Abstract

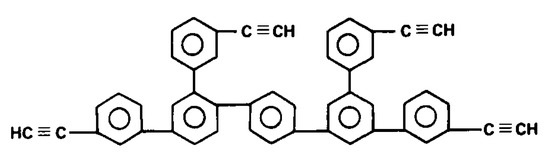

In this review, all available publications on the polymerization of all isomers of bifunctional diethynylarenes due to the opening of C≡C bonds were considered and analyzed. It has been shown that with the use of polymers of diethynylbenzene, heat-resistant and ablative materials, catalysts, sorbents, humidity sensors, and other materials can be obtained. Various catalytic systems and conditions of polymer synthesis are considered. For the convenience of comparison, the publications considered are grouped according to common features, including the types of initiating systems. Critical consideration is given to the features of the intramolecular structure of the synthesized polymers since it determines the entire complex of properties of this material and subsequent materials. Branched and/or insoluble polymers are formed as a result of solid-phase and liquid-phase homopolymerization. It is shown that the synthesis of a completely linear polymer was carried out for the first time by anionic polymerization. The review considers in sufficient detail publications from hard-to-reach sources, as well as publications that required a more thorough critical examination. The review does not consider the polymerization of diethynylarenes with substituted aromatic rings because of their steric restrictions; the diethynylarenes copolymers with complex intramolecular structure; and diethynylarenes polymers obtained by oxidative polycondensation.

1. Introduction

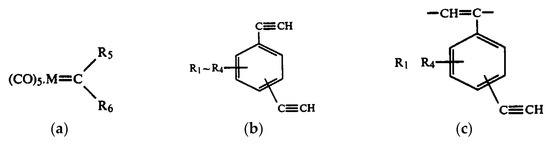

Polymerization of monomers containing internal and/or terminal C≡C bonds using various polymerization methods (solid phase or liquid phase) and various catalytic systems leads to polymers that have a complex of unique electrophysical, optical, and physicochemical properties. Various aspects of polymerization features and properties of substituted polyacetylenes are considered in numerous reviews [1,2,3,4,5,6,7,8,9,10,11].

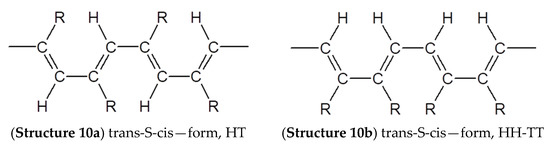

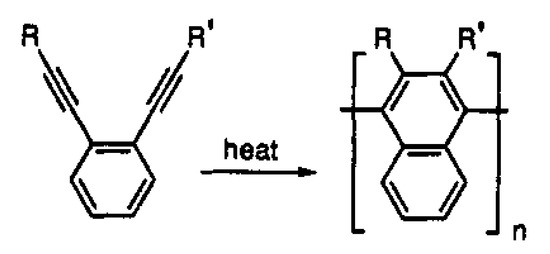

At the same time, polymers synthesized by polymerization of aromatic compounds with terminal ethynyl groups H–C≡C–Ar–C≡C–H acquire their specific properties, for example, 1,4–diethynylbenzene and 1,3-diethynylbenzene [12,13,14,15,16], 1,2-diethynylbenzene [17], 1,4-diethynyl naphthalene and 4,4′-diethynyldiphenylmethane [12], 4,4′-diethynylbiphenyl [12,14,18,19], 2,5-diethynylthiophene [20], 3,6-diethynylcarbazole [21], etc. The most frequently studied monomer of this group of compounds is p-diethynylbenzene (p-DEB), also due to the fact that it is the most commercially available compound. Initially, numerous patents and articles were devoted to the creation of homo- and copolymers based on p-DEB with the formation of prepolymer resins. These prepolymers are of interest, first of all, for the creation of specific heat-resistant and ablative materials for aviation and space technology [22,23,24,25,26,27,28]. In addition, homo- and copolymers with a complex of other interesting properties have been synthesized on the basis of DEB, for example, components of solar cells, optically active polymers, polymers with photoelectric and catalytic activity, microporous and electrochromic polymers, membranes for separating gases and liquids, humidity sensors, etc. Possible applications of synthesized polymers will be given below when considering various methods of their synthesis. Many approaches and various catalytic systems have been proposed for the synthesis of these polymers.

However, it must be kept in mind that DEB is a bifunctional monomer. Therefore, its homopolymerization can proceed both along one and both –C≡CH bonds with the formation of polymers of three different types of intramolecular structure: linear, branched, and crosslinked. In turn, the resulting structure of macromolecules will fundamentally affect the properties of the polymers being formed.

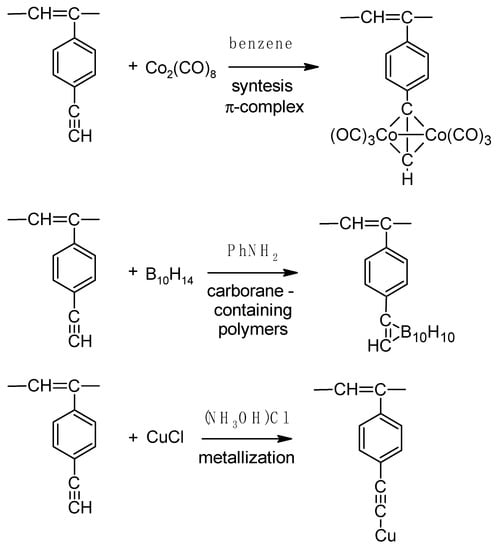

The presence of –Ph–C≡CH side substituents in DEB polymers having any of the listed intramolecular structures provides an additional opportunity for the design of final polymers. Due to the targeted selection of these substituents, it is possible to change and regulate the properties of already synthesized polymers by modifying them through polymer-analogous transformations. Ethynyl and/or phenylene fragments in the side substituents –Ph–C≡C–H can play the role of chemically active fragments capable of reactions with any organic compounds, heteroatoms, or their compounds. Figure 1 shows the schemes of various modification reactions described in [29,30,31,32,33].

Figure 1.

Schemes of the synthesis of organic element derivatives of poly-p-DEB.

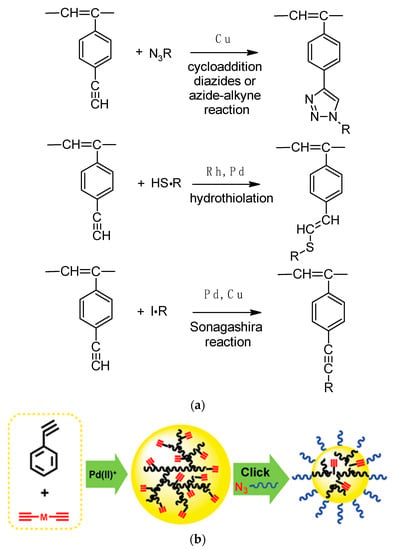

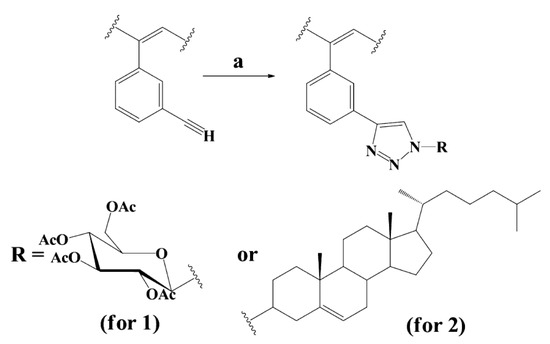

There are known click reactions of groups –C≡CH with various reagents. The same reactions can be recommended for modification of DEB polymers having side substituents –PhC≡CH, for example, reactions with aromatic diazides (cycloaddition azides) [34,35,36], the Sonogashira-Hagihara catalytic reaction with halogen derivatives [37,38] in accordance with the schemes in Figure 2a.

Figure 2.

(a) Schemes of the possible click reactions synthesis of p-DEB polymers, where R is substituents of benzene, pyridine, thiophene, carbazole, etc. (b) The azide-alkyne click reaction scheme from [39]. Reprinted with permission from [39]. Copyright 2012, American Chemical Society.

Indeed, an interesting two-stage process was demonstrated in [39]. Initially, branched copolymers of m- or p-DEB with phenylacetylene having unpolymerized groups –C≡CH were synthesized. Then, the azide-alkyne click reaction of these copolymers with azide-ended polystyrene was carried out according to the scheme shown in Figure 2b.

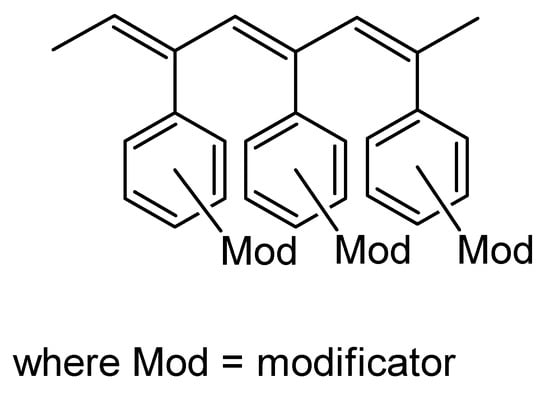

The –PhC≡CH substituents are present in all types of intramolecular structures of DEB polymers in varying amounts. However, only in soluble linear or branched poly-p-DEBs is it possible to carry out an effective, controlled modification reaction. In addition, only in strictly linear DEB polymers, substituents—PhC≡CH should be present in each link of the polymer. Therefore, only in linear modified polymers, in principle, it is possible to realize a structure that is a poly-conjugate chain, along which there will be sufficiently extended clusters (Figure 3). For the synthesis of such cluster systems, it is possible to use any heteroatoms or molecular fragments introduced by modification reactions listed above (Figure 1 and Figure 2a). Thus, knowledge of the intramolecular structure of DEB polymers is important information necessary to assess the possibility of modification and possible areas of their application.

Figure 3.

Probable structure of a polymer cluster based on linear trans-S-trans poly-DEB.

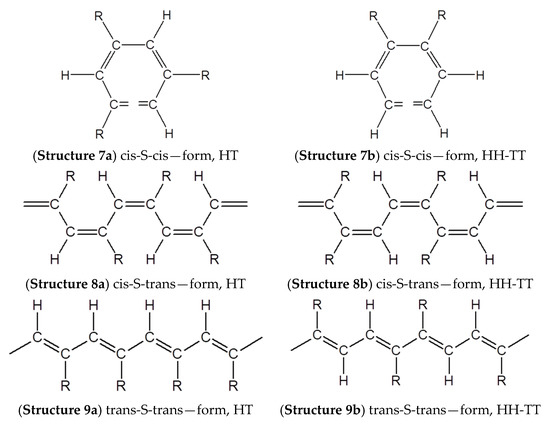

To ensure that all these modification reactions are carried out with the formation of cluster chains along the main linear polyene chain, an additional necessary condition is the absence of defects or small defects in the polymer chains of the polymers used. First of all, there must be strict repeatability of polymer units with 4-ethynylphenyl substituents. In addition, it is necessary to take into account the possibility of connecting links according to the “head-to-tail” and “head-to-head” types. Therefore, the question arises about the possibility or impossibility of synthesizing a completely linear poly-p-DEB and about the structure of its probable stereoisomers.

The review considers all the methods used for the synthesis of polymers of all DEB isomers using polymerization reactions due to the C≡C bond. In necessary cases, to understand the features of the ongoing processes, the results of experiments conducted by the authors of the articles are analyzed in more detail. The probable intramolecular structure of the obtained soluble polymers, including one proposed by the authors of the reviewed articles, is considered and analyzed. The information on possible cis-trans isomers of synthesized poly-DEBs was analyzed. In addition, the proposed applications of these synthesized polymers are considered.

The review does not consider DEB copolymers, which significantly complicate the intramolecular structure of the resulting DEB copolymers. The reactions of DEB homo- and copolycondensation with the formation of ethynylene-phenylene fragments are not considered.

