Abstract

The rapid advancement of technologies such as artificial intelligence, big data, and cloud computing has driven continuous expansion of global data centers, resulting in increasingly severe energy consumption and carbon emission challenges. According to projections by the International Energy Agency (IEA), the global electricity demand of data centers is expected to double by 2030. The construction of green data centers has emerged as a critical pathway for achieving carbon neutrality goals and facilitating energy structure transition. This paper presents a systematic review of the role of waste heat recovery technologies in data centers for achieving low-carbon development. Categorized by aspects of waste heat recovery technologies, power production and district heating, it focuses on assessing the applicability of heat collection technologies, such as heat pumps, thermal energy storage and absorption cooling, in different scenarios. This study examines multiple electricity generation pathways, specifically the Organic Rankine Cycle (ORC), Kalina Cycle (KC), and thermoelectric generators (TEG), with comprehensive analysis of their technical performance and economic viability. The study also assesses the feasibility and environmental advantages of using data center waste heat for district heating. This application, supported by heat pumps and thermal energy storage, could serve both residential and industrial areas. The study shows that waste heat recovery technologies can not only significantly reduce the Power Usage Effectiveness (PUE) of data centers, but also deliver substantial economic returns and emission reduction potential. In the future, the integration of green computing power with renewable energy will emerge as the cornerstone of sustainable data center development. Through intelligent energy management systems, cascaded energy utilization and regional energy synergy, data centers are poised to transition from traditional “energy-intensive facilities” to proactive “clean energy collaborators” within the smart grid ecosystem.

1. Introduction

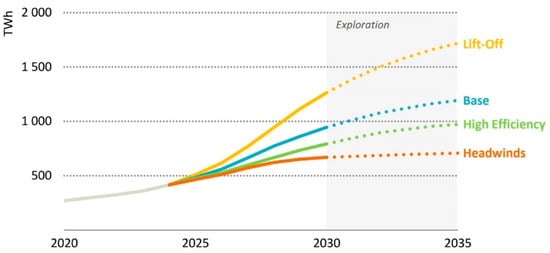

The 21st century faces two critical challenges: transforming the global energy system and developing innovative technologies to combat climate change [1]. Data centers (DCs) have become an integral part of people’s lives amidst the explosive growth in artificial intelligence (AI), data processing and data storage needs [2]. DCs are buildings, specialized spaces or clusters of buildings that process and store data and network communication technology equipment, as well as the infrastructure that powers and cools IT equipment [3]. As an important part of supporting modern IT infrastructure, the energy consumption of DCs has gradually become an important concern in global energy and environmental policies [4]. According to statistics, the power consumption of DCs has accounted for over 3% of the total global power consumption [5,6], and most of this energy is used for heat dissipation and cooling of equipment [7]. The global power consumption of DCs and future forecasts are shown in Figure 1.

Figure 1.

Global DC electricity consumption by sensitivity case, 2020–2035 [8].

Green DCs aim to reduce energy consumption and reuse waste heat through low-carbon, energy-efficient designs and technologies [9], with particular focus on minimizing energy demands in cooling and heat dissipation systems [10]. With the global emphasis on energy efficiency and environmental impact, the construction of green DCs not only helps enterprises to reduce operational costs, but also responds to the challenge of global climate change and promotes sustainable development [11]. The research and application of green energy technologies, waste heat recovery (WHR) technologies, and energy-efficiency optimization solutions constitute the core approach to achieving green transformation in data centers [12].

With the development of technology, more and more WHR systems are applied to DCs. Heat pumps (HP) [13], thermal energy storage (TES) [14], and absorption/adsorption cooling technologies [15,16,17] can effectively harvest low-grade waste heat from IT equipment in data centers. These technologies convert low-temperature heat sources into usable high-temperature outputs, thereby enhancing both the energy quality and supply stability. A study by Wahlroos et al. [5] analyzes the potential of waste heat utilization in DCs in Nordic countries. The economics and emission impacts of waste heat utilization in DH were analyzed through a life cycle assessment. Currently, the primary barriers to effective waste heat utilization lie in its low-grade quality (e.g., low temperature or unstable heat source) and high capital investment costs. The fundamental barrier to WHR and reuse is not technical limitations, but rather the absence of commercially viable solutions that enable data center (DC) operators to monetize waste heat effectively. Meanwhile, Yuan et al. [18] presented a comprehensive review of recoverable low-grade heat sources—including exhaust gases, recycled water, and coolants—across multiple application scenarios. The study also examined WHR technologies suitable for district heating (DH), refrigeration, power generation and industrial or agricultural uses. Through technical, energetic, environmental and economic analyses, the authors offered recommendations for future WHR research and development in data centers, thereby providing systematic insights for the field.

In the design of green DCs, WHR systems need to incorporate cooling systems, power generation, and DH networks simultaneously to optimize economic, energy efficiency and environmental benefits. For instance, using technologies such as waste heat-driven the Organic Rankine Cycle (ORC) [19], Kalina Cycle (KC) [20] and thermoelectric generators (TEG), low-grade waste heat can be converted into electricity to provide power support for the DCs [21]. Concurrently, the recovered thermal energy can be distributed through DH system to surrounding areas, achieving cost reduction and generating multiple synergistic benefits [22]. In the context of DH systems, the recovery and utilization of waste heat from DCs can not only provide cooling supply for the DCs themselves, but also deliver heating and hot water to surrounding residential and industrial areas [23]. This integrated combined cooling, heating and power (CCHP) system achieves high-efficiency energy utilization, reducing both energy consumption and carbon emissions [24]. Through synergistic integration with local district heating networks, it enables maximal utilization of waste heat resources. Mehrenjan et al. [25] conducted an in-depth study on the optimization of the performance of two integrated geothermal-driven polygeneration systems that have the ability to produce electrical energy, cooling water and fresh water simultaneously. The system structure integrates ORC, the absorption refrigeration cycle, a reverse osmosis desalination unit, a liquefied natural gas regasification module and TEG. The study emphasizes that system configuration significantly affects overall performance. It suggests that future work should focus on optimizing component design and coupling mechanisms to improve both energy and resource utilization efficiency. Meanwhile, the study further recommends extending these systems to larger-scale industrial applications and evaluating their performance across diverse climatic conditions. In addition, a systematic analysis of the environmental impacts throughout the system’s life cycle will help to fully understand its long-term sustainability. The introduction of more efficient multi-objective optimization algorithms is also seen as a key direction to improve the accuracy of modeling and scheduling. The study also recommends exploring new materials and engineering technologies to reduce construction and operational costs, extend system lifespan, and improve the economic feasibility of cogeneration systems in real-world applications. Zhang et al. [26] systematically reviewed Kalina Cycle (KC) research, including its working principles, performance comparisons with ORC and energy/exergy efficiency analyses. The study also evaluated the adaptability of different KC configurations across various applications. Additionally, the authors compared methods for predicting the thermophysical properties of ammonia–water mixtures, analyzing their differences in simulation accuracy and engineering applicability. The study also discusses the key issues that ammonia–water mixtures may face in practical applications, such as chemical stability, environmental impacts, safety risks and corrosion characteristics. However, the absence of a unified performance evaluation framework and robust economic assessment tools hinders the broader engineering adoption of KC systems. This limitation makes it difficult to accurately quantify their recycling efficiency, output quality and overall economic benefits.

Although the above literature proposes relevant WHR technologies, there are still some unconsidered aspects in the existing research. Firstly, much of the literature emphasizes and investigates specific WHR technologies without integrating the design and application of relevant system frameworks. Secondly, there is a lack of system performance analysis under unified metrics in the studies. It is undeniable that the researched techniques on district heating, cooling energy supply and power production with low-temperature waste heat are effective in optimizing PUE of DCs, but the quality and continuity of the system’s heat source is not considered in many studies. Finally, few research teams have designed and evaluated models for combining multi-generation (heat, cooling and electricity) WHR systems with new energy power systems, making them not really fully zero-carbonized, and still dependent on the conventional grid for some of their power needs. This is because electrical power is the only source of energy in DCs that urgently needs to be conserved and optimized.

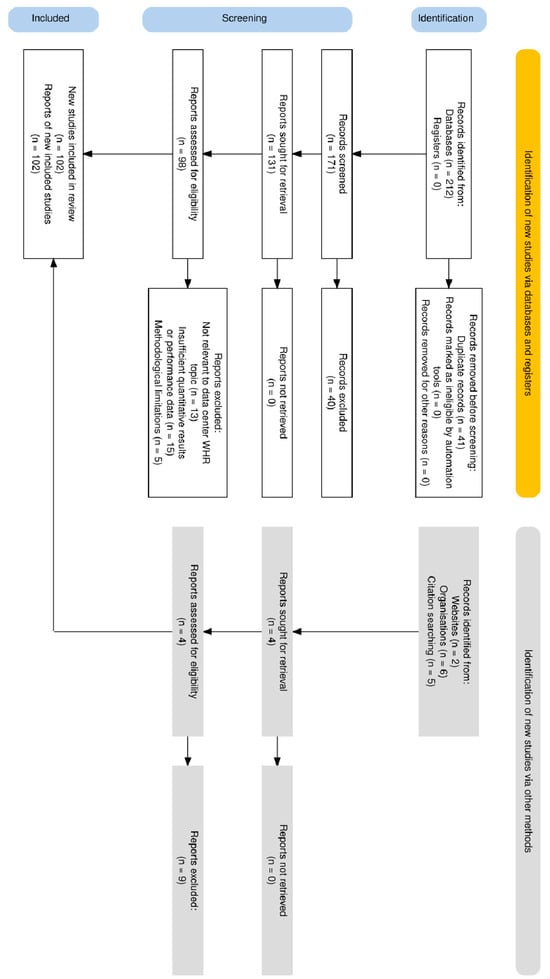

The evidence base was assembled through systematic searches of leading scholarly platforms (ScienceDirect, SpringerLink, Wiley Online Library, IEEE Xplore and Google Scholar). These searches were supplemented with reports and datasets from authoritative organizations, including the International Energy Agency (IEA), the U.S. Department of Energy (DOE), and the National Energy Administration of China (NEA). The review covers January 2000 to June 2025. The final comprehensive search and screening were completed in June 2025 to ensure timeliness and representativeness. Identification, screening, eligibility assessment and inclusion followed PRISMA 2020 and are summarized in Figure 2; the completed PRISMA 2020 checklist is provided in the Supplementary Materials.

