Abstract

Autoxidation processes to achieve curing of alkyd resins in paints, inks, and coatings are ubiquitous in many applications. Cobalt soaps have been employed for these applications for many decades and most of the paint and ink alkyd resin formulations have been optimized to achieve optimal benefits of the cobalt soaps. However, cobalt soaps are under increased scrutiny because of likely reclassification as carcinogenic under REACH (Registration, Evaluation, Authorisation, and Restrictions of Chemicals) legislation in Europe. This is critical, since such coatings are available for regular human contact. Alternative manganese- and iron-based siccatives have been developed to address this need for over a decade. They often show very high curing activity depending on the organic ligands bound to the metal centers. Recently, new classes of catalysts and modes of application have been published or patented to create safe paints, whilst delivering performance benefits via their unique reaction mechanisms. Besides the use of well-defined, preformed catalysts, paint formulations have also been developed with mixtures of metal soaps and ligands that form active species in-situ. The change from Co-soaps to Mn- and Fe-based siccatives meant that important coating issues related to radical-based curing, such as skinning, had to be rethought. In this paper we will review the new catalyst technologies and their performance and modes of action, as well as new compounds developed to provide anti-skinning benefits.

Keywords:

cobalt carboxylate; coating; autoxidation; alkyd; siccative; polymerization; iron; manganese 1. Introduction

The creation of coatings can be traced to prehistoric cave paintings from around 30,000 years ago, but the advent of lacquers for protection started in China over 2000 years ago and have since developed into a wide range of chemistries, application methods, and formulations to cope with the applications and coating performance criteria [1]. They are ubiquitous, essential, and provide both protection and beauty to all manner of surfaces, for example: Ships, mobile phones, satellites, housing, furniture, light-bulbs, paper, and bridges [2]. The coatings market is significant, worth $178 billion USD in 2018, and growing at a 4.5% compound annual growth rate [3]. A wide range of chemistries have been developed to create thermoplastic or thermosetting chemistries with common examples including (poly)urethane, -acrylic, -epoxy, and -phenolics. Technology continues to progress; in the last decade new functionalities have been developed for coatings including easy-to-clean [4], anti-pollution [5], and self-healing [6].

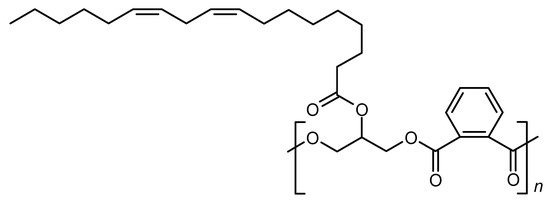

Recently coatings are moving towards using sustainable, environmentally-friendly raw materials [7,8]. This shift in approaching health, safety, and sustainability concerns does not only originate from change in legislation, but also from agreed restrictions in using less desirable raw materials, including restricting the use of organic solvents. As part of this trend, alkyd resins [2] have found renewed interest as a paint based on natural ingredients [9]—they are essentially polyesters prepared from modified vegetable oils, polyols like glycerol, natural, unsaturated fatty acids, and dibasic acids (see Figure 1 as an example) [10]. They are often used in decorative applications, vehicle coatings, coil coatings, and marine coatings [2].

Figure 1.

Structure of a typical alkyd resin with linoleic acid as side group.

1.1. Radical Curing Chemistry

Alkyd resins cure via a physical and chemical drying process that requires catalysis [11,12] (Figure 2). A liquid paint dries physically by releasing solvent (water or organic) after application to a surface. The alkyd resin within the paint accounts for most of the formulation and gives the coating its strength and durability. It forms a liquid layer containing the other components, such as pigments and surface-active components. During the physical drying, a tandem process occurs via a chemical process of air-oxidation. This hardens the film beyond a tacky consistency to give the final coating properties.

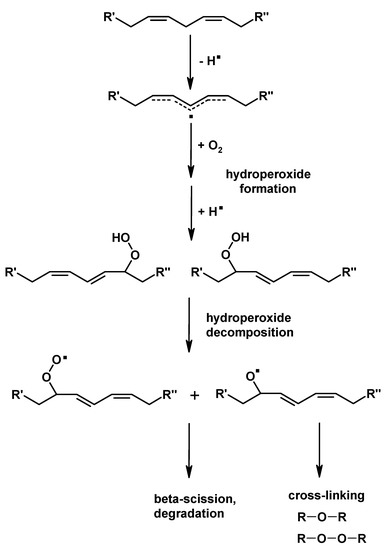

Figure 2.

Simplified scheme of mechanisms of alkyd curing via Oxidative Catalysis and O2.

The chemical air-drying process is facilitated via the available unsaturation for crosslinking. Natural drying oils like linseed oil, tung oil, dehydrated castor oil, tall oil (from wood pulp), and oitica oil can be used as they have large amounts of conjugated double-bonds, essential for better drying properties versus semi-drying oils like sunflower oil or soybean oil. The degree of unsaturation affects the dry time and final resin compatibility and amphiphilicity, important for preparing resins for water- or solvent-borne coatings. Alkyds with 55% w/w oil content are long-oil alkyds and mostly suited to solvent-borne formulations and have the slowest dry times. Medium (45–55%) and shorter oils (<45% w/w oil) dry faster but give less crosslinking in relation to the oil content. The final alkyd resin can be tuned with additional chemistry, such as the number of hydroxyl groups, degree of branching, reaction with epoxy or urethanes to make polymeric hybrids, or by simply changing the molecular weight, to improve properties such as the time to form a hard film (dry-time) or glass transition state for flexibility versus chemical resistance [10].

The oxidative cure can occur in the presence of oxygen, but it can take days to form a tack-free film and might only be active at the coating surface where the most oxygen is available for curing, leading to a soft coating and a hard surface. Long dry-times and soft coatings are not commercially viable. This has long been solved by using a catalyst, a so-called ‘primary drier (siccative)’, based on a metal soap carboxylate, that can reduce the dry-time to hours rather than days. The most commonly used are organic-acid salts of cobalt. Coatings formulations often include other (so called ‘secondary’) metal carboxylate driers (siccatives) that cannot start cross-linking, but facilitate redox processes throughout the coating, examples metals include aluminium, zirconium, and barium. Alkyd coating formulations also contain other additives to prevent adsorption of siccatives onto pigment particles retarding the drying process, such as pigment dispersants or calcium-based soaps, that can block the pigment surface.

The oxidative curing process takes place via radical autoxidation reactions (Figure 2). The radical curing reactions are initiated by metal catalysts via a peroxidation reaction involving minute amounts of alkylhydroperoxide (ROOH) present in the resin containing an unsaturated resin yielding an alkoxy radical (RO•) and (formally) a hydroxyl radical (HO•) (reaction (1)). However, as this reaction often occurs via binding of ROOH to the metal ion, an oxidized metal-oxo species is formed (reaction (2)). Both the alkoxy radical and the metal-oxo species react with unsaturated fatty acid moieties (RH), to form the alkyl radical (reactions (3) and (4)), which in turn reacts nearly diffusion limited with dioxygen to form peroxyl radicals (reaction (5)). The peroxyl radicals react efficiently with unsaturated fatty acids, yielding more alkyl radicals. Reactions (1)–(4) are known as initiation reactions and reactions (5) and (6) are propagation reactions.

In some cases, also reactions between metal ions in their lower valence state and dioxygen may take place, leading to an oxidized metal species with a superoxide radical bound (which can then react with an unsaturated fatty acid, such as depicted in reaction (6), where in this case ROO• should be read as M(OO•−)).

ROOH ➔ RO• + HO•

Mn+-OOR ➔ RO• + O=M(n + 1)+

RO• + RH ➔ ROH + R•

O=M(n+1)+ + RH ➔ Mn+-OH + R•

R• + O2 ➔ ROO•

ROO• + RH ➔ ROOH + R•

ROO• + ROO• ➔ RCHO + ROH + O2

Termination of the radical processes occur by different reactions. First, two peroxyl radicals react to form aldehyde and alcohol terminal products (reaction (7)). Further, importantly for alkyd curing, the radical intermediates (R•, RO•, and ROO•) react further with each other to form species, such as R–R, R–O–R, R–OO–R [13].

The chemistry of alkyd resin curing is rather complicated to study in detail and often a model substrate based on ethyllinoleate has been employed [10,13,14]. Various spectroscopic techniques can be used to study reactions (like Infrared and Raman spectroscopy), and using this substrate can help to understand the mechanisms of the Mn and Fe catalysts on alkyd resin curing as will be highlighted in the subsequent paragraphs.

1.2. Regulatory Changes for Cobalt

Cobalt-based siccatives have faced reclassification as a class 1b carcinogen. The main participants of this reclassification process are the Cobalt REACH consortium [15], a non-profit group tasked with preparing the registration dossiers for cobalt and cobalt compounds and a special consortium of major European producers of metal carboxylates (for siccatives) that was established in 2007 within the CoRC [16].

Recently, five cobalt salts—cobalt sulfate, cobalt dichloride, cobalt dinitrate, cobalt carbonate, and cobalt di(acetate)—have been proposed for restriction by ECHA as Carc. 1B (inhalation), Muta. 2, and classified same as Repr. 1B and skin and respiratory sensitizers. In 2016, RAC (ECHA) agreed that the cobalt salts should be considered as genotoxic carcinogens with a non-threshold mode of action and endorsed a dose–response relationship for these substances. However, in their REACH registration dossiers, industry (CoRC) identified the cobalt salts as non-genotoxic carcinogens with a threshold mode of action. A DNEL value of 40 μg Co/m3 is used by the registrants in their Chemical Safety Assessments. According to the dose-response relationship derived by RAC, work-life exposure to this DNEL value corresponds to an excess lifetime cancer risk of 4 × 10−2. The stakeholder engagement window ended June 19, 2019, and a meeting was held between ECHA and the RAC on June 6, 2019—the final opinion on reclassification is expected end of 2019. It is highly likely that the five above-mentioned salts will be classified without threshold resulting in their eventual restriction and subsequent placement on a list of substances requiring authorization before use.

The members of the Cobalt Institute and Cobalt REACH Consortium agreed to self-classify the following substances under the UN Globally Harmonized System for Classification and Labelling of Chemicals (UN GHS) as specific target organ toxicants following repeated exposure (STOT RE 1 (GI Tract); H372).

- Neodecanoic acid, cobalt salts EC No. 248-373-0. CAS No. 27253-31-2; EC No. 257-798-0; CAS No. 52270-44-7;

- Cobalt, borate Neodecanoate complexes EC No. 270-601-2; CAS No. 68457-13-6;

- Stearic acid, cobalt salts EC No. 237-016-4; CAS No. 13586-84-0. EC No. 213-694-7; CAS No. 1002-88-6;

- Resin and rosin acids, cobalt salts EC No. 273-321-9; CAS No. 68956-82-1;

- Naphthenic acids, cobalt salts EC No. 263-064-0. CAS No. 61789-51-3; EC No. 285-220-7; CAS No. 85049-49-6;

- Cobalt bis(2-ethylhexanoate), CAS No. 136-52-7. This substance has been self-classified from Repr. 2 to Repr. 1B.

