Resource-Constrained 3D Volume Estimation of Lunar Regolith Particles from 2D Imagery for In Situ Dust Characterization in a Lunar Payload

Abstract

Highlights

- Ellipsoid-based models more accurately estimate the 3D volume of lunar regolith particles from 2D images than spherical models.

- Micro-CT scans provide an effective method to validate the accuracy of 2D-based volume estimation techniques.

- This work improves the Lunaris mission’s capacity to accurately analyze lunar regolith adhesion in situ.

- The refined volume estimation directly enhances the reliability of adhesion force calculations, which are fundamentally dependent on particle mass derived from volume.

Abstract

1. Introduction

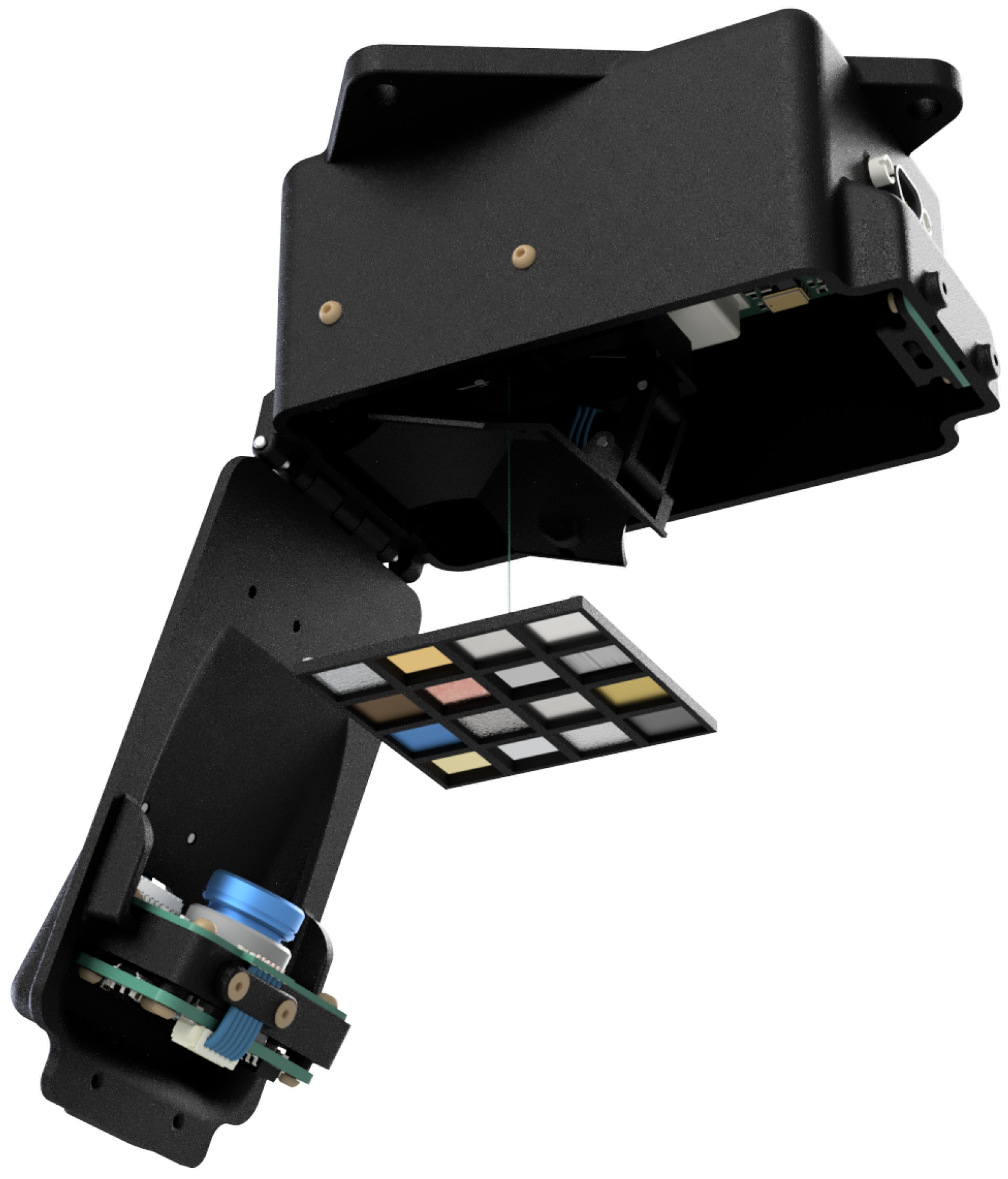

2. Lunaris Payload Overview

3. Materials and Methods

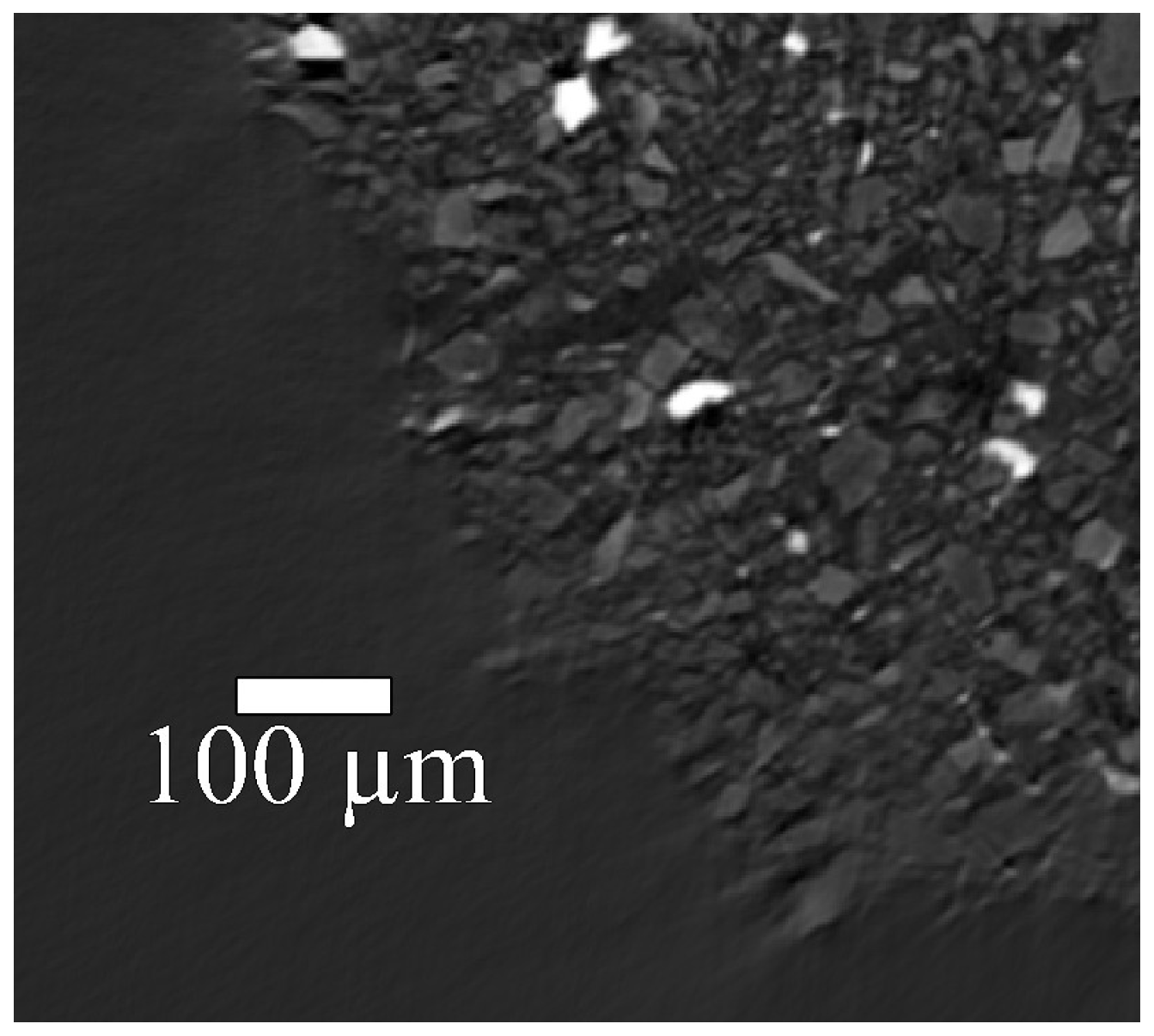

3.1. Experimental Procedure

- Sieving the regolith to obtain a controlled particle distribution below 100 µm.

- Depositing the regolith onto 2 mm PEEK disk samples, which were then mounted on a glass rod.

- Attaching a piece of low-density foam to the glass rod, to which the sample with regolith was affixed using hot glue.

- Placing the glass rod in a self-centering, rotating holder to ensure stable positioning during scanning.

- Testing two different PEEK samples (B and C), with multiple scans per sample:

- Sample B: Four scans;

- Sample C: Three scans.

