Abstract

Cotton is a globally important economic crop and the foundational raw material for the textile industry, and the planting pattern plays a crucial role in determining both the yield and quality of cotton. The results demonstrated that compared with the use of the traditional wide–narrow row (66 + 10 cm) planting pattern, the use of uniform row spacing significantly increased cotton yield (pooled effect size = 0.09, p < 0.05; average yield increase of 9.41%) when interrow distances were homogenized to optimize the population canopy structure. Moreover, this approach comprehensively improved fiber quality, yielding an average increase of 2.02% in cotton fiber length (pooled effect size = 0.02, p < 0.001), an average increase of 8.32% in cotton breaking tenacity (pooled effect size = 0.08, p < 0.001), and an average decrease of 6.76% in the cotton micronaire value (pooled effect size = −0.07, p < 0.001). This study confirms that the use of a uniform row spacing planting pattern is a key agronomic measure for simultaneously achieving high yield and superior fiber quality in cotton, providing both theoretical and practical insights into the optimization of cotton cultivation patterns.

1. Introduction

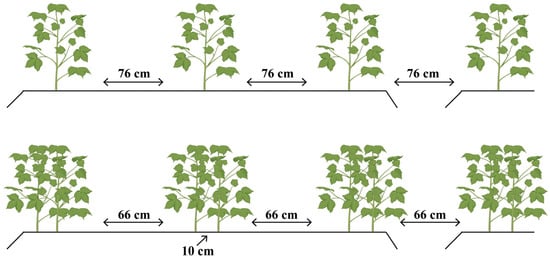

Cotton (Gossypium hirsutum), a globally important natural fiber and oilseed crop, plays a pivotal role in ensuring the supply of raw materials for the textile industry and increasing the economic returns of cotton growers. Synergistic improvements in its yield and fiber quality constitute central objectives in cotton production. In China, especially in Xinjiang, cotton is among the most important economic crops and plays a highly important role in ensuring regional economic development [1]. In 2024, the planted area of cotton in Xinjiang reached 24,479 km2, with a total output of 5.686 million tons. Currently, as the primary cotton-producing region in China, the Xinjiang cotton zone has, since the late 1990s, developed and refined a wide–narrow row (66 + 10 cm) planting pattern through years of practical production experience (Figure 1). This cultivation pattern effectively addresses the challenge of maintaining a high planting density while ensuring the feasibility of mechanical harvesting under intensive cotton cultivation conditions in Xinjiang [2]. Owing to its advantage of optimizing field ventilation and light penetration through differentiated interrow spacings, the traditional wide–narrow row configuration has long dominated cotton production. However, due to the need of mechanical harvesting for a more uniform canopy structure, the uniform row spacing (76 cm) planting pattern has received increasing attention in recent years [3]. As a critical agronomic practice in cotton cultivation, the planting pattern directly influences the population canopy structure, light energy utilization efficiency, and dry matter distribution patterns, thereby regulating yield and the stability of fiber quality in cotton [4]. Previous studies have shown that the uniform row spacing planting pattern (76 cm) increases seed cotton yield by 10.0–31.2% and lint cotton yield by 8.9–46.5% compared with the wide-narrow row pattern (66 + 10 cm) [5]. In addition to demonstrating evident advantages in cotton cultivation, the uniform row spacing pattern has been widely adopted and validated in other crops as well as in different cotton-growing regions. For instance, in maize production, uniform row spacing can increase grain yield by approximately 6% relative to wide-narrow row configurations [6]. In cotton production in Uzbekistan, a row spacing of 76 cm yields the highest rate of dry matter accumulation [7]. These cases indicate that uniform row spacing possesses universal potential for enhancing both yield and quality across diverse crops and study areas, thereby providing strong practical support for the application of this approach in cotton cultivation in the present study. However, the comprehensive effects of a uniform row spacing on fiber quality attributes, such as fiber length, breaking tenacity, and micronaire value, have not been conclusively determined in different studies. Some investigations suggest that this planting pattern has no significant adverse effects on fiber quality, whereas others emphasize that the interaction between row spacing and plant density may alter canopy microenvironments (e.g., light distribution and temperature), consequently influencing the physical properties of cotton fibers [8]. Given the existence of marked inconsistencies among previous studies regarding the effects of planting pattern on fiber quality, there is an urgent need to conduct a meta-analysis to quantitatively synthesize evidence from diverse environmental and experimental conditions, thereby clarifying the overall effect of uniform row spacing on fiber quality and identifying its potential moderating factors.

Figure 1.

Schematic illustration of the uniform row spacing (76 cm) planting pattern and the wide–narrow row (66 + 10 cm) planting pattern.

Meta-analysis is a quantitative method for synthesizing and evaluating research outcomes, in which findings from multiple studies are integrated and quantified on the basis of effect sizes to systematically assess the overall effects and factors influencing specific agricultural measures [9]. Accordingly, a systematic meta-analysis was conducted to integrate experimental data from multiple regions and cotton varieties. Using the traditional wide–narrow row (66 + 10 cm) planting pattern as the control, this study aimed to elucidate the potential of the uniform row spacing (76 cm) planting pattern in synergistically optimizing cotton yield and fiber quality, thereby providing a systematic and theoretical basis for evidence-based decision-making regarding cotton cultivation strategies in Xinjiang and across China.