Figure 2.

PRISMA flow diagram.

Search strings combined the core term “data center” with waste-heat-related keywords using Boolean operators (and truncation where appropriate): “waste heat recovery”, “Organic Rankine Cycle (ORC)”, “Kalina Cycle”, “thermoelectric generation”, “power generation”, “district heating”, “cooling”, “heat pump” and “thermal energy storage”. Searches were restricted to English-language publications. Reference lists of relevant, high-quality papers were manually screened to identify additional studies and reduce retrieval bias.

Inclusion criteria were predefined as follows: (i) clear relevance to data-center contexts; (ii) substantive treatment of waste-heat collection, upgrading, conversion or utilization and (iii) reporting of technical, environmental, and/or economic indicators (e.g., COP, thermal efficiency, PUE/ERE impact, CO2 reduction, CAPEX/OPEX, payback). Exclusion criteria were (i) non-English sources; (ii) studies unrelated to data centers without transferable methods; (iii) conceptual pieces lacking quantitative or engineering detail and (iv) duplicates or overlapping reports. Two reviewers independently screened titles and abstracts. Potentially eligible items then underwent duplicate full-text assessment. Disagreements were resolved by discussion or, when necessary, arbitration by a third reviewer. No automation or machine-learning tools were used. Data extraction used a standardized template that covered the technology route, operating conditions, performance metrics, environmental impacts, economic indicators and integration architectures.

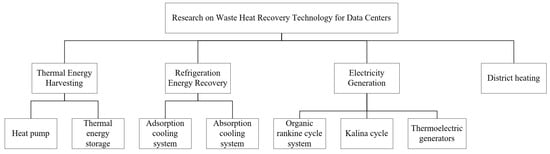

Key themes were pre-specified from the initial scope and bibliometric mapping and were refined into four categories during the screening process as shown in Figure 3 to reflect the approach from technology to system: (T1) heat collection and upgrading (e.g., heat pumps, liquid cooling, TES); (T2) waste-heat-to-power (ORC, Kalina, TEG); (T3) waste-heat-enabled cooling (adsorption/absorption systems) and (T4) coupling with district energy (space/water heating and cascade use). Accordingly, we conducted a systematic review following the PRISMA guidelines, focusing on (i) the collection and thermal upgrading of low-grade heat, (ii) conversion pathways to electricity/cooling/heat and (iii) integration with district energy systems, while quantifying technical performance, environmental benefits and implementation challenges. Further reporting details are documented in the Supplementary Materials (PRISMA 2020 Checklist).

Figure 3.

Conceptual framework of waste-heat recovery pathways for data centers.

This paper systematically reviews and analyzes the technologies for DC waste heat utilization according to common WHR methods and applications, while summarizing the applicable scenarios of WHR to meet the needs of heating, cooling and power generation. Finally, the future development trends toward zero-carbon green DCs are discussed.

2. Waste Heat Recovery Methods for Data Centers

In order to meet the growing demands of the internet, the scale of DC construction has been continuously expanding in recent years. During operation, server electronic equipment emits large amounts of low-grade thermal energy. Typically, this heat is discharged into the outdoor atmosphere as waste heat through ventilation systems, creating an additional energy consumption burden. This increases the Power Usage Effectiveness (PUE) value and also intensifies pressure on the power grid [27]. Moreover, traditional air cooling often leads to hot and cold aisle mixing, causing localized hotspots that compromise equipment performance and reliability [28]. These hotspots force specific servers to run at sustained high temperatures, reducing overall system reliability and hardware lifespan. In order to address the energy consumption and efficiency bottlenecks associated with traditional cooling methods, an increasing number of researchers are shifting toward an integrated approach to energy utilization that combines heat recovery, heating, power generation and cooling. Data centers operate continuously, generating heat with persistent availability, minimal seasonal variation and relatively low temperatures, making it a viable source of low-grade thermal energy. Optimizing low-grade heat recovery systems can significantly improve Power Usage Effectiveness (PUE), reduce greenhouse gas emissions and generate substantial economic returns [18,29].

HPs, TES and absorption/adsorption chillers in WHR are the more common heat collection technologies to realize multiple production in WHR systems [30,31,32]. The application process needs to incorporate future heat usage methods for the most efficient use of WHR methods for DCs. The temperature levels and application scenarios of several different technology types for WHR are given in Table 1. The next section will focus on the structural design, energy efficiency performance, environmental impact and application prospects of WHR technology. This will provide valuable technical references for the future green transformation of DC.

Table 1.

Characteristics of different collector technologies in WHR.

2.1. Application of Heat Pump in Waste Heat Recovery

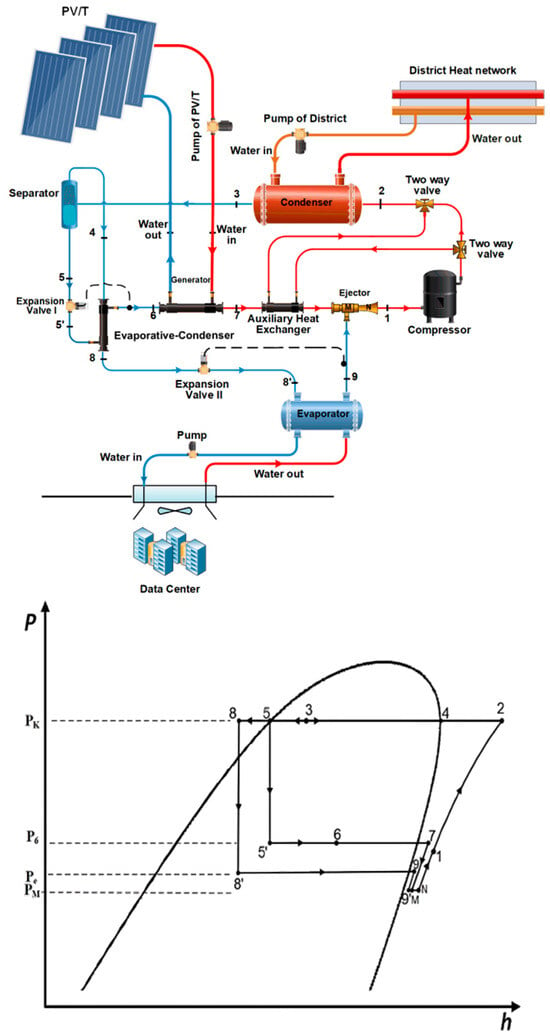

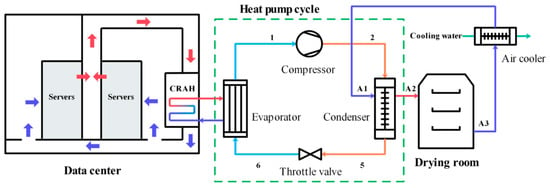

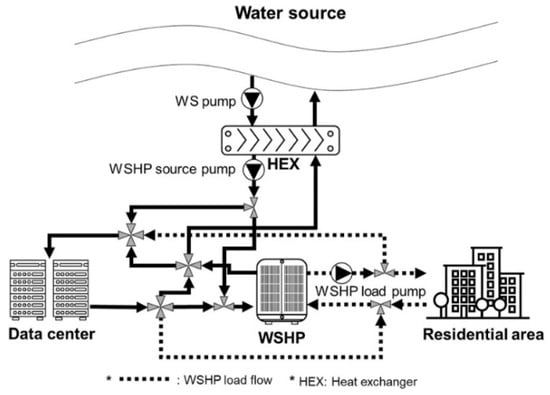

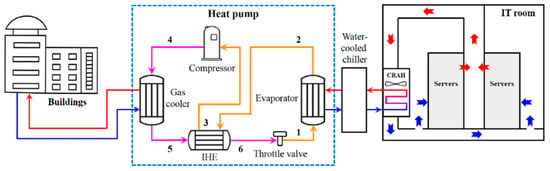

HPs are devices that transfer thermal energy from a low-temperature heat source to a high-temperature heat sink, serving as a key technology in the global transition toward secure and sustainable heating solutions [33]. Al-Sayyab et al. [45] proposed a novel compound composite photovoltaic thermal (PV/T) waste heat driven injection–HP system, as shown in Figure 4, for simultaneous heating and cooling, utilizing waste heat to improve the system performance. The system utilizes PV/T waste heat with an evaporative condenser as the driving force for the ejector, while the generated electricity is used to operate the HP compressor and pump, and the experimental results show that coefficient of performance (COP) is improved by 54% and 49% in cooling and heating modes, respectively. In a tobacco drying application illustrated in Figure 5, Ge et al. [46] utilized a heat pump to capture low-grade waste heat from a data center, elevating it to sufficient temperatures for drying processes. This approach effectively reduced fossil fuel consumption in tobacco production. For equivalent heat output, the data center waste heat drying system demonstrates superior thermodynamic and economic performance. Its specific moisture extraction rate exceeds that of air-source heat pump and coal-fired drying by 20.21% and 36.69%, respectively. The system also reduces carbon emissions by 567.16 kg and 1036.92 kg compared to these alternatives, improves energy reuse efficiency by 64.92% and saves 568.79 kWh per ton of tobacco processed. Meanwhile, a large amount of energy is consumed in heating every year; Jang et al. [47] proposed a water source HP system, as shown in Figure 6, to reduce the energy consumption for heating and cooling in DC and residential areas. TRNSYS simulation compares the performance and operational characteristics of the present study with the conventional system. The average annual PUE of the DC is reduced from 1.26 to 1.23, and the ratio of the annual COP of the residential area is improved from 1.82 to 2.64. Life cycle climate performance analysis investigated the environmental impacts of the proposed system, which can reduce CO2 emissions by 28.7% compared to the conventional system. Li et al. [48] conducted a case study based on a real data center in Beijing to analyze the economic and environmental benefits of a transcritical CO2 HPs. As illustrated in Figure 7, in this system, high-pressure CO2 further releases heat to the low-pressure CO2 in an internal heat exchanger (IHE) prior to the throttling process, thereby reducing the exergy loss during expansion. The system demonstrates a significant reduction in CO2 emissions by 12,880 tons annually. Moreover, the annual Energy Reuse Efficiency (ERE) can be decreased from 1.296 to 0.902, while the investment cost is reduced by 4.2% to 10.2%. The application of HP technology in WHR of DC shows significant energy saving and emission reduction effects, and different types of HP systems have unique advantages in improving energy efficiency, optimizing economy and reducing carbon emissions. These research results not only validate the feasibility of HP technology in the WHR of DC, but also provide an important technological reference and practical basis for the construction of green DC in the future.