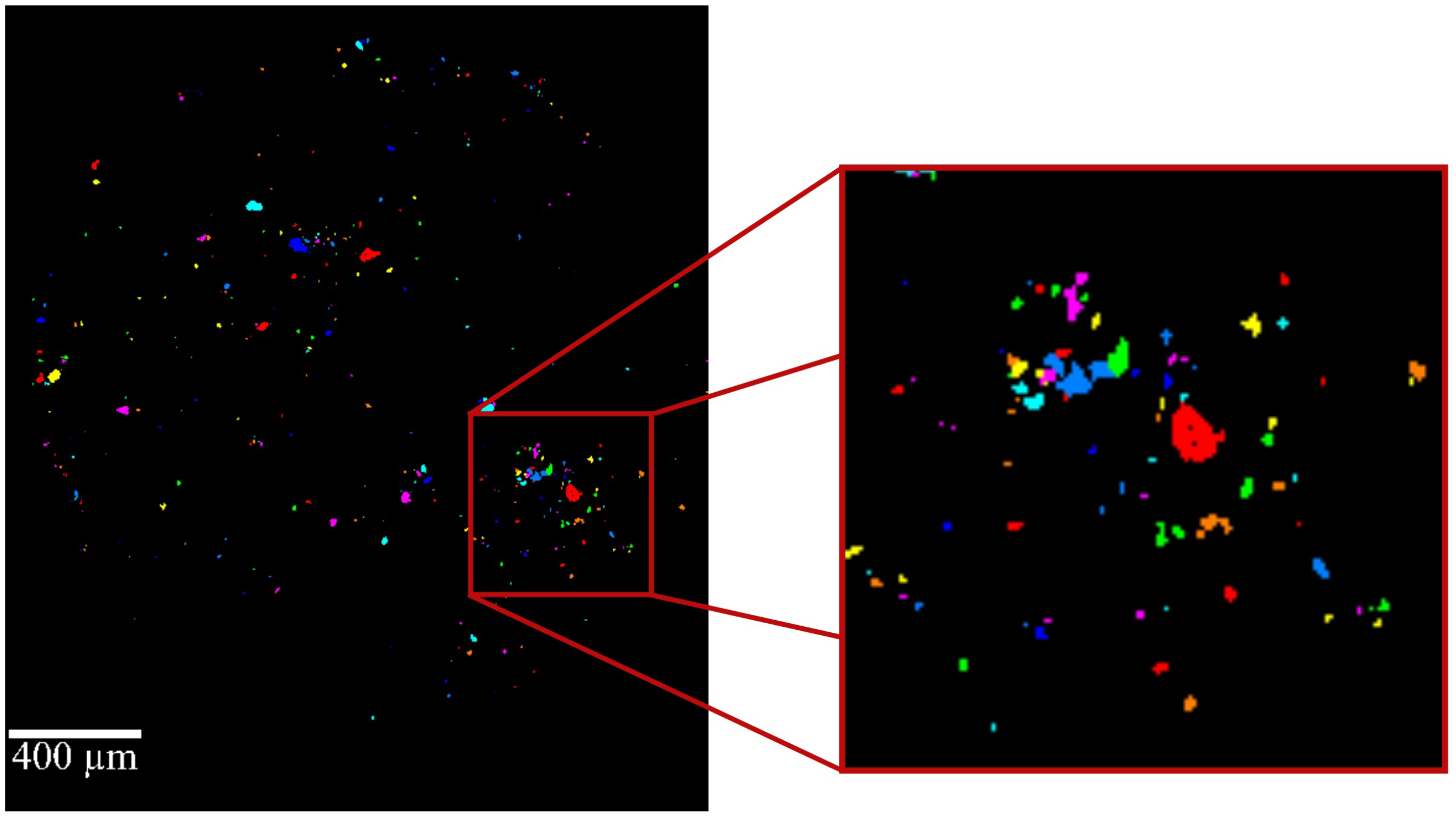

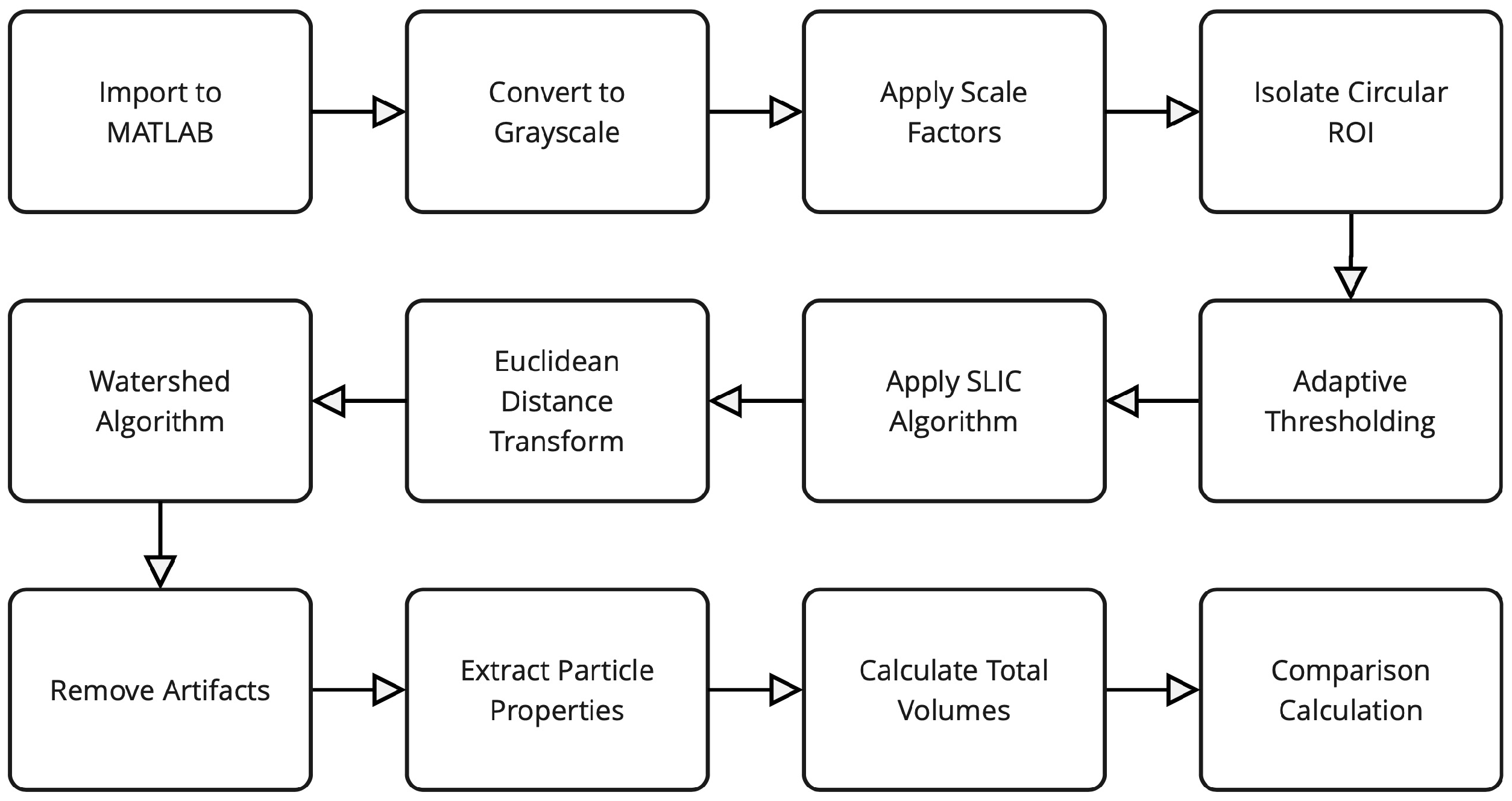

3.2. Post-Processing

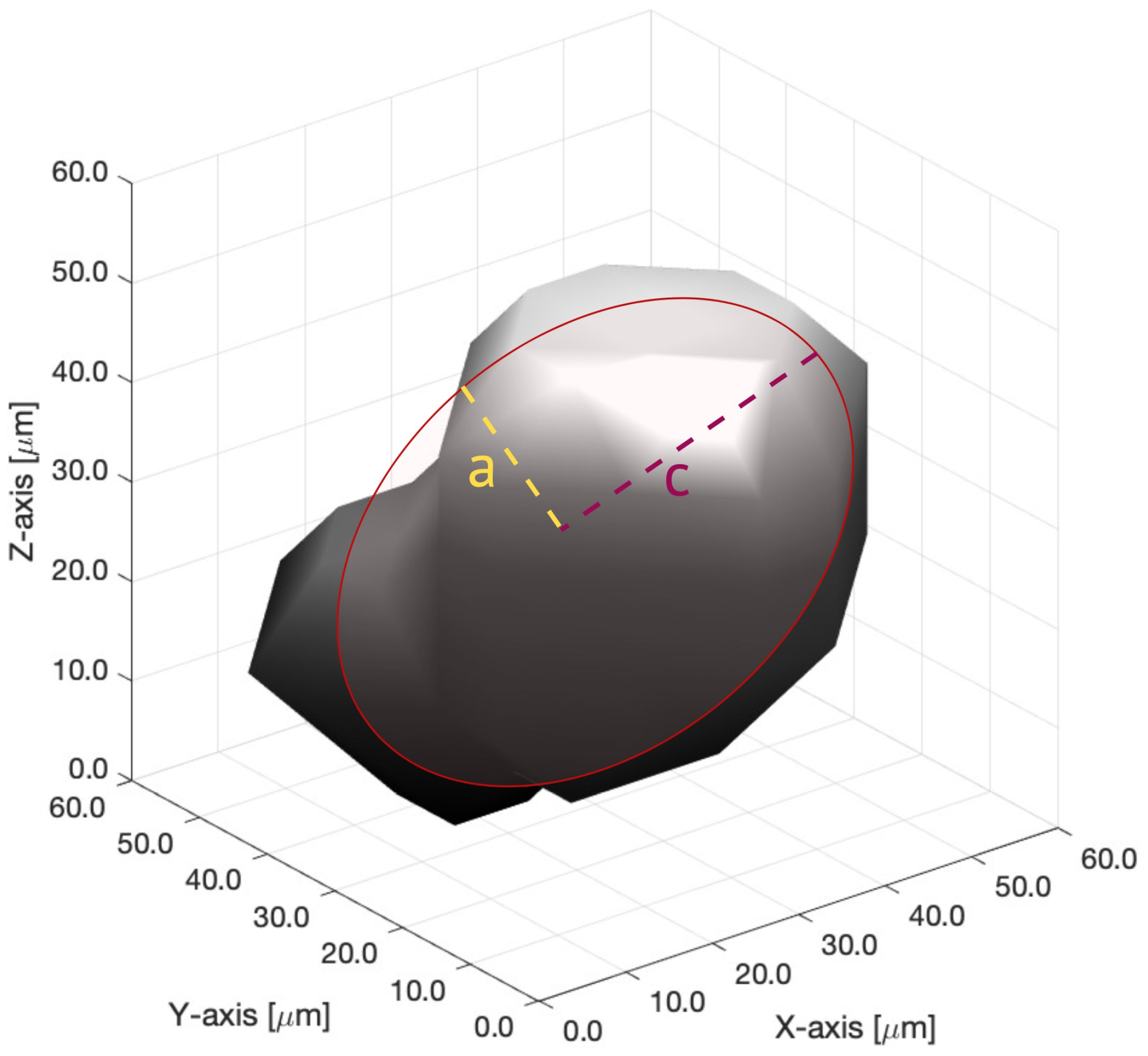

4. Volume Calculation Methods

4.1. Sphere Method

4.2. Ellipsoid with Fixed Aspect Ratio

4.3. Feret Method

4.4. Cylinder Method

4.5. Voxel Method

4.6. Adaptive Ellipsoid Method

4.7. Percentage Difference Calculation

- represents the reference volume of the particles in image i;

- is the volume estimated by method m for image i;

- is the percentage difference for method m on image i, expressed as a percentage.

Selection Rationale

5. Results

- Green (low error, ≤20%): Represents the most accurate estimations.

- Yellow (moderate error, 20–60%): Represents estimations with moderate deviations.

- Red (high error, >60%): Indicates significant deviations from the reference volume.

6. Discussion

Limitations and Future Work

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ISRU | In Situ Resource Utilization |

| CT | Computed Tomography |

| PEEK | Polyetheretherketone |

| ROI | Region of Interest |

| LED | Light-Emitting Diode |

| TVAC | Thermal Vacuum |