2. Synthesis, Structural Features, and Properties of p-Diethynylbenzene Polymers

2.1. Solid-Phase Polymerization of p-DEB Initiated by Physical Methods of Exposure

Solid-phase polymerization of p-DEB under pressure in combination with shear deformation was studied in [40]. The studies were carried out on Bridgman anvil cells, which makes it possible to obtain pressures up to 10 GPa at various temperatures. The shear stress in the sample was created by rotating one of the anvils relative to the other. It was found that at 2.5 GPa, a temperature of 22 °C, and a shear angle of 800° (2.22 complete turn), explosive polymerization occurred, accompanied by the formation of a black insoluble polymer. At a temperature of 22 °C, a shear angle of 0°, and pressures of 2.5 and 5.0 GPa, the polymer yield was 1 and 5%, respectively. The authors did not report anything about the solubility and intramolecular structure of these polymers. However, taking into account the available information about p-DEB polymers, it should be agreed that this polymer had a frequently crosslinked structure.

In article [41], it was first recorded that the crystals of p-DEB under UV or γ-irradiation in quartz cuvettes at 77 °K or at room temperature for at least 10 h acquire a yellow color. At the same time, the crystals did not change their shape, size, and surface. One of the two types of crystals formed, the darker one, showed strong dichroism. At room temperature, the irradiation was much more effective than at 77 °K. Mainly crosslinked insoluble products were formed. The soluble fraction was ≈10%. Based on optical measurements, the authors assumed that the polymer molecules formed consist of approximately 14 monomeric units. As one of the variants of the polymer chain structure, the authors proposed a linear polyene, because, in their opinion, “anisotropic absorption can be observed if predominantly one acetylene radical in each DEB molecule is involved in the polymerization reaction”. The authors consider that the reason for the termination of the photopolymerization process is the accumulation of mechanical stresses, which limit the conversion rate. However, in their opinion, the growing polymer chain does not lead to a violation of the crystal lattice of the monomer. Unfortunately, the intramolecular structure of the fractions has not been studied by any physicochemical methods, such as NMR and IR spectroscopy or the study of molecular weight distribution. The scheme of possible chain growth presented by the authors (Figure 4) is not correct, since it has an image of pentavalent carbon.

Figure 4.

The scheme of possible poly-p-DEB grew from article [41] with translated captures. Reprinted with permission from Broude, V.L. (1968). Copyright 1968 Institute of Chemical Physics RAS.

Later, a large series of articles by this group of authors was devoted to a more detailed EPR study of low-temperature (4.2–340 °K) solid-phase polymerization of crystalline p-DEB initiated by UV irradiation [42,43,44,45,46] or γ-irradiation [44,45,46,47,48]. It was found that after the termination of irradiation, the opening of the cuvettes, and the volatilization of the unreacted monomer, insoluble products remain in the main. This indirectly indicated the initial branched nature of macromolecules, although no studies of the intramolecular structure were carried out. Later, this group of authors used EPR and optical spectroscopy in the temperature range of 77–230 °K to study the generated macroradical in more detail. According to the authors, in this polymer, an unpaired electron is localized on the terminal monomeric unit of a stereoregular polymer. At 230–310 °K, its delocalization in the poly-conjugated system occurred due to the addition of a linear macroradical to the double bond of the polymer molecule. The reaction produces a branched polymer of p-DEB. Subsequently, crosslinking of polymeric branched chains with the formation of an insoluble polymer took place. The same processes occur in p-DEB, deuterated in the ethynyl group [46,47].

The same authors in [47,48,49] explain the possible reasons for the synthesis of soluble poly-p-DEB with low conversion and low molecular weight. They studied p-DEB samples by EPR after low doses of radiation (D < 500 kGy). The authors believe that at temperatures when the mobility of the polymerizing system increases (heating of irradiated samples at 77 °K; softening of the matrix during the subsequent reaction at T ≥ Troom), the macroradical has the ability to attach to the double bonds of the formed macromolecule. This leads to the formation of short, branched polymer molecules. In addition, the macroradical can “twist”. In this case, conditions are created for the transition of an unpaired electron into the plane of conjugated π-electrons of a macromolecule, where it is delocalized along the π-conjugation chain. These reasons, according to the authors [47,48,49], lead to a loss of macroradical activity, which in turn leads to a decrease in the polymerization rate and a decrease in molecular weight.

After the first report in 1968 [41] on the radiation-induced solid-phase polymerization of p-DEB, a publication appeared [50] on the study of radiation polymerization of p-DEB and some of its derivatives. For this purpose, the authors [50] sealed p-DEB crystals in glass vacuumed (~10−5 torr) ampoules. The ampoules were then irradiated with γ-rays from the 60Co source (dose rate of 9·105 rad/h) for 120 h. The brown poly-p-DEB conversion was 11%. With increasing polymerization time (125 or 150 h) an insoluble fraction appeared, and the amount of the soluble fraction decreased. The authors reported that spectral data were obtained for poly-p-DEB (1H NMR, 13C NMR, and IR spectra). However, the spectra were not given and the intramolecular structure of the polymer was not proposed.

In the article [27], an acetone-soluble prepolymer was synthesized by irradiation of solid p-DEB with 60Co γ-rays at a lower dose (10 kGy, 50 kGy, and 100 kGy) at room temperature. According to the results of mass spectrometry, the prepolymers required to create composites consisted only of dimers, trimers, and unreacted monomers. UV-Vis spectra show that the content of oligomers increases with an increase in the radiation dose. The authors converted these prepolymers into a crosslinked gel state by subsequent heating at 110 °C. Thus, even a branched polymer was not synthesized in the work.

In [48,49], the radical polymerization of p–DEB initiated by γ-radiation in a matrix of a glassy solution in dimethylformamide (DMF) was studied at temperatures of 77 and 300 °K. For the subsequent heating of the irradiated samples at 77 °K, in addition to the traditional heating method, microwave radiation was used. The studies were carried out by methods of EPR spectroscopy, calorimetry, size-exclusive chromatography, and gravimetry. Due to the two ethynyl groups in the monomer molecule, a crosslinked polymer is mainly formed in all experiments. In the case of using a dose of 750 kGy, a soluble polymer with a conversion rate of 4.5% was obtained. The polymer chains contained 4–8 monomeric units and had a fairly wide molecular weight distribution ( = 1.8, where is the weight-average molecular mass, and is the number-average molecular mass), which indicated a significant number of branches. At the end of the polymerization process, there was an increase in the number of closed groups –C≡CH and the regular formation of insoluble fractions. Unfortunately, the intramolecular structure of the soluble part has not been studied by spectral methods.

A low-temperature (100–210 °K) solid-phase polymerization process of p-DEB initiated by chlorine was described in [51]. For this, chlorine was frozen on a crystalline p-DEB at a temperature of 77 °K; then, the temperature was gradually raised to 210 °K at a rate of ~0.3 °K/min. The heating-cooling procedure was repeated. The polymerization process took place at noticeable rates near the melting point of chlorine and accelerated at its melting point. The unreacted monomer and chlorine were removed from the sample by vacuuming. When the procedure was repeated 10 times, a non-volatile product soluble in ethanol was obtained with a yield of ~15%wt. This oligomer had 2–3 units. When the procedure was repeated 20 times, a polymer fraction was also obtained, soluble only in DMF and tetrahydrofuran (THF). The synthesized polymer had 8–9 units and a very wide molecular weight distribution ( = 3.75). In this case, polymerization of p-DEB can occur only due to the presence of two reactive ethynyl groups, while the reaction of phenylacetylene under similar conditions led to the formation of only dimers [51]. The authors believed that branched poly-p-DEB is formed as a result of the reaction of a growing macroradical with the polyene chain of the formed polymer, as they had previously observed during UV- and γ-initiated solid-phase DEB polymerization [44,45,46,47,48,49]. Unfortunately, when discussing IR spectra, the authors did not even qualitatively analyze the areas of oscillations in the C≡CH group, let alone a quantitative analysis of the dynamics of changes in these groups. In all cases, all fractions contained chlorine in an amount of ~40–50%wt. The IR spectra showed bands at 738, 786, and 878 cm−1 characteristic of the C–Cl bond, but the authors did not indicate possible places of chlorine addition.

The mechanism of polymerization of acetylenes by molecular chlorine at low temperatures is considered in more detail in [52,53]. It is shown that without external energy influence, radicals are spontaneously formed. The formed radicals initiate polymerization and chlorination reactions of p-DEB, which occur when prepared at 77 °K mixtures are heated. The features of the intramolecular structure are not discussed in any way, and when discussing IR spectra, the characteristic bands of C≡C and C–H bonds in the –C≡C–H group are not even mentioned.

The depositions of p-DEB in an ultrahigh vacuum on Cu(111) substrates and subsequent annealing at temperatures from 175 to 350 °C were studied in [54]. Annealing of self-assembled DEB structures led to surface covalent aggregates and meshes that did not have a linear chain structure.

2.2. Gas-Phase Polymerization of p-DEB

The process of frontal polymerization of p-DEB occurring as a result of high-temperature initiation at elevated nitrogen pressure (P = 2–6 MPa) in a standard Crawford bomb has been studied in [55]. Thermal initiation of the process was carried out using a nichrome coil when an alternating current of 8 V was applied to it. According to the authors [55], after that, the process of intense evaporation began, followed by rapid polymerization of p-DEB in the gas phase. Due to the high thermal effect of polymerization, the temperature in the reactor remains high even after the thermal initiation impulse is switched off. The p-DEB has a low melting and boiling points, as well as high volatility. Therefore, after evaporation and polymerization of the first upper layer, each subsequent layer of p-DEB also evaporated and polymerized in the gas phase. As a result, an insoluble crosslinked polymer in the form of a black cylindrical rod was obtained. As a result of the Raman spectrum analysis, the authors assumed that the polymer had a graphite structure. Using SEM, microspheres were imaged with a rather narrow size distribution and with an average diameter of 100–200 nm. It is not excluded that in this case, condensation of p-DEB vapors into the liquid phase and subsequent liquid-phase polymerization in the melt at a high temperature may occur, similar to [56].

2.3. Liquid-Phase Polymerization of p-DEB without the Use of Catalysts

Liquid-phase polymerization is the method that, in principle, makes it possible to obtain poly-p-DEB in sufficient quantities and a controlled structure to create the required final materials.

Heating (100–280 °C) in sealed ampoules in an argon medium of mixtures of p-DEB and polynaphthalene, anthracene, and polynaphthalene copolymer with benzene [57] and with polyphenylene (1/2 wt.) [58] led to the formation of either soluble or insoluble products. According to the authors (in accordance with the IR spectra), depending on the experimental conditions, p-DEB was grafted to polyarylenes (soluble products were obtained) or polyarylenes were crosslinked with grafted p-DEB with the formation of trans-vinyl bridges.

The possibility of using p-DEB as a dispersant of solid fuels in a ramjet engine is considered in [59,60]. For this, the kinetics of heat release during its thermally initiated polymerization under isothermal conditions in the temperature range of 90–150 °C-steam in a Crawford bomb at an initial pressure of 2 MPa has been studied.

Apparently, the first attempt at liquid-phase homopolymerization of p-DEB in a melt was described in [56,61] in 1967. The authors polymerized DEB in sealed ampoules in a melt under argon for 6 h at temperatures of 100–185 °C, always obtaining a dark insoluble product. The intramolecular structure of polymers has not been investigated.

The thermal curing reaction of p-DEB was studied in [62] by comparing the activation energies of the thermal curing reactions of various acetylene monomers. p-DEB as one of the objects of comparison is considered together with other acetylene monomers: o- and m-DEB, 1,2,4- and 1,3,5-triethynylbenzenes, as well as 1,2,4,5-tetraethynylbenzene. The aim of the work was to obtain complete information about the features of the curing processes of individual phenylacetylene monomers and their various compositions in the synthesis of resins with terminal acetylene groups (PAA resins). This work did not consider the structural features of the products obtained.

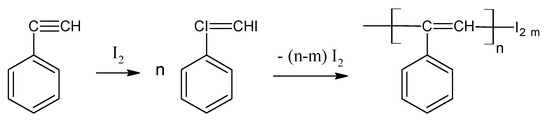

Interaction in a sealed degassed ampoule of p-DEB with iodine (DEB/iodine = 1/1 mol) at 130 °C for 6 h produced a yellow polymer containing 60–68% iodine and soluble in benzene and chloroform [63]. A solid insoluble polymer block was obtained at a ratio of p-DEB/iodine ≤ 1/0.7 mol. Increasing the heating time also resulted in the formation of an insoluble polymer.