2. Materials and Methods

2.1. Data Sources

To systematically collect experimental studies on the effects of planting patterns on cotton yield and fiber quality over the past decade, a comprehensive literature search was conducted in the China National Knowledge Infrastructure (CNKI) and the Web of Science Core Collection. The specific search strategies are described below.

In CNKI, an “Advanced Search” mode was employed using the “Topic” field (which covers titles, keywords, and abstracts). The search query was formulated as: (SU = ‘cotton’ OR SU = ‘upland cotton’) AND (SU = ‘planting pattern’ OR SU = ‘row spacing configuration’ OR SU = ‘wide–narrow row’ OR SU = ‘uniform row spacing’ OR SU = ‘row interval’) AND (SU = ‘yield’ OR SU = ‘fiber quality’ OR SU = ‘fiber length’ OR SU = ‘breaking tenacity’ OR SU = ‘micronaire’), with the document type restricted to “Academic Journals”.

In the Web of Science Core Collection, a combined search of “Title” and “Abstract” fields was performed. The search string was: (TS = (cotton OR “Gossypium hirsutum”) AND TS = (planting pattern* OR “row spacing” OR “wide–narrow row” OR “uniform row spacing”) AND TS = (yield OR “fiber quality” OR “fiber length” OR “breaking tenacity” OR “micronaire”)), where the asterisk (*) serves as a wildcard to capture plural forms. The document type was limited to “Article”. On this basis, in accordance with the requirements of meta-analysis and the objectives of the present study, the following inclusion criteria were established for literature screening: (1) all data must have originated from field experiments; (2) each experiment must encompass a minimum of three replicates; (3) the experimental treatments must include both the traditional wide–narrow row (66 + 10 cm) planting pattern and the uniform row spacing (76 cm) planting pattern; (4) the experimental sites must be located in Xinjiang, China; (5) the control and treatment groups must share consistent conditions in terms of location, climate, fertilization, tillage, irrigation, and other management practices; and (6) the studies must report relevant data on cotton yield and fiber quality, with available sample sizes and standard deviations. On the basis of these stringent selection criteria, 38 peer-reviewed publications (in both Chinese and English) were initially identified. After a further careful reading of the original texts, invalid data were excluded and different treatments were accounted for, leaving a final set of analysis data derived from 7 publications, comprising 24 independent fiber quality datasets and 6 yield datasets, all of which met the inclusion criteria [4,10,11,12,13,14,15] (Figure 2).

Figure 2.

The PRISMA flowchart of this study.

2.2. Data Processing

In this study, a meta-analysis was conducted with a random-effects model to evaluate the effects of different planting patterns (uniform row spacing and wide–narrow row planting patterns as the experimental group and the control group, respectively) on cotton yield, cotton fiber length, cotton breaking tenacity, and cotton micronaire value. As a method to ensure analytical reliability, the weighted response ratio (RR) was chosen as the primary statistical metric, and its natural logarithm (LnRR) was adopted to quantify the magnitude of the treatment effect exerted by a given planting pattern. These metrics can be calculated as follows [16]:

In Equation (1), adopting the cotton yield as an example, Xe represents the mean yield of cotton in the experimental group (i.e., the uniform row spacing planting pattern), and Xc represents the mean yield of cotton in the control group (i.e., the wide–narrow row planting pattern). In Equation (2), LnRR > 0 indicates a positive effect of the experimental treatment on the response variable (e.g., yield), reflecting a promoting influence; conversely, LnRR < 0 suggests a negative effect, indicating an inhibitory influence of the experimental treatment. This approach allows for a standardized and quantitative assessment of the relative performance of the uniform row spacing pattern compared with that of the conventional wide–narrow row pattern across multiple studies.

2.3. Methods for Publication Bias Assessment

Funnel plots and Rosenthal’s fail-safe number (N) were employed to quantitatively evaluate the potential publication bias in the collected studies. Publication bias was considered nonsignificant when the following criteria were simultaneously met: (1) a Rosenthal safety coefficient N > 5n + 10 (where N is the fail-safe number and n is the total number of included studies); (2) good symmetry in the funnel plot; and (3) a p value from Egger’s regression test greater than 0.05. These combined criteria provide a robust assessment of the reliability and comprehensiveness of the meta-analytic results, minimizing the risk of bias due to the selective publication of significant findings.

2.4. Statistical Analysis

The data were collected and organized using Microsoft Excel 2022, while statistical analyses were conducted using R software (version 4.5.1). Specifically, the random-effects model was applied to calculate the effect size and assess publication bias using the “metafor” package [17] in R. This approach ensured a standardized, reproducible, and statistically robust evaluation of the treatment effects across multiple studies.

