Abstract

Silicon carbide (SiC) has excellent mechanical and chemical properties and is used in a wide range of applications. It has the characteristic of rapidly heating up to several hundred degrees within one minute when irradiated with microwave radiation at 2.45 GHz. In this study, we investigated the oxidation curing process and microwave heating properties of polycarbosilane (PCS). A PCS disk-shaped green body was fabricated via uniaxial pressure molding. Silicon carbide was prepared by varying the pyrolysis temperature, and the heating characteristics of the microwaves were evaluated. The results showed that the samples pyrolyzed at 1300 °C after oxidation curing for 2 h at 180 °C rapidly heated up to 802 °C within 1 min, and the temperature remained constant for 120 min. The maximum temperature of the samples pyrolyzed at 1500 °C was relatively low, but the rate of heating was the highest. The microstructures and crystal structures of the microwaves as a function of the pyrolysis temperature were investigated.

1. Introduction

Silicon carbide (SiC) is a ceramic material with excellent mechanical properties and thermal and chemical stabilities and is thus widely applied in fields requiring lightweight materials with superior properties, such as the aerospace, defense, and transportation industries [,,]. In particular, silicon carbide fibers derived from polycarbosilane (PCS) serve as primary reinforcement materials for the fabrication of ceramic composites [,]. Beyond these applications, silicon carbide is also widely used as a cladding material for nuclear fuel in nuclear power plants [] and as an electromagnetic wave absorbing material in fifth-generation stealth fighter jets [], demonstrating its extensive range of applications. In particular, the silicon carbide heating phenomenon induced by microwaves is well established, and this property is anticipated to enable its application as a heating element in rapid sintering processes.

Microwaves were first used in industrial processes in the 1970s [,]; today, they are widely used for rapid processing, particularly in sintering processes []. However, a key drawback of microwave sintering is the internal heating of the sample caused by microwave energy, which often leads to an inhomogeneous density within the sintered body. To mitigate this issue, silicon carbide or zirconia (ZrO2), both of which exhibit microwave heating properties, is employed as a susceptor to aid in the heating process [,,]. Silicon carbide, with its high dielectric loss, rapidly heats to temperatures exceeding 1000 °C within one minute upon exposure to microwave radiation at 2.45 GHz. The rapid heating of silicon carbide under microwave irradiation is proposed to occur owing to mechanisms, such as dipolar loss, driven by the rotation and collision of dipoles within the material and conduction loss, resulting from electron movement and collisions within an external magnetic field, although further investigation is warranted to fully elucidate these mechanisms [,,,]. Notably, silicon carbide prepared from PCS powder contains SiO2, depending on the pyrolysis temperature, highlighting the need for studies on its heating characteristics.

The preparation of silicon carbide based on PCS preceramic polymers can be achieved by ceramization reactions using both curing and pyrolysis methods [,,]. However, a curing process for crosslinking is essential to maintain the geometry of the sample during the high-temperature pyrolysis stage []. Oxidation curing is often used because of its advantages in mass production and cost efficiency []. It involves the introduction of oxygen into the polymer at temperatures between 150 and 200 °C in an atmospheric environment, facilitating the formation of crosslinks and the achievement of structural stability through molecular recombination reactions []. However, investigations on the curing and pyrolysis processes for PCS-based silicon carbide materials have primarily focused on fibrous materials. Because of the significant challenges and costs associated with fiber spinning, technology at the commercial level is predominantly controlled by a limited number of companies globally. Consequently, there is a need to produce bulk silicon carbide materials in a disk form using PCS powder and to perform microwave heating experiments on these materials.

In this study, the effect of pyrolysis temperature on the microwave heating properties of silicon carbide materials prepared from PCS was investigated. The optimal conditions for oxidative curing and pyrolysis were carefully determined, and disk-shaped silicon carbide samples were fabricated based on these parameters. By adjusting the pyrolysis temperature at intervals of 100 °C, variations in the microstructural and crystallographic properties of the silicon carbide were observed, and the effect of these changes on the microwave heating properties was systematically evaluated.

