Abstract

Tertiary buildings, characterized by temporary uses and frequent renovations of internal spaces, present some criticalities in terms of the consumption of materials that quickly become waste, despite their high residual value, not exploited for further use. The goal of rethinking the life cycle of building products, and related construction systems, enabling multiple cycles of use and extending the life span of the products, presupposes new Organizational Models and changes throughout the whole building process. This paper presents two Pilot Projects (developed within Re-NetTA research), which experiment with innovative Organizational Models and disassembly construction solutions in the tertiary building sector with the goal of extending the life cycle of materials and products through reusing and remanufacturing. The Pilot Projects involve two key operators: a manufacturer and a Third Sector organization. The paper highlights the fundamental key role of digital technologies by analyzing the following: (i) the development of virtual models to understand the technical feasibility for disassembly and to foresee reuse and remanufacturing scenarios; and (ii) the use of digital twin, augmented reality, and web-based platforms as a support tools, to put the products on a virtual market to reach customers before the activities of remanufacturing. Finally, the enabling conditions for improving circularity are discussed in terms of design process, environmental and economic sustainability assessment, and operator networking.

1. Introduction

The European policies related to climate neutrality and circular economy transition emphasize the importance of reducing waste generation and consumption of virgin materials by increasing resource efficiency [1,2].

The construction sector is to achieve a circular and sustainable transition, because, at the European level, it is responsible for approximately 50% of all material extraction and 38.4% of total waste generation [3]. It is also responsible for 40% of primary energy demand in the EU and 36% of energy-related greenhouse gas emissions [4].

Circular strategies and practices can provide a large number of materials and products requested by the building sector, avoiding waste production and new resource consumption [5]. The construction sector’s transition to circularity presents an opportunity to rethink the life cycle management of materials and process flows of the built environment. The built environment can be considered a resource stock (“materials bank”), suitable for “urban mining” activities, where materials are collected not only for recycling, but also for building products and systems suitable for reuse or remanufacturing [6].

To close the cycle of materials and components, reuse and remanufacturing strategies are considered more sustainable than recycling. In fact, while recycling involves reprocessing of the materials, with non-negligible energy and material consumption, reuse and remanufacturing require minor reworks, with very limited impacts. Reuse and remanufacturing strategies can extend the useful life of products and, consequently, of buildings, by allowing multiple cycles of use, with limited materials and energy consumption and minimal waste generation [7]. This scenario brings economic and environmental benefits.

According to the standard BS 8887-2:2009 (Design for manufacture, assembly, disassembly, and end-of-life processing. Terms and definitions) [8], reuse is the operation by which a product, at the end of its useful life, is put back into use for the same purpose, while remanufacturing is the process that restores a used product to at least its original performance and provides it with a warranty that is equal to or greater than that of a newly manufactured equivalent. Instead, recycling concerns the process by which the waste is transformed (through industrial processes) into a secondary material to fulfill its original purpose or other purposes. However, at present, the full development of circularity in the built environment still meets barriers and obstacles due to some sector-specific characteristics, listed below, based on the literature’s findings and stakeholder interviews.

Product manufacturing involves a complex supply chain, acting both locally and globally, often with multiple intermediate processes and complex distribution networks, preventing reverse logistics. Generally, manufacturers are not involved in the management of the entire life cycle of their products, once sold products change ownerships after production and the manufacturer usually does not collect feedback information about their use, maintenance, or performance degradation. They do not consider the residual economic and performance value of end-of-life products and the advantages of improving their durability and prolonging their use [9].

Stakeholders in the construction value chain collaborate temporarily and are not used to establishing stable relationships over time: this hinders the activation of synergies along the product life cycle and networking among stakeholders [10]

Moreover, the long life of buildings does not facilitate the life cycle management of materials/products and leads to significant difficulties in predicting the resources available and the opportunities for recovery at the end of their useful life [11].

In addition, while dry-assembled solutions allow for the maintenance of high-quality product performance also after disassembly activities, facilitating reuse and remanufacturing activities, widespread traditional construction techniques, consisting of non-reversible solutions, hinder the ability to easily collect products or components from the “building materials bank”. Most construction and demolition waste consist of heterogeneous materials and, as a result, end-of-life products are usually disposed of in landfills or are downcycled/recycled [12,13].

- Considering these current obstacles, it is possible to underline the challenges and solutions for practical implementation [14]. Development to extend and intensify the use of products through reuse and remanufacturing in the construction sector requires new approaches and procedures, particularly in terms of new operational and Organizational Models and new relationships among operators, alongside all the process phases (design, construction, use, and end-of-life). In order to propose and apply these new models (different from those existing in traditional supply chains), it is necessary to implement not only new technical capabilities, but also new organizational capabilities, to share practices and to boost win–win relationships among operators (e.g., manufacturers, suppliers, customers, and other stakeholders of a value-chain) [15,16].

- Changes in the design of construction systems, with the improvement of the existing one and the development of new techniques, boosting dry-assembled and reversible solutions that facilitate the collection of end-of-useful-life building products and their reuse and remanufacturing in multiple life cycles [17] toward zero waste generation.

- Definition of tracking and classification methods (e.g., OmiClass System ISO 12006-2 standard [18]) of the elements to document and collect incrementally, through all phases of the life cycle of the building elements, the properties of the components, their changes/degradation, and the modifications made to the building as a whole (maintenance, replacements, requalification) [19].

- The definition of new Organizational Models requires, in particular, the “management” of the entire life of products, creating a chain of operators who take care of the extension of their use. These models are already applied in other sectors but are difficult to transfer to the construction sector. The most significant barrier is the long lifespan of buildings, which hinders to “follow” the entire life cycle of products (up to their end-of-life) and establish stable relationships between operators in managing them.

- However, tertiary buildings, characterized by temporary uses of spaces (offices, shops, and fairs, etc.) and frequent replacement cycles of building elements, can be a possible field of interested for applying circular improvements. In these cases, reuse and remanufacturing strategies and new operational and Organizational Models can be a promising perspective also considering that many building products with a very short “use” period and presenting non-degraded materials, still have acceptable performances and a high residual value but are currently disposed [14].

In particular, some temporary events (such as Expo, Olympics, fairs, design week/fashion week, temporary shops, exhibitions, concerts, and sports competitions) lasting a few months, weeks, or days, are particularly critical in terms of material flows management. In these cases, the very short use phase of products leads to the disposal of components that are still in excellent condition and are high performing. To provide an example, FieraMilano (an Italian fair) produces about 15,000 tons of waste per year [20]. In this context, the elements most frequently disposed of are flooring, vertical panels, and fittings that are mainly made up of materials such as textile (from carpets), plastic panels, wood/composite panels, paper, and cardboard, and that can at least be recycled as materials, but could also be reused and remanufactured as products.

Furthermore, office, retail, accommodation facilities, and hotels are characterized by frequent re-layouts of the indoor spaces due, for example, to changes in ownership (due to shortened lease contracts) or to the need for rebranding or restyling of corporate images. Also, in these cases, products that are still in good condition often become waste and are disposed of in landfills; this regards not only furniture but also building products such as interior finishes (movable walls, ceiling and flooring systems, plasterboard, carpet, ceramic flooring, acoustic insulation, and plastic coverings).

Circularity in the life cycle management of materials and building products, leveraging particularly on reuse and remanufacturing strategies, could be of economic interest to operators in the tertiary building sector. However, there are still many challenges to face in terms of legislative framework, economic condition, and stakeholder awareness [21,22].

The research Re-NetTA (Remanufacturing Networks for Tertiary Architectures–New Organizational Models and tools for the remanufacturing and reuse of short-life components coming from the renovation of tertiary buildings)—funded by Fondazione Cariplo (2018-0991) through a competitive tender—investigates these issues [14]. Re-NetTA research focuses on the application of a circular economy in the tertiary building sector, in order to maintain the economic value of building components—characterized by those from short-term uses and those from buildings under renovation—and contain environmental impacts by promoting remanufacturing and reuse strategies. One of the outcomes of the research is the proposal of some innovative organizational and operative models that could be applied to the building sector in order to boost reuse and remanufacturing and to create new supply chains, skills, and stakeholder networks.