3. Results

3.1. Results of Publication Bias Assessment

The fail-safe numbers (N) calculated via the Rosenthal method were 124 for cotton yield, 885 for fiber length, 1796 for breaking tenacity, and 1043 for the micronaire value, all of which are significantly higher than the empirical threshold of 5n + 10 (where n = 6, which denotes the total number of effect sizes included). These results indicate a low risk of publication bias. Furthermore, funnel plots and Egger’s regression tests revealed no statistically significant asymmetry or bias for any of the analyzed traits: cotton yield (p = 0.52 > 0.05), cotton fiber length (p = 0.92 > 0.05), cotton breaking tenacity (p = 0.188 > 0.05), or the cotton micronaire value (p = 0.096 > 0.05) (Figure 3A,C,E,G). These findings further support the absence of systematic publication bias in the effect size estimates reported in the included studies. Additionally, Q–Q plots showed that the majority of the data points fell within the shaded 95% confidence intervals and were generally aligned along a straight line, indicating a good fit between the sample data and the theoretical distribution (Figure 3B,D,F,H).

Figure 3.

Funnel plots and Q–Q plots: (A,B) represent cotton yield; (C,D) represent the cotton fiber length; (E,F) represent the cotton breaking tenacity; and (G,H) represent the cotton micronaire value.

In summary, the results of the current meta-analysis demonstrate that the collected literature on cotton yield and fiber quality is robust and has controllable publication bias, thereby ensuring the reliability and validity of the conclusions of the meta-analysis.

3.2. Effects of Different Planting Patterns on the Cotton Yield

The forest plot revealed that the use of a uniform row spacing (76 cm) planting pattern significantly increased the cotton yield (Figure 4). The pooled effect size for this treatment group was 0.09 (p < 0.05), demonstrating that, compared with the traditional wide–narrow row (66 + 10 cm) planting pattern, the uniform row spacing pattern led to an average increase in yield of approximately 9.41%. The corresponding heterogeneity statistics were Q = 12.56, I2 = 54.23%, and τ2 = 0.93. These findings highlight the positive effect of an optimized row configuration on productivity in cotton production systems.

Figure 4.

Effect sizes of the yield of cotton cultivated in different planting patterns [11,13,15]. CK denotes the wide–narrow row (66 + 10 cm) planting pattern, and T represents the uniform row spacing (76 cm) planting pattern. The diamond represents the pooled effect size and its 95% confidence interval. The red solid line represents the reference line, which is the point where the effect size is 0. The dashed line indicates the position of the pooled effect size.

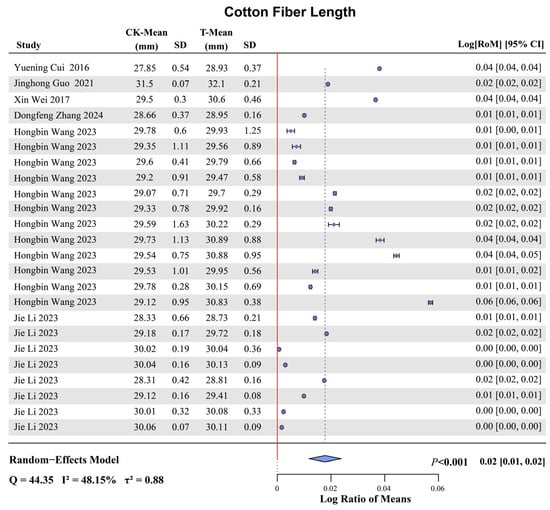

3.3. Effects of Different Planting Patterns on Cotton Fiber Length

The forest plot revealed that the use of a uniform row spacing (76 cm) planting pattern significantly increased the cotton fiber length (Figure 5). The pooled effect size for this treatment group was 0.02 (p < 0.001), indicating that, compared with the traditional wide–narrow row (66 + 10 cm) planting pattern, the uniform row spacing pattern led to an average increase in fiber length of approximately 2.02%. The corresponding heterogeneity statistics were Q = 44.35, I2 = 48.15%, and τ2 = 0.88.

Figure 5.

Effect sizes of the fiber length of cotton cultivated in different planting patterns [4,10,11,12,13,14]. CK denotes the wide–narrow row (66 + 10 cm) planting pattern, and T represents the uniform row spacing (76 cm) planting pattern. The diamond represents the pooled effect size and its 95% confidence interval. The red solid line represents the reference line, which is the point where the effect size is 0. The dashed line indicates the position of the pooled effect size.

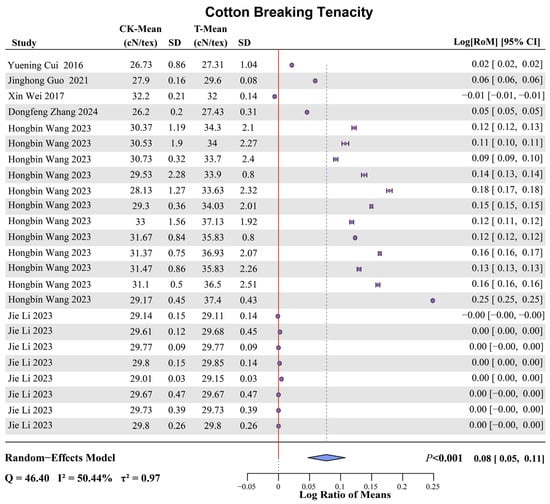

3.4. Effects of Different Planting Patterns on the Cotton Breaking Tenacity

The forest plot indicated that the use of a uniform row spacing (76 cm) planting pattern significantly increased the cotton breaking tenacity (Figure 6). The pooled effect size for this treatment group was 0.08 (p < 0.001), demonstrating that, compared with the traditional wide–narrow row (66 + 10 cm) planting pattern, the uniform row spacing pattern led to an average increase in breaking tenacity of approximately 8.32%. The corresponding heterogeneity statistics were Q = 46.30, I2 = 50.44%, and τ2 = 0.97.

