Abstract

The global E factor (EG factor) has recently been introduced, in the context of asymmetric organocatalysis, as a new green chemistry metric to take into consideration the synthesis of the catalyst in the overall economy of the synthetic process of a given chiral molecule in optically pure form. Herein, its further usefulness in comparing diverse catalytic systems, even different from organocatalysts, is shown by the analysis of four case studies.

1. Introduction

Cutting-edge strategies to build up molecules in a selective fashion, namely to obtain a single isomer of a given target compound, mostly rely on the use of catalysts. Leaving aside biocatalysis, artificial catalytic systems can be divided into metal-based and fully organic. The first group includes metal inorganic salts, metal nanoparticles, and organometallic catalysts, the latest being mainly transition metal complexes with organic molecules acting as ligands. The second group concerns organocatalysts, which can be divided on the basis of their mechanism of action, according to the general classification proposed by List and Maruoka [1]. Apart from some types of reactivity, for which the use of certain species is mandatory (e.g., palladium, thus transition metal-based catalysts, for Suzuki cross-coupling), one could be in the situation of choosing among completely different strategies to carry out a chemoselective, regioselective or stereoselective transformation. For example, the use of catalytic amounts of an organic Brønsted acid or a Lewis acidic transition metal is a suitable alternative to activate a carbonyl compound before it undergoes reactivity with a nucleophile. However, especially in the case of large-scale processes, some key features play a non-negligible role in determining the privileged strategy to employ, namely: waste amount, safety, operational simplicity, and availability of necessary equipment. All of these points directly affect the cost and the practical feasibility of the process itself and, directly or indirectly, most of them are considered in the twelve principles of green chemistry [2,3]. Very recently, we have proposed the global E factor (EG factor) as a new green chemistry metric in the context of asymmetric organocatalysis, to take into account the synthesis of the catalyst in the overall economy of the process, and demonstrated that this can importantly affect the total waste amount of the process [4] and, thus, its E factor [5] and its cost. Herein, taking advantage of the suitableness of catalytic systems possessing different natures in promoting the same transformations, we mean to give a further example of the usefulness of this parameter, by the analysis of four selected examples, which constitute our case studies [6].