The authors believe that the polymerization mechanism first involves the process of halogenation, and then dehalopolycondensation in accordance with the scheme (Figure 5) on the example of polymerization of a structural analog—phenylacetylene.

Figure 5.

The scheme of dehalopolycondensation. Reprinted with permission from Ref. [63] Copyright 1989 Elsevier.

Based on IR (including strong bond νC–I = 595 cm−1) and 1H-NMR spectra, the authors propose a branched structure of soluble poly-p-DEB (Figure 6a).

Figure 6.

(a) The schemes of p-diethinylbenzene structure, where n >> m,p; (b) The schemes of polymer complex formation. Reprinted with permission from Ref. [63] Copyright 1989 Elsevier.

Films made of soluble poly-p-DEB had σ20 = 10−10 Ω−1cm−1. After heat treatment at 130 °C, the polymer became insoluble. The iodine content decreased to 27%, and the absorption bands characteristic of C–I and C≡C bonds disappeared. The authors explained this by the process of disappearance of links with substituents –CI=CHI in accordance with the scheme shown in Figure 6b.

After boiling a 15% solution of p-DEB in DMF (b.p.= 153 °C) in a nitrogen atmosphere for 48 h, a polymer with a conversion rate of 29% and = 1459 was obtained [64]. An increase in the time of thermal polymerization to 49 h led to the formation of a gel. Based on the results of IR and NMR spectra, the authors believed that the polymer had a branched structure. The curing of poly-p-DEB was studied using dynamic and isothermal differential scanning calorimetry (DSC).

In the case of irradiation with UV light or γ-60Co (≈2 Mrad) by radiation of p-DEB solutions in ethanol (10 mmol/mol) at 77 and 300 °K, the samples, respectively, remained colorless or slightly yellow. This indicated the absence of the polymerization process of the monomer in solution under the influence of the radiation used [41,45].

Taking into account the reaction schemes given in [65], p-DEB was used in this work to create a prepolymer preliminarily. The method of creating a prepolymer is not given in full. The process of gel formation (temperature 100 °C) is unclear in the absence of any solvent since it is known that pyrolysis of p-DEB at this temperature leads to an insoluble solid product [56,61,62]. Subsequently, the prepolymer was used to create compositions with fir powder. The structure of the prepolymer is not investigated or discussed by the authors. The reaction schemes suggest the probable structure of the crosslinked product. However, these structural elements are most likely characteristic of polymers based on o-DEB and m-DEB.

2.4. Liquid-Phase Polymerization of p-DEB with the Use of Catalysts

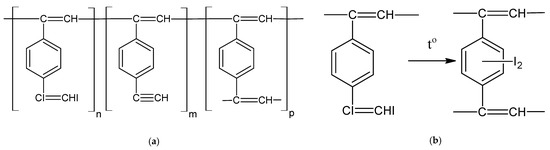

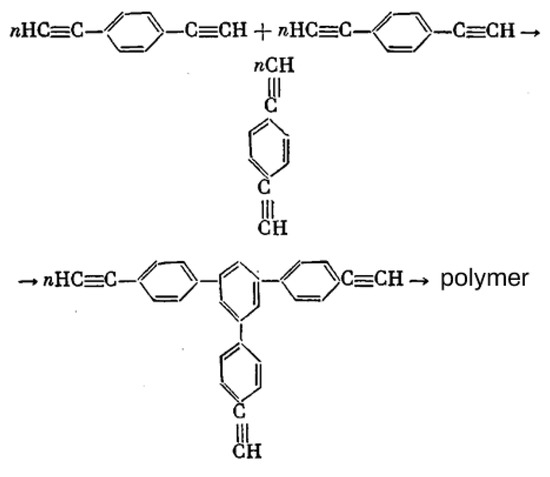

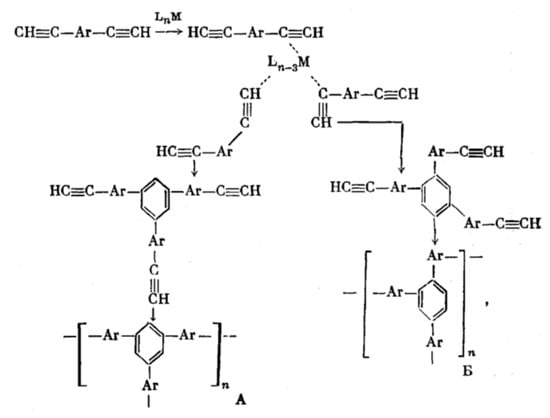

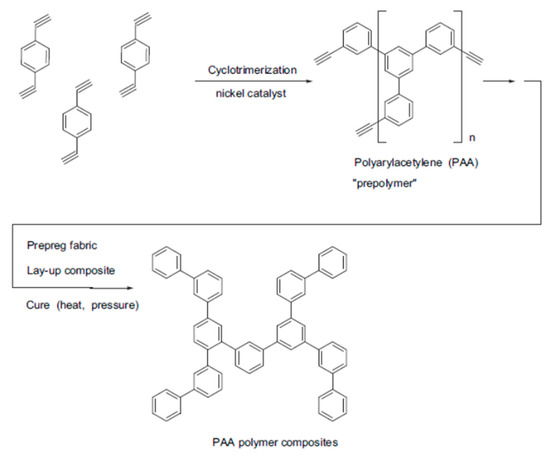

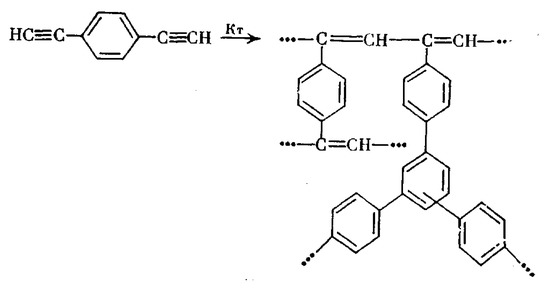

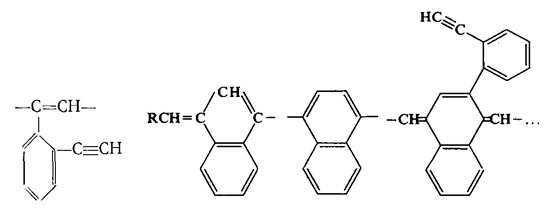

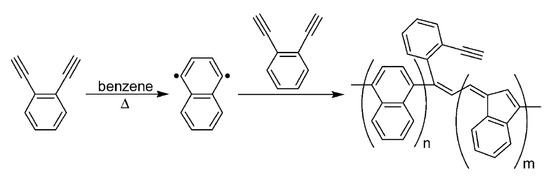

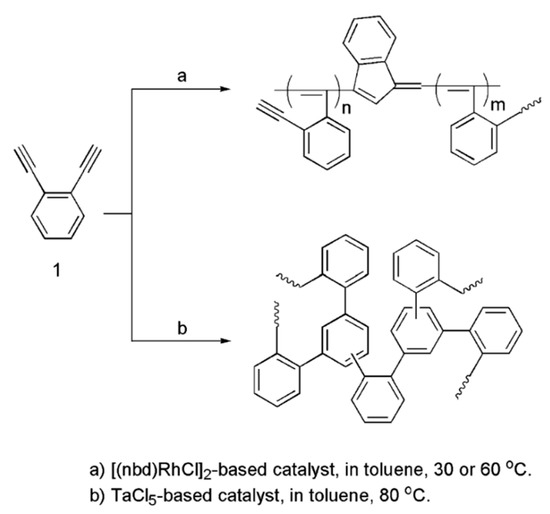

The first attempts at a liquid-phase synthesis of poly-p-DEB in the presence of catalytic systems are described in the patent [66] and in articles [67,68,69,70,71]. It was reported in [68,69] that in the presence of the iso-(C4H9)3Al—TiCl4 complex (Al/Ti = 0.5), an insoluble polymer is formed in 6 h with a yield of 40%. In [70], they only state the fact of the formation of an insoluble polymer in the presence of iso-(C4H9)3Al and TiCl4 without specifying any polymerization conditions. Nevertheless, the authors [70,72] believed that 1,2,4- or 1,3,5-cyclotrimerization of p-DEB occurs first, as was observed in the case of phenylacetylene [73]. Subsequently, the polymer mesh is formed according to the scheme (Figure 7).

Figure 7.

The schemes of polymer mesh formation from [70] with translated captures. Reprinted with permission from Korshak, V.V. (1972). Copyright 1972 Institute of Organoelement Compounds RAS.

The patent [66] reported on the polycyclotrimerization reaction of diethynylarylenes using catalysts , (where R = AlkC≤6, Hal = Cl, Br, I). The goal is the synthesis of thermosetting polymers cured at 150–200 °C. However, only one example describes the synthesis of poly-p-DEB only in the presence of triethyl phosphate cobalt iodide complex . The yield of the insoluble polymer was 70.6% for 1 h in boiling ethanol. The IR spectrum of the crosslinked polyphenyl product shows the presence of trisubstituted benzene nuclei in the polymer molecule (at 810–850 cm−1).

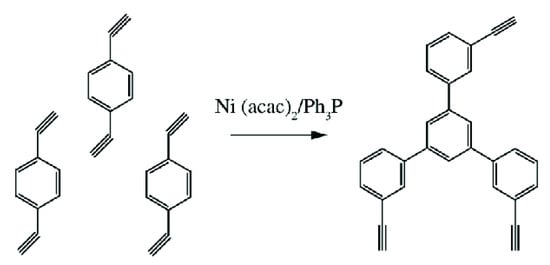

The studies [67,74] report on the continuation of studies on the homopolymerization of diethynylarylenes, including p-DEB, in the presence of various complex cobalt catalysts. Apparently, the catalyst was the complex mentioned in [66]. According to the authors, highly crosslinked polyphenylenes are formed by the mechanism of polycyclotrimerization with the formation of 1,3,5- and 1,2,4 (98%)-substituted phenylene fragments (Figure 8). At the same time, ≡CH proton signals almost completely disappear in the 1H-NMR spectra.

Figure 8.

The schemes of the mechanism of polycyclotrimerization with the formation of 1,3,5- and 1,2,4 (98%)-substituted phenylene fragments from [74] with translated captures. Reprinted with permission from Korshak, V.V. (1971). Copyright 1971 Institute of Organoelement Compounds RAS.

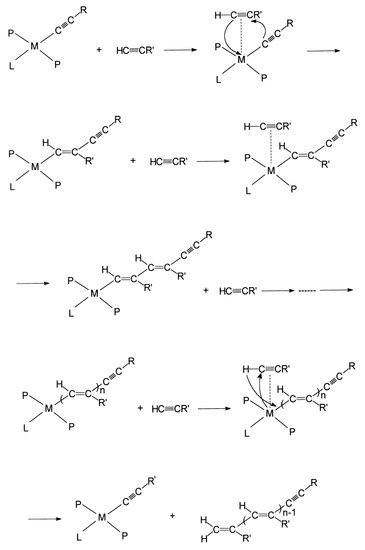

The article [75] reports on the approbation of a larger number of the same trialkylphosphate complexes of cobalt. However, the kinetic features of p-DEB polymerization are considered in the presence of only one trialkylphosphite complex of cobalt . The reaction was carried out in a solution of benzene, toluene, dioxane, or alcohol in an inert gas medium at temperatures of 50–100 °C. The total yield of non-soluble products varied in the range of 15–68%, and the total yield of soluble products was 20–44%. The molecular weight of soluble branched polymers of p-DEB reached 2600. NMR spectra showed that during polymerization, the number of ethynyl group protons gradually decreases so that by the end of the reaction, the ratio of the total number of olefin and aromatic protons to ethynyl protons is 1. This indicated the presence of branches in the polymer. The authors proposed a scheme for the polycyclotrimerization of p-DEB through the formation of a complex of three ethynyl groups with a transition metal atom (Figure 9), although they also allowed for other intermediate stages.

Figure 9.

The schemes the formation of a complex of three ethynyl groups with a transition metal atom from [75], where M is transition metal atom, L is ligands. Reprinted with permission from Korshak, V.V. (1973). Copyright 1973 Institute of Organoelement Compounds RAS.

The structure of highly branched polyphenylene for poly-p-DEB (Figure 9) synthesized using complexes and proposed in [66,67,74,75], was confirmed in [76], who studied the thermal characteristics of poly-p-DEB, and in a series of reviews [71,77,78,79].