Figure 6.

Effect sizes of the breaking tenacity of cotton cultivated in different planting patterns [4,10,11,12,13,14]. CK denotes the wide–narrow row (66 + 10 cm) planting pattern, and T represents the uniform row spacing (76 cm) planting pattern. The diamond represents the pooled effect size and its 95% confidence interval. The red solid line represents the reference line, which is the point where the effect size is 0. The dashed line indicates the position of the pooled effect size.

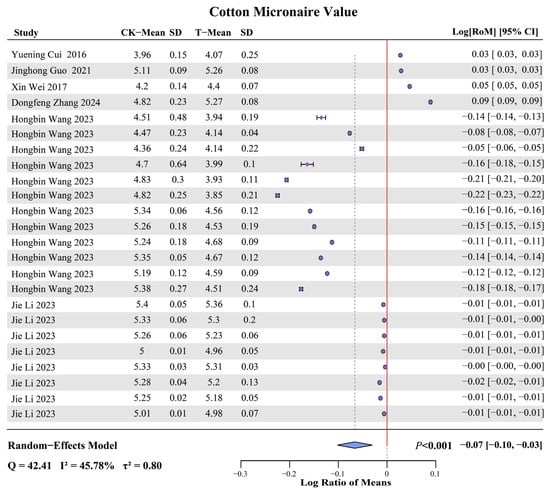

3.5. Effects of Different Planting Patterns on the Cotton Micronaire Value

The forest plot revealed that the use of a uniform row spacing (76 cm) planting pattern significantly reduced the cotton micronaire value (Figure 7). The pooled effect size for this treatment group was −0.07 (p < 0.001), indicating that, compared with the traditional wide–narrow row (66 + 10 cm) planting pattern, the uniform row spacing pattern led to an average decrease in the micronaire value of approximately 6.76%. The corresponding heterogeneity statistics were Q = 42.41, I2 = 45.78%, and τ2 = 0.80.

Figure 7.

Effect sizes of the micronaire value of cotton cultivated in different planting patterns [4,10,11,12,13,14]. CK denotes the wide–narrow row (66 + 10 cm) planting pattern, and T represents the uniform row spacing (76 cm) planting pattern. The diamond represents the pooled effect size and its 95% confidence interval. The red solid line represents the reference line, which is the point where the effect size is 0. The dashed line indicates the position of the pooled effect size.

4. Discussion

4.1. Effects of Different Planting Patterns on Cotton Yield

In this study, the meta-analysis showed that compared with the traditional wide–narrow row (66 + 10 cm) planting pattern (pooled effect size = 0.09, p < 0.05), the use of the uniform row spacing (76 cm) planting pattern significantly increased the cotton yield, corresponding to an average increase in yield of 9.41%. These findings are consistent with current research on the effects of the row configuration on the crop canopy architecture and resource use efficiency and further indicate the potential advantages of uniform row spacing patterns in high-yield cotton production patterns.

The conventional wide–narrow row (66 + 10 cm) planting pattern was originally designed to balance population density and individual growth space through the principle of the use of narrow rows for density promotion and the use of wide rows for ventilation. However, an excessively narrow row spacing may exacerbate plant lodging in the mid-to-late growth stages, leading to reduced canopy light transmittance, particularly insufficient light interception by lower-canopy leaves [18]. In contrast, the uniform row spacing (76 cm) planting pattern establishes more regular plant distribution through standardized interrow distances, fostering a top–middle–bottom three-dimensional light reception structure in the crop canopy. Research has shown that compared with wide–narrow row patterns, uniform row spacing patterns significantly increase photosynthetically active radiation (PAR) interception by upper-canopy leaves [19] while delaying light attenuation in the middle and lower canopy layers, thereby improving the overall light energy utilization efficiency. Hu et al. further confirmed that this planting pattern significantly increased both the radiation use efficiency (RUE) and lint yield in cotton production in Xinjiang [20]. The increase in yield (9.41%) observed in this study likely stems directly from improved canopy photosynthetic efficiency that was achieved through an optimized dynamic distribution of the leaf area index (LAI), which extends the effective photosynthetic duration of functional leaves and subsequently facilitates the translocation and accumulation of photosynthates to cotton bolls [21].

