Abstract

Efficient documentation and traceability of construction waste are essential for meeting the objectives of the European Green Deal and the Circular Economy. In Poland, the national Database on Products, Packaging, and Waste Management (BDO) serves as the central platform for recording and reporting waste flows, including those generated by the construction sector. However, its current structure imposes substantial administrative burdens, particularly on large-scale projects involving thousands of waste transports. This study examines the documentation workflow within the BDO system as applied to construction activities. Using process mapping, field studies, and interviews, the research identifies key bottlenecks and opportunities for improvement, especially through automation enabled by the integration of external applications connected to BDO via its public Application Programming Interface (API). Among nine identified systems, one was selected due to its comprehensive functionalities tailored to construction-sector needs. A study involving thirty users demonstrated that implementation of this system reduced the time required to issue a Waste Transfer Card (KPO) by 77% and fully automated entries in the Waste Records Register (KEO). As a result, the average administrative workload decreased by 87%. For a representative demolition company generating approximately 46,000 KPOs annually, the total time savings correspond to 8.2 months of full-time administrative work. This reduction translates into annual savings exceeding PLN 47,000 and yields a return on investment of over 100% within the first year. Sensitivity analysis indicates that the system’s effectiveness decreases with lower documentation volumes. The findings confirm that targeted automation and improved interface design can significantly enhance the efficiency, accuracy, and transparency of construction waste documentation.

1. Introduction

The European Union’s policy framework, articulated in the European Green Deal [1], aims to achieve climate neutrality by 2050 while reducing the consumption of natural resources. Its objectives also include protecting, preserving, and enhancing the EU’s natural capital, as well as safeguarding public health and well-being by eliminating environmental risks and their adverse impacts. The European Commission identifies digital technologies as key enablers of this transformation, capable of accelerating and scaling systemic change. Digitalization creates new opportunities for remote monitoring of water and air pollution and for optimising energy use, natural resource management, and waste management processes.

Digitization and automation of economic processes contribute to the optimisation of both operational procedures and decision-making processes [2,3,4,5]. This trend also extends to waste management [6,7]. In solid waste management, a wide range of digital technologies is currently employed. Geographic Information Systems (GIS) support the collection, analysis, and presentation of spatial data and are used for planning waste collection and transport, siting facilities, and identifying illegal dumping sites [8,9]. Global Positioning Systems (GPS) enable route optimisation [10]. Cyber-Physical Systems (CPS) integrate physical components with software and communication infrastructures, supporting the operation of smart containers and logistics optimisation [11,12]. The Internet of Things (IoT) facilitates direct data exchange between devices, while Radio-Frequency Identification (RFID) is used for sorting, monitoring container fill levels, and supporting logistics operations [13]. Artificial Intelligence (AI)—including machine learning, neural networks, fuzzy logic, and evolutionary algorithms—supports waste-stream forecasting, process optimisation, and automated waste segregation [14,15]. Image processing (IP) complements these technologies and is applied in tasks such as sorting and quality control [16,17].

Despite intensive research and numerous implementation efforts in the field of municipal waste management, the use of modern technologies in construction waste management remains limited [18], and full digitalization is still at an early stage of development [19]. In construction, digitalization efforts are primarily focused on Building Information Modelling (BIM) technology [20,21,22,23], which integrates design, construction, and operation within a unified digital environment. At the same time, the specific characteristics of construction production—such as variable project locations, the high heterogeneity of works (ranging from residential buildings to engineering structures, renovations, and demolitions), and strong dependence on external factors (including weather conditions, geotechnical constraints, and urban surroundings)—render most processes largely non-repetitive [24,25]. As a result, the quantitative and qualitative composition of waste varies significantly [26], requiring cooperation with multiple waste recipients and the handling of diverse logistical needs [27,28,29,30,31]. Therefore, waste management on construction sites cannot be fully standardised; instead, it requires flexible organisational approaches and tools capable of adapting to dynamic project conditions [32].

In the review publication [33], the authors examine the underlying reasons for the limited implementation of digital technologies (DTs) in supporting circular economy (CE) practices within the construction sector. They identified 37 barriers, which were grouped into nine categories: organisational, infrastructural, regulatory, standardisation-related, investment-related, construction-industry-specific, technological, stakeholder-related, and data-related barriers. Pareto analysis highlighted several key obstacles, including the slow uptake of technologies—driven by insufficient knowledge, limited competencies, and the absence of clearly defined digitalization objectives in construction—as well as high implementation costs and resistance to change. Additional challenges include the lack of sector-specific data (particularly for the end-of-life phase of buildings) and persistent issues in data management, especially regarding completeness, timeliness, and interoperability. The latter represents one of the most critical technical barriers.

In [34], the authors reviewed 197 scientific publications from 1994 to 2022 addressing the digitalization of construction sites, of which approximately 3% were Polish contributions. The review shows that the main research directions in digitalization are: (1) increasing the transparency of information on materials, workforce, and construction progress; (2) reducing downtime and optimising deliveries by integrating material planning with BIM models and other digital systems; (3) reducing accidents through the integration of sensors, data analytics, virtual reality (VR), and augmented reality (AR); and (4) achieving fully digital representation and control of construction processes—from design, through execution, to operation. Notably, issues related to information flows on construction and demolition waste are absent from this framework and are not explicitly identified as a research gap. Furthermore, the keyword analysis of digitalization in construction-site management highlights terms such as BIM, cyber–physical systems, AI, VR, AR, IoT, and blockchain, whereas “waste management” does not appear as a relevant keyword or as a distinct thematic cluster.

The literature lacks analyses of IT tools that support or streamline waste documentation within the framework of Polish legal requirements and industry practices. This study addresses that gap.

In Poland, the government-operated Database on Products, Packaging, and Waste Management (BDO) [35] serves as the national system for waste recording and reporting, including waste generated by the construction sector. The BDO system implements the EU’s requirements for waste traceability and record-keeping as defined by European framework regulations [36]. It has been in operation since 1 January 2020 and has become the sole mandatory electronic tool for maintaining waste records. During the initial implementation phase, limited organisational readiness among enterprises and system performance issues—particularly for large-scale soil and spoil transports—led to significant operational difficulties [37]. The complexity of document circulation turned BDO into a bottleneck in construction waste management, which stimulated the development of IT tools designed to automate record-keeping processes. Furthermore, starting from January 2025, new regulations require construction waste to be collected selectively on-site or delivered to authorised entities that ensure segregation [38], effectively expanding the scope of reporting from one to six waste streams.

The aim of this study is to describe the waste documentation process within the BDO system in the Polish construction sector, identify key bottlenecks, and assess the potential for reducing them through the use of available IT tools and system integration. In particular, the study seeks to answer the following research questions:

RQ1: How is the waste documentation process carried out within the BDO system in the Polish construction sector?

RQ2: What are the key bottlenecks in the BDO documentation process, and what opportunities exist for improving its efficiency?

RQ3: What IT systems supporting waste documentation are available on the market, and to what extent do they address the specific needs of the construction industry?

RQ4: What time and organisational benefits can be achieved through the implementation of a selected IT system supporting BDO operations?

The description of the digital documentation workflow in Poland (RQ1) can serve as a basis for transferring experience to developing countries and as a benchmark for cross-country comparisons of waste information systems. The analysis of bottlenecks and user needs (RQ2) provides insights into construction processes and, when combined with the system description (RQ1) and existing solutions (RQ3), offers a perspective for further development and integration in the context of Industry 4.0 implementation, both in research and practice. The answers to RQ4 provide the market with valuable evidence to support investment decisions and the adoption of digital solutions in this area.

