Abstract

Supply chains are a primary contributor to global greenhouse gas (GHG) emissions, rendering their decarbonization an essential dimension of sustainable development. Artificial intelligence (AI) provides a transformative pathway by facilitating proactive emission avoidance through operational efficiency, transparency, and resilience, in contrast to post-emission mitigation approaches such as carbon capture. This study explores the potential of AI to support indirect carbon dioxide removal (CDR) via supply chain decarbonization, adopting a comparative case study methodology. Empirical evidence is drawn from Tunisian agri-food, textile, and port logistics sectors, based on multi-source datasets spanning 6–12 months and covering fleet sizes ranging from 40 to 250,000 units. Methodological robustness was ensured through the use of pre-intervention baselines, statistical imputation for missing data (<5%), and validation against 20% out-of-sample test sets. Results indicate that AI-enabled interventions achieved annual avoided emissions between 500 and 1500 tCO2 and reduced fuel consumption by 12–15%, with sensitivity analyses incorporating ±8–12% error margins. Among the approaches tested, hybrid models integrating operational and strategic layers demonstrated the most pronounced impact, aligning immediate efficiency gains with long-term systemic decarbonization. Furthermore, AI facilitates renewable energy integration, digital twin applications, and compliance with international sustainability frameworks, notably the Paris Agreement and the United Nations Sustainable Development Goals. Nevertheless, challenges related to data quality, computational demands, limited expertise, and organizational resistance constrain scalability. The findings underscore AI’s dual role as a technological enabler and systemic driver of supply chain decarbonization, advancing its positioning within global environmental sustainability transitions.

1. Introduction

In the contemporary global context, the transition toward sustainable and low-carbon development pathways has become an imperative of paramount urgency and significance [1]. Central to this transition is the decarbonization of global supply chains, which account for a significant share of GHG emissions across diverse industrial sectors [2]. These supply chains, characterized by their multi-tiered, geographically dispersed structures encompassing extraction, production, logistics, distribution, and end-of-life management, pose both a major challenge and a critical opportunity for advancing environmental sustainability [3].

This dual nature highlights the need for strategic intervention. On the one hand, decarbonization offers substantial benefits, including notable reductions in GHG emissions, improved resource and energy efficiency, enhanced corporate environmental performance, and compliance with international climate objectives [4]. On the other hand, the transformation of such complex and dynamic networks is hindered by significant barriers, including limited transparency, volatile demand–supply dynamics, regulatory heterogeneity, and exposure to geopolitical and market disruptions [5]. Overcoming these constraints requires innovative, data-driven approaches that can manage complexity while delivering measurable and scalable environmental sustainability outcomes [6].

AI has emerged as a transformative enabler in this context. Rather than serving solely as a means of incremental efficiency improvement, AI, encompassing machine learning, neural networks, and deep learning, increasingly supports comprehensive, data-driven decarbonization strategies [7]. In contrast to carbon capture technologies, which address emissions already present in the atmosphere, AI focuses on prevention, optimizing processes to reduce energy and material waste, improve operational efficiency, and embed sustainable technologies throughout the value chain [8]. By shifting the emphasis from reactive mitigation to proactive avoidance of emissions, AI provides a critical link between high-level sustainability ambitions and their practical realization.

Theoretically, this study draws on the Natural Resource-Based View of the firm [9] and the Technology-Organization-Environment framework [10]. These lenses explain how AI serves as a strategic resource for sustainability and its adoption in supply chains, enhancing pollution prevention, product stewardship, and sustainable development capabilities while considering technological factors (e.g., AI model sophistication), organizational factors (e.g., data infrastructure and expertise), and environmental factors (e.g., regulatory pressures such as the Paris Agreement).

This paper aims to address the gap in existing literature by providing a detailed empirical analysis of AI’s role in supply chain decarbonization, specifically focusing on its indirect contribution to the avoidance of emissions through proactive measures, a less explored aspect compared to direct carbon capture technologies. In contrast to previous studies that often focus on general AI applications or specific sectors, our work adds a comparative case study approach across Tunisia’s agri-food, textile, and port logistics sectors, highlighting the efficacy of hybrid AI models and their alignment with global environmental sustainability frameworks.

The versatility of AI is evident in its ability to address multiple supply chain functions simultaneously. Emerging AI methodologies, particularly machine learning techniques such as deep learning, reinforcement learning, and natural language processing, are utilized to optimize demand forecasting, enhance logistics planning, assess supplier risks, and improve energy efficiency [11,12]. These applications enable organizations to adapt to fluctuating conditions, make real-time, data-informed decisions, and achieve simultaneous gains in operational efficiency and emission avoidance [13]. A significant recent development is the emergence of hybrid AI systems that integrate short-term operational optimization with long-term strategic forecasting. When deployed through centralized digital control towers, these systems combine real-time monitoring with predictive analytics, enhancing the capacity to phase out carbon-intensive activities and strengthen long-term sustainability [14,15]. While AI can enhance supply chain resilience, this aspect is secondary to the paper’s focus on decarbonization and is deferred to future discussions.

Beyond optimization, artificial intelligence plays a crucial role in reinforcing the resilience of supply chains. By improving resilience to disruptions, AI can prevent emission-intensive emergency measures, such as expedited air freight, thereby supporting stable, low-carbon operations [16]. In this way, AI supports the development of supply chains that are not only low-carbon but also adaptive and robust in the face of systemic shocks [17].

The efficacy of AI-enabled decarbonization approaches relies fundamentally on the integrity and robustness of the associated models and datasets. Operational models excel in tactical optimization but may lack the systemic perspective required for long-term planning. Conversely, strategic models can identify structural patterns over extended horizons but necessitate significant computational resources and access to high-quality datasets [18]. Hybrid architectures that combine both approaches offer a balanced solution, delivering the precision required for immediate operational gains while also providing the foresight essential for sustainable emission mitigation [19].

Since the early 2010s, the rapid evolution of AI capabilities has paralleled an increasing focus on environmental sustainability and social and governance performance indicators. This convergence has facilitated the accelerated incorporation of AI into sustainable supply chain management [20]. Policymakers, research institutions, and technology providers are increasingly collaborating to refine AI-based solutions that achieve decarbonization objectives while enhancing operational performance and systemic resilience [21]. Consequently, AI is now recognized not merely as a technological adjunct but as a foundational component of next-generation supply chain systems, purposefully designed to operate effectively in volatile, uncertain, and resource-constrained environments, while supporting the worldwide shift toward sustainable, low-carbon development [22].

The remainder of this paper is organized as follows: Section 2 reviews the literature on AI-powered methodologies for decarbonization and outlines our research framework. Section 3 presents the methodology and results from our case studies in Tunisia. Section 4 discusses the findings, their broader implications, and limitations. Finally, Section 5 concludes the study and suggests avenues for future research.

2. AI-Powered Methodologies for Achieving Supply Chain Decarbonization

This section outlines the primary AI methodologies applied to supply chain decarbonization. The literature review was conducted using the Scopus and Web of Science databases with keywords including “AI and supply chain”, “decarbonization”, “sustainable logistics”, and “machine learning for emission avoidance” for papers published between 2015 and 2024. Potential limitations arising from non-indexed sources or language restrictions are acknowledged. The decarbonization levers discussed in Table 1 were identified through a two-stage process: a systematic literature review to identify commonly cited high-emission points in supply chains, followed by consultations with industry experts in Tunisia to validate their relevance to the local context.