2. Discussion

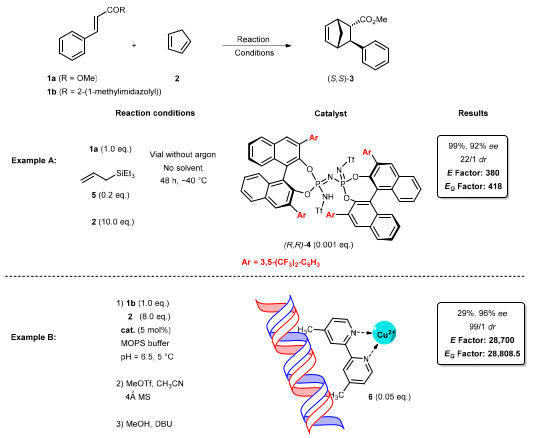

2.1. Case Study 1: Diastereo- and Enantioselective Diels-Alder Reaction

The Diels-Alder reaction is a classic example of a perfectly atom economic reaction, with a general preference towards the endo adduct (Alder’s rule) [7,8]. Therefore, the use of suitable catalytic systems, and the pursuit of high diastereo- and enantio-selectivity capable of working in sustainable conditions, make this transformation a perfect candidate to develop truly green protocols. To compare two different catalytic systems and their impact on the overall waste amount of the process, methyl (1R,2S,3S,4S)-3-phenylbicyclo [2.2.1]hept-5-ene-2-carboxylate, namely compound (S,S)-3, was selected as the model compound, resulting from the Diels-Alder cycloaddition of chalcone derivative 1 to cyclopentadiene 2. The first strategy requires the use of a paltry amount (0.1 mol%) of highly potent imidodiphosphorimidate (IDPi) (R,R)-4, which acts as a pre-catalyst, since it generates the active catalytic species in situ, in the presence 20 mol% of silylating agent 5 [9]. The reaction between 2 and methyl cinnamate 1a does not require an inert atmosphere, nor any solvent, despite the thermal conditions are not ideal in terms of energy efficiency: indeed, the reaction proceeds at −40 °C for 48 h. However, (S,S)-3 was obtained in almost quantitative yield, 22/1 dr and 92% ee, with a non-trivial simultaneous control of two stereocentres (excluding the other two, constrained by the bicyclic structure of the product). The resulting E factor of 380 is importantly affected by the purification by column chromatography, which, due to the high yield, presumably serves to separate the product from the catalyst (R,R)-4 and unreacted excess of 2. Remarkably, the use of only 0.1 mol% of the IDPi catalyst (having an E factor of 4841 [4]) contributes to an increase of 10% of the total waste amount, so that the EG factor rises to 418. Nevertheless, it must be stressed that in the same procedure, upon recovery and acidification, an IDPi analogous to (R,R)-4 has proven to be recyclable without erosion of the stereoselectivity for 5 cycles. The recyclability of the catalyst has an important role in the reduction of the mass waste, so the EG factor has to be considered only for the first catalytic cycle, while the simple E factor can be taken into account for any further transformation which employs the recycled catalytic species (as a first approximation, if minimal yield erosions and the additional material for the regeneration of the catalyst are neglected). Last but not least, the reaction has been performed on a 1.3 g scale of 1a, proving suitable for further scalability.

On the other side, a catalytic asymmetric protocol in water was developed by Roelfes and Feringa [10], in which the active catalytic species is generated in situ from an achiral bipyridine complex with cupric nitrate (compound 6) and a fragment of salmon testes DNA (st-DNA), whose buffered aqueous solution is commercially available. In this case, the important degree of association (whose constant had been previously measured by the same authors) of the achiral copper complex with the inherently chiral st-DNA fragment provides the basis for an efficient chirality transfer, in a deoxyribozyme mimic approach [11]. As in the case of biocatalysis, the use of biological material (enzymes, entire cells, or even RNA or DNA fragments, like in this case) can be defined as advantageous under the profile of waste production, since no synthetic steps are required; on the contrary, it may raise ethical dilemmas in some situations (e.g., the use of animal enzymes or cells). Therefore, from the perspective of the waste mass, the extraction of DNA has not been considered and the E factor of the catalytic system is essentially those of complex 6, which has a value of 354. In this calculation, a high-yielding industrial procedure for 4-methylpyridine homocoupling has been considered [12], including N-oxidation of 4-methylpyridine, coupling, and reduction of the resulting bipyridine N-oxide. It must be stressed that, in any case, greener approaches for the N-oxidation of 4-methylpyridine than those described in the above-mentioned procedure have been presented [13], despite not being considered in this E factor calculation. Finally, the complexation of 4,4′-dimethyl-2,2′-bipyridine with trihydrate cupric nitrate was considered to complete the overall sum of waste produced in the synthesis of complex 6 [11]. Due to the intrinsically low reactivity of α,β-unsaturated esters (like methyl cinnamate 1a) in the Diels-Alder cycloaddition [14], Roelfes and Feringa had to start from substrate 1b, arguing that a heterocyclic nitrogen atom is essential for coordination to the copper catalytic center in an aqueous environment, presumably due to competitive coordination by the oxygen atom of water itself. Only after the reaction between 1b and 2, the Diels-Alder product (1-methyl-1H-imidazol-2-yl)((1R,2S,3S,4S)-3-phenylbicyclo[2.2.1]hept-5-en-2-yl)methanone (70% yield) is treated first with methyl triflate and then with methanol, to afford the target compound (S,S)-3 (41% yield, 29% overall yield) in virtual diastereopurity and 96% ee. Unfortunately, an extremely high dilution rate and the necessity of three separate steps with two chromatographic purifications severely affect the overall waste amount, so an E factor value of 28,700 results. The synthesis of the necessary amount of catalyst (5 mol%) accounts for 0.38% additional waste and the EG factor rises to 28,808.5. It must be stressed that, in this case, the transformation has been performed on a 1 mmol scale of 1b.

This comparison shows that, even if a higher waste increase is produced by the use of a catalyst with a high E factor, like (R,R)-4, this effect is compensated by the optimal reaction conditions allowed by the use of such catalyst and by its recyclability (that has not been accounted in the calculations). On the other side, a less waste-impacting catalytic system (lower E factor of the catalyst) which, albeit working in green conditions as well, imposes to operate at high dilution rates, may not result in the optimal choice. In any case, the E factor of the selected catalytic system affects the additional waste amount produced (+10% against +0.38%). A resume of the reaction conditions and the calculated metrics is proposed in Scheme 1.

