Abstract

The lack of freshwater and the low efficiency of the traditional solar stills have led to the search to find a technology that can enhance desalination by use of vacuum-enhanced solar still technology. This review intends to investigate the impact of integrating a vacuum into solar stills, which include vacuum membrane distillation (VMD), nanoparticle-enhanced solar stills, multi-effect/tubular solar stills, geothermal integration and parabolic concentrator solar stills. The most important findings show that the productivity improves greatly: vacuum-assisted solar stills give up to 133.6% more product using Cu2O nanoparticles, and multi-effect tubular stills under vacuum (40−60 kPa) show a doubling in freshwater productivity (7.15 kg/m2) in comparison to atmospheric operation. Geothermal cooling and vacuum pump systems show a 305% increase in productivity, and submerged VMD reached 5.9 to 11.1 kg m−2 h−1 with solar heating. Passive vacuum designs further reduce the energy used down to a specific cost, using as little as USD 0.0113/kg. Nevertheless, membrane fouling, initial cost, and the complexity of the system can still be termed as the challenges. This review highlights the significance of vacuum-enhanced solar stills to address the critical issue of freshwater scarcity in arid regions. The integration of vacuum membrane distillation, nanoparticle and heat recovery into vacuum-enhanced solar stills enabled us to improve the economic feasibility. We conclude that vacuum technologies significantly boost the efficiency and economic feasibility of solar desalination as a potential approach to sustainable desalination. Specifically, these inventions will contribute to providing a renewable and cost-effective solution for freshwater production. Further investigations are required to overcome the existing challenges, such as system complexity and membrane fouling, to effusively comprehend the efficacy of vacuum-enhanced solar stills to ensure sustainable water management.

1. Introduction

Water scarcity has become one of the major global challenges of the 21st century, impacting more than 2 billion people around the globe as they currently do not have access to safely managed drinking water services [1]. Other causes of this crisis are fast population growth, industrialization, urbanization and changes in climate, which have resulted in a further increase in the demand for freshwater, at the same time leading to a decline in available freshwater sources. As a result of this increasing challenge, solar desalination technologies have become prominent in the quest to find sustainable solutions to established energy-intensive desalination processes, with potential in tapping the available free sun energy to produce freshwater in strained water areas [2,3].

Solar desalination is a feasible solution to tackle the issue of water shortage subsistence, especially in arid and semi-arid areas, where plenty of solar irradiation is available and freshwater is in short supply. Solar stills have been identified as one of the more viable options for solar desalination technologies due to their simplicity, minimum maintenance requirements and capability to run without any external energy supply. Traditional solar stills work by means of the natural evaporation and consequent condensation of water, which can be seen as a replica of a natural water cycle rearranged under a specific condition. Nevertheless, standard solar stills have major drawbacks due to their productivity and efficiency, which is generally only on average 2–5 L per square meter per day under ideal circumstances that limit its utility in the mass production of water [4].

Having solar still technology as the basic problem of solar still technology depends on the low levels of heat and mass transfer within the atmosphere pressure situations. In a traditional solar still, the evaporation rate is limited by the equilibrium vapor pressure of the water under the existing temperature that has a direct influence on water vapor generation and, hence, the condensation rate [5]. Also, non-condensable gases within the system may pose obstacles to mass transfer, leading to a further deterioration in the overall efficiency of the desalination process. These deficiencies triggered the researchers to consider different methods for increasing the performance of solar stills by either changing the basin design, the addition of a thermal storage material, nanofluids, and the addition of external cooling devices [6,7].

The current developments in solar still technology center on alleviating these basic constraints by introducing new features to the design and seeking new strategies to improve the performance of the solar still. Work on heat and mass transfer improvement has covered options such as the use of wick materials in order to have a larger evaporation surface area [8], adding phase change materials to store thermal energy [9], and adding nanofluids to increase thermal conductivity [10,11]. Although such adaptations have demonstrated positive effects towards an enhancement in the output performance of the solar stills, in many cases, they are prone to elaborate designs, extra parts, or materials used, which can add to the cost of the system and maintenance effort.

One of the most promising techniques, among others, that has been used in attempts to improve on the improvements currently being made is vacuum-enhanced solar stills since they solve the underlying problems of the conventional atmospheric pressure systems. The application of vacuum technology in solar desalination is also a redefining era, reflecting the difference from conventional practices in that direction, and it has the prospects of influencing the system and increasing the rate of evaporation as well as enhancing the overall system performance [12]. In lower-pressure conditions, the vaporization of the water occurs at lower temperatures, thereby making optimal use of the heat caused and more vapor production rates. This principle has been effectively realized during the industrial application of vacuum distillation technologies, and the introduction of solar-powered technologies promises much in terms of practical and scalable water production through solar power [13,14].

