Abstract

Hydrogenated carboxyl nitrile rubber (HXNBR) is endowed with superior mechanical performance and heat–oxygen aging resistance via emulsion hydrogenation of its precursor, i.e., carboxyl nitrile rubber (XNBR). Herein, a ruthenium-based catalyst was prepared to achieve the direct catalytic hydrogenation of XNBR latex. The effects of a series of hydrogenation conditions, such as catalyst dosage, solid content and reaction temperature, as well as the hydrogen pressure, on the hydrogenation reaction were investigated in detail. We found that the hydrogenation rate fell upon increasing the solid content of the XNBR latex, with an XNBR conversion rate of 95.01 mol% in 7 h with 11.25 wt% solid content. As the reaction temperature was increased, the hydrogenation rate first increased and then decreased. The fastest reaction hydrogenation rate was reached at 140 °C, with an XNBR conversion of 95.10 mol% in 5 h. The hydrogenation rate was positively related with the hydrogen pressure employed in the reactor. In view of the safety and cost, a pressure rate of 1300 psi was considered optimal. Similarly, the hydrogenation rate can also be enhanced by adding more catalyst. When 0.05 wt% catalyst was added, the fastest hydrogenation rate was achieved. In summary, the following optimum hydrogenation conditions were determined by using a synthesized ruthenium-based catalyst: 11.25 wt% solid content of XNBR latex, 140 °C of reaction temperature, 1300 psi of hydrogen pressure and 0.05 wt% catalyst. The vulcanization, mechanical performance, aging resistance and oil resistance of the produced HXNBR under the above reaction conditions were systematically investigated.

1. Introduction

Hydrogenation is a common chemical modification method for unsaturated olefines. The physical and chemical performances of hydrogenated polymers such as hydrogenated NBR and hydrogenated NR have been improved compared to those of unhydrogenated polymers [1,2,3,4,5]. Compared to nitrile rubber (NBR), hydrogenated nitrile rubber (HNBR) presents better heat and heat oxygen aging resistance while maintaining the original oil and wear resistance of NBR. Furthermore, the mechanical performance of HNBR, such as the tensile strength and elongation ratio, are significantly improved [1]. Therefore, HNBR has been widely used in aerospace, petroleum exploration, hoses, seals and automotive engine rubber parts.

The solution hydrogenation of NBR has been successfully industrialized, which can be carried out by following either a homogeneous or a heterogeneous catalysis route [6,7]. Based on a kinetic analysis of the hydrogenation process via a homogeneous catalytic route, Ai et al. found that a hydrogenation degree of 75 mol% was achieved with 6 mg Grubbs II catalyst at 3 h in 100 mL toluene solution of 1.0 g NBR under 725 psi hydrogen (H2) pressure and at 55 °C [8]. In the case of heterogeneous catalysis [9,10,11,12], silica and carbon nanotubes were introduced as catalyst carriers for hydrogenation reaction. However, the solution hydrogenation requires large amounts of organic solvents and cumbersome operations, which not only pollute the environment but also increase production costs [13].

In view of the fact that diene polymers are usually synthesized by semi-batch emulsion polymerization with a final product state as an emulsion, latex hydrogenation has attracted wide attention recently. Emulsion hydrogenation has been successfully achieved by means of diimine or gaseous hydrogen [14,15]. In the direction of diimine hydrogenation, the hydrogenated polymer is formed through carbon–carbon double bond reduction by diamine [16,17]. As a result, the high-pressure gaseous hydrogen, organic solvent, transition metal catalyst and expensive hydrogenation apparatus were no longer required. Wang et al. systematically studied the hydrogenation of NBR with hydrazine hydrate and sodium periodate [18]. The hydrogenation degree of NBR could reach about 95 mol% in 10 h at 60 °C with a dropping rate of 12 mL/h of sodium periodate. However, the health hazard of hydrazine hydrate and concomitant gelation have to be considered.

Catalytic latex hydrogenation is usually performed under high H2 pressure. Transition metal complexes such as rhodium, ruthenium, palladium and rhodium ruthenium, are selected as catalysts [19,20,21]. Generally, rhodium and ruthenium catalysts are commonly employed. Liu et al. explored the hydrogenation of NBR latex using water-soluble rhodium based catalysts RhCl(TPPMS)3 and RhCl(TPPTS)3 [22]. In the absence of organic solvents, the hydrogenation degree of 0.052 mmol/L RhCl(TPPMS)3 reached about 95 mol% in 8.5 h at 100 °C under 1000 psi H2 pressure, whereas RhCl(TPPTS)3 showed low reaction activity, meaning a high degree of hydrogenation could not be achieved. Wei et al. studied the hydrogenation of nitrile butadiene latex using a Wilkinson catalyst [23]. TPP was utilized as a substitute to organic solvent to ensure the catalyst molecules penetrated into latex droplets. However, the rate of the hydrogenation reaction was very slow, regardless of the amount of catalyst added, hindering further application of this technology. Wang et al. investigated the effects of the particle size, concentration and reaction temperature of the NBR latex in the hydrogenation reaction [24]. Without any organic solvent, with the condition of 1 wt% catalyst dosage at 130 °C and under 1000 psi H2, it took about 2 h to achieve 95 mol% conversion, which took 8 h with 0.5 wt% catalyst. The hydrogenation rate was directly proportional to the catalyst loading concentration and reaction temperature and inversely proportional to the particle size. Wang and Rempel also studied the mass transfer of hydrogen in the reaction, the role of TPP in the hydrogenation reaction and the catalytic mechanism of the Wilkinson catalyst [20,24]. It was revealed that the mass transfer of hydrogen is not the limiting step in the hydrogenation reaction, while TPP plays a role as a catalyst carrier, and a competition exists between nitrile group and catalysts. Therefore, the catalytic hydrogenation of latex is preferred compared with the aforementioned methods.