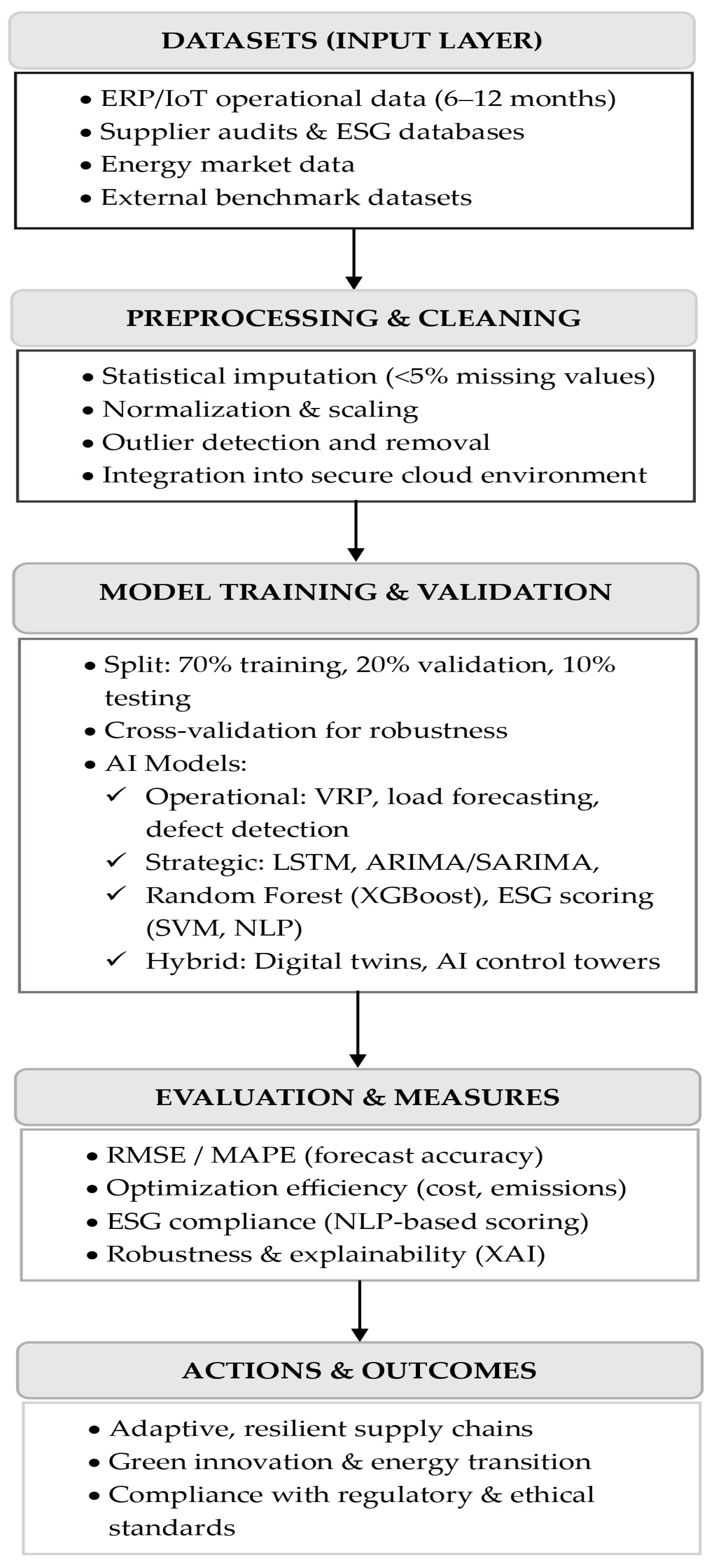

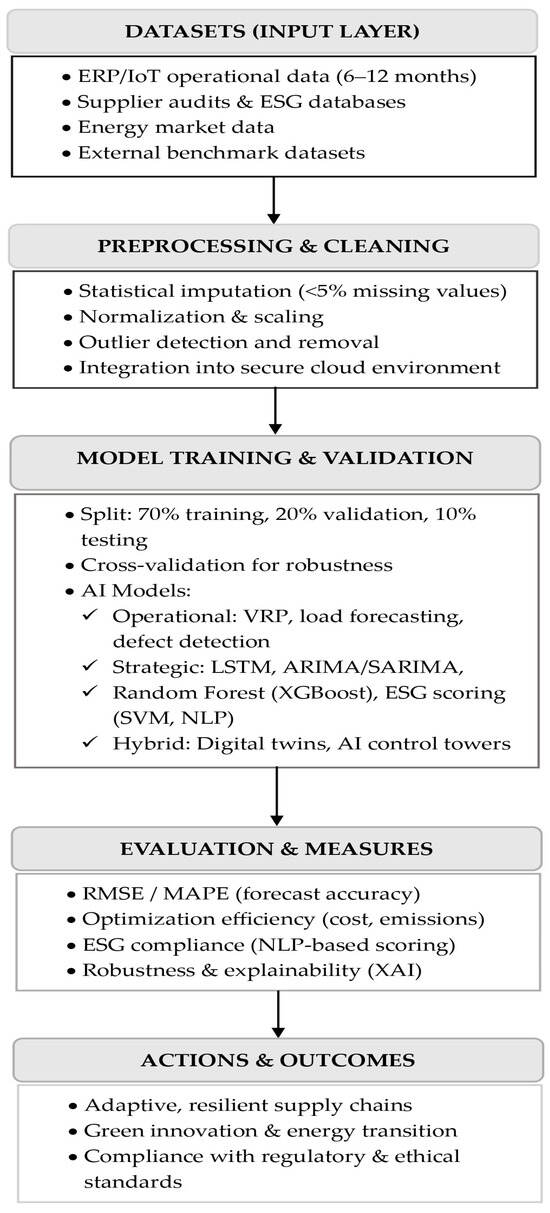

As illustrated in the conceptual framework in Figure 1, effective implementation typically unfolds in three sequential stages. First, a robust data foundation is established by systematically collecting, integrating, cleaning, and transforming relevant datasets to guarantee completeness, accuracy, and interoperability [23]. For the Tunisian pilots, datasets included 6–12 months of operational data from 40 vehicles (agri-food) and 250,000 truck visits (Rades), cleaned using statistical imputation for missing values of total) and validated with 20% out-of-sample test sets, achieving RMSE of 0.05–0.1 for model predictions. Second, AI methodologies are deployed by selecting, configuring, and training appropriate models tailored to specific decarbonization objectives [24]. Models such as VRP and LSTM were trained on 70% of the cleaned data, with hyperparameter tuning performed via grid search, and validated against 20% of the held-out data. Finally, during the testing and validation phase, model outputs are assessed using out-of-sample or recent datasets, with subsequent parameter tuning to achieve both satisfactory predictive accuracy and a measurable impact on environmental sustainability [25]. Validation included cross-checking with historical baselines and sensitivity analyses, which showed ±8–12% error margins.

Figure 1.

Conceptual Framework of AI-Driven Supply Chain Decarbonization.

The establishment of a robust and high-quality data infrastructure is fundamental to the effective deployment of AI-driven decarbonization strategies. Critical data sources include Enterprise Resource Planning (ERP) systems, logistics management platforms, and Internet of Things (IoT) sensor networks strategically deployed throughout the supply chain [26]. These internal datasets are often complemented by external sources, such as energy market data and supplier Environmental, Social, and Governance (ESG) performance indicators. Following aggregation, the data undergoes thorough normalization and cleansing procedures to resolve inconsistencies, rectify errors, and impute missing values through statistically robust techniques [27]. The processed data are then stored in scalable, secure cloud-based infrastructures capable of accommodating large-volume, high-velocity streams, thereby enabling global accessibility and real-time analytics [28]. On this foundation, AI methodologies can be classified into three main categories: operational optimization models, strategic statistical and machine learning approaches, and hybrid frameworks that integrate both dimensions. Table 1 offers a detailed summary of how these AI techniques are applied to key decarbonization levers across the supply chain.

Table 1.

Summary of AI Methodologies and Their Applications in Supply Chain Decarbonization.

Table 1.

Summary of AI Methodologies and Their Applications in Supply Chain Decarbonization.

| Decarbonization Lever | Primary AI Methodology | Key Data Inputs | Primary Carbon Impact | Key Implementation Challenge |

|---|---|---|---|---|

| Transportation and Logistics [24,25,26] | Vehicle Routing Problem (VRP) solvers; Heuristic Optimization (Genetic Algorithms, Enhanced Particle Swarm Optimization) | GPS coordinates, traffic feeds, order manifests, vehicle capacity, fuel consumption rates | Reduction in direct fuel consumption through optimized routing, improved fleet utilization, and lower idle times | High computational cost with 5–10% routing errors in rural Tunisia due to sparse GIS data; real-time integration failures in 3% of cases |

| Manufacturing and Production [29,30,31] | Convolutional neural networks (CNNs) for defect detection; Predictive Maintenance (LSTMs, Ensemble Models) | Production line imagery, IoT sensor readings (temperature, vibration, energy usage), machine logs | Reduction in embedded carbon via lower defect rates; minimized downtime and energy inefficiencies | Significant initial investment with 7–12% labeling errors in Tunisian textile imagery; IoT setup delays in 15% of facilities |

| Inventory and Demand Management [27,28,32] | Time-Series Forecasting (ARIMA, LSTMs); Stochastic Inventory Optimization Models | Historical sales records, promotional calendars, macroeconomic indicators, and supplier lead times | Reduced emissions from overproduction, obsolete stock waste, and unnecessary redistribution | Forecast accuracy drops under high volatility; errors can amplify upstream (bullwhip effect) |

| Sourcing and Supplier Management [33,34] | NLP for ESG report analysis; Supplier Risk Scoring Models (SVM, XGBoost) | Supplier ESG disclosures, audit reports, sustainability ratings, media coverage | Mitigation of Scope 3 emissions through selection of low-carbon suppliers; enhanced supply chain resilience | Dependence on unstructured, often unverifiable third-party data; susceptibility to “greenwashing” |

| System-Wide Network Design [35,36] | Digital Twins for supply chain simulation; Reinforcement Learning for strategic policy optimization | Facility geolocations, transport lanes, production capacities, regional carbon intensity of energy grids, and carbon pricing | Long-term structural emission avoidance via optimized network footprint and location strategy | Requires massive data integration; high financial and computational burden |

| Waste Management and Circular Economy [37,38] | AI-enabled waste classification (Computer Vision, ML classifiers); Predictive Waste Collection Optimization | Waste composition data, geospatial collection routes, and recycling facility throughput rates | Reduced landfill emissions and improved recycling rates through optimized collection and sorting | Variability in waste streams challenges model generalization; infrastructure readiness constraints |

| Energy Management in Transport [39] | AI-driven charging optimization for EV fleets; Energy Demand Prediction Models | Real-time battery state-of-charge, trip schedules, charging station availability, and electricity pricing | Reduced indirect CO2 emissions by integrating renewable energy in charging schedules; improved vehicle uptime | Grid integration complexity; need for synchronized vehicle and energy system data |

A comparative analysis of the primary AI model categories, highlighting their respective strengths, weaknesses, and ideal use cases, is presented in Table 2. This comparison provides a crucial context for selecting the appropriate methodology according to specific decarbonization objectives and resource availability. It directly links to the operational optimization focus discussed in Section 2.1, which is prioritized here to target immediate carbon reduction opportunities in logistics, manufacturing, and energy management, rather than general operational efficiency in general.

Table 2.

Comparison of Operational, Strategic, and Hybrid AI Models.

2.1. Operational Optimization Models

Operational optimization models apply mathematical and physical principles to predict, simulate, and optimize resource utilization, with a particular emphasis on reducing the carbon footprint of logistics, manufacturing, and facility operations to support decarbonization, rather than general operational efficiency in general [32]. These models are especially effective in contexts where detailed, high-frequency operational data are available.

