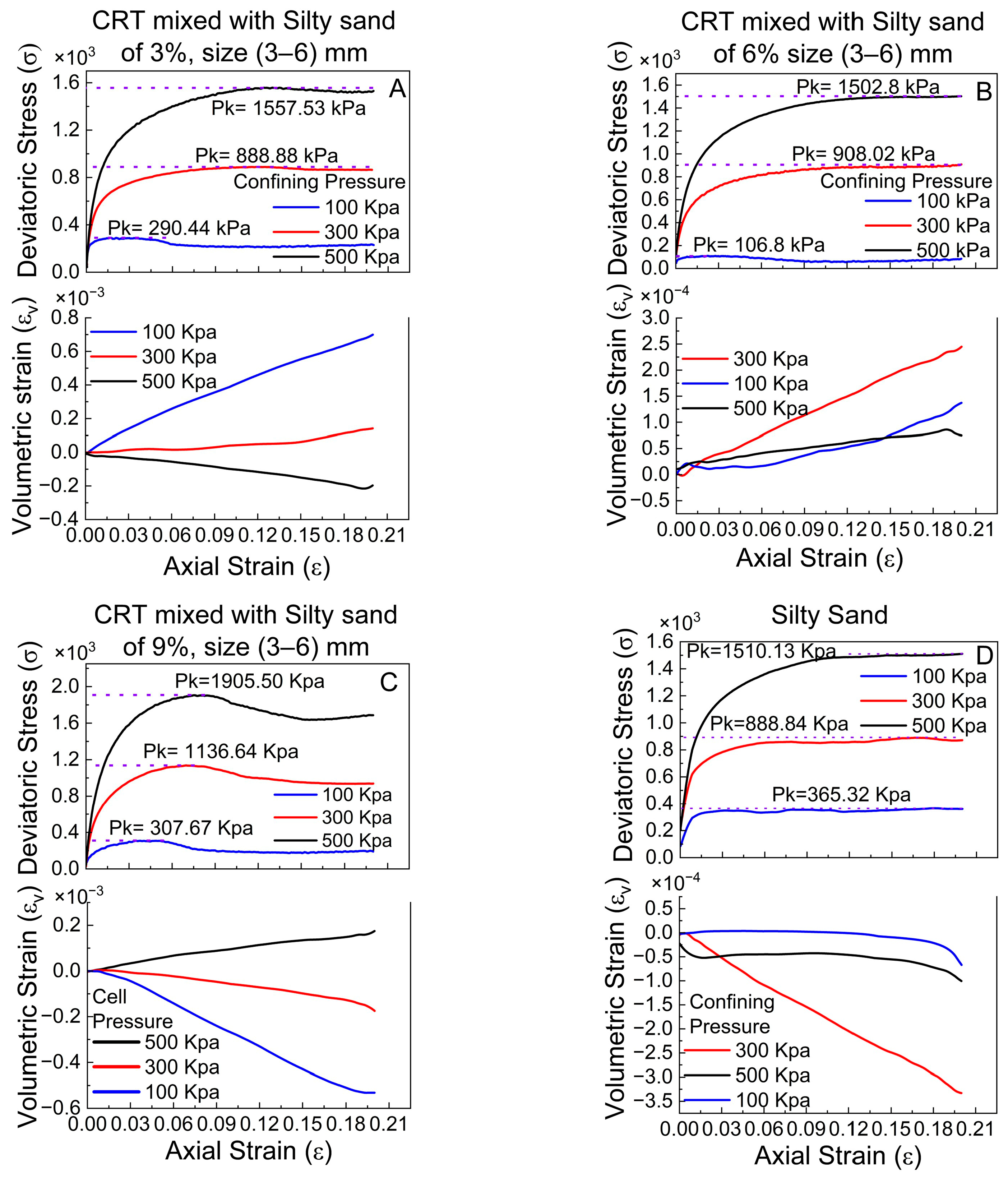

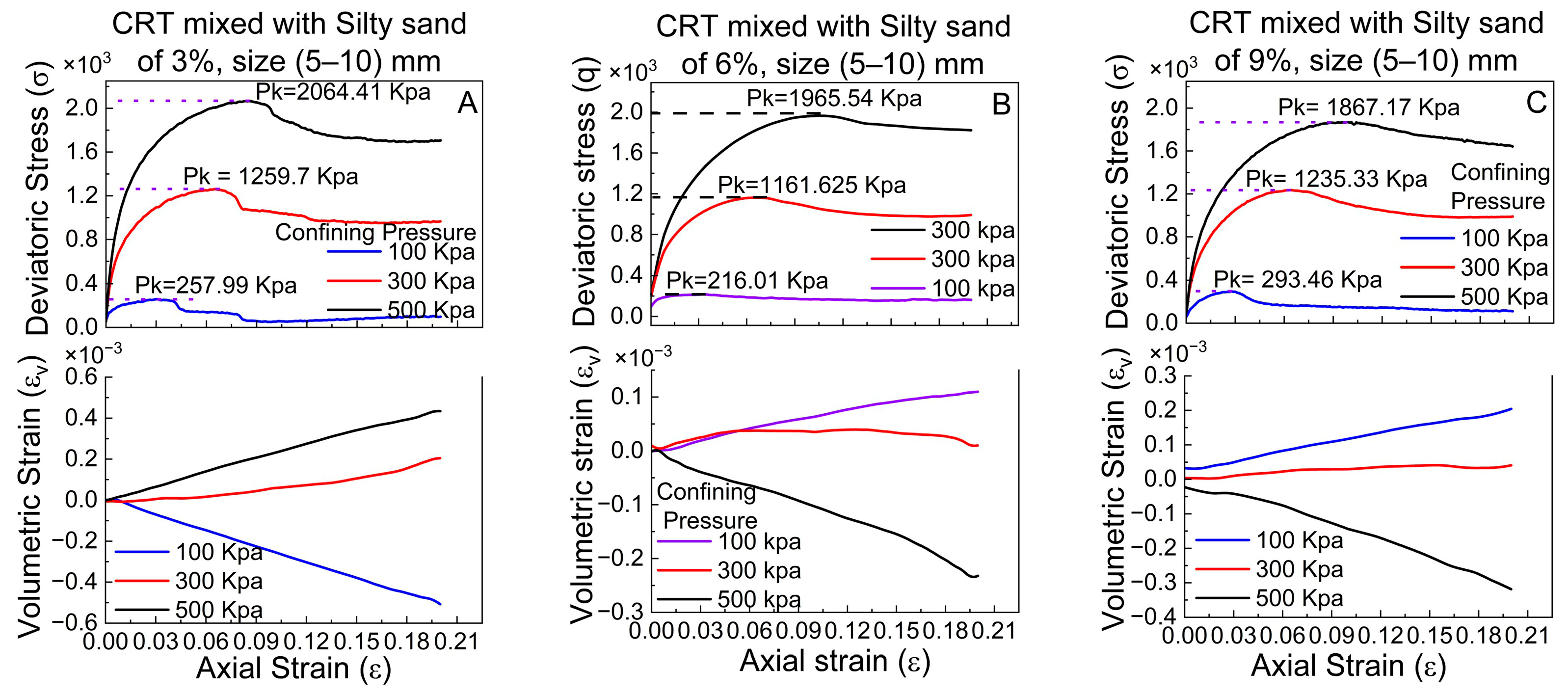

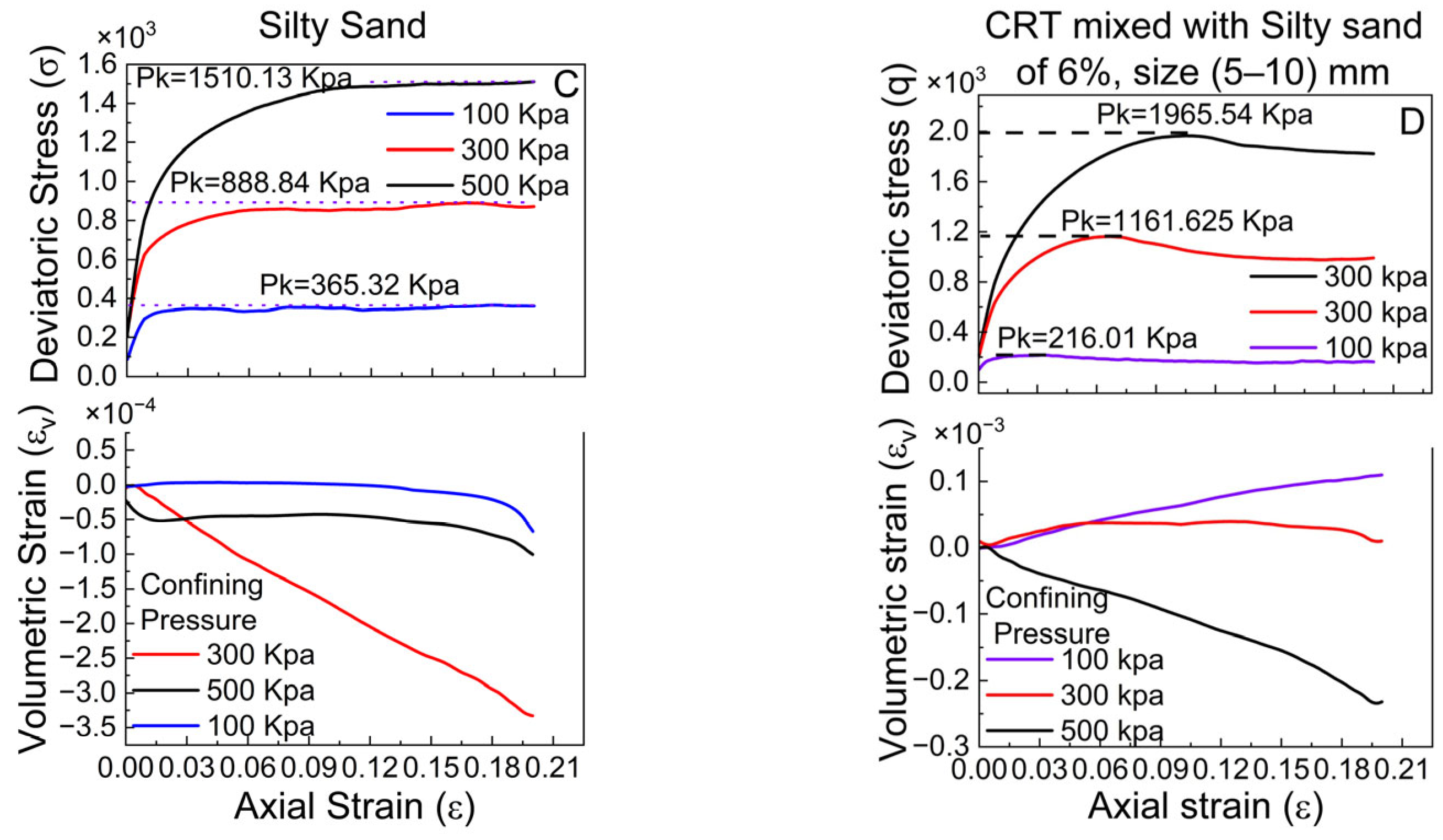

4.1. Triaxial Tests of Silty Sand and CRT Mixed with Silty Sand