This paper presents two Pilot Projects developed within the Re-NetTA research. The innovative aspect of these two Pilot Projects concerns their objective of putting into practice and testing new circular organizational and operative models and experimenting in the field of the criteria of “design for remanufacturing”. The novelty of this work is two-fold: the virtual and physical co-creation of circular solution, involving the manufacturer as key actor (Pilot Project 1); the integration of the Third Sector into remanufacturing networks and to use digital twins for managing reuse processes in tertiary buildings (Pilot Project 2). Furthermore, tests conducted on two Pilot Projects reveal the enabling conditions for the spread of circular and sustainable practices in the construction sector, with reference to product life cycle design, information traceability, and relationships along the value chain. The limitation of this work concerns the exclusive analysis of qualitative aspects. Since the solutions developed are currently in the prototype phase, it was not possible to conduct a monitoring phase dedicated to their application. In a future research phase, the prolonged application and use in the field of the technical and procedural solutions developed in the Pilot Projects will allow for the consideration and quantitative analysis of key performance indicators.

2. Materials and Methods

The Re-NetTA research applies a multidisciplinary approach, involving different disciplines and scientific areas (Technology of Architecture and Building construction, Management and Industrial Engineering, Industrial Design and Communication, Sustainable Design, and eco-design). Through this approach, the research involves multiple expertise’s related to environmental and economic sustainability, Life Cycle Thinking, business models, sharing economy, eco-design, and Sustainable Product-Service Systems.

The Re-NetTA research involved a large number of stakeholders along the value chain of the construction sector (manufacturers, suppliers, designers, facility managers, customers/users, and waste managers, etc.) with a cross-sectoral and cross-fertilization approach.

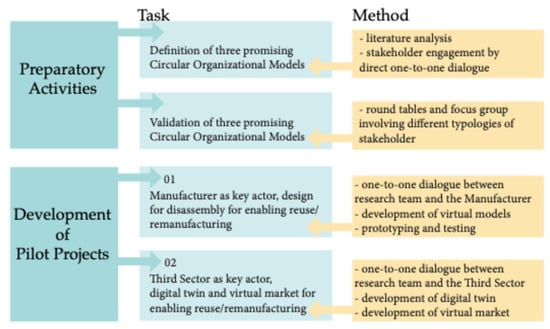

The two Pilot Projects discussed in this paper are conceptualized and developed mainly within the field of Technology of Architecture and Building construction. However, their development required an intrinsically multidisciplinary approach and the integration of various specific expertise, namely Environmental Sustainability, Facility Management, Digital Skills, and Life Cycle Thinking, in order to adopt a holistic perspective covering the entire life cycle of the building product, from the design to the end of life. The overall methodology of preparatory activities and the development of Pilot Projects is illustrated in the diagram below (Figure 1) and explained in detail in the following subparagraphs.

Figure 1.

Diagram of overall methodology of preparatory activities and development of Pilot Projects.

2.1. Definition of Three Promising Circular Organizational Models

The Re-NetTA research proposes three promising Circular Organizational Models for the building sector, validated and refined through stakeholder engagement, which helped to identify drivers and challenges for the specific context of the tertiary buildings (exhibition, office, and retail) in terms of policies, investments opportunities, technologies and innovations, standards, and certifications [23].

To this end, the research firstly assumes the fundamental paradigm shifts regarding the transition from linear to circular processes defined by the analysis of successful cross-sectoral case studies, and secondly, transposes the emerged key features of successful circular processes to the construction sector. In particular, the case studies from leading industries, selecting the most representative in terms of market share, are examined: aerospace, automotive, electrical and electronic equipment, heavy-duty and off-road equipment, machinery sector, and other sectors which include fashion, marine, transport, and consumable goods [14].

Each selected case study has been examined based on the available scientific papers, highlighting a comprehensive overview of the different remanufacturing practices, the involved actors, the contractual terms, the resource flows and the operations carried out during remanufacturing process.

The analysis of remanufacturing best practices from the different industrial sectors leads to the identification of some recurring innovative approaches (key paradigm shifts), aimed at extending the useful life of products, transferable to the construction sector in order to activate successful transitions to circularity.

The first paradigm shift concerns business models, introducing the product-as-a-service Model, which offers products as services rather than selling them. In this perspective, product ownership remains with the manufacturer or supplier, while users/customers, by paying a fixed fee, can receive an integrated mix of products and services that meet their demand [24]. This model encourages manufacturers to design longer-lasting products to put on the market for multiple uses [25].

The second paradigm shift concerns servitisation and value-added services, related to a regular maintenance offered by the manufacturer or supplier, in order to extend the duration of the product’s performance [25].

The third paradigm shift concerns the creation of stable relationships among stakeholders, assuming the principles of industrial symbiosis and reverse logistics, promoting cooperation and synergistic networking among different stakeholders that can share materials and products, preventing waste and recognizing used assets as valuable resources [26,27].

The fourth paradigm shift regards the design strategy of promoting approaches of design for remanufacturing and design for disassembly that imply solutions enabling reuse and remanufacturing through the assumption of the requirements such as reversibility, modularity, and interchangeability [28,29].

The identification of the Organizational Model’s key features derives from the deep analysis of successful circular models applied in the industrial sector and regarding some basic topics: organizational conditions; levers for the launch of successful remanufacturing processes from an economic and environmental point of view; rules for sustaining remanufacturing processes; relationship rules (organizational and procedural, etc.); assembly, disassembly, and processing procedures in relation to various technical elements; quality procedures; standards and methods for defining the characteristics of components easy to be remanufactured; and methods for exchanging materials and products.

Paradigm shifts and key features are useful for the proposition of three promising Circular Organizational Models of the tertiary sector [14]:

- Rent contracts as support for remanufacturing (OM1): instead of the traditional selling of products, the first model encourages a rental contract, which includes remanufacturing practices for components or construction systems. In this model, the products are offered to customers for rental and ownership remains with the manufacturer, who has a duty to collect them at the end of the rental period. For this reason, the model encourages manufacturers and suppliers to prioritize the design and manufacture of products with high durability and maintainability. Products are designed to be easily disassembled, for easy recovery and return to the manufacturer with high residual performances for reuse or remanufacturing. Products, returned to the original manufacturer, are restored and remanufactured and re-offered with further rental contracts for multiple life cycles.

- All-inclusive solution to support remanufacturing (OM2): the second model differs from the first one in terms of the product life-extension strategy. While the first model focuses on enabling multiple cycles of use of the same product by different customers, the second model aims to extend the initial use cycle of the product by fostering long-term relationships with the same customer (“loyalty strategy”). In this model in fact, the product is sold with a set of life-extension services, which are performed during the product use phase, such as cleaning, repair, maintenance, replacement, and remanufacturing. The customer pays for both the product and the services aimed at extending its useful life. In this model, the close partnership between the product supplier and the service supplier is crucial. The services offered aim to maximize the duration of the service life of the products.

- Alternative/secondary markets for remanufactured products (OM3): this Organizational Model is suitable for the end-of-useful-life products (partially) in good condition and with a residual value. The model prevents waste generation by reusing, repurposing, or remanufacturing post-use products. This model requires “peer-to-peer” collaboration [12] and coordination efforts between the remanufacturer, dealer, and customers, which can be at the same time, the “provider of first-hand products” and the “user of second-hand products”. To incentivize customers to return products after use (to become product suppliers), a deposit-based payment system can be implemented.

2.2. Validation of Three Promising Circular Organizational Models

The proposed promising Circular Organizational Models have been validated through the stakeholders’ engagement according to various methods: direct one-to-one dialog, round tables involving different typologies of stakeholders acting across the building value chain, and focus groups.

The investigations on the applicability of the Organizational Models highlighted how the exhibition sector is currently the sector most inclined to experiment with rent contracts or all-inclusive solutions (OM1–OM2). However, in the context of the exhibition sector, it also emerged that the main barriers to the reuse and remanufacturing of exhibition components are related to the difficulty in maintaining the performance and quality of the products at the end of their first useful life cycle. In fact, in disassembly activities, given the very short dismantling time at the end of the exhibition period, products are often damaged, compromising the possibilities of reuse and sometimes even remanufacturing. For these reasons, stakeholders emphasized the importance of increasing solutions to boost the reliability and easier disassembly of the systems.

Moreover, the stakeholders underlined that, unlike industrial sectors where remanufacturing practices are growing significantly when applied to highly standardized products, in the case of building products, since they are often customized, characterized by different uses, and unpredictable useful lives, such practices are rarely implemented.

