Abstract

Laser cladding is an essential method for strengthening and restoring component surfaces. To increase its efficacy and provide a reliable surface treatment technique, it is necessary to optimize process parameters, enhance material adhesion, and guarantee high-quality, reliable coatings. These measures help to extend the lifespan of components. In this study, the surfaces of AISI 904L stainless steel samples were cladded to prepare various Co-based composite coatings with single and multiple layers reinforced with WC–CoCr–Ni powder. The phases within the newly developed layers were investigated using X-ray Diffraction (XRD), while the microstructure was examined using Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray Spectroscopy (EDX). Further tests were performed to assess the hardness, wear resistance and corrosion performance of the deposited coatings. Analyzing and comparing the coatings, it was observed that the coating performance increased with increasing thickness and generally due to a lower amount of Fe present within the microstructure.

1. Introduction

Cobalt-based (Co-based) alloys are widely recognized for their superior mechanical strength, thermal stability, and excellent wear and corrosion resistance under harsh service environments. These alloys are particularly valuable for components operating in aerospace, petrochemical, and power generation sectors, where elevated temperature and corrosive media can severely degrade conventional steels. The outstanding performance of Co-based alloys originates from their γ–Co solid solution matrix strengthened by carbides such as M7C3, M23C6, and η phases, which provide high hardness and thermal stability [1]. Nevertheless, their intrinsic brittleness and the possibility of solidification defects during processing limit their direct application. To overcome these challenges, laser cladding (LC) has become a prominent surface engineering technique capable of producing dense, metallurgically bonded coatings with controlled dilution and tailored microstructures [2,3].

Laser cladding provides rapid solidification and localized heat input, resulting in fine-grained, defect-free microstructures with strong adhesion to the substrate. Zhou and Kong demonstrated that Ti3AlC2-reinforced Co-based coatings fabricated by LC exhibited improved frictional stability and oxidation resistance at elevated temperatures due to the formation of continuous tribo-oxide layers [4]. Similarly, Zhang et al. reported that Stellite3–Ti3SiC2–Cu composite coatings developed on Inconel 718 achieved nearly double the hardness of the substrate and exhibited excellent high-temperature oxidation resistance, attributing these enhancements to the synergistic effect between the MAX-phase reinforcement and the ductile Cu addition [5]. Furthermore, Chen et al. fabricated WC–Cu/Co composite coatings via laser cladding and found a 70% increase in hardness and a significant reduction in wear rate, emphasizing the beneficial dual effect of hard carbide phases and a lubricating metallic matrix [6]. Numerous studies have also examined the role of rare-earth oxides and refractory elements in improving coating integrity. Li et al. observed that the addition of CeO2 and graphite to Co-based plasma-cladded coatings refined the dendritic structure, decreased porosity, and increased both hardness and corrosion resistance in chloride media [7]. Similarly, Liu et al. investigated Ta-reinforced Co-based coatings fabricated by direct laser deposition, reporting that in situ TaC particles contributed to microstructural stabilization and enhanced erosion resistance [8]. These results indicate that the chemical composition and type of reinforcement have a profound influence on coating performance by modifying solidification dynamics and carbide formation behavior.

In recent years, the concept of multilayer laser-cladded coatings has gained increasing attention as a means to further enhance coating quality and reduce dilution. Multilayer architectures enable the formation of compositional and thermal gradients that help mitigate interfacial stress, improve metallurgical bonding, and enhance wear and corrosion performance. Li et al. reported that multilayer Co-based coatings exhibited reduced dilution and higher microhardness than single-layer coatings due to improved remelting control and heat dissipation [9]. Likewise, Zhang et al. demonstrated that WC–CoCr–Ni multilayer coatings provided superior wear resistance and lower friction coefficients compared to single-layer coatings, mainly because of a reduced Fe diffusion from the substrate and the formation of uniform carbide networks [10].

Despite these advances, a detailed understanding of the relationship between Fe diffusion from the substrate into the coating, coating thickness, and reinforcement distribution in multilayer Co-based systems remains incomplete. Excessive dilution of Fe from the substrate into the Co-based layer can deteriorate mechanical and corrosion properties by altering the phase composition and matrix stability [11,12,13,14]. Consequently, controlling dilution and compositional uniformity is a key objective in optimizing coating performance.

