Modification of Ti/Sb-SnO2/PbO2 Electrode by Active Granules and Its Application in Wastewater Containing Copper Ions

Abstract

:1. Introduction

2. Results and Discussion

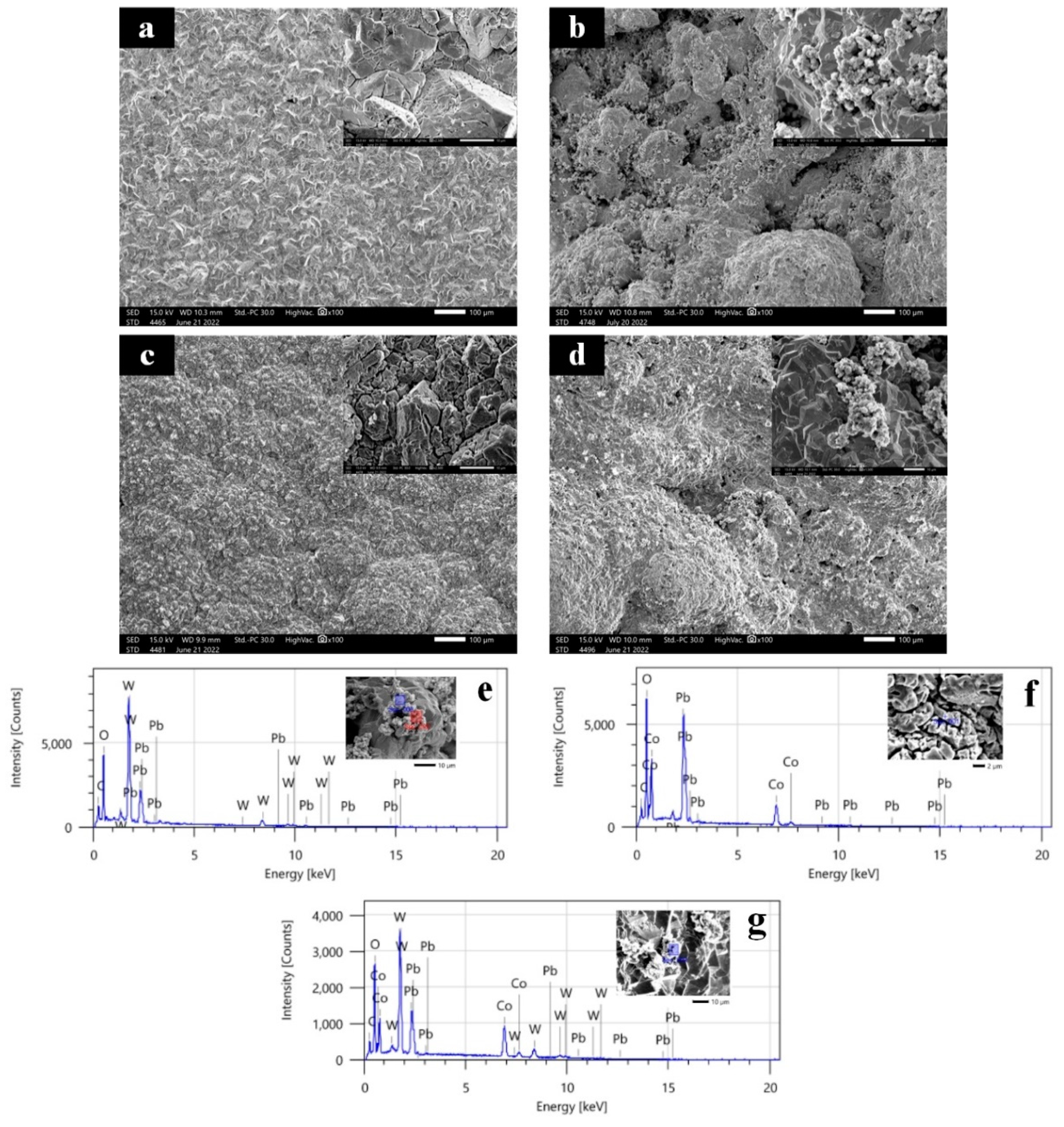

2.1. Surface Morphology Analysis of Electrodes

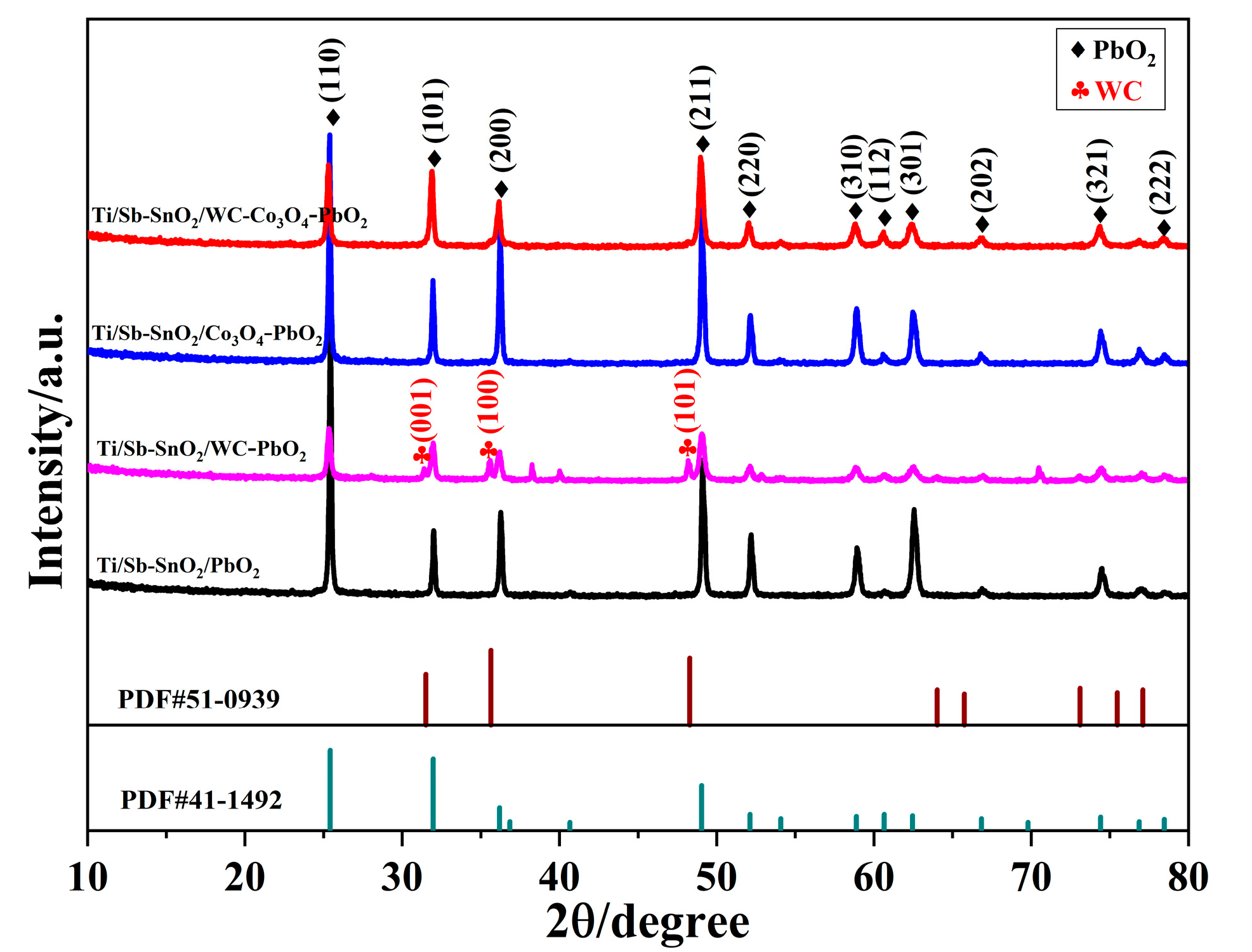

2.2. XRD Structural Characterization

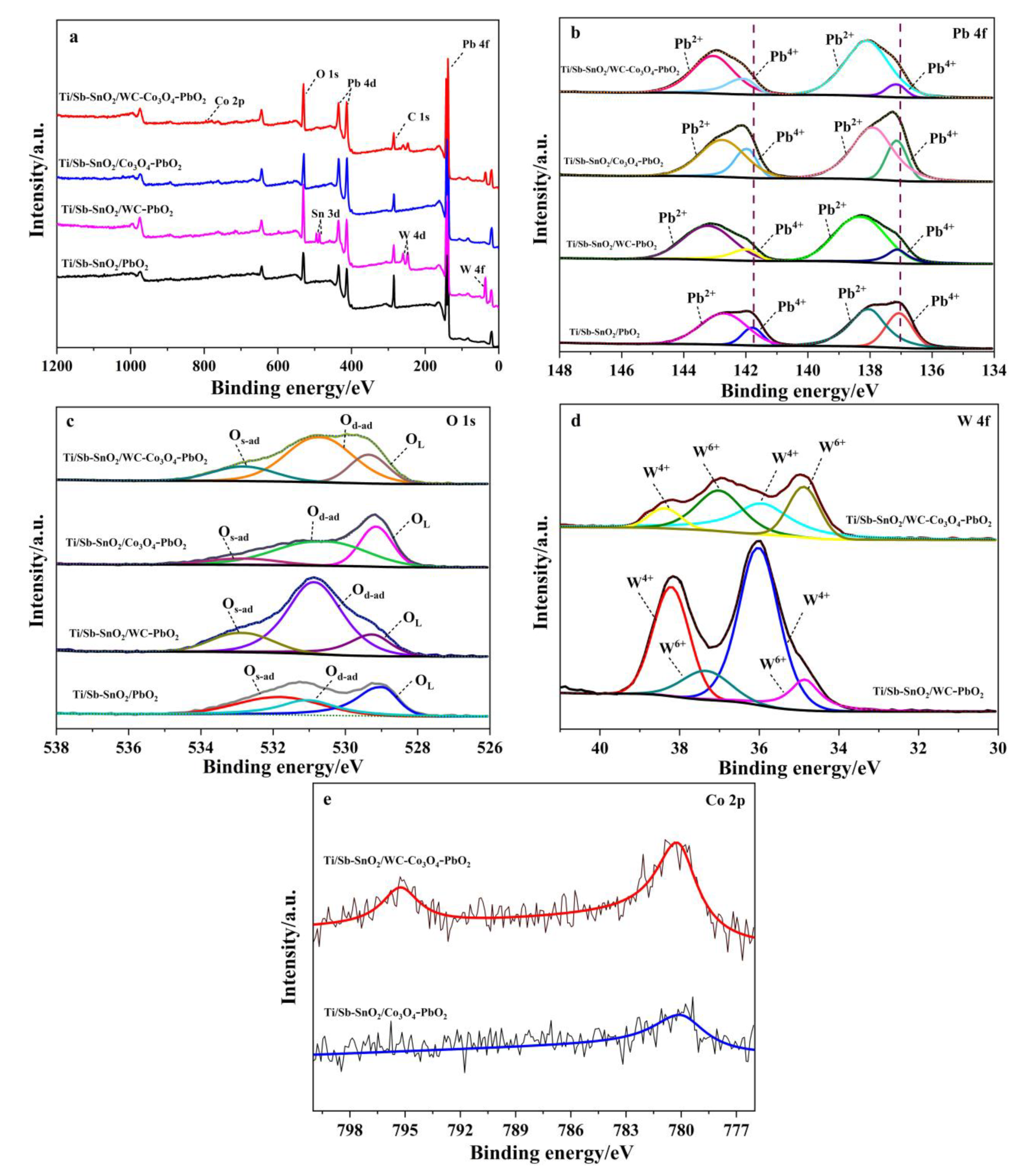

2.3. XPS Analysis

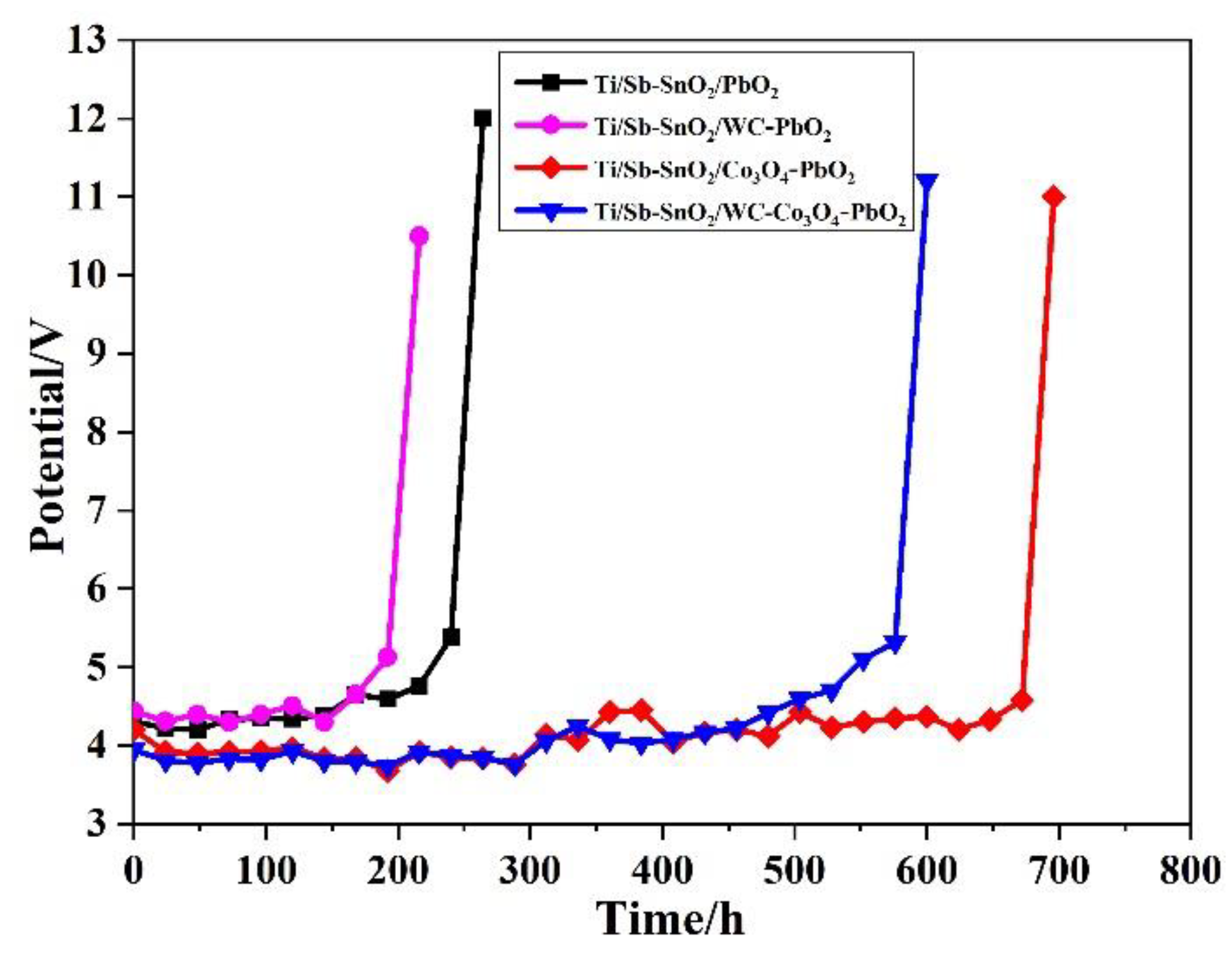

2.4. Electrochemical Properties

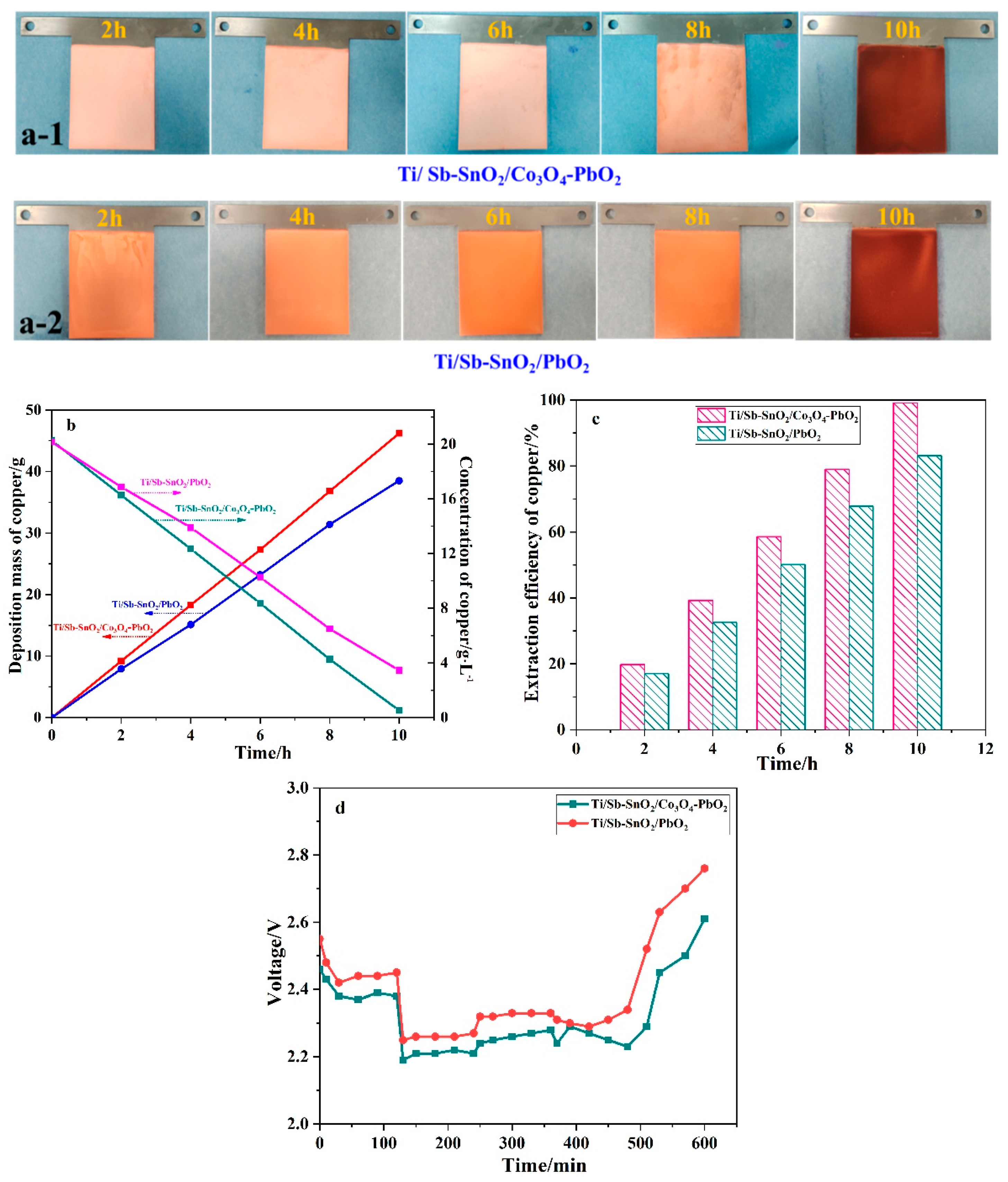

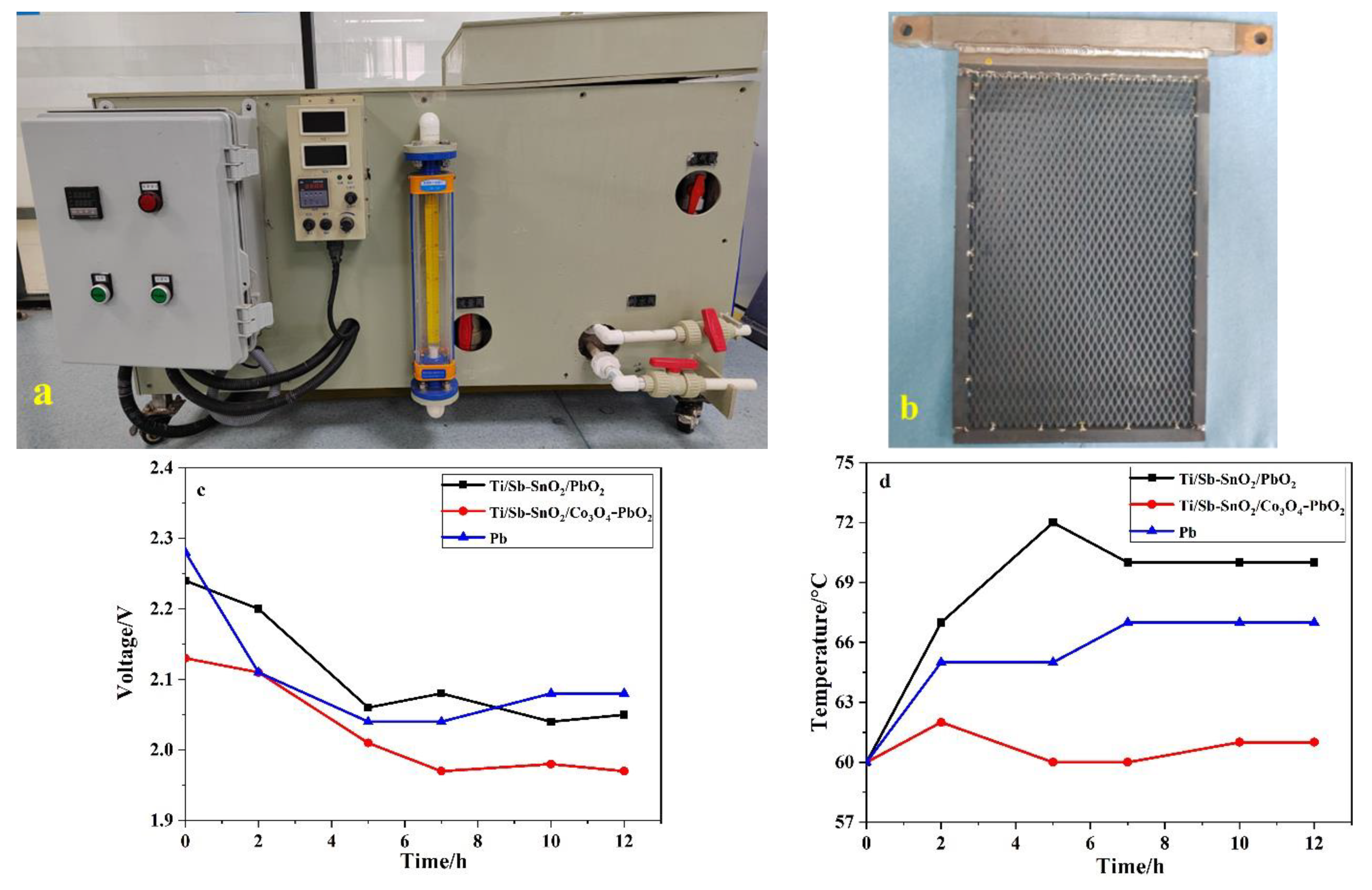

2.5. The Application of Modified Electrodes in Wastewater Containing Copper Ions

3. Experimental Details

3.1. Materials

3.2. Fabrication of Ti/Sb-SnO2/PbO2 Electrode by Active Granules

3.3. Characterization

3.4. Electrochemical Treatment of Copper-Containing Wastewater

