Abstract

Class II ceramics are a material with high permittivity but low reliability of their capacitance and bias voltage due to high the temperature sensitivity of their dielectric permittivity. In this work, a BST-based (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) (x = 0.2, 0.25, 0.3, 0.35, 0.4) composition with Y5U characteristics was investigated through compositional control to develop high-permittivity and voltage-stable ceramic compositions. Sr doping can increase the breakdown strength (Eb) but decreases the Curie temperature (Tc). The composition at x = 0.3 can obtain optimal comprehensive electrical properties, with high permittivity of 4206, low dielectric loss of ~0.009, and moderate breakdown strength (Eb) of 77.6 kV/cm, which meets Y5U specifications. Typically, a low bias-voltage dependence of capacitance is confirmed with a variation rate of 7.64% under 20 kV/cm. This strategy provides a promising candidate for high-permittivity Class II ceramic dielectrics that can be used in this field.

1. Introduction

In recent years, Ba1−xSrxTiO3 (BST) perovskite ceramics, as well as their derivatives, have been very widely investigated for energy storage, and BST ceramics are considered to be the most promising ceramic material for lead-free energy storage [1,2,3]. By doping and modifying BaTiO3 with different amounts of Sr, a series of BST ceramics with continuously adjustable properties can be obtained [4,5,6,7,8,9]. They have been widely used in electronic devices such as high-voltage ceramic capacitors, multilayer ceramic capacitors (MLCCs), and ferroelectric thin-film memories. High-voltage ceramic capacitors are among the key components used in electronic devices, requiring high permittivity, high electrical endurance, relatively low dielectric loss, excellent temperature characteristics, and good bias stability [10]. Modified BaTiO3 materials with high dielectric constants, good thermal shock resistance, and dielectric reliability are widely used in commercial MLCCs. According to the EIA standard, ceramic capacitors with high permittivity commonly have Y5V (−30~85 °C, ΔC = −82%~22%) and Y5U (−30~85 °C, ΔC = −56%~22%) characteristics belonging to Class II [11]. However, MLCCs that meet have the Y5V characteristic are not good enough to be used in some systems because of their sensitive dielectric temperature behavior. Therefore, much attention has recently been paid to MLCCs satisfying the EIA Y5U specification. The dielectric constant–temperature curve of BaTiO3-based materials can be purposely modified to be flat enough to meet these specifications by adjusting the composition. These ceramic materials typically possess high dielectric permittivity but bad reliability of their capacitance and bias voltage due to their temperature-sensitive dielectric properties. Therefore, it is of great practical significance to develop a material that simultaneously possesses Y5U characteristics and has good bias stability. Yun et al. [12] investigated Ba0.8Sr0.1Ca0.1TiO3 ceramics sintered at 1280~1400 °C with a dielectric constant of about 2000 at room temperature and a breakdown strength of about 20 kV/cm. Lee et al. [13] studied Ba0.5Sr0.4Ca0.1TiO3 ceramics doped with 1.0 wt.% Al2O3 by sintering them at 1420 °C. The dielectric constant, dielectric loss, and bias stability of the samples under an electric field of 30 kV/cm were 829, 0.0039, and 12.94%, respectively. Li et al. [14] obtained Ba0.3Sr0.6Ca0.1TiO3 ceramics doped with 1.5~4.5 wt.% MgO by sintering them at 1340 °C, and the best performance, with a dielectric constant of 1821 and a breakdown strength of 194.3 kV/cm, was obtained at 2.0 wt.% MgO doping.

The addition of CaTiO3 as a broadening agent in traditional BST-based ceramics can make the Curie peak smoother, increase the temperature stability of the material, and slightly enhance the dielectric constant with moderate doping [15,16,17,18,19]. However, the increasing trend is not significant, and when the amount exceeds 0.1, the dielectric constant slightly decreases [20]. A small substitution of Ba2+ (0.143 nm) by Ca2+ (0.106 nm) at the A site can enhance the activity of Ti4+ ions and lead to a slight increase in the dielectric constant. However, a large amount of CaTiO3 can make Ti4+ ions difficult to move and lead to spontaneous polarization, resulting in a decrease in the dielectric constant [19]. The breakdown strength (Eb) increases with Ca addition, facilitating the improvement in breakdown strength and the reduction in dielectric loss. Additionally, it has been reported that when the Ca2+/Ti4+ ratio is greater than 1, Ca2+ occupies the B-site to substitute for Ti4+, and even a small amount of Ca2+ can have a significant effect [21,22,23,24].