The structure of the article is as follows: Section 2 presents the research methodology; Section 3 provides the contextual background for the study, including the legal and organisational framework; Section 4.1 maps the administrative procedures related to waste transfer; Section 4.2 identifies and categorises the main process bottlenecks; Section 4.3 reviews and evaluates the available IT solutions supporting BDO operations; Section 4.4 presents the results of a case study demonstrating the effects of system implementation; and Section 5 summarises the findings and outlines directions for further development and integration of digital tools within the construction waste management chain.

2. Materials and Methods

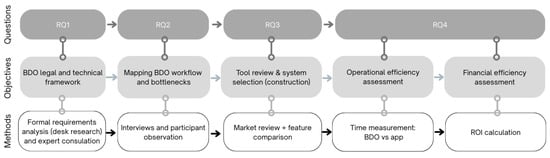

To address the research questions, a multi-stage study was conducted, and its stages are presented in Figure 1.

Figure 1.

Graphical presentation of the research process: questions, objectives and research methods. Source: Own elaboration.

In the first phase, a formal requirements analysis for maintaining records in the BDO system was conducted, based on the waste legislation framework [39]. This included a review of source materials provided by the Ministry of Climate and Environment and instructional documents, such as the Waste Record Guide [40]. This stage enabled the identification of the legal and technical framework governing the operation of the waste documentation system. Next, expert consultations were conducted with representatives of public administration—specifically, officials responsible for operating the BDO system helpline. Their purpose was to verify the accuracy of the interpretation of regulations and procedures related to waste record-keeping.

In the following step, unstructured interviews were carried out with representatives of the construction industry. These interviews made it possible to identify practical barriers and differences in how documentation obligations are implemented across companies with varying characteristics.

Subsequently, empirical research was conducted under real-world conditions in the form of a one-month internship in a construction company, during which participant observation was carried out. This involved active engagement in issuing Waste Transfer Cards (KPO) and completing Waste Record Cards (KEO), which enabled the identification of actual bottlenecks and administrative burdens. Although the observation was not formally structured, the documentation process adhered to qualitative research standards, including systematic note-taking, subsequent categorisation, and triangulation with insights from expert interviews. This provided a robust basis for developing accurate “as-is” BPMN process models and for identifying key administrative burdens relevant to the research questions.

To identify tools supporting BDO operations, a systematic market review was conducted. The search was performed using an internet search engine and mobile app stores (Google Play, App Store), with keywords such as “BDO application” and “BDO management.” Solutions were included if they: (i) explicitly supported the operation of the governmental BDO system (waste record-keeping and/or reporting) and (ii) were offered as commercial or otherwise publicly available products on the Polish market. For each solution, information on functional scope was collected from official websites and online documentation provided by software vendors. Where publicly available information was incomplete or unclear, it was supplemented through direct contact with vendors (email or telephone).

Based on the set of identified functionalities, the applications were compared in terms of whether each functionality was present or absent in the respective systems. From among the available solutions, one application dedicated to the construction industry—demonstrating the closest alignment between user needs and available features—was selected for detailed analysis. Practical tests were then conducted to assess the degree of improvement in the procedures for issuing KPOs and maintaining KEOs, as well as the extent to which manual tasks and bottlenecks could be eliminated.

The effectiveness of the selected solution was evaluated through a study involving 30 users representing various construction companies. Using the software provider as an intermediary, invitations to participate in the tests were sent to construction firms that were already clients of the provider; measurements were conducted only in companies that agreed to participate. The final sample consisted of one large enterprise (9 users), two medium-sized enterprises (4 and 6 users), three small enterprises (4, 4, and 2 users), and one microenterprise (1 user).

The researchers did not directly supervise the timing measurements; however, all participants were informed about the purpose of the study, the methodology, and the required measurement conditions to ensure the representativeness of the results. Each participant was experienced in issuing waste documentation, with a minimum job tenure of more than six months in the relevant position. Users performed predefined tasks in both the governmental BDO system and the supporting application. Operation times were recorded, and performance was compared between the two approaches, enabling a quantitative assessment of the tool’s impact on reducing administrative workload.

The direct measure of workload was the time (in seconds) required to issue a single KPO and to create the corresponding two KEO entries (generated and transferred waste). Average operation times per document were compared between the two approaches and extrapolated to an annual number of working hours for a representative demolition company, ensuring that the estimated workload reduction referred exclusively to BDO-related record-keeping activities.

Based on the time savings, the value of reduced administrative working time was calculated using the median monthly salary of administrative staff in Poland. This annual saving (Sannual) was then compared with the annual subscription cost of the application (Csub), and the cost effectiveness of the system was expressed as a return on investment (ROI), defined as:

To supplement the baseline return-on-investment analysis with the perspective of enterprises operating at different scales, a deterministic one-parameter sensitivity analysis was conducted. Its objective was to determine how the economic performance of the analysed IT system varies with the operational scale of an enterprise.

The analysis focused on the sensitivity of the return on investment (ROI) indicator to the annual number of Waste Transfer Cards (KPOs) processed by the system, which was adopted as a proxy for the scale of waste-management operations in construction enterprises.

The following parameters were treated as constant: the median monthly gross salary of administrative staff in Poland and the average time savings per documentation cycle (one KPO and two corresponding KEO entries), as determined empirically. The system’s cost structure was modelled in accordance with the software provider’s official pricing scheme, under which the subscription cost depends on the volume of processed documents; consequently, the unit cost of handling a single KPO decreases with increasing operational scale and stabilises after exceeding a defined volume threshold.

The analysis covered an annual number of KPOs in the range of 0–6000, enabling the assessment of the ROI indicator for enterprises of different sizes—from small entities to large construction and demolition companies. The sensitivity analysis was deterministic in nature and was aimed at identifying scale effects rather than modelling probabilistic uncertainty.

3. Background: The BDO System and Legal Framework

3.1. BDO System

Strategic frameworks such as the Digital Decade [41] and the European Green Deal [1] emphasise the need for interoperable, data-driven public platforms that support the monitoring, reporting, and enforcement of environmental policies. An example of such a governmental system is the Polish BDO platform. The Database on Products, Packaging, and Waste Management (BDO)—commonly referred to as the Waste Database—is a central ICT system supporting the implementation of national waste management policy across all sectors, including construction. The BDO system consists of three functional modules [40]:

- BDO Register—This module stores data on entities involved in the generation, transport, and processing of waste. It enables the verification of permits held by individual entities; however, its structure and the lack of integration with GISs limit the ability to efficiently search for entities authorised to collect specific types of waste.

- Record-Keeping Module—Launched in 2020, this module enables maintaining waste records exclusively in electronic form. In construction companies, waste documentation relies primarily on Waste Transfer Cards (KPO) and Waste Record Cards (KEO). A separate record must be maintained for each project, which requires creating a new place of business activity (MPD) and updating the system entry with location data and the scope of waste management activities.

- Reporting Module—This module is used to submit annual reports to the Regional Marshal’s Office, providing information on the quantity and types of waste generated and the methods of their management.

Thus, the BDO system fulfils three essential functions—informational, control, and analytical-statistical—supporting oversight of waste management in Poland [40,42].

The structure and functions of the BDO system outlined above define the framework within which entities involved in waste management must meet their regulatory obligations. To establish the practical role of BDO in the construction sector, the following section discusses the specific nature of construction waste and the legal obligations of contractors regarding its selective collection, recording, and transfer to authorised recipients.

3.2. Construction Waste Management

According to the Waste Act of 14 December 2012 [43] “waste” is defined as any substance or object that the holder discards, intends to discard, or is required to discard. In the context of construction activities, construction waste includes all waste generated as a result of the construction, reconstruction, assembly, renovation, or demolition of a building structure. Such waste is subject to mandatory record-keeping in the BDO system, with only a few exceptions. Packaging waste generated during construction is also subject to record-keeping, whereas municipal waste originating from construction site facilities is not [40].