2.1.1. Logistics and Routing Optimization Models

Logistics and routing optimization models utilize AI to address complex challenges, such as the VRP, by determining fuel- and time-efficient delivery routes. These models process extensive geospatial, temporal, and operational datasets, including GPS coordinates, traffic patterns, and vehicle capacities, to minimize fuel consumption and GHG emissions [35]. By integrating real-time GPS tracking and meteorological data, the models enable dynamic route adjustments in response to traffic or weather disruptions, enhancing operational efficiency and reducing CO2 emissions. Such optimizations contribute to sustainable supply chain management, aligning with the United Nations Sustainable Development Goal (SDG) 9 (Industry, Innovation, and Infrastructure) and the Paris Agreement’s emission reduction targets.

These models employ advanced computational techniques, such as heuristic and metaheuristic algorithms, including Ant Colony Optimization (ACO) and Genetic Algorithms (GAs), to generate near-optimal solutions for large-scale VRPs constrained by vehicle capacity and delivery schedules [36]. Additionally, mathematical programming methods, such as Integer Linear Programming (ILP), provide precise solutions by optimizing routing and network design under constraints, including delivery time windows [29]. By leveraging real-time data, these approaches improve fleet utilization, reduce idle times, and support sustainable logistics practices, thereby advancing global climate mitigation objectives.

2.1.2. Smart Energy Management Systems

Smart Energy Management Systems (SEMS) are deployed in energy-intensive environments such as factories and distribution centers, where they leverage AI to forecast energy load patterns and optimize high-consumption assets, including HVAC systems and industrial machinery. By integrating with building management systems and smart meters, SEMS enable predictive load balancing and adaptive scheduling to minimize peak demand and reduce energy costs [30].

These systems continuously analyze real-time data from sensors and meters to detect anomalies, anticipate demand fluctuations, and adjust operations accordingly. For instance, refrigeration units or conveyor systems can be managed during off-peak periods to ensure smooth energy consumption. In addition to operational savings, SEMS supports environmental sustainability goals by lowering carbon-intensive electricity usage, enhancing energy efficiency, and aligning energy management with production and logistics schedules.

2.1.3. Real-Time Process and Quality Control Models

In manufacturing, AI plays a pivotal role in reducing material and energy waste through advanced techniques, including computer vision and computational simulations. These models leverage high-frequency operational data to optimize production processes, accordingly enhancing resource efficiency and contributing to sustainable supply chain decarbonization. Specifically, CNNs are employed for real-time defect detection, analyzing high-resolution imagery from production lines to identify surface or structural anomalies [31]. By detecting defects early in the manufacturing process, CNNs prevent the downstream processing and transportation of faulty goods, reducing unnecessary energy consumption and associated GHG emissions. This proactive approach aligns with the United Nations’ SDG 12, which emphasizes responsible consumption and production by minimizing waste.

Complementing computer vision, computational fluid dynamics (CFD) simulations provide a sophisticated method for optimizing energy use in industrial processes. By applying fluid mechanics equations, CFD models airflow, heat transfer, and other thermodynamic parameters to identify inefficiencies in energy-intensive operations [33]. For instance, CFD enables manufacturers to optimize furnace designs or ventilation systems, consequently reducing energy consumption and mitigating emissions. These simulations contribute to sustainable manufacturing by enhancing process efficiency and supporting compliance with international climate frameworks, such as the Paris Agreement. Collectively, computer vision and CFD exemplify how AI-driven technologies can deliver immediate operational benefits while advancing long-term environmental sustainability goals in supply chain management [34].

2.2. Strategic Statistical and Machine Learning Models

These models employ mathematical and statistical techniques to analyze historical data and capture relationships between variables. They are particularly effective when substantial historical datasets are available, enabling accurate medium- to long-term forecasts that can inform proactive emission reduction strategies.

2.2.1. Classical Time-Series Models

Classical time-series models are instrumental in analyzing and predicting data collected at consistent time intervals, leveraging underlying patterns, trends, and temporal dependencies to inform supply chain decarbonization strategies. These models are particularly effective for medium- to long-term forecasting, enabling proactive avoided emissions by optimizing demand planning and resource allocation. A widely adopted approach is the Autoregressive Integrated Moving Average (ARIMA) model, which extends basic autoregressive techniques by incorporating differencing methods to address non-stationary data [37]. By transforming non-stationary time series into stationary ones, ARIMA enhances forecast accuracy, facilitating precise demand predictions that minimize overproduction and associated greenhouse gas (GHG) emissions. This capability supports sustainable supply chain management by aligning production with actual demand, thereby reducing waste and contributing to the United Nations SDG 12 (Responsible Consumption and Production).

For applications involving periodic fluctuations, such as seasonal demand patterns in agri-food or textile supply chains, Seasonal ARIMA (SARIMA) models are particularly effective [38]. SARIMA extends ARIMA by integrating seasonal components, enabling the capture of recurring patterns over time. This makes SARIMA well-suited for forecasting long-term sales and inventory requirements, which are critical for optimizing logistics and reducing carbon-intensive activities like unnecessary transportation or storage. By enabling more accurate demand forecasting, SARIMA models contribute to environmental sustainability by minimizing energy use and Scope 3 emissions across supply chains, aligning with global climate frameworks such as the Paris Agreement. Together, ARIMA and SARIMA provide robust tools for strategic planning, enhancing the environmental sustainability and operational sustainability of supply chain networks.

2.2.2. Persistence Models

Persistence models are based on the assumption that forthcoming states will resemble current or recently observed conditions. Although conceptually straightforward, such models can deliver reliable short-term forecasts in relatively stable market environments [47]. Two main variations are generally distinguished. The first, known as simple persistence, assumes that the value in the subsequent period will be identical to that of the present period. The second, persistence with trend, extends this logic by incorporating recent directional changes and projecting them into the near future, thereby capturing short-term tendencies.

Despite their simplicity, persistence models retain practical value in contexts where abundant historical data and stable demand patterns exist, such as in demand forecasting applications [39]. They are computationally efficient and relatively easy to implement, making them attractive for short- to medium-term forecasting horizons. However, their predictive accuracy diminishes under conditions of heightened market volatility or when applied to long-term forecasting. To address these limitations, persistence models can be integrated with more sophisticated machine learning techniques, thereby enhancing their adaptability and predictive performance in dynamic environments [41].

2.3. Advanced Machine Learning Methods

Machine learning, a subset of artificial intelligence, concentrates on designing algorithms that autonomously learn patterns from data and generate predictions without explicit programming instructions. By capturing complex relationships within datasets, machine learning methods can significantly improve forecasting and decision-making in supply chains.

2.3.1. Supervised Learning for Classification and Regression

Supervised learning represents one of the most extensively applied paradigms in machine learning. These models are trained on datasets containing labeled input–output pairs, which enable algorithms to infer the functional relationships embedded in the data and to generalize this knowledge to novel observations. Within supply chain decarbonization, regression models and support vector machines (SVMs) are among the most prominent supervised approaches.

Regression models, whether linear or non-linear, are employed to capture the relationship between dependent variables, such as carbon emissions, and independent predictors, such as production volumes [48]. By quantifying the influence of operational factors on environmental sustainability outcomes, regression models provide a straightforward yet powerful means of linking supply chain practices with environmental performance indicators.

Support vector machines, in contrast, are highly versatile algorithms applicable to both classification and regression tasks. In the context of sustainable supply chain management, SVMs have been applied to classify suppliers according to their ESG risk profiles. This capacity enables firms to integrate sustainability criteria into supplier selection and risk management processes, thus fostering responsible sourcing practices. Moreover, SVMs are recognized for their ability to deliver fast, reliable, and accurate predictions, which makes them especially relevant for decision-making environments where both efficiency and sustainability are critical [43].

2.3.2. Deep Learning and Ensemble Methods

These advanced methodologies are distinguished by their flexibility, since they do not rely on predetermined model structures but instead learn directly from data. This adaptability enables them to capture highly complex, non-linear interactions, which are frequently encountered in supply chain systems. Their application has expanded considerably in recent years, particularly in areas such as demand forecasting, carbon footprint assessment, and the evaluation of supplier environmental sustainability performance.

Artificial neural networks (ANNs), including deep learning techniques, which are loosely inspired by the architecture of the human brain, represent one of the most established approaches in this category. By leveraging interconnected layers of computational neurons, ANNs are capable of approximating highly complex functions. Recent progress in deep learning techniques has substantially enhanced their accuracy and efficiency, making them especially effective for large-scale predictive modeling [44]. A further development within this family includes recurrent neural networks (RNNs) and long short-term memory (LSTM) architectures, which incorporate feedback loops to retain sequential information. This property makes them particularly effective for the analysis of time-dependent data such as demand fluctuations or evolving emission patterns [45].

In addition, decision-tree–based ensemble methods, such as Random Forests, LightGBM, and XGBoost, have emerged as particularly powerful tools for predictive analytics. These approaches construct multiple independent trees and aggregate their outputs to generate more robust and accurate predictions. Among them, XGBoost has achieved prominence owing to its computational efficiency, scalability, and capacity to process large, high-dimensional datasets, which makes it highly suitable for complex forecasting and classification tasks within sustainable supply chain contexts [40].

Collectively, the systematic classification of machine learning methods allows researchers and practitioners to select algorithms that best correspond to the problem at hand. While regression models may remain adequate in cases where relationships are stable and well defined, advanced approaches such as ANNs and ensemble methods are more appropriate when capturing dynamic, non-linear processes is required. Furthermore, hybrid approaches that integrate complementary algorithms demonstrate enhanced predictive precision and robustness, offering considerable promise for improving decarbonization forecasting and sustainability-oriented decision-making in supply chains [42].

2.4. Systemic and Hybrid AI Models

Hybrid AI models integrate multiple methodologies and technologies to enhance predictive accuracy and improve operational efficiency. A representative example is a system that combines real-time logistics optimization (an operational model) with demand forecasting based on LSTM networks (a strategic model) and real-time data from IoT sensors (a technology). By leveraging the complementary strengths of each technique, such systems enhance supply chain resilience and support decarbonization efforts.