The industry is therefore increasingly responding to the reality of cobalt and cobalt-compound restrictions. The TSCA Reset in the US has led to Consent Orders (formerly known as SNURs) for new PMNs that restrict the use of cobalt siccatives for consumer use. Cobalt neodecanoate, a classic cobalt-based siccative for alkyds and inks, is a good example of restricted use (to tires, for non-consumer usage only).

It is worth mentioning that the proposed EU Harmonized Classification of cobalt metal as a carcinogen, mutagen, and reproductive toxicant will also have a significant effect on cobalt metal powder users [17]. Further, it should be mentioned that cobalt(II) carboxylates (‘soaps’) form upon hydrolysis cobalt(II) aqua species, which are the same or very similar to those present in for example cobalt(II)sulfate hexahydrate.

It is likely that cobalt carboxylates will therefore be reclassified as carcinogenic due to the read across strategies used by Competent Authorities (chemical similarity of the salts) and because cobalt itself has been classified.

As a carcinogen, cobalt can be a risk to human health since coatings and inks cured via cobalt-catalysts are often in frequent human contact (especially when applying paints or scratching out old paint layers). The industry recognizes that the continued use of cobalt catalysts risks both human health and the movement towards a sustainable future. As a result, cobalt catalysts have been continuously phased-out of alkyd (and ink) formulations as coating firms prepare for a regulatory-driven shift in the market.

1.3. Cobalt Alternative Technologies

Cobalt reclassification requires forward-thinking firms to develop new strategies and products; this is reinforced by the issue of cobalt pricing affecting manufacturers—cobalt supplies have seen major supply shortages with the advent of increased battery production for electronic cars [18].

Due to the combined pressures of regulatory change and demand leading to volatile pricing, the coatings and ink industries have been looking for alternative technologies. This area of research has been evolving for decades, as cobalt was the replacement for lead and alternatives currently exist from other metal soap carboxylates that are well known in the market, based on manganese, iron, and vanadium. The most credible carboxylate technologies have well-known disadvantages [19]. Manganese siccatives are dark and create discoloration, iron siccatives are too slow at room temperature and vanadium siccatives are toxic [20,21].

The development of cobalt-replacement strategies is discussed below, with a short review of past technologies (1.3.1), followed by a detailed review of new Fe- and Mn-based catalysts studied or used as siccatives for alkyd resin formulation in Section 1.3.2. discussed below.

1.3.1. Traditional Cobalt-Catalyst Replacement Strategies: Manganese and Iron Soaps

The use of manganese salts or soaps as alternatives to cobalt has been an appealing proposition for many years [22]. Especially, manganese(II)(2-ethylhexanoate)2 (abbreviated as MnII(2-EH)2) has been applied in various paint and ink formulations. However, as the activity towards curing of MnII(2-EH)2 is significantly lower than that of the cobalt soaps and, therefore, the inclusion level has to be much higher [13,23]. As a consequence, when strongly colored Mn(III) ions are present in the manganese soap formulation, or are formed due to oxidation processes, the color of the manganese in the paint formulation or in the applied coating layer may be apparent and this is undesired in white or light-colored paint formulations. By adding ligands that contain amine donor atoms (either aliphatic amines or aromatic amines or a combination thereof), the activity of the manganese centers can be enhanced and therefore the dose level can be lowered (vide infra).

The use of manganese soaps is limited due to the high dosage needed, which leads to an increased cost in use and often unacceptable coloring of the paint formulation or coating layer. Addition of a bidentate ligand to manganese soap, such as 2,2’-bipyridine (bpy, Figure 3), leads to a significant increase in activity, allowing a reduction of the level of manganese soap at a similar level as what is used for cobalt soap [24]. A benefit is then that the color of manganese is less apparent than without bpy added, but still the coloring issue can prohibit the use in many formulations. Bpy is often used in ink formulations in combination with manganese soaps, because inclusion of a dark colored siccative will not be noticed in these dark formulations. Detailed spectroscopic studies and X-ray analysis revealed that tetranuclear manganese clusters may be formed and involved in the catalysis [25]. However, it should be noted that in general intermediates that are crystallized and analyzed may not be the species involved in the oxidative processes.

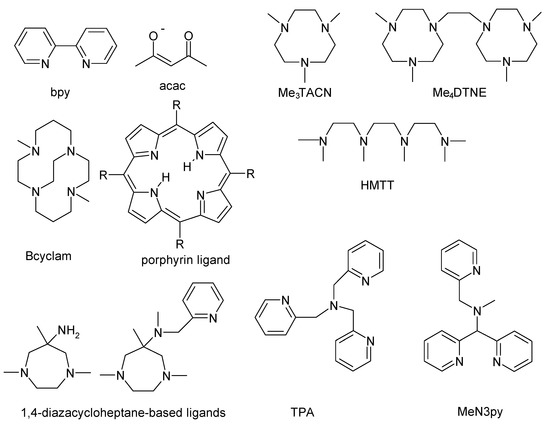

Figure 3.

Ligands and additives exhibiting paint drying activity when mixed with Mn salts or as Mn-ligand complexes discussed in the text: 2,2′-bipyridine (bpy), acetylacetonate (acac), 1,4,7-trimethyl-1,4,7-triazacyclononane (Me3TACN), 1,2-bis(4,7-dimethyl-1,4,7-triazacyclononan-1-yl)-ethane (Me4DTNE), 4,11-dimethyl-1,4,8,11-tetraazabicyclo[6.6.2]hexadecane (Bcyclam), 5,10,15,20-tetrakisphenylporphyrin (R = phenyl; porphyrin ligand), N,N,N′,N″,N′′′,N′′′-hexamethyltriethylenetetraamine (HMTT), 6-amino-1,4,6-trimethyl-1,4-diazacycloheptane and 1,4,6-trimethyl-6{N-pyridin-2-ylmethyl)-N-methylamino}-1,4-diazacycloheptane (1,4-diazacycloheptane based ligands), tris(pyridin-2-ylmethyl)amine (TPA), and N-methyl-N(pyridin-2-ylmethyl)-bis(pyridin-2-yl)methylamine (MeN3py).

The use manganese complexes with acetylacetonate (acac, Figure 3) for paint curing has been investigated [26,27,28]. When using purified ethyllinoleate that have no hydroperoxide impurities, the initiation reaction is much shorter than when MnII(2-EH)2 is used. A further improvement has been made by addition of one equivalent of bpy, which has led to the suggestion that coordination of the nitrogen donor leads to a stabilization of the Mn(II) species, thereby increasing the rate of H• abstraction of the ethyllinoleate by the Mn(III) species. A disadvantage noted was that the Mn(acac)2-bpy leads to more β-scission cleavage of the double bonds leading to formation of volatile aldehydes. As a consequence, the curing of alkyd resins will be less than optimal because the extent of polymerization will be diminished. A benefit noted by using acetylacetonate is that a reduced skinning behavior was observed [28]. As acetylacetone is volatile, it may that when bound to the metal ion it prevents it to react with the alkyd resin (or hydroperoxides present in the alkyd resin), but when the paint formulation is applied on a surface, acetylacetone that is not bound to the metal center may evaporate, allowing the metal ion to react with the peroxides to initiate the curing reactions. This assumes that there is an equilibrium, which is kinetically competent, between acetylacetonate that is bound to the manganese ion and acetylacetone that is in the paint formulation.

Iron soap drying catalysts have also been studied, but their application has been limited due to the low activity. Only in stoving enamels such siccatives have been implemented. Miccichè et al. have shown by X-ray crystallography and Mössbauer analyses that a μ3-oxo carboxylate bridged complex is formed and this may be involved in the alkyd resin oxidation process [29]. Addition of ascorbic acid palmitate enhances the reactivity of the curing process, which has been explained by an increased rate of reduction of one of the iron centers by ascorbic acid, which in turn reacts with the alkyd resin to form the alkyd resin radical species (which reacts with O2 to form peroxyl radicals as explained in Section 1.2) [10].

1.3.2. Contemporary Cobalt-Catalyst Replacement Strategies

Manganese-Based Complexes Using Polydentate Nitrogen Donor Ligands

Various other classes of Mn complexes have been patented as paint siccatives. A very active mononuclear Mn complex with a cross-bridged tetraaza macrocyclic ligand (Bcyclam, Figure 3) has been patented [30]. Model experiments with β-carotene used as a model substrate indicated that radicals are formed when methyllinoleate was added. A very good curing of linseed oil was observed.

More recently, a patent by Dura Chemicals covered the use of Mn porphyrins [31]. Examples using MnIII(5,10,15,20-tetrakisphenylporphyrin) show a good curing activity (Figure 3). As porphyrin complexes are intensely colored, such catalyst can only be used at low concentrations to prevent coloring of the paint layer.

Whilst initially the use of manganese salts or complexes did not seem to be very promising, the finding that [MnIV2(μ-O)3(Me3TACN)2](PF6)2 (Me3TACN = 1,4,7-trimethyl-1,4,7-triazacyclononane–Figure 3) was active towards curing opened up new possibilities to formulate paint compositions with alternative siccatives based on manganese [32,33]. Mixtures of MnII salts and a molar excess of Me3TACN or a molar excess of MnII salts and Me3TACN ligand have been patented for drying alkyds as an alternative to synthesized catalysts [34,35]. This compound was already known as catalyst to activate hydrogen peroxide for bleaching of stains in laundry and dishwash cleaning applications [36]. One of the features of this catalyst is that the triazacyclononane ligand is tightly bound to the manganese ion, preventing fast formation of manganese hydroxide precipitation commonly observed in the alkaline detergent formulations when manganese salts or complexes are used [37].

When an excess of ligand is used, the level of Mn can be reduced leading to diminished color by Mn in the paint formulation or coating applied [34]. Hardness improvement has been observed when an excess of Mn was used [35]. Furthermore, patents were published wherein mixtures of Mn complexes and Me3TACN were claimed, yielding improved curing activity when [MnIV2(μ-O)3(Me3TACN)2](PF6)2 was mixed with Me3TACN ligand [38], or when non-Me3TACN Mn complexes were mixed with the Me3TACN ligand [39].

Related to the Mn complexes with Me3TACN is the class of bridging triazacyclononane ligands covered in recent patent filings. The use of 1,2-bis(4,7-dimethyl-1,4,7-triazacyclononan-1-yl)-ethane (Me4DTNE, Figure 3) in alkyd resins (without Mn) has been claimed in a patent along with other classes of ligands, including the Me3TACN ligand [40]. This alkyd resin formulation that does not contain metal ions is not subject to skinning, whilst when Mn soap is added, curing of the alkyd resin can start. In another patent, the use of this ligand with a Mn soap or salt has been claimed [41]. The experiments show good curing activity of such complexes, although the nature of the active species has not been disclosed.

A different class of polydentate nitrogen-based ligands, based on 1,4-diazacycloheptane-6-amines, in conjunction with Mn salts has also been patented (Figure 3) [42]. These ligands contain tridentate aliphatic nitrogen donor ligands as a backbone to which other coordinating donor groups can be attached (such as pyridine). Compared to the triazacyclononane based ligands, the stability constants of nickel complexes are about 105 less than for an analogous complex with triazacyclononane [43], indicating that this is also the case when comparing Mn complexes containing this class of ligands with the triazacyclononane ligands. Despite this difference in stability, the experiments disclosed in the patent revealed clearly improved curing activity as compared with MnII(2-EH)2.