Scheme 1.

Comparison between two different catalytic strategies for diastereo- and enantioselective Diels Alder reaction.

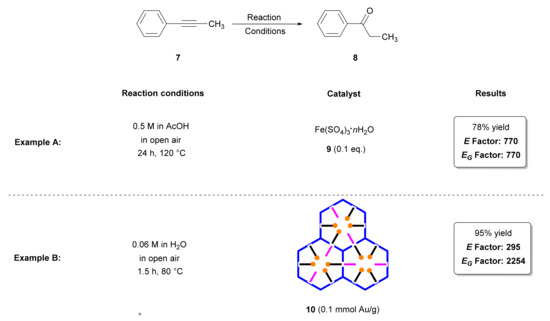

2.2. Case Study 2: Regioselective Hydration of Internal Arylalkynes

The versatility of alkynes as substrates has earned them the title of “white canvas” for organic synthesis. Indeed, their hydration is an excellent atom-economic transformation to provide carbonyl compounds, useful building blocks in C-C bond-forming reactions. Catalytic methodologies have been developed across the decades [15], either for non-regioselective or regioselective protocols (both Markovnikov and anti-Markovnikov). Most catalytic systems developed for such protocols rely on transition metals [16], especially gold [17], and, more recently, on first-row transition metals in general [18]. As our second case study, we selected the challenging Markovnikov hydration of 1-phenylpropyne 7 to propiophenone 8 (comparison in Scheme 2). In the first example, hydrate iron(III) sulfate is catalytically employed in acetic acid (0.5 M with respect to substrate 7) [19]. Mechanistic investigations unveiled a Lewis acid-assisted Brönsted acidic catalysis, the acidity of acetic acid (catalyst, solvent, and hydration agent) being enhanced by the metal salt (co-catalyst) and allowing for protonation of the triple bond, the addition of acetate, hydrolysis of the resulting acetyl enol ether and final keto-enol tautomerization. Albeit the simultaneous presence of hydrate ferric sulfate and acetic acid is mandatory, both of them are commercially available and inexpensive, so the EG factor results equal to the E factor, whose value of 770 is due to a 78% yield (78%) which demands a chromatographic purification.

Scheme 2.

Comparison between two different strategies for completely regioselective hydration of 1-phenylpropyne 7 to propiophenone 8.

Conversely, an engineered catalyst has been developed and used to realize the same transformation in higher yield (95%), shorter time (1.5 h), and lower temperature (80 °C) in water (solvent and hydration agent) by the group of Wang and Li [20]. The catalyst is constituted by gold nanoparticles covalently bounded to mesoporous silica gel functionalized with propylthio and propylsulfonic groups, for which an E factor of 625 can be calculated. Despite an important dilution rate of 7 (i.e., the concentration is only 0.06 M), the absence of chromatography accounts for a much lower E factor than the one of the iron-catalyzed protocol. However, an EG factor of magnitude over 7.5 higher than the corresponding E factor is obtained if one takes into account the waste generated in the synthesis of the necessary amount of catalyst. It must be stressed that gold nanoparticles were recoverable and recyclable for at least ten subsequent catalytic cycles. The recyclability of a catalyst is an important feature, which must be carefully evaluated to amortize the cost to synthesize it. However, this aspect is not numerically taken into account in the EG factor, since catalyst recyclability shall be verified case by case.