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, B.; Zhang, G. Estimates of electricity saving potential in chinese nonferrous metals industry. Energy Policy 2013, 60, 558–568. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, L.; Wang, M.; Yang, Q.; Liu, X.; Shen, J.; Liu, G.; Zheng, M. Concentrations and profiles of persistent organic pollutants unintentionally produced by secondary nonferrous metal smelters: Updated emission factors and diagnostic ratios for identifying sources. Chemosphere 2020, 255, 126958. [Google Scholar] [CrossRef]

- Sorour, N.; Zhang, W.; Gabra, G.; Ghali, E.; Houlachi, G. Electrochemical studies of ionic liquid additives during the zinc electrowinning process. Hydrometallurgy 2015, 157, 261–269. [Google Scholar] [CrossRef]

- Zhang, C.; Duan, N.; Jiang, L.; Xu, F. The impact mechanism of Mn2+ ions on oxygen evolution reaction in zinc sulfate electrolyte. J. Electroanal. Chem. 2018, 811, 53–61. [Google Scholar] [CrossRef]

- Karbasi, M.; Eskandar, K.A.; Elaheh, A.D. Electrochemical performance of Pb−Co composite anode during zinc electrowinning. Hydrometallurgy 2018, 183, 51–59. [Google Scholar] [CrossRef]

- Chen, B.; Wang, S.; Liu, J.; Huang, H.; Dong, C.; He, Y.; Yan, W.; Guo, Z.; Xu, R.; Yang, H. Corrosion resistance mechanism of a novel porous Ti/Sn-Sb-RuOx/β-PbO2 anode for zinc electrowinning. Corros. Sci. 2018, 144, 136–144. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, J.; Ni, S.; Bie, C.; Zhi, H.; Sun, X. A clean process for selective recovery of copper from industrial wastewater by extraction-precipitation with p-tert-octyl phenoxy acetic acid. J. Environ. Manag. 