2. Materials and Methods

PCS (DAEHO I&T, Changwon, Republic of Korea) was ground for 10 min using an alumina bowl. Oxidation curing was performed at a temperature of 180 °C for 30, 90, and 120 min to form crosslinks. The oxidation-cured PCS powder was processed using a uniaxial pressure machine (Model C; Carvel, New York, NY, USA) to 5 tons for 3 mins to produce a disk shaped green body with a diameter of 35 mm. The pyrolysis procedure for the green body was performed for over 3 h at the temperatures of 1200, 1300, 1400, and 1500 °C in an argon atmosphere to obtain a silicon carbide sample.

To examine the microwave heating properties of the pyrolyzed silicon carbide, a heating test was conducted by exposing the sample to microwave radiation at a frequency of 2.45 GHz (with a power of 2.28 kW) using a microwave oven heater (DAEHO I&T, Changwon, Republic of Korea). The heat phenomena and temperature variations were captured using a thermal imaging camera (PI 1M, Optris, Berlin, Germany), and the temperature data were categorized at intervals of 1 s or 10 min to evaluate the heat characteristics based on the rate of instantaneous heat generation, peak temperature, and thermal stability over a duration of 120 min.

The microstructure was fractured at the midpoint of the disk-shaped sample, and the microstructure and composition were analyzed using a scanning electron microscope (Apreo S, Thermo Fisher Scientific, Waltham, MA, USA) with a condition accelerating voltage of 20 kV without the surface treatment of the fracture surface. The crystal structure and crystal size of β-silicon carbide were analyzed based on the results of different crystal structures at different thermal decomposition temperatures using X-ray diffraction (XRD, SmartLab SE, Rigaku Corporation, Akishima, Japan) with Cu Kα radiation at a scanning rate of 2°/min. Additionally, the crystal size was calculated using the Scherrer equation based on the full width at half maximum (FWHM) obtained from X-ray diffraction (XRD) analysis.

3. Results

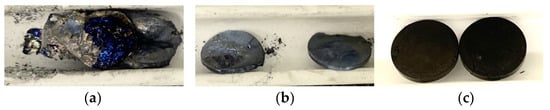

The optimal conditions for oxidation curing were analyzed to ensure the preservation of the sample shape during pyrolysis for 3 h at 1300 °C in an argon environment, and the results are shown in Figure 1. Figure 1a shows that the sample melted during pyrolysis because of inadequate crosslinking at 180 °C for 30 min. Figure 1b shows oxidation curing at 180 °C for 60 min; however, partial melting was observed owing to incomplete crosslinking. As shown in Figure 1c, after pyrolysis at 1300 °C the specimen did not melt or deform but only shrank while maintaining its initial disk shape. When oxygen is added to PCS during oxidative curing, bonds, such as Si-H, Si-Si, and C-H, are converted to Si-O-C and Si-O-Si, resulting in the formation of crosslinked bonds. The weight of the powder increases with time and temperature. During pyrolysis, degassing reactions occur owing to the dehydrogenation (H2), decarbonization (CH4), and evaporation of low molecular weight and organic compounds [,,,]. However, once crosslinking occurs, the stability of the chemical framework is ensured, the shape of the sample is preserved, and the yield of ceramization is increased []. In other words, to synthesize silicon carbide from PCS, crosslinking via an oxidative non-melting process must be first performed [,,]. In this investigation, the oxidation curing condition was 180 °C for a period of 120 min.

Figure 1.

Sample shape after pyrolysis at 1300 °C under different oxidation curing conditions: (a) 180 °C and 30 min, (b) 180 °C and 60 min, (c) 180 °C and 120 min.