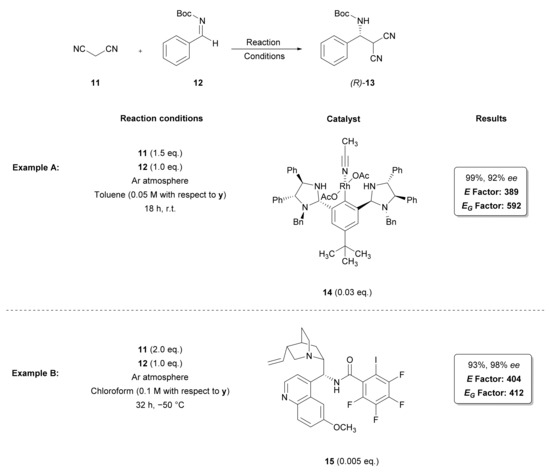

2.3. Case Study 3: Enantioselective Mannich Reaction

Among the atom-economic C-C bond-forming reactions, the Mannich reaction was chosen as the third case study, as a plethora of direct catalytic asymmetric methods to perform this transformation has been developed over the decades [21,22]. These include, in particular, several organocatalyzed strategies [23] and, within this context, it shall not be forgotten that asymmetric organocatalytic Mannich reactions themselves paved the way to a large employment of chiral phosphoric acids, perhaps one of the most important classes of Brønsted acid organocatalysts [24,25,26]. For this case study, we chose to analyze the addition of malononitrile 11 to the N-Boc-protected aldimine of benzaldehyde, namely compound 12, to afford in high enantiopurity the corresponding N-Boc-α-dicyanobenzylamine 13. None of the two compared catalytic strategies is performed in properly green conditions; indeed, an aromatic (toluene) or a chlorinated (chloroform) low polar solvent is employed with high dilution rates with respect to substrate 12 and under an inert atmosphere. However, the two protocols (both from Arai and co-workers) have a very similar E factor (389 vs. 404) and are performed on the same reaction scale (0.2 mmol of N-Boc imine 12); thus, the impact of the synthesis of the catalyst can be evaluated with particular accuracy. In the first case, the employment of 3 mol% of chiral rhodium pincer complex 14 as the organometallic active catalyst allows us to afford product 13 in 99% yield and 92% ee [27]. An E factor of 389 can be calculated for this process, which, in consideration of an E factor of 1734 for catalyst a, returns an EG factor value of 592. The latest value accounts for 52.3% additional waste, only due to the synthesis of the necessary 6.3 mg of 14. On the other side, halogen bonding organocatalyst 15 has an E factor of 626 but, more interestingly, only 0.5 mol% of 15 is sufficient to afford 13 in 93% yield and 98% ee [28]. It must be stressed that, in the latter case, a slightly larger excess of 11 (2.0 equivalents vs. 1.5 equivalents), a longer reaction time (32 h vs. 18 h), and a considerably lower temperature (−50 °C vs. r.t.) with respect to the Rh-catalyzed procedure are crucial to bringing the reaction to completion in a stereoselective fashion. Nevertheless, the EG factor (412) looks not so different from the E factor (404), accounting for a low impact of the synthesis of the necessary amount of catalyst on the overall process (1.8% additional waste). These results are summarized in Scheme 3.

Scheme 3.

Comparison between two different strategies for the enantioselective Mannich reaction of malononitrile 11 and benzaldehyde N-Boc aldimine 12.