The addition of the sintering aid Bi2O3·3TiO2 can reduce the sintering temperature due to its lower melting point (870 °C) and induce the formation of a liquid phase during the sintering process, which promotes the mass-transfer process, and thus, sintering. The presence of a suitable liquid phase greatly facilitates particle rearrangement and mass transport processes, which occur at the grain boundaries. Meanwhile, a small amount of Bi2O3·3TiO2 (1.0–7.0%) can enhance the relaxation characteristics and significantly increase the dielectric constant of the material [25]. In this work, the (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) (x = 0.2, 0.25, 0.3, 0.35, and 0.4) compositions were selected to develop high-permittivity but bias-stable Class II-type dielectrics with Y5U specifications.

2. Experimental Section

A series of (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) (x = 0.2, 0.25,0.3,0.35,0.4) ceramics were fabricated via solid-state synthesis. The analytically pure chemicals were selected, including BaCO3 (≥99.0%), SrCO3 (≥99.0%), CaCO3 (≥99.0%), TiO2 (≥98.0%), and Bi2O3 (≥99.0%). All of the raw materials used here were produced by Sinopharm Chemical Reagent Co. Ltd. The powders were milled with absolute ethyl alcohol for 24 h with using zirconia balls, with a horizontal ball mill (GMS3-4) speed of 120 r/min. The size and mass ratio of the zirconia balls used was 3mm:5mm:7mm = 3:4:3. The mixed Bi2O3 and TiO2 powders in a molar ratio of 1:3 were sintered at 800 °C for 2 h to form a Bi2O3·3TiO2 phase. Similarly, the (Ba0.9−xSrxCa0.1)TiO3 compositions were synthesized at 1100 °C for 2 h to form solid solutions. The final ceramic compositions were designed via the combination of Bi2O3·3TiO2 and (Ba0.9−xSrxCa0.1)TiO3 to be mixed via ball milling. The dried powders were calcined at 1150 °C for 2 h. The powders were mixed with PVA solutions and pressed into disc pellets at 150 MPa. The specimens were debindered at 600 °C for 2 h, and then, sintered at 1280 °C for 2 h. the ceramic pellets were covered with the final powders to avoid Bi volatilization. Finally, the ceramics were ground and polished to ~0.5 mm in thickness and coated with Ag electrodes with a diameter of nearly 6 mm.

Phase structure was evaluated via XRD analysis with a PANalytical type (PANalytical B.V., Almelo, Netherlands). The cell parameters were fitted via the Rietveld method using MDI jade 6.5 software (Livermore, CA, USA). A Quanta 450FEG-type SEM (FEI Corporation, Hillsboro, OR, USA) was employed to characterize the microstructures. The silver paste was printed on both sides of the ceramic sample for the measurement of electrical properties. An E4980A LCR analyzer was introduced to measure the dielectric constant–temperature characteristic from −40 °C to 120 °C with frequency. The bias-voltage characteristic was tested using a Concept 80 broadband dielectric spectrometer with a high-voltage module (Novocontrol GmbH, Montabaur, Germany). A PKCPE1701 ferroelectric testing system (PolyK Technologies, Philipsburg, PA, USA) was employed to measure ferroelectric P-E loops and cyclic fatigue performance.

3. Results and Discussion

Figure 1 depicts the XRD patterns of the (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) ceramics. As shown, both the (110) and (200) peaks exhibit single peaks without splitting, indicating that the ceramic samples show a typical pseudocubic phase. Moreover, the (110) and (200) diffraction peaks gradually shift towards higher angles due to the difference in the ionic radius between the Ba ion (0.135 nm) and Sr ion (0.113 nm). The cell parameters for x = 0.2, x = 0.25, x = 0.3, x = 0.35, and x = 0.4 are 3.9225 Å, 3.9006 Å, 3.8997 Å, 3.8894 Å, and 3.8856 Å, respectively.

Figure 1.

(a) XRD spectra of (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) ceramics; (b) locally enlarged (110) peak; (c) locally enlarged (200) peak. The arrow means that the diffraction peaks shift to high angle due to Sr doping.