The row spacing not only influences the aboveground population structure but also regulates root growth by altering tillage practices and rhizosphere microenvironments. The wide–narrow row (66 + 10 cm) planting pattern, characterized by frequent mechanized operations (such as intertillage and topdressing) in narrow rows, tends to cause root damage. Moreover, narrow row zones present increased risks of soil compaction, which restricts root penetration and lateral expansion [22]. In contrast, the uniform row spacing (76 cm) planting pattern minimizes differential mechanical interference with roots through standardized row intervals. When combined with modern precision sowing techniques (e.g., drip irrigation under mulch), this configuration facilitates more uniform root development in homogeneous soil environments. Research has demonstrated that compared with a wide–narrow row pattern, a uniform row spacing pattern promotes greater taproot depth and lateral root density [23], deeper taproots enable the root system to access stored water in deep soil layers during late growth stages or under drought conditions, thereby improving water use efficiency—an advantage that is particularly critical in arid cotton-growing regions such as Xinjiang. Meanwhile, the increase in lateral root density not only expands the horizontal range of water absorption but also significantly enhances the contact area between roots and soil particles, thereby strengthening the uptake capacity for mobile nutrients such as nitrate nitrogen (NO3−-N) as well as relatively immobile ions such as potassium (K+). This advantage becomes particularly critical under drought or saline–alkali stress conditions, where plants cultivated in a uniform row spacing pattern exhibit more pronounced resilience and yield stability. The yield-enhancing effect observed in this study may be attributable to improved root vigor, which increases the efficient uptake of essential nutrients (such as nitrogen and potassium) and water use efficiency. Additionally, the wide–narrow row pattern, with its excessive seeding holes, reduces the mulching effect of plastic film on soil temperature during the early growth stage, consequently delaying seedling establishment and early-season growth.

Modern cotton production is highly mechanized and requires precise alignment between row spacing configurations and the operational parameters of agricultural machinery used for seeding, topping, and harvesting. The traditional wide–narrow row (66 + 10 cm) planting pattern, characterized by substantial interrow variability, demands high adaptability from machinery (e.g., narrow-row planters for dense seeding and wide-row cultivators for interrow operations), which often leads to compromised operational efficiency or mechanical damage (such as an excessively high seeding density in narrow rows or missed cultivation in wide rows). In contrast, the uniform row spacing (76 cm) planting pattern simplifies the machinery design and operational procedures through standardized row intervals, thereby reducing management costs [24].

4.2. Effects of Different Planting Patterns on the Cotton Fiber Quality

On the basis of the results of the meta-analysis, this study systematically evaluated the comprehensive effects of the uniform row spacing (76 cm) planting pattern on cotton fiber quality, including fiber length, breaking tenacity, and micronaire value. The findings revealed that, compared with the traditional wide–narrow row (66 + 10 cm) planting pattern, the uniform row spacing pattern significantly improved fiber quality: the fiber length increased by an average of 2.02% (pooled effect size = 0.02, p < 0.001), the breaking tenacity increased by 8.32% (pooled effect size = 0.08, p < 0.001), and the micronaire value decreased by 6.76% (pooled effect size = −0.07, p < 0.001). These results indicate that the row spacing configuration not only serves as a critical factor for regulating yield but also constitutes an essential agronomic measure for optimizing fiber quality. The underlying mechanisms involve synergistic improvements in canopy microenvironment regulation, physiological metabolic processes, and fiber development dynamics.

The fiber length is primarily determined by the elongation rate of fiber cells during the early boll development stage (20–30 days post-anthesis) and is highly sensitive to the light intensity, temperature, and canopy ventilation conditions [25]. In the traditional wide–narrow row (66 + 10 cm) planting pattern, the excessively narrow row spacing leads to progressive canopy closure in the mid-to-late growth stages, markedly reducing light availability in the middle and lower canopy layers, particularly under cloudy conditions or in high-density planting scenarios [26]. This decline in light not only lowers photosynthetic efficiency but also inhibit the activity of fiber elongation-related enzymes (e.g., β-1,3-glucanase and expansins), thereby constraining the potential for fiber elongation [27]. In contrast, the uniform row spacing (76 cm) planting pattern optimizes the canopy architecture through standardized interrow distances, increasing the proportion of diffuse light and light transmittance in the lower canopy, which promotes the translocation of photosynthates to reproductive organs [28]. This provides enhanced energy and substrate supply for fiber cell elongation and mitigates adverse effects of high temperature and humidity, accounting for the observed 2.02% increase in fiber length in the present study.

Breaking tenacity, a core indicator of fiber mechanical properties, depends on fiber cell wall thickness, the compactness of the cellulose microfibril arrangement, and the contents of non-cellulosic components such as lignin and hemicellulose [29]. In the wide–narrow row planting pattern, high plant density and poor canopy ventilation during later growth stages generate a microclimate characterized by elevated daytime temperatures (2–3 °C higher than in wide row patterns) and relative humidity (10–15% higher than in wide row patterns), directly disrupts the developmental processes of fiber cells [3]. Higher temperatures accelerate polysaccharide (e.g., hemicellulose and pectin) degradation in the cell wall matrix, weakening interfibrillar bonding, whereas excess humidity induces cell wall swelling and increases microfibril spacing, resulting in a looser arrangement [30,31]. In contrast, the uniform row spacing (76 cm) planting pattern substantially improves canopy ventilation, temperature stability, and humidity, thereby suppressing excessive deposition of non-cellulosic components and favoring denser, more ordered microfibril packing, which enhances fiber strength. This mechanism is consistent with the findings of Zuo et al. [32], who reported greater fiber strength under uniform row spacing, and explains the 8.32% increase in breaking tenacity observed here.

