1. Introduction

Reducing greenhouse gas (GHG) emissions to mitigate anthropogenic impacts is a global priority. Sustainable measures, such as decarbonisation and circularity strategies, are being implemented within the construction industry to address some of these challenges. The European Union (EU) targets a 50% reduction in emissions in the building and construction sector by 2030, aiming for an economy with net-zero GHG emissions by 2050. This objective is at the heart of the European Green Deal and is legally mandated by the European Climate Law. A noteworthy strategy in this context involves the transition to net-zero carbon buildings (nZCBs), which has been widely recognised as a promising solution to energy and environmental problems, given that they offer significant advantages in energy efficiency and the reduction of carbon emissions [

1,

2]. Unlike net-zero energy buildings (nZEBs), nZCBs focus on achieving net-zero carbon emissions throughout a building’s entire life cycle. Net-zero carbon emissions are made up of embodied carbon (EC) (further divided into upfront and whole-life embodied carbon) and operational carbon (OC) (resulting from the emissions linked to operational energy (OE) and water use).

Figure 1 illustrates the scopes and life cycle stages, as defined by European standards such as EN 15978:2011 [

3].

This strategy is consistent with the Whole Life Carbon (WLC) methodology outlined in the revised Energy Performance of Buildings Directive (EPBD) [

4], which now includes comprehensive life cycle carbon assessments as a core criterion in evaluating building performance [

5], and can serve as a fundamental lever to drive the decarbonisation of the built environment [

6].

Recent literature has emphasised the crucial importance of upfront EC, particularly in the product stage, which accounts for approximately 76% of the total EC [

7]. Today, product-level environmental data is available through Label Type III, known as Environmental Product Declarations (EPDs). In recent years, the number of EPDs has increased exponentially. In Italy alone, there has been a 29% increase from 420 in 2023 to 542 in 2024 [

8]. The uptake of EPDs was primarily seen in companies in the northern part of the country (approx. 70%), followed by companies in the centre (approx. 18.2%) and approximately 10% in the south of Italy [

9].

Originally developed to support business-to-business (B2B) communication within supply chains—particularly for procurement and product comparison—Environmental Product Declarations (EPDs) are now widely used as standardised data sources for building-level E-LCAs [

10]. However, EPDs are not always available for all products included in a project. They are also not necessarily representative of the specific context of a construction intervention. In addition to production-related impacts, accurately assessing the environmental performance of a product within a given construction scenario requires careful consideration of post-gate phases, particularly those occurring pre-occupancy, such as transport (A4) and installation (A5). These stages can significantly influence overall environmental outcomes. Furthermore, even a single product with an EPD may require differentiated treatment, as real-world variations in transport and installation conditions can substantially affect its life cycle performance. Likewise, the same raw material may result in different environmental impacts depending on its extraction conditions (A1) or the location of its transformation process (A3).

Alongside environmental impacts, construction supply chains exert substantial influence on the other two pillars of sustainable development—the social and economic dimensions [

11]. In terms of social impact, the construction industry has a major influence on local communities, neighbourhoods and cities, construction workers and users, as well as on global communities through the globally interconnected supply chain that sits behind most construction products and building materials. To appreciate these impacts, S-LCA has been developed as a complementary approach to the Environmental Life Cycle Assessment (E-LCA) methodology in order to address social aspects through distinct methodological frameworks [

12].

According to the official guidelines of the United Nations Environment Programme (UNEP) and the Society of Environmental Toxicology and Chemistry (SETAC), first published in 2009 and revised in 2020 (United Nations Environment Programme 2020) [

13], the stakeholder categories included in the Social Life Cycle Assessment (S-LCA) are workers, the local community, value-chain actors, consumers, society and children. However, the required data is a complex part of S-LCA, as it includes information on health and safety, working conditions and other issues that are controversial in the industry [

14]. Despite strict legislation and efforts by institutions and social partners to improve health and safety conditions, construction is still a risky industry in Italy [

15]. Occupational safety is a critical issue in the sector due to frequent exposure to risks such as falls from heights, overexertion, and contact with hazardous materials.

According to the Italian National Institute for Insurance against Accidents at Work (INAIL) data [

16], northern Italy accounts for almost 61% of all accidents, followed by central Italy, at 20%, and southern Italy, at 19%.

This study presents a regionalised method to support social and environmental decision-making in the Italian construction sector by integrating worker health and safety indicators into the E-LCA of two representative construction products across key life cycle stages. In this way, these indicators can be integrated into the assessment of Global Warming Potential (GWP), so serving as a decision-support tool in the design process. From a design perspective, the aim is to promote a broader understanding of sustainability—encompassing both environmental and social dimensions—within building projects. Methodologically, the contribution is twofold. First, it addresses the current gap in context-specific data on the critical indicator of worker health and safety in the construction sector, an essential requirement for robust and scientifically recognised S-LCA studies. Second, it proposes a framework to combine these social indicators with LCA-based environmental impact metrics, which remain central to building-scale E-LCA assessments. The proposed method is applied to a pilot building for which potential social hotspots are examined in relation to two construction materials—stone cladding and double glazing—commonly manufactured and employed in Italian building projects.

This approach aligns with recent contributions that emphasise the need to integrate multidimensional criteria into the design process at an early stage in order to support circular transitions in the built environment. In particular, Giordano et al. (2024) have highlighted the central role of LCA-based decision tools and the shift from single-impact assessments to composite indicators, reinforcing the relevance of scalable, data-driven approaches for material selection [

17].

This study proposes a regionalised method to support social and environmental decision-making in the Italian construction sector by integrating worker health and safety indicators into the E-LCA of two representative construction products across key life cycle stages. In this way, these indicators can be integrated into the assessment of GWP, so serving as a decision-support tool in the design process.

2. Theoretical Background and Literature Review

To align with the climate objectives of the Paris Agreement and achieve climate neutrality by 2050, Italy has initiated a series of national strategic frameworks across multiple sectors, including the building industry. These cover the Integrated National Energy and Climate Plan (NECP), which sets targets for 2030; the Long-Term Strategy (LTS), which outlines the decarbonisation pathway towards 2050; and the National Strategy for the Energy Renovation of the Building Stock, aimed at enhancing energy efficiency and reducing emissions in the built environment.

However, a recent Buildings Performance Institute Europe (BPIE) report underscores that despite some progress, Italy must significantly intensify and expedite efforts to reduce emissions from its building stock in order to achieve long-term decarbonisation goals [

18]. Among the key recommendations outlined by BPIE is the need to leverage the opportunities provided by the EPBD, including the introduction of limit values for GWP across all phases of the building life cycle. This necessitates the systematic quantification of CO

2-equivalent emissions aligned with the WLC framework, which integrates both operational and embodied impacts throughout the building’s life cycle. A critical priority in this context is the reduction in EC emissions released prior to occupancy, which are primarily associated with construction products [

19,

20]. This trend has been corroborated by several recent studies examining the relationship between operational and embodied energy (EE) across diverse building typologies [

21,

22]. Findings show that in low-energy buildings, enhanced operational performance has led to a proportional increase in EC, which now accounts for approximately 30–60% of total GHG emissions [

23]. In response to this shift, the selection of construction materials plays a strategic role in minimising the carbon footprint of buildings. As widely acknowledged in the E-LCA literature, using materials with low EE and EC—together with a greater reliance on locally sourced resources—is among the most effective strategies to mitigate EC impacts. Numerous studies have reported that increasing the use of local materials can significantly reduce EE, primarily by limiting transport-related emissions [

24]. In line with these findings, Crishna et al. (2011) [

25], in a life cycle assessment of stone production in the UK, demonstrated that locally sourced stone—such as sandstone, granite and slate—has a substantially lower carbon footprint than imported alternatives, emphasising the environmental benefits of reducing transport-related emissions [

25].