Furthermore, the lack of standardized building products implies that dismantling operations generate flows of heterogeneous construction elements in non-constant quantities and in a discontinuous manner. These conditions make industrial operators still disinclined to activate product lines and processes dedicated to reuse and remanufacturing. The Re-NetTA research highlights that, to successfully activate remanufacturing supply chains in the construction sector, more flexible structures are needed. In particular, artisans are most flexible and suitable to work on small batches and on specific tasks. For artisans and small operators, the practices of reuse, repair, repurposing, and remanufacturing appear to be more economically sustainable than for industrial facilities, which have significantly higher profit margin expectations. At the same time, even in the case of artisans, in order to activate an effective critical mass capable of configuring itself as supply chain, it is necessary to find aggregative forms capable of overcoming the natural fragmentation of artisanal structures.

The investigations, carried out on virtuous circular practices in the field of tertiary architectures, highlight the existence of aggregative forms of operators, already structured thanks to Third Sector operators, who act as managerial operators linking the different actors in the supply chain related to the remanufacturing of building products. This type of organization, based on artisanal skills and with its flexibility, can be particularly suitable to operate in fragmented situations, where products coming from the use phase can be aggregated into small batches, not necessarily concentrated in the same territory with different characteristics and residual performances. The Third Sector, generally, has a synergistic, capillary, and structured network of operators within cooperatives or artisanal networks already present in the territory. The research highlighted that the Third Sector needs to be empowered to become a successful network for the reuse and remanufacturing of secondary building products.

2.3. Development of Pilot Projects

The lessons learned from stakeholders’ engagement and, in particular, the challenges emerging from the analysis of the proposed business models led to the development of Pilot Projects based on the practices of reuse and remanufacturing.

Even if three Organizational Models were identified, the funded research allowed for the development of only two Pilot Projects; consequently, OM1 and OM3 were selected for testing, as they engaged two significant stakeholders.

Pilot Project 1 is developed in collaboration with a manufacturer in the field of products for the exhibition sector. The aim is to investigate procedural and technological conditions enabling the Organizational Model based on rent contracts as support for remanufacturing (OM1). The project focuses on the development of exhibition wall solutions that can be easily assembled and disassembled in a short time, in order to be reusable for multiple life cycles, maintaining high levels of performance, and finally, once dismantled, are fully recyclable. In particular, a wall solution is designed for exhibition sites but is also potentially transferable in the office and retail sectors. The final objective is to demonstrate the role of improving construction solutions in terms of disassembly to activate new product management scenarios and consequently new Organizational Models linked to the life cycle of the elements. Pilot Project 1 is developed according to the following research steps and is the result of a series of interactions between the research team and the manufacturer via interviews and open discussions:

- The identification of alternative reversible fixing systems, useful in the case of an exhibition’s vertical wall and the definition of “circularity criteria” to assess pros and cons of each solution;

- The development of a virtual model and a full-size prototype of the system for the verification of the feasibility (e.g., interchangeable components, insertion into contexts, and aggregative configurations) and for the assessment of circularity; the virtual model (developed by research team) and the full-size prototype (developed by manufacturer) are useful for simulations and real tests of assembly, disassembly, and replacement of parts;

- The definition of re-design recommendations for the feasibility of disassembly procedures and remanufacturing actions;

- The definition of operative steps for the application of Organizational Model OM1.

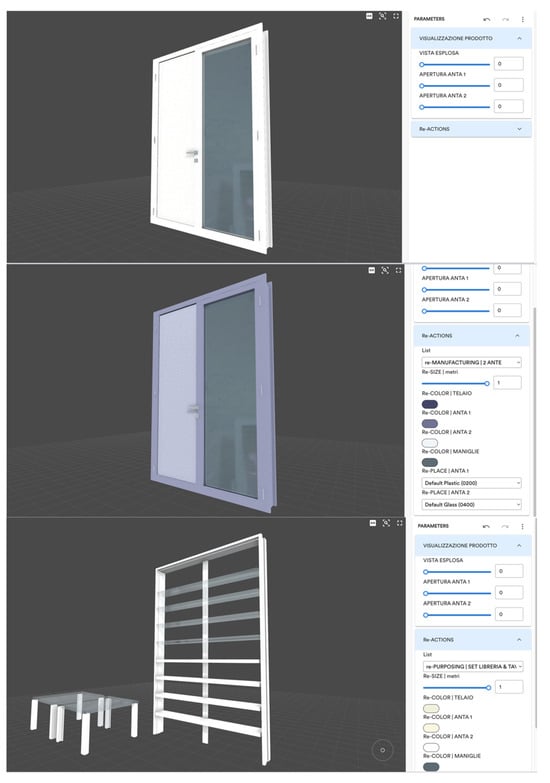

Pilot Project 2 is developed in collaboration with a Third Sector organization. The aim is to identify a supply chain configuration able to boost the Organizational Model identified as alternative/secondary markets for remanufactured products (OM3). In the perspective of a win–win strategy, Pilot Project 2 investigates the potential of a network of remanufacturers composed of artisans, coordinated by an operator of the Third Sector, in fostering a market of remanufactured products, coming from the re-layout of tertiary buildings. In the perspective of empowering the network and with the aim of encouraging on-demand second-hand products, Pilot Project 2 experiments with the use of a digital twin and augmented reality applications as “forecasting” tools for the creation of a virtual market where customers can visualize remanufactured and/or repurposed products before the remanufacturing process begins. Therefore, the digital twin is a dynamic and virtual replica of the physical system, developed with the purpose of receiving real-time inputs from the potential customers (by the web-based platform) in order to pre-view and optimize the design, the technical feasibility, and the costs of different reuse and remanufacturing scenarios, and create an on-demand remanufactured products. The main objective of this Pilot is to demonstrate the role of digital tools as operational support to encourage the customization of remanufactured products while minimizing business risk (and costs) for remanufacturing operators, in this specific case, artisans with limited investment and logistics management possibilities, increasing the possibility of involving these operators in circular activities.

Pilot Project 2 is developed according to the following research steps and is the result of a series of interactions between the research team and the Third Sector via interviews and open discussions:

- Mapping of the Third Sector operators is characterized by an organizational and technological potential for creating, managing, and training a network of artisans to involve in manufacturing activities. This step allows for the management of secondary product collection in order to avoid their disposal in landfills, and their storage in Third-Sector warehouses for allocation to a secondary market.

- The creation of a digital twin of secondary products with the aim of experimenting how the digital simulation can support the choice of the most appropriate process (between reuse, refurbishing, remanufacturing, and repurposing), the design of products in their possible configurations, and the preliminary assessment of the technical feasibility and costs.

- The experimentation of a web-based platform for a sample virtual market of on-demand remanufacturing products supported by tools and functions for the visualization through augmented reality of the effects of the various options with an estimation of time and cost processes.

- The definition of operative steps for the application of Organizational Model OM3.

3. Results

3.1. Pilot Project 1: Manufacturer as Key Actor, Design for Disassembly for Enabling Reuse/Remanufacturing

The first experiment focuses on the development of enabling technologies to boost the activation of Organizational Models related to the application of rent contracts to support remanufacturing (OM1). This experiment aims to highlight the key role of technological solutions in enabling circularity.

The experiment involved a manufacturer, which acts as key player for remanufacturing processes. In the analyzed case, the selected manufacturer was already oriented towards implementing an Organizational Model based on reuse or remanufacturing, even if they were still facing some obstacles related to reversibility and the customization of products.

Currently, the manufacturer produces and supplies a range of products for the exhibition sector, in particular, floor and wall coverings. Moreover, the manufacturer manages the logistics for installation and removal and the subsequent landfill disposal or recycling of materials. Thus, in the current Organizational Model, the manufacturer already applies a renting contract, with a reverse logistic and potential recycling of the products. In particular, the manufacturer is already taking action to recover carpets that, at the end of their use, can no longer be reused but can be recycled to produce panels. The panels generated are 100% polypropylene and divided into three layers: the core layer is composed of recycled polypropylene, derived from the carpet recycling, while the outer layers are made of virgin polypropylene. These panels have the potential to be 100% recycled but they can also be reused in multiple cycles thanks to their durability. However, at present, the fastening methods used in the exhibition sector are not reversible and the panels suffer breakages, which make them non-reusable. In addition, as is typical in exhibition stands, the products are customized for commercial and marketing benefits. Images (e.g., company logos and eye-catching images) are generally printed on the panels that form the main part of the wall coverings adopted for temporary events; until now, the potential for reprinting has not been explored.