Vacuum-enhanced solar desalination works on the underlying principle of thermodynamics, wherein a lower-pressure tension in the evaporation chamber lowers the temperature of the saturation of water and, therefore, escalates the rate of evaporation at a constant temperature [15]. This design has a number of benefits compared to traditional atmospheric pressure systems in that it is thermally efficient and reduces heat losses as well as having high mass transfer rate and can be operated in multi-effect designs. With the proliferation of solar stills with vacuum technology, synergy leads to maximum exploitation of the available solar energy and minimum thermal energy needed to evaporate water [16,17].

Solar desalinator vacuum solar desalination systems fall in a number of configurations as follows: natural vacuum systems, barometric vacuum systems and mechanically induced vacuum systems. With water vapor condensing to generate and maintain vacuum without external vacuum pumps, natural vacuum systems are especially applicable for solar-powered applications, since they do not need any electrical power input [18]. Barometric vacuum systems utilize the difference in the atmospheric pressure to sustain the vacuum conditions, and this is against the mechanically induced vacuum systems that use vacuum pumps to create and regulate the desired levels of pressure. The configurations have their associated benefits and drawbacks in connection with the complexity of the system, energy consumption and performance attributes [19,20].

Theoretical analysis and experimental confirmation of the enhanced processes of heat and mass transfer that take place in a vacuum-enhanced solar still have motivated the advancement of numerous vacuum-enhanced solar stills [21]. Research using computational fluid dynamics showed that evaporation and condensation heat transfer coefficients were much greater under vacuum conditions, resulting in an increase in distillate production rates. Such theoretical predictions have been ascertained via experimental studies, in which tremendous production increases came along daily compared to traditional solar stills working under atmospheric conditions [22,23].

Recent research has been aimed at optimizing the different components of vacuum-enhanced solar stills, such as the optimization of the vacuum level, design and optimization of condensers, system optimization and economic calculation [24]. Research on how the vacuum level would influence the performance of the system was carried out, and the results indicated the optimum range of pressures that can be used so that system performance can maximize production and use a minimal amount of energy in order to maintain the vacuum. Moreover, scientists have found a solution to new designs of condensers that maximize vapor condensation at vacuum pressure, such as internal, external and hybrid condensers [25,26].

The combination of renewable energy sources, especially the use of a solar photovoltaic system in combination with vacuum-enhanced solar stills, has led to the possibility of entirely autonomous desalination systems. Integrated systems have the potential to be independent of grid electricity and, thus, more appropriate in remote locations or other off-grid uses. Advancements in vacuum pump technology in reduced energy consumption and the development of control systems have also increased the viability of solar-powered vacuum desalination systems, allowing stable and reliable operation to take place, with fluctuating levels of solar exposure [27].

The issue of the environment has gained more and more salience with regard to creating vacuum-enhanced solar desalination systems. The environmental impact of these systems has been studied in life cycle assessment studies, which have put into consideration factors like the consumption of material used, energy requirements needed in the system, and waste production during the system life cycle. The findings suggest that vacuum-enhanced solar stills cannot be considered to have any marked impacts over the environment, as opposed to conventional desalination technologies, in the sense of smaller carbon footprint and a reduced the environmental impact when in use [28].

Economic studies that have been conducted on vacuum-enhanced solar desalination systems have shown the promise of cost-effectiveness when compared to other desalination techniques, especially in the small- to medium-sized scale uses. The lower energy needs, easier design of the systems, and opportunities to use modular constructions lead to positive economic features. Nevertheless, the high cost of the original capital investment and the necessity to maintain the vacuum suggest that these concerns have to be remedied with further technical improvements and cost-cutting measures [29].

Recent advances in the field of vacuum-enhanced solar stills revolve around research in the following main areas: optimizing the system using advanced modeling and simulation tools, combining the technology with newer technologies like photovoltaic–thermal collectors, new materials development to enhance the system, and hybrid arrangement devices that combine more than one type of enhancement. The use of machine learning and artificial intelligence methods to optimize the system and to carry out predictive maintenance is also catching on as a potential method of increasing the reliability and performance of the system [30].

