Abstract

Enhancing the supply chain resilience of the information and communications manufacturing industry is closely related to the competitiveness of enterprises and the security of the national economy, and has attracted widespread attention from all sectors of society. This study develops a multidimensional synergistic resilience framework based on the Technology-Organization-Environment theory. Using panel data from 29 Chinese provinces over the 2011–2022 period, it empirically examines the impact of artificial intelligence technology on supply chain resilience in the information and communication technology manufacturing industry and investigates its underlying mechanisms. Research findings: Artificial intelligence significantly enhances supply chain resilience, and this conclusion holds after a series of endogeneity and robustness tests. Mechanism analysis reveals that artificial intelligence promotes the low-carbon transition by optimizing energy intensity and synergistically enhances resilience effects through technological innovation. Heterogeneity analysis shows that the impact of artificial intelligence on supply chain resilience is stronger in eastern China, significantly outperforming western China, but its effect in central China is not significant. Supply chain disruptions weaken the positive effects generated by artificial intelligence when they occur. The research provides a theoretical foundation and practical basis for improving the resilience of information and communications manufacturing supply chain networks, thereby contributing to the development of intelligent, resilient and sustainable supply chain networks.

1. Introduction

Against the backdrop of profound changes in the international landscape and the accelerated restructuring of global industrial chains and supply chains, the risk of disruption to industrial chains and supply chains has risen significantly. Enhancing supply chain resilience to reduce economic risks has become a core concern for national economic security and industrial development. The Chinese government attaches great importance to this issue. The 2024 Government Work Report explicitly lists enhancing the resilience and security of industrial chains and supply chains as one of the core tasks in the construction of the modern industrial system. To further implement this strategic plan, in 2025, the Ministry of Commerce and eight other departments jointly issued the “Action Plan to Accelerate the Development of Digital Intelligent Supply Chains”, emphasizing the deeper integration of digital technology applications in supply chains through “AI+” initiatives and the construction of an efficient and resilient digital intelligent supply chain system. As a strategic pillar industry of the country, the information and communication technology (ICT) manufacturing industry plays a key role in supporting high-quality economic development. The China Business Industry Research Institute predicts that by 2025, the scale of China’s integrated circuit market will reach 1.69 trillion yuan, with a growth rate ranking first among major global economies. However, the industry still faces severe challenges in key core technology areas, with prominent bottlenecks and obvious weaknesses in supply chain resilience. The core manufacturing processes highly depend on foreign technology, with low domestic production rates for industrial software. The dependence on foreign technology for EUV (Extreme Ultra-violet) lithography machines and EDA (Electronic Design Automation) tools remains above 90%, and advanced process chips are severely constrained by export controls []. Supply chain disruptions have a huge impact on businesses, leading to an average decline in profitability of 107%, a 7% decline in sales growth, and an 11% increase in costs []. These losses are reflected not only in direct economic losses, but also in the hidden costs of the recovery process and long-term negative impacts. Under China’s macro-policy framework for the “Dual Carbon” goals, energy consumption intensity is a critical gauge of industrial energy efficiency and the low-carbon transition. However, its specific mechanisms and impact paths in enhancing supply chain resilience are still not fully revealed. Therefore, enhancing the resilience and security of the ICT manufacturing supply chain has become an urgent task to safeguard national industrial security and stabilize macroeconomic operations []. Concurrently, it provides targeted, practical guidance for balancing industrial security with sustainable development under the “Dual Carbon” goals.

Artificial Intelligence (AI) technology is regarded as a key enabler for enhancing supply chain resilience. It demonstrates significant potential in optimizing inventory management, enabling human–machine collaborative decision-making, and enhancing risk prediction accuracy, thereby driving the development of digitalized and intelligent supply chains []. Scholars have conducted numerous useful explorations from different perspectives on how artificial intelligence can improve supply chain resilience. Relative study revolves around two primary research threads: first, how to assess the resilience of industrial and supply chains, which is also the initial issue to address when examining how artificial intelligence can enhance the resilience of ICT manufacturing supply chains; second, exploring pathways through which AI can empower supply chain resilience in the ICT manufacturing industry from various perspectives.

The measurement of industrial and supply chain resilience has evolved into a systematic research architecture characterized by multiple dimensions and methodologies, primarily encompassing three approaches: subjective measurement, objective measurement, and hybrid measurement. Subjective Measurement: Scholars have dedicated efforts to identifying key influencing factors and constructing structural models. Chen & Huang integrated the cloud model with the DEMATEL-ISM approach to elucidate core elements such as social capital and organizational capabilities, along with their hierarchical relationships []. However, such methods remain relatively limited in handling the subjective uncertainty and fuzzy information inherent in expert judgments. By applying AHP weighting combined with D-S evidence theory, Rahman et al. effectively processed subjective and uncertain data in the field of additive manufacturing, thereby enhancing the fusion quality and credibility of judgment information []. Barhmi & Hajaji developed multidimensional indicators from a managerial perspective and validated the scale’s reliability and validity [], yet their indicators are somewhat static and reliant on managerial subjective cognition, failing to fully capture dynamic vulnerabilities in actual operations. Addressing this, Pettit et al. identified numerous specific vulnerability points and capability items through in-depth interviews, enhancing the operability and contextual authenticity of the indicators []. Objective Measurement: Although subjective methods can delve deeply into complex factors, the generalizability and quantifiable comparability of their conclusions are limited, and they are susceptible to researcher subjectivity. To compensate for these deficiencies, objective measurement focuses on the quantitative representation of network structure, dynamic response, and performance indicators. Methods based on SNA to extract network characteristics combined with multi-attribute decision-making for resilience comparison have emerged [], but these methods lack sufficient depiction of the dynamic time dimension of system recovery. R. Li et al. introduced the maximum allowable recovery time to measure resilience performance under disruption scenarios, strengthening the capture of temporal dynamics []. While graph theory analysis of node connectivity can measure the inhibitory effect on risk propagation [], it still fails to resolve the issue of continuously measuring overall system performance under multiple shock scenarios. The SCRAM tool quantifies system stability under dynamic disturbances by calculating the product of response time and recovery time, filling the gap in continuous tracking of dynamic performance []. Singh et al. constructed and validated a universal performance indicator system covering 17 dimensions [], but it does not emphasize industry specificity, and weight assignment relies on conventional methods. To address this, Zhu Yongguang et al., based on entropy weighting and independence adjustment, constructed a comprehensive resilience index for the copper industry chain that integrates resistance, recovery, reorganization, and renewal capabilities, achieving a combination of indicator structuring and weight optimization while reflecting the characteristics of the metal industry []. Hybrid Analysis Methods: To overcome the limitations of single methods, comprehensive assessment models attempt to integrate advantages and enhance evaluation accuracy. The integration of hesitant fuzzy linguistic terms and the CRITIC-BWM weighting scheme into an improved matter-element extension model effectively handled indicator correlation and fuzziness in low-carbon supply chain assessments []. This model enhanced complex information processing capability, but the interpretation of organizational and behavioral aspects of resilience remained insufficient. Ruel et al., starting from dynamic capability theory, integrated the resource-based view and competing values framework to construct an analytical framework for dissecting the interaction between supply chain innovation and resilience, achieving a transition from structural measurement to capability mechanism analysis []. Such models significantly enhanced the comprehensiveness and adaptability of assessments, but they impose higher demands on data quality and computational capacity, and their generalizability and interpretability sometimes face challenges. Cutting-edge research is actively promoting interdisciplinary integration, injecting new perspectives into resilience measurement. Tsolkakis et al. applied systems theory to construct a framework for assessing the interplay between governance and resilience [], advancing theoretical integration, but it still lacks effective inclusion of emerging driving mechanisms such as technology-enabled empowerment. Interdisciplinary research continues to face the dual challenges of insufficient paradigm integration and a lack of empirical validation, particularly concerning the specific pathways and effectiveness of emerging technologies in enabling resilience, which urgently requires more empirical research for support.

