Abstract

The addition of oxygen or nitrogen in refractory high-entropy alloys (HEAs) has been widely reported, but studies on boron-doped HEAs have mainly focused on the segregation of boron elements at grain boundaries. The changes in the microstructure and mechanical properties in TiZrNb-based HEAs remain enigmatic. In this work, boron-doped Ti35Zr30V10Nb25 (Ti35-xB) refractory HEAs were designed to elucidate their microstructural evolution and mechanical properties. Unlike oxygen and nitrogen, trace amounts of boron addition result in the formation of borides, and boron exhibits a strong repulsion towards Zr, leading to Zr-depleted borides. Borides distributed along the grain boundaries refine the grain size and dendritic structure. The borides and structural refinement effect enhance the strain-hardening capacity and uniform elongation, resulting in an over 15% uniform elongation for Ti35-0.25B.

1. Introduction

Refractory high-entropy alloys (HEAs) exhibit high strength, high hardness, and excellent thermal stability, demonstrating promising application prospects in aerospace engines [1,2]. Recently, HEAs also show great potential in nuclear applications due to their apparent radiation resistance [3]. Traditional refractory HEAs, such as NbMoTaW, exhibit excellent high-temperature strength but suffer from poor room temperature (RT) ductility and high density [4,5]. To balance the RT ductility and density, TiZrVNb, TiZrHfNb, and their derivatives with considerable tensile elongations and low density were designed [6,7]. To further enhance the mechanical properties of the HEAs, trace dopants doping strategies are utilized [8].

In TiZrNb-based HEAs, doping with trace amounts of oxygen or nitrogen can significantly enhance the mechanical properties, attributed to substantial solid solution strengthening, precipitation strengthening, and the formation of ordered interstitial complexes [9,10]. Unlike oxygen and nitrogen, which tend to dissolve in the matrix, boron is more likely to segregate at grain boundaries [11]. This process is driven by the reduction in Gibbs energy at the grain boundaries [12]. The addition of an appropriate amount of boron into NbMoTaW can solve the RT brittleness, as boron atoms replace oxygen atoms at the grain boundaries and promote stronger bonds with adjacent metal atoms [13]. Otherwise, doping with boron can increase the activation energy, leading to significant grain refinement and enhanced grain boundary cohesion without sacrificing ductility [14]. This phenomenon is known as grain boundary decoration. However, the microstructural evolution and mechanical properties in TiZrNb-based HEAs resulting from variations in boron content have rarely been reported, and understanding these changes in the microstructure would promote the design of high-strength and ductility boron-doped refractory HEAs.

In TiZrNb-based HEAs, TiZrVNb, with a low density (6.52 g/cm3), shows good compression yield strength at RT, and still maintains 500 MPa at 1273 K, exhibiting a wide temperature application range [15]. Furthermore, TiVZrNb stands out among one million four-component equimolar HEAs as a promising nuclear material with a low thermal neutron cross-section [16]. In our previous work, we demonstrated that the NbTiVZr series of HEAs exhibit excellent RT tensile properties, which were further enhanced through oxygen doping [6,10]. Thus, the Ti35Zr30V10Nb25 HEA, with a low density of 6.31 g/cm3, was selected to be doped with boron to systematically investigate the microstructure and mechanical properties in this work. Boron rarely dissolves in the matrix but instead precipitates as borides both within the grains and at the grain boundaries, having a significant refining effect on the microstructure. Then, the tensile properties and work-hardening capacity were analyzed.

2. Experimental Methods

2.1. Materials Preparation

The ingots with nominal compositions of (Ti35Zr30V10Nb25)-xB (x = 0, 0.25, 0.5, and 1 at.%, Ti35-xB in short) were melted from various pure metals (purity > 99.95%) by arc-melting in a high-purity argon atmosphere, ensuring that the melting temperature exceeds the melting points of the raw materials. Boron was introduced through titanium diboride. The ingots were re-melted at least five times to ensure compositional homogeneity, then the samples were obtained with the dimension of 12 × 12 × 70 mm3 using a water-cooled copper mold. The as-cast Ti35-xB strip-shaped samples were cut into the desired shape using electrical discharge wire cutting.