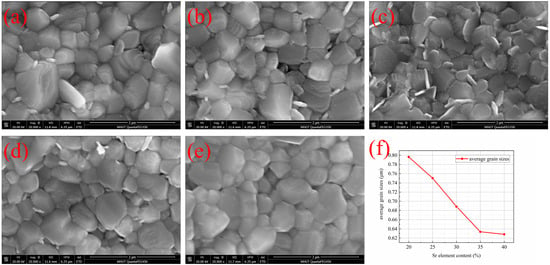

Figure 2 shows the microstructure of the (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) ceramic samples obtained via sintering at 1280 °C. The samples were subjected to cross-sectional thermal etching before testing, with a temperature 100 °C lower than the sintering temperature and a holding time of ten minutes. From the Figure, it can be seen that the (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) ceramics with different Sr element contents exhibit a uniform and dense microstructure, with clear grain boundaries and almost no pores. The average grain size and grain size distribution of the ceramics were calculated via the linear intercept method, as shown in Figure 2f. With increasing Sr content, the average grain size gradually decreases. The average grain sizes at x = 0.2, 0.25, 0.3, 0.35, and 0.4 are 0.79 μm, 0.75 μm, 0.69 μm, 0.63 μm, and 0.62 μm, respectively. This is because the substitution of smaller Ca2+ and Sr2+ ions for larger Ba2+ ions leads to a decrease in the interplanar spacing, resulting in lattice contraction and grain refinement in the ceramics [26,27,28]. This observation is consistent with the XRD analysis.

Figure 2.

SEM images of (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) bulk ceramics: (a) x = 0.2; (b) x = 0.25; (c) x = 0.3; (d) x = 0.35; (e) x = 0.4; (f) variation in the average grain size.

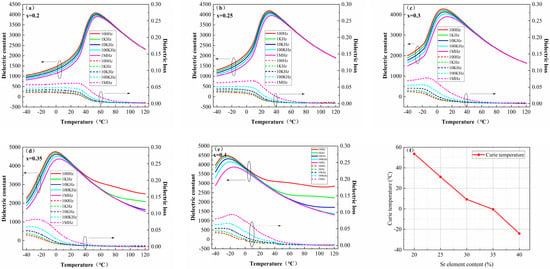

Figure 3 illustrates the dielectric constant–temperature-dependence of the (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) ceramics with frequencies from 100 Hz to 1 MHz. It can be observed that the samples exhibit typical relaxor ferroelectric characteristics with significant frequency dispersion. As the frequency increases, the Curie peak shifts towards high temperatures. Moreover, this phenomenon becomes more pronounced with increasing Sr2+ content [9,12,16]. This can be attributed to the fact that the Curie temperature of BaTiO3 is around 120 °C, while that of SrTiO3 is approximately −250 °C. Therefore, the Curie temperature of the ceramics can be adjusted by adding Sr2+. The main mechanism for this adjustment is as follows: the radius of Sr2+ (0.113 nm) is smaller than that of Ba2+ (0.135 nm). When a portion of the larger Ba2+ ions is replaced by smaller Sr2+ ions, it leads to a contraction in the unit cell volume. This reduces the mobility of Ti4+ ions in the oxygen octahedra, resulting in weaker activity of Ti4+ ions towards the oxygen atoms at lower temperatures. This leads to spontaneous polarization and a decrease in Curie temperature [8,9,28,29,30]. The efficiency of Curie temperature shifting in pure BaxSr1−xTiO3 can be calculated using the following formula:

Figure 3.

Dielectric constant–temperature spectra of the (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) ceramics with various frequencies: (a) x = 0.2; (b) x = 0.25; (c) x = 0.3; (d)x = 0.35; (e) x = 0.4; (f) the variation in Curie temperature with Sr element content.

In this formula, η represents the mobility in degrees Celsius per mole of Curie temperature shift, indicating the change in Curie temperature for each mole or 1% substitution of A-site or B-site ions. tCA is the Curie temperature of the matrix material, and tCB is the Curie temperature of the substituting material. Upon calculating the formula, η(SrTiO3) is −3.7 (°C/mol%), which means that adding 1% (molar fraction) of SrTiO3 to BaTiO3 can decrease its Curie temperature by 3.7 °C. As shown in Figure 3f, the Curie temperatures at x = 0.2, 0.25, 0.3, 0.35, and 0.4 are 53.62 °C, 31.35 °C, 9.17 °C, −0.41 °C, and −24.03 °C, respectively. The phase structure gradually transfers from a ferroelectric to a paraelectric state near room temperature due to compositional modulation [12,26,31,32,33,34].