The transformative impact of artificial intelligence on supply chains and its role in enhancing resilience have attracted significant scholarly attention. Chen Jinxiao pioneered a theoretical framework revealing how AI reshapes the foundation of supply chains through platform restructuring, ecosystem reconfiguration, and advantage reconstruction []. However, this framework does not sufficiently explain the specific cognitive mechanisms through which AI dynamically enhances supply chain resilience. To address this gap, Song Hua et al. proposed that embodied AI-driven human–machine collaboration can facilitate a phased leap in supply chain resilience [], thereby bridging the theoretical framework and practical implementation from the perspective of human–machine interaction and cognitive evolution. The import of industrial intelligent equipment reduces factor costs and extends production chains through upstream capital substitution and downstream labor efficiency gains, while diversifying import sources helps mitigate disruption risks and bolster extension capacity []. However, their research emphasizes technology introduction and diversification strategies without fully accounting for the role of domestic independent technological innovation in strengthening supply chain resilience. In response, Liu Xinxin and Han Xianfeng et al. found that AI enhances manufacturing resilience through direct effects as well as dual mediating pathways—namely, industrial specialization and agglomeration, and independent innovation—while also observing regional variations and nonlinear characteristics in these effects []. By explicitly incorporating independent innovation as a core mechanism, their work strengthens the explanatory power of the research in terms of technological endogeneity and regional adaptability. Digital technology not only improves supply chain efficiency by enhancing the accuracy of supply-demand matching and reducing external transaction costs [], but also strengthens industrial chain resilience through the dual effects of technological innovation and governance system optimization [], thereby supplementing the institutional and governance dimension beyond technical efficiency alone. Furthermore, AI technological innovation drives industrial chain modernization by advancing human capital and increasing the return on fixed assets, exhibiting a growth pattern characterized by initial suppression followed by subsequent acceleration []. Nevertheless, the influence of regional disparities under the digital economy context has not yet been thoroughly explored. Gu Cheng and Zhang Shushan et al. emphasize that the digital economy—including AI—enhances industrial chain resilience through human capital optimization and technological innovation, with non-linearly increasing marginal effects that are particularly prominent in regions with weak intellectual property protection []. Their research not only validates the role of factor upgrading, but also introduces the moderating effects of regional heterogeneity and intellectual property regimes, thereby enhancing the policy relevance of the conclusions. Data and management factors have been shown to significantly enhance supply chain resilience, with factor coordination, upstream-downstream collaboration, and cross-regional factor mobility playing key roles in the resilience system []. While this study focuses on the factor level, it has not yet been extended to the dimensions of national strategy and industrial layout. Integrating new-quality productive forces with industrial chain resilience requires achieving technological self-reliance and control, optimizing global distribution, and advancing digital-intelligent and green transformation, so as to build a secure industrial chain that supports Chinese-style modernization []. This macro-strategic perspective helps bridge the gap between micro-level factor research and firm-level studies. Although technological innovation input generally contributes to supply chain resilience, Kocabasoglu-Hillmer et al. caution that excessive innovation may disrupt established supplier production models and trigger short-term supply chain disruptions [], highlighting the need to balance innovation with a gradual approach that maintains supply chain stability.

Existing research primarily focuses on measurement methods for industrial and supply chain resilience or pathways to enhance the resilience of manufacturing supply chains. Some studies employ dynamic capability theory to construct resilience evaluation systems, analyze the impact of artificial intelligence on supply chain resilience from the perspective of technological innovation, and explore the mechanisms and pathways for enhancing resilience through digital transformation. However, under the rigid constraint of the “dual carbon” goals, most scholars have overlooked the reinforcing effect of energy intensity optimization on the resilience of manufacturing supply chains. There is a particular lack of empirical examination treating energy intensity as a key mediating mechanism between artificial intelligence and supply chain resilience, which is particularly crucial for China’s green development. Simultaneously, few scholars have directly analyzed the impact of artificial intelligence on the resilience of the ICT manufacturing supply chain, lacking both theoretical foundations and empirical evidence. Furthermore, the interplay between technological innovation and energy intensity optimization and its effect on the resilience of the ICT manufacturing supply chain has not been adequately considered. Additionally, given China’s distinct regional economic development characteristics and the unique industrial structure of ICT manufacturing, the precise impact of AI technology and energy intensity optimization on supply chain resilience remains unclear. To address these research gaps, this paper proposes the following three questions:

- (1)

- Can the application of artificial intelligence technology effectively enhance the resilience of China’s ICT manufacturing supply chain?

- (2)

- Can energy intensity optimization effectively improve the resilience of the ICT manufacturing supply chain? If so, what role does technological innovation capability play?

- (3)

- Is the impact of AI technology application and energy intensity on the resilience of the ICT manufacturing supply chain heterogeneous?

To answer these questions, this study integrates the technological characteristics of AI, the constraints of energy efficiency, and the objective of supply chain resilience into a unified analytical framework from the perspective of sustainable development. Using panel data from the ICT manufacturing industry across 29 provinces in China from 2011 to 2022, a mediation effects model is constructed to empirically examine the impact of AI technology on the resilience of the ICT manufacturing supply chain and its underlying mechanisms, aiming to provide theoretical references and practical insights for enhancing resilience in this field. The marginal contributions of this paper are threefold: First, it explicitly proposes and validates the mechanism through which AI influences the resilience of the ICT manufacturing supply chain. Second, it fully considers China’s basic national conditions under the “dual carbon” goals by incorporating energy intensity optimization into the analytical framework, thereby providing a more precise theoretical and empirical analysis of AI’s impact on the resilience of the ICT manufacturing supply chain, while also cautioning against the potential risk of the Jevons Paradox that may arise from excessive technological investment. Third, accounting for regional development disparities and the unique characteristics of the ICT manufacturing industrial structure in China, the heterogeneity of the impact of AI technology application on the resilience of China’s ICT manufacturing supply chain is empirically verified.

The remainder of this article is organized as follows: Section 2 provides a theoretical analysis and proposes two research hypotheses. Section 3 describes the model specification and variable selection. Section 4 presents the empirical analysis, and Section 5 conducts robustness checks and heterogeneity tests. The final Section 6 concludes with research findings, policy recommendations, and suggestions for future research.

2. Theoretical Analysis and Research Hypothesis

Supply chain resilience is increasingly becoming a paramount component of corporate core competitiveness. Artificial intelligence, through its holistic empowerment, provides innovative pathways to enhance a supply chain’s capabilities to withstand disruptions, absorb shocks, and achieve dynamic reconfiguration.