Two classes of tetradentate ligands with Mn salts have been patented recently that are based on tris(pyridin-2-ylmethyl)amine (TPA) and N-methyl-N(pyridin-2-ylmethyl)-bis(pyridin-2-yl)methylamine (MeN3py) (Figure 3) [44]. Despite the distinct different structures and properties of these ligands (3 aromatic N donors + 1 aliphatic ones) vs. the 1,4-diazacycloheptane-6-amines and triazayclononane ligands (3 aliphatic N donors), a clear enhancement in curing has been measured. It would be interesting to understand whether all these different Mn catalysts achieve curing of alkyd resins all following similar pathways or whether there are different reactions catalyzed for the different classes of catalysts (e.g., direct activation of the allylic CH2 moieties, activation of ROOH to yield peroxyl or alkoxy radicals, or interaction with O2 to yield O2 activation).

Iron-Based Complexes Using Polydentate Ligands

Iron ferrocene complexes have been studied by Erben and co-workers [45,46,47]. Whilst initially a good activity of the unsubstituted ferrocene was reported, follow-up studies revealed that most substituted ferrocenes and especially benzoylferrocene may be more suitable to be applied (Figure 4). Interestingly, this class of catalysts appear to be operative via a different mechanism. Ferrocenes are known for the electron transfer capabilities without changing the coordination environment (see for example [48]). Therefore, for this class of siccatives binding of alkylhydroperoxide to the metal center may not be operative. The activity of the benzoylferrocene catalyst is similar to that of Co soap (based on metal level), suggesting that cost of the catalyst may become an issue if it would be applied.

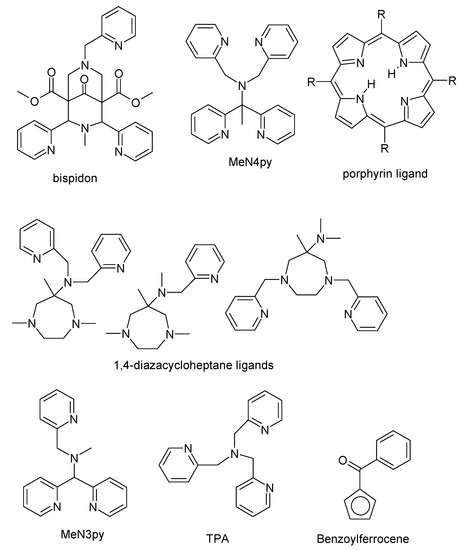

Figure 4.

Ligands exhibiting paint drying activity when mixed with Fe salts or as Fe-ligand complexes as Fe-ligand complexes. Bispidon = dimethyl 3-methyl-9-oxo-2,4-di(pyridin-2-yl)-7-(pyridin-2-ylmethyl)-3,7-diazabicyclo[3.3.1]nonane-1,5-dicarboxylate, MeN4Py = N,N-bis(pyridin-2-ylmethyl)-1,1-bis(pyridine-2-yl)-1-amino-ethane, 5,10,15,20-tetrakisphenylporphyrin (R = phenyl; porphyrin ligand), 6-dimethylamino-1,4-bis(pyridine-2-ylmethyl)-6-methyl-1,4-diazacycloheptane, 1,4,6-trimethyl-6{N-(pyridin-2-ylmethyl)-N-methylamino}-1,4-diazacycloheptane, 6,{N,N-bis(pyridin-2-ylmethyl)amino}-1,4,6-trimethyl-1,4-diazacycloheptane (1,4-diazacycloheptane based ligands), tris(pyridin-2-ylmethyl)amine (TPA), and N-methyl-N(pyridin-2-ylmethyl)-bis(pyridin-2-yl)methylamine (MeN3py), benzoylferrocene.

The manganese-based porphyrin claimed for alkyd paint curing has also been covered for Fe, Co and V [31]. Unfortunately, no examples on curing were given for the Fe porphyrins, so its activity compared with the analogous Mn-porphyrin catalyst cannot be done.

1,4-diazacycloheptane-6-amines based ligands that have been described in the previous section, are besides active with Mn salts, some of the derivatives are also active with iron naphthenate salt (Figure 4) [42]. The examples shown in the patent indicated that for this class of ligands, one or more pyridine rings should be present to achieve curing activity. This was also observed for the mixed aliphatic/aromatic N donor ligands based on tris(pyridin-2-ylmethyl)amine (TPA) and N-methyl-N(pyridin-2-ylmethyl)-bis(pyridin-2-yl)methylamine (MeN3py) (Figure 4) that were also shown to give good curing activity with Fe [44].

In this research, we will describe our process of catalyst development, and understanding their processes, as supported by applications data. These technologies have been developed for cobalt-free solutions, and via a constant screening and selection process, we have found several candidates that meet the demands of performance in both water and solvent-based alkyds.

2. Results and Discussion

2.1. Iron-Based Technology (Fe-Bispidon Catalyst, Supplied as Borchi® OxyCoat)

Recently, very active iron catalyst based on pentadentate nitrogen bispidon and MeN4py donor ligands class has been described (Figure 4) [30]. The structure of the most active and applied catalyst is [(bispidon)FeIICl]Cl, where bispidon is the abbreviation of dimethyl 3-methyl-9-oxo-2,4-di(pyridin-2-yl)-7-(pyridin-2-ylmethyl)-3,7-diazabicyclo[3.3.1]nonane-1,5-dicarboxylate) (Figure 4). This family of alkyd paint siccatives originate from studies for their use in detergent cleaning powders by Unilever. They have been shown to a high activity on food-oil stains in liquid detergents that do not contain bleaching agents such as sodium percarbonate [37,49]. Such stains originate often from unsaturated oils used in the cooking processes, which generates alkylhydroperoxides. In the presence of the Fe-bispidon or Fe-MeN4py catalyst, activation of the peroxide on the stain occurs yielding alkoxy and peroxyl radicals, which in turn react with other unsaturated oil molecules or the colorant, like lycopene found in tomatoes [37,49,50,51]. As these mechanisms are very similar to the ones described for alkyd resin curing by cobalt soap catalysts (and later-on described also for various manganese and iron catalysts), it is not a surprise that these compounds are amongst the most active ones for alkyd coating curing.

Using a medium-oil solvent borne alkyd resin, the level of Fe to obtain a good curing activity could be reduced from 0.08 wt% of Co (for a standard Co-soap formulation) to 0.0007 wt% of Fe (for the Fe-bispidon siccative) [52]. In a water-based alkyd emulsion, the activity of the Fe-bispidon is even more pronounced, it could be reduced to 0.0002 wt% versus Co-soaps that are used at between 0.005 and 0.02 wt%. Perhaps more importantly, when storing the alkyd resin emulsion, the curing activity of the iron complex remained constant versus the reduced activity of the Co-soap (the latter could be attributed to hydrolysis in the water phase leading to much less active [Co(H2O)6]2+ species). As the bispidon catalyst consists of an iron nucleus bound by a pentadentate ligand, the stability in water is very high. Other benefits reported are the low color intensity in the paint formulations thanks to the high dilution of the yellow catalyst and relatively temperature insensitive behavior of curing (whilst CoII(2-EH)2 is clearly less active at low temperatures).

Pirš et al. studied [(bispidon)FeIICl]Cl in high-solid (HS) alkyd paints and compared the properties with CoII(2-EH)2 [53]. FTIR (Fourier-transform Infrared spectroscopy) and elasto-viscosity measurements indicated that the cobalt soap siccative induced curing from the outer layer of the film, whilst [(bispidon)FeIICl]Cl gave a more uniform curing activity through the whole film. As a consequence, the films cured by the bispidon catalyst are softer than those obtained by curing using cobalt soap. These results are in agreement with the NMR (Nuclear Magnetic Resonance) experiments reported by Erich and co-workers using the same catalyst (as well as two Mn siccatives) [54]. The same bispidon catalyst has also been studied with strontium soap (Sr(EH)2) and compared with cobalt soap by Pirš et al. [55]. It was shown that Sr(EH)2 induces harder film and better curing with especially the cobalt soap. Only at the highest dosage level of Sr(EH)2 a clear increase in hardness when using the bispidon catalyst was observed.

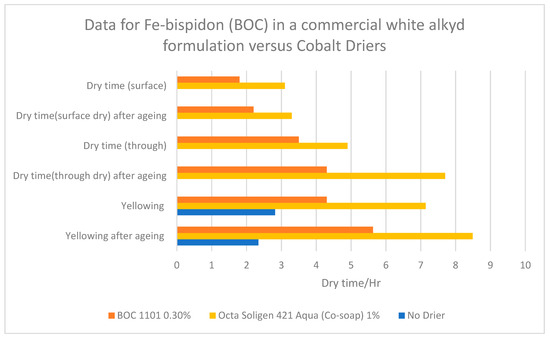

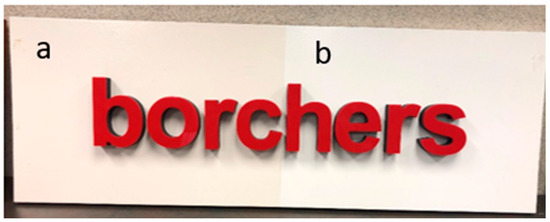

We have developed different formulations of these catalysts to enable improved anti-skinning and rheological properties, for example Borchi® OxyCoat (BOC) supplied as a dilution in propylene glycol, and BOC1101 supplied in water. Improved dry times versus conventional cobalt soaps can be seen in Figure 5, at a fraction of the concentration, and with the added benefit of significantly reduced yellowing (seen visually in Figure 6) and loss of dry after ageing (one week at 40 °C—Figure 5).

Figure 5.

Data from a commercial resin comparing Borchi® OxyCoat (BOC) 1101 with a cobalt-siccative. Note that the resin does not dry without a catalyst (no siccative). BOC 1101 is a 1% solution of Fe-bispidon catalyst in water. Octa Soligen 421 is a mixture of cobalt, zinc, and zirconium carboxylates in water-dispersible oil.

Figure 6.

A marketing tool by Borchers showing the real-life effect of yellowing using a white alkyd formulated with a cobalt-soap (a) versus BOC (b) as the siccative, after storage.