2.2. Microstructural Characterization

The phase compositions were determined by X-ray diffraction (XRD, Philips X’Pert Pro Diffractometer), with the scanning range set from 20 to 90 degrees. The grain sizes of Ti35-xB were determined by Electron Backscatter Diffraction (EBSD, Oxford Instruments, Oxford, UK). Detailed phase structures were characterized using a scanning electron microscope (SEM, SU 8000, HITACHI, Tokyo, Japan) with an accelerating voltage of 15 kV and a transmission electron microscope (TEM, FEI Talos F200X, Waltham, MA, USA) operated at 200 kV. The EBSD and SEM samples were polished down to 3000-grit SiC paper and then electrochemically polished using a solution of hydrofluoric acid + alcohol at a DC voltage of 25 V. The TEM samples were milled to a thickness of 40~60 µm and then ion milling (Gatan 691). The internal friction (IF) behavior was measured using a computer-controlled inverted torsion pendulum in forced vibration mode (MFP-1000, Hefei, China). Four different frequencies (0.5, 1, 2, and 4 Hz) were selected for each measurement run, with a heating rate of 3 K/min over a temperature range from RT to 800 °C. The maximum torsion strain amplitude was kept at 2 × 10−5 in all measurements. The size of the samples used for the IF measurements was approximately 2 × 1 × 25 mm3. The IF samples were first mechanically polishing followed by electrolytic polishing to eliminate surface stress.

2.3. Mechanical Tests

RT tensile tests were carried out using an Instron-5967 machine at a strain rate of 1 × 10−3 s−1. The dog-bone-shaped specimens with a working length of 5 mm and an effective cross-section of 1.5 × 1 mm2 were cut by electrical discharge machine for tensile experiments. The tensile samples were mechanically polished down to 3000-grit SiC paper and then electrochemically polished to obtain a smooth surface.

3. Results and Discussion

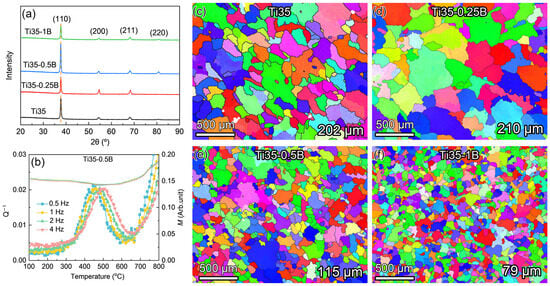

The typical XRD spectra of Ti35-xB are illustrated in Figure 1a, which indicates all the samples maintain a BCC structure without any obvious second phase. Boron, oxygen, and carbon, as interstitial atoms in HEAs, occupy octahedral or tetrahedral interstitial sites, leading to an increase in the lattice parameters [17]. However, the diffraction peaks did not show a significant shift after considering the Kα2 component, indicating that the lattice parameters remained unchanged with the boron content.

Figure 1.

(a) XRD spectra of Ti35-xB (x = 0, 0.25, 0.5, 1). (b) Temperature-dependent IF results of Ti35-0.5B. (c–f) Typical inverse pole figure (IPF) maps of Ti35-xB (x = 0, 0.25, 0.5, 1), respectively.

