1. Introduction

Titanium (Ti) and its alloys have been widely used in various areas such as aerospace, healthcare, maritime equipment, sport equipment, transportation industries, and automobile manufacturing. Their extensive use can be attributed to their excellent properties such as low density, high specific strength, superior corrosion resistance, and exceptional biocompatibility [

1,

2,

3,

4]. Moreover, Ti and its alloys demonstrate superior mechanical strength and good oxidation resistance, making them specifically competitive with Ni-based alloys and superalloys up to 550 °C [

5]. However, above this temperature, an increase in the anionic oxygen and nitrogen diffusion results in the degradation of the material due to the formation of thick oxide scales, followed by the dissolution of inner oxygen and nitrogen in the metal [

6].

For aerospace applications, Ti and its alloys are generally used for high-temperature applications during service, promoting the formation of a protective layer (titanium dioxide (TiO

2)), which decreases their oxidation resistance [

7]. In particular, high-temperature applications need materials with an appropriate combination of lightness, strength, and oxidation resistance [

8]. While serving at high temperatures, oxidation is a serious problem requiring immediate attention. During oxidation, oxide scales grow on the metal surfaces, and the oxygen on the surface penetrates into the metal substrate for Ti and its alloys due to the high solubility limit of oxygen in Ti [

9]. The process of oxygen penetration and oxide growth during oxidation leads to the embrittlement of the metal surface, which results in the degradation of the mechanical properties of Ti and its alloys [

10]. Furthermore, the alloying elements addition into Ti substrate are believed as an effective way to the improve high temperature oxidation resistance of Ti. Addition alloying elements such as Al [

11], Nb [

12], Si [

13], etc had been utilized to improve oxidation resistance of Ti.

Meanwhile, only a few reports have been found on the oxidation behavior of Ti at temperatures of 700 °C and 800 °C [

14,

15,

16]. There has been limited attention on the cyclic oxidation and hardness characteristics of thermally exposed Ti at elevated temperatures prepared by the inductive sintering method. Therefore, the objective of this study is to investigate the cyclic oxidation and hardness characteristics of Ti prepared by powder metallurgy assisted with inductive sintering at oxidation temperatures of 700 °C, 800 °C, and 900 °C, under air atmosphere. Additionally, the microstructures of Ti before and after oxidation were also observed.

2. Materials and Methods

Ti powder of micro particle size with a purity of 99.99 % was purchased from Aldrich (Finsbury, London, UK). The Ti powder was put in an 80 ml steel jar with steel balls where the ball-to-powder ratio was 5:1. The jar was placed in a high-energy ball milling (Desktop 220v High Energy Vibratory Ball Mill, which was purchased from Across International Co, Livingston, New Jersey NJ, USA). The ball mill was operated at 2000 rpm for 30 min and then taken out of the jar and sintered in a graphite die, which was 0.01 m in diameter and 0.001 m in length. Thereafter, it was placed in a high-frequency induction heat sintering furnace. The samples were sintered under a pressure of 40 MPa and temperature of 1200 °C with a holding time of 5 min.

Prior to the oxidation test, the samples were mechanically polished using a silicon carbide paper up to 2000 grit and then cleaned using ethanol under ultrasonic vibration for 10 min. The samples were placed in a quartz crucible in an alumina container. The oxidation tests were performed for 100 h (5 cycles), where the oxidized specimens from the furnace were used to determine the mass gain at every t = 20 h. Once cooled to room temperature, the weights of the samples with the quartz crucible were measured using an analytical balance with an accuracy of 1 × 10−6 g. Further, the samples were returned to the furnace for future oxidation tests, and the experiment processes were repeated three times for each temperature.

Once the oxidation tests were conducted, the phase structure of the samples before and after oxidation was analyzed using a Rigaku X-ray Diffraction (XRD) machine (Rigaku, Japan) equipped with Cu Kα radiation. The operating current and voltage of the XRD test conditions were 30 mA and 40 kV, respectively. Moreover, the sintered and oxidized samples were cut transversely to display the cross-section and the morphology of the oxidized surface. This was followed by mounting of the samples using a conductive powder, which were then mechanically polished and concisely prepared in accordance with the standard metallographic methods. The sintered Ti samples were observed using an optical microscope (OM) (Keyence, Japan) whereas the cross-section microstructure and morphology of the oxidized Ti samples were observed using scanning electron microscopy (SEM) SU-3500 (Hitachi, Japan) with energy dispersive X-ray analysis (EDX). The combination of the EDX SU-3500 (Hitachi, Japan) results and XRD pattern confirms the contents of the oxide scales formed on the surface of the Ti samples during oxidation.

The hardness of the Ti samples before and after oxidation was determined using the microhardness method equipped with a diamond pyramid (Vickers) indenter. The hardness measurements were conducted using a load of 300 gf with a dwelling time of 13 s.