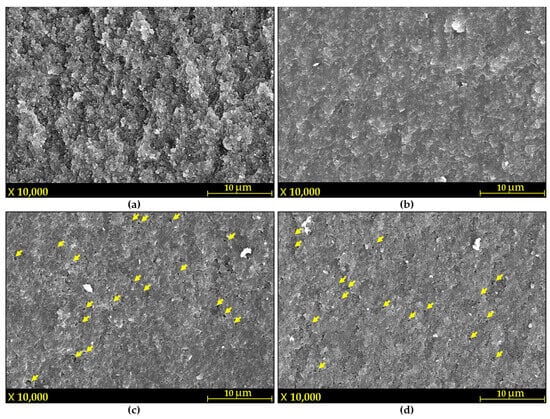

A disk shaped green body was fabricated using the oxidation-cured PCS powder. Silicon carbide was prepared through pyrolysis at 1200, 1300, 1400, and 1500 °C within an argon atmosphere for a duration of 3 h. Figure 2 and Table 1 show that variations in the microstructure and composition were observed when analyzing the fracture surface of the produced silicon carbide with respect to the pyrolysis temperature. Figure 2a shows the height of the microstructure at 1200 °C, which was observed to be at its maximum. As the pyrolysis temperature was increased to 1300, 1400, and 1500 °C, the microstructure height exhibited a reduction in roughness. However, the samples subjected to pyrolysis at 1400 and 1500 °C exhibited the presence of 3~5% numerous pores measuring 0.5 µm or smaller, as shown in Figure 2c,d. The composition analysis revealed a discernible trend of declining oxygen content with increasing pyrolysis temperature.

Figure 2.

Microstructures according to the pyrolysis temperature: (a) 1200 °C, (b) 1300 °C, (c) 1400 °C, (d) 1500 °C (yellow points: pores size > 0.5 µm).

Table 1.

Composition analysis using SEM/EDS for specimens manufactured according to pyrolysis temperature conditions.

The manifestation of microporosity in the results of microstructural analysis owing to elevated pyrolysis temperatures can be explained as follows. At a pyrolysis temperature of 1300 °C, the synthesis of SiO2 transpires, thereby promoting the densification of pores. Nevertheless, the degassing reactions involving SiO2 and CO continue to be prevalent as the pyrolysis temperature increases. Thus, it may be deduced that the concentration of SiO2 diminishes, resulting in the detected microporosity.

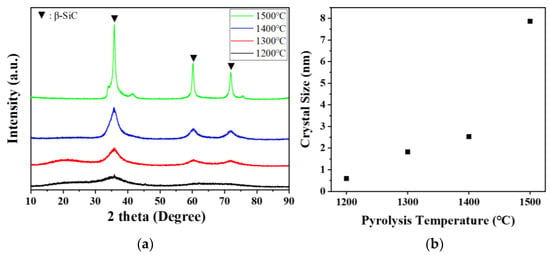

The crystal structure of the produced silicon carbide was analyzed, and the results are presented in Figure 3. Peaks between 10° and 25° were attributed to the SiO2 and amorphous phases, whereas the main peaks of β-silicon carbide were observed at 2θ = 35.73°, 60.127°, and 71.95°. At the pyrolysis temperatures of 1200 and 1300 °C, amorphous patterns presumably resulting from the presence of SiO2 and Si-O-C were observed. However, at pyrolysis temperatures exceeding 1400 °C, no evidence of SiO2 or amorphous patterns was detected, and the peak intensity of silicon carbide increased. This result is attributed to the degassing reactions occurring during pyrolysis, particularly the primary degassing reaction of SiO and CO at temperatures exceeding 1400 °C. Specifically, this observation serves as corroborating evidence for the compositional analysis and microstructural behavior, demonstrating that a decrease in the oxygen content leads to a decrease in the amorphous patterns, presumed to be SiO2 and Si-O-C structures.

Figure 3.

Crystal structure analysis of the samples fabricated at various pyrolysis temperatures using XRD: (a) XRD pattern, (b) β-silicon carbide crystal size.