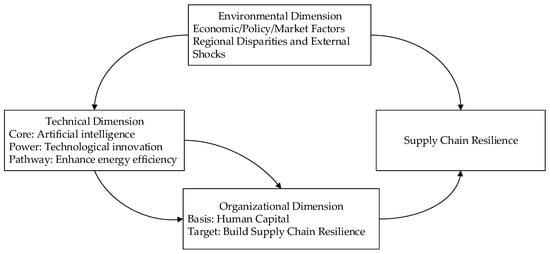

From a technical perspective, the efficacy of AI-enabled empowerment primarily depends on the deep integration of high-quality data flow and advanced analytical capabilities. As a new type of production factor, data’s dynamic aggregation and efficient transmission directly enhance the timeliness of risk perception and the agility of response decisions, forming the underlying logic for strengthening resilience. Data analysis capabilities, through the identification of potential risk patterns and the optimization of resource allocation, not only directly enhance the adaptability and resilience of the system, but also serve as a strategic fulcrum for creating differentiated competitive advantages []. It is worth noting that in complex manufacturing scenarios, the high contextual adaptability of algorithms is critical to the coordinated handling of multiple objectives and risks [,]. By dynamically adjusting prediction models and decision rules, AI significantly improves system recovery efficiency and robustness. However, technological empowerment faces two constraints. Data quality defects independently constitute a risk source for the decline in prediction accuracy [], while integration barriers between AI systems and existing supply chain management systems form a bottleneck for the release of technological value. Compatibility conflicts and sunk cost effects urgently require structural solutions. At the organizational level, AI is driving a paradigm shift in supply chain resilience from passive adaptation to proactive transformation. This process is driven by deep cognitive collaboration in human–machine interaction []. The domain knowledge of human experts and the pattern recognition capabilities of AI are iteratively integrated to jointly reconstruct the cognitive framework for risk decision-making. In this process, composite talents with expertise in both AI technology and supply chain management have become key hubs for value transformation []. Their cross-disciplinary capabilities can effectively bridge the final implementation gap between technological potential and business needs, specifically manifested in algorithm parameter optimization, scenario-based model adjustment, and the definition of human–machine responsibility boundaries. Empirical research confirms a significant positive synergistic effect between the penetration of AI within an organization and talent density [,]. The organizational cognitive capital and disruption resistance capability jointly constructed by the two are strongly positively correlated, revealing the multiplier effect of organizational capacity building on resilience outputs. Environmental dimensions, external institutional frameworks, and industrial ecosystems collectively shape the feasibility boundaries of AI empowerment. There is a significant spatial correlation between the maturity of digital infrastructure and the resilience of industrial chains, and the degree of industrial digitization positively moderates the AI empowerment effect []. Policy systems serve as a key enabling force, effectively breaking down information silos and stimulating collaborative innovation on the supply side by establishing data sharing standards, providing technical subsidies, and improving digital governance systems. The policy dividends often generate cross-period spillover effects [,]. AI-driven networked ecosystems are reshaping supply chain structures. Real-time information sharing mechanisms based on smart contracts significantly suppress the propagation of bullwhip effect fluctuations [], while distributed decision-making architectures are driving the transformation of linear supply chains into dynamic modular networks. This structural evolution endows the system with threefold resilience advantages: node redundancy enhances local interruption tolerance, network reconfigurability ensures global functionality continuity, and multi-center governance enhances risk dispersion capabilities, ultimately forming a shock-resistant structural support framework. The structural framework of the TOE theory is illustrated in Figure 1.

Figure 1.

Technology-Organization-Environment Framework Diagram.

In summary, AI constructs a theoretical framework for enhancing resilience through the dynamic interaction of technical capabilities, organizational restructuring, and environmental adaptation. The technological system provides the foundational tools but is constrained by data quality and integration capabilities. The organizational system facilitates knowledge transformation and drives the evolution of resilience paradigms, while the environmental system defines the boundaries of enablement through infrastructure and institutional design. This multi-level, cross-dimensional interdependent relationship indicates that AI-enabled supply chain resilience is essentially a process of co-evolution among technological feasibility, organizational transformative power, and institutional adaptability within a specific industrial context. Its ultimate effectiveness depends on the emergent effects generated by the dynamic matching of these three factors.

Based on this reasoning, the following hypotheses are proposed.

Hypothesis 1 (H1):

Artificial intelligence effectively enhances the resilience of the ICT manufacturing supply chain.

A profound and dynamic synergy exists between energy efficiency and supply chain resilience, rooted in their internal systemic interactions. Energy efficiency serves as a critical enabler and stabilizer for resilience. Improving energy efficiency reduces a firm’s energy intensity, which directly lowers operating costs and thereby strengthens the economic resilience of the supply chain against external shocks like price volatility and raw material shortages. From a supply chain perspective, energy efficiency management can help small and medium-sized enterprises overcome barriers like capital acquisition and lack of awareness, reducing overall costs through collaborative optimization and improving their ability to cope with market fluctuations []. On the other hand, resilience building provides strategic safeguards and an implementation framework for deep energy transformation. The diversified supply layouts, nearshoring strategies, redundancy in critical nodes, and agile response culture necessary for building resilience effectively mitigate concentrated energy supply risks arising from geopolitics or natural disasters. This redundant resilience mindset encourages companies to go beyond short-term cost considerations and proactively invest in long-term, efficient energy infrastructure such as distributed renewable energy, microgrids, and energy recovery technologies, thereby enhancing overall energy autonomy and system robustness. Thus, energy intensity and supply chain resilience are not a trade-off; instead, they form a positive feedback loop through the optimization of operational foundations and the strengthening of risk resistance.

However, technological innovation plays a central role in this co-evolution, functioning as both a hub and an accelerator. This is precisely because it serves as the primary driver that directly empowers the synergistic enhancement of both efficiency and resilience. By increasing supply chain nodes or strengthening inter-enterprise collaboration, technological innovation can enhance the complexity of supply chain networks and strengthen their resistance to interference []. Technological innovation is a core driver of energy efficiency improvements in the industrial sector. Technical efficiency contributes significantly to energy efficiency, and the role of technological progress strengthens over time. Such efficiency gains directly reduce energy consumption per unit of output, making the supply chain more resilient in terms of energy cost control and resource utilization, thereby reducing risks associated with energy price volatility or supply disruptions []. However, biased technological progress has significantly reduced energy intensity through factor substitution effects. This differential impact suggests that technological innovation must be tailored to specific industry characteristics, enhancing supply chain energy autonomy by optimizing energy structure and reducing dependence on single energy sources, thus improving risk resilience []. Secondly, the dual requirements of efficiency and resilience constitute a core pull for technological innovation. Essentially, technological innovation is not an exogenous variable. Its direction and rate are deeply shaped by the co-evolution of energy intensity and supply chain resilience targets, forming a reinforcing cycle.

To validate this perspective, this study develops a dynamic optimization model for firms, grounded in the core principles of Acemoglu’s production optimization theory [] and Sheffi’s resilience decision function []. The model seeks to elucidate the micro-level mechanism by which AI enhances supply chain resilience in the ICT manufacturing sector through the reduction in energy intensity.

Consider a representative ICT manufacturing firm that employs capital (K), labor (L), and energy (E) as inputs, with the level of AI technology application represented by A [0, 1]. Assuming that AI optimizes energy intensity to lower energy consumption per unit of output, the production function is defined as follows:

where represents the energy efficiency function. Here, α and β denote the output elasticities of capital and labor, respectively, while [0, 1] represents the output elasticity of energy. The condition ensures constant returns to scale. The coefficient captures the enhancement effect of AI on energy efficiency.

Energy intensity (EI) is defined as the ratio of energy input to total output. Substituting the production function Y into this definition yields:

Supply chain resilience is defined as the firm’s ability to maintain stable output when facing external shocks. It is quantified as the sum of energy risk and operational risk costs:

where represents the energy risk volatility coefficient, denotes the demand fluctuation sensitivity coefficient, and indicates the baseline output volatility. The term represents output variance, reflecting instability in production or order fulfillment. Greater volatility implies lower supply chain reliability.

The firm’s total cost C, which includes the costs of AI application, energy consumption, and supply chain resilience, is minimized as follows:

where is the energy price, is the cost function of a company applying AI, and satisfies increasing marginal cost.