This argument is further reinforced by long-term projections from the World Green Building Council, which estimate that more than 50% of total carbon emissions from all new buildings constructed globally between 2020 and 2050 will be attributable to EC [

26]. From an economic viewpoint, the construction sector is a cornerstone of the European economy, employing approximately 30% of the EU’s industrial workforce [

27]. Construction workers are the backbone of the sector’s workforce and are central to achieving the European Green Deal’s ambitious built environment goals [

28].

According to UNEP [

29], the built environment is responsible for approximately 7% of employment worldwide and 11–13% of gross domestic product (GDP). In Italy, the construction sector represents a significant portion of the Italian GDP in terms of direct value added, contributing to approximately 5.4% of the national GDP. When incorporating the broader real estate industry and related activities, this contribution increases to 25%, highlighting the sector’s critical role in the macroeconomic structure and its substantial impact on national economic performance [

30].

However, to transform the opportunities presented by the European Green Deal and the EU Recovery Instrument, NextGenerationEU—the Union’s landmark post-pandemic investment plan—into a successful and coherent framework, it must be anchored in all the fundamental pillars of the European Union system. This includes not only sustainable development and environmental protection but also human well-being, social equity and the structural evolution of labour relations [

31]. The creation of high-quality jobs within the green job initiatives of the EU Green Deal is closely linked to occupational safety and health (OSH) conditions, as it ensures a sustainable and resilient workforce during the transition to a greener economy.

Although the construction industry has a positive economic impact, it faces high accident rates, causing considerable financial repercussions [

27]. Ensuring decent working conditions and good health and safety standards are among the key priorities outlined in the Joint Roadmap for Competitiveness and Decarbonisation in the recent Clean Industrial Deal, also referred to as the Pact for Clean Industry [

28].

This initiative establishes a series of strategic measures to support the development and competitiveness of European industries in their decarbonisation pathways. Among these measures is the introduction of a voluntary carbon intensity label for industrial products targeting a 14% increase in material circularity by 2030, in addition to harmonising carbon accounting methodologies, providing greater transparency for consumers and recognising industry commitments towards achieving decarbonisation goals. The primary obstacle to this measure is often the lack of available data, which has left the evaluation of social impacts largely underdeveloped.

Based on the considerations outlined thus far, it is evident that actions aimed at building decarbonisation must be integrated with assessments conducted according to the S-LCA method, with particular attention paid to the worker stakeholder category, especially concerning the health and safety indicator. Although health and safety conditions are recognised as a critical factor in the construction sector, the quantification and assessment of their social impact remain, in our opinion, a methodological and data-related challenge.

2.1. Materials Considered in This Study

Within all material streams contributing to EC in buildings, this study focuses on natural stone and glass. Traditionally regarded as foundational materials in architectural history, stone and other lithic resources continue to play a significant role in contemporary construction. The stone industry has considerable economic significance both in Italy and globally, contributing to local production systems and employment capacities, particularly in specialised geographical areas [

32]. Owing to the presence of highly specialised quarrying districts and a diverse lithological resource base, Italy retains a strategic role in the production and exportation of stone materials. According to the 2021 national survey, there are 4168 authorised quarrying sites across the country, with approximately 25% integrated into the natural stone supply chain. Annual extraction volumes reach 6.2 million cubic meters, most of which are used in the construction sector [

33].

Recognising the environmental relevance of these materials, the European Commission established specific criteria for natural stone within the EU Ecolabel scheme for hard surface coverings, which was initially introduced in 2009 [

34] and revised in 2021 [

35]. More recently, natural stone has been identified among six strategic sectors included in Italy’s national E-LCA database developed within the Arcadia project, positioning stone as a key element in supporting sustainable public procurement and green purchasing policies and practices [

36,

37].

Nevertheless, the cradle-to-gate approach adopted in the Arcadia project excludes several essential downstream phases—specifically, distribution to construction sites (A4) and their on-site installation (A5)—which are crucial for a comprehensive environmental assessment of natural stone use in architecture. These phases are particularly important in Italy, where the extraction and processing of natural stone are concentrated in geographically localised quarrying districts, typically situated near major mining sites. Tuscany, Lombardy and the Province of Trento are the regions with the highest extraction volumes—collectively contributing approximately 54.2% of national production—followed by Lazio and Sardinia.

The lithotypes extracted from these districts are determined by distinct geological, technical and cultural attributes and are widely employed in both contemporary architectural projects and interventions involving the restoration and adaptive reuse of existing structures.

Consequently, transportation and installation practices vary significantly across regions, and their environmental impact is strongly influenced by geographic location.

In addition to natural stone cladding systems, the present study also investigates a second envelope component—glass sheets used in window assemblies.

This focus is driven by the recognition that materials with thermal properties capable of significantly reducing a building’s operational energy demand, e.g., insulating glass units (IGUs), play a substantial role in reducing the GWP associated with the building’s life cycle.

Although windows typically account for only 10–25% of the total building envelope surface area, they are responsible for up to 60% of overall energy losses, primarily due to their comparatively low thermal resistance relative to other envelope components [

38]. Furthermore, IGUs contribute directly and significantly to the GWP indicator, with an estimated 50% share by weight compared to other window components [

5].

2.2. EPDs as Data Sources for E-LCA

E-LCA has become a crucial tool for measuring the cradle-to-grave environmental impacts of construction products [

39,

40] and processes, covering every stage from raw material extraction to end-of-life disposal [

41]. E-LCA is widely recognised as the most effective scientific method for evaluating environmental impacts across the entire building life cycle, providing reliable, comprehensive and life cycle-spanning quantifications of EE, OE and GWP effects [

42]. In the construction sector, this methodology is valuable, as it can help identify the most sustainable design practices, provide guidance for policy and decision-making and improve the building’s overall environmental performance [

43].

At the time of writing, Italy, unlike other EU countries [

44], lacks a national methodology or harmonised framework for conducting E-LCA at the building level. The most significant recent advancement in this direction is the introduction of the Minimum Environmental Criteria (Criteri Ambientali Minimi or CAM) for public buildings, which are currently undergoing revision [

45]. In addition, the newly adopted Procurement Code requires the integration of WLC and E-LCA assessments into both new and renovated public construction projects, so aligning with CAM provisions.

With the revision of CAM, a simplified E-LCA approach is being introduced covering system boundaries A1–A4, B4, B6 and C2–C4 to ensure compliance with European standards for environmental performance assessment. E-LCA studies will be based on EN 15643:2021 [

46], EN 15978:2011 [

3], EN 17680:2023 [

47] and EN 15804+A2:2019 [

48] so as to correspond with the European framework Level(s) [

49], which promotes sustainability in the built environment and supports the integration of life cycle thinking into building design and public policy [

49]. Within this framework, EPDs play a fundamental role in verifying product compliance during construction, enabling site supervisors to assess equivalence in environmental performance between specified and proposed products, as specified in the comparability principle defined by UNI EN 15804+A2:2019 [

48].

However, the use of EPDs as input data for E-LCA presents notable methodological challenges. Although EPDs provide standardised metrics regarding the environmental impact of products, their dependence on scenario-specific assumptions may lead to inconsistencies across regional contexts due to variability in assumptions and data quality [

50]. The reliability of E-LCA results is therefore contingent on the precision and contextual relevance of the EPDs employed [

44]. This issue becomes particularly significant when construction sites are geographically distant from manufacturing facilities. For instance, the environmental footprint of a window produced in northern Italy will differ depending on whether it is installed in the northern or southern parts of the country. These differences stem not only from extended transport distances but also from variations in transport modalities (e.g., vehicle load capacity, Euro emission class) and subsequent life cycle stages after production. Such variability can markedly influence E-LCA outcomes and, by extension, affect decision-making processes in sustainable construction. Although E-LCA remains a key tool for evaluating environmental building performance, it encounters several limitations and critical issues, including its reduced inclusion of social and economic dimensions [

51,

52]. Some scholars argue that conventional E-LCA methods fail to address environmental impacts on human health and well-being and do not incorporate wider social considerations [

53].

