Fabrication and Characterization of a Flexible Polyurethane-Based Triboelectric Nanogenerator for a Harvesting Energy System

Abstract

1. Introduction

2. Methodology and Experimentation

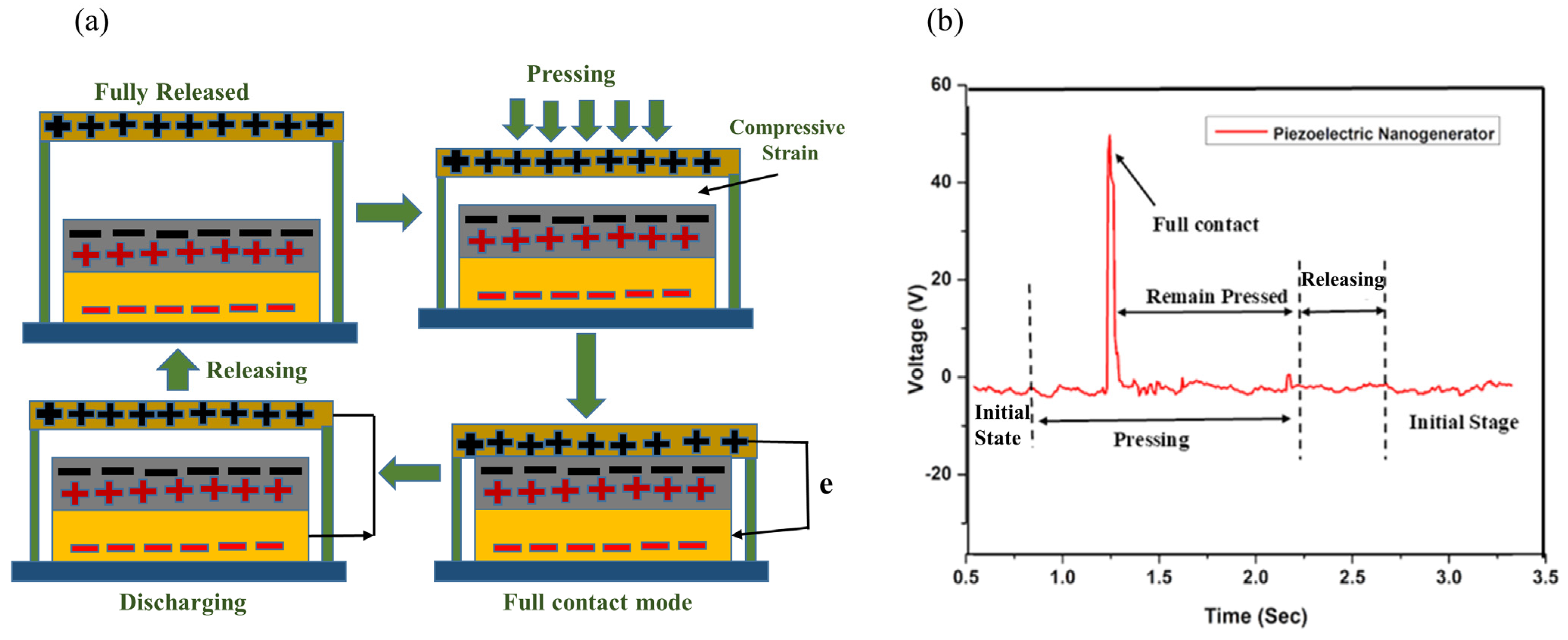

2.1. Vertical Contact Separation Mode

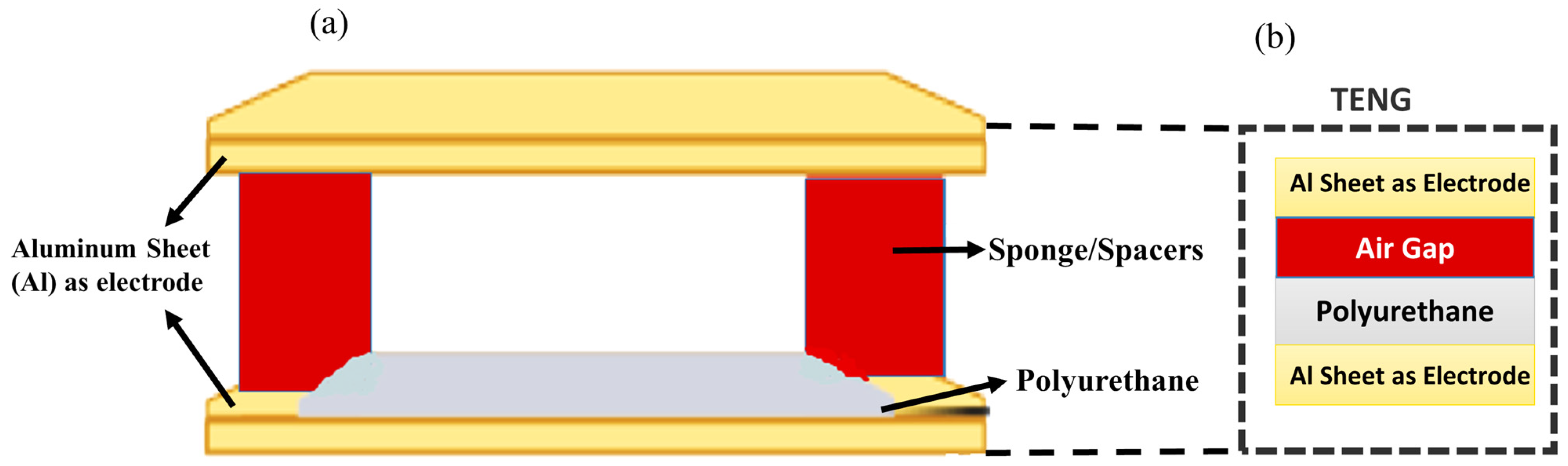

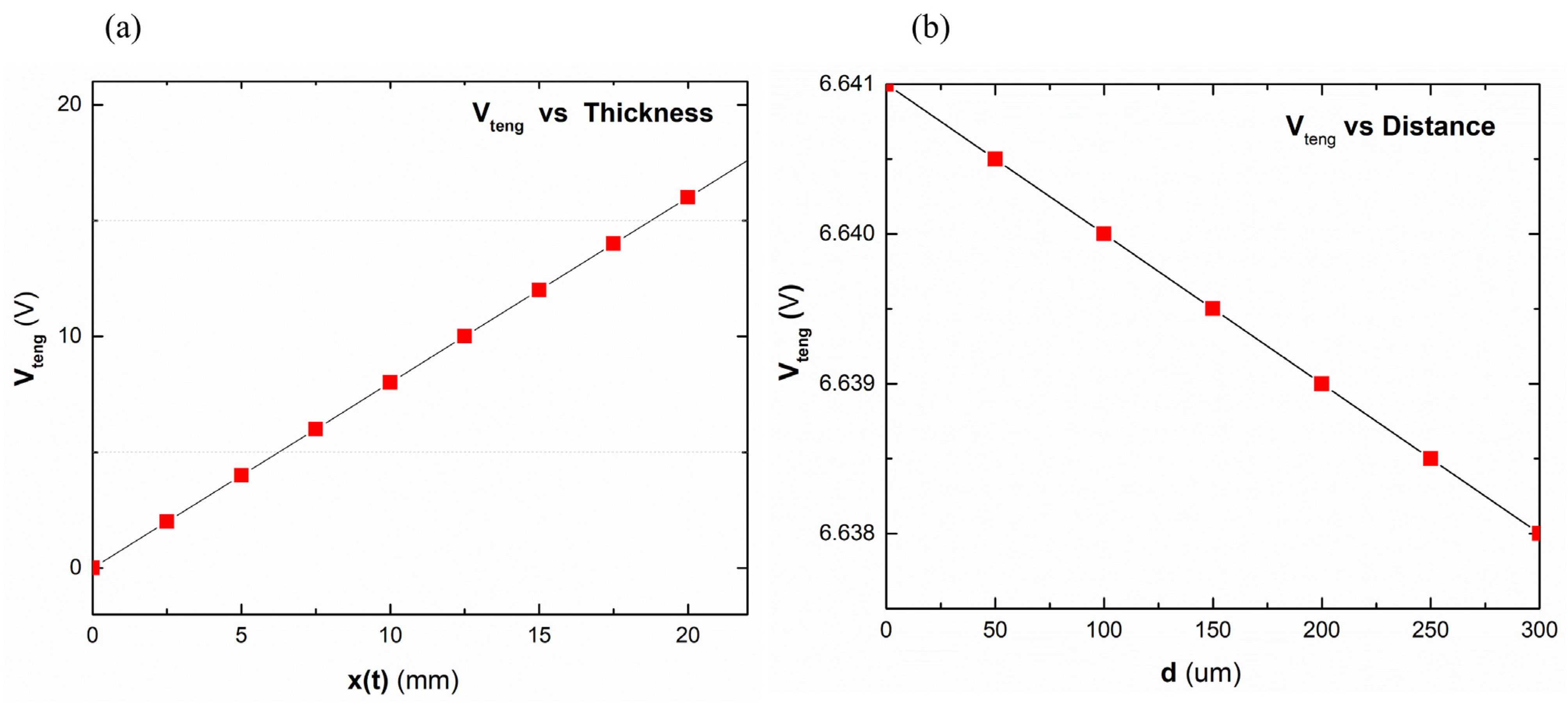

2.2. Design Principle

