Effect of Continuous Mixer Design and Parameters on the Degradation of Polylactic Acid

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

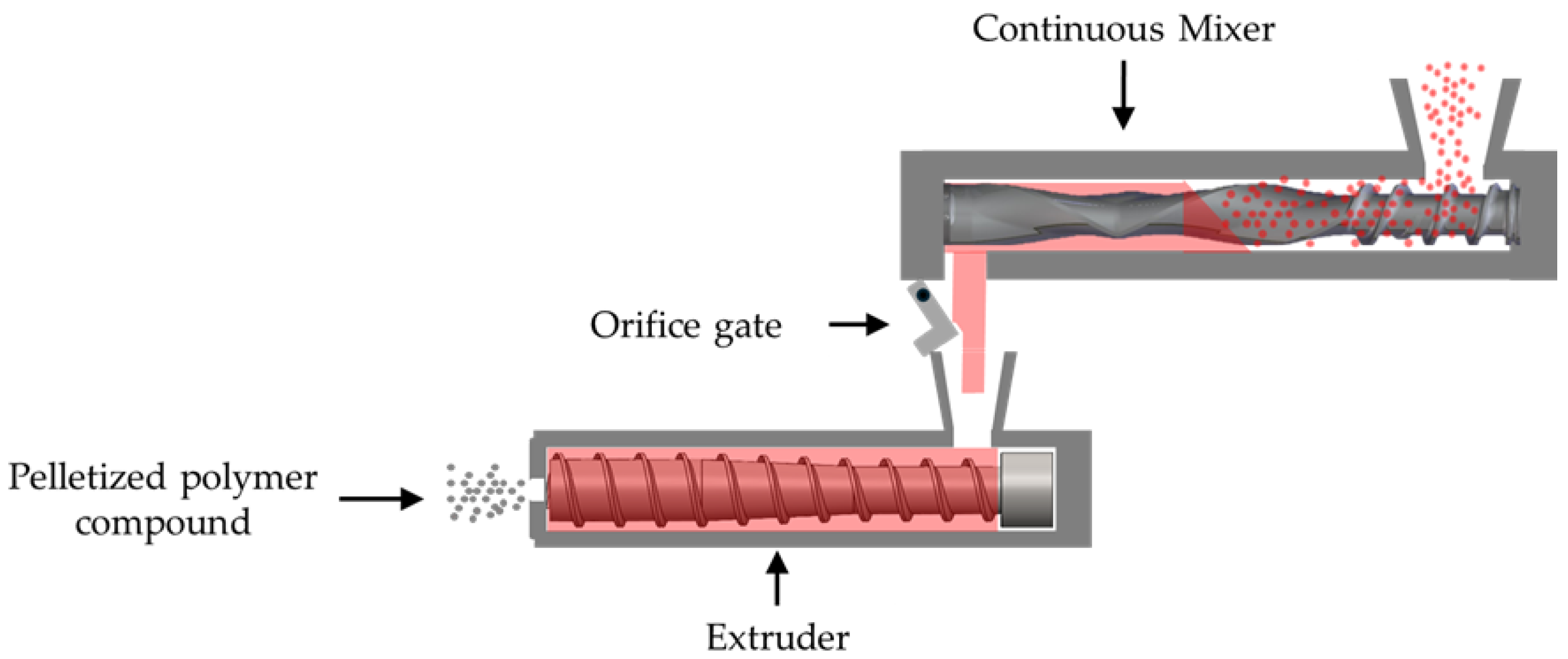

2.2. Continuous Mixer Trials

2.3. Characterization

2.3.1. Rheological Properties

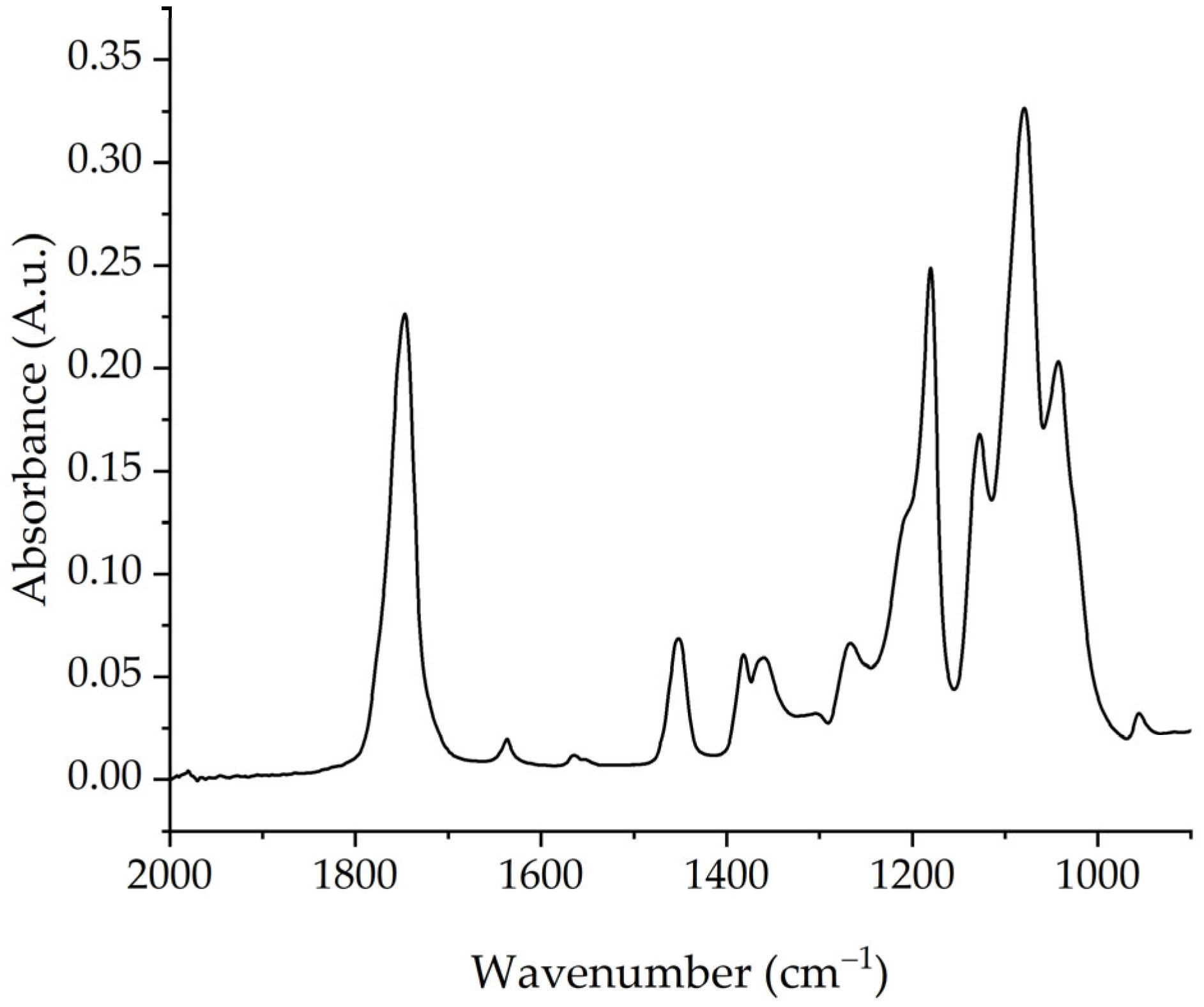

2.3.2. Fourier Transform Infrared Spectroscopy

2.3.3. Differential Scanning Calorimetry

3. Results and Discussion

3.1. Processing Parameters

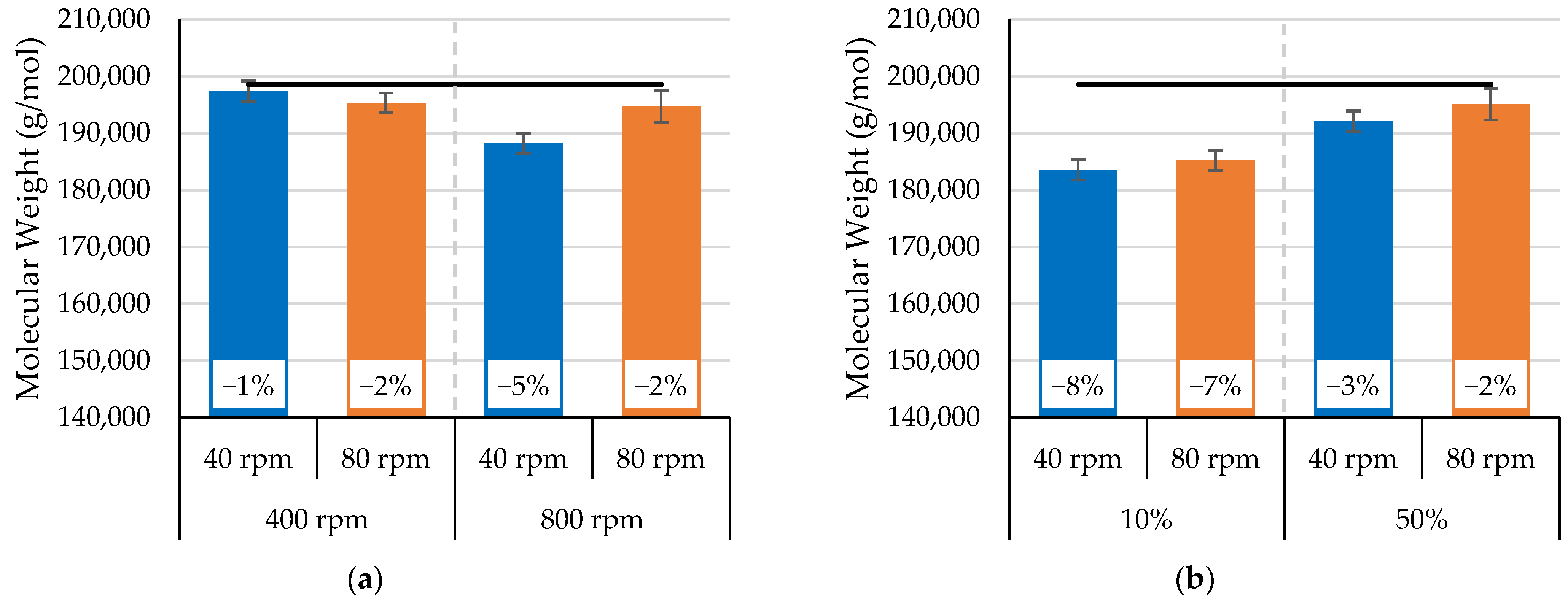

3.2. Rheological Properties

3.3. FTIR Spectroscopic Analysis

3.4. Thermal Properties Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gonçalves, F.A.M.M.; Cruz, S.M.A.; Coelho, J.F.J.; Serra, A.C. The Impact of the Addition of Compatibilizers on Poly (Lactic Acid) (PLA) Properties after Extrusion Process. Polymers 2020, 12, 2688. [Google Scholar] [CrossRef] [PubMed]

- Dedieu, I.; Peyron, S.; Gontard, N.; Aouf, C. The Thermo-Mechanical Recyclability Potential of Biodegradable Biopolyesters: Perspectives and Limits for Food Packaging Application. Polym. Test. 2022, 111, 107620. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Barrio, I.; Lorenzo, V.; del Río, B.; Martínez Urreaga, J.; de la Orden, M.U. Valorization of Poly(Lactic Acid) Wastes via Mechanical Recycling: Improvement of the Properties of the Recycled Polymer. Waste Manag. Res. 2019, 37, 135–141. [Google Scholar] [CrossRef] [PubMed]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-Lactic Acid: Production, Applications, Nanocomposites, and Release Studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef] [PubMed]

- Kosmalska, D.; Janczak, K.; Raszkowska-Kaczor, A.; Stasiek, A.; Ligor, T. Polylactide as a Substitute for Conventional Polymers—Biopolymer Processing under Varying Extrusion Conditions. Environments 2022, 9, 57. [Google Scholar] [CrossRef]

- Ray, S.S.; Bousmina, M. Biodegradable Polymers and Their Layered Silicate Nanocomposites: In Greening the 21st Century Materials World. Prog. Mater. Sci. 2005, 50, 962–1079. [Google Scholar] [CrossRef]

- Shojaeiarani, J.; Bajwa, D.S.; Rehovsky, C.; Bajwa, S.G.; Vahidi, G. Deterioration in the Physico-Mechanical and Thermal Properties of Biopolymers Due to Reprocessing. Polymers 2019, 11, 58. [Google Scholar] [CrossRef]