XNBR can serve as an ideal polymer-based composite matrix because of its ability to be cross-linked and cured with different reagents stemming from the existence of nitrile and carboxyl functional groups [25,26,27,28]. Carboxyl hydrogenated nitrile rubber has displayed better mechanical properties, as well as better heat and oxygen aging performance than XNBR, while retaining the above two functional groups [29]. Bhattacharjee et al. hydrogenated liquid XNBR by applying a homogeneous catalysis method [30]. A hydrogenation degree of 68 mol% was achieved in L-XNBR containing 0.057 carboxyl equivalent/100 g and 26.1 wt% acrylonitrile under 391 psi H2 pressure and 0.18 mmol/L catalyst at 60 °C for 1 h in acetone solution. Note that organic solution is necessary in the reaction, which stops it from being an eco-friendly approach. Yang et al. fabricated a new type of self-crosslinking film with HXNBR latex prepared by diimide reduction [29]. The results confirmed that the HXNBR latex was able to form a self-crosslinking film. Liu et al. produced functional composites with unique photoluminescence properties, excellent mechanical properties and good thermal stability via reactive blending of HXNBR and modified basic zinc carbonate (m-3Zn(OH)2·2ZnCO3) [31]. Liu et al. also used epoxy cyclohexyl polyhedral oligomeric silsesquioxane (POSS) and HXNBR to create a novel organic–inorganic composite via chemical bonding of carboxyl and the POSS epoxy group [32].

In this paper, a ruthenium-based catalyst is prepared to achieve the direct catalytic hydrogenation of XNBR latex. The emulsion hydrogenation reaction of XNBR latex under different hydrogenation conditions in the presence of catalyst is reported. The effects of the catalyst dosage, reaction temperature, hydrogen pressure and solid content on the hydrogenation rate of XNBR latex are explored in detail. In order to obtain HXNBR latex with a high hydrogenation degree, appropriate reaction conditions are delicately selected to accelerate the corresponding hydrogenation rate. The mechanical performance, oil resistance and aging resistance of HXNBR with an XNBR conversion rate of 91.02 mol% prepared under the optimal condition are also tested.

2. Results and Discussion

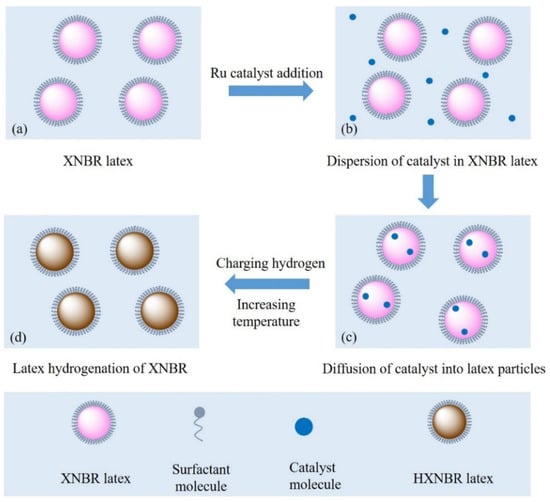

The mass transfer of catalyst in XNBR latex hydrogenation is depicted in Scheme 1. In the present experiments, a certain amount of catalyst was first added and suspended in XNBR latex (Scheme 1a). During stirring, the catalyst was gradually dispersed in latex (Scheme 1b). The catalyst molecules in contact with XNBR colloidal particles tend to penetrate into the interior (Scheme 1c). After increasing the temperature to a specified level and charging the hydrogen gas, the hydrogenation reaction of XNBR latex started. Finally, HXNBR latex was generated (Scheme 1d).

Scheme 1.

Mass transfer of catalyst in XNBR latex hydrogenation. (a) XNBR latex, (b) Dispersion of catalysts in XNBR latex, (c) Diffusion of catalysts into latex particles, (d) Latex hydrogenation of XNBR.

2.1. Fourier Transform Infrared Spectrometer (FTIR), Nuclear Magnetic Resonance Hydrogen Spectroscopy (1H NMR) and Particle Size Analysis

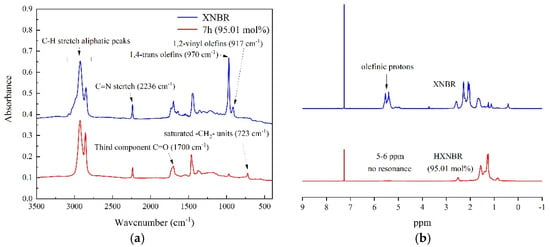

The XNBR conversion and composition of polymers could be characterized by FTIR and 1H NMR. The infrared spectra and chemical composition of XNBR with distinct XNBR conversion are shown in Figure 1a. The peak at 2236 cm−1 in the infrared spectra results from cyano group (C≡N), while the peak at 1700 cm−1 is caused by carbonyl group (C=O). Two types of additions exist in XNBR latex, i.e., 1–4 and 1–2 products. The peak at 970 cm−1 represents the characteristic peak of the 1,4-trans double bond, while the peak at 917 cm−1 is from the characteristic peak of 1,2-vinyl. There is no absorbance at 750 cm−1, the characteristic peak of the 1,4-cis double bond, which indicates that only the 1,4-trans double bond and 1,2-vinyl double bond are available in XNBR latex. Comparing the infrared spectra of XNBR with different XNBR conversions, it is found that the intensity the peaks at 970 and 917 cm−1 gradually attenuates along with the increase in XNBR conversion. Meanwhile, a new characteristic peak appears at 723 cm−1, representing the formation of (CH2)n, n > 4. The disappearance of characteristic peaks of 970 and 917 cm−1 signals the completion of the hydrogenation reaction. In this process, the contents of the cyano group and carbonyl group remain unchanged, indicating that the catalyst shows no selectivity for the cyano group or carbonyl group.