Micronaire value, an integrative index of fiber fineness and maturity (lower values indicating finer and more mature fibers), is fundamentally determined by the thickness of the fiber cell wall (maturity) and single-fiber diameter (fineness) [33]. In the traditional wide–narrow row planting pattern, narrow-row canopy closure limits light exposure of middle and lower bolls, leading to inadequate cell wall thickening after elongation (reduced maturity) and a larger single-fiber diameter (poorer fineness), typically producing micronaire values > 4.5, indicative of overmature or unevenly immature fibers [34]. In contrast, the uniform row spacing planting pattern improves light and temperature conditions, prolonging the cell wall thickening phase, thereby enhancing maturity and optimizing fineness. The 6.76% reduction in micronaire value observed in this study directly reflects this mechanism.

The fiber length, breaking tenacity, and micronaire value constitute the core indices for classifying cotton quality, and encompass interrelated yet distinct regulatory mechanisms (Figure 8). The synchronous optimization of these three indicators under the uniform row spacing (76 cm) planting pattern in this study demonstrated the comprehensive regulatory effect of the row spacing configuration on multidimensional fiber development. For premium cotton types (such as long-staple cotton or mid-to-high-end machine-harvested cotton), the coordinated enhancement in these parameters can markedly increase the market value of the fiber. Accordingly, the uniform row spacing pattern represents an important agronomic practice for synchronizing high yield with superior quality, and is particularly applicable to major high-quality cotton production regions such as Xinjiang, China.

Figure 8.

Mechanistic schematic showing yield and fiber quality variations under two planting patterns. Blue arrows indicate increases, and red arrows indicate decreases.

5. Limitations

This study has several limitations. First, heterogeneity across outcomes was moderate, indicating variation in true effects among studies, possibly due to site-specific factors such as soil type, experimental year, and cultivar, which may influence crop response to row spacing configurations. Second, the limited number of included studies and the predominance of trials under similar management practices precluded formal subgroup analyses, restricting our ability to explore sources of heterogeneity in depth. Therefore, caution is needed when interpreting pooled effects, and results should be considered applicable primarily to environments and management contexts similar to those of the included studies. Future well-designed comparative trials across a wider range of ecological zones and cultivation conditions are needed to identify moderators of row spacing effects, reduce heterogeneity, and enhance the generalizability of findings.

6. Conclusions

This meta-analysis demonstrates that, compared with the conventional wide–narrow row (66 + 10 cm) planting pattern, uniform row spacing (76 cm) significantly increases cotton yield and leads to comprehensive improvements in fiber quality, exhibiting a synergistic advantage of simultaneously enhancing yield and quality. This beneficial effect is primarily attributable to the integrated improvements in canopy architecture and root growth conditions conferred by the uniform row spacing pattern. It should be noted that a certain degree of heterogeneity exists among studies, which may be influenced by factors such as soil type, experimental year, and cultivar; accordingly, cautious evaluation is warranted when extending these findings to other contexts, taking local conditions into account. Future well-designed comparative trials conducted across a broader range of ecological zones and cultivation environments are needed to elucidate the regulatory mechanisms underlying row spacing effects and to enhance the generalizability of the conclusions, thereby providing a more robust theoretical and technical foundation for the coordinated achievement of high yield and high quality in cotton production.

Author Contributions

T.M.: Writing—review and editing, Formal analysis. R.H.: Writing—review and editing, Formal analysis. P.Z.: Resources, Project administration, Conceptualization. T.Z.: Resources, Data curation. S.L.: Resources, Data curation. T.O.: Resources, Data curation. J.L.: Resources, Data curation. P.M.: Supervision, Project administration, Conceptualization. T.M. and R.H. contributed equally to this work. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Xinjiang Tianshan Talent Training Program (2023TSYCTD004), Research and Demonstration on Key Cultivation Technologies for Cotton Quality Improvement (2024SNGGNT077), the Xinjiang Science and Technology Major Project (2023A02003–6), and the National Key Research and Development Program Project (2024YFD2300604).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Liang, Y.; Li, X.; Zheng, J.; Gong, Z.; Ai, X.; Guo, J.; Maimaiti, M.; Wang, J. Overview of Cotton Industry Situation and Existing Problems and Strategies in Xinjiang in 2019. Cotton Sci. 2020, 42, 14–20. [Google Scholar] [CrossRef]

- Sun, W.; Yang, B.; Gao, Z.; Zhou, L. Analysis of Mechanical Harvest Situation and Restricting Factors of Cotton. J. Chin. Agric. Mech. 2013, 34, 9–13. [Google Scholar] [CrossRef]