4.1.1. Sizes of 3–6 mm at 3%, 6%, and 9% Ratios

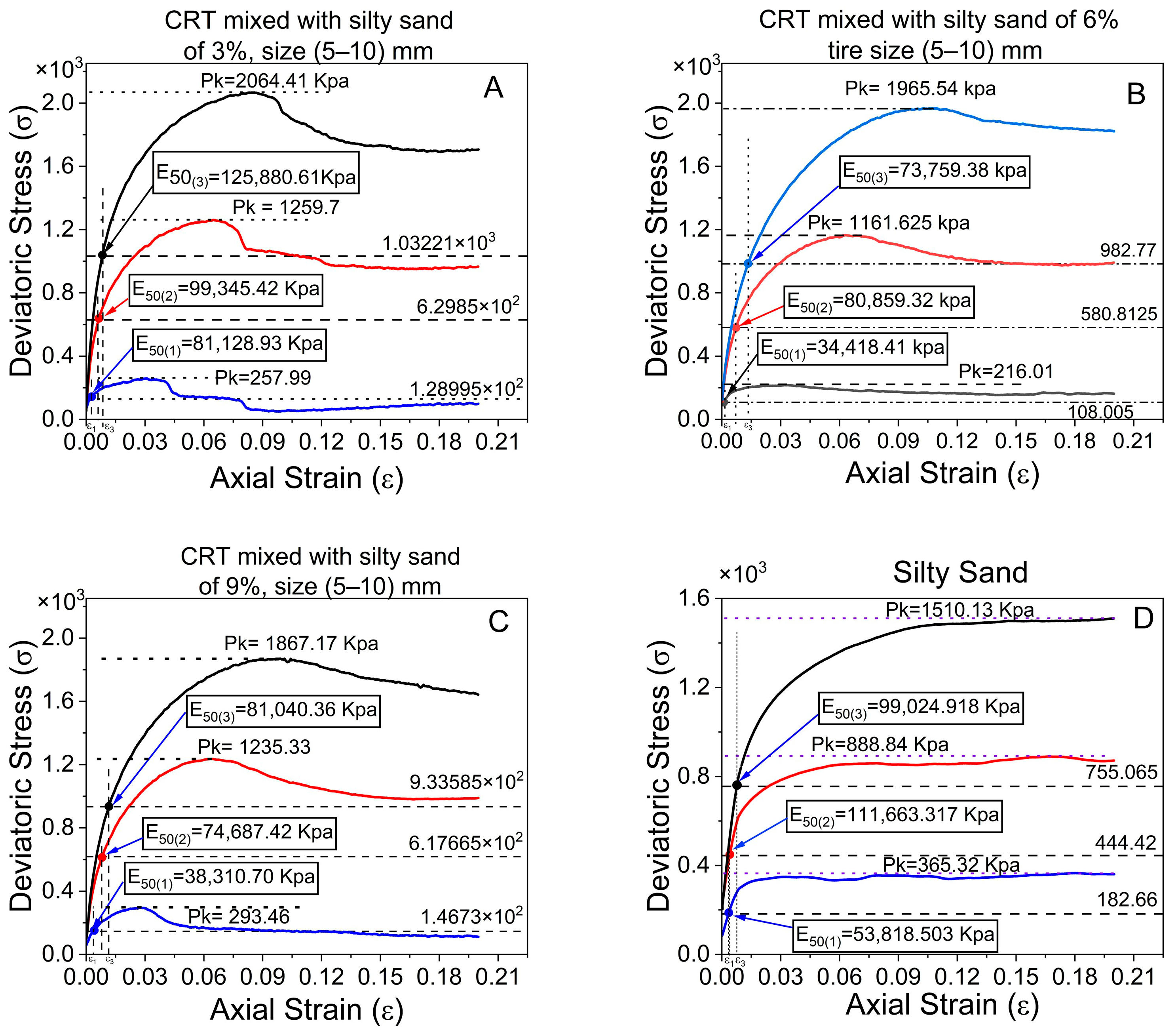

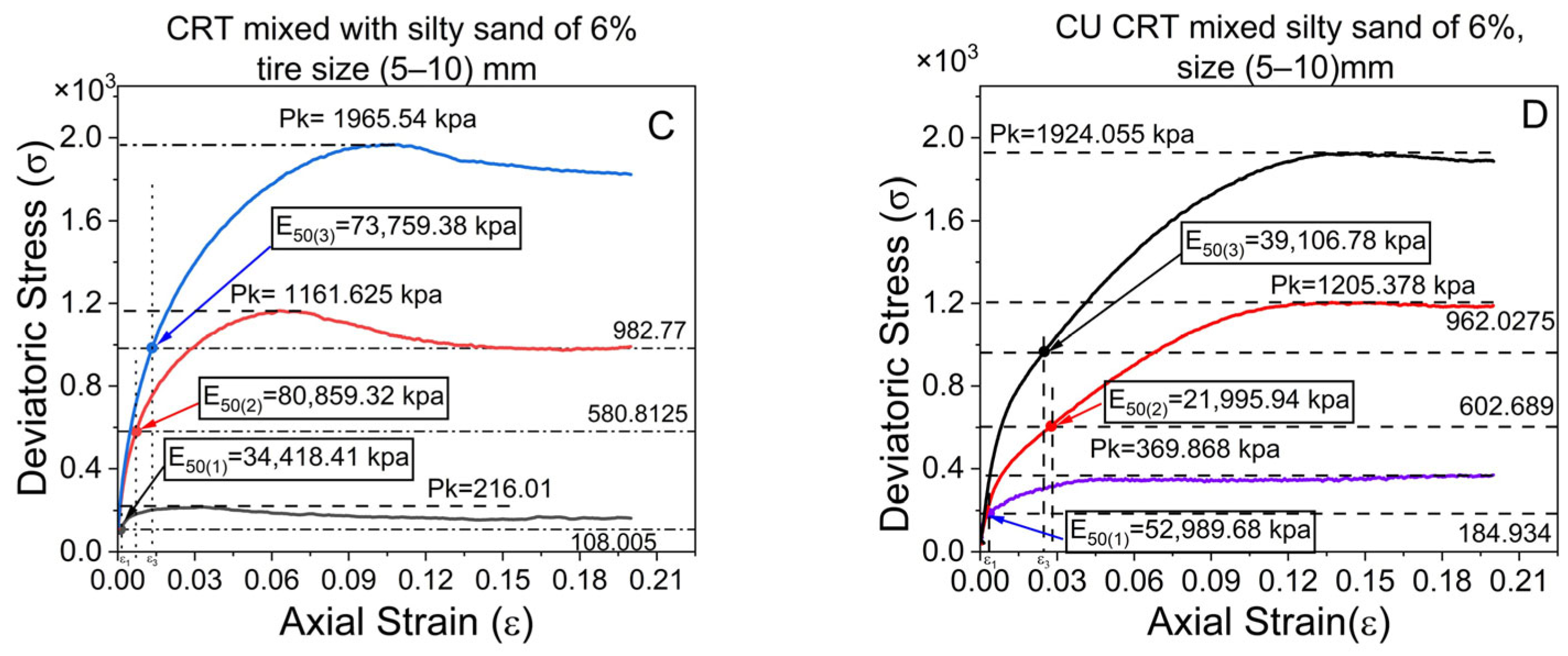

4.1.2. Sizes of 5–10 mm at 3%, 6%, and 9% Ratios

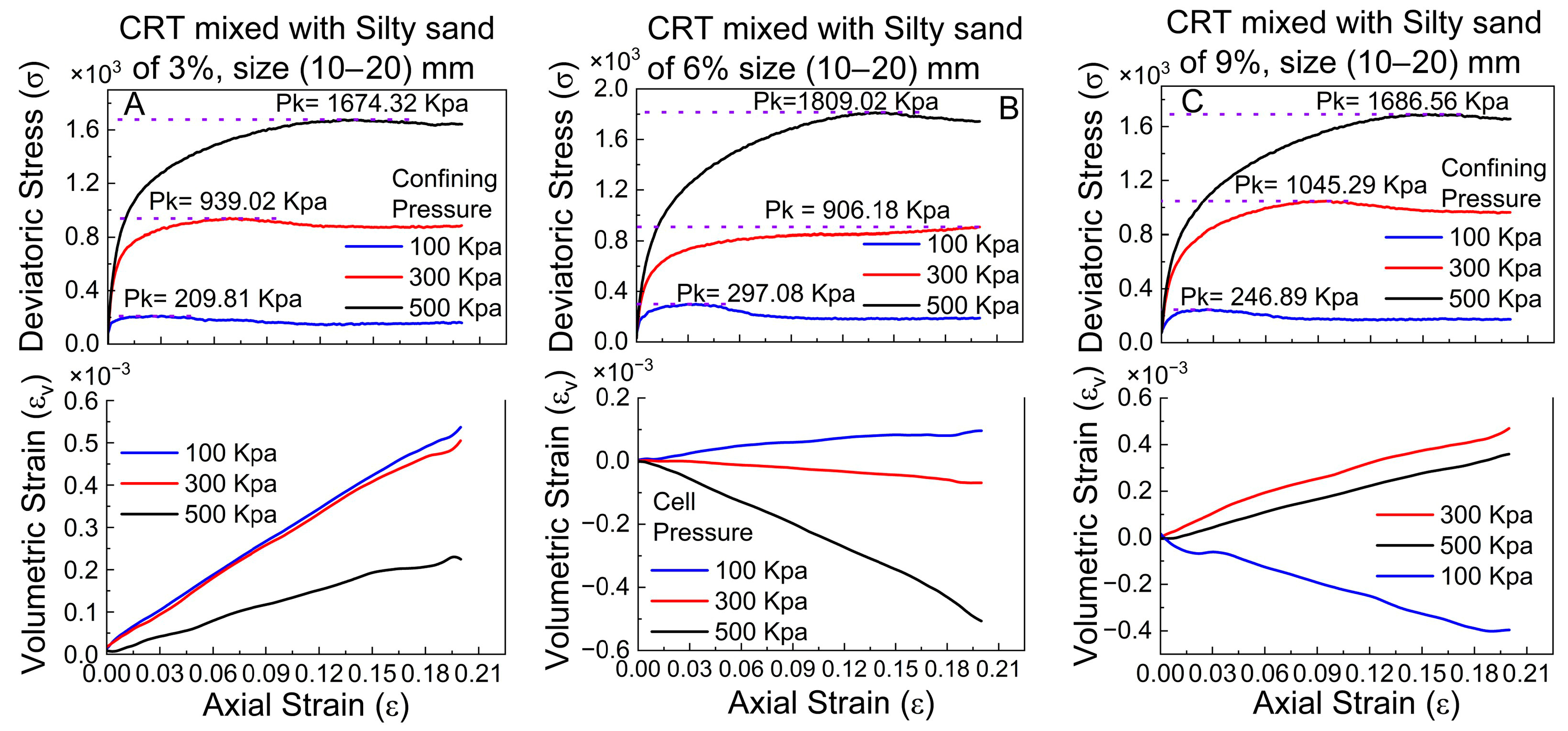