Figure 1.

Representative FTIR (a) and 1H NMR (b) spectra of both XNBR and HXNBR (95.01 mol%) with an XNBR conversion rate of 95.01 mol% (reaction conditions: catalyst = 0.035 wt%, latex solid content = 11.25 wt%, reaction temperature = 120 °C, stirring speed = 450 rpm, hydrogen pressure = 1200 psi).

The chemical shifts of the polymer structure before and after hydrogenation are characterized by 1H NMR, as shown in Figure 1b. For the original XNBR, the peak at 5.3–5.6 ppm is attributable to the trans hydrogen atom of 1,4-adduct butadiene. The peak at 4.9–5.3 ppm is attributable to 1,2-vinyl hydrogen atom. The signals of aliphatic protons are between 0.8 ppm and 2.8 ppm. The methyl peak of methacrylic acid is between 1.0 and 1.2 ppm. When XNBR conversion is about 95.01 mol%, it can be clearly seen that the peak representing olefin almost disappeared, which suggests that unsaturated double bonds have been hydrogenated.

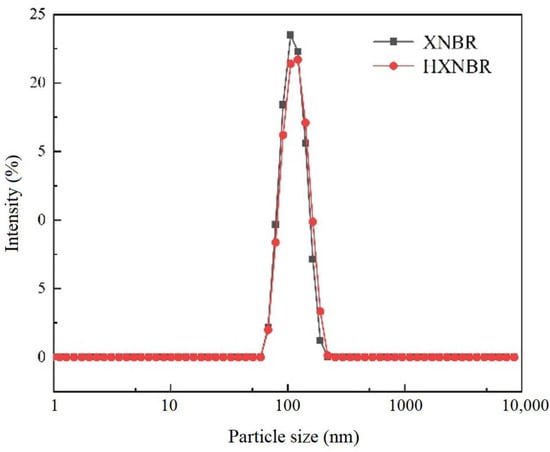

In order to explore whether the hydrogenation process affects the stability of XNBR latex, the particle size of XNBR before and after hydrogenation is compared. As shown in Figure 2, the particle size of XNBR basically remains constant before and after hydrogenation. The average size of XNBR particle before hydrogenation is about 109 nm, while HXNBR particle after hydrogenation is about 113 nm, suggesting that the particle size of polymers is not altered by hydrogenation reaction. In conclusion, the hydrogenation process does not affect the stability of XNBR latex.

Figure 2.

The size distribution of XNBR particles in latex before and after hydrogenation.

2.2. Effect of Latex Solid Content

The basic hydrogenation conditions were set as followed: 11.25 wt% of solid content, 120 °C of reaction temperature, 1200 psi of hydrogen pressure and 0.035 wt% of catalyst. Orthogonal tests were implemented to ascertain the optimum conditions.

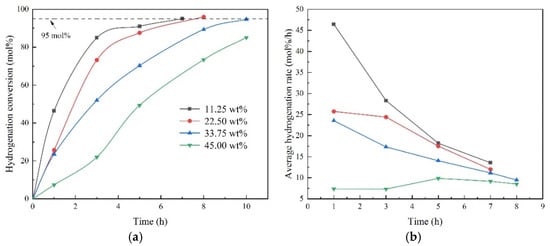

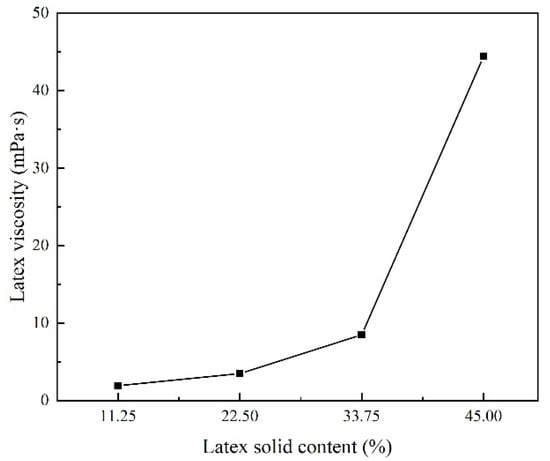

The solid content of latex plays an important role in the emulsion hydrogenation of XNBR. A series of hydrogenation experiments with different solid content levels of latex were carried out to explore the effects on the hydrogenation rate. Figure 3a shows the dependence of XNBR conversion on the latex solid content. It can be seen that after increasing the latex solid content from 11.25 to 45.00 wt%, the XNBR conversion rate drops. With 11.25 wt% latex solid content, the XNBR conversion can reach 95.01 mol% in 7 h, which represents the shortest time required for an XNBR conversion rate of 95 mol%. As the latex solid content rises to 45.00 wt%, the XNBR conversion rate can barely reach 85.10 mol% in 10 h. Figure 3b shows the average hydrogenation rate every hour with different latex solid content levels. As shown in Figure 3b, the average hydrogenation rate decreases with increased latex solid content. With low solid content levels, the instantaneous hydrogenation rate decreases with the increase in reaction time. However, the instantaneous hydrogenation rate tends to be a constant at 45.00 wt% solid content. Viscosity affects the dispersion of the catalyst, while viscosity is generally related to the solid content. As shown in Figure 4, the latex viscosity is monitored, with solid content levels ranging from 11.25 to 45.00 wt%. With the latex solid content increasing from 11.25 to 45.00 wt%, the viscosity increases from 1.93 to 44.40 mPa·s. The thickening effect arising from the high solid content deteriorates the dispersion of the catalyst in latex. As a result, the hydrogenation reaction rate is retarded.