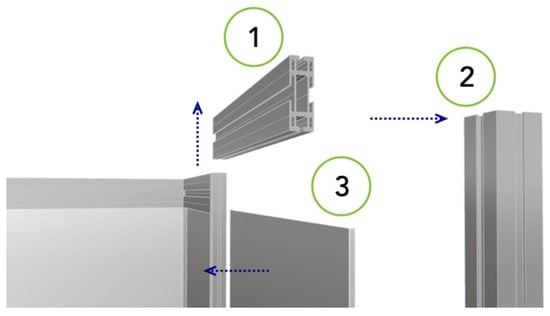

Pilot Project 1 focuses on defining reversible construction systems for the exhibition sector, which are potentially transferable to the office and retail sectors. The investigated solution regards exhibition wall systems, considering the fixing systems and the wall-covering panels.

The virtual model and some full-size prototypes (developed on-production-site by the manufacturer) allowed us to simulate and evaluate the possibility of assembly and disassembly, investigate critical issues, analyze technological feasibility, and the attitudes for possible reuse or remanufacturing.

The experiment encourages the manufacturer to pursue remanufacturing process, moving from “single use” to “multiple use” of the panels through product design innovation.

3.1.1. Identification of Alternative Reversible Fixing Systems and “Circularity Criteria”

In current practice, vertical wall systems, typically used for trade fairs, are modular systems composed of an aluminum substructure (section size of 4 cm × 4 cm) and panels. Pilot Project 1 studies how to apply recycled cladding panels (3 mm thickness) in this wall system. In particular, the fixing solutions between the substructure (frame) and the vertical panel are specifically designed and produced.

In order to reach a higher degree of reversibility, several different fixing systems are considered, regarding both “direct connections” with interlocking, mechanical, or adhesive solutions and “indirect connections” involving an additional connecting element between the panel and the substructure.

Through a co-creation process, engaging both the Re-NetTA research team and the manufacturer, three types of technical solutions with the highest reversibility potential are identified. These three typologies are studied in detail using virtual models and real full-size prototypes. In particular, the analysis takes into account one direct solution related to interlocking connection and two indirect solutions considering magnetic connectors and a hook-and-loop tape connection.

In order to analyze the critical issues and potential of the vertical exhibition wall systems, “circularity criteria” are defined through discussion with stakeholders. These circularity criteria allow for an assessment of the potentiality of reusability and remanufacturing of the system, defining improvement and innovative solutions of the current practice.

The circularity criteria assumed and related questions are as follows:

- Sensitivity to damage during assembly and disassembly: is it necessary to reinforce elements? Is it necessary to modify the assembly sequence?

- Visual esthetics of the technological solution: are there visible connections? Does the system allow for continuous printing of images on different panels?

- Technological independence of components: which is the sequence of removal of one component from the others? Can one component be disassembled without damaging other parts of system?

- Potential for reuse and remanufacturing: are the solution and components standardized? Are there dimensional tolerances? Is there the possibility of resizing the components?

- Assembly and disassembly process time: does the assembly and disassembly of components take a long time? Are operators with specialized skills needed?

3.1.2. Development of Virtual Models and Full-Size Prototype to Assess Feasibility and Circularity

The manufacturer, through the full-size prototype of the constructive systems, provided the Re-NetTA research team with experience and know-how, insights about assembly and disassembly phases (in terms of time and ease and speed of construction), in addition to information about resistance tests and possible reverse logistics. The analysis of critical issues and potential of vertical exhibition wall systems is described below.

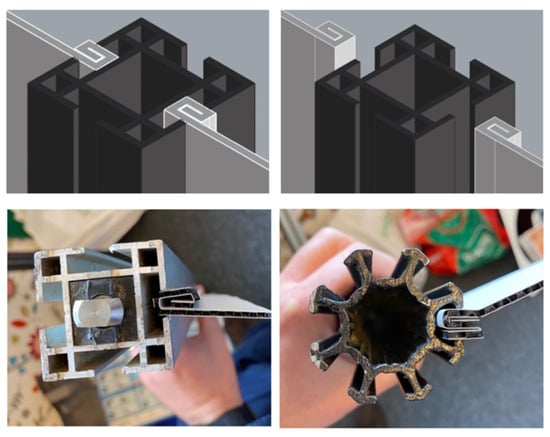

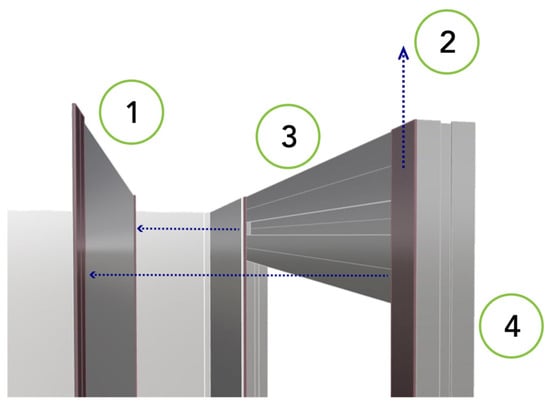

Direct Connection: Interlocking Solution

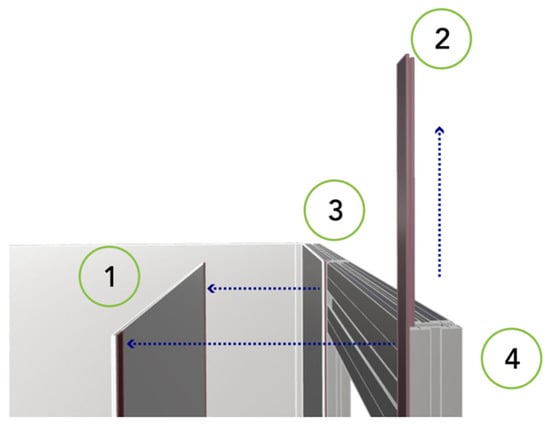

The first technical solution considers the interlocking of a panel in the groove of an aluminum frame (with a dimension of 7 mm wide). By bending the panel on itself, it is possible to create a thickness that can fit into the frame groove, using an interlocking solution (Figure 2).

Figure 2.

(Top) Virtual model of interlocking solution. (Bottom) Two full-size prototypes developed: the first consists of a square aluminum frame (more common); the second consists of a circular aluminum frame.

Folding the panel is achieved in a simple and inexpensive operation using an alternating blade-cutting plotter. The folds (depending on the cuts that can be made) allow for an adjustment of the thickness useful for interlocking. This allows us to obtain the necessary thickness needed for the joint and to use a thinner panel for the rest of the wall system (as in this case, using a panel of only 3 mm).

The solution does not use glue or other elements to increase the thickness or to make the interlocking system work. This leads to a very economical system that can be adapted to different substructure shapes.

The evaluation of circularity criteria allows us to assess the potentiality of reusability and remanufacturing of the system, as shown below.

- Sensitivity to damage during assembly and disassembly: the disassembly activities can damage the perimeter of the panel, especially along the cuts that are the most fragile part of the panel.

- Visual esthetics of the technological solution: aluminum frame remains visible, creating a frame around the panel and leaving the interlocking system with the panel visible. This constitutes the esthetic criticality since, generally, the aluminum frame used by fairs are worn and dirty (Figure 3).

Figure 3. Virtual model of exhibition wall system with interlocking solution: the aluminum frame remains visible; (left) final aesthetic result; (right) disassembly of the panel and the structure.

Figure 3. Virtual model of exhibition wall system with interlocking solution: the aluminum frame remains visible; (left) final aesthetic result; (right) disassembly of the panel and the structure. - Technological independence of components: the interlocking solution guarantees the technological independence of the components but to replace a panel, the aluminum frame has to be disassembled (Figure 4).

Figure 4. Virtual model of exhibition wall system with interlocking solution: sequence of disassembly operations. 1—Remove the upper horizontal aluminum frame; 2—remove the vertical lateral aluminum frame; 3—remove the panel and, if necessary, replace it.

Figure 4. Virtual model of exhibition wall system with interlocking solution: sequence of disassembly operations. 1—Remove the upper horizontal aluminum frame; 2—remove the vertical lateral aluminum frame; 3—remove the panel and, if necessary, replace it. - Potential for reuse and remanufacturing: the panel can also be reused with other frames (differently shaped). In addition, possible defects of the perimeter of the reused panel (e.g., on the edges) are hidden by the frame, extending the useful life of panel. Interlocking solutions are advantageous for covering accidental side chips of panels with the metal frame.