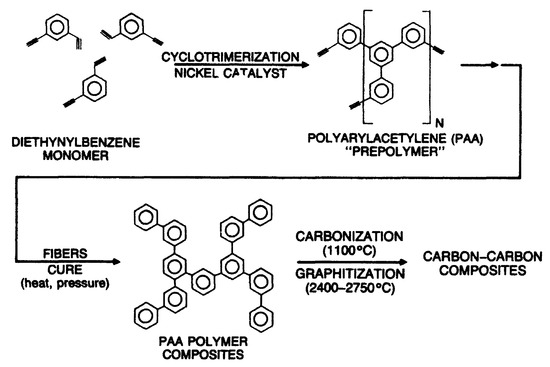

A large number of publications have been devoted to the polymerization of p-DEB in the presence of the nickel acetylacetonate/triphenylphosphine complex. In some examples of early patents [80,81,82,83], the synthesis of poly-p-DEB in N2 medium in a solution of anhydrous dioxane with a conversion of 57% was reported. The polymer is recommended to be used in compositions when creating carbon materials. Poly-p-DEB had = 2900. For synthesis, 71 parts of p-DEB, 1.062 parts of , 2.124 parts of Ph3P and 737 parts of anhydrous dioxane were loaded into the reactor. The authors of this review recalculated the mass fractions into molars in order to compare these indicators with those indicated in subsequent publications. The ratio of the values of p-DEB/Ni(Acac)/Ph3P = 137/1/2 was obtained. According to the NMR spectrum (the spectrum is not shown), the branched polymer molecules had phenylene fragments. The prepolymer contained 15.0% acetylene groups. A significant excess of the number of aromatic protons compared to the number of acetylene protons in poly-p-DEB indicated the formation of such protons due to the effective polycyclotrimerization reaction of ethynyl groups in the presence of a catalyst. However, the phrase of the authors (“Analysis by NMR as described above showed the prepolymer to have a ratio of aromatic protons to olefinic protons of greater than 30/1”) is surprising, because in PMR spectra these protons are not distinguishable. The authors probably meant acetylene protons, not olefin protons.

A group of authors in later publications [84,85,86,87,88] studied the polymerization of p-DEB in the presence of the same catalyst under various conditions: component ratio, solvent type, temperature, and effect of LiCl addition. The purpose of the research is to develop conditions for the synthesis of poly-p-DEB, capable of forming heat-resistant and easily carbonized fibers from it. The process of poly-p-DEB synthesis was carried out in a medium of dry polar solvents (DMF, DMA, or N-MP) at temperatures of 70–120 °C for 1–9 h in an inert gas medium. The conversion reached 96%. The polymer solution was subjected to preliminary structuring by heating it at 100 °C for 6 h. Then it was molded into an aqueous precipitation bath through a spinneret having 300 holes with a diameter of 0.05 mm. The fiber dried at 50 °C was subjected to heat treatment up to 250 °C at a heating rate of 5 °C/min. As a result, the authors obtained an elementary fiber with a diameter of 0.025 mm and a strength of 21–27 kg/mm2.

The patent [84] shows the only used ratio of the components of the catalytic complex = 1/2. A later patent [85] indicated a different ratio of the components of the reaction system, which was changed in the intervals of DEB/ = 1.4–1.6/0.1–0.12/0.005–0.006 mol/L. An increase in the conversion of p-DEB was noted [87] due to an increase in the concentration of Ph3P in the reaction medium and in the case of the addition of LiCl. The polymer yield was quantitative at a ratio of DEB/ = 313/1/20 mol/L. According to the authors [86], polymerization occurred with the formation of an intermediate active center—hydride acetylenide (Figure 10a)—and therefore poly-p-DEB has a linear structure of non-branched polyene (Figure 10b). The authors substantiated this assumption by comparing the intensities of the bands of phenyl (1510 cm−1) and ethynyl (3300 cm−1) groups in the IR spectra of p-DEB and poly-p-DEB [87].

Figure 10.

(a) intermediate active center—hydride acetylenide (b) linear structure of non-branched polyene in poly-p-DEB (c) trans-polyene structure with a certain number of side groups.

Unfortunately, in this article, the corresponding IR spectra were not given and the NMR spectra of poly-p-DEB were not taken, which would make it possible to determine the intramolecular structure of the polymer. Later, these authors reported in an article [30] that under the previously used [85,87] synthesis conditions, polymers are formed that “have a predominantly linear structure with a trans-transoid conformation and contain free ethynyl groups on almost every aromatic nucleus”. That is, in fact, the synthesized polymer had a certain number of branches in the main chain.

Thus, the intramolecular structure of poly-p-DEB proposed in [30,87] differs from the structure proposed in [80,83]. A possible reason may be the difference in the conditions of the p-DEB polymerization reaction. Indeed, our recalculation of the mass loading of components indicated in [80,83] for loading in the molar ratio gave the following values: = 2/1. On the other hand, in [85] a different ratio of these components was used during polymerization, as indicated above. Unfortunately, [87] it is not indicated under what specific conditions poly-p-DEB was obtained, the IR spectrum of which was studied.

In an article that appeared much later [64], the authors argued that when using the same complex catalyst, the main reaction should be polycyclotrimerization of p-DEB, proceeding according to the scheme in Figure 11. However, in the polymerization scheme (Figure 11), the authors, probably mistakenly, depicted a cyclotrimer obtained from m-DEB and not from the original p-DEB.

Figure 11.

Synthesis of cyclotrimerized PAA prepolymer and subsequent processing steps to produce PAA polymer composites. Reprinted with permission from [64] Copyright 2009 Elsevier Ltd.

The authors of this article [64] allowed a small part of the reactions to occur with the formation of linear and/or branched structures. As a result of the reaction, a soluble prepolymer was formed for 3 h with a yield of 79% and a value of 1875. It was shown that the Ni-catalyzed polymerization of diethynylbenzene is an effective way to synthesize prepolymers needed to produce composites. An increase in the polymerization time to 3.5 h led to the formation of a gel. The FT-IR spectra of soluble catalytic and thermal prepolymers showed characteristic bond vibrations of acetylene groups at 3300 cm−1 (stretching ≡C–H) and 2106 cm−1 (stretching C≡CH), respectively. The 1H-NMR spectra show the same signals, which differ in intensity for some protons, including acetylene protons (≡C–H) at 3.1–3.3 ppm. The authors believed that the spectra indicate the realization of a branched structure with the preservation of part of the groups –C≡CH. It is this structure that ensures the formation of gels when certain polymerization times are reached. Unfortunately, the absence of integral 1H-NMR spectra did not allow us to confirm this ratio of different types of units. The purpose carried out by the authors’ research is to study the curing process of poly-p-DEB, which is a good resin for creating carbon matrices. Using dynamic and isothermic DSC, it was found that the exothermic crosslinking process began at 120 °C, reached a maximum at 210 °C, and ended at 300 °C. More than 85% of –C≡CH groups reacted during curing. For comparison, thermal poly-p-DEB synthesized by boiling a solution of p-DEB in DMF was studied. It was found that the coke residue of catalytic poly-p-DEB (pyrolysis at 800 °C) was 79–86%. On the contrary, the coke residue of thermal poly-p-DEB was only 74%, which the authors explained by the presence of structural defects in polymer chains.

In [89], a soluble prepolymer from p-DEB was synthesized using 13, 16 and 19%wt. of the same catalyst according to the method taken from [64]. The conversion of the soluble polymer was 77% for 2 h (19%wt. of the catalyst), without reaching the gelation region. The prepolymer was evaluated as a polymeric precursor of monolithic vitreous carbon. Based on 1H-NMR spectra, the authors confirmed the presence of a branched polyphenylene structure. However, in the polymerization scheme (Figure 12), taken from [64], the authors also mistakenly depicted a cyclotrimer obtained from three m-DEB molecules.

Figure 12.

Cyclotrimerization reaction of 1,4-diethynylbenzene. Reprinted with permission from Oishi, S.S. (2014). Copyright 2014 Oishi S.S.

Indeed, the resin synthesized from a mixture of p- and m-DEP in the presence of or complexes is also formed due to the cyclotrimerization process (Figure 13) [23]. In addition, the cyclotrimerization of acetylenes in the presence of is indicated by the authors [24] who studied the co-cyclotrimerization of mixtures of DEB and ethylphenylacetylene isomers and proposed the branched cyclotrimer structure.

Figure 13.

The structure of p-DEB oligomers. Reprinted with permission from [23]. Copyright 2007 Taylor & Francis.

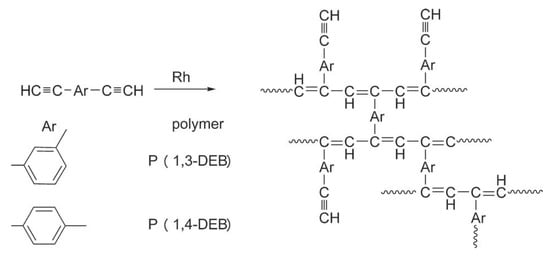

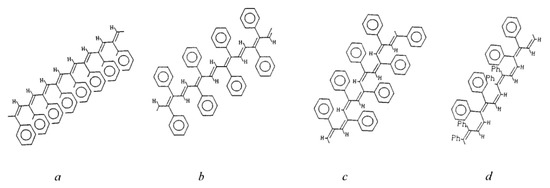

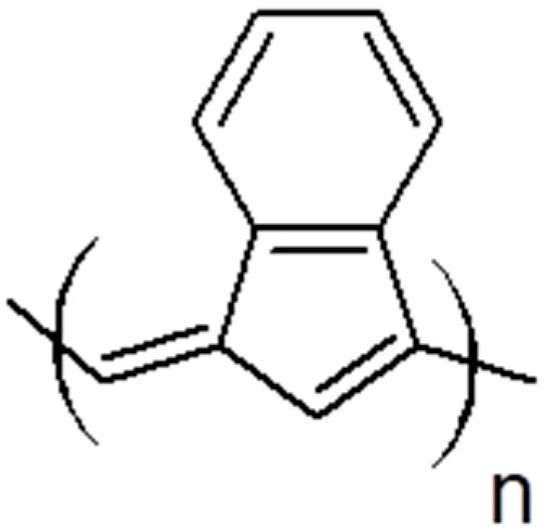

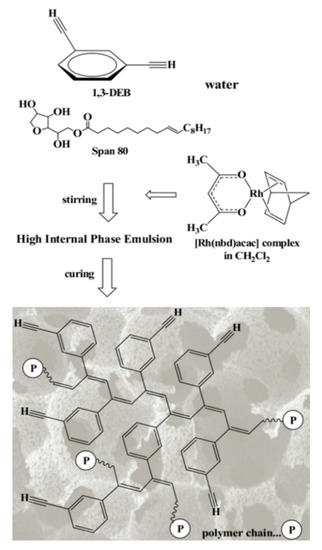

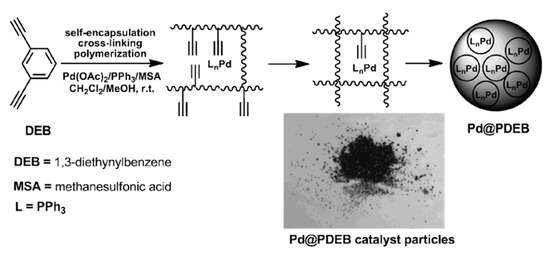

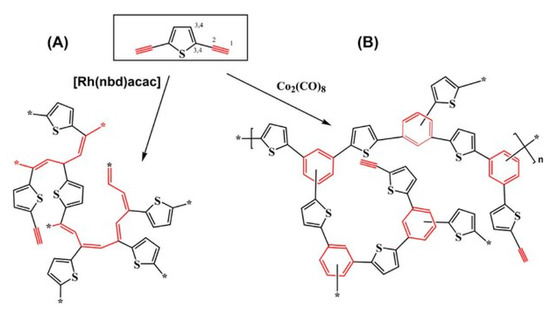

During polymerization of p-DEB and other diethynylaromatic monomers in the presence of rhodium catalysts [Rh(cod)ac] and [Rh(nbd)acac] (cod: cycloocta-1,5-diene; nbd: norborna-2,5-diene; acac: acetylacetone) in the medium of CH2Cl2, the authors [14] synthesized insoluble microporous polymers with yields of 80 and 85%, respectively. The polymers had SBET values of 512 and 809 m2 g−1, respectively, and a micropore volume of 0.160 and 0.247 cm3 g−1. The adsorption of H2 on polymers was reversible, in contrast to nitrogen adsorption. This allowed the authors to consider it possible to optimize the physical properties of polymers in order to create materials for gas storage. Using the SEC and 13C CP/MAS NMR spectroscopy, it was found that the polymer consisted of polyene conjugated meshes with ethynylarylene substituents and crosslinked with arylene linkers (Figure 14).