- Gamez-Perez, J.; Nascimento, L.; Bou, J.J.; Franco-Urquiza, E.; Santana, O.O.; Carrasco, F.; Maspoch, M. Influence of Crystallinity on the Fracture Toughness of Poly(Lactic Acid)/Montmorillonite Nanocomposites Prepared by Twin-Screw Extrusion. J. Appl. Polym. Sci. 2011, 120, 896–905. [Google Scholar] [CrossRef]

- Lamberti, F.M.; Román-Ramírez, L.A.; Wood, J. Recycling of Bioplastics: Routes and Benefits. J. Polym. Environ. 2020, 28, 2551–2571. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Jaafar, M. A Review on Degradation Mechanisms of Polylactic Acid: Hydrolytic, Photodegradative, Microbial, and Enzymatic Degradation. Polym. Eng. Sci. 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and Mechanical Properties of PLA, and Their Functions in Widespread Applications—A Comprehensive Review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Mistry, A.N.; Kachenchart, B.; Pinyakong, O.; Assavalapsakul, W.; Jitpraphai, S.M.; Somwangthanaroj, A.; Luepromchai, E. Bioaugmentation with a Defined Bacterial Consortium: A Key to Degrade High Molecular Weight Polylactic Acid during Traditional Composting. Bioresour. Technol. 2023, 367, 128237. [Google Scholar] [CrossRef] [PubMed]

- Alshammari, S.; Ameli, A. Polylactic Acid Biocomposites with High Loadings of Melt-Flowable Organosolv Lignin. Int. J. Biol. Macromol. 2023, 242, 125094. [Google Scholar] [CrossRef]

- Velghe, I.; Buffel, B.; Vandeginste, V.; Thielemans, W.; Desplentere, F. Review on the Degradation of Poly(Lactic Acid) during Melt Processing. Polymers 2023, 15, 2047. [Google Scholar] [CrossRef] [PubMed]

- Speranza, V.; De Meo, A.; Pantani, R. Thermal and Hydrolytic Degradation Kinetics of PLA in the Molten State. Polym. Degrad. Stab. 2014, 100, 37–41. [Google Scholar] [CrossRef]

- Signori, F.; Coltelli, M.B.; Bronco, S. Thermal Degradation of Poly(Lactic Acid) (PLA) and Poly(Butylene Adipate-Co-Terephthalate) (PBAT) and Their Blends upon Melt Processing. Polym. Degrad. Stab. 2009, 94, 74–82. [Google Scholar] [CrossRef]

- Atalay, S.E.; Bezci, B.; Özdemir, B.; Göksu, Y.A.; Ghanbari, A.; Jalali, A.; Nofar, M. Thermal and Environmentally Induced Degradation Behaviors of Amorphous and Semicrystalline PLAs Through Rheological Analysis. J. Polym. Environ. 2021, 29, 3412–3426. [Google Scholar] [CrossRef]

- Le Marec, P.E.; Ferry, L.; Quantin, J.C.; Bénézet, J.C.; Bonfils, F.; Guilbert, S.; Bergeret, A. Influence of Melt Processing Conditions on Poly(Lactic Acid) Degradation: Molar Mass Distribution and Crystallization. Polym. Degrad. Stab. 2014, 110, 353–363. [Google Scholar] [CrossRef]

- Taubner, V.; Shishoo, R. Influence of Processing Parameters on the Degradation of Poly(L-Lactide) During Extrusion. J. Appl. Polym. Sci. 2001, 79, 2128–2135. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Skórczewska, K.; Matykiewicz, D. Correlation between Processing Parameters and Degradation of Different Polylactide Grades during Twin-Screw Extrusion. Polymers 2020, 12, 1333. [Google Scholar] [CrossRef]

- Khankrua, R.; Pivsa-Art, S.; Hiroyuki, H.; Suttiruengwong, S. Effect of Chain Extenders on Thermal and Mechanical Properties of Poly(Lactic Acid) at High Processing Temperatures: Potential Application in PLA/Polyamide 6 Blend. Polym. Degrad. Stab. 2014, 108, 232–240. [Google Scholar] [CrossRef]

- Amorin, N.S.Q.S.; Rosa, G.; Alves, J.F.; Gonçalves, S.P.C.; Franchetti, S.M.M.; Fechine, G.J.M. Study of Thermodegradation and Thermostabilization of Poly(Lactide Acid) Using Subsequent Extrusion Cycles. J. Appl. Polym. Sci. 2014, 131, 40023. [Google Scholar] [CrossRef]