- Zhang, X.; Song, M.; Wang, X.; Pang, N.; Zhang, H.; Gui, H.; Dong, Q. Overview of the Cotton Planting Pattern “Kuanzaoyou” in Xinjiang. China Cotton 2021, 48, 1–4. [Google Scholar] [CrossRef]

- Wei, X.; Xu, J.; Zhang, J. Effects of Planting Patterns on Dry Matter Accumulationand Quality of Machine-Harvesting Cotton. Xinjiang Agric. Sci. 2017, 54, 1177–1184. [Google Scholar]

- Li, J.; Wu, P.; Xiao, S.; Cui, J.; Zhang, J. Effects of Cotton Planting Modes with Machine Picking on Defoliationand Fiber Quality of Different Plant Types. Agric. Res. Arid Areas 2019, 37, 82–88. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, X.; Chen, S.; Shao, L.; Sun, H.; Niu, J. Increasing the Planting Uniformity Improves the Yield of Summer Maize. Agron. J. 2017, 109, 1463–1475. [Google Scholar] [CrossRef]

- Muhammadov, Y.; Salomov, S.; Salomov, I. Effect of Plant Thickness and Cotton Row Spacing on Dry Mass Accumulation. BIO Web Conf. 2024, 82, 02032. [Google Scholar] [CrossRef]

- Xu, X. Effect of Row Spacing Pattern on Machine-Harvested Cotton Yield Formation and Harvest Quality. Master’s Thesis, Xinjiang Agricultural University, Urumqi, China, 2015. Available online: https://kns.cnki.net/kcms2/article/abstract?v=hyKDWyHWvTsOP9HndVxvhxBZSt5dTRE2dvLE8XKK1CGaLuXXlQGTnGhvz14TCpAqwkmapw28KUlSeeNqpD7C8WsuRnnqJ5Ae3H00aW5tvasWZEP8GgGpVqsdty2dFlQ4j04vW_mV_VJ3o9ykafddVcPjzCxbkd-Fdvkyol_aw3EwNIK47a67iv68qxjPF9CjB0nt8MU5FRw&uniplatform=NZKPT&captchaId=95470230-e8bb-4a49-a5a1-d3fd388dabe6.

- Pigott, T.D.; Polanin, J.R. Methodological Guidance Papers: High-Quality Meta-Analysis in a Systematic Review. Rev. Educ. Res. 2019, 90, 24–46. [Google Scholar] [CrossRef]

- Wang, H.; He, L.; Zhang, D.; Song, M.; Wang, H.; Wang, Z.; Liu, H. Effects of Different Plant Spacings on the Growth, Yield and Fiber Quality of Cotton Underthe “Kuanzaoyou” Planting Pattern. Cotton Sci. 2023, 35, 459–472. [Google Scholar] [CrossRef]

- Guo, J.; Zhao, H.; Yao, Y.; Li, Y. Effects of Different Planting Patterns on Main Agronomic Characters, Yield and Fiber Quality Ofthe Machine-Picking Cotton in Northern Xinjiang. China Cotton 2021, 48, 20–23. [Google Scholar] [CrossRef]

- Li, J.; Ma, T.; He, H.; Bian, Y.; Guo, L.; Guo, J.; Gulinuer, A.; Paerhati, M.; Tuerxunjiang, M.; Lou, S.; et al. Effects of Different Water Treatments on Evapotranspiration, Yield and Quality of Cotton under Two Types of Machine-Harvesting Planting Patterns. Acta Agric. Boreali-Occident. Sin. 2023, 32, 1555–1565. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, H.; He, L.; Mao, P.; Wu, X. Effects of Fully Biodegradable Mulching Film on Yield and Fiber Quality of K07-12 Under Differentcotton Planting Modes. China Cotton 2024, 51, 15–20. [Google Scholar] [CrossRef]

- Cui, Y.; Gao, Z.; Yang, B. Quality Analysis of Different Mechanical Harvesting Cotton Planting Patterns. J. Chin. Agric. Mech. 2016, 37, 235–240. [Google Scholar]

- Zhai, M. The Effects of DPC on Cotton Yield Formation and Fiber Qualityunder Different Planting Patte. Master’s Thesis, Xinjiang Agricultural University, Urumqi, China, 2023. [Google Scholar]

- Hedges, L.V.; Gurevitch, J.; Curtis, P.S. The Meta-Analysis of Response Ratios in Experimental Ecology. Ecology 1999, 80, 1150–1156. [Google Scholar] [CrossRef]

- Viechtbauer, W. Conducting Meta-Analyses in R with the Metafor Package. J. Stat. Softw. 2010, 36, 1–48. [Google Scholar] [CrossRef]

- Wang, X.; Liu, A.; Zou, X.; Xiang, F.; Ouyang, Y. Effects of Cultivation Measure on Canopy Structureand Canopy Apparent Photosynthesis. Crop Res. 2015, 29, 122–127. [Google Scholar] [CrossRef]

- Li, J.; Wang, C.; Liang, F.; Chen, H.; Tian, J.; Kang, P.; Zhang, W. Row Spacing and Planting Density Affect Canopy Structure and Yield in Ma-Chine-Picked Cotton in Xinjiang. Cotton Sci. 2017, 29, 157–165. [Google Scholar] [CrossRef]