2.2. Developing Alternative Curing Catalysts for Solvent-Borne Alkyds

2.2.1. Generation 1: [MnIV2(μ-O)3(Me3TACN)2](CH3COO)2

Our experience has shown that the bispidon-based iron catalyst is not as effective in solvent-based high oil-containing alkyds as it is in water with medium and short-oil alkyds, particularly due to skinning in specific formulations. As a response to this, we examined a series of new ligands and concepts. In the first generation, we used an existing novel catalyst, [MnIV2(μ-O)3(Me3TACN)2](CH3COO)2 sold as an aqueous solution with the trade-name DB A350. Improved curing activity using these manganese complexes was claimed in patents from DSM [56,57,58]. In one of these patents, it was shown that [MnIII2(μ-O)(μ−RCO2)2(Me3TACN)2]2+ complexes with RCO2 = benzoate and 2,6-difluorobenzoate exhibit faster alkyd paint drying activity than [MnIV2(μ-O)3(Me3TACN)2](PF6)2 [56]. Even more interestingly, it was shown in another patent with the same priority date that the curing activity of [MnIV2(μ-O)3(Me3TACN)2](CH3COO)2 is higher than the analogous compound with PF6 as counterion [57]. As this complex was supplied as a diluted aqueous solution, most of the water was removed by evaporation at 50 °C under low pressure, it might be that some of the original [MnIV2(μ-O)3(Me3TACN)2]2+ species decomposed, leading to the formation of more reactive species than the original compound. In the last patent of this series, it was shown that the activity of [MnIV2(μ-O)3(Me3TACN) 2](CH3COO)2 is higher when ascorbic acid palmitate is added [58], suggesting that lower-valent manganese (Mn(II) and/or Mn(III)) species with this ligand are involved or closely associated with the curing chemistry of alkyd resins. Whilst the dinuclear MnIII complex has two carboxylate bridges, the dinuclear MnII complex has either two carboxylate bridges and a hydroxide bridge or three carboxylate bridges, i.e., having structures such as [MnII2(μ−ΟΗ)(μ−RCO2)2(Me3TACN)2]+ or [MnII2(μ−RCO2)3(Me3TACN)2]+. The structures of both the analogous MnII2 complexes with acetate bridges have been elucidated by Wieghardt and co-workers [59]. Both species with ethylhexanoate bridges are expected to be more lypophilic than [MnIV2(μ-O)3(Me3TACN)2](CH3COO)2 due to the combination of the more lypophilic carboxylates in combination with the presence of a mono-charged complex (in contrast to most other dinuclear Mn complexes with Me3TACN which are divalent in nature [59,60]).

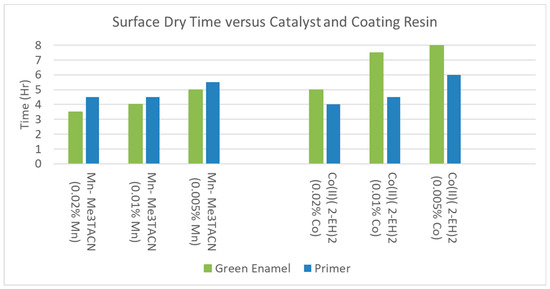

In our trials, [MnIV2(μ-O)3(Me3TACN)2](PF6)2 (Mn-Me3TACN) gave similar or faster drying activity compared to cobalt 2-ethylhexanoate (CoEH2), based on time to fully surface dry (Figure 7); saving 2 h can allow serious cost savings in labour during application.

Figure 7.

Dry times of [MnIV2(μ-O)3(Me3TACN)2](PF6)2 (abbreviated as Mn- Me3TACN) versus CoII(2-EH)2 in two formulated, commercial alkyd paints.

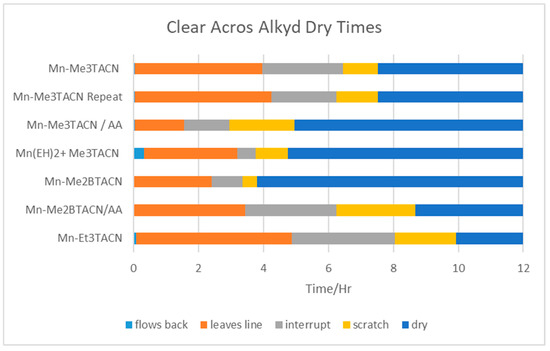

[MnIV2(μ-O)3(L)2](PF6)2 complexes with L = Me3TACN analogues, such as Me2BTACN (1-benzyl-4,7-dimethyl-1,4,7-triazacyclononane) [61] and Et3TACN (1,4,7-triethyl-1,4,7-triazacyclononane) [62] were tested as well for alkyd curing and were found to yield comparable alkyd resin curing activity as [MnIV2(μ-O)3(Me3TACN)2](PF6)2 (all in the presence of one molar equivalent of ascorbic acid) (Figure 8). Therefore, the presence of a benzyl group (instead of methyl) or three ethyl groups (instead of three methyl groups) gave no further advantage in curing activity and these might only influence ligand compatibility.

Figure 8.

Drying times of alkyd resin in the presence of 0.01 wt% Mn added as [MnIV2(μ-O)3(Me3TACN)2](PF6)2 (abbr. as Mn-Me3TACN), [MnIV2(μ-O)3(Me3TACN)2](PF6)2 with one molar equivalent of ascorbic acid (abbr. as Mn-Me3TACN/AA), Mn(EH)2 with one molar equivalent of Me3TACN (abbr. as Mn(EH)2 + Me3TACN), [MnIV2(μ-O)3(Me2BTACN)2](PF6)2 with one molar equivalent of ascorbic acid abbr. as (Mn-Me2BTACN/AA) and [MnIV2(μ-O)3(Et3TACN)2](PF6)2 (abbr. as Mn-Et3TACN/AA).

We can learn something about the reactivity from the literature, where the [MnIV2(μ-O)3(Me3TACN)2](PF6)2 catalyst in emulsions towards reactivity of ethyllinoleate with oxygen is higher than that of MnII(2-EH)2 but less than that of CoII(2-EH)2 [32]. A key problem noted for [MnIV2(μ-O)3(Me3TACN)2](PF6)2 is that the solubility in various formulations is not high. It might be that by using the complexes with other counterions [58], or by addition of reducing agent in the presence of formulations containing lipophilic soaps [57], species are formed in situ that are much better compatible with the alkyd formulations than the parent [MnIV2(μ-O)3(Me3TACN)2](PF6)2 compound.

Inclusion of N,N,N’,N’’,N’’’,N’’’-hexamethyltriethylenetetraamine (HMTT–Figure 3) in an emulsion of ethyllinoleate and [MnIV2(μ-O)3(Me3TACN)2](PF6)2 gave faster oxidations of ethyllinoleate. It is known that polyamines facilitate the decomposition of alkylhydroperoxides. Support of the latter reaction has been found by studying homogeneous solutions of the manganese catalyst, HMTT and ethyllinoleate: The reaction to yield volatile hexanal and heptanal due to β-scission of the substrate is significantly higher in the presence of HMTT [63].

Besides the reported curing activity in water-borne emulsions of this and related catalysts [57,58], this catalyst gives also good activity in solvent borne paints [34], which is of major interest as the Fe-bispidon catalyst exhibits activity at very low levels of catalysts in water-borne emulsions (vide supra). In a short oil formulation, a similar curing time as observed for CoII(2-EH)2 was observed. In a paint formulation containing a long oil alkyd resin the curing activity appeared to be good, with a notable better through-drying activity than Co-soap, albeit yielding a slightly softer film [33]. The observation that C=C bond vibrations at 1650 cm-1 as studied by IR are faster depleted at the surface for CoII(2-EH)2 than for [MnIV2(μ-O)3(Me3TACN)2](PF6)2, suggesting that whilst overall similar mechanisms may be operative, the curing activity of CoII(2-EH)2 on the surface of the film may inhibit O2 to penetrate in the deeper layers, whilst [MnIV2(μ-O)3(Me3TACN)2](PF6)2 allows O2 to diffuse through the whole paint layer and therefore it can generate an in-depth cured film [33]. This aspect has been discussed much more recently for a mixture of MnII(2-EH)2 and the Me3TACN ligand (vs. CoII(2-EH)2, a Mn porphyrin catalyst and the Fe bispidon catalyst) using NMR imaging measurements [54].

As shown in Figure 8 and elsewhere [58], adding ascorbic acid has been shown to accelerate drying when using [MnIV2(μ-O)3(Me3TACN)2](PF6)2. However, at this stage we also saw a significant improvement by moving towards an in-situ formed catalyst by blending MnII(EH)2 with Me3TACN, almost halving the dry time required (Figure 8). This prompted us to examine alternative catalyst concepts, as discussed in the next sections. The observations that adding a reducing agent to [MnIV2(μ-O)3(Me3TACN)2]2+ and that mixing ligand with MnII(EH)2 gives increased curing activity suggests that lower-valent Mn species are involved in the catalysis, in disagreement with the proposal put forward by Oyman and co-workers, where [MnIV2(μ-O)3(Me3TACN)2]2+ itself is thought to be involved in the alkylhydroperoxide activation process, via outer-sphere electron transfer (MnIVMnIV/MnIIIMnIV couple) [63].

Based on the observations that mixing ligand with MnII(EH)2 gives good alkyd-curing activity, we developed and patented an innovative way of allowing formulation flexibility and boosting resin performance by preloading the resin with ligand as an ‘accelerator’(without metal ions). The paint formulator can then afterwards add the Mn soap into the resin/ligand mixture to form active species [40]. The benefit is that when the ligand is mixed with the resin and no metal ions are present, no reaction with oxygen to obtain peroxide and therefore skinning can occur. Only after addition of the Mn soap, reactivity towards alkyd resin curing can occur. In the same patent, EPR (electron paramagnetic resonance) spectroscopy has been used to obtain more understanding on the various species formed [40]. The ligand in the resin (without MnII(2-EH)2 added) did not show any appreciable EPR signal, whilst adding MnII(2-EH)2 without ligand furnished an EPR signal of a typical Mn(II) species, as expected. When the ligand is mixed with MnII(2-EH)2, signals typical of dinuclear MnII2(Me3TACN)2 species were observed [40,60,64]. The dinuclear species may well be the same species formed when ascorbic acid palmitate was added to the [MnIV2(μ-O)3(Me3TACN)2]2+ complex [58]. This latter observation suggests that for the activation of dioxygen or hydroperoxide to achieve alkyd curing the dinuclear MnIV complex is not involved, but that more likely lower-valent Mn species react with oxygen or alkylhydroperoxide to attain alkyd curing. The studies conducted by Oyman and co-workers, indicate that the oxidation process of ethyllinoleate by air and [MnIV2(μ-O)3(Me3TACN)2](PF6)2, involve alkoxy and peroxyl radicals [32,63], reminiscent to the curing processes ascribed to CoII(2-EH)2, but no studies have been published using the lower-valent Mn-Me3TACN complexes.