Under the provisions of the Waste Act of 14 December 2012 [43], an entity performing construction services is considered both the producer and the holder of waste, unless otherwise specified in the service contract. Consequently, such an entity is obliged to manage waste in compliance with applicable regulations, including the obligation to register and record waste in the BDO system.

In accordance with the amendments to the Waste Act [38], as of 1 January 2025, business entities are required to conduct the selective collection of six fractions of construction waste: wood, gypsum, glass, mineral waste, plastics, and metals. Alternatively, waste may be transferred to an authorised entity that performs segregation on behalf of the producer (i.e., separates these fractions from mixed waste streams). Increasing the number of waste fractions has direct implications for the complexity of waste records in BDO, as each fraction requires separate documentation.

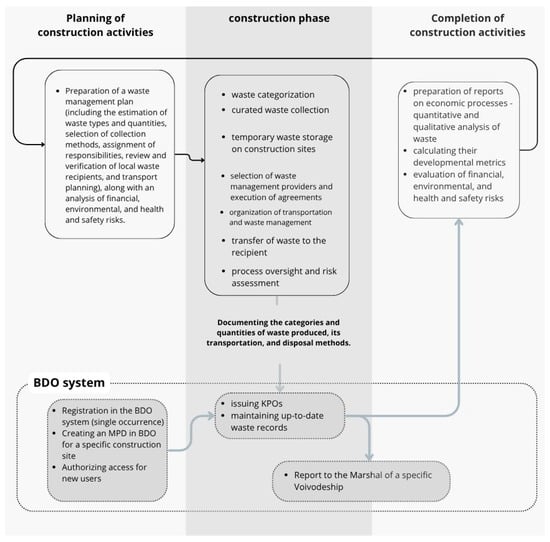

In practical terms, during the execution phase of construction works, contractors are responsible for a range of tasks related to proper waste management. These obligations are schematically illustrated in Figure 2.

Figure 2.

Schematic diagram of waste management responsibilities on a construction site. Source: Own elaboration.

The waste management process in construction companies is continuous in nature and spans all stages of project execution [44,45,46]. It begins even before construction works commence, with the development of a waste management plan [47], which defines the anticipated types and quantities of waste, methods of selective collection, and procedures for storage and transport [48,49]. At this stage, organisational responsibilities are assigned, potential waste recipients are verified, and financial, environmental, and occupational health and safety risks are assessed.

In parallel, the formal requirements within the BDO system must be prepared, including registration, the creation of a place of business activity (MPD) for the specific construction site, and the assignment of appropriate user permissions. These steps are a prerequisite for maintaining records in BDO and for the legal transfer of waste.

Waste management during the construction phase is operational in nature. Proper waste classification in accordance with the official waste catalogue, selective collection, and safe temporary on-site storage in compliance with regulatory requirements are of key importance. In parallel, waste records are maintained in the BDO system through two complementary modules:

- KPO—Waste Transfer Cards, which accompany each transport during the transfer of waste from the producer to the recipient, with the participation of the transporter (see Section 4.1.1);

- KEO—Waste Record Cards, in which generated and transferred waste is recorded (see Section 4.1.2).

By law, record-keeping must be performed “on an ongoing basis.” Since the regulations do not specify a strict update frequency, entries related to generated waste are often corrected after the exact weight is provided by the recipient. In accordance with contractual arrangements, waste is transferred to entities holding valid permits for the relevant waste stream, and each transfer is accompanied by a KPO document—issued by the producer, confirmed by the transporter, and closed by the recipient after weighing. In cases defined by law where a KPO is not required (e.g., transfer to a private individual not registered in BDO), the transaction is recorded only in the KEO, with appropriate confirmation.

Although the entire process should be subject to continuous monitoring, its practical implementation through the BDO system is challenging. BDO primarily provides outputs in presentation formats (e.g., PDF) rather than structured data files (e.g., CSV/XLSX) necessary for reproducible analytics. Consequently, this significantly increases the amount of manual data processing required and raises the risk of record-keeping errors. Although application-level errors may also occur, they are usually of a different nature—mainly system-level inconsistencies that are detected and resolved within the software environment. These aspects were beyond the scope of the present study but constitute a valuable direction for future research.

The completion stage of construction works focuses on process summarisation and analysis. The data collected in BDO enable the preparation of reports on the quantitative and qualitative structure of waste and indicators of waste management efficiency. These reports also form the basis for the legally required annual report submitted to the Regional Marshal’s Office. As noted earlier, however, data stored in BDO cannot be easily exported, and the system does not support automated report generation. Nevertheless, BDO provides a public API that allows programmatic data exchange with other IT systems, including external applications supporting waste documentation and analysis.

4. Results

4.1. Process Maps of Administrative Procedures Accompanying Waste Transfer

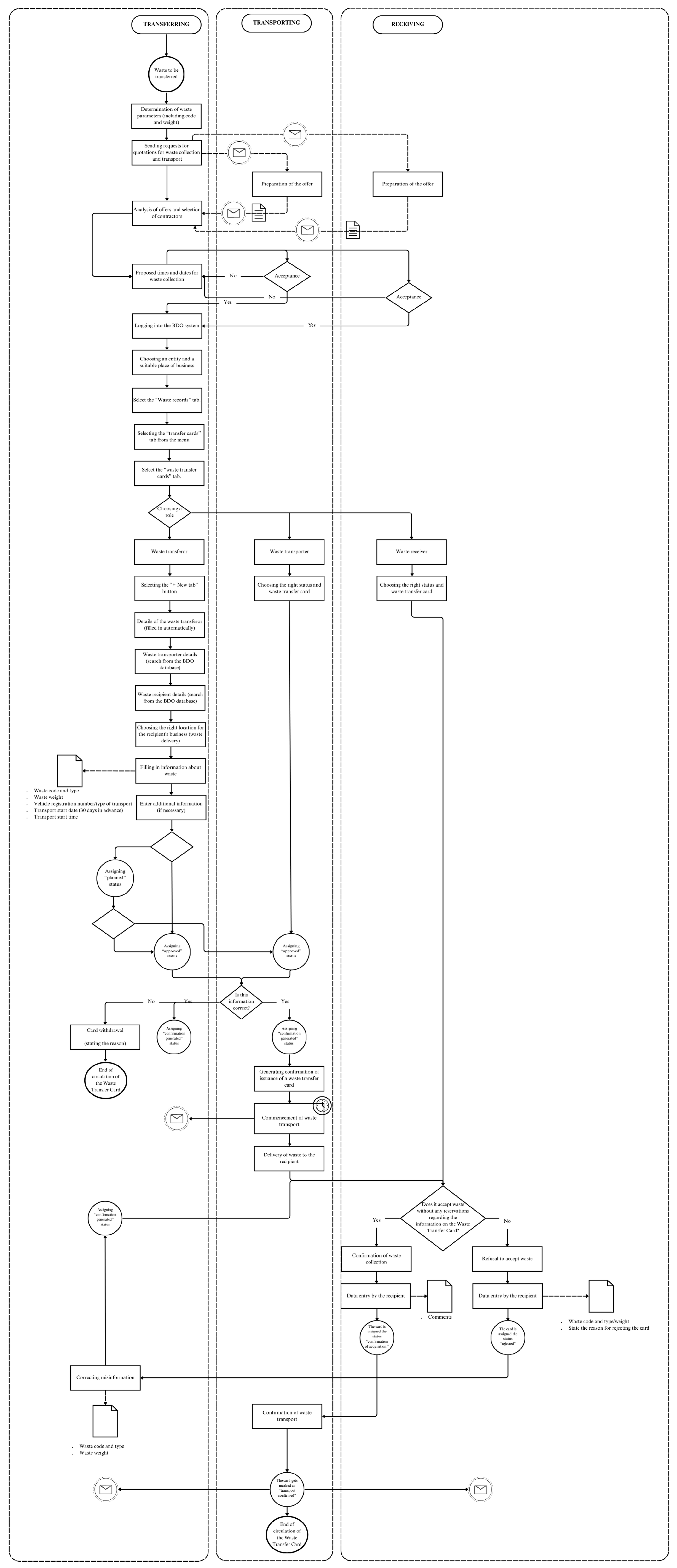

4.1.1. Waste Transfer Card (KPO)

The waste transfer process is almost always accompanied by the creation and circulation of a Waste Transfer Card (KPO) within the BDO system, with only a few exceptions. If dozens of transports of excavated material are carried out from a construction site in a single day, an equivalent number of KPO documents must be issued and completed—each representing an individual waste transport.