4.1.3. Sizes of 10–20 mm at 3%, 6%, and 9% Ratios

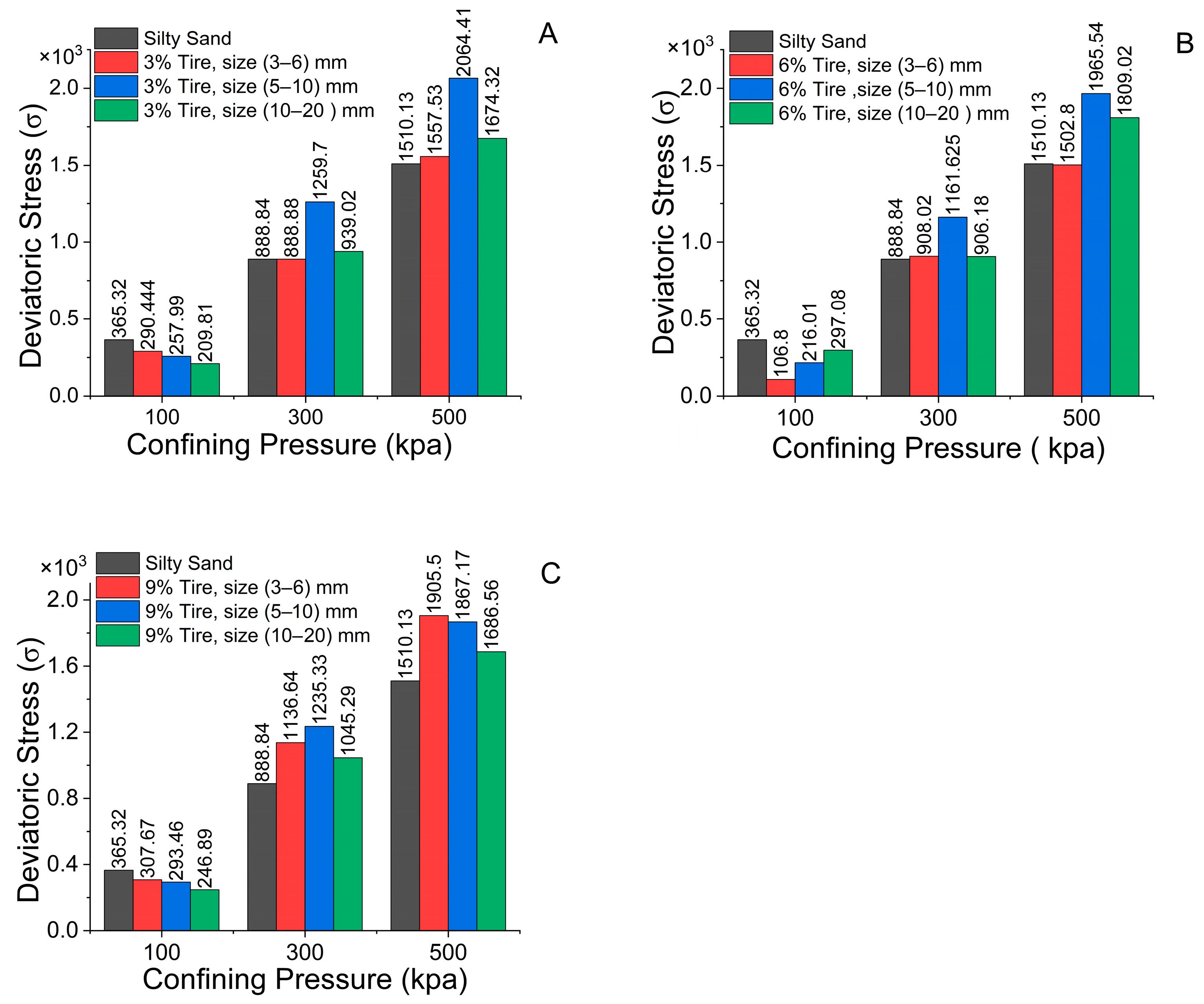

4.2. Influence of Different Crumb Rubber Tire (CRT) Sizes

4.3. Influence of the CRT Mixing Ratio

4.4. Influence of the Confining Pressure