One prominent application of hybrid models is the development of AI-powered control towers. These platforms integrate data across the entire supply chain and employ a combination of optimization algorithms and machine learning–based forecasting to provide end-to-end visibility and proactive decision support [46]. Similarly, digital twins have emerged as dynamic virtual representations of physical supply chains, continuously updated through real-time Internet of Things (IoT) data streams. These AI-enabled simulations offer a controlled environment in which to evaluate alternative decarbonization strategies without exposing the physical system to risk [49].

Recent scholarship underscores the role of advanced hybrid techniques in driving innovation for supply chain decarbonization. The composition of hybrid models is highly context-dependent, with design choices shaped by factors such as data accessibility, the temporal scope of decision-making, and the characteristics of the operational environment [50]. The central advantage of these approaches lies in their ability to leverage the complementary strengths of distinct AI techniques, yielding enhanced adaptability and improved predictive performance [51,52]. At the same time, Hybrid AI models present significant challenges, including the requirement for precise calibration, substantial computational resources, and enhanced interpretability of outputs. These challenges must be systematically addressed to ensure successful deployment in practical applications. Overcoming these obstacles is critical to fully leveraging the capabilities of hybrid AI systems, thereby enhancing operational efficiency and promoting sustainable, low-carbon supply chain management [53,54].

3. Results

This section presents the outcomes of a comparative case study of AI-driven interventions for supply chain decarbonization in Tunisia, focusing on (i) agri-food and textile supply chains and (ii) port logistics at Rades. Baseline conditions were established using historical operational data from the year prior to the intervention, which served as a reference for evaluating improvements after AI implementation.

The avoided emissions were estimated according to the following equation:

Equation (1) is adapted from standard GHG accounting methodologies, including the GHG Protocol Corporate Value Chain (Scope 3) Standard and the IPCC Guidelines for National Greenhouse Gas Inventories [55,56]. The formula aggregates reductions across multiple activities by multiplying activity levels with emission factors and reduction rates, thereby ensuring a comprehensive assessment of the impact of AI-enabled efficiency improvements.

Here, denotes the activity parameter (e.g., ton-km for freight, number of trips for trucks, or kWh for electricity), with data sourced from ERP systems and the Tunisian Port Authority database. represents the emission factor (e.g., kg CO2/L for diesel fuel or kg CO2/kWh for electricity), obtained from [56] and localized using Tunisian national energy statistics. denotes the reduction rate, expressed as the percentage change between baseline and post-AI implementation values (e.g., a 12% reduction in kilometers traveled). Finally, is the number of distinct activities or vehicle groups considered (e.g., light-duty trucks, heavy-duty trucks, and energy systems).

This parameterization enables verifiable estimates of avoided emissions, while uncertainty was addressed through sensitivity analysis. The findings highlight the contribution of AI to emission avoidance, detailing reductions, efficiency gains, and economic trade-offs. A sensitivity analysis was also performed, indicating that a 10% variation in the primary reduction rate estimates would alter total avoided emissions by approximately +/− 8–12%, confirming the robustness of the findings.

3.1. Agri-Food and Textile Supply Chains

3.1.1. Context

Tunisia’s agri-food (olive oil, seafood) and textile industries together account for approximately 14% of the national GDP and employ over 20% of the labor force [57]. In the absence of accelerated decarbonization, the implementation of the European Union’s Carbon Border Adjustment Mechanism could lead to export losses estimated at 5–10% [58]. Supply chain activities, most notably logistics, upstream sourcing of raw materials, and downstream distribution, are responsible for nearly 40% of sectoral greenhouse gas emissions. The majority of these emissions are classified as Scope 3, referring to indirect emissions generated across the value chain beyond direct operations and purchased energy [55].

3.1.2. Quantitative Outcomes

The quantitative evaluation of AI-based interventions demonstrates measurable reductions in carbon emissions across logistics, cold-chain operations, and supplier management.

In the logistics sector, VRP solvers powered by artificial intelligence, implemented using tabu search algorithms with a 50-iteration tabu list and genetic algorithms, were applied to optimize olive oil distribution in Sfax. The models were trained on six months of GPS data (January–June 2023) from a fleet of 40 commercial vehicles, benchmarked against a 2022 baseline of 120,000 km traveled annually with an average fuel consumption of 0.28 L/km. Training covered January–April, with validation in May–June. Seasonality effects were minimal variance), and the fleet composition was 70% light-duty and 30% medium-duty vehicles. Optimization reduced annual fleet distance by 12%, corresponding to 14,400 km avoided. With an average fuel consumption of 0.28 L/km and an emission factor of 2.68 kg CO2/L, this translates into approximately 4032 L of fuel saved and 10.8 tCO2 of avoided emissions annually:

Scaling across exporters (20–50 vehicle fleets) yielded 200–300 tCO2/year in avoided emissions [59,60].

In cold-chain operations, LSTM neural networks were trained on twelve months of IoT sensor and weather data to forecast energy demand for seafood cold storage facilities. The models enabled the synchronization of cooling requirements with solar energy availability, thereby reducing reliance on diesel generators by 15–20%. Approximately 60% of operations were shifted to renewable solar energy, resulting in an estimated reduction of 50–100 tCO2 per facility annually. Indirect CDR through avoided diesel consumption is expressed as:

where denotes the diesel consumption avoided, with [61,62].

Supplier management outcomes further illustrate the potential of AI for advancing sustainable practices. Natural language processing (NLP) techniques employing multilingual topic modeling (Arabic and English) were applied to analyze supplier disclosures and identify opportunities for low-carbon sourcing. This approach facilitated the adoption of organic cotton sourcing in the textile sector, contributing to reductions in Scope 3 emissions through the reconfiguration of supplier portfolios toward lower-carbon alternatives [63,64].

3.1.3. Efficiency Gains

The implementation of VRP optimization resulted in substantial operational and environmental benefits, achieving approximately 90 kg of CO2 savings per vehicle annually, based on a total reduction of 10,808 kg distributed across 120 vehicles. In parallel, LSTM-based demand forecasting and NLP-driven sourcing strategies contributed to decreased energy consumption and reduced material intensity, thereby indirectly lowering overall emissions. These findings highlight the potential of AI-driven techniques to enhance supply chain efficiency while simultaneously supporting decarbonization objectives.

3.1.4. Cost–Benefit Analysis

A cost–benefit assessment was conducted to evaluate the economic viability of the implemented AI solutions. The VRP optimization incurred a setup cost of approximately 152,500 TND and yielded annual savings ranging from 61,000 to 91,500 TND, corresponding to an estimated two-year payback period. Similarly, LSTM-based forecasting required an initial setup investment of approximately 91,500 TND, generating annual savings of 30,500–45,750 TND. NLP-driven sourcing solutions involved a setup cost of 61,000 TND and achieved annual savings ranging from 15,250 to 30,500 TND. Depreciation was assumed at 10% annually (15,250 TND for VRP), with retraining costs estimated at of the initial setup (7625 TND/year). A 5% discount rate was applied, and savings ranges were reported with a uncertainty margin. These results indicate that the adoption of AI-enabled supply chain optimization approaches can provide both economic and environmental sustainability returns within a relatively short timeframe.

Costs include software licensing, initial setup, and training. Savings are based on projected fuel and energy cost reductions, with annual depreciation, retraining costs, and a 5% discount rate. Savings ranges have a 90% confidence interval and exclude hardware depreciation beyond initial setup.

As shown in Table 3, these results demonstrate that AI interventions contribute to indirect emission avoidance by reducing emissions. However, scaling these solutions is constrained by data limitations, with VRP accuracy declining by 5–10% in rural regions. This reduced accuracy lowered avoided emissions by approximately (10–15 tCO2/year), with a worst-case scenario of accuracy loss reducing savings by 60 tCO2/year, based on rural route simulations. This degradation in accuracy is estimated to reduce potential emission savings by up to 5% in the most affected routes, a factor considered in our overall conservative estimates [56,65,66].

Table 3.

AI applications in Tunisian agri-food and textile supply chains.

3.2. Port Logistics at Rades

3.2.1. Context

The Port of Rades, handling approximately 75% of Tunisia’s container throughput (~8 Mt/year), contributes between 0.35 and 0.7 MtCO2 annually, equivalent to 1–2% of national emissions [67,68]. To align with EU sustainability frameworks, several AI pilot projects were implemented to improve operational efficiency and reduce emissions.

3.2.2. Quantitative Outcomes

The impacts of the different AI interventions were disentangled to assess their individual contributions. Baseline throughput was 7.5 Mt/year with a 20% queue rate, calibrated against 2023 fuel logs (2 L/h diesel consumption per truck). Smart berth scheduling, based on reinforcement learning (RL, Q-learning, 100,000 iterations using two years of vessel and weather data), reduced auxiliary fuel consumption by 15–25%, avoiding approximately 400 tCO2 per year [69,70,71]. Automated gate operations, employing computer vision with optical character recognition (OCR) on six months of gate imagery, decreased truck idling by 0.5 h per visit. This reduction is directly attributable to the OCR-driven smart gate system [72]. For 250,000 annual truck visits, with diesel consumption of 2 L/h and an emission factor of 2.68 kg CO2/L, this corresponds to ~670 tCO2 avoided per year, calculated as:

RL accounted for 40% (160 tCO2) and OCR for 60% (400 tCO2), with a 5% overlap attributed to systemic optimization through digital twin effects. The integration of IoT and container flow data into a port digital twin further reduced resource consumption and emissions by 10–15%, equivalent to approximately 800–1000 tCO2 annually [73,74,75]. The largest share of this saving is attributed to the systemic optimization enabled by the digital twin, which integrates the gains from the other systems.

3.2.3. Efficiency Gains

The smart gate system achieved 2.68 kg CO2 savings per truck visit. Combined with RL-based berth scheduling and digital twin implementations, these interventions produced systemic improvements, alleviating congestion, reducing local air pollution, and enhancing overall port operational efficiency.