Figure 3.

The XNBR conversion (a) and average hydrogenation (b) rates with different XNBR latex solid content levels. The same reaction conditions were applied as in Figure 1.

Figure 4.

The dependence of the XNBR latex viscosity on the solid content, with content levels ranging from 11.25 wt% to 45.00 wt%.

2.3. Effect of Reaction Temperature

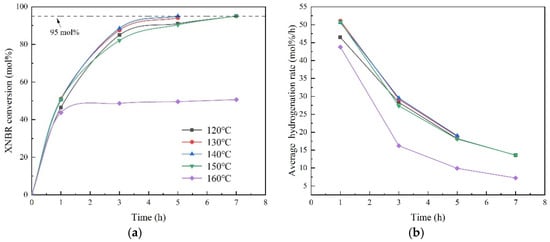

In the hydrogenation reaction of XNBR latex, the reaction temperature acts as another key factor controlling the catalytic procedure. Figure 5 shows the effects of the reaction temperature on the hydrogenation rate of XNBR. As shown in Figure 5a, as the temperature varies from 120 to 160 °C, the XNBR conversion rate first increases and then declines at a critical point. At 130 or 140 °C, the XNBR conversion reaches 95 mol% in 5 h. At 120 °C, the hydrogenation rate of 95 mol% takes 7 h, which is comparable with that observed at 150 °C. As the highest temperature of 160 °C is applied, the hydrogenation rate slows down, with an XNBR conversion rate of 50.62 mol% in 7 h. It is speculated that the temperature functions by influencing the catalyst activity. In low-temperature regions, upon increasing reaction temperature, the catalytic activity is enhanced gradually. The maximum catalytic activity is reached between 130 and 140 °C. By further increasing reaction temperature, the catalyst starts to lose its catalytic activity, so that the hydrogenation rate decreases in high-temperature zones. Figure 5b shows the average hydrogenation rate every hour under different reaction temperatures. As shown in Figure 5b, the average hydrogenation rate first increases and then declines at a critical point with an increase in reaction temperature, while the instantaneous hydrogenation rate decreases upon increasing time. Therefore, 140 °C is selected as the best reaction temperature in our reactions.

Figure 5.

The XNBR conversion (a) and average hydrogenation (b) rates under different reaction temperatures.

2.4. Effect of Catalyst Dosage

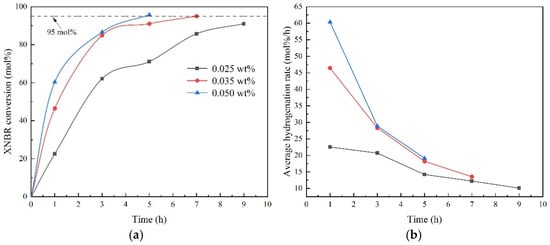

Intuitively, the catalyst dosage can accelerate the hydrogenation rate in the XNBR emulsion hydrogenation reaction. As shown in Figure 6a, the XNBR conversion rate increases significantly with the increase in catalyst dosage, as expected. While keeping other terms of the basic hydrogenation condition unchanged, the XNBR conversion can reach 91.03 mol% in 9 h with a dose of 0.025 wt%. By applying 0.035 wt% catalyst, the hydrogenation rate is dramatically accelerated, leading to 95.01 mol% XNBR conversion in 7 h. With 0.05 wt% catalyst, the XNBR conversion of 95.61 mol% is reached in 5 h. With a greater catalyst dosage in the reactor, more catalyst molecules are attached onto the colloidal particles, which boosts the efficiency of reducing C=C bonds, meaning the hydrogenation rate is improved. Finally, it can be seen that the dependence of the hydrogenation rate on dosage weakens when more catalyst added. As shown in Figure 6b, the average hydrogenation rate decreases with increased catalyst dosages. The instantaneous hydrogenation rate decreases upon increasing time, which proves that the utilization efficiency of the catalyst is reduced. Therefore, 0.05 wt% catalyst is the optimal choice.

Figure 6.

The XNBR conversion (a) and average hydrogenation (b) rates recorded with different catalyst dosages.

2.5. Effect of Hydrogen Pressure

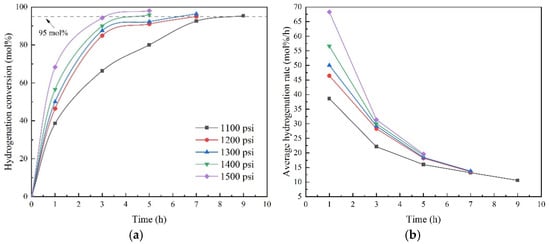

The hydrogen pressure is also an important parameter affecting the hydrogenation rate of XNBR latex. Figure 7a shows the effect of hydrogen pressure on the hydrogenation rate. As shown in Figure 7, the XNBR conversion rate gradually increases as the hydrogen pressure grows. At 1100 psi, it takes 9 h for the XNBR conversion to reach 95.38 mol%. With a hydrogen pressure of 1500 psi, the XNBR conversion can reach 94.25 mol% in only 3 h. It is posited that higher hydrogen pressure provides more possible hydrogen contacts with colloidal particles, which speeds up the hydrogenation rate. As shown in Figure 7b, the average hydrogenation rate decreases with increases in hydrogen pressure. Considering the safety and cost, 1300 psi is selected as the optimal hydrogen pressure.

Figure 7.

The XNBR conversion (a) and average hydrogenation (b) rates under a series of hydrogen pressure increases.