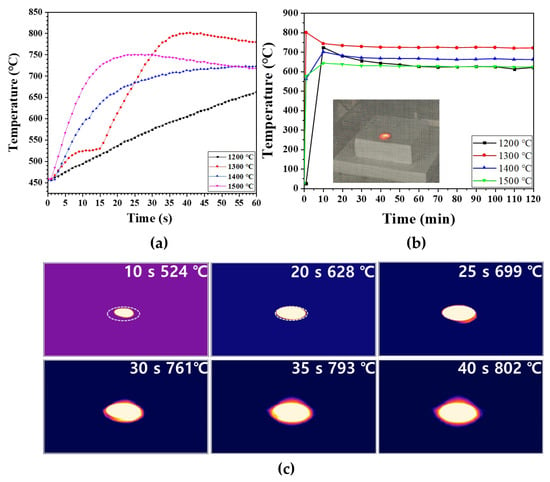

Silicon carbide produced at diverse pyrolysis temperatures was subjected to thermal evaluation via microwave irradiation. Figure 4a illustrates the rapid increase in temperature over approximately 60 s of exposure to irradiation. For the sample subjected to pyrolysis at 1200 °C, the temperature exhibited a proportional increase over time, ultimately reaching a peak value of 612 °C within 60 s (this value further increased to 721 °C following 200 s of continuous exposure). The samples that underwent pyrolysis at 1300, 1400, and 1500 °C achieved the peak temperatures of 802, 721, and 752 °C, respectively, within the same interval of 60 s. The observed rate of heating to the maximum temperature was more rapid for the samples subjected to higher pyrolysis temperatures.

Figure 4.

Microwave irradiation heating test of samples manufactured at different pyrolysis temperatures: (a) 60 s short time. Heating rate according to the thermal decomposition temperature conditions of PCS, (b) 60 min long time heating behavior of silicon carbide samples under microwave irradiation, (c) heating phenomenon according to microwave irradiation time for samples thermally decomposed at 1300 °C for 3 h.

To examine the microwave thermal stability of silicon carbide, the samples were subjected to microwave exposure for up to 120 min, and the results are shown in Figure 4b. During the prolonged microwave heating experiment, the sample that underwent pyrolysis at 1200 °C demonstrated a progressive decline in temperature to 630 °C over 60 min, subsequently achieving a relatively stable thermal state. In contrast, the samples subjected to treatment at 1300, 1400, and 1500 °C attained their maximum temperature within 60 s (as shown in Figure 4a) and exhibited a temperature decrease of approximately 25 °C over 120 min, which can be considered to indicate remarkable temperature retention characteristics.

Figure 4c illustrates the microwave heating phenomenon occurring in the samples subjected to pyrolysis at 1300 °C. At the commencement of the heating process, thermal generation was initiated within the internal regions of the samples, followed by the outward diffusion of the heat generating areas. All the regions of the samples achieved uniform heating after approximately 40 s.

Mishra [] stated that, in CMCs (ceramic matrix composites) with complex microstructures, materials with high dielectric losses exhibit preferential heating and diffusion mechanisms. Silicon carbide, which has a high dielectric loss, demonstrates excellent microwave heating characteristics [,,], with a thermal conductivity ranging from 200 to 300 W/(mK) [,]. Conversely, SiO2 is characterized by a low dielectric loss, exhibiting an extremely low microwave heating capacity with a thermal conductivity of 1.4 W/(mK) [,], which is considerably slower than that of silicon carbide. The present samples demonstrated distinct differences between silicon carbide and SiO2, although their proportions varied according to the pyrolysis temperature. When microwaves are applied, heating is expected to begin from the interior of the sample owing to the high dielectric loss of silicon carbide. The generated heat is then conducted toward SiO2, eventually resulting in uniform heating throughout the sample. This phenomenon is associated with the increased heating rates shown in the samples pyrolyzed at 1400 and 1500 °C. XRD analysis indicated an extremely low SiO2 content and a high silicon carbide content, leading to an initially rapid heating rate. However, owing to the high thermal conductivity of silicon carbide, substantial heat loss occurs at the exterior, resulting in a lower maximum temperature.

In all the samples, heating began internally and extended outward under microwave irradiation. This phenomenon is attributed to the inherent heat generation properties of microwave irradiation with a higher external heat loss rate than internal. This phenomenon appeared to be unrelated to properties, such as the microstructure and crystal structure of the sample. The relatively constant temperature for 120 min is explained by the maximum heat generation from microwaves below 800 °C. This temperature is insufficient to induce microstructural or phase changes in silicon carbide or SiO2 under atmospheric conditions, which explains the absence of alterations in the microstructure and crystal structure of the sample [,,].