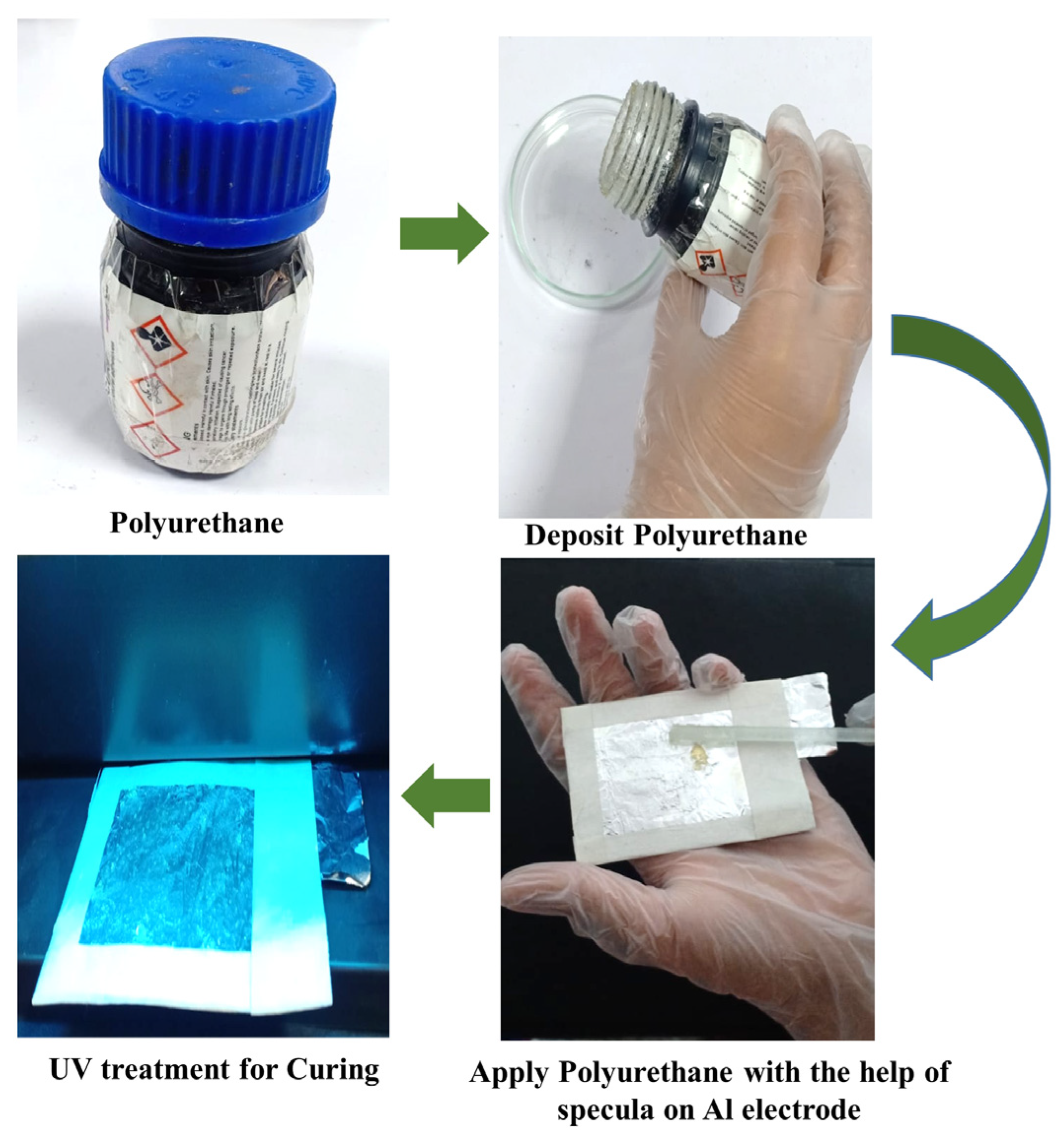

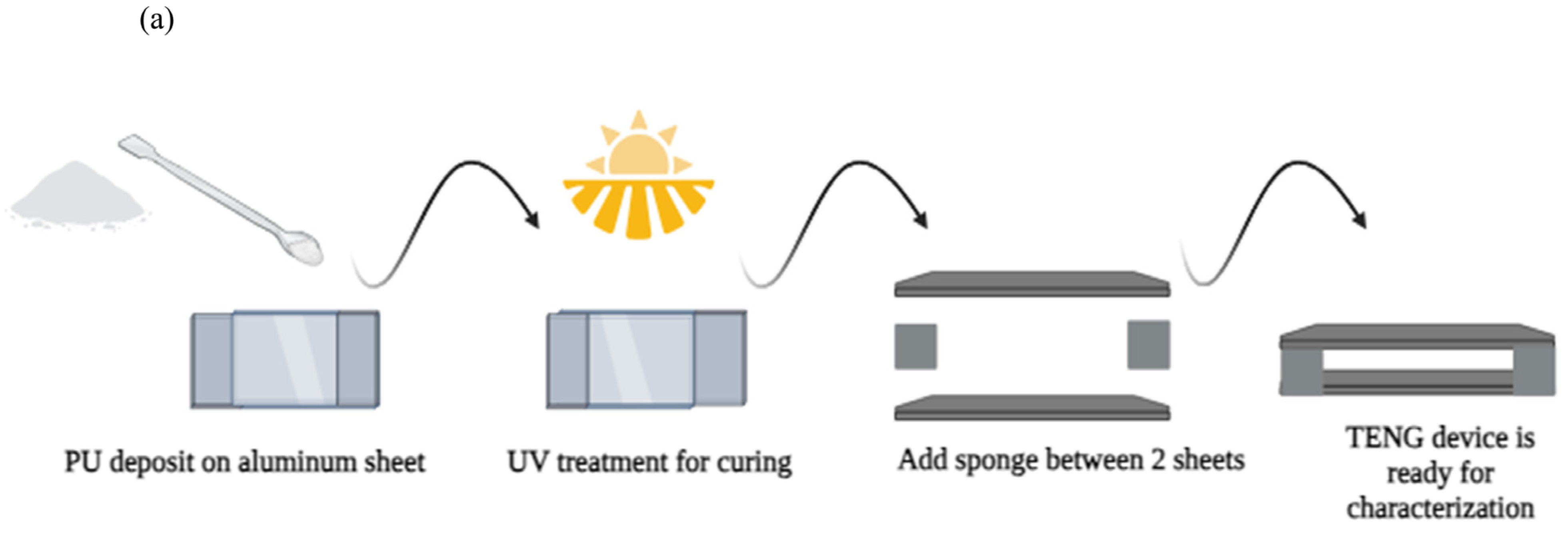

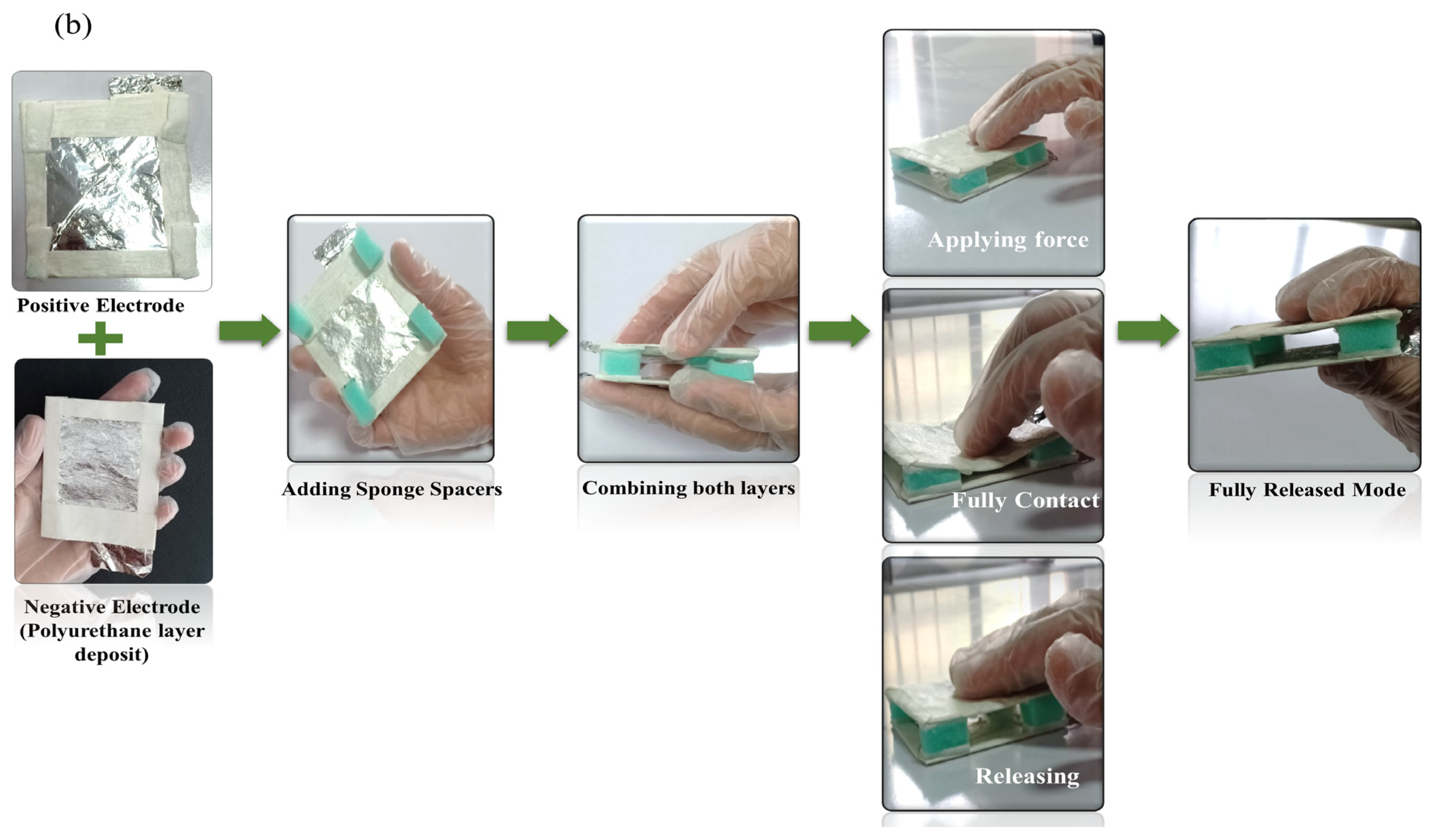

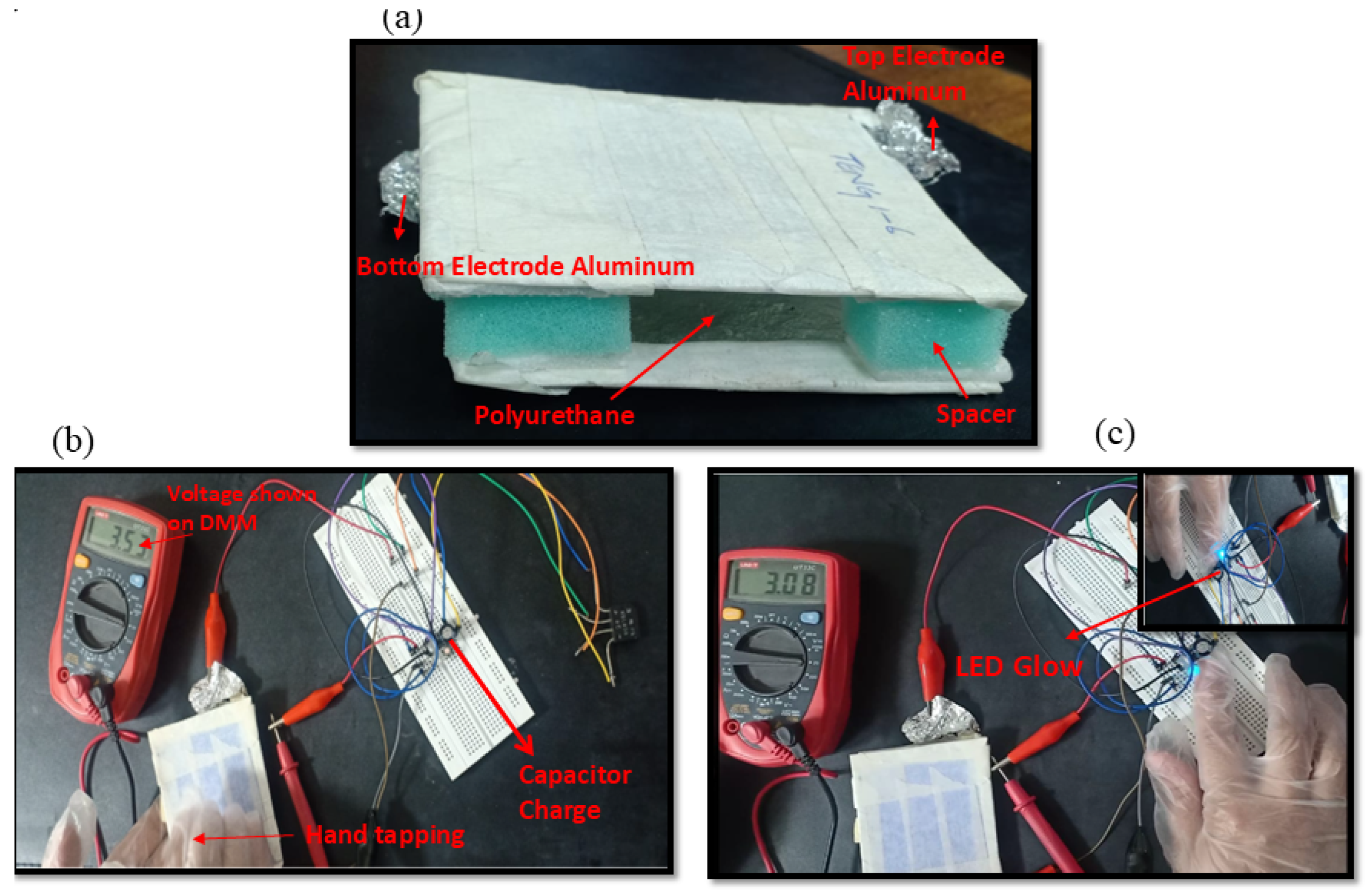

2.3. Fabrication Processes

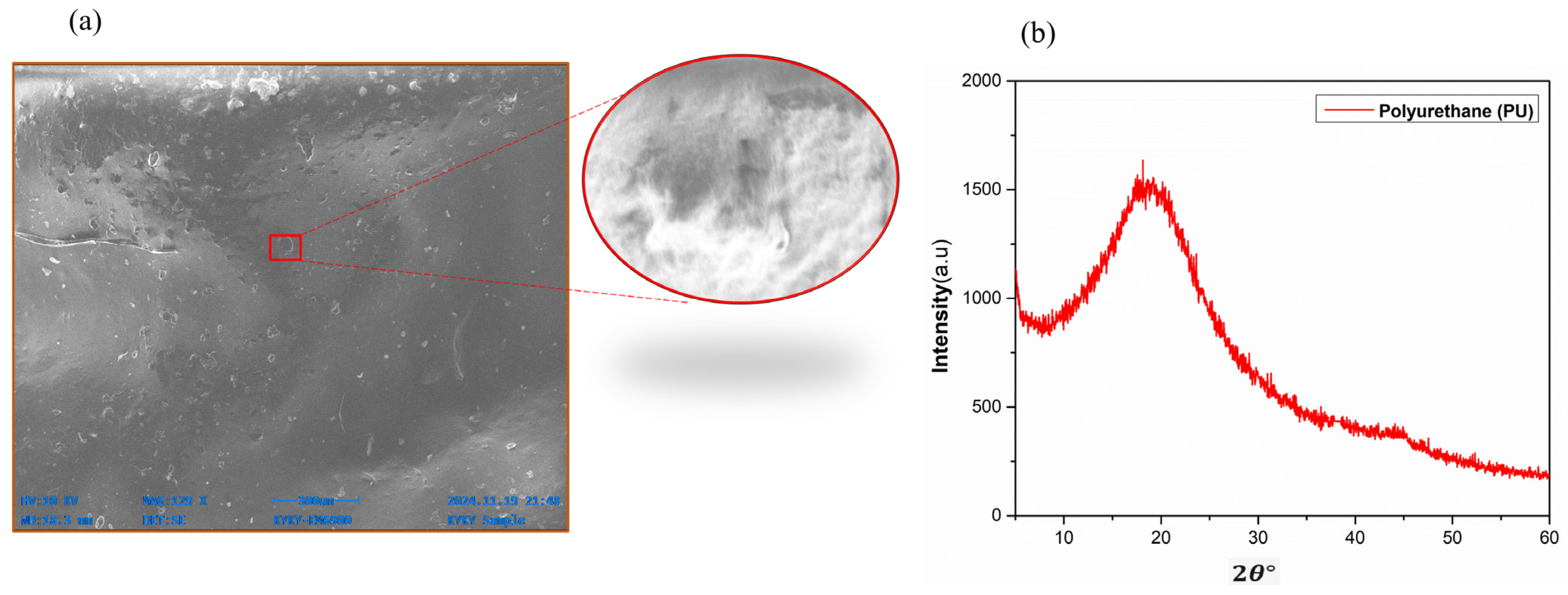

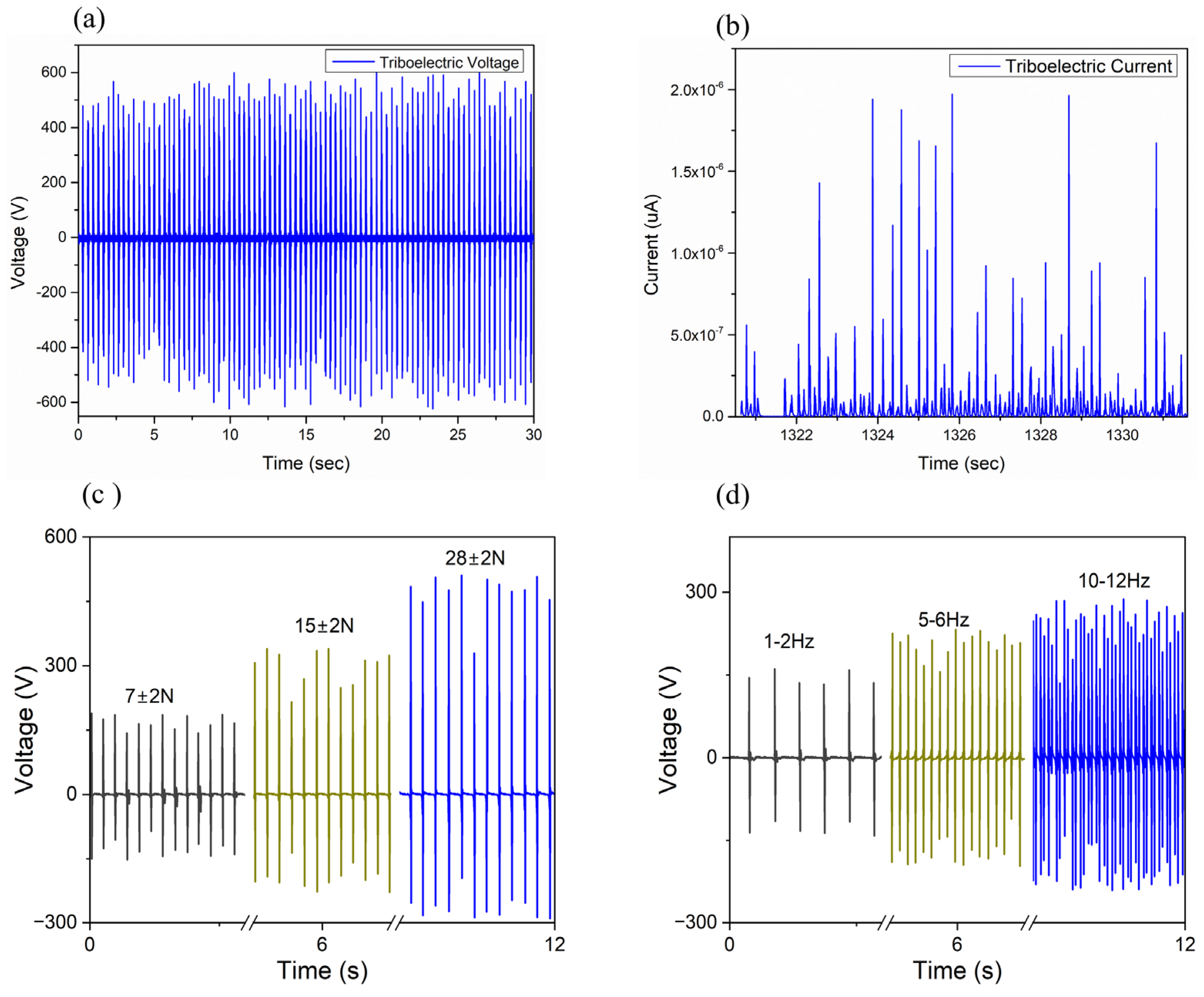

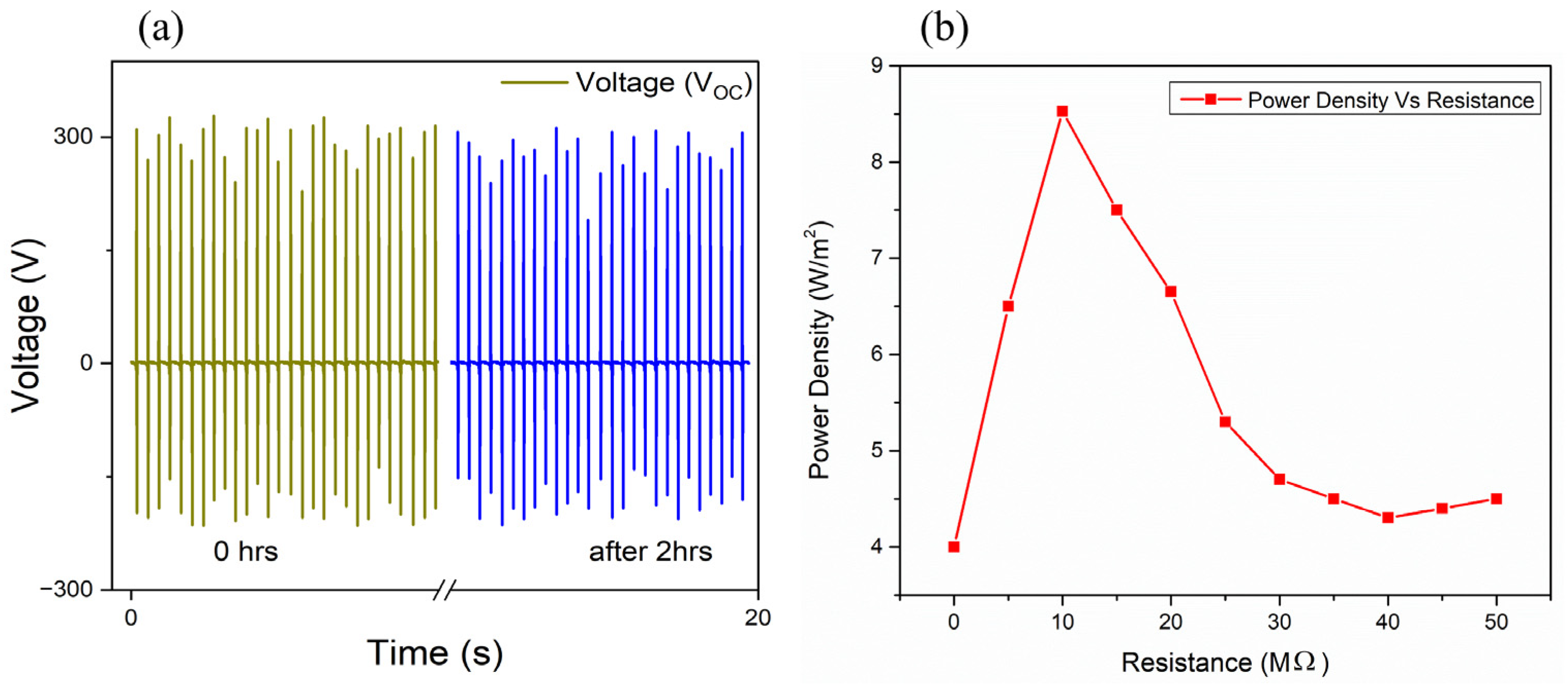

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, Y.; Zhang, Q.; Wu, L. Influence