2.3. Assessing Social Impacts in Product Systems

S-LCA expands the scope of sustainability evaluation by addressing the social impact of a product or process across its life cycle [

54]. Research has shown that S-LCA is a valuable tool for identifying social hotspots and guiding product design and policy development [

55]. S-LCA has a technical framework similar to E-LCA, adopting a four-step approach that involves defining the goal, scope and functional unit, as well as establishing the system boundaries in the first stage [

56]. Both methodologies rely on a functional unit to define the product system, ensuring consistency in the evaluation (UNEP/SETAC, 2009) [

57]. Although the E-LCA framework provides a structured methodology, the input data required for S-LCA differ significantly [

58].

The S-LCA framework adopts a stakeholder-based approach, assessing potential impacts—positive and negative—on distinct social groups that form the analytical basis of the evaluation [

13]. Social impacts are classified in function of stakeholders, with each group connected to impact subcategories representing socially significant themes or attributes. These subcategories are assessed through impact indicators, and multiple indicators may be used for evaluation (the table in

Section 3.2.2). The selection of indicators depends on the specific context of the study. While alternative classifications, such as country-based groupings, may be applied, they must be clearly justified and explained. Each stakeholder category encompasses multiple dimensions of social impact.

The S-LCA Guidelines consider six stakeholder categories—workers, local communities, value chain actors (e.g., suppliers and not including consumers), consumers, children and society [

13]. A more detailed classification is provided by the UNEP Guidelines [

13].

The social dimension of sustainability is often the most elusive in practical efforts to advance sustainable development [

59]. Although conventional discussions in the construction sector tend to underrepresent these aspects, increasing attention is being given to the broader social implications along the entire production chain, notably working conditions. S-LCA frameworks aim to incorporate these considerations more systematically. In particular, workers’ health and well-being are among the most frequently assessed indicators, serving as proxies to evaluate key social issues, such as fair wages, working hours, occupational safety, and labour rights. At the product level, S-LCA enables companies to systematically evaluate and communicate the social implications associated with their products across all stages of the value chain from raw material extraction to end of life.

Building on this approach, a promising protocol to reveal socially relevant information is the Social Product Declaration (SPD), a standardised format analogous to EPD. The concept was formally introduced in 2023 through a pilot initiative led by EPD International, RWTH Aachen University, Circular s.r.l. and Hitachi Rail, resulting in the world’s first SPD and corresponding Product Category Rules (PCR) [

60]. SPDs establish a dedicated framework to capture the specific dimensions of social sustainability, presenting key indicators, e.g., working conditions, labour rights, occupational health and safety, and community impacts in an independently verified, transparent and comparable format. The incorporation of SPDs into existing sustainability assessment frameworks provides a structured basis for enhancing transparency, accountability and evidence-based decision-making, which are consistent with UNEP Guidelines for S-LCA [

13]. When deployed alongside EPDs, SPDs contribute to a more integrated representation of product sustainability while encouraging socially responsible practices across industrial value chains.

3. Methodology

To assess their suitability within an appropriate design framework, the proposed methodological approach is tested on a certified Passive House building, selected as representative of NZEB principles and as a reference for embodied GWP assessment. Specifically, the case involves a residential building to be built in Italy that has been extensively analysed in terms of embodied and operational energy in previous research [

61]. The focus of the analysis is on two representative construction materials—natural stone and double glazing—selected for their relevance in building envelopes and fenestration systems. As an application context, it is assumed that the natural stone is sourced from Tuscany, a region historically and industrially linked to the extraction and processing of natural stone, with well-established stone districts. For double glazing, the reference region is Lombardy, which hosts numerous production hubs and is widely recognised as a key node in the national construction supply chain. To broaden the geographical scope of the analysis, additional regions were considered: Lazio, Liguria, and the Province of Bolzano, all located within a 500 km radius. These areas were selected to reflect a wider range of production contexts and logistical conditions relevant to the Italian construction sector.

Figure 2, illustrates the implementation of the study across three sequential stages.

- (1)

Definition of the goal and scope and system boundaries for both the E-LCA and S-LCA.

- (2)

Impact assessment data collection, including

- (a)

collection and selection of E-LCA data sources, such as indicators for natural stone based on a previous study [

31] and EPDs for double glazing, along with the definition of appropriate scenarios to conduct the E-LCA;

- (b)

Identification of essential S-LCA elements, including relevant stakeholder categories, impact subcategories and the social inventory required for the analysis.

- (3)

Impact characterisation of environmental impacts covering the following life cycle stages:

Production (A1–A3);

Transport (A4), accounting for site-to-site distances specified in step a;

Installation (A5) derived from EPD-aligned producer profiles.

Figure 2.

Steps of the proposed methodology.

Figure 2.

Steps of the proposed methodology.

Social impacts were further examined through regional accident data from the Italian construction industry based on official records provided by INAIL and regarding four regions: Lombardy, Liguria, Lazio and the Province of Bolzano. Subsequently, a normalisation procedure was applied to develop scoring systems for both E-LCA and S-LCA culminating in targeted recommendations aimed at guiding material selection and supporting more sustainable building design decisions.

3.1. Step 1: Definition of the Goal & Scope and System Boundaries

In line with ISO 14040 standards and the UNEP Guidelines for S-LCA methodology [

62,

63], the first step involves defining the study’s purpose by addressing the following questions:

What are the study’s objectives?

Who is the intended audience?

What specific aspects are being assessed?

Does the study contribute to decision-making processes? If so, in which domain?

Which stakeholders are specifically relevant for S-LCA?

The overarching goal is to facilitate sustainable building design and informed decision-making in the selection of construction materials and products via a life cycle-based methodology integrating both environmental and social dimensions. Although the analysis focuses on two selected materials—ornamental stone for façade cladding and glass for insulated glazing units—the proposed framework is scalable and applicable to a broader spectrum of building materials. It enables a comprehensive evaluation of impacts across the life cycle and supports design decisions that balance environmental performance with social considerations.

The functional unit adopted in this study corresponds to the total installed quantity of each selected material within the case study building, specifically 133 m

2 of ornamental stone flooring and 15 m

2 of insulated glazing units, distributed across eight windows and one French door. This building-scale definition reflects real-world procurement and design logic, and supports a comprehensive assessment of environmental and social impacts. Although results are not normalised to 1 m

2, the approach remains compatible with component-level comparisons and aligns with EN 15804+A2:2019 [

48] and ISO 21930:2017 [

64] principles.

The life cycle stages addressed include quarrying raw materials (A1), transport to the manufacturing site (A2), manufacturing process (A3), delivery to the building site (A4) and installation (A5) (

Figure 3).

Material quantities from the case study were cross-referenced with EPD data to carry out the full E-LCA process consistent with the four standardised stages. Using the stakeholder-based approach outlined in the UNEP framework, the study identifies

workers engaged in manufacturing, quarrying and construction as the principal stakeholder category. Within this group,

health and safety was selected as the key social impact subcategory given its prominence in construction-related lifecycle stages. This choice was informed by a socio-economic analysis and supported by data from Eurostat [

65]. These figures highlight that while construction is classified as a strategic sector, it remains the industry with the highest number of non-fatal occupational accidents in Europe.

3.2. Step 2: Data Collection

3.2.1. E-LCA Data Source

The aforementioned work identifies the bill of materials, including their composition and technical characteristics. From this dataset, two materials—double glazing and natural stone cladding—were selected for further analysis. In the second step, their respective quantities were correlated with GWP indicators sourced from two main reference points—(i) a detailed LCA study based on primary data collected both at the quarry and at the production facility of Italian manufacturers regarding cladding stone extracted in Tuscany, and (ii) the EPDs of the double glazing used in the window systems (

Table 1). More specifically, in order to carry out the environmental impacts across the four geographical scenarios under investigation, values from the EPDs were adapted for life cycle stages A2 (only for the natural stone), A4 and A5. Stages A1 and A3 were assumed to remain constant, as they are closely tied to core production processes.

Table 1 provides a summary of the data utilised to quantify CO

2 equivalent emissions across the relevant life cycle stages for the two selected products.