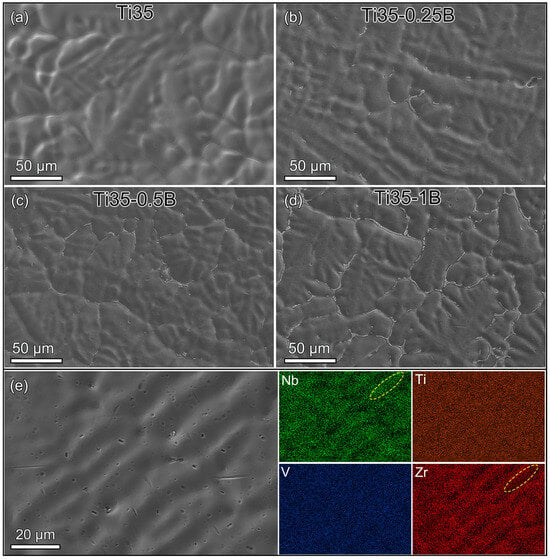

Therefore, boron is rarely in solid solution. The IF technique has been used to characterize microdefects, such as phase transitions, grain boundary structures, interactions between dislocations, and interstitial atoms [18,19,20,21]. In TiZrNb-based HEAs, oxygen and nitrogen atoms induce additional IF peaks at approximately 300–400 °C, which are attributed to interstitial-induced Snoek relaxation [9,10,22]. In Ti35-0.5B, only a high-temperature peak appears between 450 and 500 °C, corresponding to a modulus softening. The peak temperature increases with increasing frequency, showing the relaxation nature. This peak has been confirmed as a grain boundary peak [10,19]. However, no obvious low-temperature peaks were observed in Ti35-0.5B, confirming that boron has a low solubility, which is consistent with the XRD results (Figure 1b). The typical EBSD inverse pole figure (IPF) maps and corresponding grain sizes of Ti35-xB are shown in Figure 1c–f. All the samples exhibit nearly equiaxed grains with an anisotropy structure. Ti35-0.25B and Ti35 have similar grain sizes of around 200 μm, indicating that a trace amount of boron does not reduce the grain size. However, as the boron content increases, the grain sizes of Ti35-0.5B and Ti35-1B are significantly reduced to 115 μm and 79 μm, respectively; increased boron content has a significant grain refining effect. Grain refinement is typically associated with element segregation or the formation of precipitates at grain boundaries. To analyze the grain refining effect of boron, SEM characterizations were conducted on the Ti35-xB samples (Figure 2). All the samples exhibit a dendritic structure, it is noteworthy that the dendrite microstructures become significantly finer with the addition of boron (Figure 2a–d). Irregularly shaped precipitates were observed both within the grains and at the grain boundaries in the boron-doped samples. These precipitates are formed during the melting process. Moreover, the amount of precipitates increases significantly with increasing boron content, and the precipitates are mainly distributed at the grain boundaries. A large amount of precipitates is distributed along the grain boundaries in Ti35-0.5B and Ti35-1B, leading to grain refinement [23]. To further investigate the dendritic structure, the enlarged dendrite microstructure, and corresponding EDS maps are shown in Figure 2e. Severe chemical compositional fluctuations are observed, with regional segregation of Zr and Nb elements. In contrast, the distribution of Ti and Zr is uniform. The EDS maps show that Nb is enriched at the dendrites, while Zr is enriched at the interdendritic regions. This is due to the different crystallization rates of elements with different melting points caused by the rapid cooling rate during the melting process, leading to chemical inhomogeneity. This chemical inhomogeneity does not cause significant phase transformations, which is consistent with the XRD results (Figure 1a).

Figure 2.

(a–d) The SEM images of Ti35, Ti35-0.25B, Ti35-0.5B, and Ti35-1B. (e) The enlarged dendritic structure and corresponding EDS maps.