Figure 14.

Synthesis of polyacetylene-type microporous organic polymers. Reprinted with permission from [14]. Copyright 2011 John Wiley and Sons, Inc.

The soluble polymer was obtained only in the presence of a [Rh(nbd)acac] catalyst after 2–3 min (no more!) after the start of synthesis. The authors found that this poly-DEB was highly branched or partially crosslinked even at the beginning of its formation.

In a later article [15], the authors investigated the effect of reaction conditions (type of catalyst, solvent, temperature, concentration of catalyst, and monomer) on the resulting meshes of poly-p-DEB and the adsorption capacity of synthesized polymers. The use of [Rh(nbd)acac] and [Rh(nbd)Cl]2/Et3N complexes in CH2Cl2 medium provided the synthesis of insoluble, non-swellable crosslinked microporous polymers for 3 h at room temperature with yields of 85 and 77%, respectively. A red precipitate fell out immediately after mixing the reagents, or after a few minutes. An insignificant amount of unreacted –C≡C–H groups remained in the polymers (Figure 15). During the polymerization of p-DEB in the presence of [Rh(nbd)acac], the SBET value of the obtained poly-p-DEB increased depending on the solvent used in the series: THF << pentane < benzene < methanol < CH2Cl2.

Figure 15.

Chain-growth polymerization of DEB with transition metal catalysts. Reprinted with permission [15]. Copyright 2014 John Wiley and Sons, Inc.

The SBET value increased with increasing reaction time and temperature, as well as with an increase in the initial concentration of the monomer. The maximum value of SBET = 1469 m2g−1 was obtained for poly-p-DEB synthesized using [Rh(nbd)ac ac] in CH2Cl2 for 72 h at 75 °C. The diameter of the micropores was about 1 nm. In addition to micropores, poly-p-DEB contained mesopores. The heat treatment of poly-p-DEB at 280 °C caused the complete disappearance of the –C≡CH side groups with the formation of new crosslinking. The heat-treated poly-p-DEB showed a higher adsorption capacity for H2 and CO2 compared to the non-thermalized polymer. At the same time, metathesis catalysts (WCl6/Ph4Sn, MoCl5/Ph4Sn, Mo-carbene) proved to be ineffective in polymerization in benzene solution at room temperature and reaction time up to 24 h, demonstrating a conversion of 39, 2, and 11%, respectively.

The ability of numerous low molecular weight acetylene compounds (including 1,3- and 1,4-diethynylbenzenes) to catalyze model acetylation and esterification reactions was analyzed in [90]. The authors argued that acidic hydrogen of ethynyl groups –C≡CH is capable of carrying out acetylation and esterification reactions, usually catalyzed by acid. The logical development of these studies is the study of the catalytic activity of polymers having –C≡CH groups [91]. In the article, the authors [91] for the first time proved the principal possibility of the catalytic activity of this insoluble, non-swellable, super-crosslinked red poly-p-DEB with a constant micro/mesoporous structure and a specific surface area SBET up to 1007 m2g−1. The synthesis was carried out in the presence of a catalyst [Rh(nbd)acac] in accordance with the methodology [15]. Part of the groups –C≡CH was not polymerized and remained free (0.4 per monomer unit). Due to the weakly acidic hydrogen atoms of these unreacted ethynyl groups, the polymer should have been active in acid-catalyzed reactions. The authors evaluated the heterogeneous catalytic activity of the acidic acetylene hydrogen using the acetylation reaction by methanol of five aldehydes and two ketones at 60 °C. The conversion was 0.5–48% for 0.25 h and 14–49% for 7 h. The control experiment showed that polyphenylacetylene, a structural analog of poly-p-DEB, that does not have groups –C≡CH, did not activate this reaction. On the other hand, monomeric phenylacetylene catalyzed a homogeneous acetylation reaction of isopentanal with methanol with a conversion of 8%. However, the catalytic activity of phenylacetylene was naturally lower than that of poly-DEB (32%). This was explained by the lower acidity of the acetylene hydrogen atom of phenylacetylene, compared with the acidity of the acetylene hydrogen atoms present in the side substituents –PhC≡CH conjugated poly-p-DEB.

In the review devoted to the use of rhodium catalysts for the polymerization of various mono- and diacetylenes, including p-DEB [9], the main types of Rh-based catalysts, including those immobilized on both organic and silicon carriers, were considered. The review indicates that during the polymerization of various diethynylarenes, strongly crosslinked polyacetylene meshes were formed.

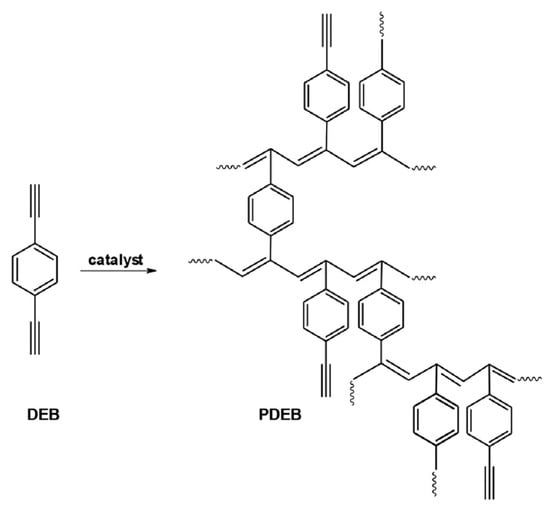

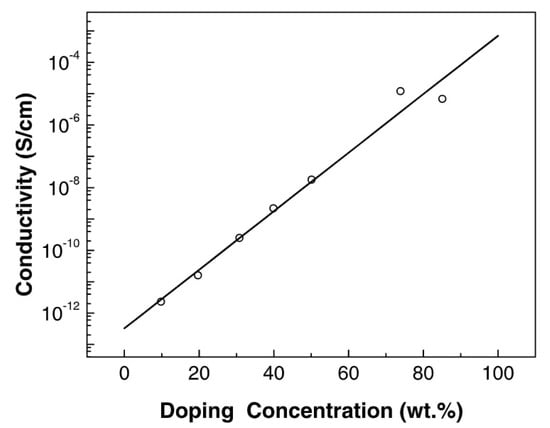

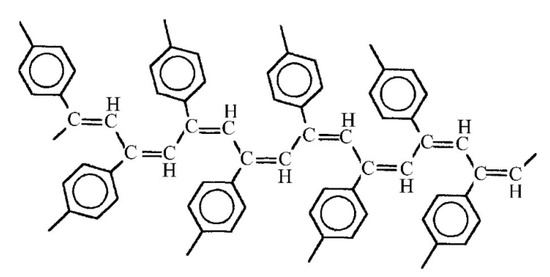

In the presence of a complex catalyst in a mixture of solvents dioxane-toluene (1/1 by volume) in an atmosphere of N2 at 25 °C for 6 h with a conversion of 70%, soluble poly-p-DEB having = 3000–30,000 was obtained [92]. The synthesized polymers had low electronic conductivity. However, in the presence of ambient humidity in tablet samples doped with chloric or sulfuric acids, the conductivity of the samples sharply increased due to proton migration through the material. The authors suggested that the mechanism of charge transfer through materials is based on the proton conductivity of a thin layer of an aqueous acid solution adhering to the polymer grains. It was proposed to use such materials in the development of humidity sensors since the doped polymers showed a reversible change in conductivity depending on humidity. In [93], the same polymer was studied as in [92], but in the form of a film sample applied to a surface acoustic wave (SAW) delay line oscillator. The polymer structure was not given. Poly-p-DEB has shown properties that made it possible to recommend it as a good moisture-sensitive material. The effect of the dopant concentration (HClO4) on the electrical properties and relative humidity of this poly-p-DEB was studied in [94]. The doped poly-p-DEB was characterized using electron spin resonance (ESR), UV-vis, IR, X-ray photoelectron spectroscopy (XPS), and scanning electron microscopy (SEM). The conductivity of the doped polymer increased by 11 orders of magnitude, reached 103 S·cm−1, and increased with an exponential trend depending on relative humidity (below 60%). The authors believed that the formation of a complex with charge transfer of poly-p-DEB with the hydroxonium ion H3O+ took place. This led to the delocalization of the charge of the π-electron along the polymer chain and a decrease in the transition energy of π→π*. A rectilinear dependence of the current (four orders of magnitude) on the relative humidity (10–60%) on a logarithmic scale was found in the doped poly-p-DEB. The authors of all these publications declared the trans-linear structure of the polymer in the absence of any instrumental studies of the intramolecular structure.

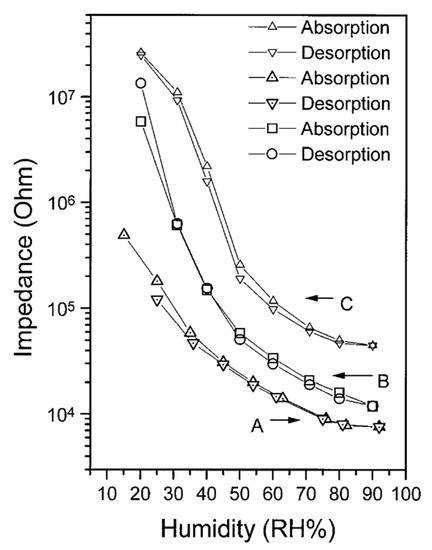

This group of authors in the following article [95] continued the research of poly-p-DEB (catalyst ) as a relative humidity (RH%) sensor. Electrical measurements were carried out on gold electrodes. Thin-film coatings for them were prepared in three ways: (A) a Langmuir-Blodgett (LB) monomolecular layer deposition, (B) spin coating, and (C) transferring PDEB film formed on the water surface. All sensors had a low impedance (in the range of 103–107 Ω in 15–92% RH) and a small hysteresis (Figure 16). However, the sensor manufactured by the LB deposition method had a better response. The authors explained this by the smallest thickness and more ordered structure of the membrane. Using 1H NMR spectroscopy, the authors introduced certainty to the knowledge of the intramolecular structure of the synthesized poly-p-DEB. They attributed a relatively strong signal at 6.85 ppm to trans-polyene protons. The ratio of the sum of olefin and aromatic protons to ethynyl protons was instead of 5/1 for the linear structure. The authors believed that the polymer had a trans-polyene structure with a certain number of side groups, probably in the branched structure in Figure 10c.

Figure 16.

Humidity response of PDEB-based sensors (A, B, and C) prepared with different methods. Reprinted with permission from Ref. [95]. Copyright 1999 John Wiley and Sons, Inc.

In [96], the optical, photoluminescent, and electroluminescent properties of poly-p-DEB synthesized in the presence of the same catalyst and under the conditions specified in [92,93,94] were investigated. Accordingly, the authors [96] declared the linear structure in Figure 10b previously proposed in [94], contrary to the information available in [95] about the presence of a branched structure in Figure 10c. For poly-p-DEB, strong photoluminescence was detected when illuminated by an ultraviolet lamp and experimental single-layer LEDs were manufactured using poly-p-DEB as an emitting layer [96]. This allowed the authors to recommend the polymer as a luminescent material for light-emitting devices. From the results of comparing the absorption spectra of poly-p-DEB, its two derivatives, and polyphenylacetylene, the authors concluded that the aryl group in the side chain has a significant effect on the absorption spectra of poly (phenylacetylene) derivatives. However, this conclusion is in contradiction with the results of the article [57], in which the hyperfine structure of the EPR spectra of nitropolyarylvinylenes, including poly-4-nitrophenyl acetylene, was investigated. The authors believe that there is no interaction between the electrons of the main chain and the pendants in the polymer. Thus, the possible reasons for the spectral differences of polymers synthesized in [96] can be different lengths of polymer chains, different cis- or trans-isomerization, as well as the presence of phenylene fragments in the chain. The conclusions in [96] will be valid provided that the same structure of the main polymer chains of the studied polymers is proved, which was not proven in this work.