In our previous study [15], Co-based composite coatings containing 0–30 wt.% WC–CoCr–Ni particles were deposited by laser cladding onto AISI 904L stainless steel. That work systematically analyzed the influence of WC content on the microstructure, phase composition, hardness, and tribo-corrosion performance of the coatings. The results indicated that the coating with Co + 30 wt.% WC exhibited the most balanced combination of wear resistance and corrosion stability, despite showing a relatively high Fe dilution from the substrate due to single-layer deposition. Building upon these findings, the present research utilizes the optimized Co + 30 wt.% WC composition from the previous work to fabricate single-, double-, and triple-layer Co-based coatings. The aim is to investigate how increasing the number of deposited layers influences Fe dilution within the Co matrix and consequently affects the mechanical, wear, and corrosion performance of the coatings. Through this approach, the study provides new insights into the optimization of multilayer Co-based composite systems fabricated by laser cladding for improved surface reliability in industrial applications.

2. Materials and Methods

Three different laser cladding layers were manufactured using a mechanical dry mixture of Amdry MM509B-C Co-based powder (Oerlikon Metco, Langenfeld, Germany) and WC–CoCr powder (Thermico GmbH, Dortmund, Germany), with the latter added in an amount of 30 wt%. The Co-based powder exhibited a particle size distribution of 45–125 µm, while the WC–CoCr powder (WC) had a particle size distribution in the range of 45–106 µm. The mixture was deposited on AISI 904L stainless steel and labeled as Sample 1 (single layer cladding), Sample 2 (dual layer cladding), and Sample 3 (triple layer cladding). The cladding was carried out using a Coherent 100F diode laser equipped with a water-cooled Precitec YC50 gun (Precitec GmbH & Co. KG, Gaggenau, Germany), operated by a six-axis robot from CLOOS. The cladding parameters used in this study have been reported in previous work [15] and were laser power of 720 W, cladding speed of 22 cm/min, and a powder feed rate of 6 g/min. Argon was used as the carrier gas for powder feeding, at a flow rate of 14 L/min. Metallographic samples were cut using a liquid-cooled cutting machine to avoid microstructural changes within the layers. After cutting, the samples were embedded in epoxy resin via hot mounting and subsequently ground with SiC abrasive papers up to 4000P grit, followed by polishing on cloths down to 1 µm. A scanning electron microscope (SEM, TESCAN VEGA, TESCAN Group, Brno, Czech Republic) was employed to examine the morphology of the etched samples, equipped with an energy-dispersive X-ray (EDX) spectrometer for local compositional analyses. The phase composition was identified by X-ray diffraction (Philips X’Pert Diffractometer, Panalytical, The Netherlands) method using a Cu Kα radiation, a scanning width of 2θ in the range of 20–100°, with a step size of 0.02° and a counting time of 0.2 s/step. The X-ray tube was operated at 40 kV and 40 mA at room temperature. The microhardness of the layers was evaluated by the Vickers method using a FALCON 600G2 hardness tester (INNOVATEST Europe BV, Maastricht, The Netherlands). Indentations were performed on the cross-sections of the specimens under a load of 300 gf with a dwell time of 15 s. The sliding wear properties of the coatings were evaluated using the pin-on-disk method with a CSM tribometer (CMS Instruments, Lausanne, Switzerland). The ASTM G99-17 standard [16] was employed for the measurements using a normal force (F) of 10 N, a wear radius of 3 mm, and a linear speed of 10 cm/s, with 10,000 laps performed. A WC-Co ball with a 6 mm diameter was used as the counterbody. Material loss volume was determined by measuring depth profiles for each track. A SP-150 potentiostat/galvanostat (Biologic, Seyssinet-Pariset, France) was used to test the corrosion performance of the layers at room temperature. The sample being investigated served as the working electrode (WE) in a standard three-electrode electrochemical cell. The 1 cm2 test area was submerged in a 3.5% NaCl solution by weight.