2.6. HXNBR Performance Test

The HXNBR compound was produced according to the formula provided in Table 1 to test its vulcanization, mechanical performance, oil resistance and heat–oxygen aging resistance.

Table 1.

Vulcanization properties of the HXNBR compound.

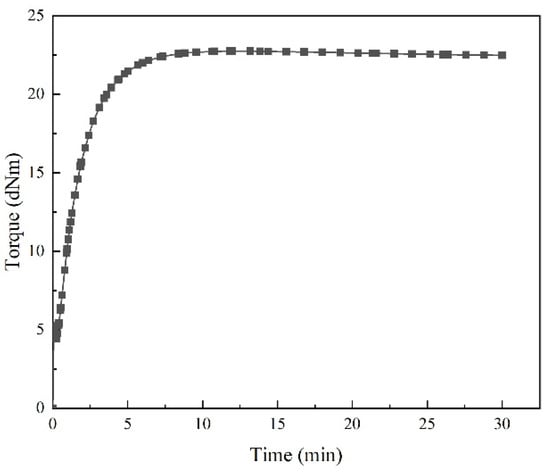

2.6.1. Vulcanization Characteristics of HXNBR Compound

The vulcanization characteristics of the produced HXNBR compound were tested using a moving die rheometer. The scorch time T10, positive vulcanization time T90, maximum torque MH and minimum torque ML were recorded, as presented in Table 1. Figure 8 shows the vulcanization curve of HXNBR at 180 °C. As shown in Table 1 and Figure 8, the HXNBR compound had a fast vulcanization speed, high crosslinking degree and good heat resistance.

Figure 8.

Vulcanization curve of HXNBR.

2.6.2. Analysis of the Heat–Oxygen Aging Performance

The mechanical performance results for the HXNBR compound before and after aging are provided in Table 2. The tensile strength of the HXNBR compound before aging was 28.6 MPa, the Shore A hardness reached 79, while the elongation at break was 193%. In comparison, after aging, both the hardness and tensile strength of HXNBR were obviously increased, yet the elongation at break was reduced. After placing the compound in a high-temperature environment for a long time, further cross-links in the rubber mixture meant the crosslinking density was too high, resulting in increased hardness and tensile strength and decreased elongation at break.

Table 2.

Mechanical properties of the HXNBR compound before and after aging.

2.6.3. Oil Resistance Analysis

For the HXNBR compound, in addition to the hot air aging performance, the oil resistance also serves as an important performance index. Table 3 and Table 4 show the mechanical performance of the HXNBR compound before and after soaking in IRM 901 and 903 standard oils at 150 °C for 72 h. After soaking in IRM 901 standard oil, both the hardness and tensile strength of the HXNBR compound were enhanced, whereas the elongation at break was reduced. It is speculated that the rubber chains with low molecular weight in the compound enter the oil phase after a long period of soaking. After soaking in IRM 903 standard oil, the hardness, tensile strength and elongation at break were all debased. Differing from the above, the oil entered the compound during prolonged immersion in IRM 903 oil.

Table 3.

Mechanical performance of the HXNBR compound before and after the oil resistance test with IRM 901 standard oil.

Table 4.

Mechanical performance of the HXNBR compound before and after the oil resistance test of IRM 903 standard oil.

3. Materials and Methods

3.1. Materials

Ultra-high purity hydrogen (99.99%) and liquid nitrogen were used as received (Qingdao Ludong Gas Co., Ltd., Qingdao, China). XNBR latex was purchased from ARLANXEO. [1,3-Bis(2,4,6-trimethylphenyl)-2-imidazolidinylidene]dichloro(2,4-diisopropoxyphenylmethylene) ruthenium was prepared according to the literature [33]. Deionized water used in the experiment was self-made in the laboratory.

Zinc oxide (ZnO) and stearic acid (SA) were purchased from Rhine Chemical Co., Ltd., Qingdao, China. Carbon black, brand N550, was purchased from Cabot Chemical Co., Ltd., Shanghai, China. Triallyl isocyanate (TAIC) was purchased from Jinchangsheng Technology Co., Ltd., Guangzhou, China. Other raw materials were commercially available industrial products.

3.2. Catalytic Hydrogenation of XNBR Latex

The catalytic hydrogenation of XNBR latex was carried out in a 300 mL Parr reactor. Firstly, XNBR latex with a specified solid content prepared by water solution was directly mixed with a certain amount of catalyst. The mixture was then rapidly vented through three nitrogen cycles and bubbled at about 30 psi for 1 h at room temperature and a fixed stirring rate of 200 rpm. Afterwards, the mixture was heated to a specified temperature and stabilized for half an hour at 450 rpm, then hydrogen gas at a certain pressure was introduced into the reactor to start the hydrogenation of XNBR latex. The reaction temperature (120–160 °C), stirring speed (450 rpm) and hydrogen pressure (1100–1500 psi) were all kept constant for 10 h. An amount of samples was extracted through the sampling tube every hour, based on which XNBR conversion was evaluated with a Fourier transform infrared spectrometer (FTIR). When the XNBR conversion reached more than 95 mol% or was unchanged, the reaction was ended manually and the final product was obtained after cooling down to room temperature and depressurization.

3.3. Basic Formula

The basic formula of HXNBR compound is shown in Table 5.

Table 5.

Formulation of the HXNBR compound.