Substituting Equation (3) into (4) obtain:

To calculate the impact of AI on energy intensity, take the partial derivative of Equation (2) to obtain Equation (5):

A significant reduction in energy intensity occurs if and only if , meaning the application level of AI must reach a certain threshold.

From (3), we can see that , which means that reducing energy intensity can directly improve supply chain resilience.

Substitute (3) and (4) into (5) to find the first-order partial derivative of C with respect to A:

Among them

When , it indicates that the application of AI technology in enterprises can reduce output fluctuations and directly enhance supply chain resilience. When , it indicates that AI technology in enterprises reduces energy intensity, thereby mitigating the impact of energy cost fluctuations on supply chain resilience.

Based on this, this paper proposes the following hypothesis.

Hypothesis 2 (H2):

Artificial intelligence enhances the resilience of the ICT manufacturing supply chain by optimizing energy intensity, and high levels of technological innovation reinforce this effect.

3. Research Design

3.1. Model Establishment

This paper treats artificial intelligence as the core explanatory variable and examines its impact on enhancing the resilience of the ICT manufacturing supply chain. Drawing on existing theories and frameworks, the following baseline regression model is constructed:

In this equation, i denotes the province, and t denotes the time period; is the dependent variable, measuring the level of supply chain resilience; is the core explanatory variable, representing the level of artificial intelligence development; denotes a set of five control variables; represents the model’s estimated intercept term; and are the coefficients of the explanatory variables and control variables, respectively; is the unobservable province-specific fixed effect; denotes unobservable time-specific fixed effects; is the random disturbance term, incorporating other unaccounted-for factors not included in the model.

3.2. Variable Selection

3.2.1. Dependent Variable: ICT Manufacturing Supply Chain Resilience (SCR)

This study draws on existing supply chain resilience measurement methods while fully incorporating the specific attributes of the ICT manufacturing sector and the multifaceted nature of its resilience. With reference to Martin’s 4R framework [], a comprehensive index system is established, organized into four key dimensions: resistance capability, recovery capability [], adaptation capability [], and innovation capability []. The specific structure of the system, which includes 4 secondary indicators, 8 tertiary indicators, and 17 fundamental observable indicators, is presented in Table 1.

Table 1.

Comprehensive Index System for ICT Manufacturing Supply Chain Resilience.

- Resistance capacity [,,];

This refers to the ability of a supply chain to withstand disruptions and maintain structural and functional stability before a disturbance occurs. It emphasizes preventive capabilities through redundancy design, which reduces the probability of interruptions by increasing intermediate nodes and alternative pathways. Since larger enterprises generally exhibit stronger risk management and control capabilities, this study evaluates resistance capacity through risk prevention and control metrics. The selected indicators include: total assets of industrial enterprises above a designated size, average number of employees, asset-liability ratio, and current assets.

- Recovery capability [,];

Recovery capability refers to the ability of a supply chain to return to its original level after being impacted, emphasizing response speed and resource restructuring efficiency. It directly corresponds to the survival threshold of enterprises, as rapid response can minimize revenue and profit losses caused by disruptions. The competitiveness of ICT manufacturing is rooted in its complex and sophisticated supporting industrial network. Whether an enterprise can quickly recover from disruptions not only determines its own viability but, more critically, affects its ability to maintain its pivotal role within the broader industrial ecosystem—preventing regional industrial chain fractures triggered by the failure of a single node. Therefore, this paper selects five evaluation indicators from the perspectives of industrial efficiency and industrial support, including cost-to-profit ratio, return on total assets, education expenditure, number of Internet broadband access ports per capita, and number of highway miles per capita.

- Adaptability [];

This reflects the supply chain’s capability to dynamically adjust strategies or structures in response to new environments. Adaptive capacity exhibits a strong correlation with resilience in ICT manufacturing, where high external dependency constitutes the primary source of vulnerability, while robust adjustment capabilities enable supply chains to proactively modify strategies and structures. When external dependencies are disrupted, such adaptive capacity facilitates the rapid establishment of new supply-demand equilibria, thereby transforming vulnerability into sustained adaptability. Four basic indicators are used: total import value, proportion of foreign investment, ratio of ICT business revenue to total manufacturing revenue, and inventory composition ratio.

- Innovation capability [].

This represents the ability to disruptively reconfigure the supply chain to achieve a new, higher-value equilibrium, emphasizing innovation and breaking away from established paradigms. The theory of post-traumatic growth suggests that the ability to innovate stems from reflection and creativity following disruption. Therefore, the level of corporate innovation has become a key indicator for measuring innovation capabilities. This paper selects four basic indicators from the perspectives of innovation input and innovation output, including the full-time equivalent of R&D personnel in high-tech enterprises, internal R&D expenditure in high-tech enterprises, the number of invention patents in high-tech enterprises, and sales of new products.

Among the basic indicators, the proportion of foreign capital and the inventory structure ratio are inverse indicators, meaning that lower values correspond to higher resilience levels. All other indicators are positive—higher values indicate stronger supply chain resilience in the ICT manufacturing sector. The raw data for all basic indicators were obtained from various statistical yearbooks or derived through secondary calculation based on yearbook data. To avoid subjectivity in assigning individual indicator weights, ensure robust and transparent results, and facilitate adjustments for robustness tests, the supply chain resilience index was measured using the linear weighting method, a common approach in indicator evaluation systems. Following the approach of Wang Xiaolu [], weights for each sub-indicator were calculated using the arithmetic mean method. The resulting composite index of supply chain resilience is denoted as SCR.

3.2.2. Core Explanatory Variable: Artificial Intelligence (AI)

Currently, there is no unified standard in academia for measuring the level of artificial intelligence. Some studies use the number of AI patent applications [,] or the intelligent computing resources held by enterprises [] as metrics. In the context of manufacturing, industrial robots serve as a physical embodiment and key manifestation of the comprehensive application of AI technologies. By incorporating perceptual intelligence such as visual recognition and force sensing, robots can understand and adapt to dynamic production environments in real time. Their operation relies on predictive analysis and cognitive automation. Through built-in algorithms and data models, robots can autonomously optimize operational paths, predict maintenance needs, and achieve precise control []. This data-driven decision-making process forms the micro-level foundation for AI-driven intelligent scheduling and process optimization in supply chains. Therefore, the installation volume of industrial robots effectively captures the comprehensive level of AI at the physical production level, where data analysis and intelligent decision-making are translated into real productivity. It serves as an effective and reliable proxy indicator for measuring AI development in the manufacturing sector. Drawing on the classical approaches of Lü Yue [] and Acemoglu [], this paper selects the annual installation count of industrial robots by province as a substitute variable for the level of artificial intelligence.

3.2.3. Mediating Variable

The theoretical analysis in the preceding Section 2 clarifies the critical role of energy intensity optimization in enhancing supply chain resilience. Accordingly, this paper introduces energy intensity as a mediating variable to examine the mechanism by which artificial intelligence influences the resilience of the ICT manufacturing supply chain.

Existing research provides partial support for this pathway. For instance, Danmaraya and Hassan et al. investigated the relationship between electricity consumption, manufacturing output, and capital investment, identifying a significant positive correlation and noting that electricity price changes exert a considerable short-term impact on consumption []. Xu Yingzhi et al. further demonstrated that spillover effects from technological efficiency improvements contribute more substantially to reducing electricity consumption in the manufacturing sector than industrial restructuring []. Additionally, Iv highlighted that lean management can help reduce indirect electricity consumption in supply chain processes such as production, inventory, and transportation []. These findings suggest that energy price fluctuations and non-essential consumption indirectly impair supply chain resilience through cost transmission and risk diffusion. This is particularly relevant in ICT manufacturing, where electricity accounts for over half of the total energy consumption throughout the product life cycle [], underscoring the importance of energy efficiency management.