on the adsorption of phenol on single-walled carbon nanotubes caused by NaCl and an electrostatic field in saline. Desalination 2020, 477, 114270. [Google Scholar] [CrossRef]

- Bu, C.; Li, F.; Yin, K.; Pang, J.; Wang, L.; Wang, K. Research Progress and Prospect of Triboelectric Nanogenerators as Self-Powered Human Body Sensors. ACS Appl. Electron. Mater. 2020, 2, 863–878. [Google Scholar] [CrossRef]

- Shi, Q.; He, T.; Lee, C. More than energy harvesting—Combining triboelectric nanogenerator and flexible electronics technology for enabling novel micro-/nano-systems. Nano Energy 2019, 57, 851–871. [Google Scholar] [CrossRef]

- Wang, M.; Shi, X.; Liu, W.; Zou, F.; Hua, P.; Zhang, M. A zwitterionic polyurethane-based self-healing triboelectric nanogenerator for efficient self-powered sensing. Mater. Lett. 2022, 333, 133629. [Google Scholar] [CrossRef]

- Jiang, Y.; Dong, K.; Li, X.; An, J.; Wu, D.; Peng, X.; Yi, J.; Ning, C.; Cheng, R.; Yu, P.; et al. Stretchable, Washable, and Ultrathin Triboelectric Nanogenerators as Skin-Like Highly Sensitive Self-Powered Haptic Sensors. Adv. Funct. Mater. 2020, 31, 2005584. [Google Scholar] [CrossRef]

- Palaniappan, V.; Bazuin, B.J.; Atashbar, M.Z.; Masihi, S.; Zhang, X.; Emamian, S.; Bose, A.K.; Maddipatla, D.; Hajian, S.; Panahi, M.; et al. A Flexible Triboelectric Nanogenerator Fabricated Using Laser-Assisted Patterning Process. In Proceedings of the 2019 IEEE SENSORS Conference, Montreal, QC, Canada, 27–30 October 2019; pp. 1–4. [Google Scholar]