The quality of environmental data was systematically assessed using the Data Quality Matrix. Pedigree scores were assigned to modules A1–A5 to ensure transparency regarding the origin, relevance, and technological alignment of the datasets used. The scores reported in

Table 1 follow a scale from 1 (very good) to 5 (very poor), with all values ranging between 1 and 2, indicating a good level of data quality and representativeness.

3.2.2. S-LCA Assumptions

Building on the stakeholder-based framework outlined in the UNEP Guidelines [

13], the study identifies workers as the principal stakeholder category and selects health and safety as the key social subcategory, given their relevance as one of the most critical issues across the life cycle stages within the system boundaries (

Table 2).

The prioritisation of this social indicator stems from an analysis of socio-economic pressures particularly affecting the construction sector, which historically shows high vulnerability to workplace accidents. According to Eurostat [

65], the construction industry accounted for 65.6% of all fatal occupational incidents and 43.0% of non-fatal accidents registered within the European Union in 2022. It also represented 21.9% of total reported workplace accidents, surpassing sectors such as transportation and storage (15.6%).

Complementary national data provided by INAIL confirms the sector’s critical status in Italy. In 2023, approximately 40,000 occupational injuries were recorded in construction, marking a 3.4% increase compared to the previous year and positioning the industry among those with the highest accident rates.

3.3. Step 3: The Characterisation of Impacts

3.3.1. Environmental Life Cycle Impacts

The GWP impacts for each life cycle stage derived from the data collected for the case study building are given in

Table 3 for the cladding stone (133 m

2) and in

Table 4 for the double glazing (15.6 m

2).

To enable comparison across regional contexts, environmental impact values were normalised with respect to the maximum observed benchmark: Bolzano (472 kg CO

2 eq.) for natural stone and Lazio (633 kg CO

2 eq.) for double glazing. Normalisation was performed using the following formula:

Subsequently, normalised values were recoded onto an ordinal scale ranging from 1 (lowest impact) to 4 (highest impact), in order to facilitate integration with the social indicator and the construction of the composite E-LCA + S-LCA score.

3.3.2. Social LCA Indicators

Workers’ health and safety have been identified as among the most critical S-LCA subcategories in evaluating corporate performance across product life cycles and supply chains [

66] (

Table 5). The challenges related to workers’ health and safety are particularly significant in the construction sector. The study conducted by Hosseinijou et al. [

67] on S-LCA for material selection highlighted that one of the inventory indicators with a strong negative impact during the pre-building stages (raw material acquisition, construction material production) and construction stages is occupational accidents among workers.

3.3.3. Scoring Definition

After collecting data by region and sector—specifically the number of occupational injuries and the corresponding workforce (

Table 5 for natural stone and

Table 6 for double glazing)—the normalised incidence rate of occupational injuries was calculated for each sector across the life cycle stages A1 to A5, disaggregated by region. As defined in Equation (1), for stages A1, A3, and A5, this rate was determined by dividing the number of recorded injuries in each sector by the number of workers employed in the given sector and region. In parallel, for stages A2 and A4, normalization was based on the number of circulating vehicles (vehicle fleet), reflecting the transport-related dimension of the analysis.

where:

Injury Rate = Occupational Injury Incidence Rate → The frequency of occupational injuries relative to the workforce size.

N° Injuries = Number of Occupational Injuries → Total recorded cases of work-related injuries.

N° Workers = Number of Workers per Sector → Total number of employees within each sector.

N° Vehicle Fleet = Number of Trucks per Region → Total number of trucks registered or operating in each region.

Table 6.

Mapping of stakeholders, social subcategories and related indicators in the glass sector, based on UNEP [

13].

Table 6.

Mapping of stakeholders, social subcategories and related indicators in the glass sector, based on UNEP [

13].

| LC Stage | Data Type | Italian Region | Source |

|---|

| Lombardy | Lazio | Liguria | Bolzano |

|---|

| A1–A3 | No. of Accidents | 43 ** | - | - | - | Italian National Institute for Social Security (INPS) database of Sector ATECO code 231—Manufacture of glass and glass products 5-year average 2019–2023 |

| No. of Workers | 5428 | - | - | - | Italian National Institute of Statistics (ISTAT) database for the manufacture of glass and glass products and cutting, shaping and finishing in the stone sector (ATECO code 231) Single-year value (2022) |

| A4 | No. of Accidents | 1683 | 693 | 373 | 196 | Italian National Institute for Social Security (INPS)—Employment data for the transport sector extracted from national social security databases 5-year average 2019–2023 |

| No. of Vehicle Fleet Distribution | 620,836 | 324,370 | 88,295 | 174,588 | Number of circulating vehicles across the five Italian regions included in the study, based on regional data from the Automobile Club of Italy (ACI), 5-year average 2019–2023 |

| A5 | No. of Accidents | 44 | 3 | 5 | 27 | National Institute for Social Security (INPS) database of tilers and cladding specialists in stone and similar materials (ATECO code 6.1.3.2.3) 5-year average 2019–2023 |

| No. of Workers | 63,381 | 31,813 | 5418 | 4595 | ISTAT data on the number of employees in construction of residential and non-residential buildings (Code sector 412) Single-year value (2022) |

Finally, to enable meaningful comparison among values, a regional scoring system was defined following the data normalisation process.

In line with the approach adopted for the E-LCA component, the social indicator was constructed using the injury rate per number of workers by sector, normalised against the highest observed value across regions. This benchmark-based approach ensures logical consistency within the scoring system and allows for the harmonised integration of environmental and social dimensions. As with the environmental data, normalised values were subsequently classified into four categories ranging from 1 (best performance) to 4 (worst performance).

Table 7 and

Table 8 present the injury rate scores by sector and the corresponding rankings for natural stone and glass, respectively.

4. Results

This section describes and analyses the results obtained from the study. First, the E-LCA values of the two products analysed within the case study building are presented for each region. Second, the assessment of social life cycle impacts is illustrated, focusing on the stakeholder category of workers and, particularly, on the health and safety indicator. Third, a comparative analysis is conducted between the combined E-LCA and S-LCA results, disaggregated by material and by region. Finally, a single impact score (E-LCA + S-LCA) is defined for each material and region.

E and S-LCA of Natural Stone Cladding Across Regions

The results of the E-LCA of natural stone extracted from a quarry located in Tuscany show that the variation in environmental impact across different geographical contexts is primarily driven by stage A4, which refers to the transport of the product from the production site to the construction site. This impact is inevitably higher in the Province of Bolzano, due to the greater distance involved, as illustrated in

Figure 4a.

The same applies to glazing, where the production site is located in the Lombardy region. Consequently, the highest transport-related impact (stage A4) is attributed to the Lazio region, which is farthest from the manufacturing site, as shown in

Figure 4b. However, the breakdown of the upfront carbon impacts of the two materials is significantly different, with the lion’s share being in stages A4 and A5 for stone cladding and in A1–A3, followed by A4, for glass.

With regard to the social dimension related to natural stone (

Figure 5a), when social impact values are normalised by the number of workers, and assuming equal contributions from stages A1 and A2, the highest impact is observed at the production stage (stage A3). This is followed by impacts associated with intermediate transport from the quarry to the manufacturing facility (A2) and final transport from the facility to the construction site (A4). Stage A5 (on-site installation) contributes significantly to the overall social impact, particularly in the Province of Bolzano. Although Bolzano does not report the highest absolute number of occupational accidents during installation—there were 27 incidents, 39% fewer than the 44 reported in Lombardy—the relative impact increases markedly when normalised by workforce size. Given that Bolzano’s workforce is approximately 76% smaller, the accident rate per worker is substantially higher.

Focusing on double glazing and assuming equal impacts during stages A1–A3 across the four geographical scenarios analysed, the variability in social impacts is primarily determined by the installation stage (A5), followed by stage A4 (transportation).

Despite recording approximately 35% fewer incidents than Lazio and around 77% fewer than the highest value observed in Lombardy, the region with the highest injury rate is Liguria. Once again, however, this figure becomes significant when normalised by the number of workers (

Figure 5b).