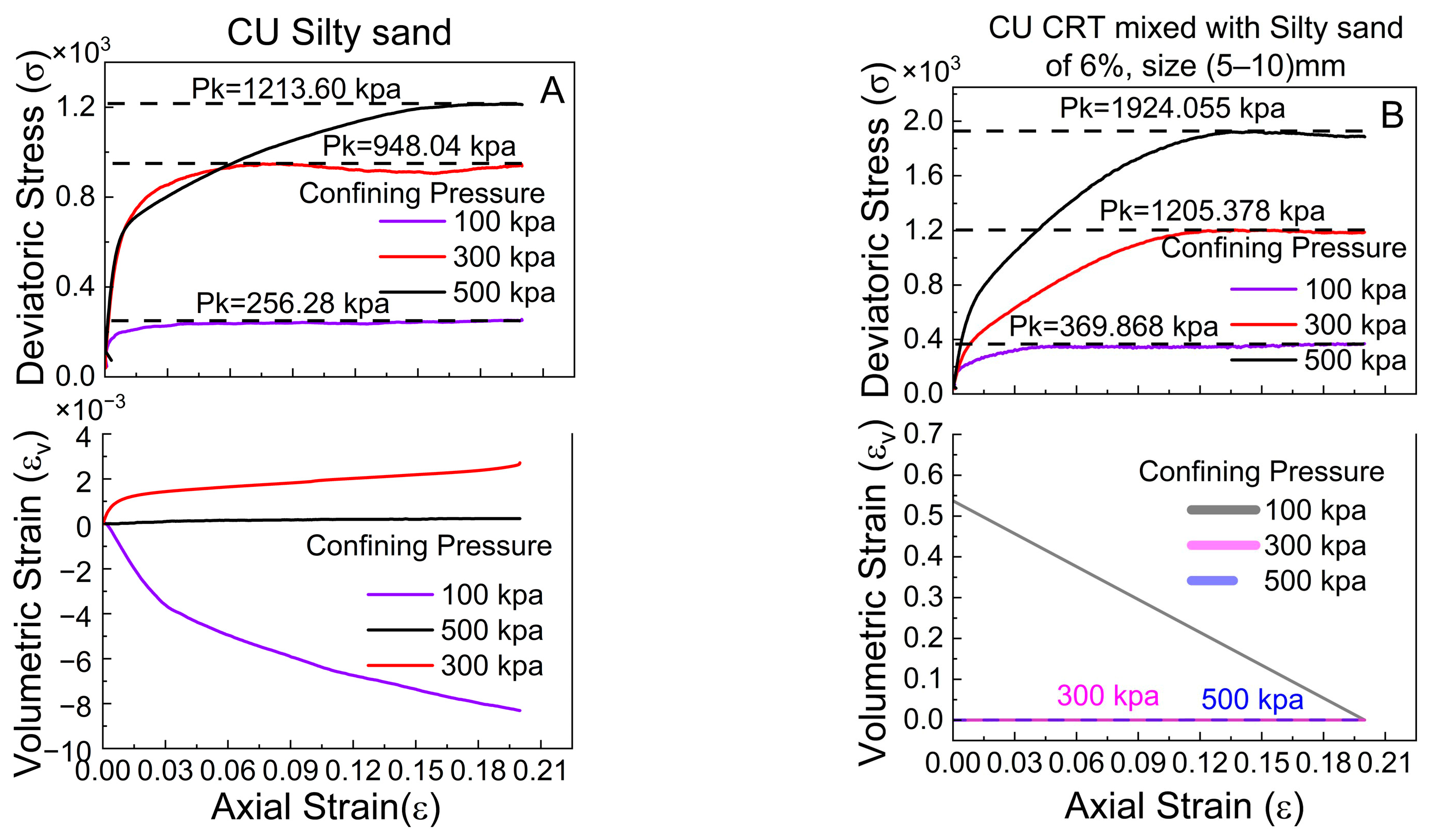

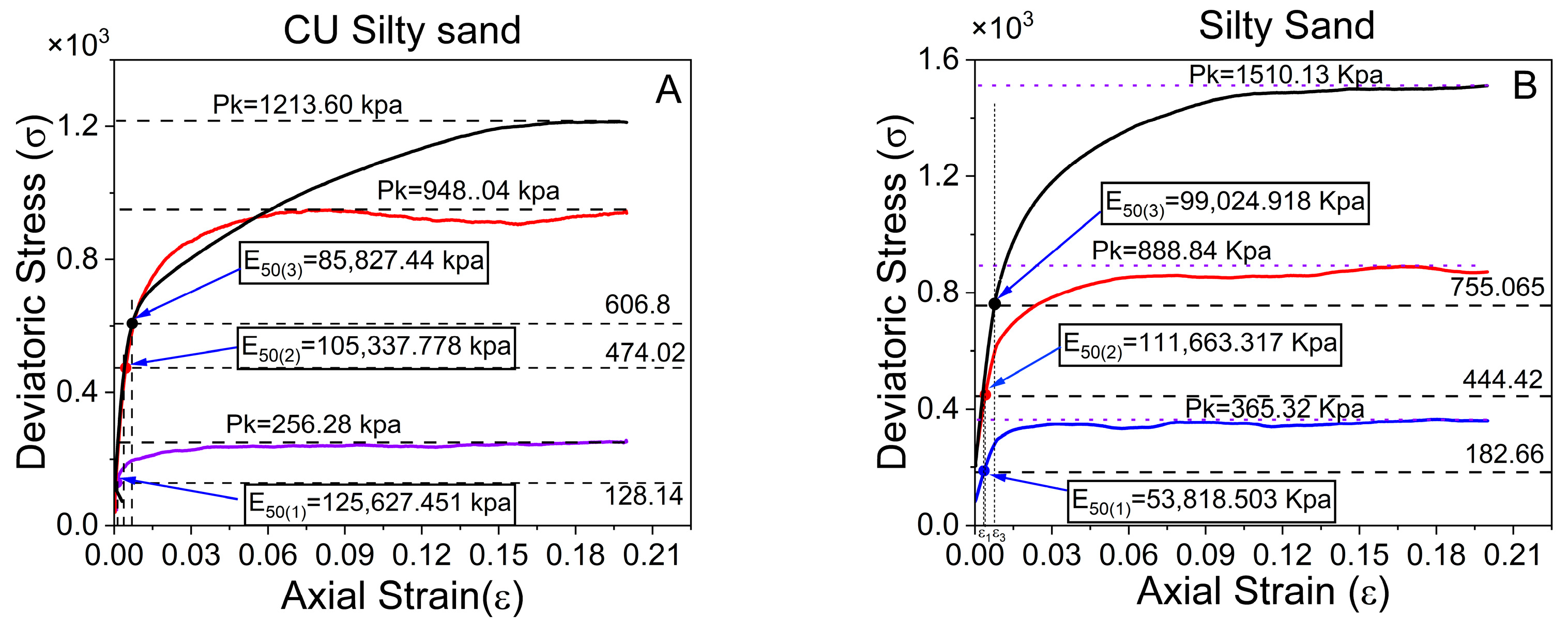

4.5. Influence of Triaxial Test Conditions

5. Determination of Triaxial Parameters

5.1. Expression Formula for Analysis of Data

5.2. The Secant Stiffness Modulus

Unconsolidated-Undrained Stiffness Moduli of Silty Sand and CRT-Mixed with Silty Sand at 3%, 6%, and 9% Crumb Tires and Sizes Ranging from 5 to 10 mm