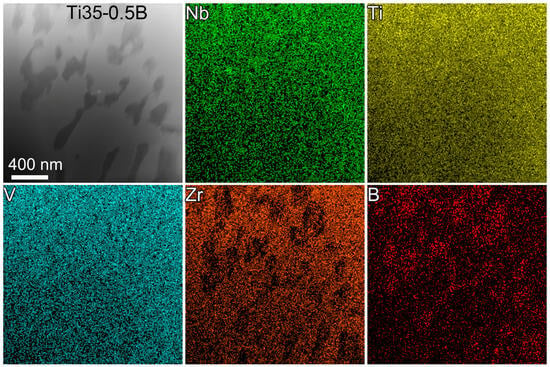

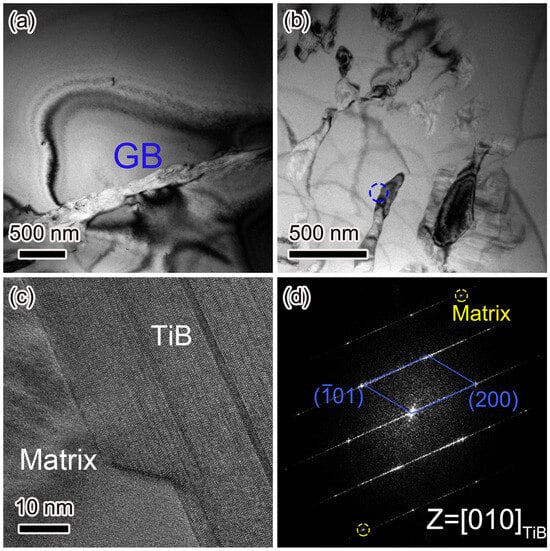

Considering that some precipitates may detach during SEM sample preparation, TEM was conducted to comprehensively analyze the precipitates. Figure 3 shows the precipitates in Ti35-0.5B and the corresponding EDS maps, indicating that the precipitates are rich in boron and depleted of Zr. Unlike oxygen, which has a strong affinity for Zr, boron exhibits a strong repulsion towards Zr, resulting in the formation of Zr-depleted borides [10]. During the solidification process, boron atoms tend to cluster together, forming precipitates rather than being uniformly distributed in the matrix. Thus, excess boron destabilizes the BCC phase, and increases nucleation sites. With an increased number of nucleation sites, the precipitation of borides becomes more favorable, leading to the formation of borides at the grain boundaries and within the grains. The bright-field (BF) TEM images of Ti35-0.5B are shown in Figure 4a,b. Amorphous precipitates are irregularly distributed within the grains, and continuous large-scale precipitates are extensively formed at the grain boundaries, which is consistent with the SEM results (Figure 2). To further determine the phase structure of the borides and their interface relationship with the matrix, Figure 4c shows the high-resolution TEM (HRTEM) image of the boride/matrix interface marked by the blue dashed box in Figure 4b, along with the corresponding fast Fourier transform (FFT) pattern illustrated in Figure 4d. The borides exhibit an orthorhombic TiB structure with high-density stacking faults and display a clear non-coherent relationship between the matrix and borides. In addition, borides affect the dendritic structure. In (Ti48Zr20Nb12Cu5Be15)100−xBx, the undissolved boride can refine the dendritic structure, leading to finer and more uniform microstructures [24]. In Ti35-xB, the dendrites are rich in Nb, and Zr segregates into the interdendritic regions, forming a chemically inhomogeneous structure with Zr and Nb segregation (Figure 2e). The Zr-depleted borides act as barriers, inhibiting the rapid growth of dendrites and thus, causing microstructural refinement. Therefore, the formation of borides simultaneously refines the grain size and the dendritic structure.

Figure 3.

The high-angle annular dark field TEM image of borides and corresponding EDS maps.

Figure 4.

(a,b) The BF TEM images of borides at grain boundary and within the grain, respectively. (c,d) A HRTEM image of the interface between borides and matrix, and corresponding FFT pattern.

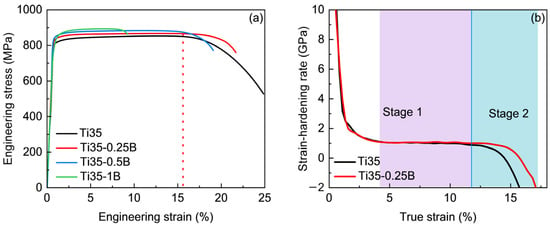

The mechanical properties of Ti35-xB are shown in Figure 5. Figure 5a shows the tensile properties at RT, indicating that boron doping enhances the yield strength and tensile strength but reduces the fracture elongation. The yield strengths of Ti35-xB (x = 0, 0.25, 0.5, 1) are 817 MPa, 841 MPa, 858 MPa, and 868 Mpa, respectively. In Ti35-xB HEAs, the yield strength () includes solid solution strengthening (), grain size strengthening (), and precipitation strengthening (). Given the low solubility of boron atoms, the solid solution strengthening effect from boron is negligible. Thus, the can be expressed as:

Figure 5.

(a) RT tensile stress–strain curves of Ti35, Ti35-0.25B, Ti35-0.5B, and Ti35-1B. (b) The strain–hardening curves of Ti35, and Ti35-0.25B.