Before performing the wear and corrosion tests, all coating surfaces were ground and polished to obtain a metallic mirror finish with an average surface roughness of approximately 0.2 µm. Therefore, the effect of surface roughness on wear and corrosion behavior was minimized, ensuring that the measured performance differences are primarily attributed to the coating microstructure and composition rather than surface irregularities.

3. Results and Discussions

3.1. Microstructure

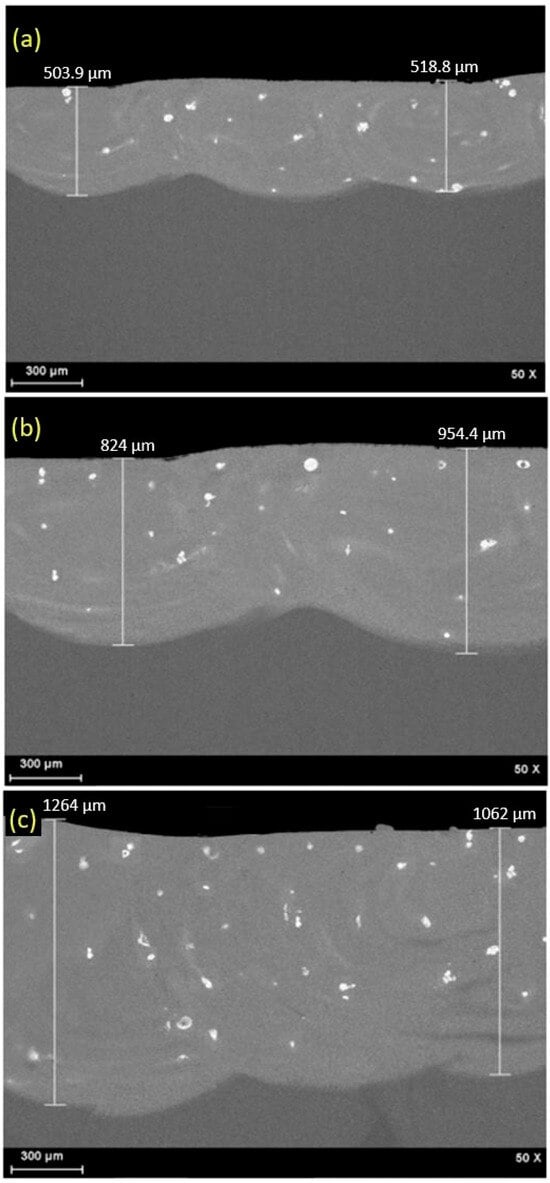

Figure 1 presents the cross-sectional macrographs of the fabricated coatings. The coatings exhibit a dense structure, indicating good metallurgical bonding, as no delamination was observed at the coating–substrate interface. All samples display WC carbide agglomeration, represented by the white particles randomly dispersed within the coatings. Macro-pores are absent in the layer structures. The coating thickness varies, particularly in samples 2 and 3, due to multiple passes, with sample 3 being the thickest as a result of the overlapping of three layers.

Figure 1.

SEM images of cross-sections of the investigated samples: (a) Sample 1; (b) Sample 2, and (c) Sample 3.