3. Results and Discussion

3.1. Oxidation Kinetics

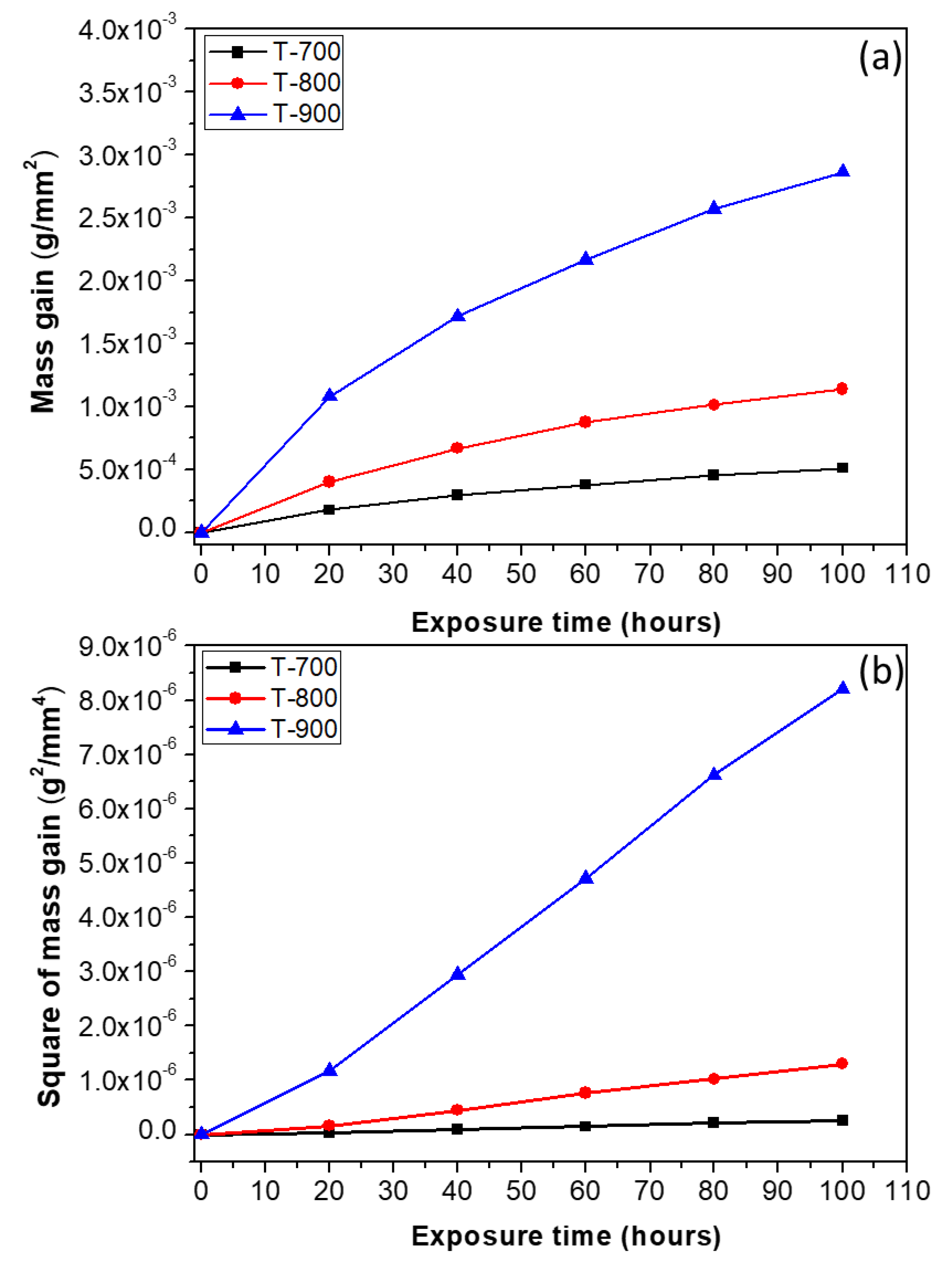

Figure 1a shows the mass gain of Ti as a function of oxidation time at 700–900 °C. The mass gain increases during the initial 20 h (early stage) of the oxidation process and then gradually increases with an increase in the oxidation time at 700 °C and 800 °C. When oxidation occurs at 900 °C, the mass gain significantly increases with an increase in the oxidation time during the first 20 h of oxidation and then periodically increases for 100 h. The rapid increase in mass gain during the early stages of oxidation is because the surface of Ti samples is contamination free after mechanical polishing. From

Figure 1a, it is evident that the mass gain versus oxidation time curves generally fit to the parabolic function at temperature range of 700–900 °C. The curves of the square of mass gain of the samples during oxidation, which are close to a linear line at all oxidation temperatures, are shown in

Figure 1b. It can be noted that the oxidation kinetics obey a parabolic law at all oxidation temperatures [

16,

17,

18]. Kofstad et al. [

19] also determined that the oxidation behavior of Ti was dependent on temperature and time, and that its oxidation behavior followed a parabolic law in the temperature range of 600 °C to 1000 °C. As the mass gain versus oxidation time curves obey the parabolic law, the parabolic rate constant (

kp) of Ti can be measured as follows [

20]:

where Δ

W is the mass change per area of the sample,

kp is the parabolic rate constant, and

t is the oxidation time. The results are listed in

Table 1. It can be noted that the results of

kp are significantly influenced by

t. In short, the higher oxidation temperature, the higher the

kp values will be.

3.2. X-ray Diffraction (XRD) Pattern

To identify the formation of constituent phases, the Ti samples that had undergone sintering and oxidation were analyzed using XRD. The sintered Ti sample is mainly composed of α-Ti phases accompanied by small amounts of β-Ti phases (

Figure 2a). Meanwhile, after oxidation at 700 °C, all the peaks demonstrate TiO

2 phase in rutile form (

Figure 2b), indicating that the α + β phases were transformed to TiO

2 phase during oxidation. This is in accordance with the study reported by Aniołek [

21], where rutile formed on the Ti surface after oxidation at 700 °C. When oxidation occurs at 900 °C, there is no change in the phase of the oxide scales formed, but some new TiO

2 peaks can be observed (

Figure 2c), indicating that the oxide scales contained more TiO

2 phases after oxidation at 900 °C than at 700 °C. Most of the investigations [

22,

23] have stated that the oxide scales were primarily composed of the TiO

2 phase in rutile form, which is in accordance with the present results.