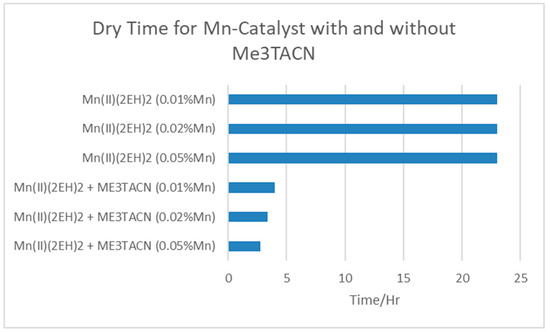

2.2.2. Generation 2: A Broad Study of Me3TACN-Catalyst Analogs

We already saw a benefit of combining Me3TACN with MnII(2-EH)2) vs. [MnIV2(μ-O)3(Me3TACN)2](PF6)2 (Figure 8), and that [MnIV2(μ-O)3(Me3TACN)2](PF6)2 compared favorably with CoII(2-EH)2) (Figure 7) regardless of dose. Although the two derivatives tested (complexes with Me2BTACN and Et3TACN) did not yield improved curing activity compared to the parent compound, we decided to investigate a wider range of alternative ligands versus Me3TACN for creating new complexes that may give improved performance. First a series of tests was conducted using different levels of MnII(2-EH)2 vs. MnII(2-EH)2 with one molar equivalent of Me3TACN (between 0.01 and 0.05% Mn) to test curing activity on a formulated alkyd paint, as shown in Figure 9. It was clear that even at 0.05% Mn, only set dry but no surface curing took place, whilst addition of one molar equivalent of Me3TACN ligand gave already good surface curing activity at 0.01%Mn level, which further improved by increasing the Mn/ Me3TACN level further (Figure 9).

Figure 9.

Surface drying activity (denoted in blue) of various level of MnII(2-EH)2 and MnII(2-EH)2 premixed with molar equivalent of Me3TACN (1,4,7-trimethyl-1,4,7-triazacyclononane). This data set was obtained from a formulated commercial alkyd.

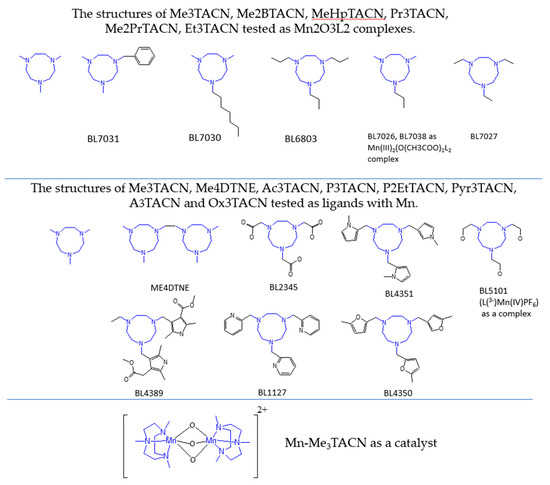

We therefore screened the ligands shown in Figure 10 in combination with equimolar levels of MnII(2-EH)2 at 0.01% Mn. In most cases we either blended the ligands with the manganese soap at a 1:1 molar ratio to form the catalyst in-situ, or the manganese complexes have been prepared [61,62] (denoted in Figure 10). For some experiments we increased the ratio of ligand to MnII(2-EH)2.

Figure 10.

Schematic structures of the ligands tested as [Mn2O3L2]2+ complexes (top) or tested as mixtures with MnII(EH)2 (middle). At the bottom of the figure, the structure of the dinuclear [Mn2O3L2]2+ complex with L = Me3TACN is depicted. The codes given are numbers as used for the ligands and complexes and are also used in the results shown in Figure 11, Figure 12 and Figure 13.

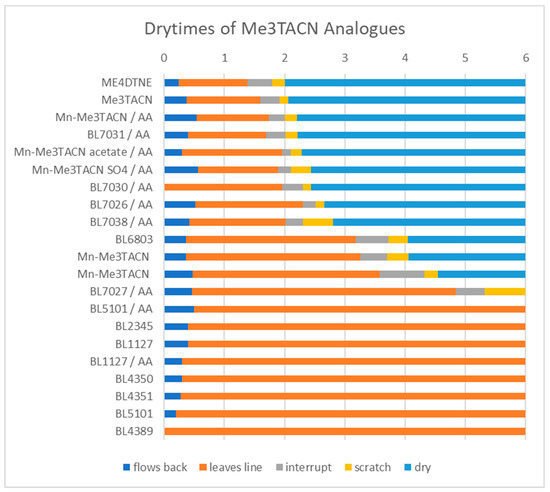

Selected comparative data in an alkyd resin, that does not contain pigments and is additive free, can be seen in Figure 11, where ligands such as Me3TACN, Me4DTNE, and Me2BTACN in combination with MnII(2-EH)2 yielded the fasted drying activity. Moreover, various preformed dinuclear Mn complexes containing Me3TACN, Me2BTACN, Me2HpTACN, and Me2PTACN ligand in combination with one molar equivalent of ascorbic acid yielded efficient curing. Whilst these complexes were tested as PF6 salt, the manganese complex with Me3TACN gave similar activities as sulfate or acetate salts (all in the presence of ascorbic acid). It should be noted that it has been shown before that the sulfate and acetate salts of the dinuclear Mn-Me3TACN complexes in the absence of ascorbic acid are significantly more active than the analogous complex as PF6 salt [58]. Selected testing showed good reproducibility for the dry times.

Figure 11.

Dry time data from selected catalysts or mixtures of ligands and MnII(EH)2 based on Me3TACN analogs shown in Figure 10. In this figure, Mn-Me3TACN stands for [MnIV2(μ-O)3(Me3TACN)2](PF6)2, Mn-Me3TACN acetate stands for [MnIV2(μ-O)3(Me3TACN)2](CH3COO)2, and Mn-Me3TACN SO4 stands for [MnIV2(μ-O)3(Me3TACN)2](SO4). When AA is written after the abbreviation, one molar equivalent of ascorbic acid was mixed to the catalyst solution prior application. The other numbers of ligands or complexes are given in Figure 10.

Interestingly, the ligands containing three longer chain aliphatic groups (Et3TACN, Pr3TACN) or other groups that may coordinate to Mn (P3TACN, Py3TACN) did not show good curing activity with Mn. More sterically demanding side groups may hinder efficient binding to the metal center. Furthermore, the ligands with the three auxiliary nitrogen donors (P3TACN and Py3TACN) may bind via six nitrogen donors to Mn(II) ions, thereby blocking the coordination sites of the Mn center that otherwise would be involved in activating the alkylhydroperoxide of the alkyd resin as explained in Section 1.2.

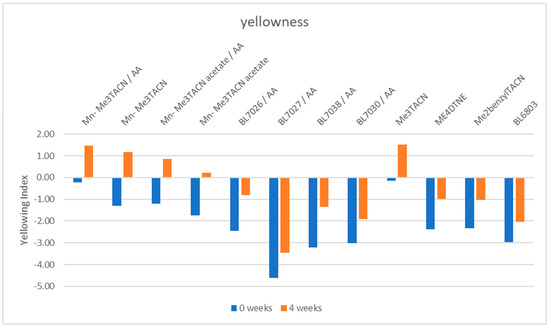

We then retested a wide range of the ligands in a white alkyd paint supplied by a commercial supplier. This was an important test, as the paint was ready-formulated, and the data would include (unknown and proprietary) additional surfaces (i.e., pigments) and emulsifiers that could interfere with the drying process. This test would also allow us to compare the effect of yellowing over time by examining the yellowing index. It is well known that alkyds can yellow over time in the dark, caused by a series of oxidative transformations of the unsaturated groups leading to decomposition products such as highly conjugated ketones [65]. It is also known that siccatives can lose performance over time if they are adsorbed onto pigments.

The dry times were very similar between Me3TACN/MnII(2-EH)2, Me2BTACN/MnII(2-EH)2, preformed [MnIV2(μ-O)3(L)2]2+ complexes and Me4DTNE/MnII(2-EH)2, all fully drying within 2 h at 0.01% Mn on resin (Figure 11). They also all gave similar hardness values of around 18 s pendulum hardness after initial drying, suggesting little difference in the crosslinking density and indicating similar curing processes. It should be noted that these coatings were particularly soft as they were not optimized via the use of secondary siccatives to prevent additional variables in our comparisons.

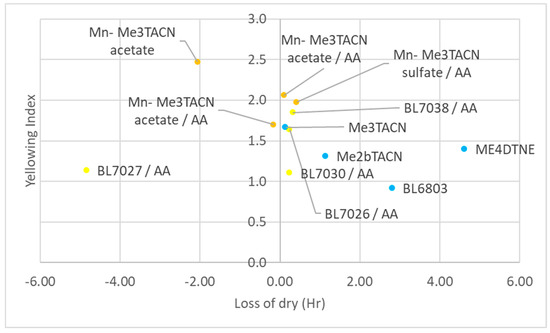

However, we saw very clear differences in both yellowing and loss of dry after four weeks storage for these classes of materials (Figure 12). The coatings made using the [MnIV2(μ-O)3(Me3TACN)2]2+ and Me3TACN siccatives exhibit significant yellowing after four weeks of storage compared with Me4DTNE, Me2BTACN and the other next-generation ligands.

Figure 12.

Yellowing Index data from selected catalysts based on Me3TACN analogues, before and after storage over four weeks. Catalysts tested from Figure 10, some with additional ascorbic acid.

Loss of dry occurs when some (or all) of the catalyst can no longer function, leading to increased dry times. This is typically caused by adsorption to a pigment surface, and can be remedied by formulation, for example by adding a calcium soap or an emulsifier such as a pigment dispersant. We examined the catalysts in the pigmented alkyd, with the best dry times versus yellowing and loss of dry after four weeks of storage (Figure 13). [MnIV2(μ-O)3(Me3TACN)2](PF6)2 gave the most yellowing, but newer generations such as BL7030/AA, Me2BTACN, BL7038/AA gave a significant improvement without incurring loss of dry. Moreover, they reduced yellowing versus the blended Me3TACN/MnII(2-EH)2 catalyst. BL7027/AA dried faster after storage, perhaps indicating improved solubility over time or slow formation of more active species; we did not investigate further.

Figure 13.

Combined Yellowing index and loss of dry data for selected Me3TACN analogs.

2.2.3. Generation 3: Non-Me3TACN-Catalyst Analogs

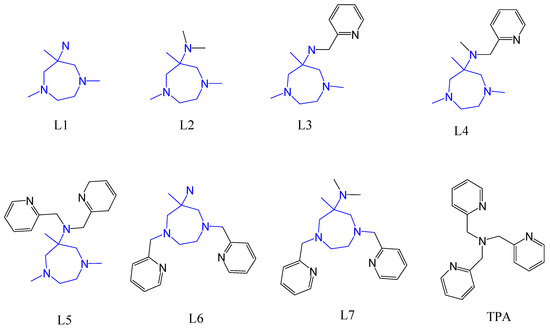

As mentioned in the introduction, another class of tridentate aliphatic nitrogen donor ligands is based on the 1,4-diazacycloheptane-6-amine backbone (Figure 14). The fact that, in contrast to the triazacyclononane ligands, these ligands do not contain the three nitrogen donors in the macrocyclic ring, the kinetic stability of metal complexes are less than that of analogous complexes with the triazacyclononane ligands [43]. An advantage of this class of ligands is that different modifications can be relatively easily achieved. Methylation of the aliphatic nitrogen atom yielded L2. Attachment of a methylpyridine-2-yl group to L1 yielded L3. In order to prevent the possibility of imine formation of the NH-CH2 unit, methylation of this nitrogen donor yielded L4. Alternatively, another the methylpyridine-2-yl group attached on this nitrogen atom, yielded the pentadentate ligand, L5. L6 and L7 are ligand variants were the nitrogen donors in the cycloheptane ring are functionalized by methylpyridine-2-yl moieties.