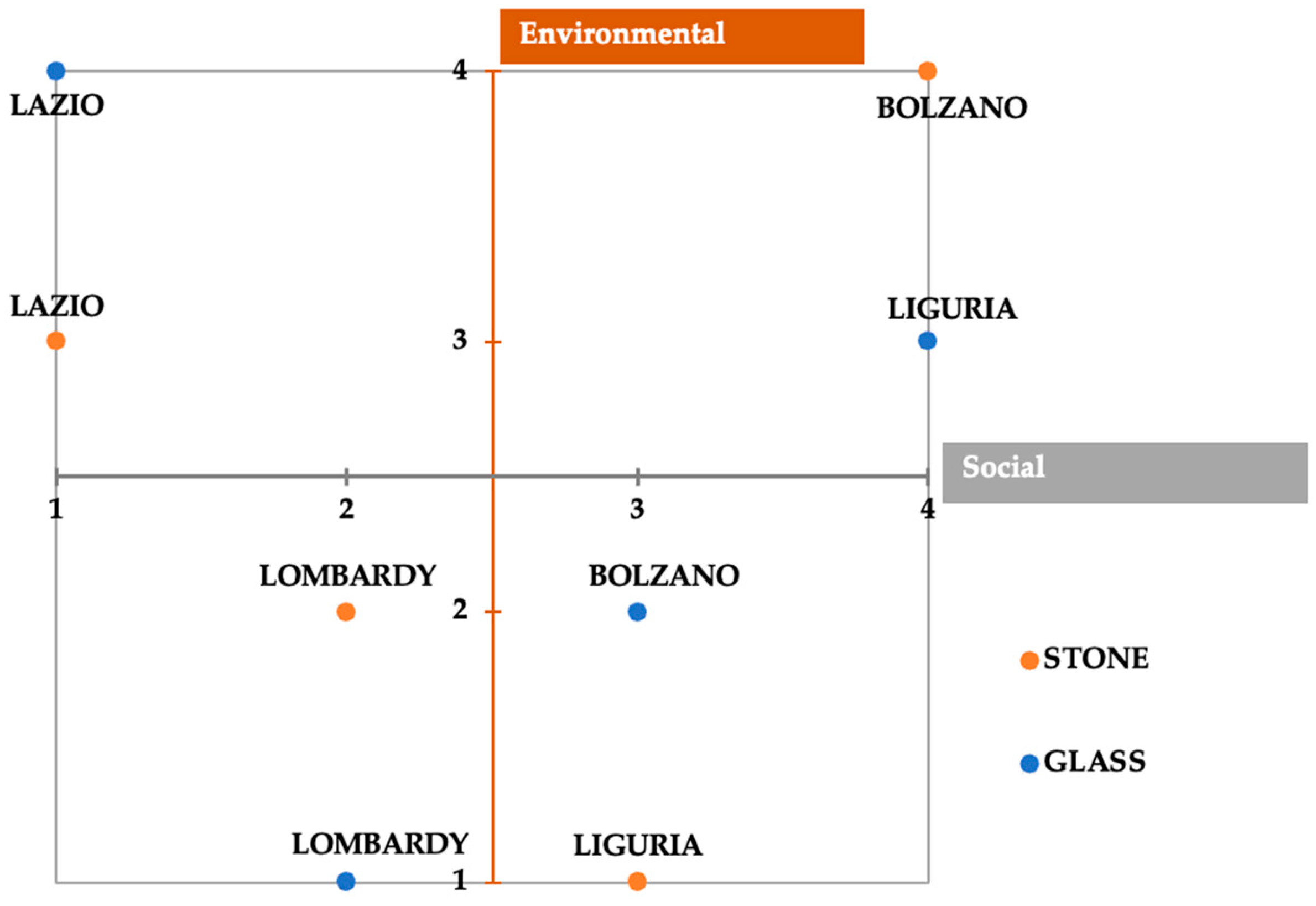

To support a clearer interpretation of trade-offs between environmental and social impacts across region–material combinations, a set of comparative visualizations was developed, including radar charts (

Figure 6) and a 2 × 2 quadrant diagram (

Figure 7). These tools enable each region to be positioned according to its performance along both dimensions, facilitating the interpretation of contextual profiles and informing procurement strategies.

In particular, the quadrant diagram in

Figure 7 highlights cases where environmental efficiency (i.e., lower A4 values) may coincide with social vulnerability (i.e., higher normalised accident rates). For example, Lazio shows relatively high environmental impact for both materials—with a score of 4 for double glazing and 3 for natural stone—while maintaining low social scores. Bolzano displays more pronounced impacts for stone, both environmentally and socially, whereas Liguria presents a more balanced profile with lower environmental impact for stone and higher social performance for glass.

Finally, in order to provide a more comprehensive visualization of both GWP and social performance—particularly regarding worker health and safety—the next step involved determining a single regional score for each indicator—E (environmental) and S (social). This composite score was obtained by combining previously normalized E-LCA and S-LCA indicators (

Figure 6) with sector-specific breakdowns provided in

Figure 8a (natural stone) and 8b (double glazing). The total score is represented by a star symbol ranging from a minimum value of 1 to a maximum of 4 with the star size indicating the score’s magnitude. In

Figure 8c, stars are labeled with “G” for glazing and “R” for natural stone, while environmental and social indicators are respectively identified by the letters “E” and “S”. As illustrated in

Figure 8c—which shows the material-specific scores for stone (S) and glass (G) obtained by summing the normalized scores for each indicator—the contribution in terms of CO

2-equivalent emissions, assuming a shared production site, is predominantly influenced in both sectors by the distance from the production facility to the construction site.

Specifically, the highest impact for natural stone is seen in Bolzano (approximately 340 km from the quarry and production site), while for glazing, it is recorded in Lazio (approximately 470 km from the manufacturing facility). With regard to social impacts, the absolute number of workplace accidents per sector and region does not by itself reflect the actual weight of the impact, as this must be normalised by the number of employees involved. The analysis conducted in this study, therefore, showed that regions with a smaller workforce tend to exhibit higher relative impact values. This indicates that a lower number of incidents may correspond to a higher relative risk exposure per worker. These findings highlight the importance of considering both absolute and normalised social indicators when assessing worker-related risks, especially in regions with limited staffing and complex or labour-intensive installation activities.

5. Discussion

The environmental sustainability of a building throughout its life cycle is strongly influenced by the materials used in its construction [

69]. However, material selection should extend beyond functional performance requirements and environmental considerations arising during the product life cycle. One such consideration is the impact on worker health, particularly due to occupational accidents, which are notably prevalent in the construction sector.

While worker health and safety are widely recognised in the literature as the most consistently addressed impact category within S-LCA [

66], the integration of regional specificities and empirical data remains limited, posing challenges in achieving a more context-sensitive and realistic evaluation of social impacts. This limitation is partly due to the restricted availability of impact data and the reluctance of stakeholders to disclose such information [

14].

Quantitative assessment of social impacts at each stage of the material life cycle is essential not only to incorporate the ‘social dimension’ into sustainable material selection from the early design phase, but also to unlock potential benefits for responsible production and consumption. In this regard, the present study contributes to bridging this gap by proposing a regionalised approach that integrates worker health and safety indicators into the life cycle assessment of construction materials.

In Italy, INAIL has developed an online statistical database that aggregates data at the provincial, regional and national levels on the number of occupational injuries and work-related illnesses, classified according to the ATECO code—the national classification of economic activities. However, the effective application of these data at the building scale requires re-elaboration and contextualisation to ensure alignment with the life cycle stages of construction products and the specific territorial characteristics of Italy and thereby present a useful tool for integrating the social dimension into sustainable design practices. Our finding that transport (stage A4) is a key driver of global warming potential aligns with Crishna et al. (2011) [

25] who identified logistics as a dominant contributor to environmental impacts in construction supply chains. Similarly, the sensitivity of social impacts to workforce size and installation complexity (stage A5) introduces a new, regionally differentiated dimension to the challenges previously noted by Hosseinijou et al. (2014) [

67] who emphasised the importance of contextual factors in assessing social risks.