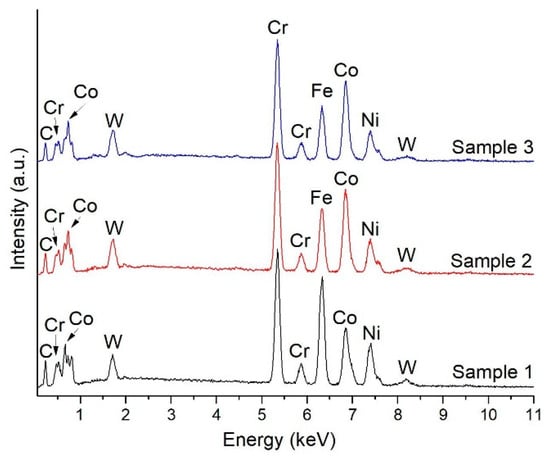

The chemical investigation was performed on the upper part of each sample, and the corresponding spectra are presented in Figure 2. In all samples, the major alloying elements detected were Cr, Co, Fe, and Ni, followed by W and C. No other elements were detected, most likely due to their low concentrations, which were below the detection limit of the technique. However, a difference can be observed in the case of Fe, identified by its major K-line peak at ~6.4 keV. With increasing coating thickness, the intensity of the Fe peak decreases. This can be attributed to the high solubility of Fe with elements such as Ni, Co, and Cr, which allows it to easily diffuse and mix into the molten pool during cladding. Therefore, iron is more abundant in Sample 1, which was prepared with a single layer. As the deposition process continues with two or three passes, as in Sample 3, the iron content decreases. In a previous study [17], an increase in Fe content within the laser-clad coating led to microstructural changes and a reduction in hardness, which was attributed to the presence of a higher number of softer phases in the composition of WC–Co/NiCrB-based coatings.

Figure 2.

EDX spectrum of samples collected in the upper region of the layers.

Based on the quantification presented in Table 1, the Fe content decreases from approximately 28 wt.% in Sample 1 to about 16 wt.% in Sample 3 as the coating thickness increases. A comparative analysis reveals that Sample 2 contains roughly 35% less Fe than Sample 1, while Sample 3 exhibits an even greater reduction, with about 43% less Fe relative to Sample 1. The increase in Co% is primarily attributed to reduced substrate dilution with increasing coating thickness, which limits Fe incorporation and enriches the coating in Co derived from the feedstock powder, while the concentrations of other alloying elements remain nearly unchanged. Similar observations were reported by Xiao et al. when investigating the effect of dilution on FeCoNiCrNb high-entropy alloy coatings fabricated with different numbers of layers [18]. Their results showed that as the number of layers increased, a reduction in Fe content was observed in the upper layers.

Table 1.

Chemical composition determined by EDX for the investigated samples.

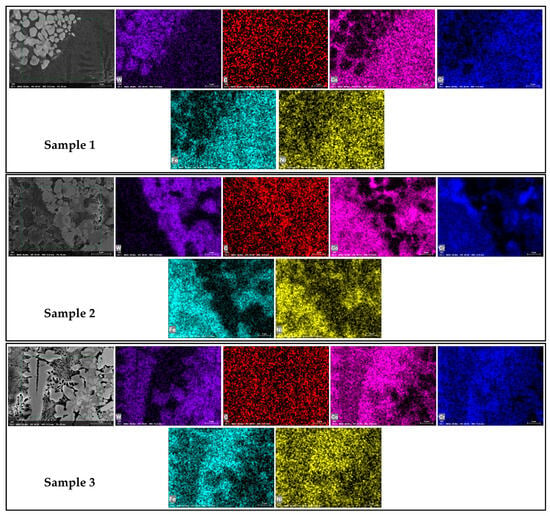

Figure 3, it can be observed that the samples exhibit a similar microstructure, which has been described previously in more detail [2]. The SEM micrographs and EDX mapping performed in cross-section at high magnification reveal various areas. The metallic matrix consists of a solid solution rich in Co, Cr, Fe, and Ni, with dark gray regions corresponding to Cr-rich areas. The white particles are WC, in some cases surrounded by light gray regions that represent W2C, which forms due to the partial melting of WC during laser cladding. In all cases, the morphology of WC particles appears slightly rounded, indicating partial dissolution, as described by Bolelli et al. [19].

Figure 3.

SEM and EDX element distribution of the investigated samples.