Figure 4.

Schematic and P-h diagram of the proposed solar-driven ejector-compression system [45].

Figure 5.

DCWHTD system [46].

Figure 6.

WSHP system construction diagram [47].

Figure 7.

IHE cycle system for CO2 transcritical HPs [48].

2.2. Thermal Energy Storage

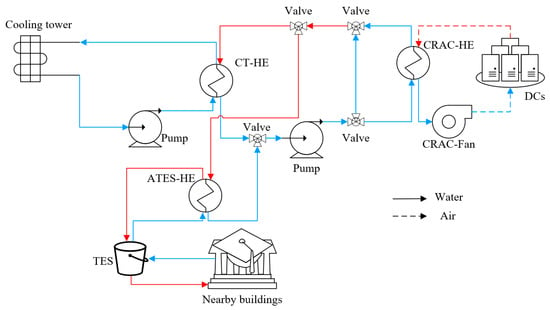

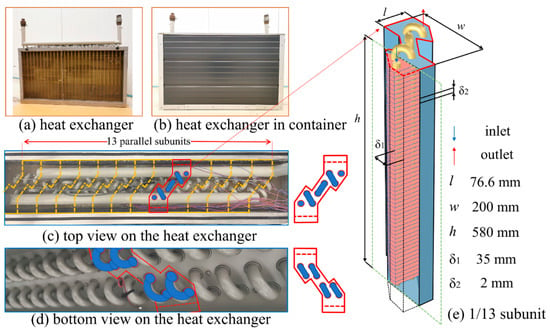

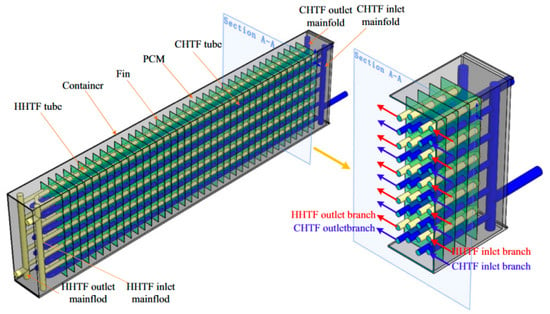

In the process of WHR in DCs, HP technology can effectively enhance the availability of low-grade thermal energy and improve the energy efficiency of heating and cooling. However, while the waste heat supply from DCs is typically continuous and stable, the actual thermal demand may exhibit temporal fluctuations, resulting in the inability to utilize the generated heat in a timely manner. To further optimize waste heat utilization efficiency, thermal energy storage (TES) technology has emerged as a critical component [49]. Li et al. [36] analyzed a Norwegian campus heating system, and proposed a water tank and borehole thermal energy storage (BTES) system to address the mismatch between the recovered WHR from the DC and the heat demand in the building. Based on research findings, the introduction of the water tank system can save 5% in annual energy costs. When energy storage efficiency remains above 80%, the payback period is less than 15 years. Other aspects show no significant improvement. In contrast, the BTES system can increase the utilization rate of low-grade waste heat in DC from 77% to 96%. CO2 emissions are reduced by up to 8%, and annual energy cost savings amount to 6%; however, its payback period extends to 19 years. Dvorak et al. [50] also proposed the aquifer thermal energy storage (ATES) system, shown in Figure 8, to improve the waste heat utilization efficiency of a university campus. A simulated DC data model was developed in TRNSYS and CONTAM using building energy simulation techniques, and a comprehensive operational prediction showed that the ATES system could reduce CO2 emissions by 680 tons per year on average, and in the future scenario, it could increase the CO2 emissions to 1000 tons. In the study of Zhu et al. [51], the heat storage device proposed by the Technical University of Denmark was used as an example, where a tube–fin heat exchanger was inserted in the melted phase change material. The heat exchanger consisted of stainless-steel coil tubes and aluminum fins. The thermal storage system has 265 parallel fins from the top to the bottom. The spacing between the fins is 2 mm and the gap between the edge of the fins and the wall of the vessel is 35 mm. Water circulates through coils to thermally charge or discharge the phase change material within the vessel, with the system layout illustrated in Figure 9. Separately, Liu et al. [52] designed and fabricated a dual-channel thermal storage heat exchanger that implements latent thermal energy storage (LTES) using metal fin-enhanced phase-change material, as shown in Figure 10. Through simulation of para-xylene-enhanced phase-change material, they investigated an efficient LTES configuration characterized by compact size, high phase-change temperature, and rapid heat transfer rates, demonstrating its potential for emergency cooling in data centers. Integrating thermal storage with the aforementioned systems enables excess heat accumulation during low-demand periods and controlled release during peak demand. This strategy addresses supply–demand mismatches, enhances overall energy utilization and reduces reliance on conventional energy sources.

Figure 8.

Using TES to store waste heat from DCs [18].

Figure 9.

The details and diagram of the latent TES for DCs cooling. (a) Heat exchanger with fins. (b) The heat exchanger in container. (c) The top view on the heat exchanger. (d) The bottom view on the heat exchanger. (e) The diagram of the subunit used in the numerical model [51].

Figure 10.

Three-dimensional diagram of the two-path LTES [52].

2.3. Waste Heat Recovery by Absorption/Adsorption Cooling Technology

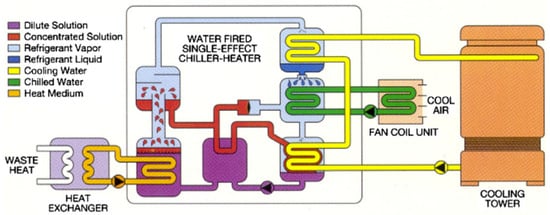

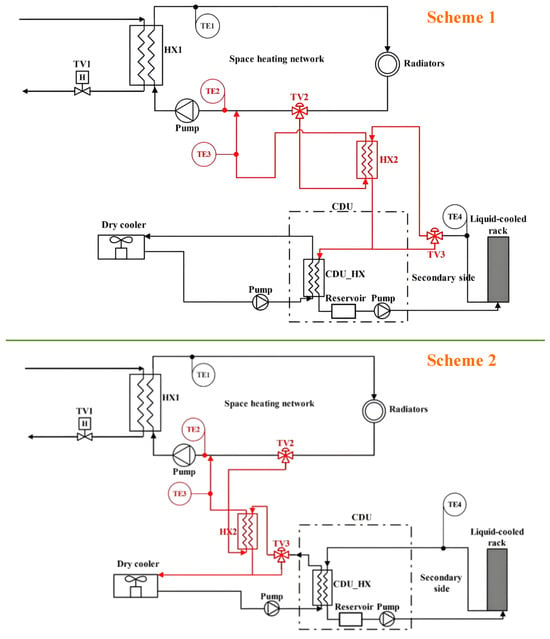

Air-cooling systems in data centers rely heavily on numerous air conditioning units and fan equipment. Not only do such systems exhibit limited cooling efficiency under high-density workloads, but they also consume substantial amounts of energy, making it difficult to meet increasingly stringent energy efficiency demands. Furthermore, constrained by ambient temperature conditions and the additional thermal load generated by the operation of cooling equipment, traditional air-cooling systems face significant challenges in reducing energy consumption and improving overall operational efficiency [17]. To address these issues, researchers have begun to explore technical ways to utilize waste heat from DCs for cooling, and to achieve energy laddering through the recycling of WHR to both reduce energy consumption and improve the overall system efficiency [7]. Haywood et al. [40] investigated the use of waste heat from DCs to drive the 10-ton single-effect lithium bromide–water (Li-Br) absorption refrigeration system shown in Figure 11 for reducing the cooling load of a computer room air conditioner (CRAC). This heat-driven system uses lithium bromide salt as the absorber and water as the refrigerant. They expect to capture 85% of the heat generated by the central processing unit (CPU) and circuit board work in the DC, and when supplemented by external heat provided by solar heat, the PUE value can be less than 1. It greatly reduces the cooling load of the traditional machine room air conditioning CRAC, and ultimately reduces the grid energy consumption of the DC. Huang et al. [41] proposed that after obtaining heat from high-performance components such as processor and memory, the coolant is further heated by solar collectors and then enters into dual-effect absorption refrigeration system. The annual electricity savings from cooling achieved by the waste heat recovery system amount to 27,978 kWh, leading to a reduction in CO2 emissions of 23.9 tons. This significantly lowers energy consumption and greenhouse gas emissions. With a payback period of approximately 4.3 years, the system demonstrates considerable economic potential and practical value. Lu et al. [53] modeled and compared two different WHR scenarios, as shown in Figure 12, using TRNSYS 18 software by connecting the heat demand side to the secondary (Scheme 1) and primary (Scheme 2) sides of the cooling distribution unit. Both scenarios were profitable within one year and resulted in significant CO2 emission reductions, with annual electricity savings of 2290.5 kWh and 905.2 kWh for Scenario 1 and Scenario 2, as well as CO2 emission reductions of 291,996 kg and 258,192 kg, respectively.

Figure 11.

Structure of a 10-ton single-effect lithium bromide–water (lithium bromide) absorption refrigeration system [40].

Figure 12.

DC waste heat utilization network [53].

These solutions augment available cooling capacity and enable the cascade use of energy, thereby accelerating the transition to green, low-carbon data centers. Absorption/adsorption cooling is likely to become a central pathway for data-center thermal management. It operates efficiently with low-grade heat (about 50~95 °C), which matches waste heat from liquid-cooled servers or heat-pump-upgraded loops. By substituting recovered heat for electricity, it reduces PUE and peak power demand. The technology uses benign, efficient working pairs and has few moving parts, which lowers maintenance and improves reliability. It is scalable, from rack- or room-level chillers to campus or district energy systems. Continued advances in high-capacity sorbents, compact heat exchangers, and WHR–heat-pump hybrid architectures are raising COP and part-load performance. Heat-driven sorption cooling provides a viable route to lower electricity use and CO2 emissions while enhancing the resilience of data-center operations.