The current review offers a new conclusion for vacuum-integrated solar still technologies by organizing and evaluating new developments in eight fields: VMD, nanoparticle-enhanced systems, multi-effect or tubular systems, geothermal application, parabolic trough systems, passive vacuum systems, heat recovery systems, and modeling of the systems. This is in contrast to past reviews that have focused on the individual features of solar desalination. For instance, Ahmed et al. [31] (2023) evaluated the improvements made in vacuum solar desalination systems powered by renewable energy, outlining notable performance enhancements at elevated water production. However, the researchers did not focus on the optimal designs of this technology and proper methods to improve heat transfer that would enable them to upgrade water prouction. During another recent review, Mohamed et al. [32] (2023) stated a significant improvement in water productivity of 100% and overall efficacy of 70% for vacuum solar still systems. However, the researchers did not focus on demonstrating the optimial designs as they ascertained a comprehensive discussion of the contrast between natural vacuum systems and traditional systems. Interestingly, the current review is rather exclusive in that it carefully builds up the comparative performance of commonly used hybrid vacuum arrangements as well as pinpointing important synergies connecting pressurization reduction, heat management, and advances in novel materials. Another contribution this review brings is an original model for analyzing vacuum-enhanced systems in terms of energy–water nexus optimization that covers the unexplored trade-offs using vacuum intensity and energy sources, as well as scalability. Through the incorporation of the underlying principles of heat-mass transfer with realistic and optimium design principles, this review is expected to provide novel answers to the next generation of solar still architecture that can resolve the long-standing deficiencies in traditional desalination systems.

2. Review Method

The systematic literature review methodology used in this review evaluates peer-reviewed articles published between 2013 and 2025 based on Elsevier and Springer Nature, IOP, AIP, and other published scientific articles in indexed journals. This review identified eight themes to group the relevant publications in terms of the selection of vacuum-enhanced solar still technology, and these themes reflect those attributed to the research. The data extraction is targeted at performance indices, operation characteristics, and technology innovations, and the comparative analysis was performed to define the trends, the restrictions, and the further perspectives of investigations. This review not only has a preference of studies, which have an experimental basis or use strong modeling methods so the technical validity is adequate, but also removes sources that are not indexed or are not peer-reviewed, considered of low academic value.

Referring to the energy analysis for clean freshwater production via vacuum-enhanced solar stills, it was systematically achieved by assessing the main performance indicators from peer-reviewed studies. Specifically, the focus was to quantify energy efficacy indices such as the specific energy consumption (SEC) and specific thermal energy consumption. For instance, the SEC can define the input energy to operate the vacuum still system (pumps and heating) in comparison to the thermal energy output from the solar stills. Thus, this review considered the operational features of vacuum solar still such as temperature and pressure profiles with an open comparison against the traditional solar distillation systems. Also, the trend of energy efficiency enhancement was pursued to elucidate the advanced technologies, design and materials integrated into vacuum solar stills to enhance thermal competence.

2.1. Vacuum Membrane Distillation (VMD)

Energy optimization through the design and integration of new technologies to streamline the process of desalinating water via membranes facilitated greater efficiency in the process presented by Gabsi and Chehbouni (2013) [33], saving energy through renewable energy sources and optimum savings in condensation energy. A flat plate collector was integrated into the system, with solar radiation, simulated as an EUFRAT model to give the daily output water temperature. Also, the authors developed a mathematical model that could characterize how a hollow fiber module, which is operated according to the principle of VMD, operates as well as allowing us to calculate instantaneous and fluctuating distillate flow and daily productivity. They also conceived and commissioned a self-contained solar desalination unit (PV-thermal collector, ca. 0.5 m3/day), which was later tested in a village of orphaned children (8.0.8 Mahares, Tunisia) in practice.

Wang et al. (2015) [34] drafted and tested an experimental desalination set with an integrated VMD system and an integrated vacuum tube solar heat collection (SHC) system. First, the parametric sensitivity of the VMD unit was examined by employing an operative heater, and then the whole system was evaluated in solar heat. Based on these results, it was found that the best performance, defined by significant trans-membrane flux, took place at higher hot feed temperatures of more than 65 °C and a cold-side pressures of less than 0.02 MPa. The SHC-VMD system showed a short start-up time (less than 10 min) and had a run time of 305 h over five months, operated intermittently, whether independently or combined with the solar heat system, and proved it can be adapted to variable solar availability and intermittent conditions. The average trans-membrane flux of the combined SHC-VMD system was about 4 kg/(m2h), and the specific heat utilized in the process was about 750 kWh/m3.