5.3. The Peak Strength

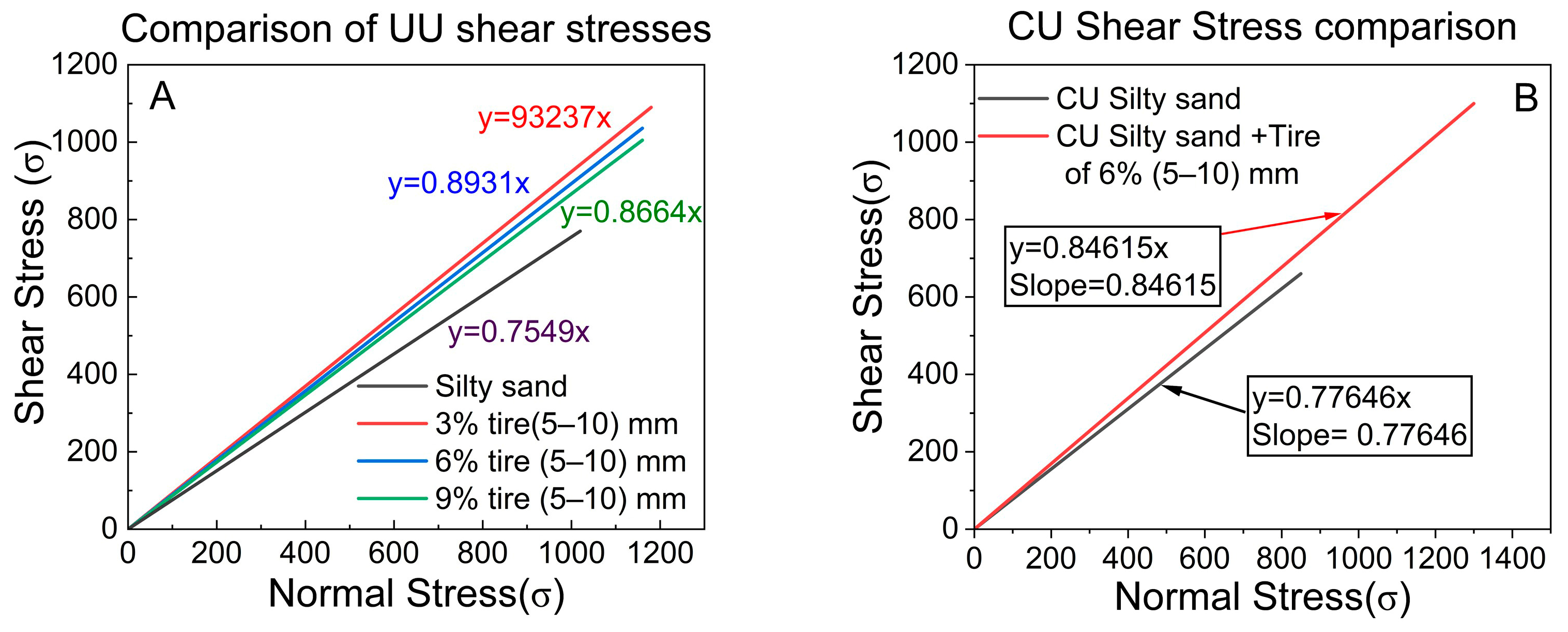

5.4. The Shear Strength

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, L.; Cui, F.; Ferreira, P.; Xiao, H.; Jie, H. Experimental study of embankments with different reinforcement materials and spacing between layers. Geotext. Geomembr. 2019, 47, 477–482. [Google Scholar] [CrossRef]

- Grammelis, P.; Margaritis, N.; Dallas, P.; Rakopoulos, D.; Mavrias, G. A review on management of end of life tires (ELTs) and alternative uses of textile fibers. Energies 2021, 14, 571. [Google Scholar] [CrossRef]

- Tiwari, B.; Ajmera, B.; Moubayed, S.; Lemmon, A.; Styler, K. Soil modification with shredded rubber tires. In GeoCongress 2012: State of the Art and Practice in Geotechnical Engineering; American Society of Civil Engineers: Reston, VA, USA, 2012; pp. 3701–3708. [Google Scholar]

- Kowalski, T.E.; Starry, D.; America, J. Modern soil stabilization techniques. In Proceedings of the Annual Conference of the Transportation Association, Saskatoon, SK, Canada, 5–8 October 2007; pp. 14–17. [Google Scholar]

- Zhang, Q.; Wang, Z.; Yao, Y.; Kong, W.; Zhao, Z.; Shao, M.; Wei, X. Effects of slope morphology and position on soil nutrients after deforestation in the hilly loess region of China. Agric. Ecosyst. Environ. 2021, 321, 107615. [Google Scholar] [CrossRef]

- Brown, C.B.; Sheu, M.S. Effects of deforestation of slopes. J. Geotech. Eng. Div. 1975, 101, 147–165. [Google Scholar] [CrossRef]

- Jones, C.J. Earth Reinforcement and Soil Structures; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Saran, S. Reinforced Soil and Its Engineering Applications; IK International Pvt Ltd.: Delhi, India, 2017. [Google Scholar]

- Ramirez, G.G.D.; Casagrande, M.D.T. Experimental Study of Granular Rubber Waste Tire Reinforced Soil for Geotechnical Applications. Key Eng. Mater. 2014, 600, 585–596. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Makusa, G.P. Soil Stabilisation Methods and Materials; Mintek: Beavercreek, OH, USA, 2012. [Google Scholar]

- Czarna-Juszkiewicz, D.; Kunecki, P.; Cader, J.; Wdowin, M. Review in Waste Tire Management-Potential Applications in Mitigating Environmental Pollution. Materials 2023, 16, 17. [Google Scholar] [CrossRef]

- Lu, N.; Mitchell, J.K. Geotechnical Fundamentals for Addressing New World Challenges; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Indraratna, B.; Athukorala, R.; Vinod, J. Estimating the Rate of Erosion of a Silty Sand Treated with Lignosulfonate. J. Geotech. Geoenviron. Eng. 2013, 139, 701–714. [Google Scholar] [CrossRef]

- Chiaro, G.; Tasalloti, A.; Banasiak, L.; Palermo, A.; Granello, G.; Rees, S. Sustainable recycling of end-of-life tyres in civil (geotechnical) engineering applications: Turning issues into opportunities in the New Zealand context. NZ Geomech. News 2020, 99, 38–47. [Google Scholar]

- Veena, U.; James, N. Natural rubber latex for improving ductility characteristics of soil: A preliminary experimental investigation. Geotech. Geol. Eng. 2022, 40, 4419–4446. [Google Scholar] [CrossRef]

- Yadav, J.S.; Hussain, S.; Tiwari, S.K.; Garg, A. Assessment of the load-deformation behaviour of rubber fibre-reinforced cemented clayey soil. Transp. Infrastruct. Geotechnol. 2019, 6, 105–136. [Google Scholar] [CrossRef]

- Fořt, J.; Kobetičová, K.; Böhm, M.; Podlesný, J.; Jelínková, V.; Vachtlová, M.; Bureš, F.; Černý, R. Environmental consequences of rubber crumb application: Soil and water pollution. Polymers 2022, 14, 1416. [Google Scholar] [CrossRef]

- Peterson, M.K.; Lemay, J.C.; Shubin, S.P.; Prueitt, R.L. Comprehensive multipathway risk assessment of chemicals associated with recycled (crumb) rubber in synthetic turf fields. Environ. Res. 2018, 160, 256–268. [Google Scholar] [CrossRef]