The silicon carbide derived from PCS exhibits a range of crystal structures, comprising varying ratios of semiconductor silicon carbide, conductive residual carbon, insulating SiO2, and amorphous Si-O-C. These structural variations are contingent on the oxidation curing and pyrolysis temperatures. The heating characteristics, such as the thermal conditions and the rate of thermal application, of silicon carbide synthesized from PCS under exposure to microwave irradiation are influenced by the interplay between the microstructural and crystallographic attributes. Further studies are essential to clarify the underlying mechanisms governing the thermal behavior by conceptualizing an expanded study of this phenomenon.

4. Conclusions

In this study, microwave silicon carbide heating materials were prepared, and the effect of the pyrolysis temperature on the heating properties was investigated. The optimal oxidation curing conditions for the pyrolysis process were determined to be 2 h at 180 °C; samples processed with shorter duration times experienced melting during pyrolysis. As pyrolysis temperatures increased from 1200 to 1500 °C, the oxygen content decreased, and micropores were observed. At temperatures above 1300 °C, where SiO and CO gas evolution reactions were substantially initiated, amorphous phases, such as SiO2 and Si-O-C, decreased significantly. When the prepared samples were irradiated with microwaves at 2.45 GHz, the silicon carbide was rapidly heated. The samples pyrolyzed at 1300 °C achieved the highest temperature of 802 °C, whereas those pyrolyzed at 1500 °C recorded a lower temperature of 750 °C. The samples processed at higher pyrolysis temperatures exhibited the highest heating rates. The microwave heating behavior is attributed to the preferential heating of silicon carbide with high conduction losses, followed by heat diffusion to SiO2, resulting in the heating of the entire sample. The rapid heating and thermal stability of silicon carbide using microwave technology can significantly reduce processing costs compared to conventional sintering methods. Therefore, further research into the heating characteristics is required in the future.

Author Contributions

Conceptualization, J.-H.B., S.-Y.K. and S.-I.K.; methodology, J.-H.B. and S.-Y.K.; software, J.-H.B. and S.-I.K.; validation, J.-H.B. and S.-Y.K.; investigation, J.-H.B. and S.-I.K.; data curation, C.-H.H.; writing—original draft preparation, C.-H.H.; writing—review and editing, C.-H.H.; visualization, C.-H.H.; supervision, S.-Y.K.; project administration, S.-Y.K.; All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the “Regional Innovation Strategy (RIS)” of the National Research Foundation of Korea (NRF) funded by the Ministry of Education (MOE) (2021RIS-003) and Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korea government (MOTIE) (20214000000480, Development of R&D engineers for combined cycle power plant technologies).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Eom, J.H.; Kim, Y.W.; Raju, S. Processing and properties of macroporous silicon carbide ceramics: A review. J. Asian Ceram. Soc. 2013, 1, 220–242. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, S.; Li, X.; Hong, C.; Zhang, X. Synthesis, properties, and multifarious applications of SiC nanoparticles: A review. Ceram. Int. 2022, 48, 8882–8913. [Google Scholar] [CrossRef]

- He, R.; Zhou, N.; Zhang, K.; Zhang, X.; Zhang, L.; Wang, W.; Fang, D. Progress and challenges towards additive manufacturing of SiC ceramic. J. Adv. Ceram. 2012, 10, 637–674. [Google Scholar] [CrossRef]

- An, Q.; Chen, J.; Ming, W.; Chen, M. Machining of SiC ceramic matrix composites: A review. Chin. J. Aeronaut. 2021, 34, 540–567. [Google Scholar] [CrossRef]

- Krenkel, W. Carbon fibre reinforced silicon carbide composites (C/SiC, C/C-SiC). In Handbook of Ceramic Composites; Springer: Boston, MA, USA, 2005; pp. 117–148. [Google Scholar]

- Sauder, C. Ceramic matrix composites: Nuclear applications. In Ceramic Matrix Composites: Materials, Modeling and Technology; Wiley: New York, NY, USA, 2014; pp. 609–646. [Google Scholar]

- Prasad, N.; Wanhill, R. Aerospace Materials and Material Technologies; Springer: Singapore, 2017; p. 343. [Google Scholar]