3.4. Rubber Mixing Process

Using a HAPRO torque rheometer (filling coefficient 0.8), internal mixing was performed at 60 °C and 50 rpm. In the first stage, HXNBR was treated in the internal mixer for 2 min before SA and ZnO were added. Then, 1 min later, the first halves of N550 and TOTM were put into the mixer. After mixing for another 1.5 min, the second halves of N550 and TOTM were added. The first stage of mixing was finished in 8 min. The first section of master rubber was triangular, which was wrapped six times with an open mixer with a roll distance of 0.3 mm and passed through the roll with a mixing mill with a roll pitch of 1.0 mm, then parked at room temperature. In the second stage of mixing, the processed rubber compound was further mixed for 6 min after F-40 and TAIC were directly added. The milling run was repeated as in the first stage.

3.5. Characterization

3.5.1. Latex Structure Composition and Hydrogenation

The structure composition and XNBR conversion of latex were determined by FTIR (Bruker tensor II, Karlsruhe, Germany). In the hydrogenation reaction, the latex samples were demulsified with anhydrous ethanol and the obtained dried solid rubber was then dissolved in butanone. The butanone solution of hydrogenated HXNBR was cast on potassium bromide tablets and dried for FTIR analysis.

The degree of hydrogenation was calculated based on the corresponding absorbance (A) peaks at 2236, 970 and 723 cm−1 from the IR spectra [24,34,35]. The 2236 cm−1 peak represents the cyano group (C≡N), while the 970 cm−1 peak corresponds to the C=C (1,4-trans). The new generated peak at 723 cm−1 is assigned to (CH2)n, n > 4.

Let Ā(723) = A(723)/A(2236), Ā(970) = A(970)/A(2236), while:

where K(723) = 0.255 and K(970) = 2.3 are constants specific to the HXNBR polymer [24,34,35].

F = 1 + Ā(723)/K(723) + Ā(970)/K(970),

Then, the relative amount of C=C remaining in HXNBR is computed as:

and the relative number of methylene groups formed through hydrogenation of C=C in XNBR is evaluated as:

C(BR) = Ā(970)/[K (970) F]

C(HBR) = Ā(723)/[K(723)F]

Finally, the degree of hydrogenation can be calculated as:

Degree of hydrogenation (mol)% = 100 − C(BR)/[C(BR) + C(HBR)] × 100

The hydrogenation conversion and structural composition were confirmed by 1H NMR recorded on Bruker 300 MHz spectrometers from Bruker Biospin GmbH (Karlsruhe, Germany). Here, 5 mg dry solid XNBR or HXNBR was dissolved in 0.5 mL deuterated chloroform solution for 1H NMR characterization.

3.5.2. Particle Size

The intensity distribution and Z-average particle size distribution of XNBR nanoparticles were determined using the DLS (Zetasizer Nano ZS, Malvern Instruments, Worcestershire, UK) at room temperature.

3.5.3. Rotation Viscosity

The viscosity of the XNBR latex with different solid content levels was measured using an NBJ-1B rotary viscometer from Changji Geological Instrument Co., Ltd., Shanghai, China.

3.5.4. Rubber Compound Analysis and Test

HXNBR was mixed using an RM-200C HAPRO torque rheometer (HAPRO Electric Technology Co., Ltd., Harbin, China).

According to GB/T 16584-1996, the rubber compound was tested using an MDR Premier Moving Die Rheometer (American Alpha Technology Company, New York, NY, USA) at 180 °C for 30 min.

According to GB/T 528-2009 and GB/T 529-2008, the tensile properties of vulcanizates were tested using a universal tensile testing machine (Zwick Roell group, Ulm, Germany). The tensile temperature was set to 25 °C and the tensile rate was fixed at 500 mm/min. According to GB 531-1983, the hardness of the vulcanized rubber was tested using a Digi Test II full-function rubber hardness tester (Bareiss Instrument Co., Ltd., Oberdischingen, Germany).

According to GB/T 3512-2014, an FD115 hot air circulation oven (BINDER) was used for aging test at 150 °C for 72 h. According to GB/T 1690-2010, a GT-7040-L thermostatic oil bath (Taiwan GOTECH Testing Machines Inc., Taichung, Taiwan) was used for oil resistance testing. The oil resistance was tested at 150 °C for 72 h.

4. Conclusions

In summary, a ruthenium-based catalyst (C34H44Cl2N2O2Ru) was prepared to obtain HXNBR through direct hydrogenation of the XNBR latex. The factors affecting XNBR hydrogenation in the latex, such as the catalyst dosage, solid content, reaction temperature and hydrogen pressure, were systematically studied. We found that the variations in hydrogenation conditions had little impact on the particle size in the emulsion. Increasing the solid content reduced the hydrogenation rate, while the XNBR conversion reached 95.01 mol% in 7 h with 11.25 wt% solid content. On the contrary, higher hydrogen pressure effectively improved the hydrogenation rate, while the XNBR conversion reached 94.25 mol% in nearly 3 h at 1500 psi. Within the temperature range explored here, the fastest hydrogenation rate was obtained at 140 °C, with 95.10 mol% XNBR conversion in 5 h. As the catalyst amount can significantly increase the hydrogenation rate, 0.05 wt% catalyst ensured 95.61 mol% XNBR conversion in 5 h. Taking account of the hydrogenation rate and experimental safety, the optimum hydrogenation conditions are listed as follows: 11.25 wt% solid content, 140 °C reaction temperature, 1300 psi hydrogen pressure and 0.05 wt% catalyst dosage. The vulcanization, mechanical properties, aging and oil resistance of the self-made HXNBR were tested after mixing. By choosing suitable hydrogenation conditions, a minimal dose of catalyst required in hydrogenation, while the hydrogenation rate is unaffected. This may have important implications in the hydrogenation of XNBR latex in the rubber industry.