2022, 304, 114164. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, Z.; Chen, P. An environmentally friendly gradient treatment system of copper-containing wastewater by coupling thermally regenerative battery and electrodeposition cell. Sep. Purif. Technol. 2022, 295, 121243. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, S. Enhanced copper extraction in the chalcopyrite bioleaching system assisted by microbial fuel cells and catalyzed by silver-bearing ores. J. Environ. Chem. Eng. 2022, 10, 108827. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, X.; Lyu, X.; Gao, W.; Su, H.; Li, C. Extraction and separation of copper and iron from copper smelting slag: A review. J. Clean. Prod. 2022, 368, 133095. [Google Scholar] [CrossRef]

- Kim, H.K.; Jang, H.; Jin, X.; Kim, M.G.; Hwang, S.J. A crucial role of enhanced Volmer-Tafel mechanism in improving the electrocatalytic activity via synergetic optimization of host, interlayer, and surface features of 2D nanosheets. Appl. Catal. B Environ. 2022, 312, 121391. [Google Scholar] [CrossRef]

- Abedini, A.; Valmoozi, A.A.E.; Afghahi, S.S.S. Anodized graphite as an advanced substrate for electrodeposition of PbO2. Mater. Today Commun. 2022, 31, 103464. [Google Scholar] [CrossRef]

- Kandasamy, K. Electrochemical degradation of sago wastewater using Ti/PbO2 electrode: Optimisation using response surface methodology. Int. J. Electrochem. Sci. 2014, 10, 1506–1516. [Google Scholar]

- Torres, J.E.; Sierra, A.; Pena, D.Y.; Uribe, I.; Estupinan, H. Corrosion rate in a lead based alloy in a sulfuric acid solution at different temperatures. Matéria 2014, 19, 183–196. [Google Scholar]

- Li, H.; Yuan, T.; Li, R.; Wang, W.; Zheng, D.; Yuan, J. Electrochemical properties of powder-pressed Pb-Ag-PbO2 anodes. Trans. Nonferrous Met. Soc. China 2019, 29, 2422–2429. [Google Scholar] [CrossRef]

- Ye, W.; Xu, F.; Jiang, L.; Duan, N.; Li, J.; Zhang, F.; Zhang, G.; Chen, L. A novel functional lead-based anode for efficient lead dissolution inhibition and slime generation reduction in zinc electrowinning. J. Clean. Prod. 2021, 284, 124767. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; Jiang, W.; Chen, C.; Yu, B.; Xu, R. Facile synthesis MnCo2O4 modifying PbO2 composite electrode with enhanced OER electrocatalytic activity for zinc electrowinning. Sep. Purif. Technol. 2021, 272, 118916. [Google Scholar] [CrossRef]