- Assembly and disassembly process time: considering the assembly and disassembly process and the time to build the wall system, the higher the panel to be inserted in the vertical frame, the greater the difficulty of assembly. Insertion into the profile is not very easy when the panel is long, because the fold is not fixed and it is necessary to press the panel to insert it manually. Moving the panel with care to remove it from the frame lengthens the disassembly time, which is generally inappropriate in the trade fair environment.

Indirect Connection: Magnetic Solution

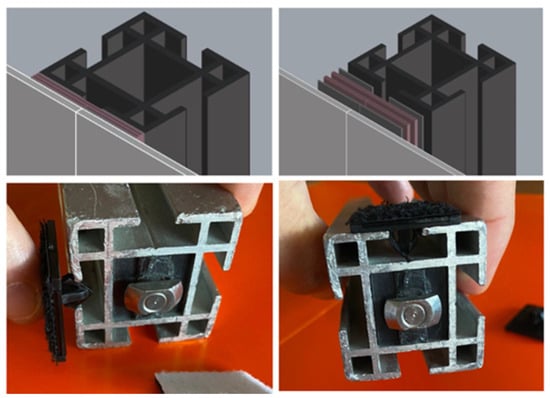

In the second technical solution, a magnetic rubber component is customized to make it insertable by sliding from top to bottom inside the profile groove. The magnetic component is placed along the entire aluminum frame because it offers the possibility of better panel adjustment. A metal sheet is glued to the back of the panel. This metal sheet can be attracted by the magnetic component and ensure the connection (Figure 5).

Figure 5.

(Top) Virtual model of magnetic solution. (Bottom) The full-size prototype developed: on the left, the magnetic component placed along the aluminum frame; on the right, the metal sheets glued to the panel.

The magnetic part of rubber component is 4 cm wide, as is the groove in the aluminum frame. The metal sheet glued to panel is 2 cm, allowing the connection of two panels to one aluminum frame. The system is designed to insert the magnetic rubber component into the aluminum frame once and continue to use it several times, connecting different and multiple panels for numerous uses, without disassembling the magnetic rubber from the aluminum frame for all cycles of use.

The construction of the magnetic system prototype, carried out at the manufacturer’s production site, provides an opportunity to evaluate the potential for circularity of the system through the circularity criteria:

- Sensitivity to damage during assembly and disassembly: the magnetic system, as seen from the prototype made, is very simple to assemble and disassemble. However, transportation and handling of the panels may suffer damage especially to the edges and edge damage in the magnetic system remains visible. Furthermore, a possible defect of the magnetic system is the durability of the bonding connection between the magnetic sheets and the panel. The glue used for fixing the metal sheet to the panel during the first test did not withstand many uses. However, the use of more long-lasting glues ensured resistance at all temperatures (e.g., glue used for building facade panels). In fact, the assembly of exhibition stands undergoes a strong change in temperature conditioning during the exhibition process (construction phase and use phase). Otherwise, according to the tests conducted, the magnet does not lose its magnetism (permanent magnetism). Therefore, there are no problems with the durability of the magnet and it can be used for multiple life cycles.

- Visual esthetics of the technological solution: with magnetic fixing, the aluminum frame is hidden and this allows for the viewing of images printed on multiple modules in continuity. In addition, magnetic fixing allows for easy adjustments of the panels to ensure that the printed images are continuous and perfectly aligned (Figure 6).

Figure 6. Virtual model of exhibition wall system with magnetic solution: the aluminum frame remains invisible; (left) final aesthetic result; (right) disassembly of the panel and the structure.

Figure 6. Virtual model of exhibition wall system with magnetic solution: the aluminum frame remains invisible; (left) final aesthetic result; (right) disassembly of the panel and the structure. - Technological independence of components: the magnetic solution ensures technological independence of the components. The panel can be removed independently, without disassembling the aluminum substructure. One difficulty in disassembly is between the metal sheet and the panel as they are joined by glue (Figure 7).

Figure 7. Virtual model of exhibition wall system with magnetic solution: sequence of disassembly operations. 1—Remove the panel and, if necessary, replace it; 2—remove the magnetic component placed along the aluminum frame; 3—remove the upper horizontal aluminum frame; 4—remove the vertical lateral aluminum frame.

Figure 7. Virtual model of exhibition wall system with magnetic solution: sequence of disassembly operations. 1—Remove the panel and, if necessary, replace it; 2—remove the magnetic component placed along the aluminum frame; 3—remove the upper horizontal aluminum frame; 4—remove the vertical lateral aluminum frame. - Potential for reuse and remanufacturing: the magnetic rubber component must be reused with the same profile frame for which it was manufactured, as its shape is not suitable for every type of profile on the market. The panel can be reused with other magnetic systems.

- Assembly and disassembly process time: assembly and disassembly time is very short on-site, as the panels are immediately connected to the magnet and are easily adjustable. The reduction in time reduces the labor cost. This could offset the higher cost of manufacturing the components. This makes the magnetic solution competitive with other solutions that are cheaper but require more assembly time (and thus more labor costs).

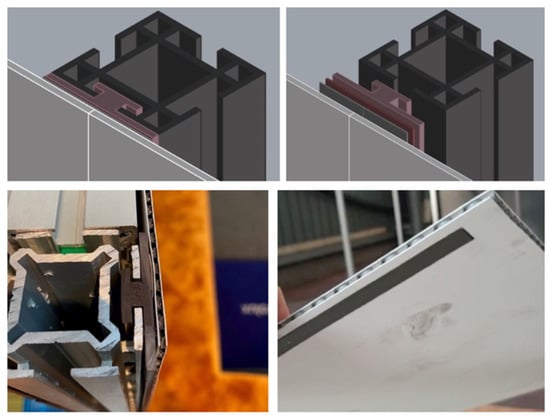

Indirect Connection: Hook-and-Loop Tape Solution

The third technical solution involves the indirect hook-and-loop tape connection, applied on a plastic joint with a shape that allows it (as well as a clip) to be inserted into the groove of the aluminum profile. The other side of the system is glued to the back of the panel (Figure 8).

Figure 8.

(Top) Virtual model of hook-and-loop tape solution. (Bottom) The full-size prototype developed; the simple clip-on connection of the plastic joint in the groove of the aluminum profile.

The hook-and-loop tape connection, like the magnetic one, can connect two panels to an aluminum frame. Again, through prototype testing at the manufacturer’s production site, the potential for circularity is evaluated.

- Sensitivity to damage during assembly and disassembly: the hook-and-loop tape system is very simple to assemble and disassemble. The panels can suffer damage especially to the edges and edge damage in the system remains visible. Another possible defect of the system is the same one detected in the magnetic solution: the possible loss of performance of adhesive connection between textile tape and the panel or frame. Therefore, even in this case, it is necessary to use long-lasting glue to ensure the durability of the connection.

- Visual esthetics of the technological solution: the hook-and-loop tape fastening hides the frame’s substructure, allowing for the continuity of images printed on multiple modules. Nevertheless, fixing does not allow for an easy adjustment of the panels to ensure that the continuously printed images are perfectly aligned; since, to adjust the alignments, it is necessary to remove the panel and hook it again. For this reason, the solution is most suitable for non-printed panels wall or in other sectors where there is more time available for assembly (Figure 9).

Figure 9. Virtual model of exhibition wall system with hook-and-loop tape solution: the aluminum frame remains invisible; (left) final aesthetic result; (right) disassembly of the panel and the structure.

Figure 9. Virtual model of exhibition wall system with hook-and-loop tape solution: the aluminum frame remains invisible; (left) final aesthetic result; (right) disassembly of the panel and the structure. - Technological independence of components: the hook-and-loop tape solution ensures technological independence between the panels and the aluminum frame. The panel can be removed independently, without disassembly the aluminum substructure. However, there are difficulties in disassembling the textile tape from the panel and the frame as they are glued (Figure 10).

Figure 10. Virtual model of exhibition wall system with hook-and-loop tape solution: sequence of disassembly operations. 1—Remove the panel and, if necessary, replace it; 2—remove the plastic joint placed in the groove of the aluminum frame; 3—remove the upper horizontal aluminum frame; 4—remove the vertical lateral aluminum frame.