- Wang, Y.; Steinhoff, B.; Brinkmann, C.; Alig, I. In-Line Monitoring of the Thermal Degradation of Poly(L-Lactic Acid) during Melt Extrusion by UV–Vis Spectroscopy. Polymer 2008, 49, 1257–1265. [Google Scholar] [CrossRef]

- IngeoTM Biopolymer 2003D Technical Data Sheet for Fresh Food Packaging and Food Serviceware. Available online: https://www.natureworksllc.com/~/media/technical_resources/technical_data_sheets/technicaldatasheet_2003d_ffp-fsw_pdf.pdf (accessed on 5 May 2025).

- Aldhafeeri, T.; Alotaibi, M.; Barry, C.F. Impact of Melt Processing Conditions on the Degradation of Polylactic Acid. Polymers 2022, 14, 2790. [Google Scholar] [CrossRef]

- Martin, C. Twin Screw Extruders as Continuous Mixers for Thermal Processing: A Technical and Historical Perspective. AAPS Pharm. Sci. Tech. 2016, 17, 3–19. [Google Scholar] [CrossRef]

- Chatrath, S.; Alotaibi, M.; Barry, C.F. Performance of Recycled Polylactic Acid/Amorphous Polyhydroxyalkanoate Blends. Polymers 2024, 16, 1230. [Google Scholar] [CrossRef] [PubMed]

- Velghe, I.; Buffel, B.; Vandeginste, V.; Thielemans, W.; Desplentere, F. Effect of Processing Conditions on Process-Induced Degradation of Poly(Lactic Acid) During Single-Screw Extrusion. J. Appl. Polym. Sci. 2025, 142, e56698. [Google Scholar] [CrossRef]

- Scoponi, G.; Francini, N.; Athanassiou, A.; Scoponi, G.; Athanassiou Smart Materials, A.; Francini, N. Production of Green Star/Linear PLA Blends by Extrusion and Injection Molding: Tailoring Rheological and Mechanical Performances of Conventional PLA. Macromol. Mater. Eng. 2021, 306, 2000805. [Google Scholar] [CrossRef]

- Scaffaro, R.; Botta, L.; Passaglia, E.; Oberhauser, W.; Frediani, M.; Di Landro, L. Comparison of Different Processing Methods to Prepare Poly(Lactid Acid)–Hydrotalcite Composites. Polym. Eng. Sci. 2014, 54, 1804–1810. [Google Scholar] [CrossRef]

- Canedo, E.L.; Valsamis, L.N. Mixing in the farrel continuous mixer. In Mixing and Compounding of Polymers; Manas-Zloczower, I., Ed.; Carl Hanser Verlag GmbH & Co., KG: München, Germany, 2009; pp. I–XXIV. [Google Scholar] [CrossRef]

- Alotaibi, M.; Barry, C.F. Impacts of Rotor Design, Screw Design, and Processing Parameters in a Farrel Continuous Mixer. Polymers 2025, 17, 619. [Google Scholar] [CrossRef]

- Galle, F.N.; White, J.L. Characterization of the Behavior and Blending Performance of a Continuous Mixer. Int. Polym. Process. 1999, 14, 241–246. [Google Scholar] [CrossRef]

- Lahmann, P.M.; Knowlton, N. The Benefits of Farrel Continuous Mixing (FCMTM) Technology in Processing Polylactide (PLA) Compounds. In Proceedings of the ANTEC® 2019, Detroit, MI, USA, 18–21 March 2019; pp. 1178–1184. [Google Scholar]

- Chen, X.; Zhang, H.; Chen, T.; Zhao, H.; Ji, H.; Ma, Y.; Sha, J.; Xie, L. The Solid-State Mixing Characteristic of Two Rotor Continuous Mixer and Its Influence on Microstructure of HDPE/CaCO3 Composite. Polym. Compos. 2019, 40, 3296–3305. [Google Scholar] [CrossRef]

- Valsamis, L.N.; Canedo, E.L. Mixing, Devolatilization, and Reactive Processing in the a Farrel Continuous Mixer. Int. Polym. Process. 1989, 4, 247–254. [Google Scholar] [CrossRef]