Figure 2 shows that the content of TiO

2 phases increased when the oxidation temperatures increased [

24]. It was also found that the intensity of TiO

2 was significantly increased (

Figure 2c), which indicates that the oxide scale thickness increases when the oxidation temperature increases.

3.3. Microstructures of Ti Samples before and after Oxidation

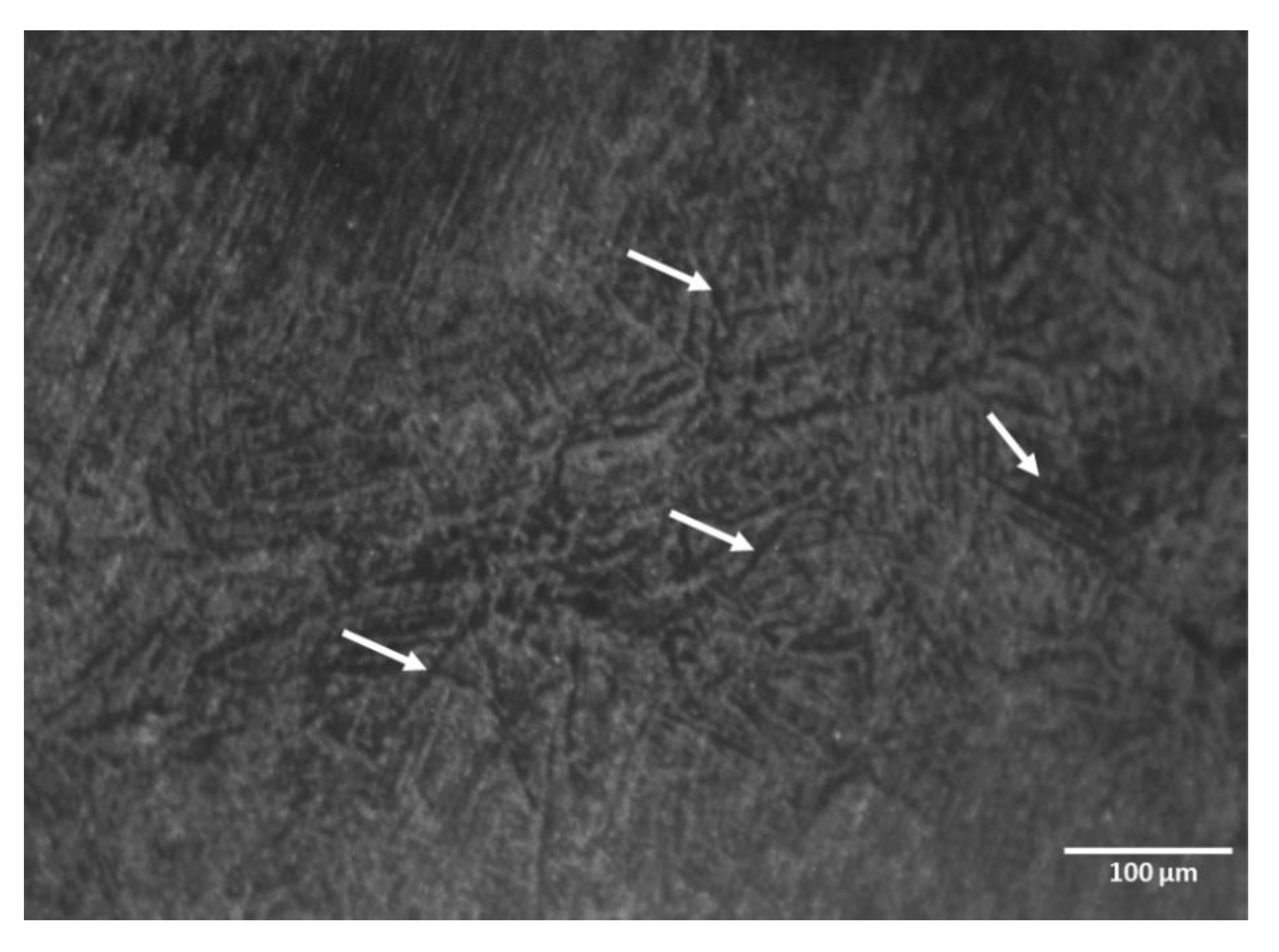

The optical micrograph of the sintered Ti sample is shown in

Figure 3. The α and β phases were found in the sintered Ti sample. Basically, the crystal lattice of β-Ti is body-centered cubic (bcc) that has a lower atomic packing factor than α-Ti, which has a hexagonal close-packed (hcp) structure [

25]. It was reported that the self-diffusion coefficient of the β-Ti phase was significantly higher than that of the α-Ti phase at sintering temperatures of above 900 °C [

26]. Consequently, the β phases (as indicated by the white arrows) might grow faster than the α phases. At a relatively high sintering temperature, the growth of the α and β phases can occur concurrently; however, the growth portion of the β-phase is larger than the α-phase [

27] based on the optical micrograph (

Figure 3).