While the study offers significant methodological contributions, several limitations should be acknowledged. First, the analysis is based on only two construction products—natural stone cladding and double glazing—which, although representative, do not capture the full diversity of materials used in the sector. Second, due to the lack of a national dataset, the environmental data for stages A1–A3 rely on a single EPD per material, which may affect the extent to which the results can be generalised. Third, the use of normalised injury rates as social indicators depends on the availability and granularity of public data, which vary across regions and sectors. Finally, the integration of qualitative dimensions—such as workers’ perceptions and lived experiences—remains an open challenge for future research, as also highlighted by Kühnen [

63] and other scholars who advocate for mixed-method approaches to capture subjective aspects of social sustainability.

6. Conclusions and Research Outlook

This study introduces a methodological advancement through the integration of E-LCA and SLCA, proposing an approach capable of capturing regional specificities and incorporating the empirical data necessary for a more realistic evaluation of social impacts across construction supply chains.

The analysis of natural stone cladding and double glazing across four regional scenarios reveals that environmental impacts are predominantly influenced by transport distances (stage A4), as reported by Crishna et al. (2011) [

25], who identify logistics as a key driver of global warming potential. Social impacts—particularly those related to worker health and safety—are shaped by workforce size and installation complexity (stage A5), adding a new regional dimension to the contextual challenges previously noted by Hosseini et al. (2014) [

67].

The integration of environmental and social assessments into a composite regional score highlights the need to consider both absolute and normalised indicators, offering a more nuanced understanding of risk exposure and sustainability performance across construction supply chains. The use of quantitative metrics, such as the number of occupational injuries and diseases in the two construction-related production sectors, provides a valid approach to quantifying objective and verifiable impacts. However, the use of workforce size as a denominator introduces methodological limitations, particularly in regions with small teams, where even a few incidents can inflate normalised rates.

In line with UNEP guidelines, an alternative approach would be to use hours worked as the denominator (e.g., injuries per million hours worked), which offers a more proportional measure of exposure. This option was not feasible due to the lack of updated and regionally disaggregated data. Available sources were either outdated (e.g., last updated in 2015) or aggregated at the national level, and did not include information on the ratio of part-time to full-time employment, which would be essential for reliable calibration.

The possibility of weighting impacts by injury severity was also explored. However, the dataset proved too generic to support meaningful classification. For example, injuries are reported by anatomical location (e.g., hand, foot), but without specifying the type of damage or degree of impairment. In the absence of a clear correlation between injury type and severity, assigning weights was deemed both methodologically weak and ethically questionable.

Another critical issue concerns the treatment of mixed employee/subcontractor crews, which is particularly relevant in sectors with high subcontracting rates. Current data sources do not distinguish between these categories, but future refinements to the scoring system should address this gap to ensure a more accurate representation of working conditions.

The decision to focus on workers as the primary stakeholder group is consistent with the life cycle stages analysed (A1–A3, A4, A5), where workers’ exposure is direct and documentable. This choice also responds to a methodological gap highlighted in the literature and regulatory frameworks, as noted in source [

14], regarding the availability of reliable social data in the construction sector.

In line with Kühnen [

66] and previous research on the critical gap in social life cycle subcategories, there is a clear need to integrate subjective perceptual indicators to capture workers’ lived experiences. This calls for a paradigm shift toward a mixed-method framework incorporating qualitative tools such as structured interviews to explore cognitive and emotional perceptions across life cycles and supply chains. Such an integrated approach would enable a more holistic assessment, combining empirical metrics with psychosocial determinants of workplace well-being and thereby enhancing the depth and accuracy of social sustainability evaluations within the life cycle sustainability assessment framework.

To guide future research, several limitations should be acknowledged. From the environmental perspective, reliance on single product-specific environmental declarations in the absence of national datasets—particularly for modules A1–A3—limits representativeness. The present application is also restricted to two products, which are insufficient to reflect the diversity of the sector. From the social perspective, key challenges include the choice of denominator for exposure metrics and the lack of disaggregated data on hours worked and injury severity. Extending the method to other national contexts by identifying databases equivalent to INAIL and mapping data across life cycle modules would strengthen the validity and transferability of the proposed framework.

Overall, this work presents a replicable methodological approach for integrating the social dimension into sustainable building design, promoting the adoption of composite metrics in decision-making processes and environmental product declarations. However, the results should not be interpreted as comparative evaluations or as a basis for defining performance benchmarks, but rather as a context-sensitive tool to support informed and responsible design choices.

Author Contributions

Conceptualisation, E.P.; methodology, E.P. and F.P.; formal analysis, E.P.; investigation, E.P.; data curation, E.P. and F.P.; writing—original draft preparation, E.P.; writing—review and editing, E.P. and F.P.; visualisation, E.P.; funding acquisition, E.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Department of Engineering and Applied Sciences (DISA), University of Bergamo, Italy, as part of a visiting research period. The views and conclusions expressed herein are solely those of the authors.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Acknowledgments

During the preparation of this work, the authors used Microsoft Copilot (October 2025 version) solely to improve language and readability. After using this tool, the authors reviewed and edited the content as needed and take full responsibility for the content of the publication.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Abbreviations

The following abbreviations are used in this manuscript:

| B2B | Business-to-Business |

| BPIE | Buildings Performance Institute Europe |

| CAM | Criteri Ambientali Minimi |

| E-LCA | Environmental Life Cycle Assessment |

| EC | Embodied Carbon |

| EE | Embodied Energy |

| EPBD | Energy Performance of Buildings Directive |

| EPD | Environmental Product Declarations |

| GDP | Gross Domestic Product |

| GWP | Global Warming Potential |

| INAIL | Istituto Nazionale per l’Assicurazione contro gli Infortuni sul Lavoro |

| ISO | International Organization for Standardization |

| LCA | Life Cycle Assessment |

| LTS | Long-Term Strategy |

| NECP | National Energy and Climate Plan |

| nZCB | Net-Zero Carbon Building |

| nZEB | Net-Zero Energy Building |

| OC | Operational Carbon |

| OE | Operational Energy |

| PCR | Product Category Rules |

| RE2020 | Réglementation Environnementale 2020 |

| S-LCA | Social Life Cycle Assessment |

| SETAC | Society of Environmental Toxicology and Chemistry |

| SPD | Social Product Declaration |

| UNI | Ente Nazionale Italiano di Unificazione |

| UNEP | United Nations Environment Programme |

| WLC | Whole Life Carbon |

References

- Zhang, S.; Huang, P.; Sun, Y. A multi-criterion renewable energy system design optimization for net zero energy buildings under uncertainties. Energy 2016, 94, 654–665. [Google Scholar] [CrossRef]

- Ohene, E.; Chan, A.P.C.; Darko, A.; Nani, G. Navigating toward net zero by 2050: Drivers, barriers, and strategies for net zero carbon buildings in an emerging market. Build. Environ. 2023, 242, 110472. [Google Scholar] [CrossRef]

- EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. CEN: Brussels, Belgium, 2011.

- European Parliament. Directive (EU) 2024/1275 of the European Parliament and of the Council of 24 April 2024 on the Energy Performance of Buildings (Recast) (Text with EEA Relevance). In Official Journal of the European Union; 2025. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:L_202401275 (accessed on 5 April 2025).

- Marinello Jorba, V.; Palumbo, E.; del Rosario, P.; Traverso, M. Interpreting environmental impacts of wooden windows based on existing EPDs: An application in Italy. Energy Build. 2024, 326, 114987. [Google Scholar] [CrossRef]

- Myint, N.N.; Shafique, M. Embodied carbon emissions of buildings: Taking a step towards net zero buildings. Case Stud. Constr. Mater. 2024, 20, e03024. [Google Scholar] [CrossRef]

- European Commission; BPIE; Directorate-General for Environment; KU Leuven; Ramboll; Le Den, X. Supporting the Development of a Roadmap for the Reduction of Whole Life Carbon of Buildings—Final Report; Publications Office of the EU: Luxembourg, 2023. Available online: https://data.europa.eu/doi/10.2779/634412 (accessed on 3 February 2025).