3. Power Generation Technology in Waste Heat Recovery

With the continuous growth of global energy demand, how to improve energy utilization efficiency and reduce carbon emissions has become an important goal of global energy transition [54]. WHR technology has received more and more attention as an effective way of energy reuse. Especially in energy-intensive industries such as DCs, how to convert low-grade WHR into electricity by recovering and utilizing it has become a hot spot in current research. However, low-grade heat energy is difficult to be directly converted into electricity due to its low temperature. Therefore, the development of power production technologies that can efficiently utilize low-grade waste heat is of great economic and environmental significance.

ORC systems, KC and TEG technologies offer a promising solution for converting low-grade thermal energy into high-quality heat sources [55]. However, although the problem of power production in low-grade WHR has been solved to some extent, these technologies still have different limitations. Meanwhile, numerous novel power generation technologies are emerging, such as combined heat and power (CHP) systems integrated with fuel cells and poly-generation systems.

Research on technologies for converting low-grade thermal energy into electricity continues to advance. Although progress has been made with techniques such as ORC, KC, and TEG, overcoming their inherent limitations, improving efficiency, reducing costs and achieving commercial viability remains a key focus for future studies.

Research on technologies for converting low-grade thermal energy into electricity continues to advance. Although progress has been made with techniques such as ORC, KC, and TEG. Nevertheless, overcoming their inherent limitations in efficiency, cost reduction and commercial viability remains a critical research challenge.

3.1. Organic Rankine Cycle System

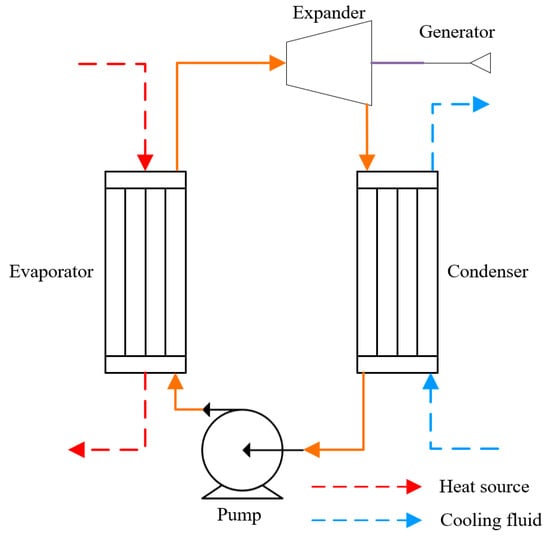

Recent research on low-grade heat recovery cascade ORC systems for power production provides new insights into energy recycling and sustainability in DCs [56]. In efforts to reduce energy consumption and reuse low-grade heat, ORC systems present a promising solution for generating electricity from these thermal sources. Figure 13 illustrates a schematic diagram of an ORC system configuration. Liu et al. [57] proposed a CHP system that integrates an ORC with a HPC through a built-in evaporator. A key feature of this system is that both the ORC and HPC sub-cycles share a common built-in evaporator, where the working fluid is split into two separate streams before entering the respective sub-cycles. This configuration offers the major advantage of maintaining relatively high input waste heat temperatures for both sub-cycles, while allowing flexible adjustment of the system’s heat-to-power output ratio. Under standard operating conditions, the system achieves a maximum thermal output of 28.3 kW and a peak thermal efficiency of 32.2%. Li et al. [58] introduced a coupled system that combines a solar collector, a dual-effect absorption refrigeration (DABC) and an ORC. A case study was conducted on a DC in Beijing. Experimental results indicate that the net power output initially increases and then decreases with the rise in evaporation temperature. In the DABC system, the COP increases with higher heat source temperatures; however, the upward trend becomes less pronounced once the COP reaches 1.3. Therefore, careful selection and optimization of parameters is crucial to maximizing the performance of the ORC system. Under initial operating conditions—with the flow distribution ratio fixed at 0.5—the system achieved an annual cooling capacity of 27.978 kWh and an annual electricity production of 12.08 kWh, potentially reducing CO2 emissions by up to 23.9 tons. Besides reducing the overall cooling load and its attendant power demand [59], the ORC system provides economic benefits through electricity generation for the DC [60]. Ebrahimi et al. [61] employed a steady-state thermodynamic model to evaluate the feasibility of using low-grade thermal energy from dual-loop DCs to drive an ORC system for power generation. This study represents the first quantitative analysis of the compatibility between ORC systems and the operational conditions of DCs. For waste heat temperatures below 85 °C, a superheater was implemented to elevate the recovery temperature; however, its additional energy consumption adversely affected system performance. A smaller temperature differential between the chip and micro-evaporator, or conversely, a higher chip temperature, can substantially degrade system efficiency. The results indicate that R245fa and R134a are the optimal working fluids for the ORC system and server cooling, respectively. Considering variations in electricity prices across regions, the investment payback period ranges from 4 to 8 years. Chen et al. [62] designed six types of combined cooling, heating, and power (CCHP) cogeneration systems, three of which incorporate ORC systems to tackle WHR challenges in DCs. Their comparative analysis of the optimal energy efficiency of ORC systems within combined cooling and power supply modes is summarized in Table 2. Future research on ORC systems should prioritize the development of environmentally friendly working fluids suitable for ultra-low-temperature heat sources, as well as the design of structurally versatile systems. These research initiatives are crucial for achieving both effectiveness and efficiency in practical implementations.

Figure 13.

Schematic representation of an ORC system.

Table 2.

ORC system efficiency.

3.2. Kalina Cycle

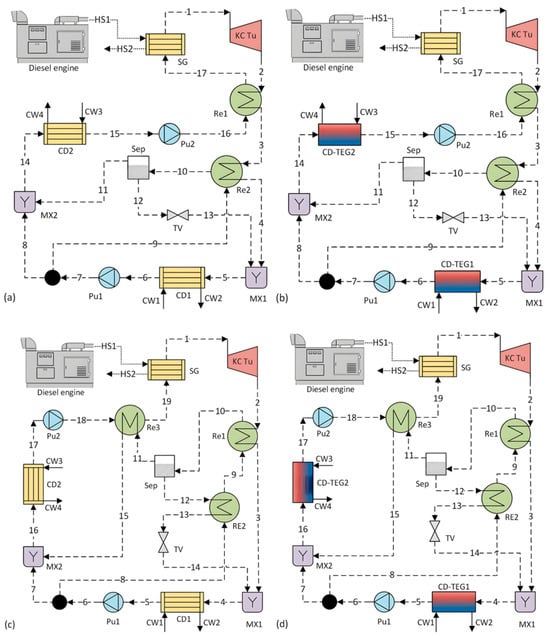

KC has been gaining popularity in recent years due to its highly efficient mechanism. KC is actually a modified ORC, and was first developed by Ferdinand Carre in 1858 using aqueous ammonia solution [70]. KC utilizes a unique distiller condenser subsystem to achieve the ammonia condensation process at low condensing pressures by varying the mass fraction of ammonia, thus improving the heat recovery efficiency from low-temperature heat sources. Through this process ammonia vapor expansion drives a turbine generator to generate electricity, realizing the conversion of waste heat to electricity [71]. Mahmoud et al. [72] carried out a detailed waste heat analysis and recovery study of a typical cement plant applying KC using ASPEN HYSIS V8.4 software. Experimental results demonstrate that the adoption of a combined WHR system based on the KC not only reduces costs by approximately 23%, but also achieves a net power output of 7.35 MW, with a payback period of 21 months. Ghaebi et al. [73] proposed a novel poly-generation system for waste heat recovery based on the Kalina Cycle (KC), which utilizes geothermal energy to simultaneously produce cooling, heating, power and freshwater. A comprehensive thermodynamic modeling and parametric study demonstrated that the system could achieve optimal performance, with a thermal efficiency of 94.84%, an exergy efficiency of 47.89%, and a sum of the unit cost of products (SUCP) of 89.95 USD/GJ. Sohrabi et al. [74] improved the thermal performance of the KC by investigating the standard and enhanced KCs, as given in Figure 14, by embedding a TEG into the condenser of a simple high-temperature KC. The net power output and condenser pinch point location were optimized using parametric optimization method. The TEG can increase the total power capacity of the high-temperature KC by about 0.29–0.82 kW. Meanwhile, the energy efficiency and exergy efficiency of the enhanced KC are 32% and 63.23%, respectively. Wang et al. [75] developed a KC simulation model based on Aspen Hysys software for waste heat with a heating temperature of 180 °C, and the efficiency of conversion of waste heat to electrical energy was calculated as an energy efficiency index. The experimental results show the highest net output power and heat conversion efficiency of 160.5 kW and 37.9%, respectively. The KC system is characterized by a more complex layout, relatively low efficiency and high cost. Some studies have shown that KC systems outperform ORC systems in certain WHR scenarios, exhibiting better performance [76]. However, the KC system also has drawbacks, particularly the use of ammonia–water mixture as the working fluid, whose corrosiveness and toxicity pose safety challenges in system design, operation and maintenance [77].

Figure 14.

Schematic diagram of WHR system based on KC. (a) Simple KC 1. (b) Enhanced KC 1. (c) Simple KC 2. (d) Enhanced KC 2. [74].