- Gao, W.C.; Wu, W.; Chen, C.Z.; Zhao, H.; Liu, Y.; Li, Q.; Huang, C.-X.; Hu, G.-H.; Wang, S.-F.; Shi, D.; et al. Design of a Superhy-drophobic Strain Sensor with a Multilayer Structure for Human Motion Monitoring. Appl. Mater. Interfaces 2022, 14, 1874–1884. [Google Scholar] [CrossRef]

- De Sousa, F.D.B.; Scuracchio, C.H.; Hu, G.H.; Hoppe, S. Effects of processing parameters on the properties of microwave-devulcanized ground tire rubber/polyethylene dynamically revulcanized blends. Appl. Polym. Sci. 2016, 133, 43503. [Google Scholar] [CrossRef]

- Noon, M.A.A.; Shah, I.; Tipu, J.A.K.; Arif, M.; Saeed, M.U.B.; Qzai, S.I.; Sharif, M.; Sharif, A. Process and production enhancement through codigestion in biogas generation. Environ. Prog. Sustain. Energy 2024, 43, 10. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors—Principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458. [Google Scholar] [CrossRef] [PubMed]

- Anwar, B.; Ali, S.; Shah, I.; Aslam Noon, M.A.; Tipu, J.A.K.; Arif, M. Proposed optimized energy plan for the largest island of South Korea based on full renewable energy resources. J. Process Mech. Eng. 2023. [Google Scholar] [CrossRef]

- Zhang, X.; He, D.; Palaniappan, V.; Maddipatla, D.; Yang, Q.; Atashbar, M.Z. A Novel Graphite/PDMS based Flexible Triboelectric Nanogenerator. In Proceedings of the 2021 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Manchester, UK, 20–23 June 2021; pp. 1–4. [Google Scholar]

- Huang, T.; Lu, M.; Yu, H.; Zhang, Q.; Wang, H.; Zhu, M. Enhanced Power Output of a Triboelectric Nanogenerator Composed of Electrospun Nanofiber Mats Doped with Graphene Oxide. Sci. Rep. 2015, 5, 13942. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.; Luo, C.; Deng, B.W.; Yin, B.; Yang, M.B. Flexible porous silicone rubber-nanofiber nanocomposites generated by supercritical carbon dioxide foaming for harvesting mechanical energy. Nano Energy 2020, 67, 104–290. [Google Scholar] [CrossRef]

- Shaukat, R.A.; Choi, J.; Jeong, C.K. Eco-Friendly Powder and Particles-Based Triboelectric Energy Harvesters. J. Korean Powder Metall. Inst. 2023, 30, 528–535. [Google Scholar] [CrossRef]

- Hassan, G.; Khan, F.; Hassan, A.; Ali, S.; Bae, J.; Lee, C.H. A flat-panel-shaped hybrid piezo/triboelectric nanogenerator for ambient energy harvesting. Nanotechnology 2017, 28, 175–402. [Google Scholar] [CrossRef] [PubMed]

- Ali, I.; Hassan, G.; Shuja, A. Fabrication of self-healing hybrid nanogenerators based on polyurethane and ZnO for harvesting wind energy. J. Mater. Sci. Mater. Electron. 2022, 33, 3982–3993. [Google Scholar] [CrossRef]

- Sun, W.; Luo, N.; Liu, Y.; Li, H.; Wang, D. A New Self-Healing Triboelectric Nanogenerator Based on Polyurethane Coating and Its Application for Self-Powered Cathodic Protection. ACS Appl. Mater. Interfaces 2022, 14, 10498–10507. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, C. Triboelectric nanogenerators based on elastic electrodes. Nanoscale 2020, 12, 20118–20130. [Google Scholar] [CrossRef]

- Matsunaga, M.; Hirotani, J.; Kishimoto, S.; Ohno, Y. High-output, transparent, stretchable triboelectric nanogen-erator based on carbon nanotube thin film toward wearable energy harvesters. Nano Energy 2020, 67, 104297. [Google Scholar] [CrossRef]

- Qin, H.; Cheng, G.; Zi, Y.; Gu, G.; Zhang, B.; Shang, W.; Yang, F.; Yang, J.; Du, Z.; Wang, Z.L. High Energy Storage Efficiency Triboelectric Nanogenerators with Unidirectional Switches and Passive Power Management Circuits. Adv. Funct. Mater. 2018, 28, 1805216. [Google Scholar] [CrossRef]

- Yi, F.; Lin, L.; Niu, S.; Yang, P.K.; Wang, Z.; Chen, J.; Zhou, Y.; Zi, Y.; Wang, J.; Liao, Q.; et al. Stretchable-Rubber-Based Triboelectric Nano-generator and Its Application as Self-Powered Body Motion Sensors. Adv. Funct. Mater. 2015, 25, 3688–3696. [Google Scholar] [CrossRef]

- Wang, W.; Yan, J.; Wang, X.; Pang, H.; Sun, C.; Sun, Y.; Wang, L.; Zhang, D. Research on the Performance of a Liquid–Solid Triboelectric Nanogenerator Prototype Based on Multiphase Liquid. Micromachines 2025, 16, 78. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Huang, X.; Liu, S.; Guo, W.; Li, Y.; Wu, H. A self-powered smart safety belt enabled by triboelectric nan-ogenerators for driving status monitoring. Nano Energy 2019, 62, 197–204. [Google Scholar] [CrossRef]

- Patel, T.; Kim, M.P.; Park, J.; Lee, T.H.; Nellepalli, P.; Noh, S.M.; Jung, H.W.; Ko, H.; Oh, J.K. Self-Healable Reprocessable Triboelectric Nanogenerators Fabricated with Vitrimeric Poly(hindered Urea) Networks. ACS Nano 2020, 14, 11442–11451. [Google Scholar] [CrossRef]

- Ma, H.Z.; Zhao, J.N.; Tang, R.; Shao, Y.; Ke, K.; Zhang, K.; Yin, B.; Yang, M.-B. Polypyrrole@CNT@PU Conductive Sponge-Based Triboelectric Nanogener-ators for Human Motion Monitoring and Self-Powered Ammonia Sensing. ACS Appl. Mater. Ad. Interfaces 2023, 15, 54986–54995. [Google Scholar] [CrossRef]