Building on these insights, this paper uses the ratio of electricity consumption to total output in the ICT manufacturing industry, denoted as EC, as a proxy for energy intensity. However, existing literature seldom incorporates energy intensity into the analytical framework of supply chain resilience. Moreover, most existing indicators are based on static or short-term relationships, failing to capture the medium- to long-term effects of factors such as AI—which operates through real-time adjustment and dynamic optimization—on energy intensity.

3.2.4. Moderating Variable

Due to variations in the definition of technological innovation variables, its use in research serves different purposes and involves multiple dimensions and influencing factors. Therefore, scholars hold divergent views on its measurement. Existing studies mostly measure the level of technological innovation from the perspectives of innovation input and innovation output. Liu Xinxun classified technological innovation into two modes—imitative innovation and independent innovation—based on the perspective of innovation drivers. They used the ratio of the total expenditure on technology introduction, digestion, absorption, and technological transformation by industrial enterprises to their main business revenue to reflect imitative innovation capability, and the number of domestic patent applications per 100,000 people to measure independent innovation capability []. Huang Liangxiong [] and Lü Yue [] suggest that the number of patent applications can, to a certain extent, represent the level of innovation in an economy. A single indicator is insufficient to accurately measure the level of technological innovation. This paper draws on the approach of Klimek [] and selects the number of enterprises with R&D institutions, the number of R&D personnel, and the number of new product development projects in the electronic and communications equipment manufacturing industry and the computer and office equipment manufacturing industry. These indicators, which capture dimensions of R&D investment and market conversion, are aggregated into a composite index to serve as a proxy variable for technological innovation, denoted as TI. The calculation method and treatment align with those of the explained variable.

3.2.5. Control Variables

To improve the accuracy of estimating the impact of core explanatory variables on the explained variable and reduce bias due to omitted variables, the following control variables are selected:

- Level of economic development;

This is measured by the ratio of each region’s GDP to the national GDP. Existing research has shown that there is a significant positive correlation between the level of economic development and the resilience of the manufacturing industry. Regions with higher levels of economic development generally possess well-developed infrastructure, a favorable market environment, and strong policy support, all of which help improve the production efficiency and technological innovation capabilities of manufacturing enterprises. Regions characterized by high-quality development tend to have a relatively higher-quality labor force, providing manufacturing enterprises with stable human capital and thereby enhancing the resilience of the manufacturing sector [,]. Moreover, a higher level of regional economic development strengthens synergies among enterprises and increases the efficiency of resource allocation, which enhances the adaptability of enterprises when facing risks [].

- 2.

- Human capital development level;

This is measured by the average number of students enrolled in higher education institutions per 100,000 population. On the one hand, human capital has a direct impact on the resilience of the manufacturing industry: higher levels of human capital are associated with a stronger ability of manufacturing enterprises to resist risks []. On the other hand, human capital plays an indirect role through technological innovation capabilities. Highly skilled employees have a significantly better understanding and application of new technologies than less skilled employees, facilitating product innovation and business process optimization within enterprises, and thereby enhancing their ability to withstand risk shocks []. The accumulation of human capital enhances the collaborative capabilities of upstream and downstream enterprises in the industrial chain, improving its robustness and flexibility [].

- 3.

- Market size;

This is measured by the ratio of the total retail sales of consumer goods in each region to its regional GDP. A larger market size helps companies enhance resilience through economies of scale, promotes technological innovation and industrial upgrading, and improves supply chain resilience.

- 4.

- Government intervention level;

This is measured by the ratio of local government general public service expenditure to regional GDP. In manufacturing enterprises, moderate government intervention can help enhance manufacturing resilience. Governments can support the manufacturing sector through policy guidance, fiscal subsidies, and tax incentives to address market failures and transition toward a service-oriented government role [,]. Cui Lianbiao et al. [] found that China’s subsidy policies for the chip industry can mitigate the impact of U.S. sanctions on the domestic economy.

- 5.

- Level of knowledge flow.

Drawing on the approach of Han Dechao [], this paper uses the ratio of technology market transaction volume to GDP in each region as a proxy variable for knowledge flow. Higher speed and greater capacity of knowledge flow are more conducive to the development of high-tech enterprises and enhance the innovation capabilities of manufacturing supply chains.

3.3. Data Selection

The application of artificial intelligence technology in supply chain resilience and risk assessment can be traced back to around 2010, when it began to be gradually adopted in the industrial manufacturing sector []. Given data availability, this study uses panel data from 29 provinces, municipalities, and autonomous regions in China from 2011 to 2022 to examine the relationship between artificial intelligence and supply chain resilience in ICT manufacturing. Due to severe data gaps in the ICT manufacturing sector, the Tibet Autonomous Region and the Ningxia Hui Autonomous Region were excluded from the analysis. Data from Hong Kong, Macao, and Taiwan are also not included. All data are obtained from sources such as the China Statistical Yearbook, China Industrial Statistical Yearbook, China High-Tech Industry Statistical Yearbook, China Science and Technology Statistical Yearbook, and China Environmental Statistical Yearbook. Missing data were supplemented using provincial statistical yearbooks, with gaps filled using the mean value method and linear interpolation.

4. Empirical Research

4.1. Empirical Results and Analysis

To mitigate omitted variable bias caused by unobserved factors and enhance the interpretability of the model, thereby estimating the impact of artificial intelligence on the resilience of the ICT manufacturing supply chain more accurately, this study sequentially conducted F-tests, Hausman tests, and LM tests. The test results indicate that, compared to other model specifications, the fixed effects model is more appropriate for the research objectives of this paper. The benchmark regression results of AI’s impact on the resilience of the ICT manufacturing supply chain are presented in Table 2. Specifically, Model 1 includes only the core explanatory variable while controlling for province fixed effects. Model 2 adds time fixed effects to Model 1. Model 3 incorporates a set of control variables in addition to the core explanatory variable, while still controlling for province fixed effects. Model 4 further introduces time fixed effects based on Model 3.

Table 2.

Benchmark regression results.

The regression results indicate that, regardless of whether province fixed effects or province-time two-way fixed effects are used, the inclusion of control variables significantly improves the model fit. According to the results in column (1) of Table 2, when control variables were excluded and only province fixed effects were controlled, the estimated coefficient of the core explanatory variable (AI) was 0.320, which was positive and statistically significant at the 1% level. Column (2) introduces time fixed effects based on column (1). Although the AI coefficient decreases slightly to 0.295, it remains significant at the 10% level. It is worth noting that although the magnitudes of the AI coefficients in columns (1) and (2) differ, their statistical significance and positive direction are highly consistent, providing preliminary evidence that the application of artificial intelligence has a robust promoting effect on the resilience of the ICT manufacturing supply chain. Column (3) further incorporates the set of control variables while maintaining province fixed effects. At this point, the AI coefficient rises back to 0.295 and is significant at the 1% level. Column (4) adds time fixed effects to the specification in column (3), leading the coefficient of AI to further increase to 0.380, which is significant at the 5% level. The above results consistently confirm that the level of artificial intelligence development has a significant positive impact on supply chain resilience. In economic terms, this implies that for every 1-unit increase in artificial intelligence penetration, supply chain resilience is expected to increase by 0.295 to 0.380 units. Omitting control variables leads to estimation bias; when they are excluded, the AI coefficient is systematically underestimated and its statistical significance is reduced.