| AR | Aspect Ratio |

| SLIC | Simple Linear Iterative Clustering |

| VGStudio | Volume Graphics Studio |

| MATLAB | Matrix Laboratory |

| GE | General Electric |

| MAPE | Mean Absolute Percentage Error |

| DEM | Discrete Element Method |

References

- Johnson, S.W.; Chua, K.M. Properties and Mechanics of the Lunar Regolith. Appl. Mech. Rev. 1993, 46, 285–300. [Google Scholar] [CrossRef]

- Crawford, I.A. Lunar resources: A review. Prog. Phys. Geogr. Earth Environ. 2015, 39, 137–167. [Google Scholar] [CrossRef]

- Neal, C.R. The Moon 35 years after Apollo: What’s left to learn? Geochemistry 2009, 69, 3–43. [Google Scholar] [CrossRef]

- Pieters, C.M.; Goswami, J.N.; Clark, R.N.; Annadurai, M.; Boardman, J.; Buratti, B.; Combe, J.P.; Dyar, M.D.; Green, R.; Head, J.W.; et al. Character and Spatial Distribution of OH/H2O on the Surface of the Moon Seen by M3 on Chandrayaan-1. Science 2009, 326, 568–572. [Google Scholar] [CrossRef]

- Isachenkov, M.; Chugunov, S.; Landsman, Z.; Akhatov, I.; Metke, A.; Tikhonov, A.; Shishkovsky, I. Characterization of novel lunar highland and mare simulants for ISRU research applications. Icarus 2022, 376, 114873. [Google Scholar] [CrossRef]

- Meurisse, A.; Carpenter, J. Past, present and future rationale for space resource utilisation. Planet. Space Sci. 2020, 182, 104853. [Google Scholar] [CrossRef]

- Guerrero-Gonzalez, F.J.; Zabel, P. System analysis of an ISRU production plant: Extraction of metals and oxygen from lunar regolith. Acta Astronaut. 2023, 203, 187–201. [Google Scholar] [CrossRef]

- Landis, G.A. Materials refining on the Moon. Acta Astronaut. 2007, 60, 906–915. [Google Scholar] [CrossRef]

- Anand, M.; Crawford, I.; Balat-Pichelin, M.; Abanades, S.; Van Westrenen, W.; Péraudeau, G.; Jaumann, R.; Seboldt, W. A brief review of chemical and mineralogical resources on the Moon and likely initial in situ resource utilization (ISRU) applications. Planet. Space Sci. 2012, 74, 42–48. [Google Scholar] [CrossRef]

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450. [Google Scholar] [CrossRef]

- Meurisse, A.; Makaya, A.; Willsch, C.; Sperl, M. Solar 3D printing of lunar regolith. Acta Astronaut. 2018, 152, 800–810. [Google Scholar] [CrossRef]