- Chang, D.; White, J.L. Experimental Study of Maleation of Polypropylene in Various Twin-Screw Extruder Systems. J. Appl. Polym. Sci. 2003, 90, 1755–1764. [Google Scholar] [CrossRef]

- Yasuda, K.; Armstrong, R.C.; Cohen, R.E. Shear Flow Properties of Concentrated Solutions of Linear and Star Branched Polystyrenes. Rheol. Acta 1981, 20, 163–178. [Google Scholar] [CrossRef]

- Cuadri, A.A.; Martín-Alfonso, J.E. Thermal, Thermo-Oxidative and Thermomechanical Degradation of PLA: A Comparative Study Based on Rheological, Chemical and Thermal Properties. Polym. Degrad. Stab. 2018, 150, 37–45. [Google Scholar] [CrossRef]

- Oliveira, M.; Santos, E.; Araújo, A.; Fechine, G.J.M.; Machado, A.V.; Botelho, G. The Role of Shear and Stabilizer on PLA Degradation. Polym. Test. 2016, 51, 109–116. [Google Scholar] [CrossRef]

- Rasselet, D.; Ruellan, A.; Guinault, A.; Miquelard-Garnier, G.; Sollogoub, C.; Fayolle, B. Oxidative Degradation of Polylactide (PLA) and Its Effects on Physical and Mechanical Properties. Eur. Polym. J. 2014, 50, 109–116. [Google Scholar] [CrossRef]

- Fischer, E.W.; Sterzel, H.J.; Wegner, G. Investigation of the Structure of Solution Grown Crystals of Lactide Copolymers by Means of Chemical Reactions. Kolloid-Z. Z. Für Polym. 1973, 251, 980–990. [Google Scholar] [CrossRef]

- Velghe, I.; Buffel, B.; Vandeginste, V.; Thielemans, W.; Desplentere, F. Effect of Melt Processing Conditions on the Degradation of PLA During Single-Screw Extrusion. AIP Conf. Proc. 2024, 3158, 140003. [Google Scholar] [CrossRef]

- Katiyar, V.; Gerds, N.; Koch, C.B.; Risbo, J.; Hansen, H.C.B.; Plackett, D. Melt Processing of Poly(L-Lactic Acid) in the Presence of Organomodified Anionic or Cationic Clays. J. Appl. Polym. Sci. 2011, 122, 112–125. [Google Scholar] [CrossRef]

- Way, C.; Wu, D.Y.; Cram, D.; Dean, K.; Palombo, E. Processing Stability and Biodegradation of Polylactic Acid (PLA) Composites Reinforced with Cotton Linters or Maple Hardwood Fibres. J Polym Env. 2013, 21, 54–70. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Improvement of Thermal Stability, Rheological and Mechanical Properties of PLA, PBAT and Their Blends by Reactive Extrusion with Functionalized Epoxy. Polym. Degrad. Stab. 2012, 97, 1898–1914. [Google Scholar] [CrossRef]

- Meng, Q.; Heuzey, M.C.; Carreau, P.J. Control of Thermal Degradation of Polylactide/Clay Nanocomposites during Melt Processing by Chain Extension Reaction. Polym. Degrad. Stab. 2012, 97, 2010–2020. [Google Scholar] [CrossRef]

- Cosate de Andrade, M.F.; Fonseca, G.; Morales, A.R.; Mei, L.H.I. Mechanical Recycling Simulation of Polylactide Using a Chain Extender. Adv. Polym. Technol. 2018, 37, 2053–2060. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Karlsson, S.; Ribes-Greus, A. Material Valorisation of Amorphous Polylactide. Influence of Thermo-Mechanical Degradation on the Morphology, Segmental Dynamics, Thermal and Mechanical Performance. Polym. Degrad. Stab. 2012, 97, 670–678. [Google Scholar] [CrossRef]

- Makwakwa, D.; Ojijo, V.; Bandyopadhyay, J.; Sinha Ray, S. Flow Characteristics, Mechanical, Thermal, and Thermomechanical Properties, and 3d Printability of Biodegradable Polylactide Containing Boehmite at Different Loadings. Polymers 2021, 13, 2019. [Google Scholar] [CrossRef]