Table 2 results further indicate that the introduction of a control variable group has a systematic improvement effect on model estimation. Specifically,(1) Government intervention effect. The variable for the level of government intervention is consistently positive and statistically significant, corroborating the positive guiding role of government in the development of the ICT manufacturing industry through industrial policy formulation, public service provision, resource allocation optimization, and targeted support measures. This mechanism effectively enhances supply chain resilience. (2) Market scale effect. In Model 3, the market scale variable shows a significant positive impact, consistent with demand-induced innovation theory. A larger market scale indirectly enhances resilience by attracting enterprises to enter the market, stimulating competition, and promoting technological upgrading. However, after time fixed effects are introduced, the variable, while retaining a positive coefficient, loses its statistical significance, suggesting that part of its effect may be absorbed by time-varying trends. (3) Human Capital Effect: The human capital variable did not pass the significance test in Model 4, which deviates from the theoretical expectation of talent-driven innovation in high-tech industries. This may be related to the time lag in variable measurement and structural matching. The realization of human capital effectiveness in high-tech industries requires a long-term process of knowledge absorption, technology transformation, and innovation accumulation. Existing human capital indicators may not adequately distinguish between general and ICT-specific skills, leading to an underestimation of their marginal contribution to supply chain resilience. (4) Knowledge Flow Paradox: The knowledge flow variable shows a negative relationship inconsistent with theoretical expectations. Although not significant, it remains insightful. This may stem from institutional frictions in China’s technology market, such as high transaction costs and inadequate intellectual property protection, which inhibit the positive effects of knowledge spillovers. On the other hand, it may also reflect the short-term structural impact of inefficient firms being cleared from the market during technology transfer processes. (5) Uncertainty in Economic Development Level: This suggests that traditional regional economic development models have limited explanatory power for the resilience of the ICT manufacturing supply chain. This result indirectly confirms that the development of the ICT industry has entered a new stage driven by digital infrastructure, innovation ecosystems, and institutional quality, while the marginal contribution of traditional economic scale indicators is diminishing.

Based on the above regression results, Hypothesis H1 can be preliminarily verified.

4.2. Endogeniety Concerns

A potential bidirectional causal relationship may exist between the explanatory and explained variables, and omitted variables in the model could also lead to endogeneity issues. Endogeneity in this study may arise from two primary sources. On the one hand, artificial intelligence enhances the resilience of the ICT manufacturing supply chain through its capabilities in predictive sensing, recognition, and intelligent decision-making. On the other hand, improvements in the foundational capacity of ICT manufacturing can drive technological upgrades, further increasing computational and communication capabilities, which in turn enable advances in artificial intelligence development and application. Although the control variables included in the baseline regression are adequate for model specification, other unobserved factors in real-world settings may also affect the resilience of the ICT manufacturing supply chain. To address endogeneity concerns, this study employs two empirical strategies. First, an instrumental variable (IV) approach is adopted. Model 1 uses the first lag of the independent variable as an instrument for the current period. The resilience of the ICT manufacturing supply chain is primarily influenced by contemporary AI application levels, while lagged AI levels exhibit a considerably weaker effect. Since current AI levels are influenced by their past values, the instrument satisfies the relevance condition. Estimation results are presented in Column 1 of Table 3. Model 2 employs the installation density of industrial robots in the United States as an instrumental variable. It primarily influences China’s AI technology development through knowledge spillover channels, thereby satisfying the relevance condition for instrumental variables. Simultaneously, as this variable is determined by the United States’ domestic industrial environment and remains exogenous to the characteristics of China’s ICT supply chain, it also meets the exogeneity requirement. Consequently, it serves as a valid instrumental variable []. Diagnostic tests including the Anderson LM statistic and the Cragg-Donald Wald F statistic indicate that neither model suffers from underidentification or weak instrument problems. Second, a Generalized Method of Moments (GMM) estimator is applied to correct for endogeneity bias. A dynamic panel model is constructed using the first lag of the dependent variable, with results shown in Model 3. Autocorrelation tests show that AR(1) is significant while AR(2) is not, and the Hansen overidentification test fails to reject the null hypothesis of valid instruments, supporting the model specification. The significantly positive coefficient (at the 5% level) on the one-period lag of supply chain resilience confirms the presence of historical dependence. Across all models, the core explanatory variable remains positive and significant, indicating that artificial intelligence significantly enhances the resilience of the ICT manufacturing supply chain even after controlling for endogeneity.

Table 3.

Results of endogenous treatment.

4.3. Robustness Test

To further validate the reliability of the research findings, robustness tests were conducted, and the results are presented in Table 4. The specific measures are as follows. (1) Replacement of the explained variable’s measurement. To address potential sensitivity in the construction of the supply chain resilience indicator, and in line with common academic practice, the composite index constructed using the linear weighting method was replaced with one calculated using the entropy method for re-estimation. Model 1 shows that the sign and significance of the core variable coefficients remain largely unchanged. (2) Exclusion of samples affected by exogenous shocks. Considering the sudden shift in ICT industry policies due to the escalation of Sino–US trade friction in 2018, as well as the structural impact of the global public health crisis on supply chains in 2020, observations from 2018 to 2020 were excluded and the fixed-effects model was re-estimated. The results in Model 2 indicate that the enhancing effect of artificial intelligence remains robust in the subsample after removing exogenous disturbances. (3) Exclusion of special samples. Given that municipalities may differ significantly in resource allocation and development stages, which could bias the estimates, we followed the sample processing approach of Liu et al. [] and excluded municipal observations before re-running the regression. Model 3 confirms that the core variable coefficients are not significantly affected by regional structural differences. (4) Outlier treatment. To reduce the influence of extreme values on parameter estimates, all continuous variables were winsorized at the 1% level on both tails before re-estimation. Model 4 shows that the winsorized coefficient estimates remain statistically significant and consistent in economic interpretation. (5) Adjustment of clustered standard errors. Drawing on the approach of Xie et al. [], provincial-level clustered standard errors were replaced with time-level clustered standard errors. The stability of coefficient signs and significance levels in Model 5 confirms that the benchmark results are not sensitive to the choice of clustering level. Across all five robustness tests, the regression coefficients of artificial intelligence remain positive and statistically significant at the 5% level or higher. Their direction, magnitude, and significance are highly consistent with the benchmark results. This strongly demonstrates that the empirical finding—that artificial intelligence enhances supply chain resilience in ICT manufacturing—is highly robust.

Table 4.

Robustness test results for benchmark regression.

5. Further Analysis

5.1. Impact Mechanism Testing

As suggested by the preceding theoretical analysis, the application of AI technology can help reduce energy intensity in enterprises, thereby enhancing supply chain resilience. In line with Jiang Ting’s [] recommendation on two-step regression analysis, and drawing on the methodology of Li Yuhua [] and Wen Wen [], this paper constructs the following model to examine the mechanism through which artificial intelligence affects energy intensity—a critical pathway in this process.

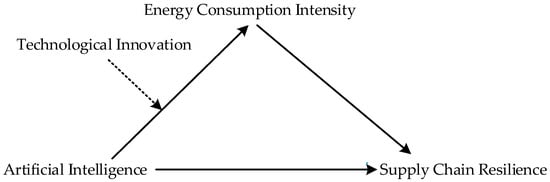

Among them, represents the mechanism variable, which stands for energy intensity (EC), with subscripts i and t representing provinces and years, respectively; all other variables are defined as in the baseline regression model (1). Equation (9) analyzes the utility of the core variable AI on the mechanism variable as the explained variable. The mechanism test is shown in Figure 2.

Figure 2.

Mediation Effect Test Path Diagram.