3.2. Phase Composition

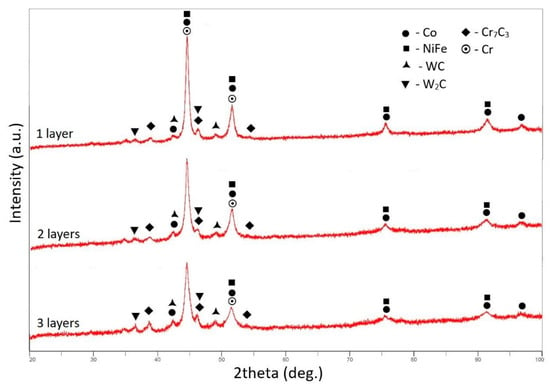

Figure 4 presents the X-ray diffraction spectra of the coatings produced by laser cladding. The spectra indicate that the layers exhibit similar patterns, with the main peaks corresponding to the metallic binder, composed of NiFe and containing metallic Co and Cr. Minor peaks corresponding to hard carbides, such as WC and Cr7C3, are also observed, along with small peaks attributed to W2C secondary carbide. The decarburization transformation occurs in the WC-based coatings because carbon is burned from WC during deposition [20]. The partial dissolution of Cr in the melt pool and its reaction with carbon from the partially decomposed WC leads to the formation of Cr7C3. According to Venkatesh et al., Cr7C3 is a stable carbide phase that forms during cladding due to rapid heating and cooling, and it is found together with the Ni-rich metallic phase in the interdendritic regions [21]. It is known that the hardness of W2C is about 30 GPa, much higher than that of WC (HV = 17 GPa). Since hardness and wear resistance are usually correlated, the presence of W2C within WC-CoCr-based coatings in a certain amount can enhance their wear performance [22].

Figure 4.

XRD patterns for the laser-clad layers.

3.3. Hardness Evaluation

The starting hardness of the coating was about 825 HV03, as obtained in our previous study [2]. The measurements were conducted exclusively in the upper part of the coating, as the objective was to assess hardness variations in cross-section at a depth of approximately 2 mm from the surface. For each sample, six measurements were performed, and the average values are presented in Table 2. An increase in coating thickness was found to correlate with higher hardness values. This enhancement in hardness can be attributed to the reduction in Fe, which promotes grain refinement in the microstructure, as reported by Liu et al. [23]. Comparable findings were also reported by Li et al., who investigated the influence of Fe content on the microstructure and wear resistance of AlCoCrFeNi coatings produced by laser cladding [24].

Table 2.

Hardness values (measured at the top of the laser-clad coatings).

3.4. Wear Performance

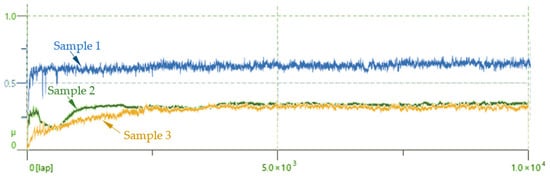

Figure 5 presents the evolution of the coefficient of friction (COF) for the different coating configurations. In all cases, a distinct rise in COF is observed during the initial stage of testing. This increase can be attributed to the limited real contact area between the polished surface of the coating and the unaltered counter ball at the beginning of the test. The small initial contact area concentrates the applied load, producing higher frictional forces, localized wear, and fluctuations in the COF [25]. As sliding continues, both the coating and the counter ball undergo progressive wear, generating debris that becomes entrapped within the contact interface. The presence of this debris initiates abrasive wear, leading to intermittent COF fluctuations as the system transitions toward a more stable contact condition.

Figure 5.

COF recorded for the investigated samples.

Among the tested samples, the single-layer coating exhibited the highest average COF (µavg = 0.621), while the double-layer (µavg = 0.323) and triple-layer (µavg = 0.318) coatings demonstrated substantially lower values. The improved frictional performance of the multilayer coatings can be associated with their enhanced structural integrity and reduced WC decomposition, which favors the formation of a higher fraction of W2C carbide. This phase contributes to increased hardness and wear resistance, thereby stabilizing the frictional response throughout the test.

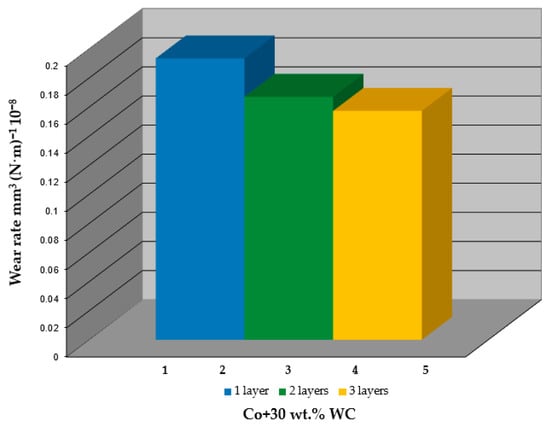

Figure 6 illustrates the corresponding wear rates for the single-layer (sample 1), double-layer (sample 2), and triple-layer (sample 3) coatings, which are 0.19, 0.16, and 0.15 × 10−8 mm3/N·m, respectively. A clear trend is observed in which wear resistance improves with increasing coating thickness. This behavior can be primarily attributed to the direct correlation between wear resistance and hardness [26]. Multilayer coatings typically possess a higher density of carbides and secondary hard phases within their microstructure, which not only enhances hardness but also improves load-bearing capacity and resistance to plastic deformation. Consequently, the multilayer architecture effectively mitigates material loss and contributes to superior overall tribological performance [25].