3.3. Thermoelectric Generators

TEG offers a direct method to convert low-grade thermal energy from DC into electricity by leveraging the Seebeck effect. In the realms of renewable energy production and industrial WHR, numerous studies have focused on the development and optimization of TEG devices [78]. Cai et al. [79] introduced a methodology for optimizing the sizing of TEG modules and systems. Through a case study utilizing truck engine exhaust as a heat source, they determined that the optimal module height was 1.5 mm, with 144 modules required. These findings offer valuable insights for the design of TEG systems and their potential for large-scale industrial applications. Wen et al. [80] investigated the structural design and performance optimization of linear Fresnel concentrator photovoltaic/thermoelectric (LFPV/T) systems, both with and without a gravity-driven heat pipe (GHP). The evaporator of the GHP is connected to the photovoltaic panel, enabling the removal and absorption of waste heat that cannot be converted into electricity. The heat pipes then transfer this energy to the TEG via an aluminum heat exchanger in the condenser. This configuration enhances the thermal performance of the entire system by effectively channeling waste heat to the high-temperature side of the thermoelectric cooler. Numerical simulations conducted using MATLAB modeling predicted an output power of 13.64 kW for the GHP-LFPV/T-TEG system. Lan et al. [81] developed a one-dimensional model to address the geometric and structural limitations affecting the economic and thermal efficiency of TEG. By focusing on the influence of thermoelectric leg geometry and structure, a comparative analysis was conducted from energy, economic and environmental perspectives. The new structure achieved an increase in output power by a factor of 1.01–3.59 and improved efficiency by 1.03–4.57 times. Under conditions of low heat source temperature and high figure of merit (ZT) materials, the cost and CO2 emissions were reduced by 1.0–72.1%. Lou et al. [82] designed coaxial cased geothermal wells with TEG layers in order to utilize low- and medium-temperature geothermal heat sources in the process of extracting power generation. A thermoelectric model was constructed using MATLAB, and experimental results indicated that the TEG system achieved an output power of 5.52 kW. The TEGs are considered promising devices for clean energy conversion from waste heat [83], offering advantages such as direct energy conversion, solid-state operation without moving parts, high reliability, scalability, long service life and compatibility with diverse systems and environments. However, the low efficiency of TEGs remains the most significant barrier to their widespread practical application [84]. To enhance their efficiency and application potential, current research in this field focuses primarily on material modification, structural optimization and system integration [77].

3.4. Electricity Production Realized by Other Technologies

Due to energy scarcity and increasingly stringent environmental requirements, how to convert low-grade waste heat into electricity has become a hot spot in current research. In the research field of WHR power production technology, besides ORC, KC and TEG, various other technologies are also emerging in the continuous exploration. Wang et al. [85] proposed a design of a DC server rack structure coupled with a proton exchange membrane fuel cell (PEMFC), considering both the electrical and thermal management coupling of the server to the PEMFC, and constructed a cabinet prototype. The study employed a Back-Air to Water Heat Exchanger (BAWHE) to recover thermal energy from the hot air exhausted by servers. The waste heat was transferred to a water medium and then distributed for thermal management in both the cooling system and the Proton Exchange Membrane Fuel Cell (PEMFC) system. This approach not only meets the cooling demands of the data center, but also effectively converts waste heat into usable thermal and electrical energy, thereby achieving carbon emission reduction and combined heat and power (CHP) generation. Kanbur et al. [86] integrated a two-phase immersion direct cooling system for data centers with a PEMFC to design a novel hybrid system. This configuration provides efficient liquid cooling for IT equipment while utilizing the waste heat to preheat hydrogen and compressed air streams for enhanced PEMFC operation. The system demonstrates stable performance across combined heat and power (CHP), trigeneration, and multi-generation modes within the specified operating range, achieving average efficiencies of 17.39%, 24.68% and 96.16%, respectively. Overall, various WHR technologies for power generation each demonstrate distinct strengths in terms of conversion efficiency, economic feasibility and environmental performance. The ongoing development in this field is moving toward greater system integration and higher efficiency. Despite numerous technical challenges, the optimization of system design, parameter matching and cross-disciplinary synergies hold promise for enabling the commercial application of low-grade thermal energy power generation technologies in the future. Such advancements could provide substantial support for building a low-carbon energy system [5].

4. Waste Heat Recovery for District Heating

Low-grade heat recovery is an effective way to improve energy efficiency, reduce carbon emissions and lower energy consumption, and WHR technology has gradually become an integral part of DH system optimization [87]. In many cold regions, DH serves as a critical conventional energy consumption approach. By effectively recovering and reusing the low-grade waste heat generated in DCs, it is possible to not only reduce reliance on conventional energy sources, but also significantly enhance the overall system efficiency [88]. The main WHR technologies currently used in DH cover HP, TES and CCHP systems, and multi-energy complementary solutions combined with renewable energy sources [27]. The following section discusses the prospects and technical challenges of its practical application.

Stock et al. [89] presented an optimization model integrated with an actual DH system, incorporating building retrofit strategies and HP installation. By utilizing decentralized HP to integrate low-temperature heat sources into the DH network, this approach achieves a cost reduction of 24.4% under building renovation scenarios. Tervo et al. [90] employed energy modeling software to analyze a 21 MW data center, assessing the CO2 reduction potential and economic feasibility of utilizing its low-grade waste heat for district heating. The results show that WHR can achieve an annual CO2 emission reduction of 9800 tons and a net production cost reduction of 6.8 EUR/MW. However, due to the instability of low product heat recovery in DCs, DH should not be dependent on a single DC as their heat source. To enhance the quality of low-grade waste heat from DCs utilized in DH, He et al. [91] proposed a distributed cooling system integrated with HP for waste heat recovery, aiming to achieve a stable and efficient district heating supply. The system layout implemented in Hohhot, China, adopts this approach, utilizing cooling water as the waste heat source in the study. The system achieves an annual electricity saving of approximately 10% and reduces coal consumption by 18,000 tons. Du et al. [92] proposed a dual short-term TES solution that facilitated peak shaving and load shifting, significantly improving the flexibility and stability of the waste heat heating system. Compared to the WHR system without TES, COP was reduced by 15%, peak demand was reduced by 10%, load shifting was improved by 2.1% and total cost was reduced by 32%. Keskin et al. [93] achieved integrated energy management for DC power, heating, cooling and WHR. Multiple case operation strategies were investigated using integer linear programming methods, and the annual power cost of a DC based on CCHP was reduced by 40.3%, with a payback period of about 6.6 years.

In a case study of a 300-rack data center in Beijing, Zhou et al. [94] designed a DH system that integrates a HP to upgrade the thermal quality of recovered waste heat. The system delivers continuous cooling for the data center while simultaneously providing space heating and domestic hot water to a six-story residential building containing twelve apartment units. Meanwhile, the system dynamically switches operation modes in response to fluctuations in load demand and outdoor conditions, thereby optimally satisfying both data center cooling and district heating requirements. The study indicates that the heating COP exhibits periodic fluctuations over a 24-h cycle throughout the year. During the time intervals of 6:00–9:00 and 21:00–24:00, the COP values were recorded at 3.87 and 4.24, respectively. Furthermore, the maximum seasonal COP during the heating period reached 5.27. The system integrates waste heat recovery with cooling processes, providing year-round domestic hot water and space heating for residential buildings during the heating season, and is characterized by high efficiency and significant energy-saving potential. However, further research is needed to address periods of low heating and hot water demand, as system operation under partial load conditions during these intervals results in reduced overall efficiency. Alarnaot-Alarnaout et al. [95] proposed a WHR scheme for DCs that integrates a semi-hermetic piston compressor and an internal heat exchanger (IHX) controlled by an electromagnetic bypass valve within a high-temperature HP. The study investigated the performance of this system for both DH and district cooling applications. The results show that the highest heating and cooling efficiencies were achieved at 2 °C/45 °C with the IHX in operation, yielding a COP of 4.24. Without the IHX, the maximum energy efficiency at the same temperature conditions exceeded 35%. Economic analysis indicated a payback period of less than five years for all configurations.

WHR technologies in DH have shown great potential for improving energy utilization efficiency, reducing carbon emissions and promoting energy conservation. Especially with innovations in technology areas such as HP and cogeneration, WHR technology is gradually becoming an integral part of DH systems [96]. However, further research and analysis are required to optimize system operation during periods of low district heating demand, with the aim of improving overall efficiency. Moreover, against the backdrop of ongoing energy structure transformation and the advancement of green low-carbon development goals, WHR technology in DH is poised to play an increasingly vital role in promoting sustainable development and addressing climate change.

5. Discussing the Future of Green Data Centers

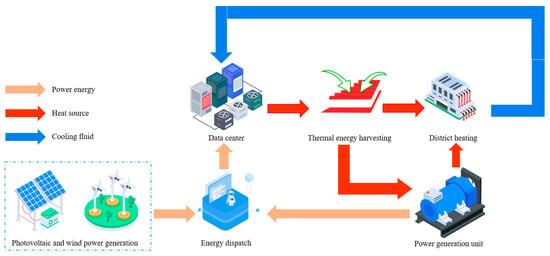

In view of the concurrent trends of continuously escalating computing power and tightening carbon constraints, the core mission of green DC has shifted from single-point energy reduction to integrated system optimization encompassing electricity, heat and cooling. Cooling and heat dissipation constitute the primary energy demands in DCs, with their consumption becoming increasingly prominent as computational density and processing capabilities advance. Achieving minimal energy consumption while ensuring computing power, reducing environmental impact, and shortening investment payback periods have become major challenges in global green DC construction [97,98,99,100,101]. Figure 15 illustrates a closed-loop system demonstrating the transformation of data centers from passive energy consumers to active nodes in campus/urban energy networks. The technical pathway is as follows: “PV/Wind Power→Data Center Operation→Waste Heat Harvesting →Power Generation→District Heating→Cooling Water Return→Energy Dispatch.” Through cross-temporal optimization of electricity, heat, cooling and storage flows, this integrated approach enables a synergistic improvement in key metrics including PUE, Energy Reuse Effectiveness (ERE) and Carbon Usage Effectiveness (CUE). Within this framework, DC transforms from mere energy consumers into comprehensive energy units capable of providing heat, flexibility and ancillary services.

Figure 15.

Conceptual framework diagram for green DC development.

The zero-carbon data center developed by China Telecom Qinghai in Xining exemplifies the successful integration of computing infrastructure with renewable energy. This demonstration project achieves synergistic coupling between computational resources and green power, characterized by regional energy coordination, low-carbon operation and intensive resource circularity [102]. By connecting to a grid with a high proportion of renewable energy, DC significantly reduces its reliance on fossil fuels and lowers carbon emissions across its entire lifecycle, driving the implementation of green transformation.