To test Hypothesis H2, this paper focuses on energy intensity optimization to investigate the mechanism through which artificial intelligence enhances supply chain resilience in ICT manufacturing, and further evaluates the reinforcing role of technological innovation in this pathway. The regression results in column (2) of Table 5 show a significant negative correlation between the core explanatory variable and the mechanism variable at the 5% level, with a coefficient of −0.571. This indicates that the application of artificial intelligence significantly reduces energy intensity in the ICT manufacturing supply chain. Reduced energy costs can alleviate the economic impact of supply chain interruptions and indirectly strengthen resilience. Moreover, a diversified energy supply enhances the system’s ability to recover quickly from external shocks, decreases reliance on a single energy source, and improves energy security, thus reducing the risk of supply chain disruptions. Previous studies have confirmed that there is a significant negative correlation between energy intensity and supply chain resilience: lower energy efficiency is associated with higher sensitivity of the supply chain to external shocks []. The application of artificial intelligence technology improves supply chain visibility and information exchange capabilities, enhancing the supply chain’s ability to respond to fluctuations in energy intensity []. Moreover, the Bootstrap test with 5000 iterations yielded a confidence interval of [0.0990, 0.3858], which excludes zero, thereby confirming the existence of the mediation pathway.

Table 5.

Results of the impact mechanism test.

This paper constructs a technological innovation index from the two dimensions of innovation input and output, and studies the reinforcing effect of technological innovation on energy intensity. Columns (3) and (4) of Table 5 present the regression results after sequentially introducing the level of technological innovation and the interaction term between artificial intelligence and technological innovation into Equation (9). The test results indicate that the coefficients of the core variables are all negative and statistically significant at the 10% level, supporting the rationality of the mechanism variable and providing further evidence for Hypothesis H2. The regression results in column (3) show a negative correlation between technological innovation and energy intensity, suggesting that technological innovation contributes to reducing energy intensity. However, in column (4), the regression coefficient of the interaction variable between AI and TI is 0.096, which is significant at the 5% level, indicating that there is a significant interaction between the two. Based on the results, the impact of artificial intelligence on energy intensity can be described as follows:

As can be seen from Equation (10), when the technological innovation level of region i in year t is at its lowest value, a 1-unit increase in artificial intelligence will promote a 0.102% reduction in energy intensity. For every 1-unit increase in technological innovation capability, artificial intelligence levels improve by 0.096 percentage points. This indicates that technological innovation amplifies the optimization effect of artificial intelligence on energy intensity, helping to improve the energy intensity of the ICT manufacturing supply chain, i.e., the technological innovation variable has a moderating effect. However, when the level of technological innovation in the region exceeds the threshold by 1.0625 units, the effect of artificial intelligence on energy intensity increases rather than decreases. This can be attributed to the rebound effect in resource consumption. In an environment with extremely strong technological capabilities, AI-driven efficiency gains may become so substantial that they trigger large-scale production expansion or give rise to new energy-intensive applications. Ultimately, the increase in total energy consumption offsets—and may even surpass—the savings obtained through efficiency improvements, leading to a rise in energy intensity. This phenomenon is known as the Jevons paradox. In summary, the effective reduction in energy intensity through artificial intelligence is contingent upon strong technological innovation capabilities. Nevertheless, enterprises should carefully manage the extent of investment in technological innovation in practical scenarios and remain vigilant about the potential risk of energy rebound resulting from excessive intelligence when technological capabilities are exceedingly high.

5.2. Heterogeneity Analysis

The empirical analysis in Section 5.1 confirms the impact of artificial intelligence and energy consumption on the resilience of ICT manufacturing supply chains. However, significant disparities exist in the development of digital infrastructure across regions, as well as variations over time and stages of development. Do these factors lead to heterogeneous effects on supply chain resilience? This paper attempts to address this issue through the following analysis, aiming to provide insights for enhancing the resilience of ICT manufacturing supply chains.

5.2.1. Analysis of Heterogeneity at the Regional Level

Artificial intelligence significantly enhances the resilience of the ICT manufacturing industry by strengthening the resistance, recovery, adaptability, and innovation capabilities of supply chains. However, its effects show significant regional heterogeneity, as shown in the first three columns of Table 6. Previous studies indicate that the eastern region benefits most markedly from artificial intelligence in promoting supply chain resilience, with increasing marginal returns, owing to its advanced information infrastructure, professional agglomeration effects, and leadership by major enterprises [,]. With policy support, western regions have achieved resilience gains through technology introduction, particularly in the areas of inventory and logistics optimization. However, due to lagging digital infrastructure, the growth rate is significantly lower than that of eastern regions. In contrast, the central region shows no significant effect of artificial intelligence on supply chain resilience, which may be attributed to structural contradictions during industrial transformation, constraints from diversified agglomeration models, and bottlenecks in corporate innovation.

Table 6.

Results of the Heterogeneity Analysis.

The prominent advantages of the eastern region originate from a triple positive-drive mechanism. First, the region benefits from highly advanced information infrastructure, where next-generation digital infrastructure provides a solid foundation for artificial intelligence technologies. This enables AI-driven real-time data analysis, accurate demand forecasting, and automated decision-making systems to operate efficiently, significantly enhancing the resilience and recovery capabilities of the supply chain. Second, well-established industrial specialization agglomerations play a pivotal role. Representative clusters such as the Yangtze River Delta Electronics Cluster enhance industrial chain specialization through AI, accelerating technological innovation and knowledge spillover, thereby directly boosting the innovative capacity of the supply chain. Finally, a virtuous cycle is formed through leadership by major firms. Large enterprises and innovative private companies, leveraging their resource advantages, actively invest in AI technology research and development. This reduces operational costs in areas such as inventory optimization and intelligent scheduling, while also establishing dynamic response mechanisms to cope with unexpected disruptions.

The western region is characterized by both policy-driven development and underlying constraints. Initiatives under the new infrastructure strategy have yielded dividends in technology adoption, where applications such as intelligent logistics systems have enhanced supply chain visibility and reduced disruption risks in the short term. However, lagging deep-layer digital infrastructure remains a bottleneck to development. Issues like insufficient network coverage and inadequate computing resources impede the depth of AI implementation and sustained efficiency improvements. In addition, cross-industry synergies have emerged as an important complementary pathway. AI-enabled upgrades in the service sector have notably enhanced the resilience of the manufacturing supply chain, establishing a synergistic enhancement mechanism between the two sectors.

The weak significance of AI’s impact in the central region can be attributed to systemic blockages arising from the “institution-technology” mismatch. The reliance of rigid production systems on traditional pathways inherently conflicts with the flexible enabling logic of AI. Meanwhile, diversified industrial agglomeration patterns hinder the spillover and accumulation of specialized knowledge, severing the core pathway through which AI enhances resilience via continuous learning. Coupled with the absence of regional innovation entities and brain drain, these factors collectively prevent AI applications from reaching the critical scale threshold, causing their positive effects to be neutralized by structural contradictions.

5.2.2. Heterogeneity Analysis Based on Time

This study selects the period from 2011 to 2022 as the sample interval, which includes the major exogenous shock of the global COVID-19 pandemic in 2020. To systematically identify the impact of this shock on the enabling effects of artificial intelligence, a dummy variable for the global COVID-19 pandemic (cov) was constructed. Based on this variable, a time heterogeneity analysis was conducted: subsamples before 2020 were assigned a value of 0, while those from 2020 onward were assigned a value of 1. Furthermore, an interaction term between the AI variable and cov was introduced into the baseline regression. As shown in the estimation results in Column 4 of Table 6, the coefficient of the AI variable is positive, while the coefficient of the interaction term between AI and cov is negative. This indicates that the shock of the COVID-19 event weakened the positive effect of artificial intelligence on the resilience of the ICT manufacturing supply chain. A possible reason for this is that the ICT manufacturing industry heavily relies on globalized supply chains. Under the impact of the pandemic, the interconnectedness of supply chains led to localized disruptions causing global collapse. In the context of globalized division of labor, relevant enterprises struggled to quickly adjust procurement and production layouts, and there was a widespread lack of contingency plans and preventive measures for large-scale supply chain disruptions []. Mere technological empowerment is insufficient to address global shocks; AI must be deeply integrated into the strategic restructuring of supply chains.