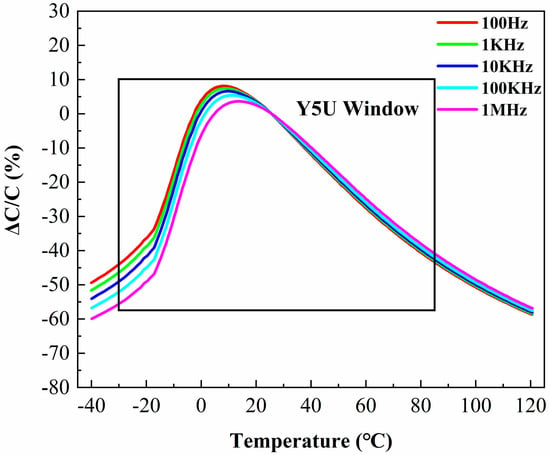

According to the Electronic Industries Association (EIA) standard, the temperature characteristics of capacitors are typically characterized by the ratio of the capacitance change ΔC/C. It can be observed in Figure 4 that the sample at x = 0.3 exhibits Y5U-type temperature characteristics.

Figure 4.

The capacitance–temperature variation rate curve for (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) ceramics.

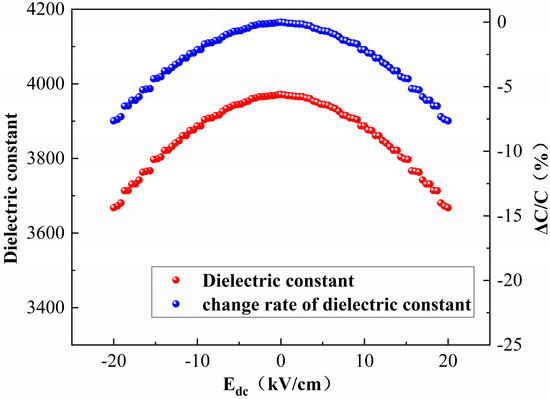

The phenomenon of a decrease in actual capacitance when a DC voltage is applied to a capacitor is called the DC bias characteristic of the capacitor. This characteristic mainly occurs in ceramic capacitor materials with high dielectric constants, such as barium titanate-based ferroelectric ceramics. For ferroelectrics, bias voltage can induce switching of the ferroelectric dipole along the electric field. For a given ceramic capacitor, it can always be used in an external electric field, which can easily impact the stability of the capacitance. Figure 5 shows the voltage dependence of the dielectric constant of (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) ceramics. As seen, the dielectric constant decreases under bias voltage, and the change rate of capacitance is only 7.64%, indicating good bias stability of the sample.

Figure 5.

Voltage dependence of dielectric constant and capacitance of the (Ba0.6Sr0.3Ca0.1)TiO3·0.03(Bi2O3·3TiO2) ceramics.

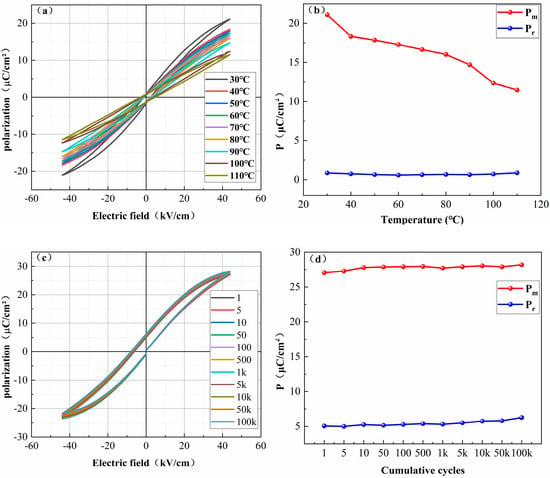

Temperature stability is an important parameter for measuring ceramic dielectric materials. Ceramic dielectric materials need to be used at different temperatures, so they need to have good temperature stability. Figure 6 depicts the temperature dependence and cyclic dependence of ferroelectric polarization of the (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) ceramics. It can be observed that as the temperature increases, the maximum polarization (Pm) of the ceramics gradually decreases, while the residual polarization (Pr) remains unchanged. This is consistent with the dielectric constant–temperature characteristic. The cyclic stability of ceramics can evaluate their long-term stability and enable us to assess whether performance degradation occurs during cycling. Figure 6c,d show the changes in the P-E loops and ferroelectric polarization of the ceramics before and after 105 cycles. It can be observed that ferroelectric polarization of the ceramic shows no significant changes after 105 cycles. The maximum polarization (Pm) of the ceramic slightly increases from 27.06 μC/cm2 to 28.19 μC/cm2, and the remnant polarization (Pr) slightly increases from 5.06 μC/cm2 to 6.27 μC/cm2, respectively. This indicates that the (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) ceramic exhibits excellent cyclic reliability in long-term use.