In [97], photoluminescence, electroluminescence, and conductivity of doped (HClO4, H2SO4, HBF4, I2, FeCl3, CH3COOH) poly-p-DEB synthesized in the presence of catalyst and under the conditions specified in [92,93,94] were investigated. However, according to the authors of this article, the polymer has a branched trans-structure (Figure 10c) with ~11,000 and a polydispersity index of 3.0. It was found that the use of HClO4 made it possible to increase the initial conductivity of poly-p-DEB (10−14–10−13 S·cm−1) by 10 orders of magnitude to 6.3·10−3 S·cm−1. Other dopants (H2SO4, CCl3COOH, HBF4, I2, FeCl3, p-CH3-C6H4-COOH, CH3COOH) showed lesser effect.

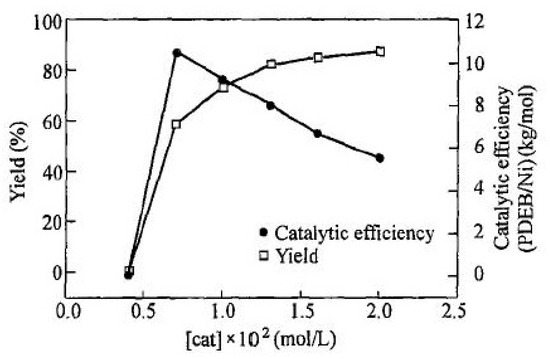

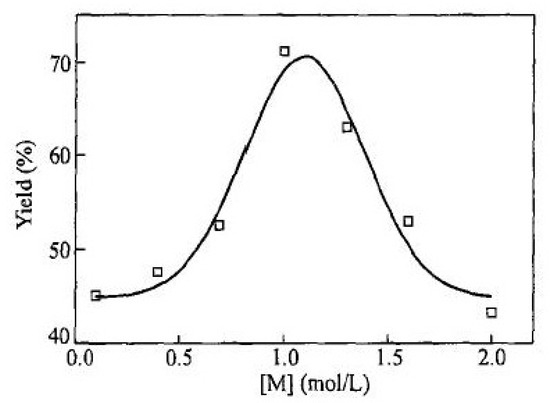

The same opinion about the existence of a branched poly-p-DEB structure is shared by the authors [98] who study the dependence of the conversion, and on various factors: the concentration of the monomer and the catalyst (Figure 17 and Figure 18), temperature (0–50 °C), gas medium (N2, CO2, H2, air), solvent type (1,4-dioxane, DMSO, THF, toluene, benzene, CH2Cl2 etc.), and additives (H2O, EtOH, Et3N, Ph3N). The authors showed that a trans polymer with up to 27,100 has a ratio of , indicating branched chains.

Figure 17.

Effect of catalyst concentration. Conditions: volume ratio of 1,4-dioxane/toluene = 1, [M] = 1.0 mol/L, 25 °C, 6 h. Reprinted with permission from [98]. Copyright 2001 Springer Nature.

Figure 18.

Effect of monomer concentration. Conditions: volume ratio of 1,4-dioxane/toluene = 1, [cat] = 0.01 mol/L, 25 °C, 6 h. Reprinted with permission from [98]. Copyright 2001 Springer Nature.

It was shown in [99] that not only , but also other Ni complexes, including those containing polar acetylides, have catalytic activity with respect to p-DEB (although to a lesser extent). Air-stable complexes , , in a mixture of 1,4-dioxane/toluene (1/1 by volume) were provided the yield of soluble poly-p-DEB 58, 28, and 52% for 10 h (at 25 °C), 48 (60 °C) and 33 (60 °C) hours, respectively. The polymers had = 13,000–28,000. Complexes containing PBu3 ligands showed lower activity than complexes containing PPh3 ligands. The authors attributed this to the higher basicity and interconnected donor capacity of PBu3, which increased the electron density of the metal–carbon bond and reduced the reactivity of this bond. The replacement of Ni by Pd in one of the complexes with the same ligands led to a decrease in the activity of the complex. For the complex, the conversion of 74.4% was achieved at a temperature of 25 °C for 3 h, while for the complex the conversion of 79.9% was achieved at a higher temperature of 60 °C in only 18 h. FT-IR, 1H, and 13C NMR spectroscopy confirmed the branched π-conjugate structure of the polyene chain poly-p-DEB. According to the authors, an additional confirmation is a wide and multimodal molecular mass distribution ( up to 3.0) and small Mark–Houwink constants (a = 0.26).

In [100], the catalytic activity of complex catalysts containing various phosphine and alkynyl ligands was compared: NiL2(C≡CR)2; NiL2(C≡CR)Cl and NiL2Cl2, where L2 = (PPh3)2, (PBu3)2 and Ph2PCH2CH2PPh2; R = p-C6H4C≡CH, C6H5, H, CH2OH, and CH2OCOCH3. Soluble π-conjugated poly-p-DEB with yields up to 95% and up to 48,000 was synthesized in an atmosphere of N2 in a mixture of dioxane/toluene at 25 °C for 3 h. It was found that the activity of nickel acetylides with various phosphine ligands decreased in the sequence: > > . The activity of nickel acetylides containing (PPh3)2 and nonpolar alkynyl ligands is slightly higher than the activity with the polar ligand C≡CCH2OCOCH3. In the case of nickel acetylides containing (PBu3)2, an inverse dependence was generally observed. The complex did not show catalytic activity. The work did not consider the structure of the resulting poly-p-DEB and did not carry out the necessary spectral studies for this.

In [101], the mechanism of polymerization of p-DEB in the presence of was investigated in a mixture of DO/toluene at 60 °C for 48 h. It was shown that additions of the electron donors hydroquinone, NEt3, EtOH, and H2O (electron donor/catalyst = 5 mole ratio) affected the conversion of the monomer, varying in the range of 54–88%. The values of and changed, respectively, in the intervals 1.0–2.7·10−4 and 1.6–8.6. The authors proposed a coordination insertion mechanism by the insertion of monomers into metal–carbon σ-bonds. According to the authors, for a large-sized p-DEB, trans-connection is most appropriate. According to the authors, the chain transfer to the monomer probably occurred during the polymerization of p-DEB. This was indicated by a decrease in the molecular weights and polydispersity index () of the polymer with an increase in the concentration of the monomer. The termination of the polymer chain occurred due to the transfer of acidic hydrogen from the π-bound p-DEB into the growing chain (Figure 19). In accordance with the scheme, an unbranched trans-poly-p-DEB was formed. However, the article does not investigate the intramolecular structure of the polymer by any spectral methods. Moreover, this conclusion contradicted the results of works [97,98,99], the authors of which reported on the branched structure of poly-p-DEB synthesized on a Ni catalyst. Later [102], this group of authors reported on the branched nature of polymer chains of poly-p-DEB obtained under similar conditions.

Figure 19.

Polymerization mechanism of alkynes by transition metal acetylide catalysts. P: PPh3, PBu3, Ph2PCH2CH2PPh2; L: C≡CR, Cl; M: Ni, Pd. Reprinted with permission from [101]. Copyright 2001 Elsevier.

The structure of the initial soluble poly-p-DEB doped with FeCl3, as well as the mechanism of doping were investigated by a set of spectral methods (FT-IR, Raman, UV, 1H, and 13C NMR spectra) in [102]. Doping was carried out through a joint solvent CHCl3. The electrical conductivity of the initial poly-p-DEB was 5.5·10−14 S·cm−1 at room temperature. The addition of 22.6–50.1%wt. FeCl3 to the polymer resulted in an increase in conductivity to 4.0·10−5 S·cm−1. A further increase in the doping concentration led to a drop in conductivity to 6.5·10−6 S·cm−1. According to the authors, this is due to a decrease in the concentration of charge carriers, and not to chlorination (results of XPS and FT-IR spectroscopy). The initial polymer was synthesized in 1,4-dioxane-toluene mixed solvent using in accordance with [98]. The authors of this article [102] have declared a branched structure in Figure 10c for poly-p-DEB, referring to an earlier publication [98]. In the 1H-NMR spectra of this polymer, the ratio was obtained.

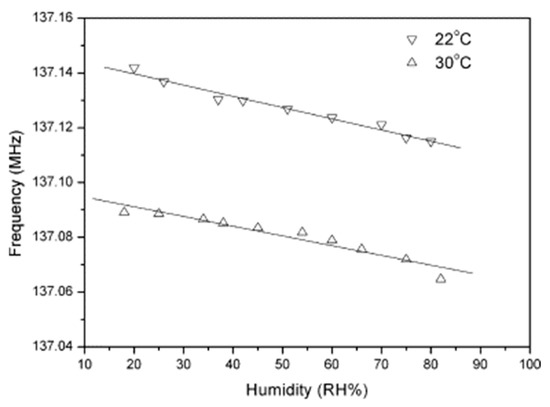

Poly-p-DEB was used to create SAW humidity sensors [103]. The PDEB-based SAW sensor was constructed by applying 10 single-molecule layers of poly-p-DEB on a piezoelectric substrate using the LB method using a polymer solution in CHCl3. The frequency characteristics of the SAW sensors were studied in the temperature range of 30–90 °C in the relative humidity range of 20–85%. A linear decrease in frequency with increasing temperature is detected; at the same time, the dependence of frequency shift on temperature was −5 kHz/°C. Thus, it became necessary to measure temperature and humidity in order to compensate for the influence of temperature on the sensor response. The frequency of the poly-p-DEB sensor decreased almost linearly with increasing humidity in the 20–85% relative humidity range. The sensitivity at 22 and 30 °C was −0.4 and −0.36 kHz/RH%, respectively (Figure 20). The poly-p-DEB sample was synthesized in accordance with [95] in the presence of under an N2 atmosphere for 6 h at 25 °C. That is why it had to have a branched structure in Figure 10c, as was found in an earlier article [95]. However, the authors of this article [103] for some reason indicated the linear structure of the polymer in Figure 3, without confirming this with any additional studies.

Figure 20.

The frequency response to the relative humidity of the SAW sensor based on PDEB at different temperatures. Reprinted with permission from [103]. Copyright 2007 Elsevier.

A series of air- and moisture-resistant nickelocene acetylides catalysts of the general formula (π-C5H5)LNi(C≡CR) (where L = PPh3, PBu3; R = p-C6H4C≡CH, C6H5, H) was studied in [104] during polymerization of p-DEB in DMSO or pyridine at temperatures of 40 or 60 °C for a time of 6 or 24 h. As a result, soluble polymers with a high yield were obtained (19–85.2%), with high values of = 10,500–23,400 and = 2.7–4.3. Complexes containing PPh3 as a ligand were more active than complexes containing PBu3. The authors explained this by the greater basicity and the associated σ-donor ability of PBu3, which increases the density of the electron cloud of the nickel-carbon bond and reduces the reactivity of this bond. The catalytic activity of the complex increased with an increase in the degree of conjugation of the corresponding alkynyl ligand. According to the results of 1H-NMR spectroscopy, the ratio , characteristic of branched poly-p-DEB, was obtained instead of 5/1 for a linear polymer. According to the authors, the branched structure of poly-p-DEB was additionally confirmed by a higher polydispersity index (= 2.7–4.3) and smaller Mark–Houwink constants (value a = 0.26). The presence of cis- or trans-isomers has not been discussed.

In [105], the features of the polymerization of p-DEB in pyridine in the presence of are considered in more detail. The influence of the concentration of monomer and catalyst, gas medium (N2, CO, H2, air, vacuum), temperature (30–50 °C), additives (H2O, EtOH, DMSO, Et3N, hydroquinone, CCl4, Ph3N,), polymerization time (1–18 h) was studied for yield (up to 86%), (up to 55,700) and (1.42–8.21). It should be noted that the addition of CCl4 and Ph3N to the reaction medium, as well as polymerization in the CO medium, completely blocked the polymerization process. Carrying out the reaction in pyridine for 6 h at concentrations of [Cat] = 0.01 mol/L and [M] = 1.5 mol/L led to the appearance of an insoluble fraction (at 45 °C) or even to a loss of solubility (at 50 °C). The trans-polymer had branched macromolecules, which was confirmed by the ratio . The polymer had typical C≡CH group signals in the IR spectra: the νC≡CH band at 3293 cm−1 and the νC≡C band at 2106 cm−1.