Figure 6.

Wear rate values of the laser-clad coatings.

3.5. Corrosion Performance

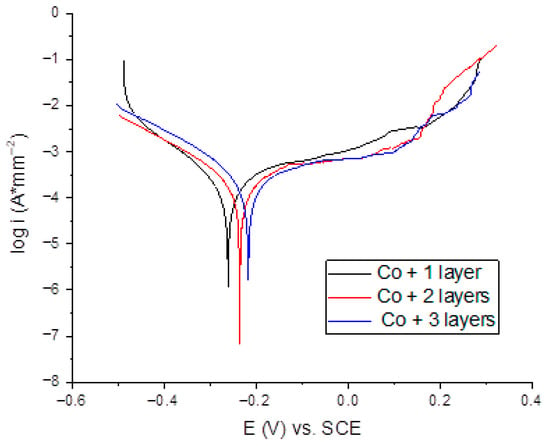

The electrochemical tests were carried out in a 3.5% NaCl solution, which is a standard medium for evaluating the corrosion resistance of metallic coatings. Before conducting the experiments, the OCP values were measured during a 30 min monitoring period. Figure 7 illustrates the polarization curves in semilogarithmic form, obtained using the Tafel extrapolation method. The graph shows the relationship between the measured potential and the logarithm of the current density. It is derived from linear polarization curves by applying a logarithmic transformation to the current density values. From these plots, key corrosion parameters—namely, the corrosion potential (Ecorr) and corrosion current density (icorr)—were determined.

Figure 7.

Potentiodynamic polarization curves.

Analysis of the polarization curves shown in Figure 7, together with the electrochemical parameters listed in Table 3, indicates that the coating with the triple-layer structure exhibited the best corrosion resistance. This is evidenced by its lowest corrosion current density values (0.091 μA·cm−2) compared with single- (0.105 μA·cm−2), and double-layer (0.117), demonstrating improved protective performance. Moreover, for sample 3, the corrosion potential shifted towards more positive values (to the right on the E vs. log i curve), indicating a more noble material. This behavior is consistent with the lower iron content in the triple-layer coating, since iron is more electrochemically active and thus prone to anodic dissolution.

Table 3.

Electrochemical test results.

The reduced Fe proportion likely promotes the formation of a denser and more stable passive film, enhancing the barrier properties of the coating [27]. Consequently, the triple-layer coating demonstrates a more stable electrochemical behavior and better durability in chloride-containing environments.

4. Conclusions

Co-based composite coatings reinforced with WC–CoCr–Ni powder were successfully deposited by laser cladding onto AISI 904L stainless steel substrates in single-, double-, and triple-layer configurations. The experimental investigation focused on evaluating the effect of the number of deposited layers on the microstructure, hardness, sliding wear resistance, and electrochemical behavior. Based on the obtained results, the following conclusions can be drawn:

- The dilution effect inherent to laser cladding led to an increased Fe content in the bottom region of the first layer. As the number of layers increased, the Fe concentration gradually decreased toward the surface.

- All coatings exhibited partial decarburization of WC, leading to the formation of W2C. This phenomenon was more pronounced in the triple-layer coating due to the higher cumulative heat input.

- The multilayer coatings had significantly lower coefficients of friction than the single-layer coating due to their improved structural integrity and reduced WC decomposition. The lower Fe content and higher W2C fraction that results enhances hardness and wear resistance, leading to a more stable frictional response during testing.

- A lower iron content in the coating improved the corrosion resistance, as evidenced by the lowest corrosion current density. This iron reduction promoted the formation of a denser and more stable passive film, resulting in the most stable electrochemical behavior.

Overall, it can be concluded that the Co-based composite coating with a triple-layer structure produced by laser cladding exhibited the most favorable combination of corrosion resistance and wear performance among all the investigated configurations.