The can be determined using the conventional Hall–Petch equation, illustrating the connection between the yield strength of materials and their grain size. The is defined as:

where K is a constant, and D is the average grain size. The K value is referenced to the HfNbTaTiZr alloy and set to 240 MPa μm1/2 [25]. The calculated strength increase from the Hall–Petch relationship due to grain refinement is 6 MPa for Ti35-0.5B, and 10 MPa for Ti35-1B. Therefore, from Equation (l), the is 24 MPa, 35 MPa, and 41 MPa for Ti35-xB (x = 0.25, 0.5, and 1), respectively.

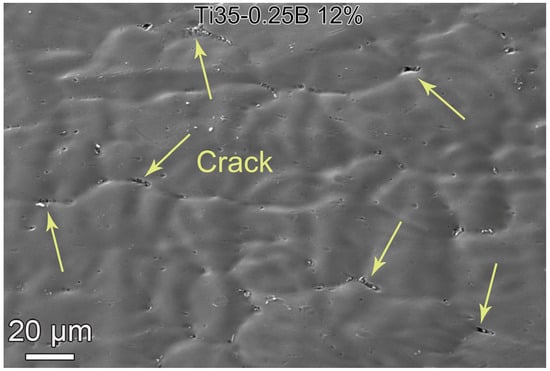

The fracture elongations of Ti35-xB (x = 0, 0.25, 0.5, 1) are 24.8%, 21.7%, 19.1%, and 9.3%, respectively. However, Ti35-0.25B has a better uniform elongation than Ti35. For the alloy design, uniform elongation is an important but challenging property to balance. For TiZrNb-based HEAs, the uniform elongation is typically below 10% due to limited work hardening capability [26,27]. As plastic deformation is typically dominated by planar slip caused by straight screw dislocations, the lack of sufficient slip systems and dislocation multiplication makes it difficult to maintain high work hardening capability [28,29]. To maintain high work hardening capability, a strategy is to form heterogeneous structures or precipitates, which pin dislocations and form dislocation accumulations [30]. However, this often leads to stress concentrations, resulting in a reduction in elongation. In particular, Ti35-0.25B has a 15.4% uniform elongation, significantly higher than TiZrNb, TiZrHfNb, and TiZrVNb [26,27,31]. Figure 5b indicates the strain–hardening curves of Ti35 and Ti35-0.25B. During deformation, Ti35 and Ti35-0.25B exhibit similar work hardening capabilities in stage 1, attributed to the severe lattice distortion and dendritic structure induced by chemical inhomogeneity in HEAs. The variations in chemical composition between dendrites and interdendritic regions lead to changes in local strength, thereby retarding dislocation movement and enhancing the work hardening capability. Despite the observed compositional fluctuations, no change in the phase structure is detected by XRD, indicating that the interfaces between dendrites and interdendritic regions are coherent and do not induce dislocation pinning. Therefore, this does not reduce the fracture elongation. As the deformation increases in stage 2, the work-hardening capability of Ti35 is significantly lower than Ti35-0.25B. In a large strain range (>10%), the cross-slip of dislocations leads to a reduction in strain-hardening capability, which can cause necking [32]. For Ti35, in stage 2 of deformation, the lack of additional dislocation sources and the reduced interaction between dislocations result in a rapid decrease in strain-hardening capability. However, for Ti35-0.25B, borides effectively hinder dislocation movement, leading to dislocation stacking. Additionally, the precipitates act as dislocation sources, increasing dislocation density and thereby enhancing work-hardening capability [33]. Meanwhile, the dendrite refinement effect provides more dendrite boundaries, similar to phase boundaries, which make the dislocation motion sluggish, leading to dislocation accumulation at the interfaces and promoting dislocation interactions. The combined effects of these two mechanisms enable Ti35-0.25B to maintain a high strain-hardening rate even at 15% tensile strain and delay the onset of necking. To investigate the effect of borides on fracture elongation, SEM was conducted on Ti35-0.25B at 12% tensile strain, as shown in Figure 6. Cracks are evident around the borides, as indicated by the yellow arrows in Figure 6. The non-coherent borides increase the interface energy, weaken the phase boundary cohesion, and cause stress concentrations under external loading, acting as crack initiation sites and reducing fracture elongation (Figure 4 and Figure 5a). Hence, the precipitation of an appropriate amount of borides can enhance the strength, strain-hardening capability, and uniform elongation, but it also reduces the fracture elongation.