- Frost, R.L.; Martens, W.N.; Duong, L.; Kloprogge, J.T. Evidence for Molecular Assembly in Hydrotalcites. J. Mater. Sci. Lett. 2002, 21, 1237–1239. [Google Scholar] [CrossRef]

- Benvenuta-Tapia, J.J.; Vivaldo-Lima, E. Reduction of Molar Mass Loss and Enhancement of Thermal and Rheological Properties of Recycled Poly(Lactic Acid) by Using Chain Extenders Obtained from RAFT Chemistry. React. Funct. Polym. 2020, 153, 104628. [Google Scholar] [CrossRef]

- Agüero, A.; Morcillo, M.D.C.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Lascano, D.; Torres-Giner, S.; Fenollar, O. Study of the Influence of the Reprocessing Cycles on the Final Properties of Polylactide Pieces Obtained by Injection Molding. Polymers 2019, 11, 1908. [Google Scholar] [CrossRef]

- Tesfaye, M.; Patwa, R.; Gupta, A.; Kashyap, M.J.; Katiyar, V. Recycling of Poly (Lactic Acid)/Silk Based Bionanocomposites Films and Its Influence on Thermal Stability, Crystallization Kinetics, Solution and Melt Rheology. Int. J. Biol. Macromol. 2017, 101, 580–594. [Google Scholar] [CrossRef] [PubMed]

- Beltrán, F.R.; Arrieta, M.P.; Moreno, E.; Gaspar, G.; Muneta, L.M.; Carrasco-Gallego, R.; Yáñez, S.; Hidalgo-Carvajal, D.; de la Orden, M.U.; Urreaga, J.M. Evaluation of the Technical Viability of Distributed Mechanical Recycling of PLA 3D Printing Wastes. Polymers 2021, 13, 1247. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-Looped Recycling of Polylactic Acid Used in 3D Printing: An Experimental Investigation and Life Cycle Assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

| Trial | Rotor Design | Rotor Speed (rpm) | Orifice Opening (%) | Screw Speed (rpm) |

|---|---|---|---|---|

| 1 | 15/15 std | 400 | 30 | 40 |

| 2 | 15/15 std | 600 | 30 | 40 |

| 3 | 15/15 std | 800 | 30 | 40 |

| 4 | 15/15 std | 600 | 10 | 40 |

| 5 | 15/15 std | 600 | 50 | 40 |

| 6 | 15/7 std | 400 | 30 | 40 |

| 7 | 15/7 std | 600 | 30 | 40 |

| 8 | 15/7 std | 800 | 30 | 40 |

| 9 | 15/7 std | 600 | 10 | 40 |

| 10 | 15/7 std | 600 | 50 | 40 |

| 11 | 15/7 HD | 400 | 30 | 40 |

| 12 | 15/7 HD | 600 | 30 | 40 |

| 13 | 15/7 HD | 800 | 30 | 40 |

| 14 | 15/7 HD | 600 | 10 | 40 |

| 15 | 15/7 HD | 600 | 50 | 40 |

| Std Rotors | HD Rotor | |

|---|---|---|

| Mixer Chamber 1 (°C) | 80 | 120 |

| Mixer Chamber 2 (°C) | 180 | 180 |

| Orifice (°C) | 180 | 180 |

| Extruder Cylinder 1 (°C) | 180 | 180 |

| Extruder Cylinder 2 (°C) | 180 | 180 |

| Die (°C) | 180 | 180 |

| Trial | Rotor Design | Screw Speed (rpm) | Orifice Opening (%) | Rotor Speed (rpm) |

|---|---|---|---|---|

| 1 | 15/7 std | 40 | 10 | 600 |

| 2 | 15/7 std | 80 | 10 | 600 |

| 3 | 15/7 std | 40 | 50 | 600 |

| 4 | 15/7 std | 80 | 50 | 600 |

| 5 | 15/7 std | 40 | 30 | 400 |

| 6 | 15/7 std | 80 | 30 | 400 |

| 7 | 15/7 std | 40 | 30 | 800 |

| 8 | 15/7 std | 80 | 30 | 800 |

| Rotor Design | Rotor Speed (rpm) | ΔHcc (J/g) | ΔHm (J/g) | Tcc (°C) | Tm (°C) | Xc (%) |