Figure 10. Virtual model of exhibition wall system with hook-and-loop tape solution: sequence of disassembly operations. 1—Remove the panel and, if necessary, replace it; 2—remove the plastic joint placed in the groove of the aluminum frame; 3—remove the upper horizontal aluminum frame; 4—remove the vertical lateral aluminum frame. - Potential for reuse and remanufacturing: the panel could be reused in other solutions and attached to other types of support, but always with a hook-and-loop tape system. A limit is given by the durability of the solution, related to how long the hook-and-loop tape remains clean and able to engage.

- Assembly and disassembly process time: if the panels do not have continuous prints on side-by-side panels to align, the system is quick to assemble. Removing the panel upright is quick.

3.1.3. Definition of Re-Design Recommendations

Experiments and analysis of potential reversibility provide a lot of feedback in terms of technological opportunities to enable reuse and remanufacturing scenarios. All experimented and tested systems show some necessary re-design actions to improve the multiple use of products.

Experiments have also shown that the panel could suffer edge damage during handling, moving for assembly and disassembly. In the case of the magnetic solution and the hook-and-loop tape solution, therefore, it is recommended to reinforce the edge by thinking of specific rigid plastic inserts inside the middle layer of the panel, then cover them with the outer layers of virgin polypropylene (instead, in the case of interlocking, the problem is solved as the edge is hidden by the frame).

Furthermore, to improve the possibility of reusing the panels in the magnetic and hook-and-loop tape systems, a design of fixings adaptable to multiple types of frames would be necessary. In order to completely avoid gluing between the panel and the magnetic sheet or hook-and-loop tape, the development of mechanical joining systems is recommended.

To extend the life cycle, the wall panel damaged on the edge can be resized and cut to smaller sizes, thus removing the damaged parts, and it reused with other sizes for the same purpose (probably using it horizontally rather than vertically) or for other purposes (e.g., signage panels).

A key obstacle to the application of remanufacturing and reuse practices is the customization of panels through printing. To this end, it is extremely important to find solutions that overcome the technical barriers to superimposing multiple prints on the same panel (through the test of different printing technologies) or to use alternative technologies than direct printing on the panel, including replacing traditional printing with an additional layer that can be easily removed after use without compromising the supporting panel. Innovative options concern, for example, washable and/or erasable printing or printed textile. Another option is to use printed films applied to the panel, which are easily removable after use.

3.1.4. Operative Steps for the Application of Organizational Model OM1

As final part of Pilot Project 1, thanks to the experimentation of co-creation and knowledge sharing with the key actor (manufacture), the Re-NetTA research provides the definition of operative steps for the application of Organizational Model OM1 and a summary of the key aspects that enable the potential replication and transfer of the circular model to other experiences (e.g., different products and different sectors).

The main steps (listed below), based on win–win strategy supported by the developed reversible construction technologies, are particularly relevant for putting into practice the theorized Circular Organizational Model based on rent contracts as a support for remanufacturing (OM1):

- The manufacturer provides only reversible, easily assembled/disassembled, and durable technologies that can allow for multiple opportunities for customization of graphics or finishes.

- Provision to customer of products as a service by the form of a rental contract (OM1) (e.g., leasing and pay-per-use).

- In the case of a rental contract of longer duration and aimed at less temporary sectors than the exhibition sector (e.g., retail, offices, and hotels), the manufacturer may also offer remanufacturing services (in collaboration with external operators) during the rental contract to extend the life cycle of the products. Furthermore, the manufacturer provides not only one product (e.g., wall panels), but the entire construction system (e.g., wall panels and associated aluminum frame). At the end of the rental period, the items come back to the manufacturer, who takes care of the reverse logistics and independently carries out the product remanufacturing operations.

- The Organizational Model based on reuse and remanufacturing furthermore highlights the establishing contract between a manufacturer/supplier and a client from a logistical perspective, which are as follows:

- Take-back agreement between manufacturer, supplier, and client when the supplier returns products to the manufacturer;

- Take-back agreement, in the case of a long-term agreement and big quantity of rented products, when the manufacturer independently takes care of the reverse logistics;

- Deposit-based mechanism to especially encourage clients to return small volumes of products to the manufacturer, (retaking the initial surcharge).

- The manufacturer performs a remanufacturing process to extend the life of products with residual value and puts remanufactured products back into the market with the rental model.

3.2. Pilot Project 2: Third Sector as Key Actor, Digital Twin, and Virtual Market for Enabling Reuse and Remanufacturing

The second experiment focuses on the applicability of the Organizational Model related to Alternative/Secondary Markets for Remanufactured Products (OM3). Pilot Project 2 concerns the activation of a network involving the Third Sector, which acts as managerial player of the supply chain involved in remanufacturing processes.

The tertiary sector frequently discards large quantities of technical elements and products that are still in excellent physical and performance condition, often made with valuable materials and finishes (and therefore expensive on the market), which end up in landfill only because a change in the interior layout or corporate image is necessary. Pilot Project 2 focuses on the opportunity to divert these material flows from landfill to reuse/remanufacturing.

Pilot Project 2 provides the opportunity to investigate the key role of digital technologies to support reverse logistics and, in particular, (i) to experiment with the use of the digital twin to define different possible product re-configurations, through the parametric design, to guide reuse and remanufacturing activities predicting costs and potential new value; and (ii) to develop web-based platforms to place products on a virtual market able to reach customers before the product’s remanufacturing, thus customizing the product based on actual needs and sales potential. One of the major barriers to activating secondary reuse supply chains stems from the logistics and storage of products until a new buyer is found. Verifying the saleability of the product before remanufacturing it optimizes the processes, already tailored to the customer’s needs, and ensures that a customer already exists for the product before taking on the product, thus optimizing and saving costs.

Pilot Project 2 involves a non-profit cooperative that plays the role of a proactive actor in the Third Sector. The cooperative is already based on an innovative Organizational Model and participatory governance; through a complex network of artisans and the employment of vulnerable social workers, it activates recovery processes in various sectors (e.g., food and textiles) with the aim of reducing waste and extending the useful life of products.

3.2.1. Organizational and Technological Potential of the Third Sector

The application area of the experimentation is a set of doors still in excellent condition, deriving from renovation activities in some offices of the Politecnico di Milano, which was originally intended to be sent to landfill. The doors measure 1.58 × 2.23 m and the principal material is PVC. Each door consists of two symmetrical doors; one made of PVC and the other of plexiglass.

In the first step of Pilot Project 2, the Re-NetTa research team managed the interaction between the owner of the doors (the university) and the Third Sector cooperative. The first barrier to solve was related to the legislative and bureaucratic aspects of transferring the doors from the owner to the cooperative, in order to avoid their disposal in landfill. In the specific case of the Pilot Project, since the university is a public entity, it is not possible to proceed with a “purchase” of secondary materials, as publicly owned products cannot be sold. Therefore, as the first outcome of the research, a procedure for donation is developed and tested. This modality appears to be potentially extendable to other situations as well and is well suited to the Third Sector.

The second barrier is related to managing small non-constant quantities of products (small group of secondary products with different status conditions) both in recovery logistics and in processing. The Third Sector is a flexible organization able to manage these conditions. First of all, reverse logistics management is carried out by the cooperative: thanks to its means and the expertise (people, vehicles procedures, and permits to transport the waste), the collection, transportation, and storage of the small quantities of post-consumer doors turned out to be economically and logistically feasible. Furthermore, the cooperative demonstrates its capability to perform remanufacturing and repurposing both in making available its own technical equipment and machinery and in networking thanks to the collaboration with other cooperatives already present in the territory.

The last barrier is the identification of sales channels for remanufactured products. The Third Sector demonstrates its abilities in organizing the sale of remanufactured products in alternative or secondary markets (activating networks of possible buyers, involving associations and other Third Sector entities, and making available spaces, etc.).

The cooperative has technical skills and equipment and has already activated some sales channels (thrift stores/second-hand shops) to manage a remanufacturing supply chain, but a problem still remains regarding how to reach economical sustainability in remanufacturing activities when customizing products in small batches. This barrier, highlighted by the Third-Sector stakeholders involved, is related to the risk of starting remanufacturing processes without any certainty about the saleability of the product, deriving from the product’s appeal on the market (client interest) and its economic sustainability (price compared to new products). Pilot Project 2 explored how digitalization can support both the design for remanufacturing and the sale of second-hand products.