6. Conclusions and Policy Implications

Based on China’s provincial panel data from 2011 to 2022, this study empirically examines the impact of artificial intelligence on the resilience of the ICT manufacturing supply chain and its sustainable development path. The research finds that AI significantly enhances supply chain resilience through data intelligence and process optimization, with its core mechanism being the optimization of energy intensity. However, this process is also moderated by factors such as the level of technological innovation, and vigilance is required against the potential energy rebound effect that may arise from improved energy efficiency. Further analysis indicates that the enabling effects of AI are regionally unbalanced: the eastern region demonstrates the most significant outcomes due to its advantages in technology agglomeration and structural upgrading, followed by the western region, while the central region has not yet formed an effective driver. Furthermore, when facing major external shocks, the positive effects of AI can be weakened. From a sustainable development perspective, this study reveals the synergistic mechanisms of AI in building a green, efficient, and resilient supply chain system, providing a theoretical basis and policy insights for advancing the intelligent upgrading and low-carbon development in the ICT manufacturing supply chain.

To systematically enhance the resilience of the ICT manufacturing supply chain and promote its green transition, it is recommended to deepen the integration and application of AI technology across three levels: regional coordination, enterprise action, and the national system. At the regional level, implement targeted support policies: encourage the eastern region to focus on AI cutting-edge R&D and high-end manufacturing applications; support the western region in undertaking computing power and manufacturing transfers and deploying green data centers; simultaneously, help the central region address its shortcomings in digitalization and talent. At the enterprise level, guide them to deploy AI solutions across the entire production, inventory, and logistics processes; introduce intelligent energy management systems and incorporate energy-saving results into carbon accounting and developing new models like distributed manufacturing to enhance risk resistance. At the national level, propose the establishment of a unified energy consumption cloud platform and a supply chain visualization and early warning platform; include AI-powered energy-saving projects within the scope of green finance and fiscal/tax incentives; establish a green computing power dispatch mechanism; and strengthen industry-university-research collaboration to tackle “bottleneck” technologies in key areas.

Future research should explore the impact of artificial intelligence on different dimensions of ICT manufacturing supply chain resilience, striking a balance between technological advancement, theoretical contributions, and practical implementation. Emphasis should be placed on how AI can contribute to building a more resilient, sustainable, and intelligent supply chain system through pathways such as human–machine collaboration, technology integration, and institutional adaptation. Will this have spillover effects on other manufacturing industries? Whether improving the resilience of the ICT manufacturing supply chain will in turn promote the development of the artificial intelligence industry, and how this will work, will be one of the issues for future research. In addition, it is still unclear whether the influence of artificial intelligence on the resilience of China’s ICT manufacturing supply chain exhibits nonlinear characteristics, such as threshold effects or diminishing returns. Subsequent studies should incorporate more nuanced analytical methods to explore these potential nonlinear dynamics.

Author Contributions

Conceptualization, D.H. and D.J.; methodology, D.H. and D.J.; software, D.J.; validation, D.J. and Y.T.; formal analysis, D.J.; investigation, D.H. and D.J.; resources, D.H. and D.J.; data curation, D.J.; writing—original draft preparation, D.J.; writing—review and editing, D.H., D.J. and Y.T.; visualization, D.J. and Y.T.; supervision, D.H. and D.J.; project administration, D.H. and D.J.; funding acquisition, D.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the General Program of the National Social Science Fund of China (Grant No. 24BGL099).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original data presented in the study are openly available in the China Statistical Yearbook, China Industrial Statistical Yearbook, China High-Tech Industry Statistical Yearbook, China Science and Technology Statistical Yearbook, and China Environmental Statistical Yearbook. Alternatively, Pandas download code and raw data may be requested directly from the authors.

Acknowledgments

We sincerely thank the editor and reviewers for their meticulous work in handling our manuscript. Their thorough review and constructive feedback have been immensely helpful in improving our research, allowing us to refine and enhance our paper.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Analysis of the Current Development Status and Future Prospects of the Semiconductor Industry in 2025. Available online: https://www.chinairn.com/scfx/20250606/173932934.shtml (accessed on 26 July 2025).

- McKinsey & Company. Risks, Resilience, and Rebalancing of Global Value Chains. Available online: https://www.mckinsey.com/capabilities/operations/our-insights/risk-resilience-and-rebalancing-in-global-value-chains (accessed on 26 July 2025).

- Wang, B.; He, J.; Wang, H. The Macroeconomic Effects of Decoupling in the Information and Communication Technology Industry: A Perspective from Production Networks. Econ. Theory Econ. Manag. 2024, 44, 143–162. [Google Scholar]

- Song, H. AI-based Intelligent Supply Chain: Theoretical Exploration and Prospects. China Circ. Econ. 2024, 38, 44–54. [Google Scholar] [CrossRef]

- Chen, J.-K.; Huang, T.-Y. The Multi-Level Hierarchical Structure of the Enablers for Supply Chain Resilience Using Cloud Model-DEMATEL–ISM Method. Sustainability 2022, 14, 12116. [Google Scholar] [CrossRef]

- Rahman, S.; Hossain, N.U.I.; Govindan, K.; Nur, F.; Bappy, M. Assessing Cyber Resilience of Additive Manufacturing Supply Chain Leveraging Data Fusion Technique: A Model to Generate Cyber Resilience Index of a Supply Chain. CIRP J. Manuf. Sci. Technol. 2021, 35, 911–928. [Google Scholar] [CrossRef]

- Barhmi, A.; Hajaji, O. Multidisciplinary Approach to Supply Chain Resilience: Conceptualization and Scale Development. Cent. Eur. Bus. Rev. 2023, 12, 43–69. [Google Scholar] [CrossRef]

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring Supply Chain Resilience: Development of a Conceptual Framework. J. Bus. Logist. 2010, 31, 1–21. [Google Scholar] [CrossRef]

- Kazemian, I.; Torabi, S.A.; Zobel, C.W.; Li, Y.; Baghersad, M. A Multi-Attribute Supply Chain Network Resilience Assessment Framework Based on SNA-Inspired Indicators. Oper. Res. 2022, 22, 1853–1883. [Google Scholar] [CrossRef]

- Li, R.; Dong, Q.; Jin, C.; Kang, R. A New Resilience Measure for Supply Chain Networks. Sustainability 2017, 9, 144. [Google Scholar] [CrossRef]

- Sezer, M.D.; Ozbiltekin-Pala, M.; Kazancoglu, Y.; Garza-Reyes, J.A.; Kumar, A.; Kumar, V. Investigating the Role of Knowledge-Based Supply Chains for Supply Chain Resilience by Graph Theory Matrix Approach. Oper. Manag. Res. 2023, 16, 1220–1230. [Google Scholar] [CrossRef]

- Singh, C.S.; Soni, G.; Badhotiya, G.K. Performance Indicators for Supply Chain Resilience: Review and Conceptual Framework. J. Ind. Eng. Int. 2019, 15, 105–117. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, W.; Wang, D.; Dou, S.; Xu, D. Resilience evaluation of China’s copper resources industrial chain and supply chain. Resour. Sci. 2023, 45, 1761–1777. [Google Scholar] [CrossRef]