Figure 6.

(a) Temperature-dependent P-E loops, (b) temperature-dependent ferroelectric polarization, (c) P-E loops for 100 k cycles, and (d) ferroelectric polarization of the (Ba0.6Sr0.3Ca0.1)TiO3·0.03(Bi2O3·3TiO2) ceramics after 100 k cycles.

4. Conclusions

In this study, a series of (Ba0.9−xSrxCa0.1)TiO3·0.03(Bi2O3·3TiO2) ceramics (x = 0.2, 0.25, 0.3, 0.35, 0.4) with Y5U characteristics were prepared using the solid-state method. The XRD test results indicated that all samples exhibited the typical perovskite structure. The SEM results revealed that the samples displayed a dense microstructure. The dielectric property test results showed that with an increase in Sr content, the Curie temperatures of the samples shifted towards lower temperatures. The samples transformed from the ferroelectric phase to the paraelectric phase. At x = 0.3, they were in a phase transition phase (morphotropic phase boundary) and achieved optimal performance. The optimal electrical properties can be achieved with a high dielectric constant εr of 4206, low dielectric loss tanδ of 0.009, and high breakdown strength Eb of 77.6 kV/cm, which meets the Y5U specification. Additionally, the capacitance variation rate is only 7.64% under a high bias voltage of 20 kV/cm, which is indicative of good bias-voltage stability. It can be concluded that the ceramics exhibit high capacitance, good cyclic stability, and bias-voltage stability suitable for potential use in Y5U-type ceramic capacitors.

Author Contributions

Data curation, W.L. and Z.Y.; Project administration, Z.Y. and H.H.; Supervision, Z.Y. and H.L.; Writing—original draft, W.L. and Z.Y.; Writing—review & editing, Z.Y., W.L., M.C. and H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the National Natural Science Foundation of China (51872213), Sanya Science and Education Innovation Park of Wuhan University of Technology (2021KF0014), and Guangdong Basic and Applied Basic Research Foundation (2022B1515120041 and 2022A1515010073).

Data Availability Statement

All data generated or analyzed during this study are contained in this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Randall, C.A.; Yousefian, P. Fundamentals and practical dielectric implications of stoichiometry and chemical design in a high-performance ferroelectric oxide: BaTiO3. J. Eur. Ceram. Soc. 2022, 42, 1445–1473. [Google Scholar] [CrossRef]

- Jain, A.; Wang, Y.G.; Shi, L.N. Recent developments in BaTiO3 based lead-free materials for energy storage applications. J. Alloys Compd. 2022, 928, 167066. [Google Scholar] [CrossRef]

- Alexandru, H.V.; Berbecaru, C.; Stanculescu, F.; Ioachim, A.; Banciu, M.G.; Toacsen, M.I.; Nedelcu, L.; Ghetu, D.; Stoica, G. Ferroelectric solid solutions (Ba,Sr)TiO3 for microwave applications. Mater. Sci. Eng. B 2005, 118, 92–96. [Google Scholar] [CrossRef]

- Liu, B.; Wang, X.; Zhang, R.; Li, L. Energy storage properties of ultra fine-grained Ba0.4Sr0.6TiO3-based ceramics sintered at low temperature. J. Alloys Compd. 2017, 691, 619–623. [Google Scholar] [CrossRef]

- Nayak, R.; Miglani, Y.; Bhardwaj, S. Synthesis and characterization of ferroelectric Barium strontium titanate Ceramics. Mater. Today Proc. 2023, 78, 839–841. [Google Scholar] [CrossRef]

- Pullar, R.C.; Zhang, Y.; Chen, L.; Yang, S.; Evans, J.R.G.; Petrov, P.K.; Salak, A.N.; Kiselev, D.A.; Kholkin, A.L.; Ferreira, V.M.; et al. Manufacture and measurement of combinatorial libraries of dielectric ceramics. J. Eur. Ceram. Soc. 2007, 27, 4437–4443. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, Y.; Jin, Y.; Kong, F.; Gao, J.; Li, S. Enhanced dielectric tunability and reduced dielectric loss in various donor–acceptor co-doped Ba0.675Sr0.325TiO3 ceramics. Mater. Chem. Phys. 2022, 291, 126702. [Google Scholar] [CrossRef]