Figure 6.

The SEM image of Ti35-0.25B at 12% tensile strain, cracks are indicated by yellow arrows.

4. Conclusions

In summary, the microstructure and mechanical properties of Ti35-xB HEAs with varying boron content were systematically investigated. Boron has low solubility and primarily exists as TiB-type borides with an orthorhombic structure. A trace of boron addition is unable to reduce the grain size, but the grain size decreases rapidly as the amount of borides at the grain boundaries increases. Additionally, the Zr-depleted borides at the grain boundaries are confirmed to inhibit dendrite growth, thus refining the dendritic structure. Borides and refined dendritic structures can enhance strain-hardening capability over a large strain range (>10%), thereby delaying the onset of necking. Ti35-0.25B exhibits a high uniform elongation of over 15%, higher than that of TiZrNb, TiZrVNb, and TiZrHfNb refractory multi-component alloys.

Author Contributions

Conceptualization, X.W. (Xinggang Wang) and M.S.; methodology, X.W. (Xinggang Wang); software, X.W. (Xinggang Wang); validation, W.J.; formal analysis, X.W. (Xinggang Wang) and M.S.; investigation, J.L. and X.L.; resources, Q.F.; data curation, X.W. (Xianping Wang); writing—original draft preparation, X.W. (Xinggang Wang); writing—review and editing, X.W. (Xinggang Wang) and M.S.; visualization, X.W. (Xianping Wang); supervision, Q.F.; project administration, X.W. (Xianping Wang); funding acquisition, X.W. (Xianping Wang). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Strategic Priority Research Program of the Chinese Academy of Sciences [grant number XDB0470303], National Natural Science Foundation of China [grant numbers 52101159, 52173303, 52471213].

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, F.; Balbus, G.H.; Xu, S.; Su, Y.; Shin, J.; Rottmann, P.F.; Knipling, K.E.; Stinville, J.C.; Mills, L.H.; Senkov, O.N.; et al. Multiplicity of dislocation pathways in a refractory multiprincipal element alloy. Science 2020, 370, 95–101. [Google Scholar] [CrossRef] [PubMed]

- Couzinié, J.P.; Heczko, M.; Mazánová, V.; Senkov, O.N.; Ghazisaeidi, M.; Banerjee, R.; Mills, M.J. High-temperature deformation mechanisms in a BCC+B2 refractory complex concentrated alloy. Acta Mater. 2022, 233, 117995. [Google Scholar] [CrossRef]

- Shi, T.; Su, Z.; Li, J.; Liu, C.; Yang, J.; He, X.; Yun, D.; Peng, Q.; Lu, C. Distinct point defect behaviours in body-centered cubic medium-entropy alloy NbZrTi induced by severe lattice distortion. Acta Mater. 2022, 229, 117806. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Wang, X.G.; Sun, M.; Liu, J.X.; Liu, X.Q.; Ke, Y.B.; Jiang, W.B.; Wang, H.; Fang, Q.F.; Wang, X.P. Effects of vanadium content on the microstructure and tensile properties of NbTiVxZr high-entropy alloys. J. Alloys Compd. 2024, 987, 174227. [Google Scholar] [CrossRef]

- Wu, Y.D.; Cai, Y.H.; Wang, T.; Si, J.J.; Zhu, J.; Wang, Y.D.; Hui, X.D. A refractory Hf25Nb25Ti25Zr25 high-entropy alloy with excellent structural stability and tensile properties. Mater. Lett. 2014, 130, 277–280. [Google Scholar] [CrossRef]

- He, M.Y.; Shen, Y.F.; Jia, N.; Liaw, P.K. C and N doping in high-entropy alloys: A pathway to achieve desired strength-ductility synergy. Appl. Mater. Today 2021, 25, 101162. [Google Scholar] [CrossRef]