Three user roles participate in the KPO circulation process: the sender, the transporter, and the receiver. In some cases, a single system user may perform multiple roles within the waste management process. For example, an entity may generate or receive waste while also transporting it independently. Another example is a company that acts simultaneously as a waste producer and transporter and also operates its own processing or recycling facility (usually associated with a separate place of business activity—MPD).

The process begins with the authentication (login) of the user responsible for transferring the waste in the BDO system, followed by the selection of the appropriate entity and place of business activity for which the record will be created. Once these steps are completed, the user can proceed to the Waste Transfer Card (KPO) management module and begin entering data.

The KPO form consists of five sections—information on the sender, receiver, transporter, waste details, and additional information—which must be completed sequentially using the data summarised in Table 1.

Table 1.

Data required when creating a waste transfer card (KPO).

After completing the form, the sender assigns one of the following statuses to the Waste Transfer Card (KPO):

- Planned—used in the preliminary phase when the waste transfer is being arranged but the implementation details (e.g., recipient or transport date) are not yet confirmed.

- Approved—assigned once the basic information, such as the recipient and transporter details, is known; this status still allows modification of certain data, such as the waste mass or transport date.

- Confirmation generated—used after all information, including the waste mass and collection time, has been verified. Only at this stage is a KPO number generated.

Once a KPO reaches the “confirmation generated” status, the waste transport may begin.

In the next step, the waste receiver performs both the physical and formal acceptance of the waste, which results in the KPO being assigned either the completed acceptance status or the rejected status. If discrepancies occur—such as an incorrect waste mass or an erroneous waste code—the receiver rejects the KPO and requests a correction, resulting in the “rejected” status.

In practice, within the construction industry, waste is rarely accepted without first rejecting and correcting the KPO. This is due to the absence of on-site weighing systems, which leads to the initial entry of estimated waste mass and its later correction after weighing at the recipient’s facility. A common—but improper—practice is to bypass the rejection process and accept the waste with an adjusted mass directly in order to simplify operations; however, this creates a risk of financial penalties for incorrect record-keeping.

When a KPO is rejected, formal acceptance of the waste does not occur—although in practice the waste often remains physically with the recipient, as the transporter typically leaves after unloading. Meanwhile, the sender corrects the KPO, after which the receiver confirms the waste acceptance in the BDO system using the corrected data.

Finally, the transporter must close the KPO circulation within the BDO system by assigning the status “confirmed transport.” A graphical representation of the waste transfer process is provided in Appendix A.

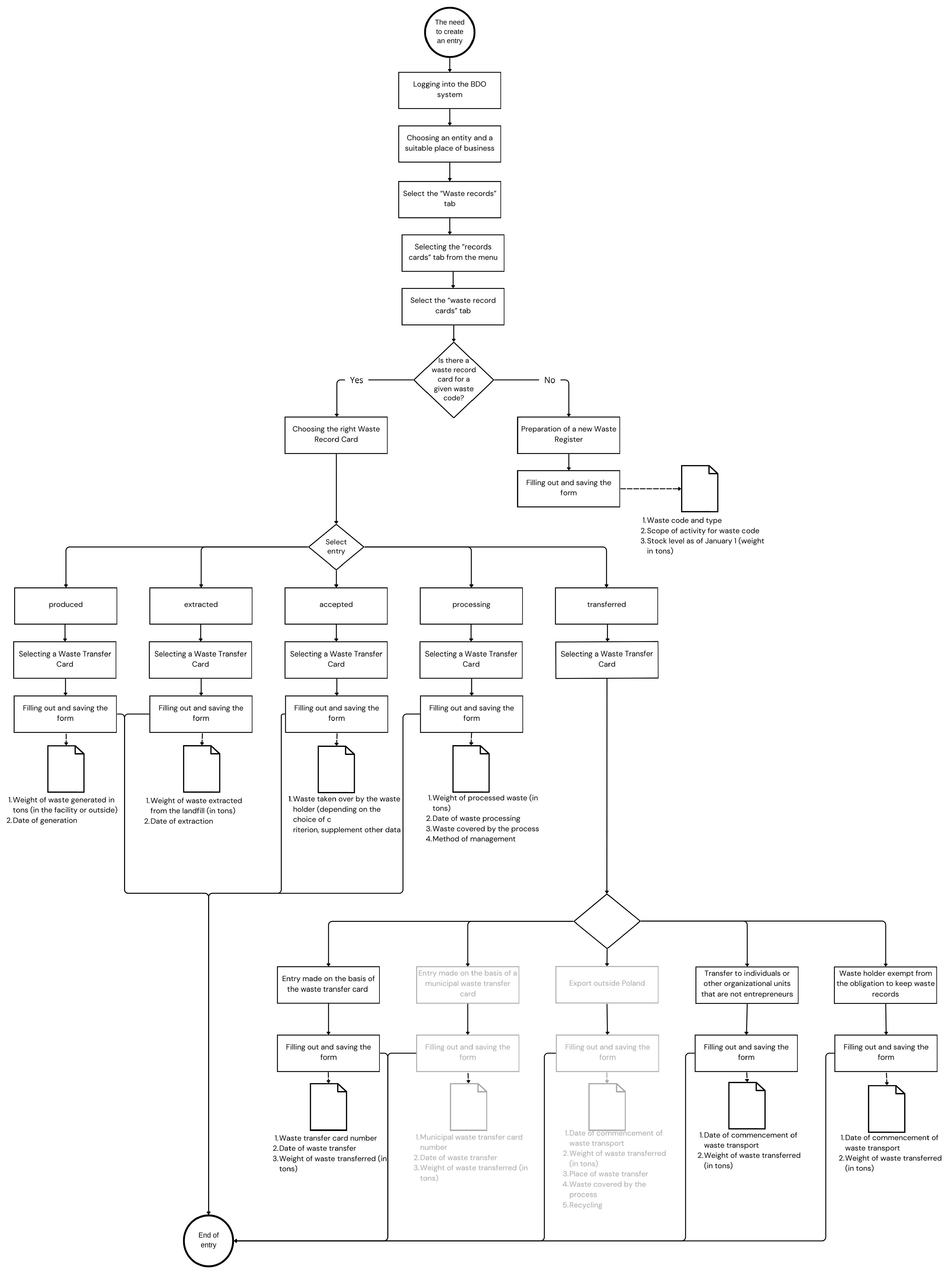

4.1.2. Waste Record Cards (KEO)

In addition to the circulation of KPOs, each construction site is required to maintain ongoing waste records in the BDO system using Waste Record Cards (KEO). The management of KEOs consists of two stages:

The first stage involves creating a KEO for each waste code. Only one record card per waste code may be created annually for a given place of business activity (MPD). To create a KEO, the user must enter the following information: the waste code and type; the scope of activity related to that waste code (i.e., disposal, recovery, collection, or generation of waste); and the stock level as of 1 January.