- Shateri, A.A.A.; Zhuo, F.; Shuaibu, N.S.; Wan, R.; Xu, L.; Hazarika, D.; Gyawawli, B.; Wang, X. Generating a Full Cycle of Alternative Current Using a Triboelectric Nanogenerator for Energy Harvesting. Micromachines 2025, 16, 11. [Google Scholar] [CrossRef]

- Sun, J.; Pu, X.; Liu, M.; Yu, A.; Du, C.; Zhai, J.; Zhai, J.; Hu, W.; Wang, Z.L. Self-Healable, Stretchable, Transparent Triboelectric Nanogenerators as Soft Power Sources. ACS Nano 2018, 12, 6147–6155. [Google Scholar] [CrossRef]

- Lee, J.H.; Hinchet, R.; Kim, S.K.; Kim, S.; Kim, S.W. Shape memory polymer-based self-healing triboe-lectric nanogenerator. Energy Environ. Sci. 2015, 8, 3605–3613. [Google Scholar] [CrossRef]

- Parida, K.; Thangavel, G.; Cai, G.; Zhou, X.; Park, S.; Xiong, J.; Lee, P.S. Extremely stretchable and self-healing conductor based on thermoplastic elastomer for all-three-dimensional printed triboelectric nanogenerator. Nat. Commun. 2019, 10, 2158. [Google Scholar] [CrossRef] [PubMed]

- Doganay, D.; Cicek, M.O.; Durukan, M.B.; Altuntas, B.; Agbahca, E.; Coskun, S.; Unalan, H.E. Fabric based wearable triboelectric nanogenerators for human machine interface. Nano Energy 2021, 89, 106412. [Google Scholar] [CrossRef]

- Zhu, P.; Mu, S.; Huang, W.; Sun, Z.; Lin, Y.; Chen, K.; Pan, Z.; Haghighi, M.G.; Sedghi, R.; Wang, J.; et al. Soft mul-tifunctional neurological electronic skin through intrinsically stretchable synaptic transistor. Nano Res. 2024, 17, 6550–6559. [Google Scholar] [CrossRef]

- Srither, S.R.; Shankar Rao, D.S.; Krishna Prasad, S. Triboelectric Nanogenerator Based on Biocompatible and Easily Available Polymer Films. Chem. Sel. 2018, 3, 5055–5061. [Google Scholar] [CrossRef]

- Jiang, J.; Guan, Q.; Liu, Y.; Sun, X.; Wen, Z. Abrasion and Fracture Self-Healable Triboelectric Nanogenerator with Ultrahigh Stretchability and Long-Term Durability. Adv. Funct. Mater. 2021, 31, 2105380. [Google Scholar] [CrossRef]

- Park, S.I.; Lee, D.M.; Kang, C.W.; Lee, S.M.; Kim, H.J.; Ko, Y.-J.; Kim, S.-W.; Son, S.U. Triboelectric energy harvesting using conjugated microporous polymer nanoparticles in polyurethane films. Mater. Chem. A 2021, 9, 12560–12565. [Google Scholar] [CrossRef]

- Li, C.; Yin, Y.; Wang, B.; Zhou, T.; Wang, J.; Luo, J.; Tang, W.; Cao, R.; Yuan, Z.; Li, N.; et al. Self-Powered Electrospinning System Driven by a Triboelectric Nanogenerator. ACS Nano 2017, 11, 10439–10445. [Google Scholar] [CrossRef] [PubMed]

- Dharmasena, R.D.I.G.; Wijayantha, K.G.U. Theoretical and experimental investigation into the asymmetric external charging of Triboelectric Nanogenerators. Nano Energy 2021, 90, 106511. [Google Scholar] [CrossRef]

- Yang, S.; Larionova, T.; Kobykhno, I.; Klinkov, V.; Shalnova, S.; Tolochko, O. Graphene-Doped Thermoplastic Polyu-rethane Nanocomposite Film-Based Triboelectric Nanogenerator for Self-Powered Sport Sensor. Nanomaterials 2024, 14, 1549. [Google Scholar] [CrossRef] [PubMed]

- Flores, J.M.B.; Rivera, J.M.; Ortiz, G.R.; Ahuactzi, I.F.H.; Chavarria, J.J.C.; Melecio, H.A.A.; Sanchez, P.D.A.; Ceron, V.H.A. Energy harvesting through the triboelectric nanogenerator (TENG) based on polyurethane/cellulose nanocrystal. Int. J. Renew. Energy Dev. 2024, 13, 1162–1174. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ejaz, S.; Shah, I.; Aziz, S.; Hassan, G.; Shuja, A.; Khan, M.A.; Jung, D.-W. Fabrication and Characterization of a Flexible Polyurethane-Based Triboelectric Nanogenerator for a Harvesting Energy System. Micromachines 2025, 16, 230. https://doi.org/10.3390/mi16020230

Ejaz S, Shah I, Aziz S, Hassan G, Shuja A, Khan MA, Jung D-W. Fabrication and Characterization of a Flexible Polyurethane-Based Triboelectric Nanogenerator for a Harvesting Energy System. Micromachines. 2025; 16(2):230. https://doi.org/10.3390/mi16020230

Chicago/Turabian StyleEjaz, Saba, Imran Shah, Shahid Aziz, Gul Hassan, Ahmed Shuja, Muhammad Asif Khan, and Dong-Won Jung. 2025. "Fabrication and Characterization of a Flexible Polyurethane-Based Triboelectric Nanogenerator for a Harvesting Energy System" Micromachines 16, no. 2: 230. https://doi.org/10.3390/mi16020230

APA StyleEjaz, S., Shah, I., Aziz, S., Hassan, G., Shuja, A., Khan, M. A., & Jung, D.-W. (2025). Fabrication and Characterization of a Flexible Polyurethane-Based Triboelectric Nanogenerator for a Harvesting Energy System. Micromachines, 16(2), 230. https://doi.org/10.3390/mi16020230