- Chen, S.; Chen, B.; Wang, S.; Yan, W.; He, Y.; Guo, Z.; Xu, R. Ag doping to boost the electrochemical performance and corrosion resistance of Ti/Sn-Sb-RuOx/α-PbO2/β-PbO2 electrode in zinc electrowinning. J. Alloys Compd. 2020, 815, 152551. [Google Scholar] [CrossRef]

- Zhang, F.; Zuo, J.; Jin, W.; Xu, F.; Jiang, L.; Xi, D.; Wen, Y.; Li, J.; Yu, Z.; Li, Z.; et al. Size effect of γ-MnO2 precoated anode on lead-containing pollutant reduction and its controllable fabrication in industrial-scale for zinc electrowinning. Chemosphere 2022, 287, 132457. [Google Scholar] [CrossRef]

- Gao, G.; Zhang, X.; Wang, P.; Ren, Y.; Meng, X.; Ding, Y.; Zhang, T.; Jiang, W. Electrochemical degradation of doxycycline hydrochloride on Bi/Ce co-doped Ti/PbO2 anodes: Efficiency and mechanism. J. Environ. Chem. Eng. 2022, 10, 108430. [Google Scholar] [CrossRef]

- Duan, P.; Qian, C.; Wang, X.; Jia, X.; Jiao, L.; Chen, Y. Fabrication and characterization of Ti/polyaniline-Co/PbO2-Co for efficient electrochemical degradation of cephalexin in secondary effluents. Environ. Res. 2022, 214, 113842. [Google Scholar] [CrossRef]

- Shao, D.; Li, W.; Wang, Z.; Yang, C.; Xu, H.; Yan, W.; Yang, L.; Wang, G.; Yang, J.; Feng, L.; et al. Variable activity and selectivity for electrochemical oxidation wastewater treatment using a magnetically assembled electrode based on Ti/PbO2 and carbon nanotubes. Sep. Purif. Technol. 2022, 301, 122008. [Google Scholar] [CrossRef]

- Macounová, K.M.; Pittkowski, R.K.; Nebel, R.; Zitolo, A.; Krtil, P. Selectivity of Ru-rich Ru-Ti-O oxide surfaces in parallel oxygen and chlorine evolution reactions. Electrochimi. Acta. 2022, 427, 140878. [Google Scholar] [CrossRef]

- Preez, S.P.; Jones, D.R.; Warwick, M.E.A.; Falch, A.; Sekoai, P.T.; das Neves Quaresma, A.M.; Bessarabov, D.G.; Dunnill, C.W. Thermally stable Pt/Ti mesh catalyst for catalytic hydrogen combustion. Int. J. Hydrog. Energy 2020, 45, 16851–16864. [Google Scholar] [CrossRef]

- Ma, D.; Ngo, V.; Raghavan, S.; Sandoval, S. Degradation of Ir-Ta oxide coated Ti anodes in sulfuric acid solutions containing fluoride. Corros. Sci. 2020, 164, 108358. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, M.; Wang, C.; Meng, X.; Zhang, W.; Chen, Z.; Crittenden, J. Electrochemical degradation of methylisothiazolinone by using Ti/SnO2-Sb2O3/α, β-PbO2 electrode: Kinetics, energy efficiency, oxidation mechanism and degradation pathway. Chem. Eng. J. 2019, 374, 626–636. [Google Scholar] [CrossRef]

- Chen, X.; Guo, H.; Luo, S.; Wang, Z.; Li, X. Effect of SnO2 intermediate layer on performance of Ti/SnO2/MnO2 electrode during electrolytic-manganese process. Trans. Nonferrous Met. Soc. China 2017, 27, 1417–1422. [Google Scholar] [CrossRef]

- Hakimi, F.; Rashchi, F.; Ghalekhani, A.; Dolati, A.; Astaraei, F.R. Effect of a synthesized pulsed electrodeposited Ti/PbO2-RuO2 nanocomposite on zinc electrowinning. Ind. Eng. Chem. Res. 2021, 60, 11737–11748. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, C.M.; Schmidt, W.; Spliethoff, B.; Schüth, E.B.F. Weakly ferromagnetic ordered mesoporous Co3O4 synthesized by nanocasting from vinyl-functionalized cubic Ia3d mesoporous silica. Adv. Mater. 2004, 17, 53–56. [Google Scholar] [CrossRef]

- Alhaddad, M.; Ismail, A.A.; Alghamdi, Y.G.; Al-Khathami, N.D.; Mohamed, R.M. Co3O4 nanoparticles accommodated mesoporous TiO2 framework as an excellent photocatalyst with enhanced photocatalytic properties. Opt. Mater. 2022, 134, 112643. [Google Scholar] [CrossRef]