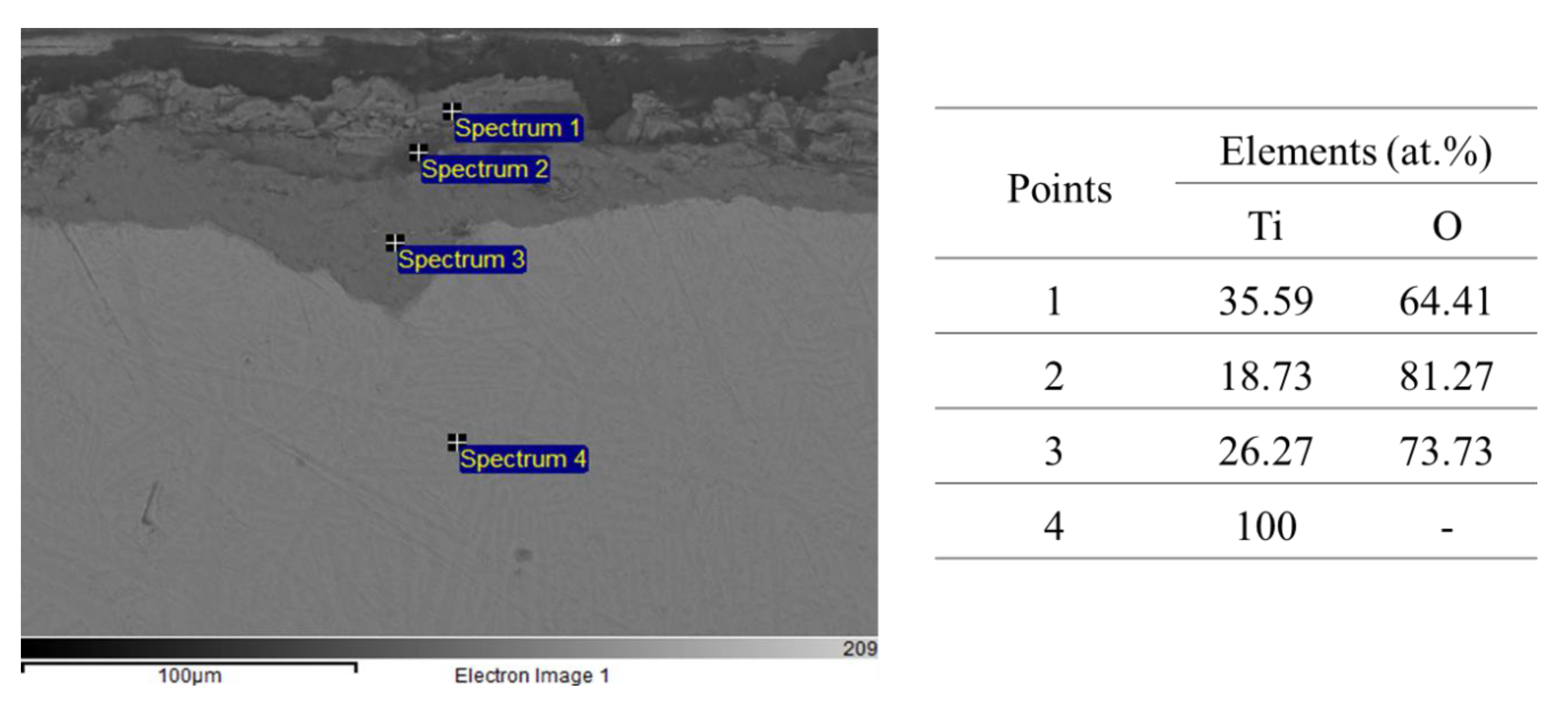

The SEM images of the Ti samples after oxidation at 700 °C and 900 °C along with their energy-dispersive X-ray spectroscopy (EDS) analysis results are shown in

Figure 4 and

Figure 5, respectively. In

Figure 4, four positions have been selected to analyze the composition of Ti samples after oxidation at 700 °C, where points 1–3 refer to the TiO

2 phases formed after oxidation. This confirms that the oxide scales formed on the surface of the Ti sample are mainly composed of TiO

2 phases. For oxidation at 900 °C, the trend followed was similar to that of the oxidized sample at 700 °C, where the oxide scales consisted of the TiO

2 phases, as shown in

Figure 5. Nevertheless, higher oxidation temperatures produced thicker oxide scales on the surface of the Ti sample after oxidation at 900 °C (

Figure 5). It can, therefore, be concluded that the oxidation temperature influences the oxidation rates of the Ti samples, which may affect the thickness of the oxide scales formed on the surface of the Ti samples [

28]. More interestingly, the pores (indicated by yellow arrows) and cracks were also observed in

Figure 5. The formation of pores was attributed to the high diffusion rate and activity of oxygen at oxidation temperature of 900 °C. The oxygen atoms penetrated into the Ti substrate, and then Ti atoms diffused to the surface from the cores and cracks of the oxides scales, causing the thicker oxide scales (

Figure 5); however, as a consequence, the bonding strength between the oxide scales and the substrate became weaker [

29]. In addition, the presence of pores and cracks deteriorated the parabolic oxidation rate of Ti sample after oxidation at 900 °C for 100 h, as presented in

Table 1.