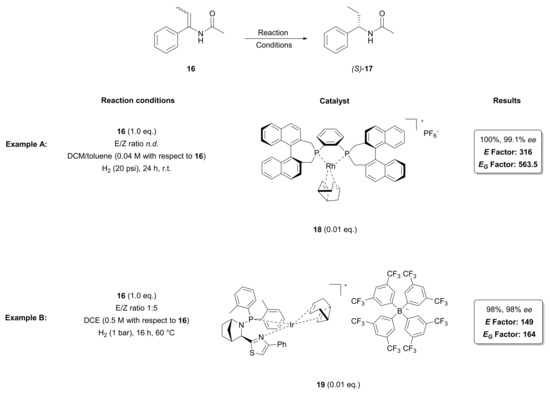

2.4. Case Study 4: Convergent Enantioselective Hydrogenation of Enamides

As the last case study, a completely different atom-economic transformation, namely the hydrogenation of enamides, was selected. Albeit hydrogenations are generally characterized by the complete incorporation of all of the atoms of the reactants into the products (AE = 100%), additional concerns may rise from stereochemical issues, since a limited number of chiral catalysts can convert both the E and Z isomers to the same enantiomer of the product, which means to perform a convergent enantioselective transformation. This means that such selective catalysts can convert E/Z mixtures of the enamide; vice versa, a pure geometrical isomer of the starting material is needed. Restricting the focus to catalysts able to perform highly stereoselective convergent hydrogenations, these rely on chiral complexes of Rh(I) [29,30], Ni(II) [31], and Ru(II) [32]. The convergent enantioselective hydrogenation of E/Z mixtures of N-(1-phenylprop-1-en-1-yl)acetamide 16 to pure N-acetylamine (S)-17 promoted by two chiral catalysts based on Rh(I) and Ir(I), respectively, will be therefore taken into account. In the first example, by the Zhang group, bis biaryl diphosphine ligand (R,R)-binaphane is employed to generate in situ the active catalytic species 18, in the presence of [Rh(COD)2]PF6 [33]. A high E factor of 4603.5 can be estimated for catalyst 18, so that, even if only 1 mol% of the Rh-based catalyst is sufficient to afford the desired optically pure product in quantitative yield and 99.1% ee, an additional 78.1% waste can be taken into account from the synthesis of 18, giving an EG factor value of 563.5. This value, as well as the classical E factor, which is 316 for the protocol by Zhang [33], is particularly high, and is due to the filtration of the catalyst on silica gel and the high dilution rate (final concentration of 0.04 M); after all, except for the temperature, the reaction conditions cannot be defined green. However, the most astonishing observation regards the additional waste percentage due to the synthesis of only 1 mol% of the catalyst, which is generated in the reaction environment and then filtered off without being recyclable. It must be stressed that the reaction is run on a 0.1 mmol scale, therefore a reduction of the overall waste amount may result from optimization of the solvent amount on a larger scale (not presented in the original paper, in any case).

In the second example [34], the hydrogenation reaction of the two geometrical isomers of compound 16 is prone to happen in the presence of Ir-based complex 19 (1 mol%) proposed by the Andersson group [35] and having an E factor of 1676.5, a value almost 3 times lower than that of Rh-based catalyst 18, the catalyst loading being the same. No particular advantages characterize the latter procedure in terms of reaction environment benignity (i.e., DCE is a chlorinated class 1 solvent like DCM), but a pleasant reduction of the solvent amount can be noticed, due to a more than 10 times higher concentration of substrate 16 (0.5 M against 0.04 M). Furthermore, the higher price paid in terms of energy efficiency (60 °C for 16 h against r.t. for 24 h) is compensated by a much lower waste amount. Indeed, the E factor of the process is 149, and is less affected by the synthesis of catalyst b, with a +10% waste produced, affording an EG factor of 164. In summary, the employment of more expensive Ir starting material for the preparation of the catalyst is balanced by a lower E factor of the final species 19 and this means an overall more sustainable process, considering also the similar employed hydrogen pressure, purification procedure (i.e., filtration on silica gel) final yield and ee (Scheme 4).

Scheme 4.

Comparison between two different strategies for an efficient convergent enantioselective hydrogenation of enamide 16.

3. Materials and Methods

The calculation of the E factor and the EG factor is performed on the same algorithm as Ref. [4], following the general formulas reported in Equation (1) and Equation (2), respectively:

Experimental details for the calculation of the E factor have been taken from the supporting information of the original literature papers and the calculation has been normalized to the amount of the final target product. The necessary amount of silica gel and eluent for chromatographic columns has been calculated from the algorithm described in [6]. All columns have been considered to be manually packed with a moderately difficult level of separation for the title compound, unless for specified chromatographic conditions in the experimental procedure. In the case of filtrations, one-third of the material (stationary phase, eluent) for standard chromatography has been taken into account. The amounts of MgSO4 and Na2SO4 (density = 2.66 g/cm3, 1 flat-rate spoon = 1 cm3) were calculated as follows: 1 flat-rate spoon for each 25 mL of the solution to be desiccated). Pressure gas and recycling of species have not been taken into account in the E factor calculation. Further details for the calculations are available in the Supplementary Materials.