The second stage consists of recording data within the established KEOs concerning generated, transferred, received, extracted, and processed waste (see Table 2). This study focuses only on entries for generated and transferred waste, as the remaining types of records are rarely used on construction sites and are therefore omitted from further analysis. It is also worth noting that KEO entries supplement information on waste transfers that do not take place on the basis of a KPO document.

Table 2.

Data included in waste record entries.

The procedure for making entries in the KEO within the BDO system is presented in Appendix B.

4.2. Process Bottlenecks

The BDO system is a cross-sectoral platform serving multiple industries, while record-keeping in the construction sector is inherently multi-stage. This complexity generates a significant administrative workload, particularly in cases involving large-scale, repetitive waste transports (e.g., excavated soil or demolition debris). Each transport requires the creation of a separate Waste Transfer Card (KPO) for a single waste code before the transport begins, followed by processing that involves three user roles (sender, transporter, and receiver). This necessitates a sequence of confirmations and potential corrections, which in practice scales linearly with the number of transports.

Analyses indicate that large construction companies generate tens of thousands of KPOs annually. Similarly, demolition contractors also produce high volumes of documentation—one leading company in the demolition sector issues nearly 46,000 KPOs per year.

A key improvement to the processes associated with BDO operations would be the implementation of solutions that automate selected stages of these procedures. Based on expert interviews, field observations, and process analyses of BDO operations (see Appendix A and Appendix B), Table 3 summarises potential opportunities for improving the efficiency of BDO-related workflows in the construction industry.

Table 3.

Process bottlenecks and opportunities for improving BDO operations.

The full automation of KEO entries proposed in Table 3 may appear controversial, as, from a logical standpoint, records of generated waste should be created before issuing a KPO. However, in practical construction operations, KEO entries are typically made in connection with KPOs due to the need to verify the actual quantity of waste produced. This verification is not performed on-site but is based on weighing slips provided by the waste recipient.

4.3. Identification and Comparison of IT Tools Streamlining the Process

Owing to the availability of a public Application Programming Interface (API), numerous IT tools have been developed to support BDO operations. These solutions differ in their functional scope, user interface design, and access models, reflecting the diverse requirements of various industries. The analysis conducted in this study identified nine independent platforms dedicated to BDO management [50,51,52,53,54,55,56,57,58], including:

- One mobile application available in Google Play and App Store;

- Five web-based applications;

- Two desktop systems requiring local installation on workstations;

- One browser extension.

Table 4 compares these nine commercial IT solutions currently available on the market. The evaluation considered 15 functionalities related to the management of Waste Transfer Cards (KPO) and Waste Record Cards (KEO).

Table 4.

Overview and comparison of available systems.

The BDO Manager application was selected for further analysis because it demonstrated the highest functional coverage (11 functionalities in total, including 9 of particular relevance to the construction industry), especially in the areas of automation and reporting.

4.4. Evaluation of IT Tool Implementation Efficiency in Construction Companies

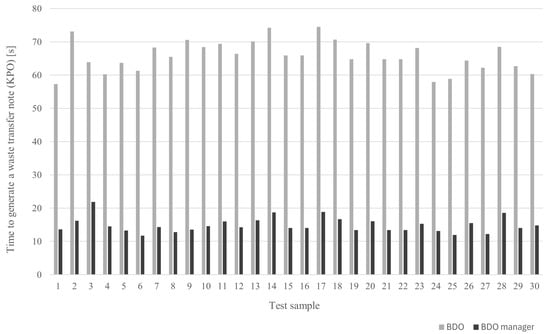

To assess the efficiency of IT tools supporting BDO operations, the operational time required to issue Waste Transfer Cards (KPO) and to create entries in the Waste Record (for both generated and transferred waste) was compared between the standard BDO system and the application [58], an industry-specific tool dedicated to the construction sector.

The study was conducted among seven construction companies that regularly handle waste management responsibilities, including the issuance of KPOs and the maintenance of waste records. A total of 30 active users of the BDO Manager application participated in the study and provided reliable data on the efficiency of both systems. Participants were asked to measure the time required to issue a Waste Transfer Card (KPO) and to create a record entry using both the official BDO system and the application.

Figure 3 presents a comparison of the time required to issue a Waste Transfer Card (KPO) using two solutions: the standard BDO system and the supporting application.

Figure 3.

Time required to issue a waste transfer card (KPO) in the BDO System and via the application. Source: Own elaboration.

Based on the measurement data collected from application users, it was determined that the average time required to issue a single KPO using the BDO system is 66.21 s (standard deviation: 7%), whereas with the application, this time is reduced to 14.92 s (standard deviation: 15%). The variability of results is low for the BDO system and moderate for the application. This variability arises from the fact that the tasks were performed by different users and, in the case of the application (where variability is higher), on different devices (laptops, mobile phones, desktop computers). However, the experiment did not record the type of device used during each measurement, which represents an interesting but unexplored research issue.

Ultimately, based on the average values, the times required to process a single document when using the application are reduced by 77.46% compared to the standard BDO system.

The second parameter analysed was the time required to create two waste record entries (transferred and generated). These entries are most frequently made by the waste sender, who also issues the KPO. When completed manually, the average time required for this operation is 49.0 s. However, when using the automatic entry generation feature provided by the application, this task requires no user intervention, resulting in a completion time of 0 s—equivalent to a 100% time saving.

The total average time saved when using the application for one KPO and two KEO entries (generated and transferred) amounts to 100.3 s, which corresponds to an 87% reduction in administrative workload in this area.

For a representative demolition company generating approximately 46,000 Waste Transfer Cards (KPO) annually, the total time savings resulting from the implementation of the IT system are estimated at 8.2 months of full-time administrative work (assuming an 8 h workday and 21 working days per month). This means that the employer avoids the cost of employing an additional full-time worker for that period.

Given a median monthly administrative salary of PLN 5810 gross [59], this translates into an annual saving of approximately PLN 47,603. After accounting for the annual subscription cost of the system (PLN 23,000), the resulting return on investment (ROI) is calculated as follows:

The obtained ROI value indicates that implementation of the analysed system results in a full return on investment in less than one year, while also generating tangible economic benefits through the reduction in administrative labour costs. In addition, qualitative benefits were observed, such as a decrease in the number of errors and the elimination of repetitive, time-consuming tasks, as confirmed by user interviews. Although errors may also occur when using the application, they are of a different nature—primarily system-level inconsistencies that are detected and corrected within the software environment. This aspect was not included within the scope of the present study but represents an interesting direction for future research.

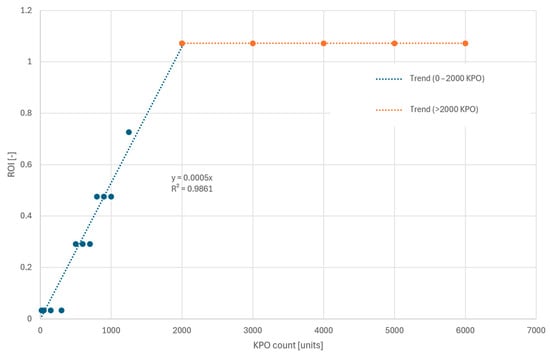

The study also included a sensitivity analysis of ROI with respect to the number of KPOs processed in the system (Figure 4).

Figure 4.

Sensitivity analysis of ROI with respect to the number of Waste Transfer Cards (KPO). Source: Own elaboration.