Author Contributions

Conceptualization, I.-M.A. and I.-D.U.; methodology, A.P. and I.H.; software, D.H.W. and I.-M.A.; validation, I.-D.U. and G.M.; formal analysis, I.H. and D.H.W.; investigation, I.-M.A., D.H.W. and A.P.; resources, I.-D.U. and A.P.; data curation, I.-M.A., I.H. and I.-D.U.; writing—original draft preparation, I.-M.A., I.H. and I.-D.U.; writing—review and editing, I.-D.U., I.H. and G.M.; visualization, I.-M.A., A.P., I.H., D.H.W., I.-D.U. and G.M.; supervision, I.-D.U., I.H. and G.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Davis, J.R. Surface Engineering for Corrosion and Wear Resistance; ASM International: Novelty, OH, USA, 2001. [Google Scholar]

- Bartkowski, D.; Młynarczak, A.; Piasecki, A.; Dudziak, B.; Gościański, M.; Bartkowska, A. Microstructure, microhardness and corrosion resistance of Stellite-6 coatings reinforced with WC particles using laser cladding. Opt. Laser Technol. 2015, 68, 191–201. [Google Scholar] [CrossRef]

- Poloczek, T.; Lont, A.; Górka, J. The structure and properties of laser-cladded Inconel 625/TiC composite coatings. Materials 2023, 16, 1265. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Kong, D. Friction–wear performances and oxidation behaviors of Ti3AlC2 reinforced Co–based alloy coatings by laser cladding. Surf. Coat. Technol. 2021, 408, 126816. [Google Scholar] [CrossRef]

- Zhang, S.-Y.; Liu, X.B.; Zhu, Y.; Liu, Y.F.; Meng, Y.; Liang, J.; Zhang, S.H. Stellite3–Ti3SiC2–Cu composite coatings on IN718 by laser cladding. Surf. Coat. Technol. 2022, 446, 128766. [Google Scholar] [CrossRef]

- Chen, G.-D.; Liu, X.-B.; Zhang, F.-Z.; Liu, Q.-S.; Ou, H.-Z.; Zhang, S.-H. Fabrication and tribological properties of laser cladding WC–Cu/Co-based composite coatings. Surf. Coat. Technol. 2023, 472, 129930. [Google Scholar] [CrossRef]

- Li, D.; Zhang, Z.; Cui, X.; Feng, L.; Zhang, D.; Jin, G.; Liu, J.; Zheng, W. Effect of graphite/CeO2 on microstructure and tribological property of plasma cladded Co-based coatings. Mater. Chem. Phys. 2022, 280, 125756. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, T.; Lv, H.; Hu, D.; Zhang, Y.; Chen, H.; Chen, Y.; She, J. Microstructure and properties of Ta-reinforced cobalt based composite coatings processed by direct laser deposition. Surf. Coat. Technol. 2022, 447, 128874. [Google Scholar] [CrossRef]

- Li, M.; He, Y.; Sun, G. Microstructure and wear resistance of laser clad cobalt-based alloy multi-layer coatings. Appl. Surf. Sci. 2004, 230, 108802. [Google Scholar]

- Angelastro, A.; Campanelli, S.L.; Casalino, G.; Ludovico, A.D. Optimization of Ni-Based WC/Co/Cr Composite Coatings Produced by Multilayer Laser Cladding. Adv. Mater. Sci. Eng. 2013, 2013, 615464. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Z.; Chen, J.; Qiao, Y.; Zhang, J.; Huang, Y. Effect of Rare Earth Oxides on Microstructure and Corrosion Behavior of Laser-Cladding Coating on 316L Stainless Steel. Coatings 2019, 9, 636. [Google Scholar] [CrossRef]

- Costa, J.M.; Porto, M.B.; Amancio, R.J.; Almeida Neto, A.F. Effects of Tungsten and Cobalt Concentration on Microstructure and Anticorrosive Property of Cobalt-Tungsten Alloys. Surf. Interfaces 2020, 20, 100626. [Google Scholar] [CrossRef]