- Taylor, S.L.; Jakus, A.E.; Koube, K.D.; Ibeh, A.J.; Geisendorfer, N.R.; Shah, R.N.; Dunand, D.C. Sintering of micro-trusses created by extrusion-3D-printing of lunar regolith inks. Acta Astronaut. 2018, 143, 1–8. [Google Scholar] [CrossRef]

- Freundlich, A.; Ignatiev, A.; Horton, C.; Duke, M.; Curreri, P.; Sibille, L. Manufacture of solar cells on the moon. In Proceedings of the Conference Record of the Thirty-first IEEE Photovoltaic Specialists Conference, Lake buena Vista, FL, USA, 3–7 January 2005; pp. 794–797. [Google Scholar] [CrossRef]

- Lin, H.; Lin, Y.; Yang, W.; He, Z.; Hu, S.; Wei, Y.; Xu, R.; Zhang, J.; Liu, X.; Yang, J.; et al. New Insight Into Lunar Regolith-Forming Processes by the Lunar Rover Yutu-2. Geophys. Res. Lett. 2020, 47, e2020GL087949. [Google Scholar] [CrossRef]

- Robinson, M.S.; Brylow, S.M.; Tschimmel, M.; Humm, D.; Lawrence, S.J.; Thomas, P.C.; Denevi, B.W.; Bowman-Cisneros, E.; Zerr, J.; Ravine, M.A.; et al. Lunar Reconnaissance Orbiter Camera (LROC) Instrument Overview. Space Sci. Rev. 2010, 150, 81–124. [Google Scholar] [CrossRef]

- Lin, H.; Yang, Y.; Lin, Y.; Liu, Y.; Wei, Y.; Li, S.; Hu, S.; Yang, W.; Wan, W.; Xu, R.; et al. Photometric properties of lunar regolith revealed by the Yutu-2 rover. Astron. Astrophys. 2020, 638, A35. [Google Scholar] [CrossRef]

- Plescia, J. Lunar Surface Environmental Conditions: Challenges of Developing an Outpost and Exploiting in Situ Resources. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009. [Google Scholar] [CrossRef]

- Crawford, I.; Anand, M.; Cockell, C.; Falcke, H.; Green, D.; Jaumann, R.; Wieczorek, M. Back to the Moon: The scientific rationale for resuming lunar surface exploration. Planet. Space Sci. 2012, 74, 3–14. [Google Scholar] [CrossRef]

- Gaier, J.R. The Effects of Lunar Dust on EVA Systems During the Apollo Missions; NASA/TM—2005-213610/REV1; NASA: Washington, DC, USA, 2007.

- Budzyn, D.H.; Zare-Behtash, H.; Cowley, A.; Cammarano, A. Compliant mechanisms for dust mitigation in Lunar hardware development: Technology and material considerations. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1287, 012001. [Google Scholar] [CrossRef]

- Cannon, K.M.; Dreyer, C.B.; Sowers, G.F.; Schmit, J.; Nguyen, T.; Sanny, K.; Schertz, J. Working with lunar surface materials: Review and analysis of dust mitigation and regolith conveyance technologies. Acta Astronaut. 2022, 196, 259–274. [Google Scholar] [CrossRef]

- Shkuratov, Y. Regolith Layer Thickness Mapping of the Moon by Radar and Optical Data. Icarus 2001, 149, 329–338. [Google Scholar] [CrossRef]

- Xiao, Z.; Zeng, Z.; Ding, N.; Molaro, J. Mass wasting features on the Moon – how active is the lunar surface? Earth Planet. Sci. Lett. 2013, 376, 1–11. [Google Scholar] [CrossRef]

- Zhang, Q.W.L.; Yang, M.H.; Li, Q.L.; Liu, Y.; Yue, Z.Y.; Zhou, Q.; Chen, L.Y.; Ma, H.X.; Yang, S.H.; Tang, X.; et al. Lunar farside volcanism 2.8 billion years ago from Chang’e-6 basalts. Nature 2025, 643, 356–360. [Google Scholar] [CrossRef] [PubMed]

- Mathew, N.; Durga Prasad, K.; Mohammad, F.; Aasik, V.; Vajja, D.P.; Ram Prabhu, M.; Satheesh Chandran, M.; Subhajayan, K.P.; Antony, K.J.; Pramod, P.P.; et al. Thermal conductivity of high latitude lunar regolith measured by Chandra’s Surface Thermophysical Experiment (ChaSTE) onboard Chandrayaan 3 lander. Sci. Rep. 2025, 15, 7535. [Google Scholar] [CrossRef]

- Sakai, S.; Kushiki, K.; Sawai, S.; Fukuda, S.; Miyazawa, Y.; Ishida, T.; Kariya, K.; Ito, T.; Ueda, S.; Yokota, K.; et al. Moon landing results of SLIM: A smart lander for investigating the Moon. Acta Astronaut. 2025, 235, 47–54. [Google Scholar] [CrossRef]

- Lederer, S.M. Commercial Lunar Payload Services (Clps): Contracted Deliveries 510 of Nasa Payloads to the Moon. In Proceedings of the Annual Meeting of the Lunar Exploration Analysis Group, Laurel, MD, USA, 20–22 September 2023. [Google Scholar]

- Astrobotic. Orbital Space Announces Historic First Privately Funded Lunar Mission from the Arab World, 2024. Available online: https://www.astrobotic.com/orbital-space-announces-historic-first-privately-funded-lunar-mission-from-the-arab-world/ (accessed on 2 October 2025).