Further, the oxide scales thickness as a function of the oxidation temperature is illustrated in

Figure 6. It can be noted that an increase in the oxidation temperature increases the oxide scales thickness. In the initial stage, oxidation commences with the adsorption of oxygen from air under furnace environment, followed by the nucleation of oxides. The potential chemical reactions that occur at high temperatures under air atmosphere are as follows:

As Ti has great affinity to oxygen, especially at elevated temperatures [

30], it is essential to study the oxidation of Ti. As investigated, the affinity energy of TiO resulting from Ti and oxygen is −28.27 eV. However, TiO is an unstable oxide as it has an anion vacancy. Therefore, the affinity energy of TiO

2 resulting from Ti and oxygen is determined to be −54.99 eV. In short, the TiO

2 phase is more frequently observed than the TiO phase as the monoxide quickly oxidizes to dioxide [

31]. Due to continuous chemical reactions, a TiO

2 thin oxide layer finally forms on the surface of Ti after its nucleation. When the oxidation temperature is increased to 900 °C, the formation of TiO

2 oxide scales is intensified with a higher thickness [

32]. In addition, the TiO

2 oxide scales can be classified into two regions: (i) a thin outer layer that grows outward and (ii) a thicker inner region that grows inward.

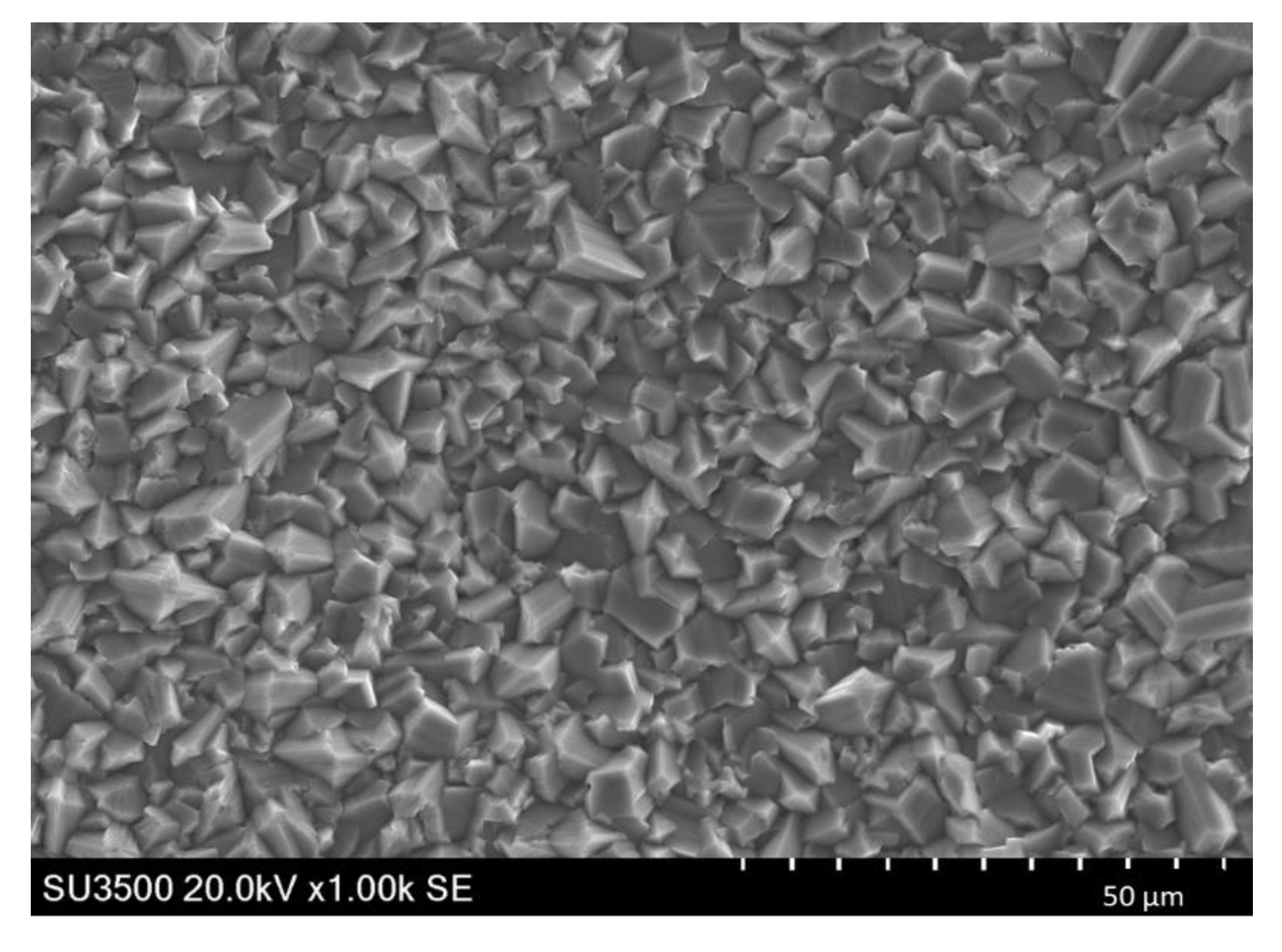

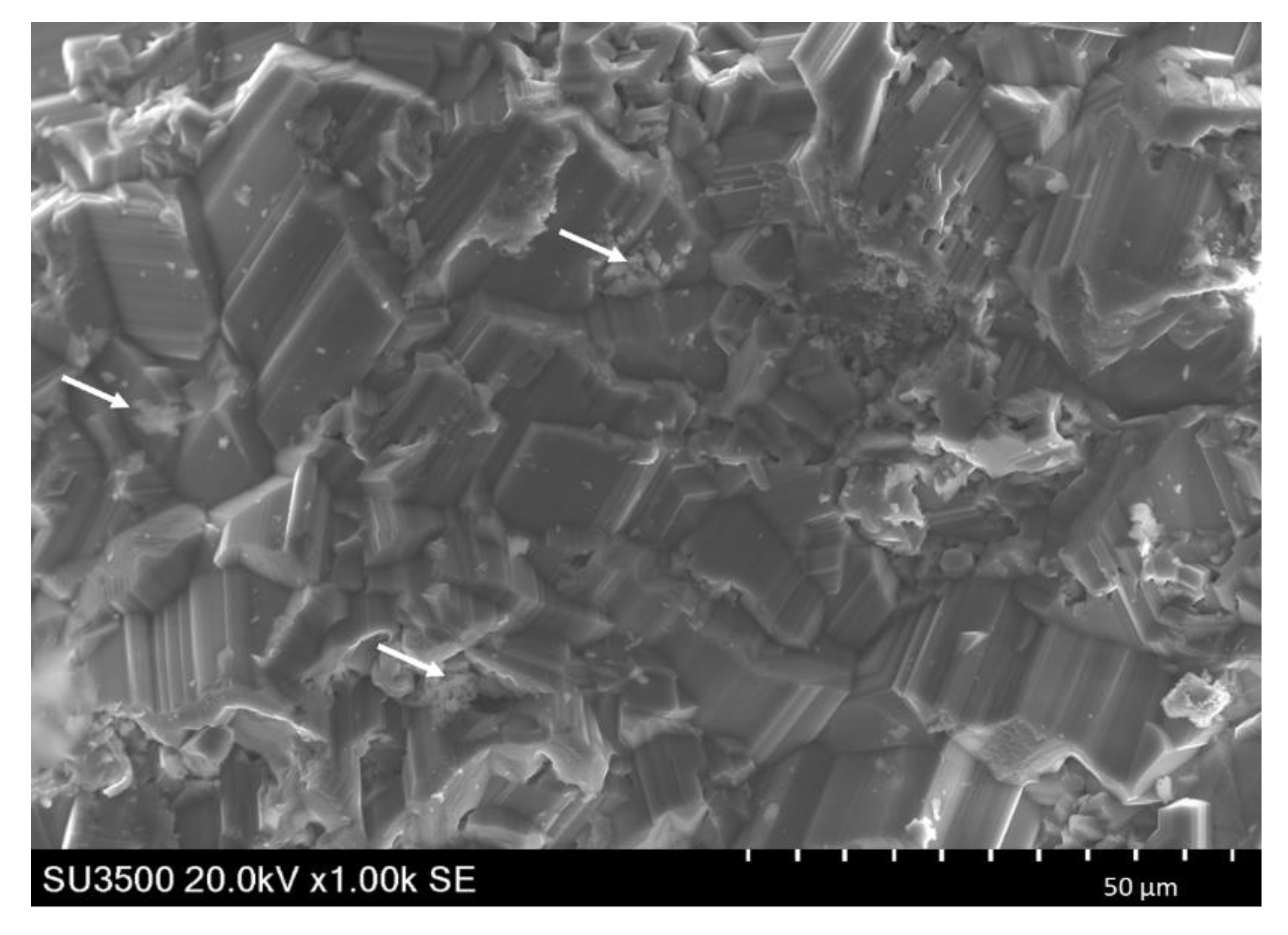

3.4. Surface Morphology of the Oxidized Ti Samples

Figure 7 shows the surface morphology of the Ti sample after oxidation at 700 °C for 100 h. During the initial stages of oxidation, the TiO

2 scale is formed through the inward diffusion of oxygen on the surface of the Ti samples. Smooth homogeneous TiO

2 grains were observed after oxidation at 700 °C for 100 h. The TiO

2 grains entirely covered the oxidized Ti sample. The particle size of the rutile crystal varies, as shown in

Figure 7. On the other hand, after oxidation at 900 °C for 100 h, relatively dense TiO