The roadmap for green data center development is projected to progress through three distinct phases. The initial phase focuses on implementing direct waste heat recovery systems at both cabinet and room levels, enabling thermal energy to displace electrical power consumption. Phase two involves deploying phase change thermal storage to manage peak loads and accommodate renewable energy fluctuations, while implementing a “renewables-first, grid–auxiliary operation” strategy through an energy dispatch platform. This configuration ensures operational reliability while establishing a closed-loop system that integrates thermal energy capture, cooling processes, and waste heat utilization. The medium- and high-temperature waste heat streams will be directed to embedded power generation units, while the low-grade thermal energy will be upgraded through heat pumps for integration into district heating networks. The dispatch layer will incorporate predictive and optimization capabilities, supported by the deployment of medium- to long-duration thermal storage systems such as BTES and ATES thermal energy storage. This transformation will reposition data centers from mere energy consumers to multi-functional nodes that provide thermal energy and grid flexibility services, achieving reduced peak power demand, increased local consumption of renewable electricity, and expanded external heat supply capacity. The final development phases will establish regional energy coordination and near-zero-carbon operations. With standardized thermal interfaces and metering and settlement mechanisms in place, data centers will routinely exchange energy with urban infrastructure, functioning as flexible assets within the integrated energy system. Stable delivery of medium-temperature heat enables participation in demand response and ancillary services, converting the adjustability of cooling and power generation units into tradable flexibility. The energy dispatch platform evolves into a digital twin hub, incorporating carbon-constrained optimization and Life Cycle Assessment (LCA) assessment to achieve synergistic optimization of computing power, energy and carbon emissions.

This is not merely a stacking of equipment, but rather a system-level coordination based on temperature zone matching, energy storage stratification, partial load performance, and market signals. By leveraging coordinated operation of heat collection and storage technologies, it enhances output temperature zones and smooths load profiles. Technologies like ORC, KC and TEG recover electricity within suitable temperature zones, bolstering system resilience. AI-driven scheduling enables rolling forecasts and decisions across minute-to-seasonal timeframes, consistently balancing energy efficiency, economic viability and carbon efficiency. Non-technical factors—including standardized interfaces, metering and settlement mechanisms, data security and operational capabilities—define the boundaries for waste heat to be “accessible, measurable and tradable”, forming the critical foundation for large-scale implementation.

6. Conclusions

This paper systematically reviews the core technologies and application pathways for WHR in DC. It emphasizes the integration of heat collection and elevation systems comprising HP, TES and absorption/adsorption refrigeration. These systems are coupled with waste heat-to-power conversion systems featuring ORC, KC and TEG technologies. This creates a dual-channel utilization model for power generation and heating. By deploying energy conversion systems across multiple temperature gradients, this configuration facilitates low-grade heat to power generation, thereby reducing peak electricity demand and grid dependency. Concurrently, HP elevation and tiered heating enable the distribution of low-to-medium-temperature waste heat to outside district heating systems, enhancing renewable energy integration and energy recycling efficiency. The synergy between WHR, renewable power, thermal electrical storage and intelligent dispatch simultaneously improves energy efficiency, reduces carbon intensity and enhances economic viability.

Based on recent research and demonstrations, future efforts should focus on the following:

- (1)

- Establishing a unified cross-scenario evaluation framework to refine coupled calculations of metrics, including PUE, COP and LCA;

- (2)

- Conduct empirical studies across diverse climates and operational models to develop replicable integrated power–heating engineering templates and investment models;

- (3)

- Advanced prediction, optimization, and control frameworks for multi-energy systems, integrated with comprehensive uncertainty analysis, enable synergistic coordination of power generation and thermal energy utilization while maintaining guaranteed computational reliability.

The optimal solution for green DC lies not in a single technology, but in an integrated approach encompassing electricity, heat, cooling, storage, networks and markets. This approach is underpinned by temperature zone matching, layered energy storage, digital twins and AI-driven scheduling. It significantly reduces carbon intensity within a foreseeable timeframe, positioning green DC as near-zero-carbon hubs that support the high-quality development of computing infrastructure.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su172210101/s1, Table S1: PRISMA 2020 checklist for the review. References [103,104] are cited in the

Supplementary Materials.

Author Contributions

L.Z.: conceptualization, funding acquisition, resources, supervision, writing—original draft; Z.Z.: conceptualization, methodology, software, investigation, formal analysis, writing—original draft; B.C.: writing—review and editing, supervision; M.Z.: software, validation; Y.C.: visualization, investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| AI | Artificial intelligence | KC | Kalina cycle |

| ATES | Aquifer thermal energy storage | LFPV/T | Linear Fresnel concentrator photovoltaic/thermoelectric |

| BTES | Borehole thermal energy storage | LTES | Latent thermal energy storage |

| CARC | Computer room air conditioner | ORC | Organic Rankine Cycle |

| CCHP | Combined cooling, heating and power | PEMFC | Proton exchange membrane fuel cell |

| COP | Coefficient of performance | PUE | Power usage efficiency |

| DC | Data center | PV/T | Photovoltaic thermal |

| DH | District heating | TEG | Thermoelectric generators |

| GHP | Gravity-driven heat pipe | TES | Thermal energy storage |

| HP | Heat pump | WHR | Waste heat recovery |

| IHE cycle | Add an internal heat exchanger in the simple cycle | Li-Br | Bromide–water |

| IHX | Internal heat exchanger | CO2 | Carbon dioxide |

| LCA | Life Cycle Assessment |

References

- Fuchs, N.; Yanez, G.; Nkongdem, B.; Thomsen, J. Evaluating low-temperature heat sources for large-scale heat pump integration: A method using open-source data and indicators. Appl. Energy 2025, 377, 124487. [Google Scholar] [CrossRef]

- Li, F.; Xing, L.; Su, W.; Lin, X.; Liang, Y.; Shi, W. An idea to construct integrated energy systems of data center by combining CO2 heat pump and compressed CO2 energy storage. J. Energy Storage 2024, 75, 109581. [Google Scholar] [CrossRef]

- Huang, P.; Copertaro, B.; Zhang, X.; Shen, J.; Löfgren, I.; Rönnelid, M.; Fahlen, J.; Andersson, D.; Svanfeldt, M. A review of data centers as prosumers in district energy systems: Renewable energy integration and waste heat reuse for district heating. Appl. Energy 2020, 258, 114109. [Google Scholar] [CrossRef]

- Liaqat, K.; Soleimani, S.; Schaefer, L. Low-grade heat utilization: Techno-economic assessment of a hybrid CO2 heat pump and organic rankine cycle system integrated with photovoltaics and thermal storage. Appl. Therm. Eng. 2025, 268, 125959. [Google Scholar] [CrossRef]

- Wahlroos, M.; Pärssinen, M.; Rinne, S.; Syri, S.; Manner, J. Future views on waste heat utilization—Case of data centers in northern Europe. Renew. Sustain. Energy Rev. 2018, 82, 1749–1764. [Google Scholar] [CrossRef]

- Law, M. Energy Efficiency Predictions for Data Centres in 2023. 2022. Available online: https://datacentremagazine.com/articles/efficiency-to-loom-large-for-data-centre-industry-in-2023 (accessed on 16 May 2025).

- Ebrahimi, K.; Jones, G.F.; Fleischer, A.S. A review of data center cooling technology, operating conditions and the corresponding low-grade waste heat recovery opportunities. Renew. Sustain. Energy Rev. 2014, 31, 622–638. [Google Scholar] [CrossRef]

- Energy and AI, International Energy Agency. 2025. Available online: https://www.iea.org/reports/energy-and-ai (accessed on 16 May 2025).

- Li, G.; Sun, Z.; Wang, Q.; Wang, S.; Huang, K.; Zhao, N.; Di, Y.; Zhao, X.; Zhu, Z. China’s green data center development:Policies and carbon reduction technology path. Environ. Res. 2023, 231, 116248. [Google Scholar] [CrossRef] [PubMed]

- Lin, W.; Lin, J.; Peng, Z.; Huang, H.; Lin, W.; Li, K. A systematic review of green-aware management techniques for sustainable data center. Sustain. Comput. Inform. Syst. 2024, 42, 100989. [Google Scholar] [CrossRef]

- Naili, N.; Nouicer, O.; Attar, I.; Mgadmi, G. Optimization and behavior result analysis of a solar assisted ground source heat pump system using TRNSYS simulation tool. Geothermics 2025, 131, 103353. [Google Scholar] [CrossRef]

- Ammari, A.C. Optimizing the use of renewable energy to minimize operational costs in distributer green data centers. Renew. Energy Prod. Distrib. 2023, 2, 461–489. [Google Scholar] [CrossRef]

- Chen, J.; Guo, C.; Feng, C.; Qu, X.; Tan, S.; Jiang, Y. Research of CO2 high temperature heat pump for industrial steam generation with data center heat source. Int. J. Refrig. 2025, 173, 185–200. [Google Scholar] [CrossRef]

- Chen, L.; Wang, J.; Lou, J.; Cheng, Z.; Wang, N.; Cheng, S.; Sun, L. Thermo-economic analysis of a pumped thermal energy storage combining cooling, heating and power system coupled with photovoltaic thermal collector: Exploration of low-grade thermal energy storage. J. Energy Storage 2024, 96, 112718. [Google Scholar] [CrossRef]

- Velte-Schäfer, A.; Teicht, C.; Stahlhut, M.; May, T.; Herrmann, R.; Urbaneck, T.; Füldner, G. Utilizing waste heat from data centers with adsorptive heat transformation—Heat exchanger design and choice of adsorbent. Energy Convers. Manag. 2024, 310, 118500. [Google Scholar] [CrossRef]

- González, R.C.; Díaz, A.J.; Rojas O, D.; Sarmiento-Laurel, C. Assessing solar absorption chillers for data center cooling across diverse climatic conditions. Energy Build. 2025, 331, 115376. [Google Scholar] [CrossRef]

- Liang, A.; Yang, S.; Ding, Y.; Ma, S. Triple effect absorption refrigeration systems for the deep recovery of low grade waste heat. Appl. Therm. Eng. 2024, 250, 123500. [Google Scholar] [CrossRef]

- Yuan, X.; Liang, Y.; Hu, X.; Xu, Y.; Chen, Y.; Kosonen, R. Waste heat recoveries in data centers: A review. Renew. Sustain. Energy Rev. 2023, 188, 113777. [Google Scholar] [CrossRef]

- Marshall, Z.M.; Duquette, J. A techno-economic evaluation of low global warming potential heat pump assisted organic rankine cycle systems for data center waste heat recovery. Energy 2022, 242, 122528. [Google Scholar] [CrossRef]