Figure 14.

Non-Me3TACN Ligands tested with Mn and Fe salts towards alkyd resin curing.

As now a wider variety of tridentate, tetradentate, and pentadentate ligands has been prepared, we decided to test these ligands not only with Mn salts, but also with Fe salts (or test the preformed Fe and Mn complexes). Results are given and discussed below.

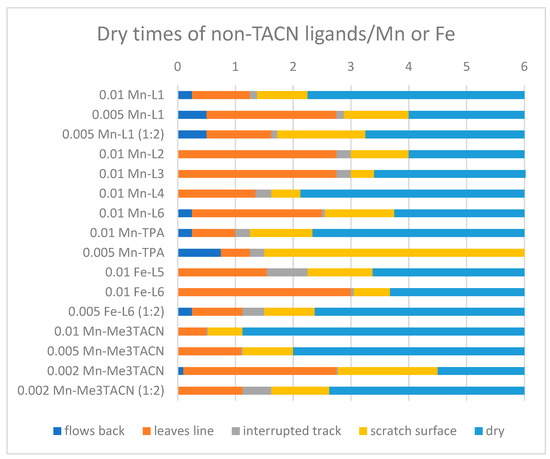

Ligands L1, L3, L4, and Me3TACN in combination with MnII(2-EH)2 at 0.01% Mn level and L5 and L6 with FeCl2 at 0.01% Fe level all showed efficient drying (Figure 15). L2 yielded a lower activity with Mn than L1, L3, or L4. Interestingly, L5 and L6 worked best with the Fe-source, whilst with MnII(2-EH)2 and L5 no drying activity was observed. For L7 a similar (relatively low) drying activity was found for both Mn and Fe. The ligands L1–L4 did not show activity with FeCl2. L5 and L6 are both pentadentate ligands, like the bispidon and N4py ligands that are known to be very active towards alkyd resin curing when bound to Fe(II) [30]. Probably, ligands with less coordination sites may bind to Fe(II), but will yield less stable iron complexes. On the other hand, tetradentate ligands such as TPA (Figure 14) and N3py (Figure 4) did show activity with the iron source, albeit less efficiently than the pentadentate bispidon ligand. Thus, the choice of the metal centers in combination with the ligand is critical for the alkyd curing activity. In most cases, we found no benefit from using the pre-formed metal complexes vs. mixing the metal-soap/salts with ligands.

Figure 15.

Alkyd resin curing activity of the ligands L1–L6, Me3TACN, and TPA mixed with either MnII(EH)2 (abbr. as Mn) or FeCl2 (abbr. as Fe). The numbers of the ligands refer to the structures given in Figure 14. Results of Mn-L5 and Mn-L7 were omitted, because no or low curing activity was observed.

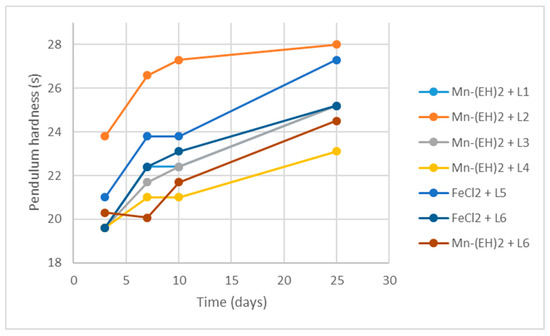

As with the other ligands, we generally saw that increasing catalyst concentration increased drying activity as expected. The hardness development of all generation 2 siccatives in a formulated commercial alkyd was in same range, highest hardness for Mn-L2 (Figure 16), although the faster curing L4 gave the softest film, perhaps due to poor through-drying activity.

Figure 16.

Hardening data in a commercial white alkyd formulation (without optimization using, i.e., secondary and sacrificial siccatives).

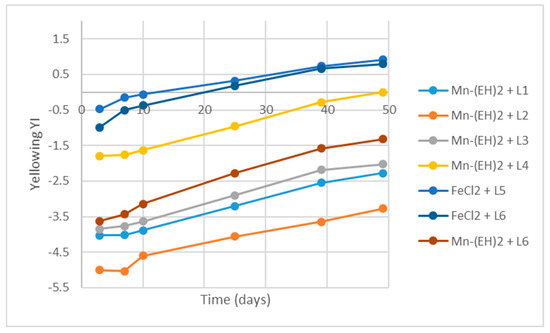

The increase of yellowness on storage (Figure 17) could be seen for all generation 2 siccatives. In general, Fe based dries showed higher initial yellowness, but Mn siccatives showed slightly more yellowing (increase in yellowness). Based on our research in other resins, we rank the activity thusly: Mn-Me3TACN > Mn-TPA > Mn-L4 > Mn/Fe-L6 > Mn-L1 > Mn-L3 > Fe-L5 > Mn-L2 > Mn/Fe-L7.

Figure 17.

Yellowing data in a commercial white alkyd formulation (without optimization using, i.e., secondary and sacrificial siccatives).

From the tests discussed in Section 2.2 and Section 2.3, different interesting metal–ligand complexes have been identified to be of interest for alkyd paint curing. From the TACN family (Section 2.2.1 and Section 2.2.2), the fully methylated ligand (Me3TACN), benzyl-substituted TACN (Me2BTACN), n-heptyl-substituted TACN (Me2HpTACN), propyl-substituted TACN (Me2PrTACN), and bridged TACN ligand (Me4DTNE) showed all good and similar curing activity in conjunction with a Mn-soap or as a Mn complex (with ascorbic acid added). Similarly, manganese complexes with Mn-TPA, Mn-L4, L6, and Mn-L1, discussed in this section, show a good curing activity and all similar or better than that of Co-soap. Whilst the structures of the active driers are very different, they all have a common feature: The nature of the polydentate nitrogen ligand aids in stabilizing the active metal complexes from hydrolyzing/decomposition into free metal salts, that are much less active towards curing.

However, as shown in subsequent tests, the rate and extent of yellowing of the alkyd resin and the development of the hardness of the cured film are affected to a large extent by the choice of the Mn or Fe drier.

Therefore, whilst it may be tempting to design an optimal alkyd resin curing catalyst based on the curing activity alone, the paint producer will make a choice to replace Co-soaps as driers not only based on the high curing activity. Yellowing, hardness development, but also storage stability will be essential attributes. To a significant extent the properties of the paint formulation can be altered by using different alkyd resins, secondary driers, different pigments, etc. However, as most of the formulations have been previously been optimized for the compatibility with Co-soap, the paint formulations need to be adapted to optimize the properties of the coating (i.e., good curing activity, low yellowing, good storage stability, and appropriate hardness development). At this stage of the development it is not feasible to make a good prediction which is the best metal–ligand combination in conjunction with the optimal paint formulation.

2.3. Anti-Skinning Agents in Combination with Fe Catalysts

Oxygen reacts at the surface of an alkyd paint to begin the crosslinking process, this leads to a skin on the surface of the paint that can account for a 2% loss in production. Therefore, anti-skinning agents are typically added to the alkyd paint formulations that work by retarding oxidation. They typically work by inhibiting free radical-induced oxidations, by reacting alkoxy or peroxyl radicals formed, or by saturating in the head space to reduce the available oxygen to the paint surface or by both mechanisms. Typical examples of anti-skinning agents include amines, phenols, oximes, or the most popular and effective being ketoximes like methyl ethylketoxime (MEKO) [66]. However, ECHA classifies MEKO as toxic and possibly carcinogenic (EC number 202-496-6). As a result, alternatives have been developed such as acetylacetonate [67], isoascorbate [68], ureas [69], and ketoxime-based analogues such as 2-pentanone oxime [70].

MEKO works by suppressing the reaction of radicals on the surface of the alkyd paint layer with oxygen (present in the headspace of the paint can), due to its volatility and capability to react alkoxy radicals [71]. Further, it has weakly coordination capabilities to cobalt soaps [71], thereby blocking the possibility of the cobalt siccative to react with oxygen or hydroperoxyl species to initiate radical-induced polymerization of the paint formulation in the can. When the paint coating is applied on a surface, MEKO can evaporate and the equilibrium shifts to non-coordinated MEKO, allowing the cobalt soap ion to react to induce radical curing of the alkyd resin.

The iron-bispidon ligand catalyst does not work efficiently with conventional anti-skinning agents like MEKO and other ketoximes, which is likely caused by steric hindrance of the bulky pentadentate bispidon ligand preventing co-ordination into the central iron center. Another possibility is that the ketoxime is a poor ligand for the Fe(II) center, and therefore it is much less effective as anti-skinning agent than what has been found for Co soaps. Moreover, for Fe-TPA a poor anti-skinning effect of MEKO was observed, suggesting that for this complex with the less sterically crowded ligand, poor binding of MEKO to the metal center may be the main explanation of these observations.

One solution for the Fe-bispidon catalyst is via the use of water as co-solvent [72]. Although not specified in this patent application, it might be that phase-separation of the hydrophilic Fe-bispidon catalyst in water from the hydrophobic alkyd resin may be the reason why such approach has shown to give benefits.

Typically, volatile anti-skinning agents such Borchers non-ketoxime Borchers® Ascinin 0444 work very effectively with conventional metal carboxylates and iron-bispidon and do not suffer the regulatory issues of MEKO, meaning the combination is a perfect formulation fit for the regulatory environment for water-borne alkyds and inks. Borchers® Ascinin 0444 contains N,N-diethylhydroxylamine, a volatile amine that helps hinder oxidation via saturating the headspace of the paint can and acts as an oxygen scavenger. In this research, we introduce our initial results for developing a bespoke anti-skinning solution for the iron-bispidon catalyst, as part of an ongoing investigation to complement MEKO-free anti-skinning agents.

For some solvent-borne high-oil alkyds, the Fe-bispidon catalyst shows skinning behavior also in the presence of MEKO or Borchers® Ascinin 0444. Raman and FT-IR spectroscopies have been used to study iron-bispidon’s reactivity with ethyllinoleate [52]. Like observed for CoII(2-EH)2 and various other Mn and Fe alkyd resin curing catalysts, autoxidation, radical based oxidation processes appear to take place, which is likely also operative in the skinning behavior of Fe-bispidon. However, when using the Fe-bispidon catalyst the oxygen scavenging and headspace process of Borchers® Ascinin 0444 do not have as significant effect on preventing skinning when compared with CoII(2-EH)2.

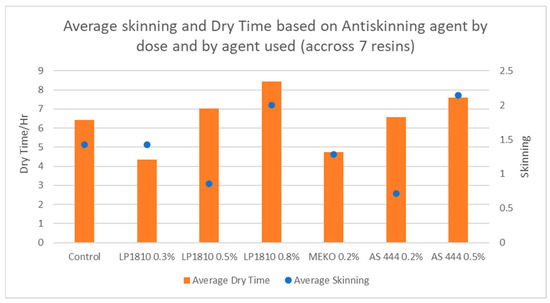

In our laboratories, through a process of formulating drier combinations, we have discovered that a combination of a ketoxime and cerium octanoate (named LP1810) helped to improve anti-skinning behavior to the same degree as Borchers® Ascinin 0444 (Figure 18). This effect has been observed using different ketoxime anti-skinning agents, including 2-pentanone oxime. We observed a small variation in skinning behavior across seven different resins, of between one–two units, even despite different dose levels. More interestingly, we can see the dry times are significantly impacted by using different anti-skinning agents. As expected, increasing anti-skinning agent dose levels lead to reduced dry time as the oxidative process of crosslinking has been retarded. The best combination of dry time and anti-skinning came from the MEKO and LP1810 agents at low dose, showing we had identified an improved MEKO-free solution.