- Schneider, K.; Bierwisch, A.; Kaiser, E. ERASSTRI-European risk assessment study on synthetic turf rubber infill—Part 3: Exposure and risk characterisation. Sci. Total Environ. 2020, 718, 137721. [Google Scholar] [CrossRef]

- Alade, S.M. Correlation of unified and AASHTO soil classification systems for soils classification. J. Earth Sci. Geotech. Eng. 2018, 8, 39–50. [Google Scholar]

- Kovačević, M.S.; Jurić-Kaćunić, D. European soil classification system for engineering purposes. Građevinar 2014, 66, 801–810. [Google Scholar]

- Bell, F.G. Engineering Properties of Soils and Rocks; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Gee, G.W.; Or, D. 2.4 Particle-size analysis. Methods Soil Anal. Part 4 Phys. Methods 2002, 5, 255–293. [Google Scholar]

- Elfaki, J.T.; Gafer, M.A.; Sulieman, M.M.; Ali, M.E. Hydrometer method against pipette method for estimating soil particle size distribution in some soil types selected from Central Sudan. Int. J. Eng. Res. Adv. Technol. 2016, 2, 25–41. [Google Scholar]

- Wen, B.; Aydin, A.; Duzgoren-Aydin, N.S. A comparative study of particle size analyses by sieve-hydrometer and laser diffraction methods. Geotech. Test. J. 2002, 25, 434–442. [Google Scholar] [CrossRef]

- Huluka, G.; Miller, R. Particle size determination by hydrometer method. South. Coop. Ser. Bull. 2014, 419, 180–184. [Google Scholar]

- Moss, A.; Green, P. Sand and silt grains: Predetermination of their formation and properties by microfractures in quartz. J. Geol. Soc. Aust. 1975, 22, 485–495. [Google Scholar] [CrossRef]

- ASTM D6270-20; Standard Practice for Use of Scrap Tires in Civil Engineering Applications. ASTM International: West Conshohocken, PA, USA, 2008.

- Battista, M.; Gobetti, A.; Agnelli, S.; Ramorino, G. Post-consumer tires as a valuable resource: Review of different types of material recovery. Environ. Technol. Rev. 2020, 10, 1–25. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in used tyres management in the European Union: A review. Waste Manag. 2012, 32, 1742–1751. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. The impact of end-of-life tires on the mechanical properties of fine-grained soil: A Review. Environ. Dev. Sustain. 2017, 21, 485–568. [Google Scholar] [CrossRef]

- Wood, L.A. Synthetic Rubbers: A Review of Their Compositions, Properties, and Uses. Rubber Chem. Technol. 1940, 13, 861–885. [Google Scholar] [CrossRef]

- Taa, P.D.S.; Rahardjo, P.P.; Djayaputra, A.A. Experimental study on the determination of shear strength parameter of bouldery soils using large triaxial calibration chamber. Int. J. Sci. Eng. Res. 2018, 9, 1592–1599. [Google Scholar]

- Lacasse, S.; Berre, T. Triaxial testing methods for soils. Adv. Triaxial Test. Soil Rock ASTM STP 1988, 977, 264–289. [Google Scholar]

- Bai, J.; Diao, Y.; Jia, C.; Liu, C.; Zhang, M.; Wang, C. A review of advances in triaxial tests: Instruments, test techniques and prospects. KSCE J. Civil Eng. 2022, 26, 3325–3341. [Google Scholar] [CrossRef]

- Liu, Z.; Xie, S.; Shao, J.-F.; Conil, N. Effects of deviatoric stress and structural anisotropy on compressive creep behavior of a clayey rock. Appl. Clay Sci. 2015, 114, 491–496. [Google Scholar] [CrossRef]

- Lu, N.; Godt, J.W. Hillslope Hydrology and Stability; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Rafael, S. Statistical and regression analyses of sands stiffness in triaxial tests and application of the results. Rock Soil Mech. 2022, 43, 8. [Google Scholar]

- Noorzad, R.; Raveshi, M. Mechanical Behavior of Waste Tire Crumbs-Sand Mixtures Determined by Triaxial Tests. Geotech. Geol. Eng. 2017, 35, 1793–1802. [Google Scholar] [CrossRef]

- Balani, D.M.P.; Kikumoto, M.; Cui, Y. Enhanced sand strength through low-density polyethylene reinforcement. Constr. Build. Mater. 2023, 409, 133928. [Google Scholar] [CrossRef]

- Surarak, C.; Likitlersuang, S.; Wanatowski, D.; Balasubramaniam, A.; Oh, E.; Guan, H. Stiffness and strength parameters for hardening soil model of soft and stiff Bangkok clays. Soils Found. 2012, 52, 682–697. [Google Scholar] [CrossRef]

- Wichtmann, T.; Triantafyllidis, T. On the correlation of “static” and “dynamic” stiffness moduli of non-cohesive soils. Bautechnik 2009, 86, 28–39. [Google Scholar] [CrossRef]

- Xu, Y.; Wu, S.; Williams, D.J.; Serati, M. Determination of peak and ultimate shear strength parameters of compacted clay. Eng. Geol. 2018, 243, 160–167. [Google Scholar] [CrossRef]

- Balaban, E.; Smejda, A.; Onur, M.I. Influence of tire crumbs on mechanical properties of sand-fine soil mixtures. Geomech. Geoengin. 2019, 17, 64–79. [Google Scholar] [CrossRef]

| Soil Type | Density kg/m3 | Moisture Content % | Internal Friction Angle | Cohesion Angle | Permeability cm/s |

|---|---|---|---|---|---|

| Silt sand | 1580 | 27.45 | 37.04 | 0 | 1.54 × 10−5 |

| N | Name | Chemical Structure | Function |

|---|---|---|---|

| 1 | Quartz | SiO2 | Is the most prevalent mineral in sandy soils. It is chemically inert, stable, and weather-resistant, making it a key framework component. |

| 2 | Feldspar | KAlSi3O8-NaAlSi3O8-CaAl2Si2O8 | It is a series of aluminum silicate minerals that are less durable than quartz; they are prone to chemical weathering and can convert into clay minerals over time. |

| 3 | Mica, also known as muscovite | KAl2(AlSi3O10)(OH)2 | A sheet silicate mineral occurring in small particles helps to maintain the flexibility and cohesion of silty and clayey soil fractions. |

| 4 | Clay minerals, including kaolinite | Al2Si2O5(OH)4 | Affect soil swelling, plasticity, and cation exchange capacity. |

| n | Name | Chemical Structure | Function |

|---|---|---|---|

| 1 | Natural rubber (cis-1,4-polyisoprene) | -(C5H8) n-. | Allows for chemical crosslinking during vulcanization, increasing flexibility and robustness. |

| 2 | Styrene-butadiene rubber (SBR): | (C8H8), and (C4H6) | This copolymer has higher abrasion resistance and ageing stability than natural rubber, hence it is commonly utilized in tire manufacture. |