2 grains existed on the surface of the Ti sample, as shown in

Figure 8. The particle size of the TiO

2 grains further expanded at higher oxidation temperatures. However, TiO

2 grains consisting of agglomerated fine grains with varying directions, which were overgrown in certain areas (indicated by arrows), were observed after oxidation at 900 °C. Further, the surface of the TiO

2 grains shows directional growth at both the oxidation temperatures (

Figure 7 and

Figure 8).

3.5. Hardness Measurements of Ti Samples before and after Oxidation

Hardness measurements were carried out on the substrate, and oxide scales formed on the Ti samples. The variation in hardness values of the Ti samples before and after oxidation is shown in

Figure 9. The hardness values of the Ti substrate decrease when the oxidation temperature increases, whereas the hardness values of the oxide scales increase when the oxidation temperature increases. The increase in oxidation temperature accelerates the diffusion rate of Ti from the substrate to the surface. Further, this reacts with the oxygen available in the surroundings to form TiO

2 oxide scales [

33]; however, pores and cracks were found in Ti sample after oxidation at 900 °C (

Figure 5), resulting in a decrease of its hardness. On the other hand, the lack of Ti concentration in the substrate results in a decrease in its hardness at all oxidation temperatures. The results obtained are in accordance with the previous investigation reported by Alansari and Sun [

34]. Additionally, the TiO

2 phase in rutile form has high hardness, good thermal stability, high refractive index, and high Young’s modulus value [

35]. It was reported by Kofstad [

36] that the oxides formed on titanium at temperatures below 1000 °C under atmospheric oxygen pressure are multilayered rutile. This confirms that TiO

2 formed during oxidation is mainly rutile, which is harder than anatase [

37]; therefore, the formation of rutile in the oxide scales increases the hardness of the Ti samples [

38].