4. Conclusions

Several elements have to be considered when choosing how to perform a given transformation on a multigram scale, even more so when highly selective catalytic systems are needed, possibly performing in optimal conditions with large substrate scopes. All of these key factors include the availability of the necessary equipment to work in some conditions (e.g., inert atmosphere, cryostat, paddle stirrer, etc.), but also a high standard of purity and lack of traces of certain metal impurities (this is the case of pharmaceuticals). On the other side, the growing attention towards process sustainability demands a careful look at waste reduction, energy efficiency, safety, operational simplicity, and, in general, all of the aspects covered by the twelve principles of green chemistry. Some selective catalytic technologies have nowadays been less implemented on an industrial scale with respect to others. For instance, the hybrid catalytic system by Roelfes and Feringa described in our first case study has not been scaled up; but, even more generally, the field of asymmetric organocatalysis, for whose development the Nobel Prize for chemistry has recently been awarded to List and MacMillan, is still waiting for more industrial applications [36,37]. The four case studies presented in this perspective, selected on the basis of the feasibility of a given selective transformation in the presence of catalytic systems having different natures, represent a practical example of the usefulness of a numerical parameter like the EG factor in supporting all the above-mentioned considerations. Furthermore, a few applicative examples in which the EG factor has been taken into account in the development of new catalysts [38] or in the choice of the catalyst for a particular reaction within the framework of a multi-step transformation [39] are already present in the literature, and green chemistry metrics, in general, are gaining increasing attention even for what concerns synthetic routes to active pharmaceutical ingredients [40].

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/catal13010102/s1.

Author Contributions

Conceptualization, A.A.; methodology, A.A.; validation, S.D., A.A.; formal analysis, S.D. and A.A.; calculations, A.A.; data curation, A.A.; writing—original draft preparation, A.A.; writing—review and editing, S.D. and A.A.; visualization, S.D. and A.A.; supervision, S.D. and A.A.; project administration, A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- List, B.; Maruoka, K. Asymmetric Organocatalysis; Thieme Chemistry: Stuttgart, Germany, 2012. [Google Scholar]

- Anastas, P.T.; Warner, J.C. Green Chemistry: Theory and Practice; Oxford University Press: Oxford, UK, 1998. [Google Scholar]

- Anastas, P.; Eghbali, N. Green Chemistry: Principles and practice. Chem. Soc. Rev. 2010, 39, 301–312. [Google Scholar] [CrossRef] [PubMed]

- Antenucci, A.; Dughera, S.; Renzi, P. Green Chemistry Meets Asymmetric Organocatalysis: A Critical Overview on Catalysts Synthesis. ChemSusChem 2021, 14, 2785–2853. [Google Scholar] [CrossRef]

- Sheldon, R.A. The E factor 25 years on: The rise of green chemistry and sustainability. Green Chem. 2017, 19, 18–43. [Google Scholar] [CrossRef]

- Pessel, F.; Augé, J.; Billault, I.; Scherrmann, M.-C. The weight of flash chromatography: A tool to predict its mass intensity from thin-layer chromatography. Beilstein J. Org. Chem. 2016, 12, 2351–2357. [Google Scholar] [CrossRef] [PubMed]

- Diels, O.; Alder, K. Über die Ursachen der “Azoesterreaktion”. Liebigs Ann. Chem. 1926, 450, 237–254. [Google Scholar] [CrossRef]

- Diels, O.; Alder, K. Synthesen in der hydroaromatischen Reihe. Liebigs Ann. Chem. 1928, 460, 98–122. [Google Scholar] [CrossRef]

- Gatzenmeier, T.; Turberg, M.; Yepes, D.; Xie, Y.; Neese, F.; Bistoni, G.; List, B. Scalable and Highly Diastereo- and Enantioselective Catalytic Diels–Alder Reaction of α,β-Unsaturated Methyl Esters. J. Am. Chem. Soc. 2018, 140, 12671. [Google Scholar] [CrossRef]

- Boersma, A.J.; Feringa, B.L.; Roelfes, G. α,β-Unsaturated 2-Acyl Imidazoles as a Practical Class of Dienophiles for the DNA-Based Catalytic Asymmetric Diels−Alder Reaction in Water. Org. Lett. 2007, 9, 3647–3650. [Google Scholar] [CrossRef]

- Roelfes, G.; Boersma, A.J.; Feringa, B.L. Highly enantioselective DNA-based catalysis. Chem. Commun. 2006, 635–637. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, W.; Guo, L.; Li, Y.; Xu, X. Preparation Method of 4,4′-dimethyl-2,2′-dipyridyl. CN104892494 B, 2017. [Google Scholar]