Author Contributions

Conceptualization, Y.L., J.S. and H.W.; methodology, Y.L. and H.W.; validation, X.L., Y.F., S.Z. and D.Z.; formal analysis, X.L. and H.C.; investigation, X.L. and Y.F.; resources, Y.L., J.S., S.Z. and H.W.; data curation, X.L., Y.F. and D.Z.; writing—original draft preparation, X.L.; writing—review and editing, Y.L., J.S. and H.W.; visualization, Y.L., J.S. and H.W.; supervision, H.W.; funding acquisition, Y.L., J.S., S.Z. and H.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Shandong Province, grant numbers ZR2019MB001 and ZR2018BEM014; the Taishin Scholar Project of Shandong Province, grant number ts201712047; the National Natural Science Foundation of China, grant numbers 51802170, 21801150 and 21674055; and the Introduction of Urgently Needed Talents In Key Supporting Regions of Shandong Province project (Shangdong Dongdu Auto Parts Co., Ltd., Rizhao, China).

Conflicts of Interest

The authors hereby declare no conflict of interest.

References

- Wang, H.; Yang, L.; Rempel, G.L. Homogeneous Hydrogenation Art of Nitrile Butadiene Rubber: A Review. Polym. Rev. 2013, 53, 192–239. [Google Scholar] [CrossRef]

- Piya-areetham, P.; Prasassarakich, P.; Rempel, G.L. Organic solvent-free hydrogenation of natural rubber latex and synthetic polyisoprene emulsion catalyzed by water-soluble rhodium complexes. J. Mol. Catal. A Chem. 2013, 372, 151–159. [Google Scholar] [CrossRef]

- Ji, M.; Yue, D.; Wu, X.; Zhao, S.; Sun, S.; Zhang, L. Structure and performance of hydrogenated natural rubber prepared by the latex method. Plast. Rubber Compos. 2017, 46, 245–250. [Google Scholar] [CrossRef]

- Schulz, G.A.S.; Comin, E.; de Souza, R.F. Catalytic hydrogenation of nitrile rubber using palladium and ruthenium complexes. J. Appl. Polym. Sci. 2007, 106, 659–663. [Google Scholar] [CrossRef]

- Kotzabasakis, V.; Georgopoulou, E.; Pitsikalis, M.; Hadjichristidis, N.; Papadogianakis, G. Catalytic conversions in aqueous media: A novel and efficient hydrogenation of polybutadiene-1,4-block-poly(ethylene oxide) catalyzed by Rh/TPPTS complexes in mixed micellar nanoreactors. J. Mol. Catal. A Chem. 2005, 231, 93–101. [Google Scholar] [CrossRef]

- Parent, J.S.; Mcmanus, N.T.; Rempel, G.L. Selectivity of the OsHCl(CO)(O2)(PCy3)2 catalyzed hydrogenation of nitrile butadiene rubber. J. Appl. Polym. Sci. 2001, 79, 1618–1626. [Google Scholar] [CrossRef]

- Yue, D.M.; Shen, Z.M.; Xu, R.Q.; Wei, Y.K. A New Bimetallic Complex Catalyst for NBR Hydrogenation and Properties of Hydrogenated NBR. J. Elastomers Plast. 2016, 34, 225–237. [Google Scholar] [CrossRef]

- Ai, C.; Gong, G.; Zhao, X.; Liu, P. Selectively catalytic hydrogenation of nitrile-butadiene rubber using Grubbs II catalyst. Macromol. Res. 2017, 25, 461–465. [Google Scholar] [CrossRef]

- Zou, R.; Li, C.; Zhang, L.; Yue, D. Selective hydrogenation of nitrile butadiene rubber (NBR) with rhodium nanoparticles supported on carbon nanotubes at room temperature. Catal. Commun. 2016, 81, 4–9. [Google Scholar] [CrossRef]

- Cao, P.; Huang, C.; Zhang, L.; Yue, D. One-step fabrication of RGO/HNBR composites via selective hydrogenation of NBR with graphene-based catalyst. RSC Adv. 2015, 5, 41098–41102. [Google Scholar] [CrossRef]

- Ge, B.; Hu, Y.; Zhang, H.; Xu, J.; Zhang, P.; Yue, Y.; Zhu, H.; Lin, S.; Yuan, P. Zirconium promoter effect on catalytic activity of Pd based catalysts for heterogeneous hydrogenation of nitrile butadiene rubber. Appl. Surf. Sci. 2021, 539, 148212. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, H.; Wang, S.; Lei, X.; Yang, J.; Li, Z.; Zhu, H.; Bao, X.; Yuan, P. Effect of support morphology on the activity and reusability of Pd/SiO2 for NBR hydrogenation. J. Mater. Sci. 2020, 55, 12876–12883. [Google Scholar] [CrossRef]

- Ai, C.; Li, J.; Gong, G.; Zhao, X.; Liu, P. Preparation of hydrogenated nitrile-butadiene rubber (H-NBR) with controllable molecular weight with heterogeneous catalytic hydrogenation after degradation via olefin cross metathesis. React. Funct. Polym. 2018, 129, 53–57. [Google Scholar] [CrossRef]

- Lin, X.; Pan, Q.; Rempel, G.L. Hydrogenation of nitrile-butadiene rubber latex with diimide. Appl. Catal. A Gen. 2004, 276, 123–128. [Google Scholar] [CrossRef]

- Schulz, G.A.S.; Comin, E.; de Souza, R.F. Hydrogenation of NBR latex by diimide reduction using selenium catalysts. J. Appl. Polym. Sci. 2010, 115, 1390–1394. [Google Scholar] [CrossRef]

- Ou, H.; Wang, Y.; Zhou, W.; Peng, X. Kinetics investigation on the hydrogenation of acrylonitrile-butadiene rubber latex by using new catalytic reaction system. Catal. Commun. 2016, 84, 183–187. [Google Scholar] [CrossRef]