3.2.4. Cost–Benefit Analysis

The setup of RL and OCR systems required an investment of approximately 305,000 TND, yielding annual throughput gains of 20% and estimated savings between 152,500 and 244,000 TND. The digital twin implementation involved a setup cost of around 610,000 TND, with annual savings of approximately 305,000 TND. A staged rollout plan includes monthly increments: Months 1–3 for RL (76,250 TND), Months 4–6 for OCR (152,500 TND), and Months 7–12 for the digital twin (305,000 TND). National cost curves estimate 1.5 million TND total, with marginal abatement costs of 500 TND/tCO2. Depreciation is 10% (61,000 TND/year), retraining is 5% (30,500 TND/year), and a 5% discount rate applies, with savings ranging at 90% confidence. These results underscore the economic and environmental viability of AI-driven solutions in port operations.

As indicated in Table 4, the interventions at the Port of Rades achieved emission reductions equivalent to removing approximately 150 trucks from circulation annually [76]. Implementation challenges remain, including IoT accuracy gaps of 10–15% [77,78] and the need for effective inter-agency coordination. Nevertheless, evidence from Durban, where reinforcement learning–based scheduling achieved 10% emission reductions [79,80], highlights the potential scalability of such AI-enabled measures across Africa, particularly when supported by Nationally Determined Contributions (NDC)–aligned incentives [81].

Table 4.

Estimated CO2 avoidance at the Port of Rades via AI-enabled smart gate system.

3.3. Comparative Analysis and Scalability

3.3.1. Quantitative Comparison

The agri-food and textile case studies yielded annual carbon reductions ranging from 10.8 to 300 tCO2 per firm, whereas the Port of Rades achieved substantially higher reductions, estimated between 670 and 1000 tCO2 annually (as shown in Table 5). Firm-level interventions, such as VRP and LSTM, generated incremental gains by enhancing route optimization and demand forecasting. However, their overall impact remained limited in scope. In contrast, system-level interventions, including reinforcement learning and digital twin applications, demonstrated markedly greater reductions, reflecting their ability to optimize entire networks rather than isolated processes.

Table 5.

Comparative results of Tunisian AI case studies.

Performance evaluation was conducted using three KPIs: avoided emissions (tCO2/year), cost-effectiveness (TND/tCO2), and payback period (years). Interventions were considered effective when they achieved more than 10% avoided emissions, maintained costs below 1000 TND per tCO2, and demonstrated a payback period of less than three years. Within this framework, the agri-food VRP satisfied these thresholds, delivering 200–300 tCO2 savings annually, cost-effectiveness of 500–750 TND per tCO2, and a two-year payback. Similarly, the digital twin deployed at Rades exceeded these criteria, achieving 800–1000 tCO2 savings annually, with cost-effectiveness ranging from 600 to 800 TND per tCO2 and an equivalent two-year payback.

These findings confirm that while firm-level AI models can offer cost-effective and accessible entry points for decarbonization, system-level applications yield more robust and scalable results, positioning them as critical enablers of long-term carbon reduction strategies.

3.3.2. Efficiency Gains

On a normalized basis, AI interventions in the agri-food and textile sectors achieved approximately 90 kg CO2 savings per vehicle annually, whereas port-level operations realized 2.68 kg CO2 savings per truck visit. A more detailed comparison using normalized Key Performance Indicators (KPIs) is presented in Table 6. While the firm-level interventions show high savings per unit (vehicle), the system-level intervention at the port achieves a far greater total impact due to the massive volume of units (truck visits) processed.

Table 6.

Normalized KPI Comparison of AI Interventions.

3.3.3. Scalability Potential

The scalability of AI-enabled interventions varies by sector. In the agri-food and textile industries, replication across roughly 2500 exporters could potentially avoid between 27,000 and 750,000 tCO2 per year through modular AI adoption. In the logistics sector, extending AI solutions to secondary ports, including Sfax, Bizerte, and Gabès, could achieve annual emissions reductions exceeding 2000 tCO2, positioning AI as a key instrument for national logistics decarbonization strategies.

3.3.4. Indirect Contributions

Both case studies also indirectly contributed to environmental and economic goals by reducing energy consumption in warehouses and mitigating urban air pollution, thereby decreasing reliance on fossil fuels. These findings demonstrate that artificial intelligence can simultaneously enhance operational efficiency and promote environmental sustainability within supply chains. This dual function highlights AI’s potential to support decarbonization efforts beyond direct emissions reductions by influencing complementary environmental sustainability factors.

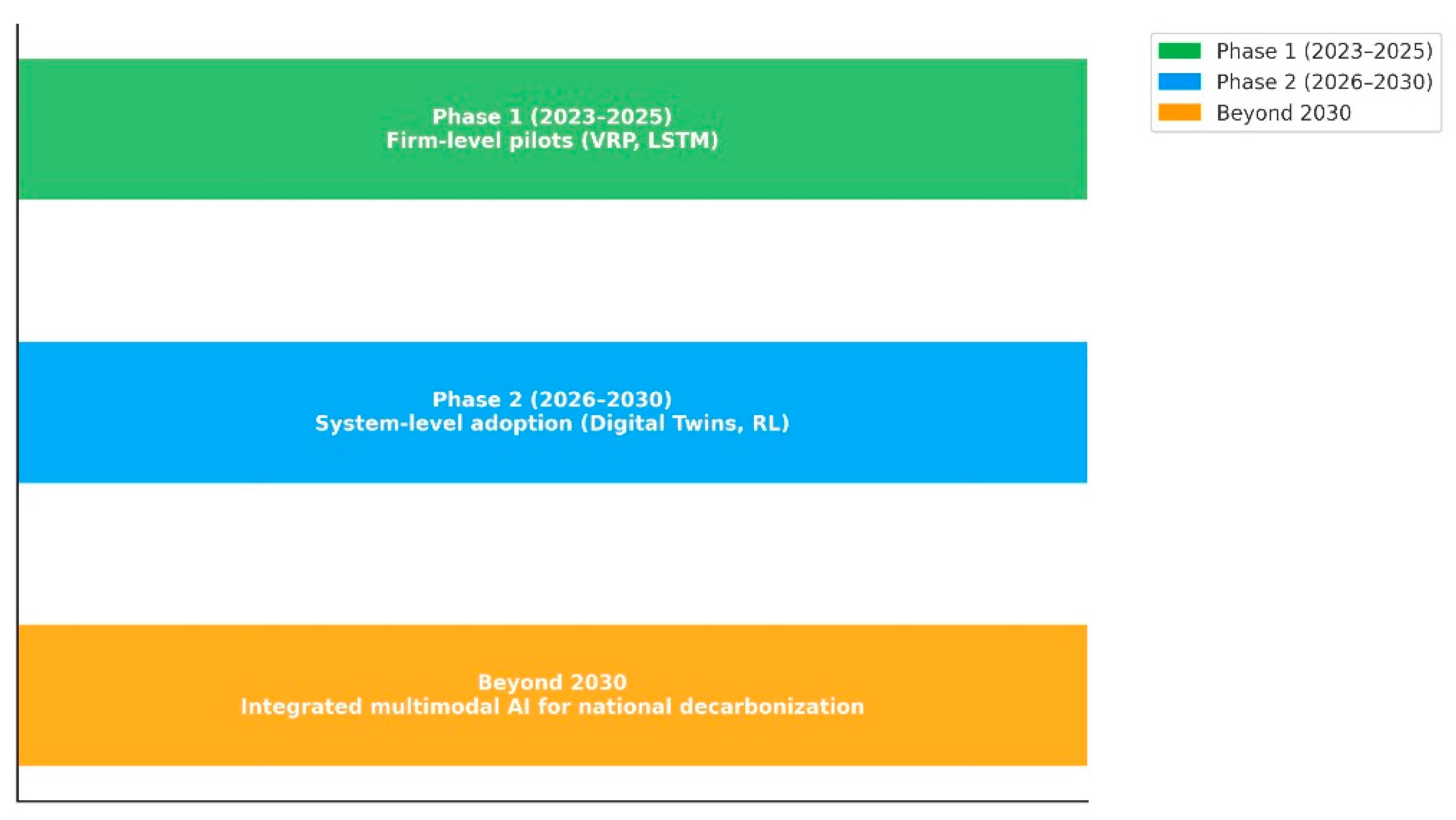

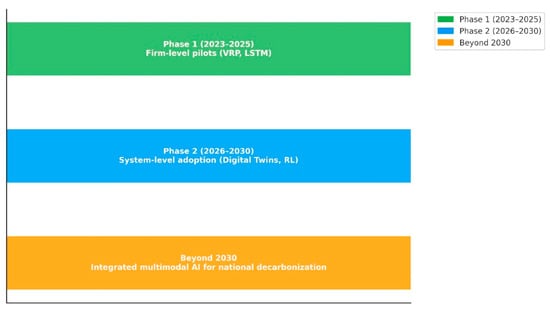

Overall, the interventions collectively avoided between 500 and 1500 tCO2 per year, illustrating their feasibility in resource-constrained contexts. As depicted in Figure 2, a phased roadmap is proposed: Phase 1 (2023–2025) focuses on VRP and LSTM deployment, while Phase 2 (2026–2030) emphasizes digital twin adoption, supported by EU partnerships. To ensure effective implementation, governance measures include adherence to AI explainability standards (e.g., SHAP values for model transparency), the establishment of training programs for 500 local engineers, systematic risk monitoring through quarterly audits of adoption barriers (e.g., data gaps, cost overruns), and stakeholder alignment with NDCs. Evidence from Kenya, where port emissions were reduced by 8–12% through similar AI-enabled interventions [80,81], further confirms the potential scalability of these measures across Africa, provided that data standardization and capacity-building initiatives are prioritized.