- Lei, Z.F.; Liu, X.J.; Wu, Y.; Wang, H.; Jiang, S.H.; Wang, S.D.; Hui, X.D.; Wu, Y.D.; Gault, B.; Kontis, P.; et al. Enhanced strength and ductility in a high-entropy alloy via ordered O complexes. Nature 2018, 563, 546–550. [Google Scholar] [CrossRef]

- Wang, X.G.; Sun, M.; Liu, X.Q.; Ke, Y.B.; Shi, T.; Liu, J.X.; Jiang, W.B.; Lu, C.Y.; Wang, X.P.; Fang, Q.F. Ultrabroad distribution of multiple anelasticities in O-doped refractory multiprincipal element alloys. Acta Mater. 2024, 271, 119911. [Google Scholar] [CrossRef]

- Son, S.; Lee, J.; Asghari-Rad, P.; Gu, G.H.; Haftlang, F.; Kim, H.S. A facile strengthening method by co-doping boron and nitrogen in CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2022, 846, 143307. [Google Scholar] [CrossRef]

- Pang, J.; Zhang, H.; Zhang, L.; Zhu, Z.; Fu, H.; Li, H.; Wang, A.; Li, Z.; Zhang, H. Simultaneous enhancement of strength and ductility of body-centered cubic TiZrNb multi-principal element alloys via boron-doping. J. Mater. Sci. Technol. 2021, 78, 74–80. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Wu, H.H.; Wu, Y.; Huang, H.L.; Zhu, X.Y.; Zhang, Y.J.; Zhu, H.H.; Yuan, X.Y.; Chen, Q.; Wang, S.D.; et al. Solving oxygen embrittlement of refractory high-entropy alloy via grain boundary engineering. Mater. Today 2022, 54, 83–89. [Google Scholar] [CrossRef]

- Seol, J.B.; Bae, J.W.; Li, Z.; Han, J.C.; Kim, J.G.; Raabe, D.; Kim, H.S. Boron doped ultrastrong and ductile high-entropy alloys. Acta Mater. 2018, 151, 366–376. [Google Scholar] [CrossRef]

- Jia, Y.; Zhang, L.; Li, P.; Ma, X.; Xu, L.; Wu, S.; Jia, Y.; Wang, G. Microstructure and Mechanical Properties of Nb–Ti–V–Zr Refractory Medium-Entropy Alloys. Front. Mater. 2020, 7, 00172. [Google Scholar] [CrossRef]

- King, D.J.M.; Cheung, S.T.Y.; Humphry-Baker, S.A.; Parkin, C.; Couet, A.; Cortie, M.B.; Lumpkin, G.R.; Middleburgh, S.C.; Knowles, A.J. High temperature, low neutron cross-section high-entropy alloys in the Nb-Ti-V-Zr system. Acta Mater. 2019, 166, 435–446. [Google Scholar] [CrossRef]

- Liu, C.; Cui, J.Z.; Cheng, Z.Y.; Zhang, B.Z.; Zhang, S.Y.; Ding, J.; Yu, R.; Ma, E. Direct Observation of Oxygen Atoms Taking Tetrahedral Interstitial Sites in Medium-Entropy Body-Centered-Cubic Solutions. Adv Mater. 2023, 35, 2209941. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Jiang, W.; Ke, Y.; Ge, B.; Wang, X.; Fang, Q. Tetragonal dipole dominated Zener relaxation in BCC-structured Fe-17at%Ga single crystals. Acta Mater. 2023, 258, 119245. [Google Scholar] [CrossRef]

- Sun, M.; Liu, X.Q.; Jiang, W.B.; Lei, Y.W.; Ke, J.G.; Liu, R.; Wang, X.P.; Wu, X.B.; Fang, Q.F.; Liu, C.S. Grain boundary relaxation behavior and phase stability of AlCrTiVx (x = 0, 0.5 and 1) high-entropy alloys. Scr. Mater. 2021, 204, 114144. [Google Scholar] [CrossRef]

- Choi, W.S.; Lee, J.; De Cooman, B.C. Internal-friction analysis of dislocation–interstitial carbon interactions in press-hardened 22MnB5 steel. Mater. Sci. Eng. A 2015, 639, 439–447. [Google Scholar] [CrossRef]