- EPDItaly. Crescita delle EPD e delle PCR. EPD Italy News. 30 July 2024. Available online: https://www.epditaly.it/2024/07/30/crescita-delle-epd-e-delle-pcr/ (accessed on 3 February 2025).

- Ottolenghi, M.; Amorusi, A.; Bartolini, C. La Diffusione Degli Strumenti Volontari per la Gestione della Sostenibilità in Emilia-Romagna; Ambiente Regione Emilia-Romagna: Bologna, Italy, 2023. [Google Scholar]

- Brisson Stapel, E.; Balouktsi, M.; Grau Sørensen, C.; Birgisdottir, H. Methodological challenges in aligning EPDs with Whole Life Carbon limits for buildings: A B2B approach. IOP Conf. Ser. Earth Environ. Sci. 2024, 1402, 012025. [Google Scholar] [CrossRef]

- Josa, I.; Borrion, A. Rebuilding or retrofitting? An assessment of social impacts using Social Life Cycle Assessment. Environ. Impact Assess. Rev. 2025, 112, 107794. [Google Scholar] [CrossRef]

- Barbero, I.; Rezgui, Y.; Beach, T.; Petri, I. Social Life Cycle Assessment in the construction sector: Current work and directions for future research. Int. J. Life Cycle Assess. 2024, 29, 1827–1845. [Google Scholar] [CrossRef]

- Benoît Norris, C.; Traverso, M.; Neugebauer, S.; Ekener, E.; Schaubroeck, T.; Russo Garrido, S.; Berger, M.; Valdivia, S.; Lehmann, A.; Finkbeiner, M.; et al. (Eds.) Guidelines for Social Life Cycle Assessment of Products and Organizations, 2nd ed.; UNEP/SETAC Life Cycle Initiative: Paris, France, 2020; Available online: https://www.lifecycleinitiative.org/wp-content/uploads/2021/12/Guidelines-for-Social-Life-Cycle-Assessment-of-Products-and-Organizations-2021-ITA.pdf (accessed on 3 March 2025).

- Backes, J.G.; Traverso, M. Social life cycle assessment in the construction industry: Systematic literature review and identification of relevant social indicators for carbon reinforced concrete. Environ. Dev. Sustain. 2023, 26, 7199–7233. [Google Scholar] [CrossRef]

- INAIL. Construction Focus: Trends in Occupational Injuries and Work-Related Illnesses; INAIL: Rome, Italy, 2024; No. 11, November; ISSN 2035-5645. Available online: https://olympus.uniurb.it/index.php?option=com_content&view=article&id=33334 (accessed on 24 September 2025).

- INAIL. Occupational Database [Banca Dati Delle Professioni]. Available online: https://www.inail.it/cs/internet/attivita/banca-dati.html (accessed on 11 July 2025).

- Giordano, V.; Castagnoli, A.; Pecorini, I.; Chiarello, F. Identifying technologies in circular economy paradigm through text mining on scientific literature. PLoS ONE 2024, 19, e0312709. [Google Scholar] [CrossRef]

- BPIE. Italy Buildings Climate Tracker: Is Italy on Track to Decarbonise its Building Stock? BPIE Report; BPIE: Brussels, Belgium, 2025. [Google Scholar]

- Morris, F.; Allen, S.; Hawkins, W. On the embodied carbon of structural timber versus steel, and the influence of LCA methodology. Build. Environ. 2021, 206, 108285. [Google Scholar] [CrossRef]

- Keyhani, M.; Abbaspour, A.; Bahadori-Jahromi, A.; Mylona, A.; Janbey, A.; Godfrey, P.; Zhang, H. Whole Life Carbon Assessment of a typical UK residential building using different embodied carbon data sources. Sustainability 2023, 15, 5115. [Google Scholar] [CrossRef]

- Palumbo, E.; Politi, S. Improving building envelope efficiency: Interaction between embedded energy and operational energy. TECHNE—J. Technol. Archit. Environ. 2018, 16, 247–257. [Google Scholar] [CrossRef]

- Kamazani, M.A.; Dixit, M.K.; Shanbhag, S.S. Optimizing interconnected embodied and operational energy of buildings: An embodied energy factor approach. Build. Environ. 2025, 276, 112902. [Google Scholar] [CrossRef]

- LETI. Embodied Carbon Primer: Supplementary Guidance to the Climate Emergency Design Guide; London Energy Transformation Initiative: London, UK, 2020; Available online: https://www.leti.uk/ecp (accessed on 3 March 2025).

- Pomponi, F.; Moncaster, A. Embodied carbon mitigation and reduction in the built environment—What does the evidence say? J. Environ. Manag. 2016, 181, 687–700. [Google Scholar] [CrossRef]

- Crishna, N.; Banfill, P.F.G.; Goodsir, S. Embodied energy and CO2 in UK dimension stone. Resour. Conserv. Recycl. 2011, 55, 1265–1273. [Google Scholar] [CrossRef]

- World Green Building Council. Bringing Embodied Carbon Upfront: Coordinated Action for the Building and Construction Sector to Tackle Embodied Carbon. WorldGBC. 2019. Available online: https://www.worldgbc.org/bringing-embodied-carbon-upfront (accessed on 3 March 2025).

- Martínez-Aires, M.D.; López-Alonso, M.; de la Hoz-Torres, M.L.; Aguilar-Aguilera, A.; Arezes, P. Occupational risk prevention in the European Union construction sector: 30 years since the publication of the Directive. Saf. Sci. 2024, 177, 106593. [Google Scholar] [CrossRef]

- European Commission. The Clean Industrial Deal: A Joint Roadmap for Competitiveness and Decarbonisation; COM(2025) 85 Final; European Commission: Brussels, Belgium, 26 February 2025. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52025DC0085 (accessed on 3 May 2025).

- United Nations Environment Programme (UNEP). Sustainable Buildings; UNEP: Nairobi, Kenya, 2021; Available online: https://www.unep.org/topics/cities/buildings-and-construction/sustainable-buildings (accessed on 24 September 2025).

- Bellicini, L. Ma Quanto Vale il Settore delle Costruzioni per L’economia Italiana? Il 5%, il 14% o, con L’immobiliare, il 25%; Cresme Daily: Rome, Italy, 2024. [Google Scholar]

- García Vaquero, M.; Sánchez-Bayón, A.; Lominchar, J. European Green Deal and Recovery Plan: Green jobs, skills and wellbeing economics in Spain. Energies 2021, 14, 4145. [Google Scholar] [CrossRef]

- Palumbo, E.; Traverso, M. Social life cycle indicators towards a sustainability label of a natural stone for coverings. In Towards a Sustainable Future—Life Cycle Management; Klos, Z.S., Kalkowska, J., Kasprzak, J., Eds.; Springer International Publishing: Geneva, Switzerland, 2025. [Google Scholar]

- Legambiente; Kyoto Club. Il Settore Edilizio verso una Nuova Sfida: La Decarbonizzazione delle Costruzioni; Legambiente: Rome, Italy, 2022; Available online: https://www.legambiente.it/wp-content/uploads/2022/11/La-decarbonizzazione-delle-costruzioni_report-2022.pdf (accessed on 3 May 2025).