- Alexandru, H.V.; Berbecaru, C.; Ioachim, A.; Toacsen, M.I.; Banciu, M.G.; Nedelcu, L.; Ghetu, D. Oxides ferroelectric (Ba, Sr)TiO3 for microwave devices. Mater. Sci. Eng. B 2004, 109, 152–159. [Google Scholar] [CrossRef]

- Moussi, R.; Bougoffa, A.; Trabelsi, A.; Dhahri, E.; Graça, M.P.F.; Valente, M.A.; Barille, R.; Rguiti, M. Investigation of the effect of Sr-substitution on the structural, morphological, dielectric, and energy storage properties of BaTiO3-based perovskite ceramics. Inorg. Chem. Commun. 2022, 137, 109225. [Google Scholar] [CrossRef]

- Zhang, J.; Hao, H.; Guo, Q.; Yao, Z.; Cao, M.; Liu, H. Dielectric and anti-reduction properties of BaTiO3-based ceramics for MLCC application. Ceram. Int. 2023, 49, 24941–24947. [Google Scholar] [CrossRef]

- Gong-An, Y.; Yong-Ping, P.; Jin-Fei, W.; Xiao-Long, C.; Yong-Yong, Z. Investigation on the Microstructure and Dielectric Properties of BaTiO3-Nb2O5-Fe2O3Materials Doped with La2O3. J. Am. Ceram. Soc. 2009, 92, 1891–1894. [Google Scholar] [CrossRef]

- Yun, S.; Wang, X.; Li, B.; Xu, D. Dielectric properties Ca-substituted barium strontium titanate ferroelectric ceramics. Solid State Commun. 2007, 143, 461–465. [Google Scholar] [CrossRef]

- Lee, S.-G.; Kim, C.-I.; Kim, B.-C. Dielectric properties of screen-printed (Ba,Sr,Ca)TiO3 thick films modified with Al2O3 for microwave device applications. J. Eur. Ceram. Soc. 2004, 24, 157–162. [Google Scholar] [CrossRef]

- Li, Y.; Dong, G.; Liu, Q.; Wu, D. Preparation and investigation on properties of BST-base ceramic with high-energy storage density. J. Adv. Dielectr. 2013, 3, 13500057. [Google Scholar] [CrossRef]

- Cheng, X.; Shen, M. Enhanced spontaneous polarization in Sr and Ca co-doped BaTiO3 ceramics. Solid State Commun. 2007, 141, 587–590. [Google Scholar] [CrossRef]

- Luo, G.; Zhang, G.; Zhang, Y.; Li, A.; Sun, Y.; Tu, R.; Shen, Q. Wide temperature range of stable dielectric properties in relaxor BaTiO3-based ceramics by co-doping synergistic engineering. Mater. Chem. Phys. 2023, 302, 127629. [Google Scholar] [CrossRef]

- Ali, A.; Uddin, S.; Iqbal, Z.; Lal, M.; Jameel, M.H.; Zaman, A.; Ahmad, A.; Khan, W. Synthesis and characterizations of (Ba1−xCax)Ti4O9, 0 ≤ x ≤ 0.9 ceramics. J. Mater. Res. Technol. 2021, 11, 1828–1833. [Google Scholar] [CrossRef]

- Hsiang, H.-I.; Yang, Y.-H.; Huang, C.-Y.; Yang, K.-H. Dielectric properties of BaTiO3 and Ba0.95Ca0.05TiO3 sintered in a reducing atmosphere. Ceram. Int. 2023, 49, 28751–28757. [Google Scholar] [CrossRef]

- Qin, W.; Wu, W.; Cheng, J.; Meng, Z. Calcium-doping for enhanced temperature stability of (Ba0.6Sr0.4)1−xCaxTiO3 thin film dielectric properties. Mater. Lett. 2007, 61, 5161–5163. [Google Scholar] [CrossRef]

- Yoon, M.-S.; Ur, S.-C. Effects of A-site Ca and B-site Zr substitution on dielectric properties and microstructure in tin-doped BaTiO3–CaTiO3 composites. Ceram. Int. 2008, 34, 1941–1948. [Google Scholar] [CrossRef]