- Sun, H.; Li, D.; Gao, H.; Wu, Y.; Shen, Z.; Liu, Z.; Li, Y. Measuring adhesion of microparticles in lunar regolith simulant BHLD1000 by centrifugal technique. Planet. Space Sci. 2022, 220, 105535. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, X.; Zhang, J.; Mu, M.; Wang, M.; Zhu, Y.; Wang, W. Adhesion effect analysis of ultra-fine lunar dust particles on the aluminum-based rough surface based on the fractal theory. Adv. Space Res. 2022, 69, 2745–2755. [Google Scholar] [CrossRef]

- Barker, D.C.; Olivas, A.; Farr, B.; Wang, X.; Buhler, C.R.; Wilson, J.; Mai, J. Adhesion of lunar simulant dust to materials under simulated lunar environment conditions. Acta Astronaut. 2022, 199, 25–36. [Google Scholar] [CrossRef]

- Goguen, J.; Sharits, A.; Chiaramonti, A.; Lafarge, T.; Garboczi, E. Three-dimensional characterization of particle size, shape, and internal porosity for Apollo 11 and Apollo 14 lunar regolith and JSC-1A lunar regolith soil simulant. Icarus 2024, 420, 116166. [Google Scholar] [CrossRef]

- Wu, H.; Zou, Y.; Zhang, C.; Yang, W.; Wu, B.; Yung, K.; Zhao, Q. Micro-CT Characterization of the Chang’e-5 Lunar Regolith Samples. J. Geophys. Res. Planets 2025, 130, e2024JE008787. [Google Scholar] [CrossRef]

- Stark, A.; Paddock, A.; Nguyen, T.; Woodham, K. Windform® XT 2.0 Use as 3U CubeSat 530 Primary Structure; Utah State University: Logan, UT, USA, 2023. [Google Scholar]

- Wylęgała, F.; Uhl, T. Investigating Lunar Regolith Adhesion Through the Lunaris Payload. In Selected Proceedings of the 7th Space Resources Conference; Lupa, M., Uhl, T., Staszel, J., Pargieła, K., Malczewska, A., Eds.; Series Title: Springer Aerospace Technology; Springer Nature Switzerland: Cham, Switzerland, 2025; pp. 285–290. [Google Scholar] [CrossRef]

- He, W.; Li, C.; Guo, Y.; Wei, Z.; Guo, B. A Two-Stage Gradient Ascent-Based Superpixel Framework for Adaptive Segmentation. Appl. Sci. 2019, 9, 2421. [Google Scholar] [CrossRef]

- Sun, H.; Luo, Y. Adaptive watershed segmentation of binary particle image. J. Microsc. 2009, 233, 326–330. [Google Scholar] [CrossRef]

- Fayed, M.E.; Otten, L. (Eds.) Handbook of Powder Science & Technology; Springer US: Boston, MA, USA, 1997. [Google Scholar] [CrossRef]

- Tripathi, P.; Lee, S.J.; Lee, C.H.; Shin, M. Towards 3D Shape Estimation from 2D Particle Images: A State-of-the-Art Review and Demonstration. KONA Powder Part. J. 2025, 42, 37–56. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Luo, L. Comparison Analysis of the Calculation Methods for Particle Diameter. Crystals 2022, 12, 1107. [Google Scholar] [CrossRef]

- Garboczi, E. Three dimensional shape analysis of JSC-1A simulated lunar regolith particles. Powder Technol. 2011, 207, 96–103. [Google Scholar] [CrossRef]

- Ueda, T. Estimation of three-dimensional particle size and shape characteristics using a modified 2D–3D conversion method employing spherical harmonic-based principal component analysis. Powder Technol. 2022, 404, 117461. [Google Scholar] [CrossRef]

- Cuzzi, J.N.; Olson, D.M. Recovering 3D particle size distributions from 2D sections. Meteorit. Planet. Sci. 2017, 52, 532–545. [Google Scholar] [CrossRef] [PubMed]

- Etcheverry, M.; Arson, C. Three-dimensional biphase fabric estimation from 2D images by deep learning. Sci. Rep. 2024, 14, 8957. [Google Scholar] [CrossRef]