- Limnios, D.; Kokotos, C.G. 2,2,2-Trifluoroacetophenone as an Organocatalyst for the Oxidation of Tertiary Amines and Azines to N-Oxides. Chem. Eur. J. 2014, 20, 559–563. [Google Scholar] [CrossRef] [PubMed]

- Allgäuer, D.S.; Jangra, H.; Asahara, H.; Li, Z.; Chen, Q.; Zipse, H.; Ofial, A.R.; Mayr, H. Quantification and Theoretical Analysis of the Electrophilicities of Michael Acceptors. J. Am. Chem. Soc. 2017, 139, 13318–13329. [Google Scholar] [CrossRef]

- Hintermann, L.; Labonde, A. Catalytic Hydration of Alkynes and Its Application in Synthesis. Synthesis 2007, 8, 1121–1150. [Google Scholar] [CrossRef]

- Alonso, F.; Beletskaya, I.P.; Yus, M. Transition-Metal-Catalyzed Addition of Heteroatom−Hydrogen Bonds to Alkynes. Chem. Rev. 2004, 104, 3079–3160. [Google Scholar] [CrossRef] [PubMed]

- Zuccaccia, D.; Del Zotto, A.; Baratta, W. The pivotal role of the counterion in gold catalyzed hydration and alkoxylation of alkynes. Coord. Chem. Rev. 2019, 396, 103–116. [Google Scholar] [CrossRef]

- Salvio, R.; Bassetti, M. Sustainable hydration of alkynes promoted by first row transition metal complexes. Background, highlights and perspectives. Inorg. Chim. Acta 2021, 522, 120288. [Google Scholar] [CrossRef]

- Antenucci, A.; Flamini, P.; Fornaiolo, M.V.; Di Silvio, S.; Mazzetti, S.; Mencarelli, P.; Salvio, R.; Bassetti, M. Iron(III)-Catalyzed Hydration of Unactivated Internal Alkynes in Weak Acidic Medium, under Lewis Acid-Assisted Brønsted Acid Catalysis. Adv. Synth. Catal. 2019, 361, 4517–4526. [Google Scholar] [CrossRef]

- Zhu, F.-X.; Wang, W.; Li, H.-X. Water-Medium and Solvent-Free Organic Reactions over a Bifunctional Catalyst with Au Nanoparticles Covalently Bonded to HS/SO3H Functionalized Periodic Mesoporous Organosilica. J. Am. Chem. Soc. 2011, 133, 11632–11640. [Google Scholar] [CrossRef]

- Cόrdova, A. The Direct Catalytic Asymmetric Mannich Reaction. Acc. Chem. Res. 2004, 37, 102–112. [Google Scholar] [CrossRef]

- Saranya, S.; Harry, N.A.; Krishnan, K.K.; Anilkumar, G. Recent Developments and Perspectives in the Asymmetric Mannich Reaction. Asian J. Org. Chem. 2018, 7, 613–633. [Google Scholar] [CrossRef]

- Verkade, J.M.M.; van Hemert, L.J.C.; Quaedfliegb, P.J.L.M.; Rutjes, F.P.J.T. Organocatalysed asymmetric Mannich reactions. Chem. Soc. Rev. 2008, 37, 29–41. [Google Scholar] [CrossRef] [PubMed]

- Akiyama, T.; Itoh, J.; Yokota, K.; Fuchibe, K. Enantioselective Mannich-Type Reaction Catalyzed by a Chiral Brønsted Acid. Angew. Chem. Int. Ed. 2004, 43, 1566–1568. [Google Scholar] [CrossRef]

- Akiyama, T.; Itoh, J.; Yokota, K.; Fuchibe, K. Enantioselective Mannich-Type Reaction Catalyzed by a Chiral Brønsted Acid. Angew. Chem. 2004, 116, 1592–1594. [Google Scholar] [CrossRef]

- Uraguchi, D.; Terada, M. Chiral Brønsted Acid-Catalyzed Direct Mannich Reactions via Electrophilic Activation. J. Am. Chem. Soc. 2004, 126, 5356–5357. [Google Scholar] [CrossRef]

- Arai, T.; Moribatake, T.; Masu, H. Chiral Bis(imidazolidine)-Derived NCN Pincer Rh Complex for Catalytic Asymmetric Mannich Reaction of Malononitrile with N-Boc Imines. Chem. Eur. J. 2015, 21, 10671–10675. [Google Scholar] [CrossRef] [PubMed]