- Chen, C.; Zhuang, H.; Zhu, X.; Zhang, D.; Zhou, K.; Yan, H. Effect of Ca substitution sites on dielectric properties and relaxor behavior of Ca doped barium strontium titanate ceramics. J. Mater. Sci. Mater. Electron. 2015, 26, 2486–2492. [Google Scholar] [CrossRef]

- Hsiang, H.-I.; Yang, Y.-H.; Huang, C.-Y.; Yang, K. Effects of calcination on the dielectric properties and insulation resistance of Ba0.95Ca0.05TiO3 ceramics sintered in a reducing atmosphere. J. Alloys Compd. 2023, 960, 170919. [Google Scholar] [CrossRef]

- Jongprateep, O.; Sato, N. Effects of sintering temperatures on microstructure and dielectric constant of Ba0.05SrxCa0.95−xTiO3 where (x = 0, 0.475 and 0.95). Mater. Today Proc. 2019, 17, 1898–1905. [Google Scholar] [CrossRef]

- Li, C.-X.; Yang, B.; Zhang, S.-T.; Zhang, R.; Cao, W.-W. Effects of sintering temperature and poling conditions on the electrical properties of Ba0.70Ca0.30TiO3 diphasic piezoelectric ceramics. Ceram. Int. 2013, 39, 2967–2973. [Google Scholar] [CrossRef]

- Wang, X.; Chen, F.; Gao, J.-X.; Wang, H.; Jiang, H.; Lu, W. Dielectric properties of (1−x)Sr0.84Pb0.16TiO3−x-xBi2O3 · 3TiO2 ceramics for high voltage capacitor application. Ferroelectrics 2016, 504, 242–251. [Google Scholar] [CrossRef]

- Mao, C.; Yan, S.; Cao, S.; Yao, C.; Cao, F.; Wang, G.; Dong, X.; Hu, X.; Yang, C. Effect of grain size on phase transition, dielectric and pyroelectric properties of BST ceramics. J. Eur. Ceram. Soc. 2014, 34, 2933–2939. [Google Scholar] [CrossRef]

- Song, Z.; Liu, H.; Zhang, S.; Wang, Z.; Shi, Y.; Hao, H.; Cao, M.; Yao, Z.; Yu, Z. Effect of grain size on the energy storage properties of (Ba0.4Sr0.6)TiO3 paraelectric ceramics. J. Eur. Ceram. Soc. 2014, 34, 1209–1217. [Google Scholar] [CrossRef]

- Jeon, J.-H. Effect of SrTiO3 concentration and sintering temperature on microstructure and dielectric constant of Ba1−xSrxTiO3. J. Eur. Ceram. Soc. 2004, 24, 1045–1048. [Google Scholar] [CrossRef]

- Tang, X.G.; Chew, K.H.; Chan, H.L.W. Diffuse phase transition and dielectric tunability of Ba(ZryTi1−y)O3 relaxor ferroelectric ceramics. Acta Mater. 2004, 52, 5177–5183. [Google Scholar] [CrossRef]

- Kathait, G.S.; Panwar, N.S.; Maini, S. Dielectric, piezoelectric and energy storage properties of large grain Ba1−xSrxTiO3 (BST) ceramic system for 0.17 ≤ x ≤ 0.26. Mater. Sci. Eng. B 2023, 297, 116786. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Liu, H.; Zhai, J.; Yao, X. Dielectric nonlinear properties of BaTiO3–CaTiO3–SrTiO3 ceramics near the solubility limit. Mater. Chem. Phys. 2008, 112, 675–678. [Google Scholar] [CrossRef]

- Liu, W.; Ren, X. Large Piezoelectric Effect in Pb-Free Ceramics. Phys. Rev. Lett. 2009, 103, 257602. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.W.; Choi, H.I.; Lee, M.H.; Park, J.S.; Kim, D.J.; Do, D.; Kim, M.H.; Song, T.K.; Kim, W.J. Electrical properties and phase of BaTiO3–SrTiO3 solid solution. Ceram. Int. 2013, 39, S487–S490. [Google Scholar] [CrossRef]

- Curecheriu, L.P.; Mitoseriu, L.; Ianculescu, A. Nonlinear dielectric properties of Ba1−xSrxTiO3 ceramics. J. Alloys Compd. 2009, 482, 1–4. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).