Figure 2.

Roadmap of AI integration for Tunisian supply chain decarbonization, aligned with NDC targets and EU Green Deal funding.

4. Discussion

The findings of this study highlight the potential of AI as a transformative enabler of sustainable supply chain decarbonization. Across the Tunisian agri-food, textile, and logistics sectors, AI interventions demonstrated measurable reductions in carbon emissions, ranging from 500 to 1500 tCO2 annually. While these reductions may appear modest in absolute terms, they are significant within the regional context and illustrate the broader principle that digital intelligence can deliver systemic environmental benefits even in resource-constrained environments.

A key contribution of this research lies in demonstrating the comparative advantages of hybrid AI models. While a direct, perfectly controlled comparison is challenging due to the differing operational contexts, the superior performance of hybrid models in this study can be inferred from the magnitude and scope of their impact. By integrating short-term operational optimization with long-term strategic forecasting, these models produced more robust and scalable decarbonization outcomes. As shown in Table 5 and Table 6, while operational models such as VRP and OCR delivered valuable, targeted savings, the hybrid digital twin at the Port of Rades achieved the largest overall emission reduction by optimizing an entire ecosystem. This result resonates with recent evidence from European logistics networks, where hybrid digital twins not only secured immediate fuel savings but also enhanced long-term emission forecasting capacities.

The results further confirm that AI supports decarbonization not only through efficiency gains but also by facilitating alignment with international sustainability frameworks. For instance, the optimization of cold chains using LSTM models directly reduced energy dependency, advancing targets consistent with SDG 12. Similarly, AI-enabled digital twins in port operations strengthened resilience and adaptability, reflecting systemic sustainability principles central to the EU Green Deal. These findings underscore that AI contributes to climate goals not merely by reducing emissions at the operational level but also by embedding sustainability into the design, governance, and long-term orientation of supply chains.

Despite the demonstrated benefits of AI-driven interventions, several barriers hinder scalability. Limited data quality and accessibility, high computational costs, and organizational resistance emerged as recurrent challenges. These findings empirically validate the barriers summarized in Table 1. For example, the observed 5–10% decline in VRP accuracy in rural areas illustrates the challenge of integrating real-time data when geospatial information systems (GIS) are incomplete. Likewise, the initial setup costs reported in Table 3 highlight the barrier of high upfront investments, which remain prohibitive for many small and medium-sized enterprises (SMEs). These observations are consistent with recent studies conducted in Asia and North America, which emphasize that without standardized data infrastructures and sufficient digital capabilities, the full sustainability potential of AI cannot be realized. Nonetheless, as shown in Table 7, the operational models developed in this study delivered measurable efficiencies that offset part of these challenges, demonstrating the practicality of AI adoption in resource-constrained contexts.

While this study focuses on Tunisia, its findings have broader relevance for other emerging economies facing similar structural conditions. Challenges such as limited data infrastructure, reliance on legacy systems, and the need for cost-effective solutions are common across countries in the Middle East, Africa, and Southeast Asia. The success of modular, high-impact AI applications, such as VRP optimization, digital twins, and smart gate systems, suggests a viable pathway for decarbonization in these regions.

Evidence from Morocco and Egypt highlights how such applications could mitigate Scope 3 emissions in agri-food supply chains under growing export pressures from the EU’s Carbon Border Adjustment Mechanism. In Sub-Saharan Africa, Kenya and South Africa show potential for RL-based port optimizations to reduce national emissions by 1–2%, supporting Paris Agreement NDCs. In Southeast Asia, integration with existing IoT infrastructures in Vietnam’s textile sector could reduce energy consumption by 10–15%. Pilot projects in Indonesia and Brazil further illustrate the scalability of hybrid AI models, which achieve annual reductions of 100,000–500,000 tCO2 in port operations.

Scaling these solutions requires targeted policy support. Subsidies for AI training, open data-sharing platforms, and incentives for cross-sector collaboration remain critical enablers. Pilot projects in Indonesia and Brazil further illustrate the scalability of hybrid AI models, which have demonstrated the potential to reduce CO2 emissions by between 100,000 and 500,000 t annually in port operations. These implications position AI as a global tool for decarbonization, with the Tunisian case providing a replicable blueprint for resource-limited economies seeking to align sustainable development with enhanced competitiveness.

Finally, this study identifies avenues for future research. Comparative cross-regional analyses could clarify how contextual factors influence AI adoption outcomes. Future work should additionally explore the integration of AI with other Industry 4.0 and Industry 5.0 technologies, such as blockchain for transparent carbon tracking and collaborative robots for energy-efficient warehousing. Key research questions include: (1) How can integrated digital ecosystems amplify decarbonization efforts beyond what individual AI models can achieve? and (2) What governance models are needed to manage the ethical and social implications of these interconnected systems?

Table 7.

Barriers to AI Implementation in Supply Chain Decarbonization and Mitigation Strategies.

Table 7.

Barriers to AI Implementation in Supply Chain Decarbonization and Mitigation Strategies.

| Barrier | Impact on Decarbonization | Proposed Solutions or Best Practices |

|---|---|---|

| Data Quality and Accessibility [1,3,6] | Inaccurate, incomplete, or incompatible data lead to flawed AI models and ineffective decarbonization strategies. Poor interoperability between disparate data sources hinders decision-making. | Invest in robust data governance; deploy advanced data cleaning and validation techniques; implement data integration platforms with standardized formats. |

| High Computational Cost and Carbon Footprint of AI [4,8,12] | The high energy consumption of training and running complex AI models can offset the carbon savings achieved through supply chain optimization. | Adopt lightweight AI methods (TinyML, model pruning, knowledge distillation); use energy-efficient hardware; schedule intensive computations during periods of renewable energy availability. |

| Lack of AI Talent and Skills [2,7,15] | A shortage of professionals skilled in both AI and supply chain management delays or prevents successful model deployment. | Launch upskilling and reskilling programs; partner with universities for talent pipelines; leverage low-code/no-code AI solutions to reduce skill barriers. |

| Organizational Resistance and Lack of Trust [5,13,14] | Fear of job loss, limited understanding, and the “black box” nature of AI reduce stakeholder buy-in, slowing adoption. | Implement Explainable AI (XAI) frameworks; involve stakeholders in co-design and validation processes; start with small-scale pilots to demonstrate value. |

| System Integration and Legacy Systems [2,11,15] | Integrating AI with outdated IT infrastructure is complex, time-consuming, and costly, delaying operationalization. | Use a modular, API-first integration strategy; plan phased migration from legacy systems; adopt middleware to bridge compatibility gaps. |

| Economic Constraints and High Initial Costs [6,12,14] | Significant capital is needed for technology acquisition, training, and integration, creating barriers for SMEs and resource-limited organizations. | Conduct cost–benefit analyses; seek joint ventures, public–private partnerships, or innovation grants; implement AI in incremental phases to spread costs. |

| Change Management Challenges [5,13,15] | Without structured change management, resistance to process transformation can undermine AI implementation. | Develop formal change management frameworks; communicate benefits clearly; assign AI adoption champions within the organization. |

| Ethical and Social Implications [1,5,7] | Potential bias in AI algorithms, privacy concerns, and workforce displacement risks can damage organizational reputation and hinder adoption. | Establish ethical AI guidelines; perform algorithmic bias audits; implement transparent data usage policies; create workforce transition plans. |

5. Conclusions

This study provides evidence that AI constitutes a pivotal enabler of sustainable supply chain decarbonization, primarily through its capacity to facilitate proactive emission avoidance and thereby contribute indirectly to climate mitigation. Drawing on empirical analyses in Tunisia’s agri-food, textile, and logistics sectors, the results demonstrate that AI-enabled interventions can achieve annual avoided emissions ranging between 500 and 1500 tCO2, validated by datasets of 6–12 months, baselines from pre-intervention years, and sensitivity analyses with ±8–12% error margins. While operational models delivered significant efficiencies, the evidence from our case studies indicates that hybrid approaches, integrating operational optimization with strategic forecasting, hold the potential to generate superior decarbonization outcomes. Key Performance Indicators (KPIs) such as avoided emissions (e.g., 800–1000 tCO2 at Rades), cost-effectiveness (<1000 TND/tCO2), and payback period (<3 years) were used, with evaluation rules requiring >10% in avoided emissions; hybrid models met these thresholds (e.g., digital twin at 800–1000 tCO2, 600–800 TND/tCO2, 2 years), outperforming operational models. Nevertheless, given that the case studies employed heterogeneous calculation methods, this observation should be regarded as indicative rather than conclusive. Accordingly, the findings point to the importance of developing standardized evaluation frameworks that enable robust cross-sector comparability and more reliable generalization, including consistent datasets, cleaning processes, and validation measures.

Beyond efficiency gains, the findings highlight that AI strengthens the alignment of supply chain practices with global sustainability frameworks, including the Paris Agreement, the European Green Deal, and the United Nations Sustainable Development Goals. Such alignment situates AI not as an isolated technological instrument but as an integral component of systemic environmental sustainability transitions. Nevertheless, structural barriers, including data quality deficiencies, computational intensity, and organizational resistance, remain critical impediments to widespread adoption. These were quantified in Table 1 with specific failure rates (e.g., 3% real-time integration failures), and mitigation strategies like data governance and phased rollouts were proposed in Table 7. Addressing these challenges requires targeted policy support, investment in digital infrastructure, and interdisciplinary collaboration to enhance trust and scalability.

In conclusion, this research affirms that AI should be conceptualized as both a technological enabler and a systemic driver of decarbonization. By embedding sustainability principles into decision-making processes, enhancing resource efficiency, and fostering resilience in complex supply networks, AI complements conventional CDR technologies and broadens the spectrum of available climate mitigation strategies. To substantiate this, a roadmap in Section 3.3.4 includes governance rules (e.g., SHAP-based explainability), training for 500 engineers, and risk tracking via quarterly audits, aligning with NDC targets. Future scholarship should therefore prioritize comparative cross-sectoral studies with harmonized methodologies, in conjunction with the development of lightweight, context-adaptable AI models and standardized data frameworks, to better substantiate the contribution of AI to global sustainability imperatives.