In the range of 0–2000 KPO, the relationship between ROI and the number of processed documents is linear (y = 0.0005x), which results from the pricing structure set by the system provider for handling individual KPOs. Above this threshold, ROI stabilises at approximately 1.07, indicating the attainment of a scale-benefit plateau driven by the minimum unit cost of processing a single document within the system. It is worth noting that even with smaller document volumes, the ROI is positive, which demonstrates the benefits of implementing the system. However, the presented ROI indicator is simplified in nature and refers solely to the system’s operational phase. The calculations include only the annual subscription cost of the application and the value of administrative working time saved as a result of reduced documentation handling time. They do not account for one-time implementation costs on the part of the company (such as system configuration, potential integration with other IT solutions, preparation of internal procedures, or user training), nor for any temporary decrease in productivity during the adaptation period.

5. Discussion and Conclusions

The following conclusions are presented in relation to the research questions formulated in the study:

RQ1. The BDO system is a cross-sectoral platform serving multiple industries, while waste record-keeping in the construction sector is inherently multi-stage. This structure generates a significant administrative workload, particularly in the case of large-scale, repetitive waste transports (e.g., excavated soil or demolition debris). In the Polish construction sector, the waste documentation process consists of two parallel, continuous activities: the circulation of KPOs and the maintenance of KEOs, along with the preparation of an annual report. In practice, the same waste stream is often transferred repeatedly—frequently involving dozens of KPOs per day—and ensuring data accuracy requires frequent corrections after weighing by the recipient. The as-is process mapping revealed a high number of manual steps and substantial sensitivity to input data errors. There is also a clear need for efficient reporting and data verification; however, retrieving information directly from the governmental BDO system remains cumbersome and time-consuming.

RQ2. The most burdensome elements of the process include: the lack of mobile functionality, the need to repeatedly select the entity/MPD, manual completion of repetitive forms, individual confirmation of multiple transports, limited search filter capabilities, manual KEO entry, and laborious reporting. Proposed improvements include user setting memory, KPO templates and duplication, batch confirmation of transports, enhanced filtering options, KEO automation, and one-click generation of annual reports.

RQ3. A total of nine IT solutions supporting waste documentation processes in Poland were identified, including mobile, web-based, desktop, and browser extension systems connected to BDO via its public API. These solutions were evaluated against 15 operationally significant functionalities. For detailed analysis, the BDO Manager application was selected due to its focus on the construction industry and its broad range of features addressing real on-site needs—such as templates, duplication, batch confirmations, KEO automation, reporting, and bulk KPO retrieval.

RQ4. The average time to issue a KPO decreases from 66.21 s (BDO) to 14.92 s (–77.46%), while KEO entries for the most common operations can be fully automated (from ~49.03 s to 0 s). Combined (KPO + two KEO entries), this results in an average time saving of approximately 100.3 s per cycle, corresponding to an 87% reduction in administrative workload. Field research conducted among seven companies (30 users) confirmed a significant reduction in processing time and a noticeable simplification of operations.

In a high-volume scenario (≈46,000 KPOs per year), the time savings amount to approximately 8.2 months of full-time administrative work annually. With a median monthly administrative salary of PLN 5810 gross, this translates into annual savings of about PLN 47,603. Given an annual subscription cost of PLN 23,000, the resulting ROI is approximately 107%. The sensitivity analysis showed that the ROI increases with the volume of processed documents and stabilises at around 107% from 2000 KPO onward.

The analysis of the BDO system (RQ1), the burdensome elements identified in the process (RQ2), and the wide range of software tools supporting waste documentation (RQ3) lead to two key conclusions:

- The national BDO platform does not directly address the specific functional needs of the construction sector. However, the decision to provide an open API was appropriate, as it enabled the development of supporting systems, including solutions with functionalities tailored to construction-industry requirements. The literature emphasises that a lack of system interoperability can hinder digitalisation efforts [33]. This study confirmed that the interoperability of the BDO system allowed external tools to be adapted to the specific needs of construction users, thereby improving the efficiency of digital document workflows.

- The lack of sector-specific profiling of the platform’s functionalities results in additional administrative burdens. Although companies may use commercially available supporting tools, this inevitably increases their operational costs.

The problems identified in the construction sector (RQ2), together with the improvements observed in existing applications (RQ3), indicate that the currently available solutions are predominantly low-technology, while also revealing considerable potential for further development. These insights may be taken into account when designing digital systems in other developing countries or in the further development of the Polish system.

Further enhancement of such systems requires their integration with on-site digital environments, as also noted in [32]. There is a growing need for consistent interfaces with BDO, as well as interoperability with BIM and digital-twin platforms and logistics–financial systems (ERP/TMS/GIS) [60], along with the inclusion of predictive analytics and quality or risk management mechanisms. Only within such an integrated framework will it be possible to move from local optimisations to a holistic digitalisation of construction waste management aligned with Circular Economy (CE) principles and the objectives of the European Green Deal. However, the literature review highlights numerous barriers hindering the implementation of these solutions. In this context, system interoperability deserves particular attention, as it is a prerequisite for effective cooperation among newly developed digital tools in construction—including those supporting processes in other operational areas, as shown in previous studies [33,34]. To ensure efficient information exchange between systems, harmonisation of data formats would be advisable.

Although cost is identified as one of the barriers in [33], well-functioning, standardised and highly efficient systems that meet user needs may, through economies of scale, overcome barriers to widespread adoption and reduce operating costs [33,34].

The findings confirm that even low-technology improvements can substantially reduce administrative workload. Integrating functionalities and enhancing interface ergonomics—without relying on advanced algorithms—already provide measurable gains in productivity and record-keeping quality. Although the improvements described to date do not require complex technological methods, incorporating selected elements of Industry 4.0 could further enhance the value of existing solutions.

One potential direction for further development is deeper system integration. Sensors installed in waste containers could monitor fill levels and, once a predefined threshold is reached, automatically generate a Waste Transfer Card (KPO) and issue a notification signalling that the waste is ready for collection. The entire process could be monitored by a system integrated with GPS transmitters, enabling real-time tracking of the transport route and automatic confirmation of each stage of the haulage process. At the waste receiver’s facility, the process could be further automated using intelligent weighing systems that automatically update the recorded waste mass and assign subsequent KPO statuses. After the service is completed, the system could automatically register it in the settlement module and transfer the relevant data to the enterprise’s ERP invoicing system. This example illustrates only one possible pathway for further automation; the design, implementation, and testing of such extended systems represent an important and promising direction for future research.

The study demonstrates that targeted automation of BDO processes significantly reduces the time and labour intensity of waste documentation, improves data quality, and minimises the risk of errors—thereby enhancing regulatory compliance and the transparency of waste flows on construction sites. The economic effect (ROI ≈ 107% in the reference scenario) indicates that implementing such a tool is financially justified, particularly for organisations handling a high volume of KPOs. The sensitivity analysis showed that the ROI decreases for enterprises managing waste documentation on a smaller scale. However, even for relatively low documentation volumes, the ROI remains positive; it should be noted, though, that it reflects only operational costs, as discussed in the limitations section.

This study has several limitations that should be acknowledged. First, the analysis was limited to one IT solution—BDO Manager—which, although representative for the construction sector, may not reflect the functionality of other tools integrated with the national waste database. Second, the BDO system itself is specific to the Polish legal and administrative framework; therefore, the results should be interpreted with caution in different regulatory contexts.

Although conclusions regarding the identified barriers were based on interviews with only 14 engineers and construction managers, they were additionally supported by observations and process analysis. It should be emphasised that no data on respondents’ age, gender, or professional experience were collected. The absence of such information limits the potential for deeper inference that might reveal correlations with digital competence levels—an issue highlighted in recent studies on AI and digital literacy, which show that barriers to technological adoption often stem from limited organisational capability, gaps in training, or insufficient digital skills among managers [61].