- Roeinfard, N.; Moosavi, A. Thermodynamic analysis and optimization of the organic rankine and high-temperature kalina cycles for recovering the waste heat of a bi-fuel engine. Fuel 2022, 322, 124174. [Google Scholar] [CrossRef]

- Chen, X.; Bai, J.; Fu, L.; Lei, Y.; Zhang, D.; Zhang, Z.; Luo, Q.; Gong, S.; Shen, B. Complementary waste heat utilization from data center to ecological farm: A technical, economic and environmental perspective. J. Clean. Prod. 2024, 435, 140495. [Google Scholar] [CrossRef]

- Said, L.B.; Ali, A.B.M.; Aminian, S.A.; Sharma, K.; Dhawan, A.; Sharma, P.; Becheikh, N.; Kolsi, L. Optimal utilization of geothermal energy through three organic cycles combined with a thermoelectric generator and an electrolysis unit. Case Stud. Therm. Eng. 2025, 71, 106149. [Google Scholar] [CrossRef]

- Wang, P.; Kowalski, S.; Gao, Z.; Sun, J.; Yang, C.-M.; Grant, D.; Boudreaux, P.; Huff, S.; Nawaz, K. District heating utilizing waste heat of a data center: High-temperature heat pumps. Energy Build. 2024, 315, 114327. [Google Scholar] [CrossRef]

- Gimelli, A.; Iossa, R.; Karimi, A.; Muccillo, M.; Braccio, S.; Phan, H.T. Energy-saving and economic feasibility of a battery-integrated combined cooling, heating and power (CCHP) plant through waste heat recovery for H2O-NH3 based absorption, power and cooling (APC) system. Energy 2025, 317, 134640. [Google Scholar] [CrossRef]

- Mehrenjani, J.R.; Shirzad, A.; Adouli, A.; Gharehghani, A. Data-driven optimization of two novel geothermal-powered systems integrating LNG regasification with thermoelectric generation for eco-friendly seawater desalination and data center cooling. Energy 2024, 313, 133846. [Google Scholar] [CrossRef]

- Zhang, X.; He, M.; Zhang, Y. A review of research on the kalina cycle. Renew. Sustain. Energy Rev. 2012, 16, 5309–5318. [Google Scholar] [CrossRef]

- Hao, Y.; Zhou, H.; Tian, T.; Zhang, W.; Zhou, X.; Shen, Q.; Wu, T.; Li, J. Data centers waste heat recovery technologies: Review and evaluation. Appl. Energy 2025, 384, 125489. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, Z.; Cao, S.; Du, T.; Guo, H.; Deng, J. An investigation into the cooling effect of air desuperheater tower: A novel method to mitigate the heat island effect. J. Clean. Prod. 2022, 367, 133080. [Google Scholar] [CrossRef]

- Lin, X.; Zuo, L.; Yin, L.; Su, W.; Ou, S. An idea to efficiently recover the waste heat of data centers by constructing an integrated system with carbon dioxide heat pump, mechanical subcooling cycle and lithium bromide-water absorption refrigeration cycle. Energy Convers. Manag. 2022, 256, 115398. [Google Scholar] [CrossRef]

- Ibrahim, N.I.; Yahiaoui, A.; Garkuwa, J.A.; Mansour, R.B.; Rehman, S. Solar cooling with absorption chillers, thermal energy storage, and control strategies: A review. J. Energy Storage 2024, 97, 112762. [Google Scholar] [CrossRef]

- Shamim, J.A.; Nawaz, K.; Hu, M.-H.; Pasqualin, P.; Krishnan, E.N.; Kowalski, S.P.; Bhowmik, P.K.; Parameshwaran, R.; Hsu, W.-L.; Hwang, Y.; et al. Review of the potential and challenges of MOF-based adsorption heat pumps for sustainable cooling and heating in the buildings. Energy 2025, 323, 135846. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Solé, A.; Barreneche, C. Review on sorption materials and technologies for heat pumps and thermal energy storage, Renew. Energy 2017, 110, 3–39. [Google Scholar] [CrossRef]

- Aridi, M.; Pannier, M.-L.; Aridi, R.; Lemenand, T. A comprehensive review of life cycle assessments for domestic heat pumps: Environmental footprint and future directions. Energy Build. 2025, 336, 115605. [Google Scholar] [CrossRef]

- Adebayo, P.; Jathunge, C.B.; Darbandi, A.; Fry, N.; Shor, R.; Mohamad, A.; Wemhöner, C.; Mwesigye, A. Development; modeling, and optimization of ground source heat pump systems for cold climates: A comprehensive review. Energy Build. 2024, 320, 114646. [Google Scholar] [CrossRef]

- Akbarzadeh, S.; Sefidgar, Z.; Valipour, M.S.; Elmegaard, B.; Arabkoohsar, A. A comprehensive review of research and applied studies on bifunctional heat pumps supplying heating and cooling. Appl. Therm. Eng. 2024, 257, 124280. [Google Scholar] [CrossRef]

- Li, H.; Hou, J.; Hong, T.; Ding, Y.; Nord, N. Energy, economic, and environmental analysis of integration of thermal energy storage into district heating systems using waste heat from data centres. Energy 2021, 219, 119582. [Google Scholar] [CrossRef]

- Oltmanns, J.; Sauerwein, D.; Dammel, F.; Stephan, P.; Kuhn, C. Potential for waste heat utilization of hot-water-cooled data centers: A case study. Energy Sci. Eng. 2020, 8, 1793–1810. [Google Scholar] [CrossRef]

- Du, S.; Cui, Z.; Wang, R.Z.; Wang, H.; Pan, Q. Development and experimental study of a compact silica gel-water adsorption chiller for waste heat driven cooling in data centers. Energy Convers. Manag. 2024, 300, 117985. [Google Scholar] [CrossRef]

- Manu, S.; Chandrashekar, T.K. On-chip waste heat-driven absorption cooling system for sustainable data center environment: Simulation. Int. J. Sustain. Eng. 2018, 11, 224–239. [Google Scholar] [CrossRef]

- Haywood, A.; Sherbeck, J.; Phelan, P.; Varsamopoulos, G.; Gupta, S.K.S. Thermodynamic feasibility of harvesting data center waste heat to drive an absorption chiller. Energy Convers. Manag. 2012, 58, 26–34. [Google Scholar] [CrossRef]

- Huang, C.; Shao, S.; Wang, N.; Guo, Y.; Wu, W. Performance analysis of compression-assisted absorption refrigeration-heating system for waste heat recovery of liquid-cooling data center. Energy 2024, 305, 132325. [Google Scholar] [CrossRef]

- Pan, Q.; Peng, J.; Wang, R. Application analysis of adsorption refrigeration system for solar and data center waste heat utilization. Energy Convers. Manag. 2021, 228, 113564. [Google Scholar] [CrossRef]

- Zhou, X.; Xin, Z.; Tang, W.; Sheng, K.; Wu, Z. Energy, economic and environmental analysis of a combined cooling, power generation, and energy storage system: A case study of data center in shenzhen. J. Energy Storage 2024, 97, 112968. [Google Scholar] [CrossRef]

- She, X.; Li, X.; Xu, M.; Zhou, J.; Chen, J.; Huai, X.; He, Z. Thermodynamic analysis for new solutions of data center cooling with adsorption refrigeration and heat pipe. Int. J. Refrig. 2024, 160, 341–356. [Google Scholar] [CrossRef]

- Al-Sayyab, A.K.S.; Navarro-Esbrí, J.; Mota-Babiloni, A. Energy, exergy, and environmental (3E) analysis of a compound ejector-heat pump with low GWP refrigerants for simultaneous data center cooling and district heating. Int. J. Refrig. 2022, 133, 61–72. [Google Scholar] [CrossRef]

- Ge, Z.; Zhou, Y.; Li, J.; Zhang, X.; Xu, J.; Yang, F. Multi-objective optimization and benefit evaluation of heat pump system for tobacco drying using waste heat from data center. J. Clean. Prod. 2024, 448, 141623. [Google Scholar] [CrossRef]

- Jang, Y.; Lee, D.; Kim, J.; Ham, S.H.; Kim, Y. Performance characteristics of a waste-heat recovery water-source heat pump system designed for data centers and residential area in the heating dominated region. J. Build. Eng. 2022, 62, 105416. [Google Scholar] [CrossRef]

- Li, J.; Yang, Z.; Li, H.; Hu, S.; Duan, Y.; Yan, J. Optimal schemes and benefits of recovering waste heat from data center for district heating by CO2 transcritical heat pumps. Energy Convers. Manag. 2021, 245, 114591. [Google Scholar] [CrossRef]

- Leindals, L.; Grønning, P.; Dominković, D.F.; Junker, R.G. Context-aware reinforcement learning for cooling operation of data centers with an aquifer thermal energy storage. Energy AI 2024, 17, 100395. [Google Scholar] [CrossRef]

- Dvorak, V.; Zavrel, V.; Galdiz, J.I.T.; Hensen, J.L.M. Simulation-based assessment of data center waste heat utilization using aquifer thermal energy storage of a university campus. Build. Simul. 2020, 13, 823–836. [Google Scholar] [CrossRef]

- Zhu, Y.; Englmair, G.; Huang, H.; Dragsted, J.; Yuan, Y.; Fan, J.; Furbo, S. Numerical investigations of a latent thermal energy storage for data center cooling. Appl. Therm. Eng. 2024, 236, 121598. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, Q.; Zhai, Z.J.; Zhao, X. A simplified method to simulate tube-in-tank latent thermal energy storage with fin-enhanced phase change material in data center. J. Energy Storage 2022, 55, 105757. [Google Scholar] [CrossRef]

- Lu, T.; Lü, X.; Välisuo, P.; Zhang, Q.; Clements-Croome, D. Innovative approaches for deep decarbonization of data centers and building space heating networks: Modeling and comparison of novel waste heat recovery systems for liquid cooling systems. Appl. Energy 2024, 357, 122473. [Google Scholar] [CrossRef]

- Feng, X.; Shi, F.; Qiao, G.; Li, Y.; Liu, C. Integrating organic rankine cycle with thermoelectric generator in various applications utilizing low-grade energy: A review. Sustain. Energy Technol. Assess. 2024, 68, 103882. [Google Scholar] [CrossRef]