Author Contributions

Conceptualization, M.A.F.; methodology, M.M.; software, M.A.F.; validation, M.A.F. and M.M.; formal analysis, M.M.; investigation, M.A.F.; resources, M.A.F.; data curation, M.M.; writing original draft preparation, M.A.F.; writing review and editing, M.M.; visualization, M.A.F.; supervision, M.A.F.; project administration, M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Deanship of Scientific Research, Vice Presi-dency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia [Grant No. 253673].

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| Abbreviation | Definition |

| AI | Artificial Intelligence |

| ARIMA | Autoregressive Integrated Moving Average |

| CBAM | Carbon Border Adjustment Mechanism |

| CDR | Carbon Dioxide Removal |

| CNN | Convolutional Neural Network |

| ERP | Enterprise Resource Planning |

| ESG | Environmental, Social, and Governance |

| GHG | Greenhouse Gas |

| IoT | Internet of Things |

| LSTM | Long Short-Term Memory |

| MENA | Middle East and North Africa |

| NDC | Nationally Determined Contribution |

| NLP | Natural Language Processing |

| OCR | Optical Character Recognition |

| RL | Reinforcement Learning |

| SHAP | SHapley Additive exPlanations |

| SARIMA | Seasonal Autoregressive Integrated Moving Average |

| SVM | Support Vector Machine |

| VRP | Vehicle Routing Problem |

| XAI | Explainable Artificial Intelligence |

References

- Ahmad, T.; Zhang, D.; Huang, C.; Zhang, H.; Dai, N.; Song, Y.; Chen, H. Artificial Intelligence in Sustainable Energy Industry: Status Quo, Challenges and Opportunities. J. Clean. Prod. 2021, 289, 125834. [Google Scholar] [CrossRef]

- Ding, T.; Li, J.; Shi, X.; Zhang, H.; Chen, Y. Is artificial intelligence associated with carbon emissions reduction? Case of China. Resour. Policy 2023, 85, 103892. [Google Scholar] [CrossRef]

- Amado Mateus, M. The duality of artificial intelligence in supply chain sustainability: A narrative review. Eur. Public Soc. Innov. Rev. 2024, 9, 1–16. [Google Scholar] [CrossRef]

- Chen, Y.; Jin, S. Artificial Intelligence and Carbon Emissions in Manufacturing Firms: The Moderating Role of Green Innovation. Processes 2023, 11, 599. [Google Scholar] [CrossRef]

- Riad, M.; Naimi, M.; Okar, C. Enhancing Supply Chain Resilience Through Artificial Intelligence: Developing a Comprehensive Conceptual Framework for AI Implementation and Supply Chain Optimization. Logistics 2024, 8, 111. [Google Scholar] [CrossRef]

- Shlash Mohammad, A.A.; Al-Ramadan, A.M.; Ibrahim Mohammad, S.; Al Oraini, B.; Vasudevan, A.; Turki Alshurideh, M.; Chen, Q.; Ali, I. Enhancing Metadata Management and Data-Driven Decision-Making in Sustainable Food Supply Chains Using Blockchain and AI Technologies. Data Metadata 2025, 3, 683. [Google Scholar] [CrossRef]

- Ren, B.; Qiu, Z.; Liu, B. Supply Chain Decarbonisation Effects of Artificial Intelligence: Evidence from China. Int. Rev. Econ. Financ. 2025, 101, 104198. [Google Scholar] [CrossRef]

- Al-Sakkari, E.G.; Ragab, A.; Dagdougui, H.; Boffito, D.C.; Amazouz, M. Carbon Capture, Utilization and Sequestration Systems Design and Operation Optimization: Assessment and Perspectives of Artificial Intelligence Opportunities. Sci. Total Environ. 2024, 917, 170085. [Google Scholar] [CrossRef]

- Hart, S.L. A Natural-Resource-Based View of the Firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar] [CrossRef]

- Tornatzky, L.G.; Fleischer, M. The Processes of Technological Innovation; Lexington Books: Lexington, MA, USA, 1990. [Google Scholar]

- Benzidia, S.; Makaoui, N.; Bentahar, O. The Impact of Big Data Analytics and Artificial Intelligence on Green Supply Chain Process Integration and Hospital Environmental Performance. Technol. Forecast. Soc. Change 2021, 165, 120557. [Google Scholar] [CrossRef]

- Hussain, J.; Lee, C.-C.; Lev, B. Optimizing AI-Based Emission Reduction Efficiency and Subsidies in Supply Chain Management: A Sensitivity-Based Approach with Duopoly Game Dynamics. J. Clean. Prod. 2025, 494, 144991. [Google Scholar] [CrossRef]

- Cao, Q.; Chi, C.; Shan, J. Can Artificial Intelligence Technology Reduce Carbon Emissions? A Global Perspective. Energy Econ. 2025, 143, 108285. [Google Scholar] [CrossRef]

- Yurtay, Y. Carbon Footprint Management with Industry 4.0 Technologies and ERP Systems in Sustainable Manufacturing. Appl. Sci. 2025, 15, 480. [Google Scholar] [CrossRef]

- Mao, H. The Optimization Strategy and Application Practice of Business Management Supply Chain Based on Artificial Intelligence Technology. Procedia Comput. Sci. 2025, 261, 707–715. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Song, C.; Wang, J.; Liu, R. Impact of Artificial Intelligence on Renewable Energy Supply Chain Vulnerability: Evidence from 61 Countries. Energy Econ. 2024, 131, 107357. [Google Scholar] [CrossRef]

- Chen, C.-T.; Khan, A.; Chen, S.-C. Modeling the Impact of BDA-AI on Sustainable Innovation Ambidexterity and Environmental Performance. J. Big Data 2024, 11, 124. [Google Scholar] [CrossRef]

- Cavalcante, I.M.; Frazzon, E.M.; Forcellini, F.A.; Ivanov, D. A Supervised Machine Learning Approach to Data-Driven Simulation of Resilient Supplier Selection in Digital Manufacturing. Int. J. Inf. Manag. 2019, 49, 86–97. [Google Scholar] [CrossRef]

- Patro, P.K.; Acquaye, A.; Jayaraman, R.; Salah, K. A framework for carbon accounting for sustainable supply chains using Blockchain, Internet of Things, and Artificial Intelligence. In Proceedings of the IISE Annual Conference and Expo, Montreal, QC, Canada, 18–21 May 2024. [Google Scholar]

- Hasan, M.Z.; Hussain, M.Z.; Umair, S.; Waqas, U. Understanding Artificial Intelligence in Supply Chain and Innovation Performance. In Human Perspectives of Industry 4.0 Organizations: Reviewing Sustainable Performance; CRC Press: Boca Raton, FL, USA, 2024. [Google Scholar]

- Luo, Q.; Wang, J. The Impact of Artificial Intelligence Development on Embodied Carbon Emissions: Perspectives from the Production and Consumption Sides. Energy Policy 2025, 199, 114535. [Google Scholar] [CrossRef]

- Han, F.; Qin, Q.; Zhou, S. Suppliers’ AI Adoption and Customers’ Carbon Emissions: Firm-Level Evidence from China. Appl. Econ. 2025, 57, 3281–3295. [Google Scholar] [CrossRef]

- Mrad, M.; Frikha, M.A.; Boujelbene, Y. A Comprehensive Survey of Artificial Intelligence and Robotics for Reducing Carbon Emissions in Supply Chain Management. Logistics 2025, 9, 104. [Google Scholar] [CrossRef]

- Younesse, O.; Soumia, Z. NW Logistics: System Architecture and Design for Sustainable Road Logistics. Int. J. Adv. Comput. Sci. Appl. 2025, 16, 4105. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, F.; Mo, C. Optimisation Methods for Cold Chain Logistics Path Considering Carbon Emission Costs in Time-Varying Networks. Promet-Traffic Transp. 2024, 36, 1103–1119. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, H.W.; Wang, X.Q.; Yin, W.J.; Zhao, T.Z.; Dong, J. Mode Choice for Intermodal Transportation Considering Carbon Emissions. In Proceedings of the 2011 IEEE International Conference on Service Operations, Logistics and Informatics (SOLI), Beijing, China, 10–12 July 2011; IEEE: Piscataway, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Palakurti, N.R. Leveraging AI-Driven Predictive Analytics for Demand Forecasting, Route Optimization, and Minimizing Food Waste in the Supply Chain. In Cutting-Edge Solutions for Advancing Sustainable Development: Exploring Technological Horizons for Sustainability—Part 2; Springer: Singapore, 2025; pp. 157–172. [Google Scholar] [CrossRef]

- Fathima, F.; Inparaj, R.; Thuvarakan, D.; Fernando, I. Impact of AI-Based Predictive Analytics on Demand Forecasting in ERP Systems: A Systematic Literature Review. In Proceedings of the International Research Conference on Smart Computing and Systems Engineering (SCSE 2024), Moratuwa, Sri Lanka, 4 April 2024; pp. 45–52. [Google Scholar]

- Velrani, K.S.; Shanthi, T.S.; Senthil, T.S.; Kavitha, T.; Deepa, P.; Muthuvel, S. A Study on IoT and AI-Integrated Advanced Lightweight Materials for Eco-Friendly Production. In Innovations in Energy Efficient Construction Through Sustainable Materials; González-Lezcano, R.A., Ed.; IGI Global: Hershey, PA, USA, 2025; Chapter 1; pp. 1–32. [Google Scholar] [CrossRef]