| 3 | Carbon black | c | It is used as a reinforcing filler. It improves the rubber’s mechanical strength, wear resistance, and UV stability. |

| 1. Tire Size (3–6) mm | ||||

|---|---|---|---|---|

| TEST TYPE | Name | % of Tires | Confining Pressure | Number of Tests |

| UU | Silty sand | 0% | (100 kpa,300 kpa and 500 kpa) | 3 |

| CRT mixed with silty sand | 3% | (100 kpa,300 kpa and 500 kpa) | 3 | |

| CRT mixed with silty sand | 6% | (100 kpa, 300 kpa and 500 kpa) | 3 | |

| CRT mixed with silty sand | 9% | (100 kpa, 300 kpa and 500 kpa) | 3 | |

| 2. Tire Size (5–10) mm | ||||

| TEST TYPE | Name | % of Tires | Confining Pressure | Number of Tests |

| UU | CRT mixed with silty sand | 3% | (100 kpa, 300 kpa and 500 kpa) | 3 |

| CRT mixed with silty sand | 6% | (100 kpa, 300 kpa and 500 kpa) | 3 | |

| CRT mixed with silty sand | 9% | (100 kpa, 300 kpa and 500 kpa) | 3 | |

| 3. Tire size (10–20) mm | ||||

| TEST TYPE | Name | % of Tires | Confining Pressure | Number of Tests |

| UU | CRT mixed with silty sand | 3% | (100 kpa, 300 kpa and 500 kpa) | 3 |

| CRT mixed with silty sand | 6% | (100 kpa, 300 kpa and 500 kpa) | 3 | |

| CRT mixed with silty sand | 9% | (100 kpa, 300 kpa and 500 kpa) | 3 | |

| Tire Size (5–10) mm | ||||

|---|---|---|---|---|

| TEST TYPE | Name | % of Tires | Confining Pressure | Number of Tests |

| CU | CRT mixed with silty sand | 0% | (100 kpa,300 kpa and 500 kpa) | 3 |

| CRT mixed with silty sand | 6% | (100 kpa, 300 kpa and 500 kpa) | 3 | |

| Soil Type | Applied Confining Pressure | Average (kPa) | ||

|---|---|---|---|---|

| 100 kPa | 300 kPa | 500 kPa | ||

| Silt Sand | 365.32 | 888.84 | 1510.13 | 921.430 |

| 3% Tire, size (3–6) mm | 290.444 | 888.88 | 1557.53 | 912.285 |

| 6% Tire, size (3–6) mm | 106.8 | 908.02 | 1502.8 | 839.207 |

| 9% Tire, size (3–6) mm | 307.67 | 1136.64 | 1905.5 | 1116.603 |

| 3% Tire, size (5–10) mm | 257.99 | 1259.7 | 2064.41 | 1194.033 |

| 6% Tire, size (5–10) mm | 216.01 | 1161.625 | 1965.54 | 1114.392 |

| 9% Tire, size (5–10) mm | 293.46 | 1235.33 | 1867.17 | 1131.987 |

| 3% Tire, size (10–20) mm | 209.81 | 939.02 | 1674.32 | 941.050 |

| 6% Tire, size (10–20) mm | 297.08 | 906.18 | 1809.02 | 1004.093 |

| 9% Tire, size (10–20) mm | 246.89 | 1045.29 | 1686.56 | 992.913 |

| Stiffness at Cell Pressure | Silty Sand | CRT Mixed with Silty Sand at 3% | CRT Mixed with Silty Sand at 6% | CRT Mixed with Silty Sand at 9% |

|---|---|---|---|---|

| E50 at 100 kPa | 53,818.5 | 81,128.93 | 34,418.41 | 38,310.7 |

| E50 at 300 kPa | 111,663.317 | 99,345.42 | 80,859.32 | 74,687.4 |

| E50 at 500 kPa | 99,024.91 | 125,880.61 | 73,759.38 | 81,040.36 |

| Average | 88,168.9 | 10,2118.32 | 63,012.37 | 64,679.48 |

| Soil Type | E50 at 100 kPa | E50 at 300 kPa | E50 at 500 kPa | Average |

|---|---|---|---|---|

| UU Silty sand | 53,818.5 | 111,663.317 | 99,024.918 | 88,168.9 |

| CU Silty sand | 125,627.45 | 105,337.77 | 85,827.4 | 105,597.54 |

| Soil Type | E50 at 100 kPa | E50 at 300 kPa | E50 at 500 kPa | Average |

|---|---|---|---|---|

| UU CRT mixed with silty sand 6% | 34,418.41 | 80,859.32 | 73,759.38 | 63,012.37 |

| CU CRT mixed with silty sand 6% | 52,989.68 | 21,995.94 | 39,106.78 | 38,030.80 |

| Soil Type | Cohesion Angle (c) | Friction Angle (∅) |

|---|---|---|

| UU Silty sand | 0 | 37.0 |

| UU CRT mixed with silty sand at 3% | 0 | 42.9 |

| UU CRT mixed with silty sand at 6% | 0 | 41.7 |

| UU CRT mixed with silty sand at 9% | 0 | 40.9 |

| Soil Type | Cohesion Angle (c) | Friction Angle (∅) |

|---|---|---|

| CU silty sand | 0 | 37.8 |

| CU CRT mixed with silty sand at 6% | 0 | 40.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Theogene, S.; Sun, J.; Wang, Y.; Xu, R.; Sun, J.; Tao, Y.; Zhang, C.; Sun, Q.; Wu, J.; Yue, H.; et al. Analysis of Mechanical Properties of Crumb Rubber Tires Mixed with Silty Sand of Various Sizes and Percentages. Polymers 2025, 17, 2144. https://doi.org/10.3390/polym17152144

Theogene S, Sun J, Wang Y, Xu R, Sun J, Tao Y, Zhang C, Sun Q, Wu J, Yue H, et al. Analysis of Mechanical Properties of Crumb Rubber Tires Mixed with Silty Sand of Various Sizes and Percentages. Polymers. 2025; 17(15):2144. https://doi.org/10.3390/polym17152144

Chicago/Turabian StyleTheogene, Sindambiwe, Jianxiu Sun, Yanzi Wang, Run Xu, Jie Sun, Yuchen Tao, Changyong Zhang, Qingshuo Sun, Jiandong Wu, Hongya Yue, and et al. 2025. "Analysis of Mechanical Properties of Crumb Rubber Tires Mixed with Silty Sand of Various Sizes and Percentages" Polymers 17, no. 15: 2144. https://doi.org/10.3390/polym17152144

APA StyleTheogene, S., Sun, J., Wang, Y., Xu, R., Sun, J., Tao, Y., Zhang, C., Sun, Q., Wu, J., Yue, H., & Zhang, H. (2025). Analysis of Mechanical Properties of Crumb Rubber Tires Mixed with Silty Sand of Various Sizes and Percentages. Polymers, 17(15), 2144. https://doi.org/10.3390/polym17152144