The same soluble branched trans-poly-p-DEB synthesized using according to the method [104,105] was used in [106] in the study of its iodine doping. The doping mechanism of poly-p-DEB has been investigated using UV-vis, FT-IR, FIR, Raman, XPS, and ESR spectroscopies. In the EPR spectra, a signal with a g-factor close to the g value of the free electron was observed. The concentration of unpaired spins slightly increased in the doped poly-p-DEB. However, it was less than expected: not every ligand molecule formed one poly-p-DEB radical cation. The authors believed that the formation of sufficiently stable particles occurred during doping. After doping with iodine, the conductivity of poly-p-DEB increased exponentially depending on the doping concentration by several orders of magnitude and reached a value of 10−4 S·cm−1 (Figure 21).

Figure 21.

Conductivity as a function of iodine doping concentration. Reprinted with permission from [106]. Copyright 2002 Elsevier.

The processes of curing soluble homopolymers of p-DEB, m-DEB, and their copolymer, as well as the ongoing structural changes in the polymers, were compared using DSC and FTIR analysis [107]. Poly-p-DEB had a higher curing rate than poly-m-DEB. The authors reported that a “nickel catalyst” was used for polymerization, which, according to the authors, contributed to the formation of a highly branched poly-p-DEB having cis-S-trans polyene fragments and phenylene fragments due to the cyclotrimerization reaction. However, Figure 4 of this article shows only cis-polyene without aromatic fragments (Figure 22).

Figure 22.

Structure of cis-polyene without aromatic fragments. Reprinted with permission from [107]. Copyright 2001 East China University of Science and Technology.

The fact of the formation of cis-polyenes is surprising and of interest, since the widely used and various Ni-containing catalysts Ni(C5H7O2)2 Ph3P, and provide the synthesis of trans-polyenes. The results of any spectral studies of polymers are not given in the article.

In [108], this group of authors studied the rheological properties of arylacetylene prepolymers, probably of the nature that were studied in the previous article [107]. The prepolymers were a Newtonian liquid in the studied temperature range. The viscosity of the prepolymers changed little during 90 min at 60–80 °C, but gradually increased at room temperature.

It was shown in [100] that in the presence of (π-C5H5)(PPh3)NiCl, polymerization of p-DEB proceeded much worse than in the presence of a similar and described above catalyst . Under the same synthesis conditions ([cat] = 0.02 M; [M] = 1.5 M; DMSO; time: 24 h; temperature: 30 °C), the conversion was 6.5 and 42.8%, respectively. The branched π-conjugate polyene structure was indicated by the ratio according to FT-IR and 1H-NMR spectroscopy.

Thus, the analysis of numerous publications devoted to the synthesis and use of the catalyst leads to the final conclusion that the use of this catalyst leads to the synthesis of branched soluble trans-poly-p-DEB structure in Figure 10c.

The influence of ligands on the activity of palladium catalytic complexes was considered in [99,109]. In the presence of and complexes, the conversion of p-DEB was 79.9 and 58.2%, respectively, at 60 °C for 18 h in pyridine. The synthesized poly-p-DEBs had values of = 18,000 and 15,000, respectively, as well as wide = 3.8 and 3.3. At the same time, the substitution of the PPh3 ligand for PBu3 in these complexes led to a complete loss of activity of both catalytic complexes (conversion of 0% even in 88 h). The authors associated this with higher basicity and the interconnected donor capacity of PBu3, which increases the electron density of the metal–carbon bond and reduces the reactivity of this bond. According to the results of FT-IR, 1H, and 13C NMR spectroscopy, the polymers had a branched structure, as in the case of similar nickel-based complexes.

Nonlinear optical properties were studied in [110] using soluble poly-p-DEB synthesized using the complex with a conversion of 80%, probably in pyridine. Poly-p-DEB had = 4670, = 3.77 and had a heat resistance of up to 420 °C. The authors indicated the trans-polyene structure of the branched polymer in the figure but did not provide any evidence for this. Apparently, this statement is true, and the structure of the polymer corresponds to the structure of the polymer synthesized as in [109]. The polymer was characterized by a nonlinear optical susceptibility of the third order χ(3)=6.7·10−13 esu and a second-order hyperpolarizability having γ = 1.8·10−31 esu in the non-resonant region.

The effect of phosphine and alkynyl ligands bound to metal atoms on the polymerization of p-DEB was studied in [111] on the example of PdL2 (C≡CR) catalytic complexes, where (L = PPh3, PBu3; R = p-C6H4C≡CH, C6H5, H, CH2OH, CH2OCOCH3, CH2OCOC6H5, CH2OCOC6H4OH-o) resistant to air and moisture. During 15–18 h at a temperature of 60 °C, the yield of soluble poly-p-DEB reached 56–84% in the presence of palladium complexes containing the PPh3 ligand. Complexes containing the PBu3 ligand were inactive (polymer yield 0%), as in the case of the Ni analog [109]. Complexes containing polar alkynyl ligands were more active than corresponding complexes containing nonpolar ligands. The catalytic activity of complexes containing nonpolar alkynyl ligands increased with an increase in the degree of alkynyl ligand conjugation. The polymers had values of = 1.1–1.8·104 and a wide molecular mass distribution = 2.6–3.8. The authors did not discuss the features of the intramolecular structure of poly-p-DEB, but the polymer chains should be branched since the synthesis was carried out in accordance with [109,110].

The catalytic activity of numerous transition metals of the VIII group in the form of chloride and acetylide complexes ML2(C≡CC6H5)2 and ML2Cl2 (M = Co, Ni, Pd, and Pt; L = PPh3 and PBu3) was compared in [109]. Polymerization of p-DEB was carried out in a medium of various solvents (dioxane/toluene, HNEt2/toluene, DMSO, pyridine), at a temperature of 25–60 °C for 3–24 h. Poly-p-DEB was synthesized with a conversion of 51–90%, = 1.2–2.6·104 and = 1.8–3.2. On the whole, the catalytic activity of the complexes increased in the order Pt < Pd < Ni < Co. It was found that the complexes Pt(PPh3)2Cl2, Pd(PBu3)2Cl2, Pt(PBu3)2Cl2, Pt(PPh3)2(C≡CC6H5)2, Pd(PBu3)2(C≡CC6H5)2, Pt(PBu3)2(C≡CC6H5)2 had no catalytic activity. The structure was determined using IR, 1H, and 13C-NMR spectra. The ratio of olefin and aromatic protons to ethynyl protons was . This indicated the branched nature of polymer chains. The type of transition metals did not affect the structure of trans-polyene branched polymers with side groups p-C6H5C≡CH. In the example of the IR spectrum of poly-p-DEB synthesized in the presence of given in the article, in addition to the band at 3293 cm−1 (νC≡CH), there was a band at 2106 cm−1 (νC≡C).

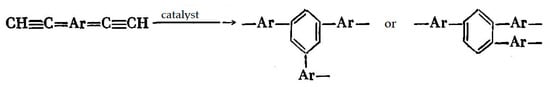

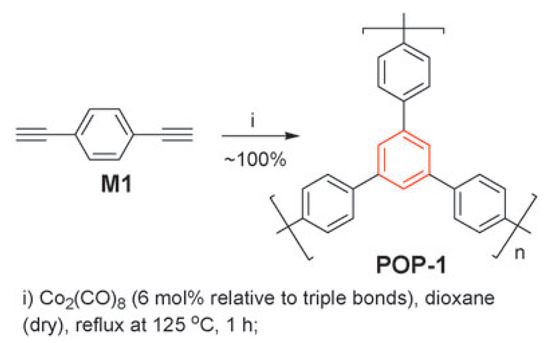

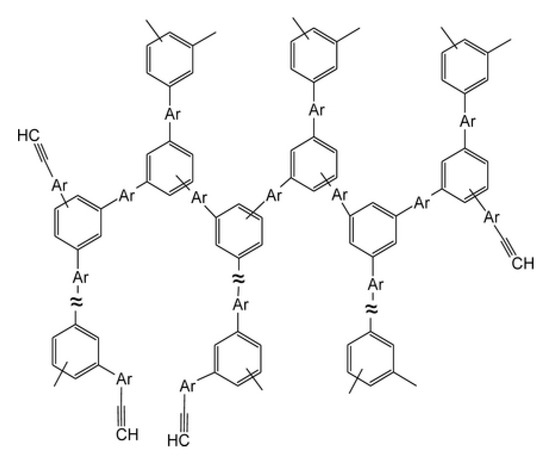

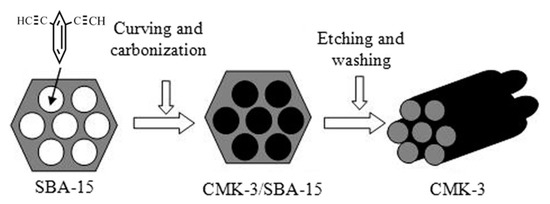

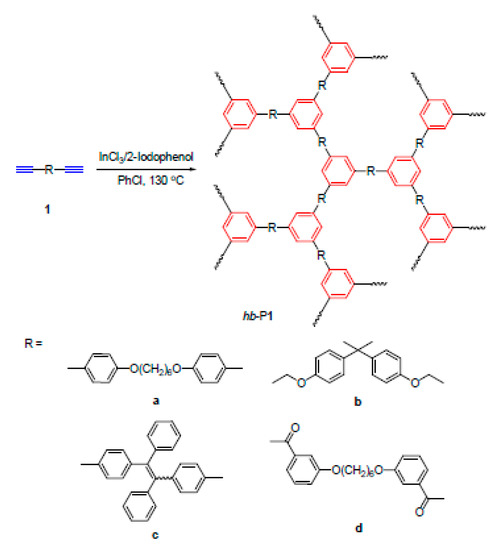

Insoluble cross-linked polycyclotrimers (Figure 23) were obtained with quantitative yield by polycyclotrimerization of p-DEB catalyzed by in anhydrous 1,4-dioxane in an argon atmosphere. The reaction was carried out initially at room temperature with further heating at 125 °C for 1 h [112]. In accordance with the above polymerization scheme (Figure 23), C≡CH bonds disappeared. For this reason, the characteristic vibration band ≡C–H at 3300 cm−1 disappeared for poly-p-DEB. The brown polymer showed no signs of decomposition up to 360 °C and had a BET surface of about 1000 m2g−1, and a pore size of ≈0.83 nm.

Figure 23.

Preparation of POP-1 (benzene in red indicates one of the potential trimerization pathways from ethynyl groups). Reprinted with permission from [112]. Copyright 2010 The Royal Society of Chemistry.

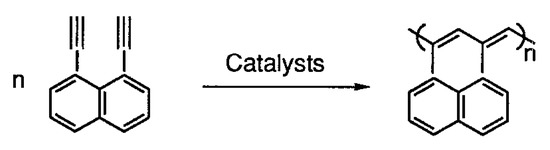

Homopolymerization of p-DEB was carried out on a complex catalyst in benzene, toluene, or N-MP with a conversion of 8–100% [113,114]. At the ratio [M]0/[I]0 = 62, insoluble, brown, paramagnetic polymers were formed between 5 and 120 min. At short polymerization times τ (up to 40 min in boiling benzene), a finely dispersed gel appeared, which was suspended in the reaction system. With an increase in the reaction time, an insoluble product was already formed in the reaction system. An interesting observation was made: polymerization occurred at a high rate exclusively during the boiling of the reaction mixture. If the reaction was carried out at a temperature below the boiling point of the solvent, then the conversion Y was very small (Table 1). If the reaction mixture was sealed into ampoules and heated to the boiling point of benzene, then boiling did not occur due to temperature depression due to an increase in pressure in the ampoule. At the same time, there was no polymerization. From these results, it followed that only boiling can ensure the reaction on this catalyst, apparently due to any cavitation phenomena.

Table 1.

Influence of polymerization conditions by DEB conversion.

According to FT-IR, 1H and 13C-NMR spectra, poly-p-DEB was a polyene with lateral ethynylphenyl substituents, some of which reacted to form a 3D homopolymer grid.