- Dan, Y.; Lu, H.; Liu, X.; Lin, H.; Zhao, J. Ti/PbO2 + nano-Co3O4 composite electrode material for electrocatalysis of O2 evolution in alkaline solution. Int. J. Hydrogen Energy 2011, 36, 1949–1954. [Google Scholar] [CrossRef]

- He, S.; Xu, R.; Hu, G.; Chen, B. Electrosynthesis and performance of WC and Co3O4 co-doped α-PbO2 electrodes. RSC Adv. 2016, 6, 3362–3371. [Google Scholar] [CrossRef]

- Tang, C.; Lu, Y.; Wang, F.; Niu, H.; Yu, L.; Xue, J. Influence of a MnO2-WC interlayer on the stability and electrocatalytic activity of titanium-based PbO2 anodes. Electrochim. Acta 2020, 331, 135381. [Google Scholar] [CrossRef]

- Wan, C.; Zhao, L.; Wu, C.; Lin, L.; Liu, X. Bi5+ doping improves the electrochemical properties of Ti/SnO2-Sb/PbO2 electrode and its electrocatalytic performance for phenol. J. Clean. Prod. 2022, 380, 135005. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhou, W.; Yu, J.; Chen, Y.; Liu, M.; Shao, Z. Enhancing electrocatalytic activity of perovskite oxides by tuning cation deficiency for oxygen reduction and evolution reactions. Chem. Mater. 2016, 28, 1691–1697. [Google Scholar] [CrossRef]

- Kosmulski, M.; Mączka, E. Zeta potential and particle size in dispersions of alumina in 50-50 w/w ethylene glycol-water mixture. Colloid. Surfaces A 2022, 654, 130168. [Google Scholar] [CrossRef]

| Electrode | Pb4+ 4f7/2/eV | Pb4+ 4f5/2/eV | Pb2+ 4f7/2/eV | Pb2+ 4f5/2/eV |

|---|---|---|---|---|

| Ti/Sb-SnO2/PbO2 | 137.07 | 141.79 | 138.02 | 142.70 |

| Ti/Sb-SnO2/WC-PbO2 | 137.12 | 141.94 | 138.26 | 143.22 |

| Ti/Sb-SnO2/Co3O4-PbO2 | 137.14 | 141.95 | 137.89 | 142.76 |

| Ti/Sb-SnO2/WC-Co3O4-PbO2 | 137.13 | 142.05 | 138.10 | 143.05 |

| Electrode | OL/eV | OL/% | Od-ad/eV | Od-ad/% | Os-ad/eV | Os-ad/% |

|---|---|---|---|---|---|---|

| Ti/Sb-SnO2/PbO2 | 529.01 | 27.69% | 531.01 | 20.91% | 531.82 | 29.56% |

| Ti/Sb-SnO2/WC-PbO2 | 529.25 | 17.06% | 530.84 | 64.53% | 532.83 | 18.41% |

| Ti/Sb-SnO2/Co3O4-PbO2 | 529.15 | 34.53% | 530.55 | 54.72% | 532.77 | 10.75% |

| Ti/Sb-SnO2/WC-Co3O4-PbO2 | 529.35 | 21.16% | 530.67 | 59.91% | 532.81 | 18.93% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, X.; Wu, J.; Wei, Z.; Jia, B.; Feng, Q.; Xu, S.; Wang, Y. Modification of Ti/Sb-SnO2/PbO2 Electrode by Active Granules and Its Application in Wastewater Containing Copper Ions. Catalysts 2023, 13, 515. https://doi.org/10.3390/catal13030515

Kang X, Wu J, Wei Z, Jia B, Feng Q, Xu S, Wang Y. Modification of Ti/Sb-SnO2/PbO2 Electrode by Active Granules and Its Application in Wastewater Containing Copper Ions. Catalysts. 2023; 13(3):515. https://doi.org/10.3390/catal13030515

Chicago/Turabian StyleKang, Xuanqi, Jia Wu, Zhen Wei, Bo Jia, Qing Feng, Shangyuan Xu, and Yunhai Wang. 2023. "Modification of Ti/Sb-SnO2/PbO2 Electrode by Active Granules and Its Application in Wastewater Containing Copper Ions" Catalysts 13, no. 3: 515. https://doi.org/10.3390/catal13030515

APA StyleKang, X., Wu, J., Wei, Z., Jia, B., Feng, Q., Xu, S., & Wang, Y. (2023). Modification of Ti/Sb-SnO2/PbO2 Electrode by Active Granules and Its Application in Wastewater Containing Copper Ions. Catalysts, 13(3), 515. https://doi.org/10.3390/catal13030515