4. Conclusions

The cyclic oxidation and hardness characteristics of thermally exposed Ti were investigated at 700–900 °C for 100 h. The Ti samples were prepared using the powder metallurgy method followed by inductive sintering under a pressure of 40 MPa and temperature of 1200 °C with a holding time of 5 min. The conclusions of the study are as follows:

(1) The oxidation kinetics of Ti obey the parabolic law at oxidation temperatures of 700 °C to 900 °C for 100 h. The kp values increase with an increase in the oxidation temperature and time.

(2) The α + β phases were detected after inductive sintering at a pressure of 40 MPa and temperature of 1200 °C with a holding time of 5 min. Meanwhile, when oxidation was performed at 700–900 °C, the TiO2 phase, referring to rutile form, was detected as a single phase for all the oxidation conditions.

(3) In general, the hardness of oxide scales was increased with increasing oxidation temperatures at 700 °C and 800 °C but it was rather dropped at 900 °C due to the presence of pores and cracks. In contrast, the hardness of the substrate decreased due to the diffusion of Ti atoms at the surface to form oxide scales.

Author Contributions

Conceptualization, F.H.L. and E.-S.M.S.; Methodology, F.H.L., A.S.W., W.B.W., and H.S.A.; Validation, F.H.L. and E.-S.M.S.; Formal Analysis, A.S.W., W.B.W., and H.S.A.; Investigation, A.S.W., W.B.W., and H.S.A.; Resources, F.H.L. and E.-S.M.S.; Data Curation, F.H.L., A.S.W., W.B.W., and H.S.A.; Writing—Original Draft Preparation, F.H.L. and E.-S.M.S.; Writing—Review and Editing, F.H.L. and E.-S.M.S.; Visualization, F.H.L. and E.-S.M.S.; Supervision, F.H.L. and E.-S.M.S.; Project Administration, F.H.L. and E.-S.M.S.; Funding Acquisition, E.-S.M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Deanship of Scientific Research at King Saud University via the Research Group Project No. RGP-160.

Acknowledgments

The authors would like to extend their sincere appreciation to the Deanship of Scientific Research at King Saud University for funding this research through the Research Group Project No. RGP-160. The authors would also like to express high gratitude for having opportunity to utilize some characterization facilities in Research Center for Physics, Indonesian Institute of Sciences.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gong, X.; Chen, R.; Wang, Q.; Wang, Y.; Zhang, N.; Zhang, Z.; Fu, H. Cyclic oxidation behavior and oxide scales adhesion of Al/NiCrAlY coating on Ti alloy. J. Alloys Compd. 2017, 729, 679–687. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants–A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially Ti. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Luana, Q.; Britton, T.B.; Jun, T.S. Strain rate sensitivity in commercial Ti: The competition between slip and deformation twinning. Mater. Sci. Eng. A 2018, 734, 385–397. [Google Scholar] [CrossRef]

- Huda, Z.; Edi, P. Materials selection in design of structures and engines of supersonic aircrafts: A Review. Mater. Des. 2013, 46, 552–560. [Google Scholar] [CrossRef]

- Stringer, J. The oxidation of Ti in oxygen at high temperatures. Acta Mater. 1960, 8, 758–766. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Ti science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Zhang, M.M.; Shen, M.L.; Xin, L.; Ding, X.Y.; Zhu, S.L. High vacuum arc ion plating TiAl coatings for protecting Ti alloy against oxidation at medium high temperatures. Corros. Sci. 2016, 112, 36–43. [Google Scholar] [CrossRef]

- Kitashima, T.; Liu, L.J.; Murakami, H. Numerical analysis of oxygen transport in alpha Ti during isothermal oxidation. J. Electrochem. Soc. 2013, 160, C441–C444. [Google Scholar] [CrossRef]

- Wallace, T.A. The effect of oxidation on the mechanical properties of Timetal-1100, Ti ’95: Science and Technology. In The Institute of Materials; Blenkinshop, P.A., Evans, W.J., Flower, H.M., Eds.; The University Press: Birmingham, UK, 1995; pp. 1943–1950. [Google Scholar]

- Dai, J.; Zhu, J.; Zhuang, L.; Li, S. Effect of surface aluminizing on long-term high-temperature thermal stability of TC4 titanium alloy. Surf. Rev. Lett. 2016, 23, 1552102. [Google Scholar] [CrossRef]

- Yoshihara, M.; Miura, K. Effect of Nb addition on oxidation behavior of TiAl. Intermetallics 1995, 3, 357–363. [Google Scholar] [CrossRef]

- Weihao, X.; Liang, Z.; Huiren, J. Effects of Si on high temperature oxidation resistance of TiAl alloy. J. Beijing Univ. Aeronaut. Astronaut. 2006, 32, 365–368. [Google Scholar]

- Kanjer, A.; Lavisse, L.; Optasanu, V.; Berger, P.; Gorny, C.; Peyre, P.; Herbst, F.; Heintz, O.; Geoffroy, N.; Montesin, T.; et al. Effect of laser shock peening on the high temperature oxidation resistance of Ti. Surf. Coat. Technol. 2017, 326, 146–155. [Google Scholar] [CrossRef]