Finally, it should be reiterated that the reported ROI value represents a simplified estimate and refers exclusively to the operational phase of system use. The calculation accounts only for the annual subscription cost of the application and the monetary value of administrative working time saved through reduced documentation handling. It does not include one-off implementation expenses (such as system configuration, potential integration with other IT tools, preparation of internal procedures, or user training), nor does it consider any temporary decline in productivity during the adaptation period, which has been noted in the literature as a significant cost component [62].

Furthermore, the time-measurement exercise did not differentiate between users’ levels of proficiency or the types of devices used (desktop computers, laptops, mobile devices). The values used in the ROI analysis therefore represent aggregated averages across these groups and reflect typical working conditions within the surveyed companies. Consequently, the resulting ROI should be interpreted as indicative: in organisations with higher implementation costs or lower digital competencies, the actual first-year return on investment may be proportionally lower.

The results strongly confirm the thesis that digitalisation is an appropriate direction for supporting sustainable development. However, the presented ROI coefficient should not be generalised, as it is based on a case study of a specific system and a predetermined supplier price list.

Finally, the study focused primarily on administrative efficiency (time and cost reduction) rather than data-quality aspects, and it did not include long-term performance monitoring.

Author Contributions

Conceptualization, J.S.; Methodology, J.S.; Validation, J.S.; Formal analysis, J.S.; Investigation, J.S. and P.W.; Resources, J.S.; Data curation, J.S.; Writing—original draft, J.S. and P.W.; Writing—review & editing, J.S.; Visualization, J.S. and P.W.; Supervision, J.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Dataset available on request from the authors.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Appendix B

References

- European Commission. The European Green Deal. 2019. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 16 December 2025).

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, Investments, and Challenges for Enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Schmidt, G.A.; Kelley, M.; Nazarenko, L.; Ruedy, R.; Russell, G.L.; Aleinov, I.; Bauer, M.; Bauer, S.E.; Bhat, M.K.; Bleck, R.; et al. Configuration and Assessment of the GISS ModelE2 Contributions to the CMIP5 Archive. J. Adv. Model. Earth Syst. 2014, 6, 141–184. [Google Scholar] [CrossRef]

- Nowotarski, P.; Paslawski, J. Industry 4.0 Concept Introduction into Construction SMEs. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 52043. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Maresova, P.; Krejcar, O.; David, O.O. Industry 4.0 for the Construction Industry: Review of Management Perspective. Economies 2019, 7, 68. [Google Scholar] [CrossRef]

- Fatimah, Y.A.; Govindan, K.; Murniningsih, R.; Setiawan, A. Industry 4.0 Based Sustainable Circular Economy Approach for Smart Waste Management System to Achieve Sustainable Development Goals: A Case Study of Indonesia. J. Clean. Prod. 2020, 269, 122263. [Google Scholar] [CrossRef]

- Vitorino de Souza Melaré, A.; Montenegro González, S.; Faceli, K.; Casadei, V. Technologies and Decision Support Systems to Aid Solid-Waste Management: A Systematic Review. Waste Manag. 2017, 59, 567–584. [Google Scholar] [CrossRef]

- Pokorski, G.; Zaskórski, P. Systemy Informacji Geoprzestrzennej w Zarządzaniu Procesami Biznesowymi. Nowocz. Syst. Zarządzania 2018, 13, 107–127. [Google Scholar] [CrossRef]

- Mati Asefa, E.; Bayu Barasa, K.; Adare Mengistu, D. Application of Geographic Information System in Solid Waste Management; IntechOpen: London, UK, 2022. [Google Scholar]

- Hidalgo-Crespo, J.; Álvarez-Mendoza, C.I.; Soto, M.; Amaya-Rivas, J.L. Quantification and Mapping of Domestic Plastic Waste Using GIS/GPS Approach at the City of Guayaquil. Procedia CIRP 2022, 105, 86–91. [Google Scholar] [CrossRef]

- Fatimah, Y.A.; Widianto, A.; Hanafi, M. Cyber-Physical System Enabled in Sustainable Waste Management 4.0: A Smart Waste Collection System for Indonesian Semi-Urban Cities. Procedia Manuf. 2020, 43, 535–542. [Google Scholar] [CrossRef]

- Akkad, M.Z.; Haidar, S.; Bányai, T. Design of Cyber-Physical Waste Management Systems Focusing on Energy Efficiency and Sustainability. Designs 2022, 6, 39. [Google Scholar] [CrossRef]

- Schützenhofer, S.; Kovacic, I.; Rechberger, H.; Mack, S. Improvement of Environmental Sustainability and Circular Economy through Construction Waste Management for Material Reuse. Sustainability 2022, 14, 11087. [Google Scholar] [CrossRef]

- Na, S.; Heo, S.; Han, S.; Shin, Y.; Lee, M. Development of an Artificial Intelligence Model to Recognise Construction Waste by Applying Image Data Augmentation and Transfer Learning. Buildings 2022, 12, 175. [Google Scholar] [CrossRef]

- Ali, T.H.; Akhund, M.A.; Memon, N.A.; Memon, A.H.; Imad, H.U.; Khahro, S.H. Application of Artifical Intelligence in Construction Waste Management. In Proceedings of the 2019 8th International Conference on Industrial Technology and Management (ICITM), Cambridge, UK, 2–4 March 2019; pp. 50–55. [Google Scholar]

- Xiao, W.; Yang, J.; Fang, H.; Zhuang, J.; Ku, Y. A Robust Classification Algorithm for Separation of Construction Waste Using NIR Hyperspectral System. Waste Manag. 2019, 90, 1–9. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, H.; Qiu, Y.; Zheng, W. Object Detection for Construction Waste Based on an Improved YOLOv5 Model. Sustainability 2022, 15, 681. [Google Scholar] [CrossRef]

- Jin, R.; Yuan, H.; Chen, Q. Science Mapping Approach to Assisting the Review of Construction and Demolition Waste Management Research Published Between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, T.; Wang, F.; Osmani, M.; Demian, P. Blockchain Enhanced Construction Waste Information Management: A Conceptual Framework. Sustainability 2022, 14, 12145. [Google Scholar] [CrossRef]

- Sivashanmugam, S.; Rodriguez Trejo, S.; Rahimian, F. BIM-Integrated Semantic Framework for Construction Waste Quantification and Optimisation. Autom. Constr. 2024, 168, 105842. [Google Scholar] [CrossRef]

- Rehman, I.U.; Mazher, K.M.; Wuni, I.Y. Systematic Review of 4D BIM Benefits in Construction Projects. Results Eng. 2025, 28, 107091. [Google Scholar] [CrossRef]

- Schamne, A.N.; Nagalli, A.; Soeiro, A.A.V.; Poças Martins, J.P.D.S. BIM in Construction Waste Management: A Conceptual Model Based on the Industry Foundation Classes Standard. Autom. Constr. 2024, 159, 105283. [Google Scholar] [CrossRef]

- Ganiyu, S.A.; Oyedele, L.O.; Akinade, O.; Owolabi, H.; Akanbi, L.; Gbadamosi, A. BIM Competencies for Delivering Waste-Efficient Building Projects in a Circular Economy. Dev. Built Environ. 2020, 4, 100036. [Google Scholar] [CrossRef]

- Jiang, F.; Awaitey, J.; Xie, H. Analysis of Construction Cost and Investment Planning Using Time Series Data. Sustainability 2022, 14, 1703. [Google Scholar] [CrossRef]

- Twort, A.; Rees, G. Civil Engineering Project Management; Taylor & Francis Group: Abingdon, UK, 2020; ISBN 9781138470262. [Google Scholar]

- Bossink, B.A.G.; Brouwers, H.J.H. Construction Waste: Quantification and Source Evaluation. J. Constr. Eng. Manag. 1996, 122, 55–60. [Google Scholar] [CrossRef]

- Sobotka, A. Logistics of Companies and Projects Construction; Wydawnictwa AGH: Kraków, Poland, 2010; ISBN 978-83-7464-299-6. [Google Scholar]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Zillante, G. Attitudinal and Behavioural Approaches to Improving Waste Management on Construction Projects in Australia: Benefits and Limitations. Int. J. Constr. Manag. 2015, 15, 137–147. [Google Scholar] [CrossRef]

- Enobie, B.; Okwandu, A.C.; Abdulwaheed, S.A.; Iwuanyanwu, O. Effective Waste Management in Construction: Techniques and Implementation. Int. J. Appl. Res. Soc. Sci. 2024, 6, 1642–1652. [Google Scholar] [CrossRef]

- Construction Waste Management Handbook; Homestead FL, USA, 2012.