- Chitra, P.; Raja, R.P.B.V.; Ananthi, A.; Saritha, G.; Balasuadhakar, A.; Boopathi, S. Integrating Machine Learning and Computational Intelligence for Green Manufacturing Processes. In Using Computational Intelligence for Sustainable Manufacturing of Advanced Materials; IGI Global: Hershey, PA, USA, 2025; Chapter 9; pp. 1–28. [Google Scholar] [CrossRef]

- Mrad, M.; Boujelbene, Y. Leveraging AI and Robotics for Low-Carbon Supply Chain Optimization: A Bibliometric Analysis. In Proceedings of the 2025 16th International Conference on Logistics and Supply Chain Management (LOGISTIQUA), Casablanca, Morocco, 28–30 May 2025. [Google Scholar] [CrossRef]

- Singh, B. Revolutionizing Supply Chains for Optimized Demand Planning, Inventory Management, and Logistics: An In-Depth Analysis of AI and ML Solutions in the Modern Era. In Supply Chain Transformation Through Generative AI and Machine Learning; IGI Global: Hershey, PA, USA, 2025; pp. 1–26. [Google Scholar] [CrossRef]

- Raut, S.; Hossain, N.U.I.; Kouhizadeh, M.; Fazio, S.A. Application of Artificial Intelligence in Circular Economy: A Critical Analysis of the Current Research. Sustain. Futures 2025, 9, 100784. [Google Scholar] [CrossRef]

- Aguilar Ortiz, J.; Simancas-Acevedo, E.; Domínguez-Mayorga, C.R. Artificial Intelligence to Achieve Sustainable Development Goal 12 Responsible Consumption and Production. In Machine and Deep Learning Solutions for Achieving the Sustainable Development Goals; IGI Global: Hershey, PA, USA, 2025; pp. 1–24. [Google Scholar] [CrossRef]

- Huang, R.; Mao, S. Carbon Footprint Management in Global Supply Chains: A Data-Driven Approach Utilizing Artificial Intelligence Algorithms. IEEE Access 2024, 12, 89957–89967. [Google Scholar] [CrossRef]

- Ghosh, S.; Sarkar, S.K.; Roy, P. Application of Automation and Artificial Intelligence (AI) in Green Transportation System. In Driving Green Transportation System Through Artificial Intelligence and Automation; Khang, A., Ed.; Lecture Notes in Intelligent Transportation and Infrastructure; Springer: Cham, Switzerland, 2025; Chapter 2; pp. 21–42. [Google Scholar] [CrossRef]

- Farghali, M.; Osman, A.I. Revolutionizing Waste Management: Unleashing the Power of Artificial Intelligence and Machine Learning. In Advances in Energy from Waste: Transformation Methods, Applications and Limitations under Sustainability; Woodhead Advances in Pollution Research; Woodhead Publishing: Cambridge, UK, 2024; pp. 225–279. [Google Scholar] [CrossRef]

- Olawade, D.B.; Fapohunda, O.; Wada, O.Z.; Usman, S.O.; Ige, A.O.; Ajisafe, O.; Oladapo, B.I. Smart Waste Management: A Paradigm Shift Enabled by Artificial Intelligence. Waste Manag. Bull. 2024, 2, 244–263. [Google Scholar] [CrossRef]

- Miller, T.; Durlik, I.; Kostecka, E.; Łobodzińska, A.; Matuszak, M. The Emerging Role of Artificial Intelligence in Enhancing Energy Efficiency and Reducing GHG Emissions in Transport Systems. Energies 2024, 17, 6271. [Google Scholar] [CrossRef]

- Carpenter, R. Industrial automation unites the best of OT and IT: As operational and information technology roles progressively overlap in the industrial automation space, a hybrid operational technology/information technology (OT/IT) solution becomes increasingly necessary. Consult. Specif. Eng. 2021, 58, 45–48. [Google Scholar]

- Sultan, M. Strategic Planning for Business Leaders Using AI. In Reshaping Organizational Management and Workplace Culture With AI; IGI Global: Hershey, PA, USA, 2025; pp. 193–222. [Google Scholar]

- Merilehto, J.; Poudel, D. AI and Strategy: The Three Perspectives Framework. In Marketing Intelligence, Part B; Emerald Publishing Limited: Bingley, UK, 2025; pp. 293–317. [Google Scholar]

- Sakshi, T.M.; Tyagi, P.; Jain, V. Emerging trends in hybrid information systems modeling in artificial intelligence. In Hybrid Information Systems: Non-Linear Optimization Strategies with Artificial Intelligence; Springer: Cham, Switzerland, 2024; p. 115. [Google Scholar]

- Schlup, B.; Corradini, A. A flexible multi-agent systems task environment for simulating hybrid intelligence. In Proceedings of the 2024 IEEE 12th International Conference on Intelligent Systems (IS), Varna, Bulgaria, 29–31 August 2024; pp. 1–7. [Google Scholar]

- Zheng, N.N.; Liu, Z.Y.; Ren, P.J.; Ma, Y.Q.; Chen, S.T.; Yu, S.Y.; Xue, J.R.; Chen, B.D.; Wang, F.Y. Hybrid-augmented intelligence: Collaboration and cognition. Front. Inf. Technol. Electron. Eng. 2017, 18, 153–179. [Google Scholar] [CrossRef]

- Balomenos, K. Strategic Communication as a Mean for Countering Hybrid Threats. In Handbook for Management of Threats: Security and Defense, Resilience and Optimal Strategies; Springer: Cham, Switzerland, 2023; pp. 371–390. [Google Scholar]

- Suganya, R.; Joseph, L.M.I.L.; Kollem, S. Integrating Artificial Intelligence in Electric Vehicles and Optimizing Logistics for Sustainable Transportation. In Advances in Sustainable Transportation and Logistics; IGI Global: Hershey, PA, USA, 2025; p. 418. [Google Scholar] [CrossRef]

- Piazzoli, A. AI and Strategy: How New Tools Can Boost the Evolution of Strategic Decision-Making. In Socio-Economic Impact of Artificial Intelligence: A European Management Perspective; Springer: Cham, Switzerland, 2025; pp. 247–260. [Google Scholar]

- Ben Rjab, A.; Mellouli, S.; Corbett, J. Barriers to Artificial Intelligence Adoption in Smart Cities: A Systematic Literature Review and Research Agenda. Gov. Inf. Q. 2023, 40, 101814. [Google Scholar] [CrossRef]

- Raj, A.; Dwivedi, G.; Sharma, A.; Jabbour, A.B.L.d.S.; Rajak, S. Barriers to the Adoption of Industry 4.0 Technologies in the Manufacturing Sector: An Inter-Country Comparative Perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and Lean Manufacturing Practices for Sustainable Organisational Performance in Indian Manufacturing Companies. Int. J. Prod. Res. 2020, 58, 1319–1337. [Google Scholar] [CrossRef]

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial Intelligence in Supply Chain Management: A Systematic Literature Review. J. Bus. Res. 2021, 122, 502–517. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big Data Analytics as an Operational Excellence Approach to Enhance Sustainable Supply Chain Performance. Resour. Conserv. Recycl. 2020, 153, 104559. [Google Scholar] [CrossRef]

- Ghasemi Abyaneh, A.; Ghanbari, H.; Mohammadi, E.; Amirsahami, A.; Khakbazan, M. An Analytical Review of Artificial Intelligence Applications in Sustainable Supply Chains. Supply Chain Anal. 2025, 12, 100173. [Google Scholar] [CrossRef]

- GHG Protocol. Technical Guidance for Calculating Scope 3 Emissions; World Resources Institute: Washington, DC, USA, 2013. [Google Scholar]

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019. [Google Scholar]

- World Bank. Tunisia Economic Monitor: Rebuilding the Potential—Investing in Human Capital and Innovation; World Bank: Washington, DC, USA, 2023. [Google Scholar]

- European Commission. Carbon Border Adjustment Mechanism (CBAM); European Commission: Brussels, Belgium, 2023; Available online: https://trade.ec.europa.eu/access-to-markets/en/content/carbon-border-adjustment-mechanism-cbam (accessed on 5 September 2025).

- Elhedhli, S.; Merrick, R. Green Supply Chain Network Design to Reduce Carbon Emissions. Transp. Res. Part D Transp. Environ. 2012, 17, 370–379. [Google Scholar] [CrossRef]

- Dorigo, M.; Stützle, T. Ant Colony Optimization; MIT Press: Cambridge, MA, USA, 2004. [Google Scholar]

- Hochreiter, S.; Schmidhuber, J. Long Short-Term Memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef] [PubMed]

- IRENA. Renewable Energy in the MENA Region: Opportunities and Challenges; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2022. [Google Scholar]

- Blei, D.M.; Ng, A.Y.; Jordan, M.I. Latent Dirichlet Allocation. J. Mach. Learn. Res. 2003, 3, 993–1022. [Google Scholar]

- Mrad, M.; Frikha, M.A. Robust Control of Cyber-Physical Teleoperation Systems for Synchronized Healthcare Supply Chain Management. Int. J. Adv. Comput. Sci. Appl. 2025, 16, 673–678. [Google Scholar] [CrossRef]

- United Nations. Paris Agreement; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Zhang, Y.; Chen, X.D. An Optimization Model for the Vehicle Routing Problem in Multi-Product Frozen Food Delivery. J. Appl. Res. Technol. 2014, 12, 239–250. [Google Scholar] [CrossRef]

- Port of Rades Authority. Annual Report 2023; Office de la Marine Marchande et des Ports: Tunis, Tunisia, 2023. [Google Scholar]

- IMO. Fourth IMO GHG Study 2020; International Maritime Organization: London, UK, 2020. [Google Scholar]

- Sutton, R.S.; Barto, A.G. Reinforcement Learning: An Introduction, 2nd ed.; MIT Press: Cambridge, MA, USA, 2018. [Google Scholar]