- Jones, D.A.; Lelyveld, T.P.; Mavrofidis, S.D.; Kingman, S.W.; Miles, N.J. Microwave heating applications in environmental engineering—A review. Resour. Conserv. Recycl. 2002, 34, 75–90. [Google Scholar] [CrossRef]

- Oliver Kappe, C. Controlled Microwave Heating in Modern Organic Synthesis. Angew. Chem. Int. Ed. 2004, 43, 6250–6284. [Google Scholar] [CrossRef] [PubMed]

- Olevsky, E.; Dudina, D.V. Chapter 7. Microwave Sintering. In Field-Assisted Sintering: Science and Applications; Springer: Cham, Switzerland, 2018; pp. 237–274. [Google Scholar]

- Yun, S.Y.; Woo, H.Y.; Jin, H.W.; Lee, J.G. Comparison and Analysis of Sintering Techniques for Lunar Construction Materials: A Review. J. Korea Concr. Inst. 2023, 35, 645–655. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Basak, T. A review on the susceptor assisted microwave processing of materials. Energy 2016, 97, 306–338. [Google Scholar] [CrossRef]

- Borrell, A.; Salvador, M.D. Advanced ceramic materials sintered by microwave technology. In Sintering Technology—Method and Application; Liu, M., Ed.; InTech: Vienna, Austria, 2018; Volume 10, pp. 3–24. [Google Scholar]

- Joo, Y.J.; Cho, K.Y. Microwave-assisted heating behavior of amorphous SiC fibers derived from polycarbosilane. Mater. Res. Express 2021, 8, 035603. [Google Scholar] [CrossRef]

- Ke, C.; Liu, T.; Zhang, Y.; Xiong, Q. Energy absorption performances of silicon carbide particles during microwave heating process. Chem. Eng. Process. 2022, 172, 108796. [Google Scholar] [CrossRef]

- Shen, Z.; Chen, J.; Li, B.; Li, G.; Zhang, Z.; Hou, X. Recent progress in SiC nanowires as electromagnetic microwaves absorbing materials. J. Alloys Compd. 2020, 815, 15238. [Google Scholar] [CrossRef]

- Sugawara, H.; Kashimura, K.; Hayashi, M.; Ishihara, S.; Mitani, T.; Shinohara, N. Behavior of microwave-heated silicon carbide particles at frequencies of 2.0–13.5 GHz. Appl. Phys. Lett. 2014, 105, 034103. [Google Scholar] [CrossRef]

- Li, H.; Zhang, L.; Cheng, L.; Wang, Y.; Yu, Z.; Huang, M.; Xia, H. Effect of the polycarbosilane structure on its final ceramic yield. J. Eur. Ceram. Soc. 2008, 28, 887–891. [Google Scholar] [CrossRef]

- Taki, T.; Ohamura, K.; Sato, M. A study of the oxidation curing mechanism of polycarbosilane fibre by solid-state high-resolution nuclear magnetic resonance. J. Mater. Sci. 1989, 24, 1263–1267. [Google Scholar] [CrossRef]

- Narisawa, M.; Shimoda, M.; Okamura, K.; Sugimoto, M.; Seguchi, T. Reaction Mechanism of the Pyrolysis of Polycarbosilane and Polycarbosilazane as Ceramic Precursors. Bull. Chem. Soc. Jpn. 1995, 68, 1098–1104. [Google Scholar] [CrossRef]

- Joo, Y.J.; Joo, S.H.; Cho, K.Y. Effect of pyrolysis temperature and pressing load on the densification of amorphous silicon carbide block. J. Korean Cryst. Growth Cryst. Technol. 2020, 30, 271–276. [Google Scholar]

- Hong, J.; Cho, K.Y.; Shin, D.G.; Kim, J.I.; Riu, D.H. Iodine diffusion during iodine-vapor curing and its effects on the morphology of polycarbosilane/silicon carbide fibers. J. Appl. Polym. Sci. 2015, 132, 42687. [Google Scholar] [CrossRef]

- Ly, H.Q.; Taylor, R.; Day, R.J.; Heatley, F. Conversion of polycarbosilane (PCS) to SiC-based ceramic Part 1. Characterisation of PCS and curing products. J. Mater. Sci. 2001, 36, 4037–4043. [Google Scholar] [CrossRef]