- Lan, Y.; Wang, S.; Lu, J.; Zhai, H.; Mu, L. Comparative analysis of organic rankine cycle, kalina cycle and thermoelectric generator to recover waste heat based on energy, exergy, economic and environmental analysis method. Energy Convers. Manag. 2022, 273, 116401. [Google Scholar] [CrossRef]

- Corigliano, O.; Algieri, A.; Fragiacomo, P. Turning data center waste heat into energy: A guide to organic rankine cycle system design and performance evaluation. Appl. Sci. 2024, 14, 6046. [Google Scholar] [CrossRef]

- Liu, L.; Wu, J.; Zhong, F.; Gao, N.; Cui, G. Development of a novel cogeneration system by combing organic rankine cycle and heat pump cycle for waste heat recovery. Energy 2021, 217, 119445. [Google Scholar] [CrossRef]

- Li, P.; Xu, J.; Wang, B.; Liu, J.; Zhao, W.; Han, Z. Performance analysis of a coupled system based on organic rankine cycle and double effect absorption refrigeration for waste heat recovery in data center. J. Therm. Sci. 2025, 34, 188–205. [Google Scholar] [CrossRef]

- Araya, S.; Jones, G.F.; Fleischer, A.S. The design and construction of a bench-top organic rankine cycle for data center applications. In Proceedings of the 2016 15th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 31 May–3 June 2016; IEEE: New York, NY, USA, 2016; pp. 404–408. [Google Scholar] [CrossRef]

- Araya, S.; Jones, G.F.; Fleischer, A.S. Organic rankine cycle as waste heat recovery system in data centers: Design and construction of a prototype. In Proceedings of the 2018 17th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), San Diego, CA, USA, 29 May–1 June 2018; IEEE: New York, NY, USA, 2018; pp. 850–858. [Google Scholar] [CrossRef]

- Ebrahimi, K.; Jones, G.F.; Fleischer, A.S. The viability of ultra low temperature waste heat recovery using organic Rankine cycle in dual loop data center applications. Appl. Therm. Eng. 2017, 126, 393–406. [Google Scholar] [CrossRef]

- Chen, X.; Pan, M.; Li, X.; Zhang, K. Multi-mode operation and thermo-economic analyses of combined cooling and power systems for recovering waste heat from data centers. Energy Convers. Manag. 2022, 266, 115820. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Parametric analysis and optimization of a solar driven trigeneration system based on ORC and absorption heat pump. J. Clean. Prod. 2017, 161, 493–509. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Li, X.; Wang, J. Performance analysis of a novel power/refrigerating combined-system driven by the low-grade waste heat using different refrigerants. Energy 2014, 73, 543–553. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Y.; Gao, L. Parametric analysis and optimization for a combined power and refrigeration cycle. Appl. Energy 2008, 85, 1071–1085. [Google Scholar] [CrossRef]

- Sanaye, S.; Refahi, A. A novel configuration of ejector refrigeration cycle coupled with organic rankine cycle for transformer and space cooling applications. Int. J. Refrig. 2020, 115, 191–208. [Google Scholar] [CrossRef]

- Nami, H.; Anvari-Moghaddam, A. Small-scale CCHP systems for waste heat recovery from cement plants: Thermodynamic, sustainability and economic implications. Energy 2020, 192, 116634. [Google Scholar] [CrossRef]

- Rostarnzadeh, H.; Ebadollahi, M.; Ghaebi, H.; Shokri, A. Comparative study of two novel micro-CCHP systems based on organic rankine cycle and kalina cycle. Energy Convers. Manag. 2019, 183, 210–229. [Google Scholar] [CrossRef]

- Zheng, B.; Weng, Y.W. A combined power and ejector refrigeration cycle for low temperature heat sources. Sol. Energy 2010, 84, 784–791. [Google Scholar] [CrossRef]

- Wang, J.; Yan, Z.; Zhou, E.; Dai, Y. Parametric analysis and optimization of a kalina cycle driven by solar energy. Appl. Therm. Eng. 2013, 50, 408–415. [Google Scholar] [CrossRef]

- Sun, J.; Fu, L.; Zhang, S. A review of working fluids of absorption cycles. Renew. Sustain. Energy Rev. 2012, 16, 1899–1906. [Google Scholar] [CrossRef]

- Mahmoud, E.S.; Rady, M.; Abuhabaya, A.A.; Elsamahy, A.A. Separate and combined integration of kalina cycle for waste heat recovery from a cement plant. Therm. Sci. 2022, 26, 1907–1925. [Google Scholar] [CrossRef]

- Ghaebi, H.; Namin, A.S.; Rostamzadeh, H. Performance assessment and optimization of a novel multi-generation system from thermodynamic and thermoeconomic viewpoints. Energy Convers. Manag. 2018, 165, 419–439. [Google Scholar] [CrossRef]

- Sohrabi, A.; Asgari, N.; Imran, M.; Shahzad, M.W. Comparative energy, exergy, economic, and environmental (4E) analysis and optimization of two high-temperature kalina cycles integrated with thermoelectric generators for waste heat recovery from a diesel engine. Energy Convers. Manag. 2023, 291, 117320. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, Q.; Wang, M.; Feng, X. Thermodynamic performance comparison between ORC and kalina cycles for multi-stream waste heat recovery. Energy Convers. Manag. 2017, 143, 482–492. [Google Scholar] [CrossRef]

- Bombarda, P.; Invernizzi, C.M.; Pietra, C. Heat recovery from diesel engines: A thermodynamic comparison between kalina and ORC cycles. Appl. Therm. Eng. 2010, 30, 212–219. [Google Scholar] [CrossRef]

- Liu, G.; Ji, D.; Markides, C.N. Progress and prospects of low-grade thermal energy utilization technologies. Appl. Therm. Eng. 2024, 254, 123859. [Google Scholar] [CrossRef]

- Zhou, H.; Tian, T.; Wang, X.; Li, J. Combining looped heat pipe and thermoelectric generator module to pursue data center servers with possible power usage effectiveness less than 1. Appl. Energy 2023, 332, 120539. [Google Scholar] [CrossRef]

- Cai, H.; Ye, Z.; Liu, G.; Romagnoli, A.; Ji, D. Sizing optimization of thermoelectric generator for low-grade thermal energy utilization: Module level and system level. Appl. Therm. Eng. 2023, 221, 119823. [Google Scholar] [CrossRef]

- Wen, X.; Ji, J.; Song, Z.; Li, Z.; Xie, H.; Wang, J. Comparison analysis of two different concentrated photovoltaic/thermal-TEG hybrid systems. Energy Convers. Manag. 2021, 234, 113940. [Google Scholar] [CrossRef]

- Lan, Y.; Lu, J.; Wang, S. Study of the geometry and structure of a thermoelectric leg with variable material properties and side heat dissipation based on thermodynamic, economic, and environmental analysis. Energy 2023, 282, 128895. [Google Scholar] [CrossRef]

- Lou, Y.; Ye, Z.; Liu, G.; Romagnoli, A.; Ji, D. TEG-ORC combined cycle for geothermal source with coaxial casing well. Appl. Therm. Eng. 2023, 226, 120223. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Ali, H. Thermoelectric generator performance analysis: Influence of pin tapering on the first and second law efficiencies. Energy Convers. Manag. 2015, 100, 138–146. [Google Scholar] [CrossRef]

- Tohidi, F.; Holagh, S.G.; Chitsaz, A. Thermoelectric generators: A comprehensive review of characteristics and applications. Appl. Therm. Eng. 2022, 201, 117793. [Google Scholar] [CrossRef]

- Wang, Z.-X.; He, P.; Li, N.; He, Y.-L.; Tao, W.-Q. A fuel cell powered rack prototype for data center application with waste heat recovery: Design consideration and experimental verification. Energy Convers. Manag. 2024, 318, 118892. [Google Scholar] [CrossRef]

- Kanbur, B.B.; Wu, C.; Duan, F. Combined heat and power generation via hybrid data center cooling-polymer electrolyte membrane fuel cell system. Int. J. Energy Res. 2020, 44, 4759–4772. [Google Scholar] [CrossRef]

- Montagud-Montalvá, C.; Navarro-Peris, E.; Gómez-Navarro, T.; Masip-Sanchis, X.; Prades-Gil, C. Recovery of waste heat from data centres for decarbonisation of university campuses in a mediterranean climate. Energy Convers. Manag. 2023, 290, 117212. [Google Scholar] [CrossRef]

- Socci, L.; Rocchetti, A.; Verzino, A.; Zini, A.; Talluri, L. Enhancing third-generation district heating networks with data centre waste heat recovery: Analysis of a case study in italy. Energy 2024, 313, 134013. [Google Scholar] [CrossRef]

- Stock, J.; Schmidt, T.; Xhonneux, A.; Müller, D. Optimisation of district heating transformation for the efficient integration of a low-temperature heat source. Energy 2024, 308, 132461. [Google Scholar] [CrossRef]

- Tervo, S.; Syri, S.; Hiltunen, P. Reducing district heating carbon dioxide emissions with data center waste heat—Region perspective. Renew. Sustain. Energy Rev. 2025, 208, 114992. [Google Scholar] [CrossRef]

- He, Z.; Ding, T.; Liu, Y.; Li, Z. Analysis of a district heating system using waste heat in a distributed cooling data center. Appl. Therm. Eng. 2018, 141, 1131–1140. [Google Scholar] [CrossRef]

- Du, H.; Zhou, X.; Nord, N.; Carden, Y.; Cui, P.; Ma, Z. A new framework for evaluating and enhancing the performance of district heating systems integrated with data centres using short-term thermal energy storage. Energy 2025, 319, 134934. [Google Scholar] [CrossRef]

- Keskin, I.; Soykan, G. Optimal cost management of the CCHP based data center with district heating and district cooling integration in the presence of different energy tariffs. Energy Convers. Manag. 2022, 254, 115211. [Google Scholar] [CrossRef]

- Zhou, F.; Tian, X.; Song, Y.; Ma, G. Dynamic performance of an integrated heat pump system coupled free cooling and waste heat recovery in data centers. Energy 2025, 323, 135838. [Google Scholar] [CrossRef]