- Gálvez-Martos, J.-L.; Istrate, I.-R. 4—Construction and Demolition Waste Management. In Advances in Construction and Demolition Waste Recycling; Pacheco-Torgal, F., Ding, Y., Colangelo, F., Tuladhar, R., Koutamanis, A., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Sawston, UK, 2020; pp. 51–68. ISBN 978-0-12-819055-5. [Google Scholar]

- Iyiola, C.O.; Shakantu, W.; Daniel, E.I. Digital Technologies for Promoting Construction and Demolition Waste Management: A Systematic Review. Buildings 2024, 14, 3234. [Google Scholar] [CrossRef]

- Thirumal, S.; Udawatta, N.; Karunasena, G.; Al-Ameri, R. Barriers to Adopting Digital Technologies to Implement Circular Economy Practices in the Construction Industry: A Systematic Literature Review. Sustainability 2024, 16, 3185. [Google Scholar] [CrossRef]

- Takva, Ç.; Cudzik, J.; İlerisoy, Z.Y. Digitalization of Building Site Management in the Construction Industry. Int. J. Sustain. Constr. Eng. Technol. 2023, 14, 171–193. [Google Scholar] [CrossRef]

- BDO: Rejestr Podmiotów. Available online: https://rejestr-bdo.mos.gov.pl/Registry/Index (accessed on 24 October 2025).

- European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; European Union: Brussels, Belgium, 2008. [Google Scholar]

- Sagan, J. Selective Waste Collection on Construction Sites: Evaluation of the Current State, Legal Requirements and Market Challenges. Mater. Bud. Technol. Rynek Wykon. 2024, 1, 44–49. [Google Scholar]

- Ustawa z Dnia 17 Listopada 2021 r. o Zmianie Ustawy o Odpadach Oraz Niektórych Innych Ustaw (Dz. U. Poz. 2151 z Późn. Zm.). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20210002151 (accessed on 16 December 2025).

- Waste Act of 14 December 2012 (as Amended); 2014; p. 107. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20130000021 (accessed on 16 December 2025).

- Szewski, A.; Budziszewski, A. Ewidencja Odpadów 2025. Poradnik BDO Ewidencja Odpadów Oraz Sprawozdawczość Odpadowa; KartaEwidencji.pl: Warsaw, Poland, 2025; ISBN 978-83-956279-6-5. [Google Scholar]

- European Parliament and the Council of the European Union. Decision (EU) 2022/2481 of the European Parliament and of the Council of 14 December 2022 Establishing the Digital Decade Policy Programme 2030. Off. J. Eur. Union 2022, 1–23. [Google Scholar]

- Werner, A. BDO: Baza Danych o Produktach i Opakowaniach Oraz o Gospodarce Odpadami. Przegląd Pap. 2020, 76, 606–608. [Google Scholar]

- Sejm Rzeczypospolitej Polskiej, Ustawa z Dnia 14 Grudnia 2012 r. o Odpadach (Dz.U. 2013 Poz. 21); Sejm Rzeczypospolitej Polskiej: Warszawa, Poland, 2012; pp. 1–171.

- Sobotka, A.; Sagan, J. Cost-Saving Environmental Activities on Construction Site—Cost Efficiency of Waste Management: Case Study. Procedia Eng. 2016, 161, 388–393. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W.Y. Construction and Demolition Waste Management Contributing Factors Coupled with Reduce, Reuse, and Recycle Strategies for Effective Waste Management: A Review. J. Clean Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Sobotka, A.; Sagan, J.; Baranowska, M.; Mazur, E. Management of Reverse Logistics Supply Chains in Construction Projects. Procedia Eng. 2017, 208, 151–159. [Google Scholar] [CrossRef]

- Tam, V.W.Y. 2—Improving Waste Management Plans in Construction Projects. In Handbook of Recycled Concrete and Demolition Waste; Pacheco-Torgal, F., Tam, V.W.Y., Labrincha, J.A., Ding, Y., de Brito, J., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Sawston, UK, 2013; pp. 9–24. ISBN 978-0-85709-682-1. [Google Scholar]

- 48; Saad, A.; Bal, M.; Khatib, J. The Need for a Proper Waste Management Plan for the Construction Industry: A Case Study in Lebanon. Sustainability 2022, 14, 12783. [Google Scholar] [CrossRef]

- Ismaeel, W.S.E.; Kassim, N. An Environmental Management Plan for Construction Waste Management. Ain Shams Eng. J. 2023, 14, 102244. [Google Scholar] [CrossRef]

- Twoje BDO—Zmieniamy BDO Na Dobre. Available online: https://twojebdo.pl/ (accessed on 24 October 2025).

- Zarządzanie Odpadami—SOTEKO—Program Do Gospodarki Odpadami. Available online: https://soteko.pl/ (accessed on 24 October 2025).

- Darsoft—Oprogramowanie Do Zarządzania Ewidencją Odpadów. Available online: https://darsoft.pl/ (accessed on 24 October 2025).

- Strona Główna—Ebdo.Pl. Available online: https://ebdo.pl/ (accessed on 24 October 2025).

- SimplyBDO—Program Do Obsługi BDO. Available online: https://simplybdo.pl/ (accessed on 24 October 2025).

- Program Do Obsługi BDO. Ewidencja Odpadów. Available online: https://eko-soft.pl/ (accessed on 24 October 2025).

- Easy BDO. Available online: https://www.easybdo.pl/ (accessed on 24 October 2025).

- BDO Mobile—Szybko i Sprawnie Zarządzaj Odpadami w Swojej Firmie. Available online: https://bdomobile.com/ (accessed on 24 October 2025).

- BDO Manager—Zarządzaj Kartami Przekazania Odpadów z Dowolnego Miejsca Na Budowie. Available online: https://bdomanager.pl/ (accessed on 24 October 2025).

- Ile Zarabia Pracownik Administracji—Zarobki Pracownika Administracji—Wynagrodzenia.Pl. Available online: https://wynagrodzenia.pl/moja-placa/ile-zarabia-pracownik-administracji (accessed on 28 October 2025).

- Li, H.; Chen, Z.; Yong, L.; Kong, S.C.W. Application of Integrated GPS and GIS Technology for Reducing Construction Waste and Improving Construction Efficiency. Autom. Constr. 2005, 14, 323–331. [Google Scholar] [CrossRef]

- Benlian, A.; Pinski, M. The AI Literacy Development Canvas: Assessing and Building AI Literacy in Organizations. Bus. Horiz, 2025; in press. [Google Scholar] [CrossRef]

- Neumeyer, X.; Liu, M. Managerial Competencies and Development in the Digital Age. IEEE Eng. Manag. Rev. 2021, 49, 49–55. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.