- Xie, Z.; Gou, Y. Polyaluminocarbosilane as precursor for aluminum-containing SiC fiber from oxygen-free sources. Ceram. Int. 2016, 42, 10439–10443. [Google Scholar] [CrossRef]

- Yu, Y.; Guo, Y.; Cheng, X.; Zhang, Y. Pyrolysis behavior of titanium-containing polycarbosilane in air. J. Inorg. Organomet. Polym. Mater. 2010, 20, 714–719. [Google Scholar] [CrossRef]

- Song, Y.; Joo, Y.J.; Shin, D.G.; Cho, K.Y.; Lee, D. Thermal and rheological characterizations of polycarbosilane precursor by solvent treatment. Compos. Res. 2022, 35, 23–30. [Google Scholar]

- Hasegawa, Y.; Okamura, K. Synthesis of continuous silicon carbide fibre: Part 3 Pyrolysis process of polycarbosilane and structure of the products. J. Mater. Sci. 1983, 18, 3633–3648. [Google Scholar] [CrossRef]

- Li, X.; Xu, Z.; Chen, L.; Hong, L.; Li, Y. Thermal oxidation curing polycarbosilane fibers by alternating air and vacuum process. RSC Adv. 2020, 10, 26052–26058. [Google Scholar] [CrossRef]

- Usukawa, R.; Oda, H.; Ishikawa, T.; Usukawa, R.; Oda, H.; Ishikawa, T. Conversion process of amorphous Si-Al-CO fiber into nearly stoichiometric SiC polycrystalline fiber. J. Korean Ceram. Soc. 2016, 53, 610–614. [Google Scholar] [CrossRef]

- Ishikawa, T.; Oda, H.; Ishikawa, T.; Oda, H. Structural control aiming for high-performance SiC polycrystalline fiber. J. Korean Ceram. Soc. 2016, 53, 615–621. [Google Scholar] [CrossRef]

- Mishra, R.R.; Sharma, A.K. Microwave–material interaction phenomena: Heating mechanisms, challenges and opportunities in material processing. Compos. Part A-Appl. 2016, 81, 78–97. [Google Scholar] [CrossRef]

- Perry, M.; Lentz, R. Susceptors in microwave packaging. In Development of Packaging and Products for Use in Microwave Ovens; Elsevier: Amsterdam, The Netherlands, 2009; pp. 207–236. [Google Scholar]

- Petersen, E.M.; Rao, R.G.; Vance, B.C.; Tessonnier, J.P. SiO2/SiC supports with tailored thermal conductivity to reveal the effect of surface temperature on Ru-catalyzed CO2 methanation. Appl. Catal. B-Environ. Energy. 2021, 286, 119904. [Google Scholar] [CrossRef]

- Sanghera, J.; Kim, W.; Villalobos, G.; Baker, C.; Frantz, J.; Shaw, B.; Aggarwal, I. Transparent ceramics for high power solid state lasers. Proc. SPIE—Int. Soc. Opt. Eng. 2011, 8039, 803–903. [Google Scholar]

- Burzo, M.G.; Komarov, P.L.; Raad, P.E. Thermal transport properties of gold-covered thin-film silicon dioxide. IEEE Trans. Compon. Packag. Technol. 2003, 26, 80–88. [Google Scholar] [CrossRef]

- Jacobson, N.S.; Myers, D.L. Active oxidation of SiC. Oxid. Met. 2011, 75, 1–25. [Google Scholar] [CrossRef]

- Varadachari, C.; Bhowmick, R.; Ghosh, K. Thermodynamics and oxidation behaviour of crystalline silicon carbide (3C) with atomic oxygen and ozone. Int. Sch. Res. Not. 2012, 1, 108781. [Google Scholar] [CrossRef]

- Ly, H.Q.; Taylor, R.; Day, R.J.; Heatley, F. Conversion of polycarbosilane (PCS) to SiC-based ceramic Part II Pyrolysis and characterisation. J. Mater. Sci. 2001, 36, 4045–4057. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).