- Zhou, S.; Bai, H.; Wang, J. Hydrogenation of acrylonitrile butadiene rubber latexes. J. Appl. Polym. Sci. 2010, 91, 2072–2078. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Han, Y.; Shi, X.; Wang, W.; Yue, D. New method for hydrogenating NBR latex. J. Appl. Polym. Sci. 2013, 127, 4764–4768. [Google Scholar] [CrossRef]

- Wang, H.; Yang, L.; Scott, S.; Pan, Q.; Rempel, G.L. Organic solvent-free catalytic hydrogenation of diene-based polymer nanoparticles in latex form. Part II. Kinetic analysis and mechanistic study. J. Polym. Sci. Part A Polym. Chem. 2012, 50, 4612–4627. [Google Scholar] [CrossRef]

- Wang, H.; Rempel, G.L. Organic solvent-free catalytic hydrogenation of diene-based polymer nanoparticles in latex form: Mass transfer of hydrogen in a semibatch process. J. Ind. Eng. Chem. 2015, 25, 29–34. [Google Scholar] [CrossRef]

- Wang, H.; Yang, L.; Rempel, G.L.; Pan, Q. Hydrogenation of a Tri-layer High Performance Elastomer: Substrate Synthesis, Catalytic Latex Hydrogenation, and Catalyst Recovery. Top. Catal. 2014, 57, 1512–1518. [Google Scholar] [CrossRef]

- Liu, Y.; Kim, H.; Pan, Q.; Rempel, G.L. Hydrogenation of acrylonitrile–butadiene copolymer latex using water-soluble rhodium catalysts. Catal. Sci. Technol. 2013, 3, 2689–2698. [Google Scholar] [CrossRef]

- Wei, Z.; Wu, J.; Pan, Q.; Rempel, G.L. Direct Catalytic Hydrogenation of an Acrylonitrile-Butadiene Rubber Latex Using Wilkinson’s Catalyst. Macromol. Rapid Commun. 2005, 26, 1768–1772. [Google Scholar] [CrossRef]

- Wang, H.; Pan, Q.; Rempel, G.L. Diene-based polymer nanoparticles: Preparation and direct catalytic latex hydrogenation. J. Polym. Sci. Part A Polym. Chem. 2012, 50, 2098–2110. [Google Scholar] [CrossRef]

- Jie, H.; Sheng, J.; Xiong, Y. Sound Absorption Properties of Single-Hole Hollow Polyester Fiber Reinforced Hydrogenated Carboxyl Nitrile Rubber Composites. Autex Res. J. 2017, 17, 263–267. [Google Scholar] [CrossRef]

- Ibarra, L.; Rodríguez, A.; Mora-Barrantes, I. Crosslinking of unfilled carboxylated nitrile rubber with different systems: Influence on properties. J. Appl. Polym. Sci. 2008, 108, 2197–2205. [Google Scholar] [CrossRef]

- Laskowska, A.; Zaborski, M.; Boiteux, G.; Gain, O.; Marzec, A.; Maniukiewicz, W. Ionic elastomers based on carboxylated nitrile rubber (XNBR) and magnesium aluminum layered double hydroxide. Express Polym. Lett. 2014, 8, 374–386. [Google Scholar] [CrossRef]

- Liu, Q.-X.; Ding, X.-B.; Zhang, H.-P.; Yan, X. Preparation of high-performance damping materials based on carboxylated nitrile rubber: Combination of organic hybridization and fiber reinforcement. J. Appl. Polym. Sci. 2009, 114, 2655–2661. [Google Scholar] [CrossRef]

- Han, Y.; Mao, L.; Meng, H.; Zhang, L.; Yue, D. Novel self-crosslinking film from hydrogenated carboxylated nitrile rubber latex. J. Appl. Polym. Sci. 2014, 131, 1082–1090. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Bhowmick, A.K.; Avasthi, B.N. Homogeneous catalytic hydrogenation of liquid carboxylated nitrile rubber. J. Polym. Sci. Part A Polym. Chem. 1992, 30, 1961–1968. [Google Scholar] [CrossRef]

- Liu, Q.; Ren, W.; Yong, Z.; Zhang, Y.X. Hydrogenated carboxylated nitrile rubber/modified zinc carbonate basic composites with photoluminescence properties. Eur. Polym. J. 2011, 47, 1135–1141. [Google Scholar] [CrossRef]

- Liu, Q.; Ren, W.; Zhang, Y.; Zhang, Y. Curing reactions and properties of organic-inorganic composites from hydrogenated carboxylated nitrile rubber and epoxycyclohexyl polyhedral oligomeric silsesquioxanes. Polym. Int. 2011, 60, 422–429. [Google Scholar] [CrossRef]

- Zaja, M.; Connon, S.J.; Dunne, A.M.; Rivard, M.; Buschmann, N.; Jiricek, J.; Blechert, S. Ruthenium olefin metathesis catalysts with modified styrene ethers: Influence of steric and electronic effects. Tetrahedron 2003, 59, 6545–6558. [Google Scholar] [CrossRef]

- Brück, D. IR spectrometric determination of the proportions of acrylonitrile, butadiene and hydrogenated butadiene in hydrogenated acrylonitrile-butadiene rubbers. Part 1. Principles. Kautsch. Gummi Kunstst. 1989, 42, 107–110. [Google Scholar]

- Brück, D. IR spectrometric determination of the proportions of acrylonitrile, butadiene and hydrogenated butadiene in hydrogenated acrylonitrile-butadiene rubbers. Part 2. Residual double bonds in commercial HNBR products. Kautsch. Gummi Kunstst. 1989, 42, 194–197. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).