- Coddet, C.; Chaze, A.M. The role of nitrogen in the oxidation behaviour of Ti and some binary alloys. J. Less Common. Met. 1986, 124, 73–84. [Google Scholar]

- Gemelli, E.; Camargo, N.H.A. Oxidation kinetics of commercially Ti. Materia 2007, 12, 525–531. [Google Scholar]

- Gemelli, E.; Scariot, A.; Camargo, N.H.A. Thermal characterization of commercially Ti for dental applications. Mater. Res. 2007, 10, 241–246. [Google Scholar] [CrossRef]

- Aniołek, K.; Kupka, M.; Barylski, Ł.; Mieszczak, A. Characteristic of oxide scales obtained on Ti in the process of thermal oxidation. Arch. Metall. Mater. 2016, 61, 853–856. [Google Scholar] [CrossRef]

- Kofstad, P.; Hauffe, K.; Kjöllesdal, H. Investigation on the oxidation mechanism of titanium. Acta Chem. Scand. 1958, 12, 239–266. [Google Scholar] [CrossRef]

- Al-Hatab, K.A.; Al-Bukhaiti, M.A.; Krupp, U. Cyclic oxidation kinetics and oxide scales morphologies developed on alloy 617. Appl. Surf. Sci. 2014, 318, 275–279. [Google Scholar] [CrossRef]

- Aniolek, K. The influence of thermal oxidation parameters on the growth of oxide scales on Ti. Vacuum 2017, 144, 94–100. [Google Scholar] [CrossRef]

- Bailey, R.; Sun, Y. Corrosion and tribocorrosion performance of thermally oxidized commercially Titanium in a 0.9% NaCl solution. J. Mater. Eng. Perform. 2015, 24, 1669–1678. [Google Scholar] [CrossRef]

- Jamesh, M.; Sankara Narayanan, T.S.N.; Chu, P.K. Thermal oxidation of titanium: Evaluation of corrosion resistance as a function of cooling rate. Mater. Chem. Phys. 2013, 138, 565–572. [Google Scholar] [CrossRef]

- Arslan, E.; Totik, Y.; Demirci, E.; Alsaran, A. Influence of surface roughness on corrosion and tribological behavior of CP-Ti after thermal oxidation treatment. J. Mater. Eng. Perform. 2010, 19, 428–433. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, W.Y.; Lim, S.H. Microstructure and elastic modulus of Ti–Nb–Si ternary alloys for biomedical applications. Script. Mater. 2006, 54, 887–891. [Google Scholar] [CrossRef]

- Zadra, M.; Casari, F.; Girardini, L.; Molinari, A. Microstructure and mechanical properties of cp-titanium produced by spark plasma sintering. Powder Metall. 2008, 51, 59–65. [Google Scholar] [CrossRef]

- Asl, M.S.; Namini, A.S.; Motallebzadeh, A.; Azadbeh, M. Effects of sintering temperature on microstructure and mechanical properties of spark plasma sintered titanium. Mater. Chem. Phys. 2018, 203, 266–273. [Google Scholar]

- Yang, Y.; Kitashima, T.; Hara, T.; Hara, Y.; Iwasaki, S. Effect of temperature on oxidation behaviour of Ga-containing near-α Ti alloy. Corros. Sci. 2018, 133, 61–67. [Google Scholar] [CrossRef]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Guili, L.; Yong, L. The electronic theory study on high-temperature oxidation mechanism of TiAl alloy. Acta Phys. Sin. 2012, 61, 1–5. [Google Scholar]

- Krishna, D.S.R.; Brama, Y.L.; Sun, Y. Thick rutile layer on titanium for tribological applications. Tribol. Int. 2007, 40, 329–334. [Google Scholar] [CrossRef]

- Gaddam, R.; Shefer, B.; Pederson, R.; Antti, M.L. Oxidation and alpha-case formation of Ti-6Al-2Sn-4Zr-2Mo alloy. Mater. Charact. 2015, 99, 166–174. [Google Scholar] [CrossRef]

- Alansari, A.; Sun, Y. A comparative study of the mechanical behaviour of thermally oxidised commercially Titanium and zirconium. J. Mech. Behav. Biomed. Mater. 2017, 74, 221–231. [Google Scholar] [CrossRef] [PubMed]

- Chuang, L.C.; Luo, C.H.; Yang, S.H. The structure and mechanical properties of thick rutile–TiO2 films using different coating treatments. Appl. Surf. Sci. 2011, 258, 297–303. [Google Scholar] [CrossRef]

- Kofstad, P. High Temperature Corrosion; Elsevier Applied Science: London, UK, 1988. [Google Scholar]

- Hanaor, D.A.H.; Sorrell, C.C. Review of the anatase to rutile phase transformation. J. Mater. Sci. 2011, 46, 855–874. [Google Scholar] [CrossRef]

- Hannora, A.; Ataya, S. Structure and compression strength of hydroxyapatite/titania nanocomposites formed by high energy ball milling. J. Alloys Compds. 2016, 658, 222–233. [Google Scholar] [CrossRef]

- Kumar, C.A.V.; Rajadurai, J.S. Influence of rutile (TiO2) content on wear and microhardness characteristics of aluminium-based hybrid composites synthesized by powder metallurgy. T. Nonferr. Metal Soc. 2016, 26, 63–73. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).