- Kuwano, S.; Suzuki, T.; Hosaka, Y.; Arai, T. A chiral organic base catalyst with halogen-bonding-donor functionality: Asymmetric Mannich reactions of malononitrile with N-Boc aldimines and ketimines. Chem. Commun. 2018, 54, 3847–3850. [Google Scholar] [CrossRef]

- Burk, M.J.; Feaster, J.E.; Nugent, W.A.; Harlow, R.L. Preparation and use of C2-symmetric bis(phospholanes): Production of α-amino acid derivatives via highly enantioselective hydrogenation reactions. J. Am. Chem. Soc. 1993, 112, 10125–10138. [Google Scholar] [CrossRef]

- Koenig, K.E.; Knowles, W.S. Use of deuterium to investigate E-Z isomerizations during rhodium-catalyzed reduction. Asymmetric induction and mechanistic implications. J. Am. Chem. Soc. 1978, 100, 7561–7564. [Google Scholar] [CrossRef]

- Long, J.; Gao, W.; Guan, Y.; Lv, H.; Zhang, X. Nickel catalyzed highly enantioselective hydrogenation of β-acetylamino vinylsulfones: Access to chiral β-amido sulfones. Org. Lett. 2018, 20, 5914–5917. [Google Scholar] [CrossRef]

- Zhou, Y.-G.; Tang, W.; Wang, W.-B.; Li, W.; Zhang, X. Highly effective chiral ortho-substituted BINAPO ligands (o-BINAPO): Applications in Ru-catalyzed asymmetric hydrogenations of β-aryl-substituted β-(acylamino) acrylates and β-keto esters. J. Am. Chem. Soc. 2002, 124, 4952–4953. [Google Scholar] [CrossRef]

- Xiao, D.; Zhang, Z.; Zhang, X. Synthesis of a Novel Chiral Binaphthyl Phospholane and Its Application in the Highly Enantioselective Hydrogenation of Enamides. Org. Lett. 1999, 1, 1679–1681. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Massaro, L.; Krajangsri, S.; Singh, T.; Su, H.; Silvi, E.; Ponra, S.; Eriksson, L.; Ahlquist, M.S.G.; Andersson, P.G. Combined Theoretical and Experimental Studies Unravel Multiple Pathways to Convergent Asymmetric Hydrogenation of Enamides. J. Am. Chem. Soc. 2021, 143, 21594–21603. [Google Scholar] [CrossRef]

- Li, J.Q.; Paptchikhine, A.; Govender, T.; Andersson, P.G. Bicyclic phosphine-thiazole ligands for the asymmetric hydrogenation of olefins. Tetrahedron Asymm. 2010, 21, 1328–1333. [Google Scholar] [CrossRef]

- Carlone, A.; Bernardi, L. Enantioselective organocatalytic approaches to active pharmaceutical ingredients—Selected industrial examples. Phys. Sci. Rev. 2019, 4, 20180097. [Google Scholar] [CrossRef]

- Aukland, M.H.; List, B. Organocatalysis emerging as a technology. Pure Appl. Chem. 2021, 93, 1371–1381. [Google Scholar] [CrossRef]

- Antenucci, A.; Messina, M.; Bertolone, M.; Bella, M.; Carlone, A.; Salvio, R.; Dughera, S. Turning Renewable Feedstocks into a Valuable and Efficient Chiral Phosphate Salt Catalyst. Asian J. Org. Chem. 2021, 10, 3279–3284. [Google Scholar] [CrossRef]

- Volpe, C.; Meninno, S.; Crescenzi, C.; Mancinelli, M.; Mazzanti, A.; Lattanzi, A. Catalytic Enantioselective Access to Dihydroquinoxalinones via Formal α-Halo Acyl Halide Synthon in One Pot. Angew. Chem. Int. Ed. 2021, 60, 23819–23826. [Google Scholar] [CrossRef]

- Becker, J.; Manske, C.; Randl, S. Green chemistry and sustainability metrics in the pharmaceutical manufacturing sector. Curr. Opin. Green Sustain. Chem. 2021, 33, 100562. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).