- Zhai, Y.; Guo, X.; He, Y.; Li, Z. Corrosion resistance and mechanical properties of electrodeposited Co–W/ZrO2 composite coatings. Int. J. Electrochem. Sci. 2023, 18, 100015. [Google Scholar] [CrossRef]

- Ding, L.; Hu, S. Effect of Nano-CeO2 on Microstructure and Wear Resistance of Co-Based Coatings. Surf. Coat. Technol. 2015, 276, 256–257. [Google Scholar] [CrossRef]

- Anghel, I.-M.; Uțu, I.-D.; Pascu, A.; Hulka, I.; Woelk, D.H.; Mărginean, G. Microstructure and properties of Co-based laser cladded composite coatings. Mater. Test. 2024, 66, 665–674. [Google Scholar] [CrossRef]

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2017.

- Hulka, I.; Utu, D.; Serban, V.A.; Negrea, P.; Lukáč, F.; Chráska, T. Effect of Ti Addition on Microstructure and Corrosion Properties of Laser Cladded WC-Co/NiCrBSi(Ti) Coatings. Appl. Surf. Sci. 2020, 504, 144349. [Google Scholar] [CrossRef]

- Xiao, D.; Jiang, F.; Song, T.; Wei, C.; Zhang, Y.; Liang, P.; Yang, F. Impact of Dilution on the Microstructural Evolution and Corrosion Behavior in High-Entropy Alloy Coatings Applied via Laser Cladding on Marine Engineering Equipment. Eng. Fail. Anal. 2025, 171, 109337. [Google Scholar] [CrossRef]

- Bolelli, G.; Hulka, I.; Koivuluoto, H.; Lusvarghi, L.; Milanti, A.; Niemi, K.; Vuoristo, P. Properties of WC—FeCrAl Coatings Manufactured by Different High Velocity Thermal Spray Processes. Surf. Coat. Technol. 2014, 247, 74–89. [Google Scholar] [CrossRef]

- Korobov, Y.; Alwan, H.; Soboleva, N.; Makarov, A.; Lezhnin, N.; Shumyakov, V.; Antonov, M.; Deviatiarov, M. Cavitation Resistance of WC-10Co4Cr and WC-20CrC-7Ni HVAF Coatings. J. Therm. Spray Technol. 2022, 31, 234–246. [Google Scholar] [CrossRef]

- Venkatesh, L.; Samajdar, I.; Tak, M.; Doherty, R.D.; Gundakaram, R.C.; Prasad, K.S.; Joshi, S.V. Microstructure and Phase Evolution in Laser Clad Chromium Carbide-NiCrMoNb. Appl. Surf. Sci. 2015, 357, 2391–2401. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Gee, M.; Zhang, H.; Liu, X.; Song, X. Sliding Wear Resistance Enhancement by Controlling W2C Precipitation in HVOF Sprayed WC-Based Cermet Coating. Surf. Coat. Technol. 2020, 387, 125533. [Google Scholar] [CrossRef]

- Liu, W.; Li, L.; Mi, G.; Wang, J.; Pan, Y. Effect of Fe Content on Microstructure and Properties of Laser Cladding Inconel 625 Alloy. Materials 2022, 15, 8200. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Shi, Y.; Li, S.; Yan, X.; Wang, S.; Zhuo, X. Effect of Fe Content on the Microstructure and Wear Resistance of AlCoCrFeNi High-Entropy Alloy Coating Prepared by Laser Cladding. Appl. Surf. Sci. 2025, 685, 162019. [Google Scholar] [CrossRef]

- Yu, Y.; Ding, W.; Wang, X.; Mo, D.; Chen, F. Study on Microstructure and Wear Resistance of Multi-Layer Laser Cladding Fe901 Coating on 65 Mn Steel. Materials 2025, 18, 3505. [Google Scholar] [CrossRef]

- Zhu, H.; Ouyang, M.; Hu, J.; Zhang, J.; Qiu, C. Design and Development of TiC-Reinforced 410 Martensitic Stainless Steel Coatings Fabricated by Laser Cladding. Ceram. Int. 2021, 47, 12505–12513. [Google Scholar] [CrossRef]

- Potgieter, J.H. Alloys cathodically modified with noble metals. J. Appl. Electrochem. 1991, 21, 471–482. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).