|---|---|---|---|---|---|---|

| Unprocessed PLA (1st heating cycle) | - | 36.3 | - | 152.3 | 39.03 | |

| Unprocessed PLA (2nd heating cycle) | - | - | - | - | - | |

| 15/15 std | 400 | 16.7 ± 0.9 | 17.2 ± 0.6 | 123.6 | 150.8 | 0.58 ± 0.2 |

| 15/15 std | 600 | 19.0 ± 0.4 | 19.7 ± 1 | 122.8 | 150.5 | 0.71 ± 0.3 |

| 15/15 std | 800 | 16.3 ± 0.56 | 18.5 ± 0.7 | 122.5 | 151.1 | 2.41 ± 1 |

| 15/7 std | 400 | 14.0 ± 0.8 | 14.0 ± 0.5 | 122.1 | 151.6 | 0.02 ± 0.01 |

| 15/7 std | 600 | 18.5 ± 0.6 | 18.7 ± 0.7 | 121.7 | 150.3 | 0.18 ± 0.1 |

| 15/7 std | 800 | 15.1 ± 0.9 | 16.3 ± 0.23 | 122.1 | 151.5 | 1.28 ± 0.6 |

| 15/7 HD | 400 | 14.2 ± 0.6 | 15.1 ± 0.4 | 123.2 | 151.0 | 0.97 ± 0.5 |

| 15/7 HD | 600 | 12.5 ± 0.8 | 13.5 ± 0.4 | 122.9 | 151.6 | 1.08 ± 0.5 |

| 15/7 HD | 800 | 16.8 ± 0.9 | 17.8 ± 0.9 | 121.5 | 150.6 | 1.10 ± 0.6 |

| Rotor Design | Orifice Opening (%) | dHcc (J/g) | dHm (J/g) | Tcc (°C) | Tm (°C) | Xc (%) |

|---|---|---|---|---|---|---|

| 15/15 std | 10 | 18.2 ± 0.8 | 19.4 ± 0.5 | 121.7 | 150.6 | 1.26 ± 0.6 |

| 15/15 std | 30 | 19.0 ± 0.4 | 19.7 ± 0.8 | 122.8 | 150.5 | 0.71 ± 0.3 |

| 15/15 std | 50 | 16.8 ± 0.7 | 17.0 ± 1 | 123.9 | 151.7 | 0.23 ± 0.2 |

| 15/7 std | 10 | 18.6 ± 0.4 | 18.8 ± 0.5 | 122.2 | 150.9 | 0.22 ± 0.1 |

| 15/7 std | 30 | 18.5 ± 0.7 | 18.7 ± 0.5 | 121.7 | 150.3 | 0.18 ± 0.09 |

| 15/7 std | 50 | 17.6 ± 0.5 | 17.7 ± 0.7 | 123.5 | 151.1 | 0.04 ± 0.02 |

| 15/7 HD | 10 | 18.2 ± 0.6 | 19.4 ± 0.2 | 122.3 | 150.5 | 1.31 ± 0.6 |

| 15/7 HD | 30 | 12.5 ± 0.5 | 13.5 ± 0.4 | 123.9 | 151.6 | 1.08 ± 0.3 |

| 15/7 HD | 50 | 16.7 ± 0.8 | 16.9 ± 0.4 | 123.8 | 150.7 | 0.29 ± 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alotaibi, M.; Shah, J.; Sadani, A.; Barry, C.F. Effect of Continuous Mixer Design and Parameters on the Degradation of Polylactic Acid. Polymers 2025, 17, 1568. https://doi.org/10.3390/polym17111568

Alotaibi M, Shah J, Sadani A, Barry CF. Effect of Continuous Mixer Design and Parameters on the Degradation of Polylactic Acid. Polymers. 2025; 17(11):1568. https://doi.org/10.3390/polym17111568

Chicago/Turabian StyleAlotaibi, Mansour, Jainam Shah, Aniket Sadani, and Carol Forance Barry. 2025. "Effect of Continuous Mixer Design and Parameters on the Degradation of Polylactic Acid" Polymers 17, no. 11: 1568. https://doi.org/10.3390/polym17111568

APA StyleAlotaibi, M., Shah, J., Sadani, A., & Barry, C. F. (2025). Effect of Continuous Mixer Design and Parameters on the Degradation of Polylactic Acid. Polymers, 17(11), 1568. https://doi.org/10.3390/polym17111568