- Tsuchiyama, A.; Sakurama, T.; Nakano, T.; Uesugi, K.; Ohtake, M.; Matsushima, T.; Terakado, K.; Galimov, E.M. Three-dimensional shape distribution of lunar regolith particles collected by the Apollo and Luna programs. Earth Planets Space 2022, 74, 172. [Google Scholar] [CrossRef]

- Oudayer, P.; Mateo-Velez, J.C.; Puybras, C.; Roussel, J.F.; Hess, S.; Sarrailh, P.; Murat, G. Development of a new test bench dedicated to adhesion characterization of lunar dust simulants in space environment. In Proceedings of the International Symposium on Materials in Space Environment (ISMSE 2018), Biarritz, France, 1–5 October 2018. [Google Scholar]

- Ilse, K.; Khan, M.Z.; Lange, K.; Gurumoorthy, H.N.; Naumann, V.; Hagendorf, C.; Bagdahn, J. Rotational force test method for determination of particle adhesion—From a simplified model to realistic dusts. J. Renew. Sustain. Energy 2020, 12, 043503. [Google Scholar] [CrossRef]

- Wohl, C.J.; Atkins, B.M.; College, R.; Connell, J.W. Method and Apparatus for the Quantification of Particulate Adhesion Forces on Various Substrates; NASA: Washington, DC, USA, 2011. [Google Scholar]

| Mineral Phase | Volume Fraction [vol%] |

|---|---|

| Plagioclase feldspar (Labradorite) | 38.4 |

| Pyroxene (Augite) | 41.9 |

| Olivine (Forsterite) | 18.4 |

| Titanomagnetite | 1.0 |

| Alkali Feldspar | 0.3 |

| Image | Scale Factor (µm/Pixel) |

|---|---|

| 1B | 3.8462 |

| 2B | 3.7031 |

| 3B | 3.8462 |

| 4B | 3.8462 |

| 1C | 3.7736 |

| 2C | 3.6980 |

| 3C | 3.7031 |

| Image | Particles | Reference Volume | Sphere | Ellipsoid_AR1 | Feret Method | Cylinder | Voxel | Adaptive Ellipsoid |

|---|---|---|---|---|---|---|---|---|

| 1B | 1987 | 78,390,888 | 64,477,518 (17.75%) | 32,238,759 (58.87%) | 102,714,739 (31.03%) | 96,716,277 (23.38%) | 38,686,511 (50.65%) | 32,636,083 (58.37%) |

| 2B | 2784 | 4,790,720 | 11,204,390 (133.88%) | 5,602,195 (16.94%) | 17,333,278 (261.81%) | 16,806,585 (250.82%) | 6,722,634 (40.33%) | 5,688,187 (18.73%) |

| 3B | 709 | 836,632 | 1,665,194 (99.04%) | 832,597 (0.48%) | 2,600,915 (210.88%) | 2,497,791 (198.55%) | 999,117 (19.42%) | 915,138 (9.38%) |

| 4B | 277 | 195,112 | 389,406 (99.58%) | 194,703 (0.21%) | 477,892 (144.93%) | 584,109 (199.37%) | 233,644 (19.75%) | 185,263 (5.05%) |

| 1C | 2806 | 3,395,408 | 8,843,351 (160.45%) | 4,421,675 (30.23%) | 14,421,407 (324.73%) | 13,265,027 (290.68%) | 5,306,011 (56.27%) | 4,883,668 (43.83%) |

| 2C | 116 | 20,328 | 56,541 (178.15%) | 28,270 (39.07%) | 61,914 (204.58%) | 84,812 (317.22%) | 33,925 (66.89%) | 27,513 (35.35%) |

| 3C | 38 | 31,376 | 28,921 (7.82%) | 14,460 (53.91%) | 28,671 (8.62%) | 43,382 (38.27%) | 17,353 (44.69%) | 12,588 (59.88%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wylęgała, F.; Uhl, T. Resource-Constrained 3D Volume Estimation of Lunar Regolith Particles from 2D Imagery for In Situ Dust Characterization in a Lunar Payload. Remote Sens. 2025, 17, 3450. https://doi.org/10.3390/rs17203450

Wylęgała F, Uhl T. Resource-Constrained 3D Volume Estimation of Lunar Regolith Particles from 2D Imagery for In Situ Dust Characterization in a Lunar Payload. Remote Sensing. 2025; 17(20):3450. https://doi.org/10.3390/rs17203450

Chicago/Turabian StyleWylęgała, Filip, and Tadeusz Uhl. 2025. "Resource-Constrained 3D Volume Estimation of Lunar Regolith Particles from 2D Imagery for In Situ Dust Characterization in a Lunar Payload" Remote Sensing 17, no. 20: 3450. https://doi.org/10.3390/rs17203450

APA StyleWylęgała, F., & Uhl, T. (2025). Resource-Constrained 3D Volume Estimation of Lunar Regolith Particles from 2D Imagery for In Situ Dust Characterization in a Lunar Payload. Remote Sensing, 17(20), 3450. https://doi.org/10.3390/rs17203450