- Donatello, S.; Garbarino, E.; Sanfelix, J.; Fernandez Carretero, A.; Wolf, O. EU Ecolabel Criteria for Hard Covering Products. Final Technical Report: Criteria and Supporting Rationale; EUR 30682 EN; Publications Office of the European Union: Luxembourg, 2021; ISBN 978-92-76-36360-6. [Google Scholar] [CrossRef]

- European Commission. Commission Decision of 9 July 2009 Establishing the Ecological Criteria for the Award of the Community Eco-Label to Hard Coverings (2009/607/EC). Off. J. Eur. Union 2009, L 208, 21–38. [Google Scholar]

- Palumbo, E.; Panozzo, C.; Cellurale, M.; Rinaldi, C. Studio LCA della Filiera delle Pietre Ornamentali; ENEA: Roma, Italy, 2025; ISBN 978-88-8286-511-5. Available online: https://www.pubblicazioni.enea.it/le-pubblicazioni-enea/edizioni-enea/anno-2025/studio-lca-della-filiera-delle-pietre-ornamentali.html (accessed on 3 March 2025).

- Legambiente. Rapporto Cave 2021; Legambiente: Roma, Italy, 2021; Available online: https://www.legambiente.it/wp-content/uploads/2021/07/Rapporto-Cave-2021.pdf (accessed on 3 May 2025).

- Salazar, J. Life Cycle Assessment (LCA) of windows and window materials. In Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Pacheco-Torgal, F., Cabeza, L.F., Labrincha, J., de Magalhaes, A., Eds.; Woodhead Publishing: Cambridge, UK, 2013; pp. 502–527. ISBN 9780857097675. [Google Scholar]

- Carvalho, J.P.; Bragança, L.; Mateus, R. Optimising building sustainability assessment using BIM. Autom. Constr. 2019, 102, 170–182. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Potrč Obrecht, T.; Alaux, N.; Röck, M.; Soust-Verdaguer, B.; Di Bari, R.; Horn, R.; Kiss, B.; Szalay, Z.; Hollberg, A.; Veselka, J.; et al. IEA Annex 72: The LCA Decision Support Tool for Building Designers (Accompanying the Design Process). SSRN 2024. [Google Scholar] [CrossRef]

- Palumbo, E.; Soust-Verdaguer, B.; Llatas, C.; Traverso, M. How to obtain accurate environmental impacts at early design stages in BIM when using environmental product declaration: A method to support decision-making. Sustainability 2020, 12, 6927. [Google Scholar] [CrossRef]

- Islam, N.; Sandanayake, M.; Muthukumaran, S.; Navaratna, D. Review on sustainable construction and demolition waste management—Challenges and research prospects. Sustainability 2024, 16, 3289. [Google Scholar] [CrossRef]

- Hasselsteen, L.; Brisson Stapel, E.; Birgisdottír, H.; Sørensen, C.G.; Kanafani, K. Evaluating the environmental impact of construction waste: A comprehensive analysis of end-of-life scenarios in environmental product declarations. Build. Environ. 2025, 280, 113159. [Google Scholar] [CrossRef]

- Ministry of the Environment and Energy Security (Italy). Minimum Environmental Criteria for the Procurement of Design Services and Works for New Construction, Renovation, and Maintenance of Public Buildings; Ministerial Decree No. 194 of 27 May 2024; Ministry of the Environment and Energy Security: Rome, Italy, 2024. Available online: https://www.mase.gov.it (accessed on 24 September 2025).

- EN 15643:2021; Sustainability of Construction Works—Framework for Assessment of Buildings and Civil Engineering Works. CEN: Brussels, Belgium, 2021.

- EN 17680:2023; Sustainability of Construction Works—Evaluation of the Potential for Sustainable Refurbishment of Buildings. CEN: Brussels, Belgium, 2023.

- EN 15804:2012+A2:2019; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. CEN: Brussels, Belgium, 2019.

- Dodd, N.; Cordella, M.; Traverso, M.; Donatello, S. Level(s)—A Common EU Framework of Core Sustainability Indicators for Office and Residential Buildings: Parts 1 and 2: Introduction to Level(s) and How It Works (Beta v1.0); EUR 28899 EN; Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-76914-6. [Google Scholar] [CrossRef]

- Khasreen, M.M.; Banfill, P.F.G.; Menzies, G.F. Life-Cycle Assessment and the environmental impact of buildings: A review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Negishi, K.; Tiruta-Barna, L.; Schiopu, N.; Lebert, A.; Chevalier, J. An operational methodology for applying dynamic Life Cycle Assessment to buildings. Build. Environ. 2018, 144, 611–621. [Google Scholar] [CrossRef]

- Fnais, A.; Rezgui, Y.; Petri, I.; Beach, T.; Yeung, J.; Ghoroghi, A.; Kubicki, S. The application of life cycle assessment in buildings: Challenges and directions for future research. Int. J. Life Cycle Assess. 2022, 27, 627–654. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Härri, A.; Levänen, J.; Niinimäki, K. Exploring the role of Social Life Cycle Assessment in transition to circular economy: A systematic review. Resour. Conserv. Recycl. 2024, 207, 107702. [Google Scholar] [CrossRef]

- Mármol, C.; Martín-Mariscal, A.; Picardo, A.; Peralta, E. Social Life Cycle Assessment for industrial product development: A comprehensive review and analysis. Heliyon 2023, 9, e22861. [Google Scholar] [CrossRef]

- Caetano, N.S.; Martins, F.F.; Oliveira, G.M. Life Cycle assessment of renewable energy technologies. In Encyclopedia of Sustainable Technologies, 2nd ed.; Jafarinejad, S., Beckingham, B.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 37–79. [Google Scholar] [CrossRef]

- Dyson, B. Integration of life cycle and life cycle sustainability assessments into decision analytic approaches for sustainable technologies. In Encyclopedia of Sustainable Technologies, 2nd ed.; Jafarinejad, S., Beckingham, B.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; Volume 3, pp. 643–655. [Google Scholar]

- Ashby, M.F. Chapter 6—Social Life Cycle Assessment (S-LCA). In Earth and Planetary Sciences Topics; ScienceDirect, Elsevier: Amsterdam, The Netherlands, 2022; Available online: https://www.sciencedirect.com/topics/earth-and-planetary-sciences/social-life-cycle-assessment (accessed on 3 August 2025).

- Nasirzadeh, F.; Ghayoumian, M.; Khanzadi, M.; Cherati, M.R. Modelling the social dimension of sustainable development using fuzzy cognitive maps. Int. J. Constr. Manag. 2019, 20, 223–236. [Google Scholar] [CrossRef]

- EPD International. The World’s First Social Product Declaration. 6 December 2023. Available online: https://www.environdec.com/news/the-worlds-first-social-product-declaration (accessed on 3 August 2025).

- Palumbo, E. Effect of LCA data sources on GBRS reference values: The envelope of an Italian passive house. Energies 2021, 14, 1883. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 21930:2017; Sustainability in Buildings and Civil Engineering Works—Core Rules for Environmental Product Declarations of Construction Products and Services. International Organization for Standardization: Geneva, Switzerland, 2017.

- Eurostat. Accidents at Work Statistics—Statistics Explained, European Commission. October 2024. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Accidents_at_work_statistics (accessed on 3 March 2025).

- Kühnen, M.; Hahn, R. Indicators in Social Life Cycle Assessment: A review of frameworks, theories, and empirical experience. J. Ind. Ecol. 2017, 21, 1547–1565. [Google Scholar] [CrossRef]

- Hosseinijou, S.A.; Mansour, S.; Shirazi, M.A. Social life cycle assessment for material selection: A case study of building materials. Int. J. Life Cycle Assess. 2014, 19, 620–645. [Google Scholar] [CrossRef]

- Automobile Club of Italy (ACI). Regional Vehicle Fleet Statistics 2015–2024, ACI Gov. 2024. Available online: https://aci.gov.it/attivita-e-progetti/studi-e-ricerche/annuario-statistico (accessed on 3 March 2025).

- BPIE (Buildings Performance Institute Europe). How to Establish Whole Life Carbon Benchmarks: Insights and Lessons Learned from Emerging Approaches in Ireland, Czechia and Spain; BPIE: Brussels, Belgium, 2024; Available online: https://www.bpie.eu/publication/how-to-establish-whole-life-carbon-benchmarks-insights-and-lessons-learned-from-emerging-approaches-in-ireland-czechia-and-spain/ (accessed on 3 May 2025).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).