Figure 18.

Average skinning (shown as blue dots) and dry times (shown as orange bars) of seven resins using anti-skinning agents with Borchi® Oxy Coat Fe-bispidon catalyst. Seven commercial, high-oil alkyds were used, and an average dry time and skinning was taken for each anti-skinning agent. Formulations were mixed using a speed mixer DAC 150.FVZ at 3500 RPM for 1.5 min and left for 24 h before being applied to glass plates at 100 µM. Dry time conditions: 23 °C at 50% relative humidity. In all cases 0.5% (w/w) of a 1% (w/w) Fe-bispidon catalyst dissolved in propylene glycol was added, together with an anti-skinning agent, LP1810, MEKO, or AS0444 was added in the amounts given in the figure. LP1810 is a mixture of 12% Cerium hex Cem and Borchi® Nox C3, MEKO is methylethylketoxime and AS0444 is Borchers® Ascinin 0444 from Borchers. Skinning is a qualitative scale where 0 = no change, 1 = very thin skin, 2 = thin skin, 3 = medium-thin, 4 = hard skin, 5 = very hard skin.

We are still developing an understanding of why cerium soap and ketoximes furnish a strong retardation effect of the skinning. Even though a full understanding has not been achieved at this stage, highlighting this observation may be useful for developers of new paint formulations which includes the iron bispidon catalyst. We can infer some rational from the literature, for example in a recent paper it has been shown that the Fe-bispidon complex with 2-ethylhexanoate as sixth ligand instead of chloride showed increased solubility in organic solvents and as a consequence shows different activity in the autoxidation processes [73]. Improved catalyst performance has also been seen by adding a potassium salt of a carboxylic acid to an iron-bispidon catalyst [74]—we believe this leads to an ion-exchange of Cl for the carboxylate leading to improved resin compatibility. We believe that with LP1810 the cerium carboxylate works in the same way, whilst the ketoxime saturates the headspace to prevent easy access to oxygen. This combination can be prepared by formulators that wish to use the Fe-bispidon catalyst because of its powerful curing profile and non-yellowing aspect. However, this is not a solution for all alkyds. For that reason, we have also investigated the new ligands made specifically as cobalt-free siccatives for solvent-borne alkyds.

With the new ligands it is expected that less sterically hindered structures might enable a combination of activity retardation through binding to the metal center, as well as headspace protection. This would enable alternative strategies for reducing skin, and this research is currently under investigation.

3. Materials and Methods

3.1. Methods

Coatings were typically applied at a thickness of 75 μM, using a cube applicator, onto 30 × 2.5 cm glass plates. The amount of catalyst added was based on the metal wt% on total resin formulation, since the resin content was not always known.

Yellowing index (YI) was measured according to ASTM method E313, using the equation 8, where X, Y, and Z are the CIE tristimulus values measured using a Minolta CM-3700D spectrophotometer.

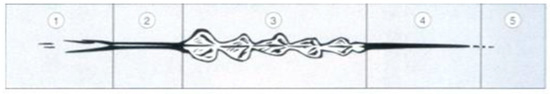

Drying times were measured using a BK-3 drying recorder, where the different stages of drying can be observed by the pattern created by a needle dragged across the coating surface, in Figure 19, starting from (1) wet (reflow of the scratch) to dry (no needle penetration).

Figure 19.

The different stages of dry time as determined visually versus time. Stage 5 is considered dry.

Hardness was determined by using a pendulum hardness tester (by TQC Sheen) on a formulated resin applied at a thickness of 75 μM, using a cube applicator, onto glass plates.

Skin formation was monitored by monitoring the flow of a formulated resin (6 g) within a closed vial (20 mL), every working day for 2 weeks and after that on weekly basis till 7 weeks. Once a week, the jar is opened to allow air (oxygen) in/out of the jar. If a skin is formed, the resin did not flow anymore. Skinning is a qualitative scale where:

- 0 = no change;

- 1 = very thin skin, can barely be seen when vial is tipped, breaks with gentle force;

- 2 = thin skin, can be seen when the vial is tipped, breaks with gentle force;

- 3 = medium-thin, can be seen when tipped, breaks with force;

- 4 = hard skin, can be seen without tipping vial, breaks with force;

- 5 = very hard thick skin, can be seen without tipping vial, cannot be broken easily with force.

Alkyd Paint and Catalyst Preparation

Table 1 gives an example of how catalysts were prepared as a 1:1 ratio, they were then added into 5 g of the alkyd resin or formulated alkyd paint, mixed, and left for 24 h before application.

Table 1.

Mn = the preparation of example ligands with MnII(2-EH)2 (as the Mn) prior to formulation. The ligand numbers refer to those discussed in Figure 14. The dose of these catalysts in a formulation would then be calculated and set as a %Mn content versus formulation mass for comparison purposes.

Generally, samples were prepared either as 5 or 10 g of resin (or paint) in 20 mL glass vials. As a general rule the siccative was added as 0.2 mL solution per 3 g of resin/formulation. The solvent used to dissolve the ligand/metal salt or complex depended on the solubility in the ligand/metal salt or complex in that solvent and solubility in the alkyd resin formulation. Used solvents were typically propylene glycol, Dowanol PM (1-methoxy-2-propanol), acetonitrile, ethanol, or methanol. For example, if a level of 0.05 wt% Mn (as Mn(EH)2) is included in the alkyd mixture, 25 mg of Mn(EH)2 dissolved in 50 μL ethanol. Separately a solution of the ligand that needs to be mixed with an equimolar amount of Mn in the paint formulation is prepared. Depending on the molecular weight of the ligand, the right amount of ligand is weighed into 50 μL ethanol. Table 1 gives an example of how catalysts were prepared as a 1:1 ratio. Each of the solutions were added to 5 g of the alkyd resin or formulated alkyd paint, mixed via stirring, and then left for 24 h before application.

In case that preformed Mn complexes were tested, these were dissolved generally in ethanol or water to yield 30 mM, which was then added to the paint or alkyd resin formulation to obtain the desired level of Mn (typically between 0.005 and 0.02 wt% Mn). If the influence of ascorbic acid was tested, an equimolar amount was premixed with the above-mentioned Mn complex dissolved in water or ethanol and then added to the paint or alkyd resin formulation.

The solutions of Borchi® OxyCoat 1101 (BOC1101) in paint formulations were prepared by adding anything from 0.3 to 1% of BOC1101 by mass on total formulation. As an example, used for data in Figure 5, 0.3% of BOC1101 in 100 g of an alkyd paint would mean adding 0.3 g of BOC1101 (which is 1% w/w) to the formulation, meaning 0.003% (w/w) of BOC actives on total formulation. Due to differences in reactivity, less BOC is required for optimal performance (of anti-skinning and dry time) versus cobalt siccatives, therefore comparisons are based on the optimal does levels, using 1% (w/w) of Octa Soligen 421 cobalt siccative on total formulation. Unlike the Mn materials, the BOC was not calculated as metal on solids due to historical calculation methods for ease of use with unknown customer formulations. For further information, 1% actives BOC contains 8 × 10−4 wt% of iron.

3.2. Materials

Ligands and Mn complexes were supplied by Catexel (Leiden, The Netherlands), the Fe-bispidon catalyst is supplied by Borchers as Borchi® OxyCoat (Langenfeld, Germany), MnII(2-EH)2 (containing 6 wt% Mn) from Alfa Aesar (Ward Hill, MA, USA), MnII(acetate)2 from Sigma Aldrich (Saint Louis, MO, USA), FeIICl2 from Merck (Kenilworth, NJ, USA). Alkyd resin (70% in white spirits) was supplied by Acros Organics (Geel, Belgium). Commercial formulated resins are confidential, and the information cannot be shared. Dowanol PM is a commercial product from Dow (Midland, MI, USA). All other chemicals, including Dowanol PM, were purchased from VWR International (Amsterdam, The Netherlands).

4. Concluding Remarks

This article covers the history of our development work until present day for iron and manganese catalysts with polydentate nitrogen donor ligands for alkyd coating formulations. The toxic nature of cobalt has presented a difficult future for its use in alkyd resins where they will come into human contact. Examples of new catalyst systems and innovative delivery processes that are meeting the demand and that will continue to deliver the future catalysts for oxidatively cured coatings and inks have been described. Testing of the new ligands with Mn and Fe salts has revealed that even slight modifications of the structure of the ligand can have a profound effect on curing activity, dark yellowing, and hardness development. This may point to potentially different curing mechanisms, or at least different rates of activation of various processes. One aspect that has not been discussed in this paper is the fact that many paint formulations have been optimized for cobalt soaps for many years. It will be likely that the new catalysts will become more efficient when the paint formulations are further optimized, e.g., type of alkyd resin, secondary driers, fillers, or solvents.

We learned that the presence of polydentate nitrogen ligands is important to stabilize active metal–ligand catalyst species, but it is still elusive how each part of the curing/yellowing/hardening mechanisms are affected by each of the catalytically active species. Undoubtedly, new insights by studies both in academia on the fundamentals and industry on applications will enhance this understanding, which in turn will lead to catalysts that meet all requirements in various types of paint formulations.

Author Contributions

Writing—original draft preparation, review and editing, data curation, co-supervision, project administration, and funding, N.S.; investigation, data curation, specific lab applications, and development work on anti-skinning agents and method development, K.M.; method development, dry time evaluations, formal analysis of data, and catalyst preparations, Y.R.; contribution to literature review, co-supervision, review and editing, funding, and catalyst technology development leader, R.H.

Funding

This project was a collaboration between Borchers and Catexel, both sides funded their own research. Some evaluation research of Borchi® Oxycoat catalysts and of anti-skinning agents were performed by Sonja Esser of Borchers under the direction of Neil Simpson.

Acknowledgments

Max Shumba of Borchers, for updated information on the regulatory landscape of cobalt-replacement. We are grateful to Sonja Esser for the studies on the BorchiOxy Coat catalyst and the anti-skinning agents. The authors would also like to acknowledge Hans de Boer for the synthesis of various ligands and complexes described in Section 2.2 and the EPR studies on manganese complexes described in Section 2.2.1.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Brock, T.; Groteklaes, M.; Mischke, P. European Coatings Handbook; Vincentz Network GmbH & Co KG: Hannover, Germany, 2000. [Google Scholar]

- Paul, S. Chapter 8—Types of Coatings. In Surface Coatings Science and Technology; John Wiley & Sons Ltd.: Chichester, UK, 1996; pp. 654–667. [Google Scholar]

- Paints and Coatings Market 2019 Size, Share, Trends, Type, Production Growth, Industry Demand, Global Manufacturers, Equipment, Revenue Analysis and Forecast 2025. Available online: https://www.reuters.com/brandfeatures/venture-capital/article?id=92459 (accessed on 21 August 2019).