- Hu, L.; Pan, X.; Wang, X.; Hu, Q.; Wang, X.; Zhang, H.; Xue, Q.; Song, M. Cotton Photosynthetic Productivity Enhancement through Uniform Row-Spacing with Optimal Plant Density in Xinjiang, China. Crop Sci. 2021, 61, 2745–2758. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Z.; Yu, S.; Li, S.; Fang, J.; Tong, W. Effects of Planting Density on Canopy Photosynthesis, Canopystructure and Yield Formation of High-Yield Cottonin Xinjiang, China. Acta Phytoecol. Sin. 2004, 28, 164–171. [Google Scholar]

- Li, S.; Wang, C.; Wang, C.; Zhang, W. Studies on the Root Growth of High-Yield Cotton in North Xinjiang I The Distribuding Pattern and Construction of Root System. J. Shihezi Univ. Sci. 1999, 3, 15–25. [Google Scholar] [CrossRef]

- Luo, L.; Xiao, Q.; Dong, H.; Xu, W.; Li, P.; Ma, Y.; Sun, M.; Shao, J.; Zhang, Y.; Zheng, C. Response of Cotton Root Distribution to Irrigation Frequency under the One Film-Threerows Cultivation Mode in Southern Xinjiang. Cotton Sci. 2023, 35, 51–62. [Google Scholar] [CrossRef]

- Ou, H.; Xi, Y.; Ma, H.; Aimaierjiang, A.; Dai, L.; Li, X.; Liu, R.; Luo, D.; Zhu, G.; Chen, J. Effects of the “Kuanzaoyou” Cotton Planting Pattern on the Growth, Yield and Fiber Quality ofXinluzhong 40 in Aksu Prefecture, Xinjiang. China Cotton 2024, 51, 17–22. [Google Scholar] [CrossRef]

- Liu, L.; Li, C.; Hu, F.; Zhao, J.; Zameer, R.; Li, J.; Yu, C.; Shi, H.; Li, Z.; Song, C.-P.; et al. Enhancements in Cotton Fiber Length Phenotyping and Optimization of Weighted Gene Co-Expression Network Analysis through Fiber Elongation Rate Metrics. New Crops 2026, 3, 100080. [Google Scholar] [CrossRef]

- Zhao, D.; Oosterhuis, D.M. Cotton Responses to Shade at Different Growth Stages: Growth, Lint Yield and Fibre Quality. Exp. Agric. 2000, 36, 27–39. [Google Scholar] [CrossRef]

- Fan, Y.; Lin, S.; Lyu, Y.; Shang, H.; Yuan, Y.; Tang, Z.; Jiao, C.; Chen, A.; Xing, P.; Zhang, L.; et al. The Plasmodesmata-Associated β-1,3-Glucanase Gene GhPdBG Regulates Fiber Development in Cotton. Crop J. 2023, 11, 1665–1674. [Google Scholar] [CrossRef]

- Li, L.; Dong, H.; Li, P.; Tian, L.; Li, C.; Ma, Y.; Zhang, N.; Wang, F.; Xu, W. Effects of Machine Harvesting Planting Methods on PhotosyntheticCharacteristics and Dry Matter Accumulation of Different PlantTypes of Cotton. J. Agric. Sci. Technol. 2022, 24, 172–181. [Google Scholar] [CrossRef]

- Berkley, E.E. Cotton—A Versatile Textile Fiber. Text. Res. J. 1948, 18, 71–88. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; He, S.-P.; Xu, S.-W.; Li, L.; Zheng, Y.; Li, X.-B. The Transcription Factor ERF108 Interacts with AUXIN RESPONSE FACTORs to Mediate Cotton Fiber Secondary Cell Wall Biosynthesis. Plant Cell 2023, 35, 4133–4154. [Google Scholar] [CrossRef]

- He, Q.; Yu, Y.; Qin, Z.; Duan, Y.; Liu, H.; Li, W.; Song, X.; Zhu, G.; Shang, X.; Guo, W. COBRA-LIKE 9 Modulates Cotton Cell Wall Development via Regulating Cellulose Deposition. Plant Physiol. 2024, 197, kiae675. [Google Scholar] [CrossRef]

- Zuo, W.; Wu, B.; Wang, Y.; Xu, S.; Chen, M.; Liang, F.; Tian, J.; Zhang, W. Optimal Row Spacing Configuration to Improve Cotton Yield or Quality Is Regulated by Plant Density and Irrigation Rate. Field Crops Res. 2024, 305, 109187. [Google Scholar] [CrossRef]

- Foulk, J.A.; McalisterIII, D.D. Single Cotton Fiber Properties of Low, Ideal, and High Micronaire Values. Text. Res. J. 2002, 72, 885–891. [Google Scholar] [CrossRef]

- Lai, Y.; Guo, C.; Zhan, D.; Su, L.; Wu, X. Effect of Different Planting Density on Yield and Fiber Quality of Cotton in Xinjiang. China Cotton 2019, 46, 16–18. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.