- Almeida, L.; Niemeyer, T.; Pires, K.; Grandini, C.; Pintao, C.; Florencio, O. Anelastic relaxation processes due oxygen in Nb–3.1 at.% Ti alloys. Mater. Sci. Eng. A 2004, 370, 96–99. [Google Scholar] [CrossRef]

- Lei, Z.F.; Wu, Y.; He, J.Y.; Liu, X.J.; Wang, H.; Jiang, S.H.; Gu, L.; Zhang, Q.H.; Gault, B.; Raabe, D.; et al. Snoek-type damping performance in strong and ductile high-entropy alloys. Sci. Adv. 2020, 6, eaba7802. [Google Scholar] [CrossRef]

- Shvindlerman, L.S.; Jannot, E.; Gottstein, G. On precipitation-controlled grain size in the presence of solute segregation. Acta Mater. 2007, 55, 3397–3401. [Google Scholar] [CrossRef]

- Sun, L.; Cao, J.; Li, L.; Li, J.; Wang, J. Boron-induced microstructure evolution and mechanical properties of in situ Ti-based bulk metallic glass composites. Intermetallics 2024, 165, 108156. [Google Scholar] [CrossRef]

- Juan, C.C.; Tsai, M.H.; Tsai, C.W.; Hsu, W.L.; Lin, C.M.; Chen, S.K.; Lin, S.J.; Yeh, J.W. Simultaneously increasing the strength and ductility of a refractory high-entropy alloy via grain refining. Mater. Lett. 2016, 184, 200–203. [Google Scholar] [CrossRef]

- Wang, S.; He, Y.; Zhang, X.; Wang, J.; Wu, M.; Shu, D.; Tang, H.; Sun, B. The effects of interstitial oxygen on mechanical properties of TiZrNb medium-entropy alloy over a wide temperature range. J. Alloys Compd. 2024, 989, 174394. [Google Scholar] [CrossRef]

- Wang, S.; Shu, D.; Shi, P.; Zhang, X.; Mao, B.; Wang, D.; Liaw, P.K.; Sun, B. TiZrHfNb refractory high-entropy alloys with twinning-induced plasticity. J. Mater. Sci. Technol. 2024, 187, 72–85. [Google Scholar] [CrossRef]

- Ma, E.; Wu, X. Tailoring heterogeneities in high-entropy alloys to promote strength–ductility synergy. Nat. Commun. 2019, 10, 5623. [Google Scholar] [CrossRef]

- Lilensten, L.; Couzinié, J.P.; Perrière, L.; Hocini, A.; Keller, C.; Dirras, G.; Guillot, I. Study of a bcc multi-principal element alloy: Tensile and simple shear properties and underlying deformation mechanisms. Acta Mater. 2018, 142, 131–141. [Google Scholar] [CrossRef]

- Qin, S.; Yang, M.; Jiang, P.; Wang, J.; Wu, X.; Zhou, H.; Yuan, F. Designing structures with combined gradients of grain size and precipitation in high entropy alloys for simultaneous improvement of strength and ductility. Acta Mater. 2022, 230, 117847. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, X.G.; Jiang, Z.Q.; Chen, M.; Sun, M.; Zhang, X.F. Phase transition and mechanical performance evolution in TiVZr-Nbx alloys. J. Alloys Compd. 2023, 937, 168458. [Google Scholar] [CrossRef]

- Bu, Y.; Wu, Y.; Lei, Z.; Yuan, X.; Wu, H.; Feng, X.; Liu, J.; Ding, J.; Lu, Y.; Wang, H.; et al. Local chemical fluctuation mediated ductility in body-centered-cubic high-entropy alloys. Mater. Today 2021, 46, 28–34. [Google Scholar] [CrossRef]

- He, F.; Chen, D.; Han, B.; Wu, Q.F.; Wang, Z.J.; Wei, S.L.; Wei, D.X.; Wang, J.C.; Liu, C.T.; Kai, J.J. Design of D022 superlattice with superior strengthening effect in high entropy alloys. Acta. Mater. 2019, 167, 275–286. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).