- Ganesh, V.A.; Raut, H.K.; Naira, A.S.; Ramakrishna, S. A review on self-cleaning coatings. J. Mater. Chem. 2011, 21, 16304–16322. [Google Scholar] [CrossRef]

- McInnis, B.M.; Hurt, J.D.; McDaniel, S.; Kemp, L.K.; Hodges, T.W.; Nobles, D.R. Carbon Capture Coatings: Proof of Concept Results and Call to Action. Coat. World 2019, 24, 82–91. [Google Scholar]

- Li, G.; Meng, H. Recent Advances in Smart Self-Healing Polymers and Composites. In Chapter 8—Self-Healing Coatings; Hughes, A.E., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 211–241. [Google Scholar]

- Challenger, C. An Update on Sustainability in the Coatings Industry. Coat. Technol. 2018, 15, 22–28. [Google Scholar]

- Mash, T. Sustainability in the Coatings Industry. PCI Magazine. Available online: https://www.pcimag.com/articles/100363-sustainability-in-the-coatings-industry (accessed on 1 April 2015).

- Van Haveren, J.; Oostveen, E.A.; Miccichè, F.; Noordover, B.A.J.; Koning, C.E.; van Benthem, R.A.T.M.; Frissen, A.E.; Weijnen, J.G.J. Resins and additives for powder coatings and alkyd paints, based on renewable sources. J. Coat. Technol. Res. 2007, 4, 177–186. [Google Scholar] [CrossRef]

- Honzíček, J. Curing of Air-Drying Paints: A critical Review. Ind. Eng. Chem. Res. 2019, 58, 12485–12505. [Google Scholar] [CrossRef]

- Tuck, N. Waterborne and Solvent Based Alkyds and their End User Application. In Surface Coating Technology—Volume VI; SITA Technology; Wiley: London, UK, 2000. [Google Scholar]

- Hubert, J.C.; Venderbosch, R.A.M.; Muizebelt, W.J.; Klaassen, R.P.; Zabel, K.H. Singlet Oxygen Drying of Alkyd Resins and Model Compounds. J. Coat. Technol. 1997, 69, 59–64. [Google Scholar] [CrossRef]

- Bieleman, J.H. Driers. Chimia 2002, 56, 184–190. [Google Scholar] [CrossRef]

- Miccichè, F.; van Haveren, J.; Oostveen, E.; Ming, W.; van der Linde, R. Oxidation and oligomerization of ethyl linoleate under influence of the combination of ascorbic acid 6 palmitate/iron-2-ethylhexanoate. Appl. Catal. A 2006, 297, 174–181. [Google Scholar] [CrossRef]

- Cobalt REACH Consortium. Cobalt REACH Consortium (CoRC). Available online: http://cobaltreachconsortium.org/ (accessed on 7 August 2019).

- Reach Metal Consortium. Welcome to the REACH Metal Carboxylates (Driers & Catalysts) Consortium Ltd. (RMC). Retrieved from Reach Metal (Driers and Catalysts) Consortium. Available online: https://www.metal-carboxylates.org/ (accessed on 7 August 2019).

- Powder Metallurgy Review. Proposed Cobalt Reclassification Raises Concerns for Metal Powder Users. Powder Metallurgy Review. Available online: https://www.pm-review.com/proposed-cobalt-reclassification-raises-concerns-metal-powder-users/ (accessed on 18 October 2017).

- Sanderson, H. Cobalt hits 2-year low as DRC ramps up supply. Financial Times, 6 February 2019. [Google Scholar]

- Steinert, A. Effective drying without cobalt. Eur. Coat. J. 2005, 3, 84–88. [Google Scholar]

- Ha, D.; Joo, H.; Ahn, G.; Kim, M.J.; Bing, S.J.; An, S.; Kim, H.; Kang, K.G.; Lim, Y.K.; Jee, Y. Jeju ground water containing vanadium induced immune activation on splenocytes of low dose γ-rays-irradiated mice. Food Chem. Toxicol. 2012, 50, 2097–2105. [Google Scholar] [CrossRef]

- Srivastava, A.K. Anti-diabetic and toxic effects of vanadium compounds. Mol. Cell. Biochem. 2000, 206, 177–182. [Google Scholar] [CrossRef] [PubMed]

- Soucek, M.D.; Khattab, T.; Wu, J. Review of autoxidation and driers. Prog. Org. Coat. 2012, 73, 435–454. [Google Scholar] [CrossRef]

- Bieleman, J.H. Progress in the Development of Cobalt-free Drier Systems. Macromol. Symp. 2002, 187, 811–821. [Google Scholar] [CrossRef]

- Van Gorkum, R.; Bouwman, E. The oxidative drying of alkyd paint catalysed by metal complexes. Coord. Chem. Rev. 2005, 249, 1709–1728. [Google Scholar] [CrossRef]

- Warzeska, S.T.; Zonneveld, M.; van Gorkum, R.; Muizebelt, W.J.; Bouwman, E.; Reedijk, J. The influence of bipyridine on the drying of alkyd paints. A model study. Prog. Org. Coat. 2002, 44, 243–248. [Google Scholar] [CrossRef]

- van Gorkum, R.; Bouwman, E. Fast Autoxidation of ethyl linoleate catalyzed by [Mn(acac)3] and bipyridine: A possible drying catalyst for alkyd paints. Inorg. Chem. 2004, 43, 2456–2458. [Google Scholar] [CrossRef]

- Oyman, Z.O.; Ming, W.; van der Linde, R.; Gorkum, R.; Bouwman, E. Effect of [Mn(acac)3] and its combination with 2,2′-bipyridine on the autoxidation and oligomerisation of ethyl linoleate. Polymer 2005, 46, 1731–1738. [Google Scholar] [CrossRef]

- Van Gorkum, R.; Bouwman, E.; Reedijk, J. Drier for Alkyd-Based Coating. Patent EP 1382648 A, 21 January 2004. [Google Scholar]

- Miccichè, F.; Long, G.J.; Shahin, A.M.; Grandjean, F.; Ming, W.; van Haveren, J.; van der Linde, R. The combination of ascorbic acid 6-palmitate and [Fe(III)(μ3-O)]7+ as a catalyst for the oxidation of unsaturated lipids. Inorg. Chim. Acta 2007, 360, 535–545. [Google Scholar] [CrossRef]

- Hage, R.; Wesenhagen, P.V. Unilever, Liquid Hardening. Patent WO2008003652, 10 January 2008. [Google Scholar]

- Santhanam, R. Additives for Curable Liquid Compositions. Patent WO2012092034, 5 July 2012. [Google Scholar]

- Oyman, Z.O.; Ming, W.; Micciche, F.; Oostveen, E.; van Haveren, J.; van der Linde, R. A promising environmentally friendly manganese-based catalyst for alkyd emulsion coatings. Polymer 2004, 45, 7431–7436. [Google Scholar] [CrossRef]

- Oyman, Z.O.; Ming, W.; van der Linde, R.; ter Borg, J.; Schut, A.; Bieleman, J.H. Oxidative drying of alkyd paints catalysed by a dinuclear manganese complex (MnMeTACN). Surf. Coat. Int. Part B 2005, 88, 269–275. [Google Scholar] [CrossRef]

- Meijer, M.D.; van Weelde, E.; van Dijk, J.T.M.; Flapper, J. Drier for Auto-Oxidisable Coating Compositions. Patent EP2794786B, 27 July 2013. [Google Scholar]

- Meijer, M.D.; van Weelde, E.; van Dijk, J.T.M.; Flapper, J. Drier for Auto-Oxidisable Coating Compositions. Patent EP2794787B, 27 July 2013. [Google Scholar]

- Hage, R.; Iburg, J.E.; Kerschner, J.; Koek, J.H.; Lempers, E.L.M.; Martens, R.J.; Racherla, U.S.; Russell, S.W.; Swarthoff, T.; van Vliet, M.R.P.; et al. Efficient manganese catalysts for low-temperature bleaching. Nature 1994, 369, 637–639. [Google Scholar] [CrossRef]

- Hage, R.; Lienke, A. Applications of Transition-Metal Catalysts to Textile and Wood-Pulp Bleaching. Angew. Chem. Int. Ed. Engl. 2006, 45, 206–222. [Google Scholar] [CrossRef] [PubMed]

- Meijer, M.D.; Flapper, J. Drier for Auto-Oxidisable Coating Compositions. Patent EP2935435B, 26 June 2014. [Google Scholar]

- Maaijen, K.; Hage, R. Method of Preparing an Oxidatively Curable Coating Formulation. Patent WO2017/134463, 10 August 2017. [Google Scholar]

- de Boer, J.W.; Hage, R.; Maaijen, K. Drier for Alkyd-Based Coating. Patent WO2014/122433, 31 January 2014. [Google Scholar]

- de Boer, J.W.; Hage, R.; Maaijen, K. Oxidative Curable Coating Composition. Patent WO2014/122432, 31 January 2014. [Google Scholar]

- Hage, R.; de Boer, J.W.; Maaijen, K. Oxidative Curable Coating Composition. Patent WO2014/122434, 31 January 2014. [Google Scholar]

- Peralta, R.A.; Neves, A.; Bortoluzzi, A.J.; Casellato, A.; dos Anjos, A.; Greatti, A.; Xavier, F.R.; Szpoganicz, B. First transition-metal complexes containing the ligands 6-amino-6-methylperhydro-1,4-diazepine (AAZ) and a new functionalized derivative: Can AAZ act as a mimic for 1,4,7-triazacyclononane? Inorg. Chem. 2005, 44, 7690–7692. [Google Scholar] [CrossRef]

- Maaijen, K.; Hage, R. Oxidatively Curable Coating Composition. Patent WO2017103620, 22 June 2017. [Google Scholar]

- Kalenda, P.; Holeček, J.; Veselý, D.; Erben, M. Influence of methyl groups on ferrocene on rate of drying of oxidizable paints by using model compounds. Prog. Org. Coat. 2006, 56, 111–113. [Google Scholar] [CrossRef]

- Stava, V.; Erben, M.; Veselý, D.; Kalenda, P. Properties of metallocene complexes during the oxidative crosslinking of air drying coatings. J. Phys. Chem. Solids 2007, 68, 799–802. [Google Scholar] [CrossRef]

- Erben, M.; Veselý, D.; Vinklárek, J.; Honzíček, J. Acyl-substituted ferrocenes as driers for solvent-borne alkyd paints. J. Mol. Catal. A 2012, 353–354, 13–21. [Google Scholar] [CrossRef]

- Dong, S.; Wang, B.; Lui, B. Amperometric glucose sensor with ferrocene as an electron transfer mediator. Biosens. Bioelectron. 1992, 7, 215–222. [Google Scholar] [CrossRef]

- Hage, R.; de Boer, J.W.; Gaulard, F.; Maaijen, K. Manganese and iron bleaching and oxidation catalysts. Adv. Inorg. Chem. 2013, 65, 85–116. [Google Scholar]