Extremely scarce and contradictory information is given in [115] on the synthesis of insoluble poly-p-DEB in the presence of Nb catalysts. Probably, the polymerization conditions were the same as for the polymerization of α, ω-alkadiynes studied in this article: NbCl5 catalyst; [M]0/[I]0 = 50/1; solvents benzene (toluene); 55–65 °C; N2 atmosphere; polymerization time was 5 h.

Very limited information on the polymerization of p-DEB in the presence of complexes under the action of UV radiation or TaCl5/Ph4Sn is available in [21]. The authors reported that polymerization was fast. The resulting polymer products were completely insoluble due to the presence of crosslinking reactions, which indicated the appearance of branching directly during the polymerization process.

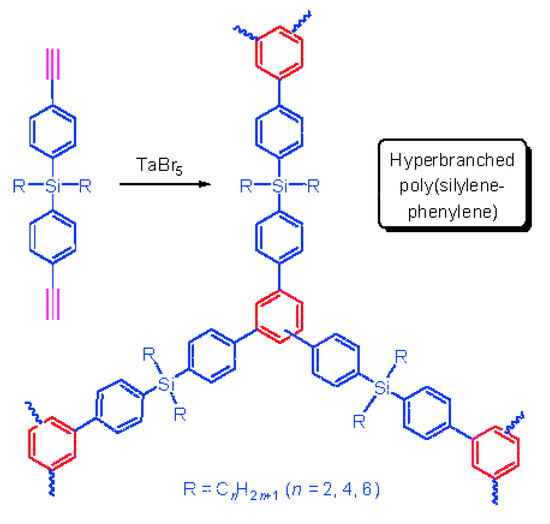

The polymerization of p-DEB in the presence of TaCl5/Ph4Sn is considered in more detail in [116]. The reaction was carried out at an initial ratio of [M]0 = 0.6 mol L−1, [TaCl5]0 = 0.015 mol L−1, [Ph4Sn]0 = 0.015 mol L−1 in benzene at room temperature for 24 h. The conversion rate was 97%. Solid yellow-orange polycyclotrimers did not dissolve in THF, CH2Cl2, CHCl3, and benzene and had a crosslinked structure. The 13C-CP/MAS NMR and IR spectra demonstrated an insignificant number of unreacted groups in the polymer –C≡CH. Signals in the area of 70–85 ppm and bands at 3290 cm−1 (νC≡CH) and 2100 cm−1 (νC≡C) were recorded, respectively. The authors believed that the crosslinking of polymer chains occurred due to the formation of 1,3,5- and 1,2,4-trisubstituted aromatic linkers (Figure 24) since the formation of such trimers occurs during cyclotrimerization of acetylene derivatives in the presence of TaCl5 [117,118].

Figure 24.

The scheme of polycyclotrimers of diethynylarenes. Reprinted with permission from [116]. Copyright 2013 John Wiley and Sons, Inc.

This version was confirmed by the authors [116] by the pattern of substitution of aromatic rings from IR in the region of 600–900 cm−1, as well as in the region of 1660–2000 cm−1 (overtones and bands of combined tones). N2 isotherms demonstrated that adsorption/desorption hysteresis occurs already at low equilibrium pressures. The CO2 isotherms demonstrated that the time allotted for measurement affects both the maximum adsorption capacity and the hysteresis during desorption. For poly-p-DEB, the values of the micropore volume VMI = 0.472 cm3 g−1, SBET = 1299 m2 g−1, the maximum sorption capacity (the highest amounts of nitrogen and hydrogen adsorbed), for H2 and CO2, respectively, a(H2)= 1.26%wt. (100 kPa, 77 °K) and a(CO2)= 10.8%wt. (100 kPa, 273 °K).

In a very short publication [119], it was reported about a vigorous exothermic polymerization of p-DEB in the presence of PR3 (R = Me2NO, Et, Ph, Bu,) with the formation of a black insoluble substance with a conversion of up to 90%. The authors noted that the conversion was always high “at any Monomer/Phosphine ratios, even with catalytic amounts of the phosphorus component”. Of the experimental conditions, the authors cited only time (5–30 min) and temperature (90 °C or 130 °C in one experiment). In the presence of dimethylbenzylamine, the conversion was only 30% during 60 min at 130 °C. The authors suggested the zwitterionic nature of the initiation of the polymerization process, as it occurs in the presence of amines and phosphines [120].

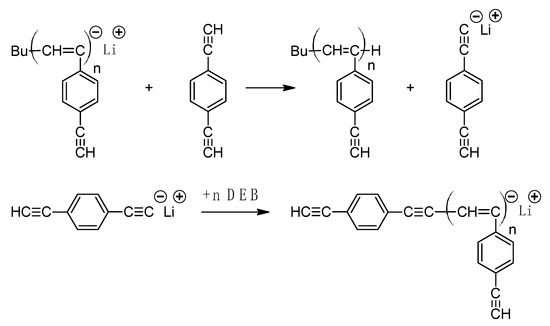

The preparation of poly-p-DEB by electroinitiated anionic polymerization in an inert atmosphere at 10 °C in polar solvents was described in [121]. The current intensity was changed in the range of 0–70 mA. The efficiency of electrolytes decreased in the series (C4H9)4 Cl > (CH3)4NClO4 > (C2H5)4NClO4. The soluble fraction conversion was up to 30%. It was found that polymerization proceeded with good results in N,N-dimethylformamide and especially in N,N-dimethylacetamide. Separated oligomers were obtained in methylene chloride. In acetonitrile, the electrolyte decomposed at any current; the characteristic color of the polymer did not appear, which indicated the absence of polymerization. According to the authors, electropolymerization began with a direct reduction of the monomer on the electrode surface. Then the reaction proceeded according to the classical anionic mechanism:

The authors pointed out that only one ethynyl group of the monomer participates in the reaction, which, according to the authors, “indicates the presence of a large number of unreacted triple bonds in accordance with absorption at 3250–3260 cm−1 in the IR spectra”. However, they did not provide any direct evidence for the synthesis of a linear polymer, including an assessment of the results using the 1H-NMR spectra they obtained. Nevertheless, it is most probable that branched poly-p-DEB with a reduced number of –C≡CH groups was obtained in this work, since at the end of the article, it is indicated that “the second ethynyl group of the monomer molecule is transformed to a lesser extent, obeying the same principle of reduction on the electrode surface”. This is confirmed by the fact that an insoluble fraction is present in the synthesized polymers, which are sequentially formed from branched polymer molecules.

In an early work [122], p-DEB was polymerized in CH3NH2 in ampoules ([DEB]/[CH3NH2] = 1/5 mol) at 260 °C. In 1 or 5 h, an insoluble polymer was obtained with a conversion rate of 87 and 94%, respectively. There are no spectral studies of polymers in the article. Nevertheless, according to the authors, poly-p-DEB polyene chains have two types of side substituents (including phenylene fragments) in accordance with the polymerization scheme (Figure 25).

Figure 25.

The scheme of polymerization of p-DEB, where KT is a catalyst. Reprinted with permission from Sergeev, V.A. (1977). Copyright 1977 Institute of Organoelement Compounds RAS.

In our opinion, in this case, most likely, zwitter-ionic polymerization took place with the initial formation of a linear polyene polymer. In this case, CH3NH2 amine played the role of not only a solvent but also a classical zwitter-ion initiator. Subsequently, due to the extremely high temperature, a regular crosslinking of the chains occurred due to the opening of triple bonds in the –C≡CH groups. A similar process of pyrolysis of DEB polymers was later described in numerous publications. As a result, the proposed structure of an insoluble polymer having phenylene fragments seems implausible. Probably, such a structure (Figure 25) is formally borrowed from the publications of these authors, who at that time studied catalytic cyclotrimerizing complexes (where R = AlkC≤6, Hal = Cl, Br, I) in articles [67,74]. Most likely, the polymer structure can be represented by the formula shown in Figure 15.

At [123] carried out soft chemical functionalization of the silicon surface using p-DEB in the dark at room temperature. In this case, only individual p-DEB molecules are fixed on the silicon surface without the formation of polymers or even oligomers. The subsequent click reaction with azidomethylferrocene made it possible to create a ferrocenyl-modified coating.

2.5. Synthesis of Linear Unbranched Poly-DEB

Thus, as a rule, only branched and/or insoluble poly-p-DEB was synthesized by various groups of researchers by direct polymerization of p-DEB. It seemed that direct chemical (including electrochemical) synthesis of linear, unbranched poly-p-DEB by selective polymerization of the p-DEB monomer at only one C≡C bond was impossible. For this reason, it may not be possible to synthesize clusters along a one-dimensional poly-conjugated chain.

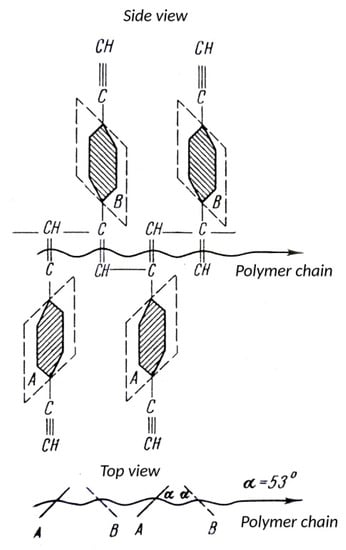

However, in 1981, we reported the synthesis by our research group of a linear soluble polymer p-DEB in a solution of hexamethylphosphoramide (HMPT) in the presence of an anionic initiator [124,125]. Later, in [33,126], the features of the intramolecular structure of this polymer were examined in more detail using IR, 1H- and 13C-NMR spectroscopy, and HPLC methods. The effect of p-DEB polymerization conditions on the yield and properties of poly-p-DEB is shown in Table 2 [33].

Table 2.

Poly-DEB polymerization conditions, yield, and properties (initiator n-BuLi; 55 °C; [M]0/[I]0 = 15; [M]0 = 0.7 mol/L) [33].

It was found that the polymerization of p-DEB in HMPT produces a completely soluble linear unbranched polymer. The ratio was found in its 1H-NMR spectrum. This corresponded to the presence of one ethynyl group in each elementary link of the macromolecule. The increase in polymerization time did not lead to a significant increase in polymer yield. However, at the same time, the number of C=C bonds in the polymer decreased (an increase in the ratio of ). Decreasing the solvent polarity resulted in only weakly branched polymers. For polymers with a deficiency of –C≡CH groups, chain transfer to the monomer occurred during polymerization (Figure 26), which explained this deficiency.

Figure 26.

The scheme of chain transfer reaction to p-DEB. Reprinted from Ref. [33].

In [31,32,33], the principal possibility of modifying synthesized poly-p-DEB was demonstrated by the interaction of groups –C≡CH with reagents containing heteroatoms: , B10H14, CuCl. As a result, poly-p-DEB derivatives having copper, boron, and cobalt in some links were synthesized and analyzed (Figure 1). This approach demonstrated the fundamental possibility of creating various clusters along the main polyene polymer chain. In addition, synthesized anionic poly-p-DEB has been used to create and modify various materials.

Poly-p-DEB, as well as other phenyl-containing polyacetylenes, was used in the creation of colored, dense, homogeneous, photo-resistive skin layers with a thickness of 0.1–10 microns by vacuum spraying these polymers. The resulting layers had both negative and positive photo-resistive properties, depending on the method of their processing [127,128]. It was found that the short-term irradiation of the layers with UV light in a vacuum through a photomask led to the appearance of a latent image due to the intermolecular crosslinking of polymers in the irradiated areas. After the layers were heated in a vacuum at an optimal temperature of 200–350 °C, the non-irradiated uncrosslinked part of the polymers evaporated. As a result, a visible contrast image appeared. On the contrary, the long-term irradiation of the sprayed films with UV light through a photomask in the air led to the disappearance of the areas of the sprayed layers in the places that the light hit and to the appearance of a contrasting positive image. This process was explained by the authors [127,128] by the formation of ozone from air oxygen under the action of UV rays and the subsequent course of the oxidation reaction of unsaturated bonds of sprayed polymers by ozone. In this case, in accordance with the values of the rate constants of the interaction of ozone with organic compounds [129] (Table 3), an ozone attack on the C=C bonds of polyene chains is most probable. Only this reaction of the destruction of polyene chromophores forming the sprayed layers will lead to the appearance of a visible image.

Table 3.

PolyDEB polymerization conditions, yield, and properties (catalyst ) [137].