3.2.2. Digital Twin to Support the Design of Multiple Scenarios of Reuse and Remanufacturing

The design phase begins with the evaluation of the characteristics and residual performance of the recovered products (the doors) in search for the most appropriate circular strategy in relation to the specific products, their state, and the expected service life duration.

Comparative Table 1 [30] highlights the main differences between the re-manufacturing and repair processes in terms of applicability to the type of object (used or defective), the process of restoring the product’s properties, and characteristics, e.g. in terms of the nature of the work, final conditions, ownership and warranty.

Table 1.

Remanufacturing/repair checklist for the interior doors of Pilot Project 2 (source of the criteria: [30]).

Based on the criteria listed in Table 1, the symbol (✓) highlights what concerns the pilot project, which falls between the two recovery options: namely, the type of product, the process that is carried out, and the final characteristics of the remanufactured product (doors).

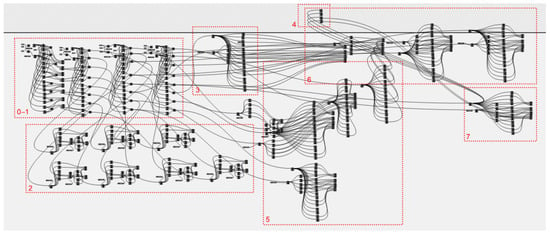

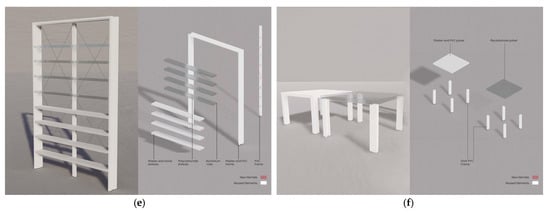

Through the application of parametric design techniques, the development of a digital twin enables the simulation of different possible final configurations of repurposed and remanufactured products and assesses the related remanufacturing processes (Figure 11). The digital twin allows us to create a dynamic and virtual replica of the real system in order to visualize, in advance, various design options for the remanufactured doors, develop on demand solutions, and predict the costs of each option.

Figure 11.

GH code organized in clusters, used to launch generative modeling of remanufacturing and repurposing solutions and estimate the final cost (Cluster description: 0. Import Geometry; 1. Model Structure/Clustering; 2. Disassembly Process; 3. Base Element; 4. Life Cycle Mapping (optional); 5. Interfaces/Connections; 6. Generative Modeling Run; 7. Parametric Cost Estimation).

Starting from a detailed BIM-oriented 3D modeling of the office doors (LOD F–as built according to UNI 11337-4: 2017 [31]), the Python 3 script developed in Rhinoceros Grasshopper (Figure 11) permitted us to structure and make a replicable methodological workflow, organized in operational clusters, that automatically generates possible substitutions, partial or complete re-assemblies, and repurposes of the base elements reclaimed from the original products (Table 2):

Table 2.

Remanufacturing workflow developed in Rhino.Inside.Revit Grasshopper.

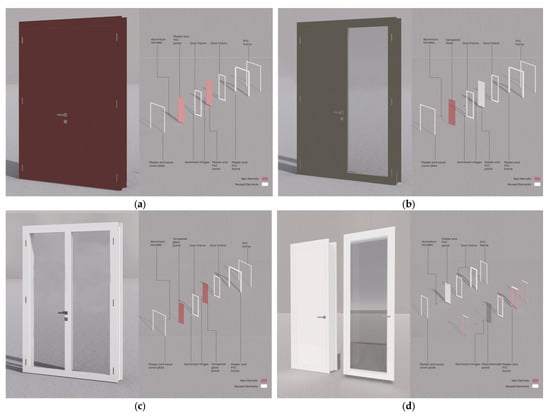

Different remanufacturing actions, from small interventions to radical transformations, are simulated and assessed through the digital twin (Figure 12):

Figure 12.

Real door pre-disassembled and its digital twin (the image and digital twin show the two sides of the door).

- Color door and substitute glass panel with opaque panel (Figure 13a);

Figure 13. Different options for remanufacturing actions on the doors. (a) Reused and new elements to obtain a door with different color and opaque panel; (b) reused and new elements to obtain a door with different color and glass panel; (c) reused and new elements to obtain a door with two panel of glass; (d) reused and new elements to create two doors; (e) reused and new elements to obtain shelf; (f) reused and new elements to obtain two tables.

Figure 13. Different options for remanufacturing actions on the doors. (a) Reused and new elements to obtain a door with different color and opaque panel; (b) reused and new elements to obtain a door with different color and glass panel; (c) reused and new elements to obtain a door with two panel of glass; (d) reused and new elements to create two doors; (e) reused and new elements to obtain shelf; (f) reused and new elements to obtain two tables. - Color door and change type of glass panel (Figure 13b);

- Change both panels with tempered glass (Figure 13c);

- Separate the door from the fixed opaque panel (Figure 13d);

- Resize panels for a shelf (Figure 13e);

- Resize panels for tables (Figure 13f).

A cost analysis is carried out for each action’s scenario related to the repurposing or remanufacturing processes. The analysis compares the cost of each activity, calculated through an average estimation between the 2021 Lombardy Region Price List (on behalf of article 23 of Legislative Decree 50/2016 and subsequent amendments) and the discounts declared by the Third Sector operators, investigated through structured interviews. The evaluation of estimated time and cost for the different repurposing and remanufacturing processes, therefore, affects the final cost of the product to place on the market, e.g., the 2021 Lombardy Region Price List reports that the unit price for removing peeling paint and polishing coatings from metal or vinyl surfaces, including countertops and strip-out assistance work, is €3.62 per square meter, with 70% allocated to consumables and 10% to labor. Considering the involvement of benefit companies with minimal profit margins (business profits are set at 4% of total work for each project, while overhead costs are estimated at 15%), it is possible to assess whether the final market price (including costs for all the working tasks needed to complete the product’s remanufacturing or re-purposing) remains competitive relative to a newly manufactured benchmark product.

3.2.3. Creation of On-Demand Virtual Market of Remanufacturing Products

The ability to envision a product’s remanufacturing scenarios, combined with an evaluation of manufacturing costs and therefore a price hypothesis for the final product, can be linked to the definition of customer desires and the exploration of their financial availability for the purchase.

The solution suggested in Pilot Project 2 is to identify “second-hand buyers” in advance (before activating the reverse logistics of collection and remanufacturing processes). In this case, a web-based digital platform can act as an enabler matching secondary product supply and customer demand.

Through a digital platform (Figure 14), it is possible to exchange information about post-consumer products available for remanufacturing; the basic information to trace and to integrate with photographs and documents is related to the manufacturer, the product’s characteristics, location, number of pieces, manufacturer’s technical data, and dimensions, etc.).

Figure 14.

Digital platform for on-demand virtual market of remanufactured products.

In addition, the digital platform can also host the digital twin of the post-consumer products simulating, in advance, various solutions deriving from repurposing and/or remanufacturing processes, allowing the buyer to customize the product (e.g., the color) and also estimate the potential selling price.

As a result, the economic risks of having unsold products (after an investment in remanufacturing actions) and the problem of storing products for long periods before selling them, would be avoided. The product can be collected from the refurbishment site only if it is already sold and the remanufacturing supply chain can be defined by also considering logistic optimization.

3.2.4. Replicability and Transferability of Organizational Model Experimented in the Pilot Project

The Pilot Project provides the opportunity of experimental co-creation and knowledge sharing with the involvement of the key actors of the Third Sector. From this experience, some steps can be highlighted in the perspective of a procedure for the application of the Circular Organization Model based on alternative/secondary markets for remanufactured products (OM3) to other categories of products and sectors:

- Creation of a web-based platform by the potential remanufacturer;

- Active role by the operator who has products to dispose of coming from the tertiary sector undergoing renovation (such as furniture, doors, movable walls, and false ceilings, etc.), with publication on the platform of a report containing information on the product;

- Initial feasibility assessment, with a possible development of the product’s digital twin to simulate some possible configurations (in relation to maintenance, transformation, adaptation, and repurposing, etc.); identification of the activities and the necessary human resources; and estimation of the selling price;

- Proposal of alternative remanufacturing solutions for the product through the digital platform with definition of the related price, technical characteristics, sale area, and duration of the offer, etc., to identify possible customers in advance;

- Expression of interest from possible buyers;

- When reaching the minimum threshold of buyers, activation of the team of transporters for the collection of products and of the network of artisans for remanufacturing activities;

- At the end of the remanufacturing activities, delivery of the remanufactured product to the customers by a team of transporters.

Finally, at the end of the second life of the remanufactured product, it is possible to activate a new cycle. In this case, if the Third Sector operator can manage both the remanufacturing and the sale phases, the logistical process of “take back” becomes even more effective and successful.

4. Discussion and Conclusions

The experience of Re-NetTA Pilot Project 1 and Pilot Project 2 highlights the common challenges involved in putting into practice circular life cycle management for materials and products when introducing remanufacturing strategies in the building sector. Numerous issues have been identified and certainly deserve further study, particularly regarding the following:

- (i)

- The role of design and the management of information related to products;

- (ii)

- The definition of Organizational Models and the update of legislative frameworks;

- (iii)

- The assessment of environmental and economic sustainability;

- (iv)

- The process of building a network of operators to activate a remanufacturing supply chain and the new skills required by the remanufacturing activities.

(i) The shift towards a life cycle design approach is fundamental to activating a circular flow of materials for building products: the Product Life Cycle Design (LCD) considers reuse and remanufacturing in the perspective of a broader and integrated strategy for the lifespan extension of materials. The experiment highlights that the characteristics of the product (e.g., dry-assembled connections, dimensions, and location, etc.), the disassembly process, and the interdependence of building elements can decisively influence the remanufacturing or the direct reuse of the products. Useful information, which must be tracked and maintained over time, includes not just technical aspects, but also logistical, economic, redesign, and procedural aspects. As experimented thanks to Pilot Project 1, the virtual model can enable a preview of the technical feasibility and an assessment of the various possible scenarios (reuse, remanufacturing, refurbishing, and repurposing). A 3D-modeling software (e.g., Building Information Modeling–BIM) can be a valuable support for the creation of virtual model able to simulate, from the early stages of the design (and re-design) process, the behavior of the products in relation to their location inside the buildings [32], and it can keep track of product information [33]. Moreover, Pilot Project 2 shows that creating a digital twin which receives real-time inputs from potential customers can be useful for predicting remanufacturing scenarios, the relative costs and feasibility, and sharing information online to foster relationships between stakeholders.

Product redesign, with a focus on disassembly for facilitating remanufacturing, is not the only element that must be considered.

(ii) The product designed for remanufacturing must also be supported by an Organizational Model that manages the process throughout the supply chain. Both Pilot Projects show how these aspects increase the effectiveness of circular strategies and optimize the product life cycle. If the product is designed to be remanufactured, we can move toward models that not only expand but also intensify its use, such as the “product-as-a-service” business model [24]. However, in practical applications, many Organizational Models related to reuse and remanufacturing encounter regulatory obstacles. Experimentations and investigations with stakeholders during the Re-NetTA research highlight the need to deepen the legislative framework regarding the insurance issue of remanufactured products and the “end of waste status” in order to manage some procedures currently not completely clarified by law, such as supplies of recoverable material and waste, transportation of post-consumer products from disposal, and used materials storage, etc.

(iii) In terms of sustainability, reuse and remanufacturing are strategies that can activate a circular flow of materials and processes, reducing new production processes and waste disposal. However, for a wide vision of the actual sustainability of circular strategies, environmental and economic assessments should be developed considering multiple use cycles since benefits at a single life cycle stage could shift environmental impacts to other phases. In this perspective, the Life Cycle Assessment (LCA), and related standards EN15804 and EN15978, certainly provides useful support for both the assessment and the choice of possible improvements of technologies and processes [34]. The application of a Life Cycle Assessment implies that it is necessary to improve the traceability and collection of environmental information throughout the life cycle of circular products.

Traceability involves the collection of information on various aspects, encompassing the whole life of the products. From a life cycle point of view, it is necessary to trace the information regarding the following:

- The raw materials/recycled materials and their source;

- The manufacturing process;

- The product’s composition;

- The transport of products (logistics);

- The management of the product, considering the maintenance work and partial replacements that will occur during the use phase;

- The expected service life and durability;

- The end-of-life management (e.g., reverse logistics), considering the end-of-life scenarios for the specific product and related transport in relation to various cycles of use.

Often, a lot of this information is predicted during the design phase by hypothesizing scenarios; but it is becoming increasingly necessary to be able to gather information by monitoring what actually happens during the product’s life cycle. The process of data collection and management could be supported by digital technologies such as Internet of Things (IoT), which enables remote tracking of the product—even in real time—gathering useful information such as location, usage profiles, and current maintenance conditions, etc. From an operational point of view, traceability tools involve various players cooperating horizontally along the building life cycle, in particular: designers, suppliers, manufacturers, builders, facility managers, end-of-life managers, and re-manufacturers. Moreover, for the purpose of collecting product life cycle information over time, networks among stakeholders can facilitate the process of information exchange.

(iv) Networking operators, not only in the “initial” part of production but involving them throughout the entire life of the product, up to the end of use is necessary to activate remanufacturing processes, overcoming the current issues connected with value chain fragmentation. In this perspective, there is clearly a need for structured networking, enabled by flexible types of agreements between the different stakeholders in the value chain (original product manufacturer, remanufacturer, service-provider, facility manager, construction company, logistics providers, transport, and storage operators, etc.). The Pilot Projects also highlight the need for new professional figures and multi-sectoral supply chains to complete the network. This need derives from the current lack of adequate cross-sectoral skills and expertise on technical and operational aspects (e.g., regulatory framework, certification tools, procurement, and contracting, etc.) related to the different stages of the building process and of the product life cycle. Finally, stakeholder involvement, developed during the Re-NetTA research, reveals the importance of defining shared rules and tools. All stakeholders agree on the need for a common terminology, rules for managing relationships, shared procedures, KPIs (Key Performance Indicators) for circularity, methods of analysis to choose the most appropriate and feasible strategies (remanufacturing, recondition, reuse, and repurpose), and support for the sustainability assessment (economic, environmental, and social).

The Re-NetTA Pilot Projects are pioneering examples for the implementation of circular models based on reuse and remanufacturing; they have demonstrated the feasibility of organizational and technological changes, but it is evident that many open issues must be still deepened when searching for the winning leverages able to push the shift from the current linear model to a circular one.

Author Contributions

Conceptualization, methodology investigation, and data curation: S.G., N.A.,A.D.V., S.V., M.L. and C.M.L.T.; writing—original draft preparation: S.G., N.A., A.D.V. and S.V.; writing—review and editing: M.L. and C.M.L.T.; supervision: M.L. and C.M.L.T. All authors have read and agreed to the published version of the manuscript.

Funding

The work is part of the results of the project “Re-NetTA. Re-manufacturing Networks for Tertiary Architectures. New organizational models and tools for re-manufacturing and re-using short life components coming from tertiary buildings renewal”, developed at Politecnico di Milano (2018–2021) and supported by Fondazione Cariplo, grant n° 2018-0991 (call “Circular Economy for a sustainable future 2018”).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to thank all the stakeholders that participated in the debates and round tables of the Re-NetTA research. A particular thank to the company Montecolino S.p.a. (Lombardy, Italy), which contributed as a manufacturer actor in Pilot Project 1, experimenting with the full-size prototypes reported in Figure 2, Figure 5 and Figure 8. A particular thank to the social cooperative CAUTO (Lombardy, Italy), which contributed as a Third Sector actor in Pilot Project 2.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- European Commission. COM(2020) 98 Final. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:9903b325-6388-11ea-b735-01aa75ed71a1.0017.02/DOC_1&format=PDF (accessed on 13 February 2025).

- European Commission. COM(2020) 662 Final. A Renovation Wave for Europe—Greening Our Buildings, Creating Jobs, Improving Lives. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:0638aa1d-0f02-11eb-bc07-01aa75ed71a1.0003.02/DOC_1&format=PDF (accessed on 13 February 2025).

- European Commission. Buildings and Construction. Available online: https://single-market-economy.ec.europa.eu/industry/sustainability/buildings-and-construction_en (accessed on 13 February 2025).

- European Parliament and Council. Directive (EU) 2024/1275 of the European Parliament and of the Council of 24 April 2024 on the Energy Performance of Buildings. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=OJ:L_202401275 (accessed on 13 February 2025).