The study of Triki et al. (2017) [35] of an autonomous solar-specific VMD is a study on the performance of a seawater desalination system, including significant indicators of membrane flux rate (MFR), gained output ratio (GOR), performance ratio (PR), recovery ratio (RR) and specific thermal energy consumption (STEC). In comparison to the available literature on solar-powered membrane distillation systems, the best values they unveiled are 14 L/h MFR, 3.3 GOR, 0.95 PR and 4.66 radical recovery; the lowest STEC was 290 kWh/m through the recovery of latent heat. A sensitivity test revealed that better GOR performance is obtained where both the flow rate of feed and temperatures of feed used and degree of vacuum as well as the area of solar collector are smaller. Such findings serve as an indication of the efficiency of the system and the effect of the parameters in its operative activity.

In a recent study, Zhou et al. (2018) [36] used a novel solar VMD regeneration technique of a liquid desiccant air conditioning (L DAC) system, and they proposed a mathematical model of the VMD as well as conventional thermal (TH) regeneration to achieve this analysis in terms of heat balance and mass balance. They constructed a simulation model that was validated against previous experimental observations using MATLAB (version MATLAB 8.4 R2014b) and found to be well matched with a maximum deviation of less than 6%. They conclude that the VMD regenerator seems to work better in a humid environment because it is superior to conventional TH regeneration when the temperature of the air is lower than 32 C, ratio of humidity exceeds 19 g/kg, and airflow is lower than 0.13 kg/s. Also, VMD has demonstrated greater outlet concentrations, as compared to TH regeneration at temperatures below 60 °C, during its solution and is more suitable for low-grade energy. Energy analysis showed that VMD energy use leads to 10 37% less power for each kilogram of desiccant than desiccant TH energy use.

Recently, a solar-heated submerged vacuum membrane distillation (S-VMD) unit with an evacuated tube collector being applied as a feed vessel was proposed by Bamasag et al. (2021) [37]. Characterization of the system was performed both through steady-state tests indoors and experimentally outside in real weather conditions focusing on the minimisation of temperature and concentration polarisation by means of aeration and internal circulation techniques. The findings showed that the S-VMD system of solar driving yielded a permeate flux of 5.9 to 11.1 kg m−2 h−1, which depended on the solar intensity, with aeration enhancing the flux by 9% and circulation raising the flux by 22% in the outdoor tests. The system also had a large rate of water production that reached up to 0.96 kg m−2 h−1, with consistent flux and good-quality water, even as it operated under long durations of time.

Chang et al. (2022) [38] proposed S-VMD to desalinate seawater in aquaculture facilities that has no feed-pumping system by submerging hydrophobic hollow fiber membranes into a feed tank with an internal solar-evacuated tube collector to act as the heat source. The research was conducted to compare the indoor steady-state test and the outdoor experiments that were carried out under varying solar intensity to evaluate the feasibility and practicality of the system. In the outdoor test, the solar-operated S-VMD set attained permeate flux of 2.12–5.2 kg/m2 h that varied with the intensity of the solar radiation. Bubbling of air as a flow-enhancing and anti-fouling strategy was used to minimize the boundary-layer polarization of the membrane. The findings indicated that the bubbling process had a positive effect on the enhancement of flux, fouling and permeate quality improvement over the non-bubbling process.

ElKasaby et al. (2023) [39] developed a dynamic simulation model in TRNSYS, which added a new type of vacuum membrane module. The original system design that provided a solar fraction of ~20% delivered an annual average gained output ratio of 2.51 and a specific thermal energy consumption of 133.5 kWh/m3, whilst the levelized water cost was 14.7 USD/m3 and the payback period 1.53 years. Enlargement of the solar collector area by 100 m 2 and doubling of the storage volume to 0.7 m3 increased the water cost by 14.54%, and the solar fraction increased by 101.39%, respectively. An increase in the membrane area by 0.3 to 0.5 m area enhanced the ratio of gained output by 76.75% and water costs by 14.79% less. The technology of internal heat regeneration through brine recirculation increased performance at lower ratios; otherwise, the water expenditure would have increased by 117.41% and the system could satisfy the daily water requirement in only 90 days per annum.

Hammad et al. (2023) [40] described a new type of dome-shaped solar distiller that is characterized by the use of a multi-tray conical absorber basin and a fountain to feed the supply to increase the level of vaporization and freshwater output. Their modified design, when compared with a conventional dome-shaped solar distiller, recorded an average daily freshwater production of 9.27 kg/m2 d, which is 41.0% more than that of a traditional dome-shaped solar distiller, which was 5.57 kg/m2 d. The modified design of the solar distiller was also more efficient, with daily energic and exergic efficiencies of 69.35% and 6.62%, which are an improvement of 40.65 and 94.70 compared to the traditional model.

2.2. Nanoparticle-Enhanced Solar Stills

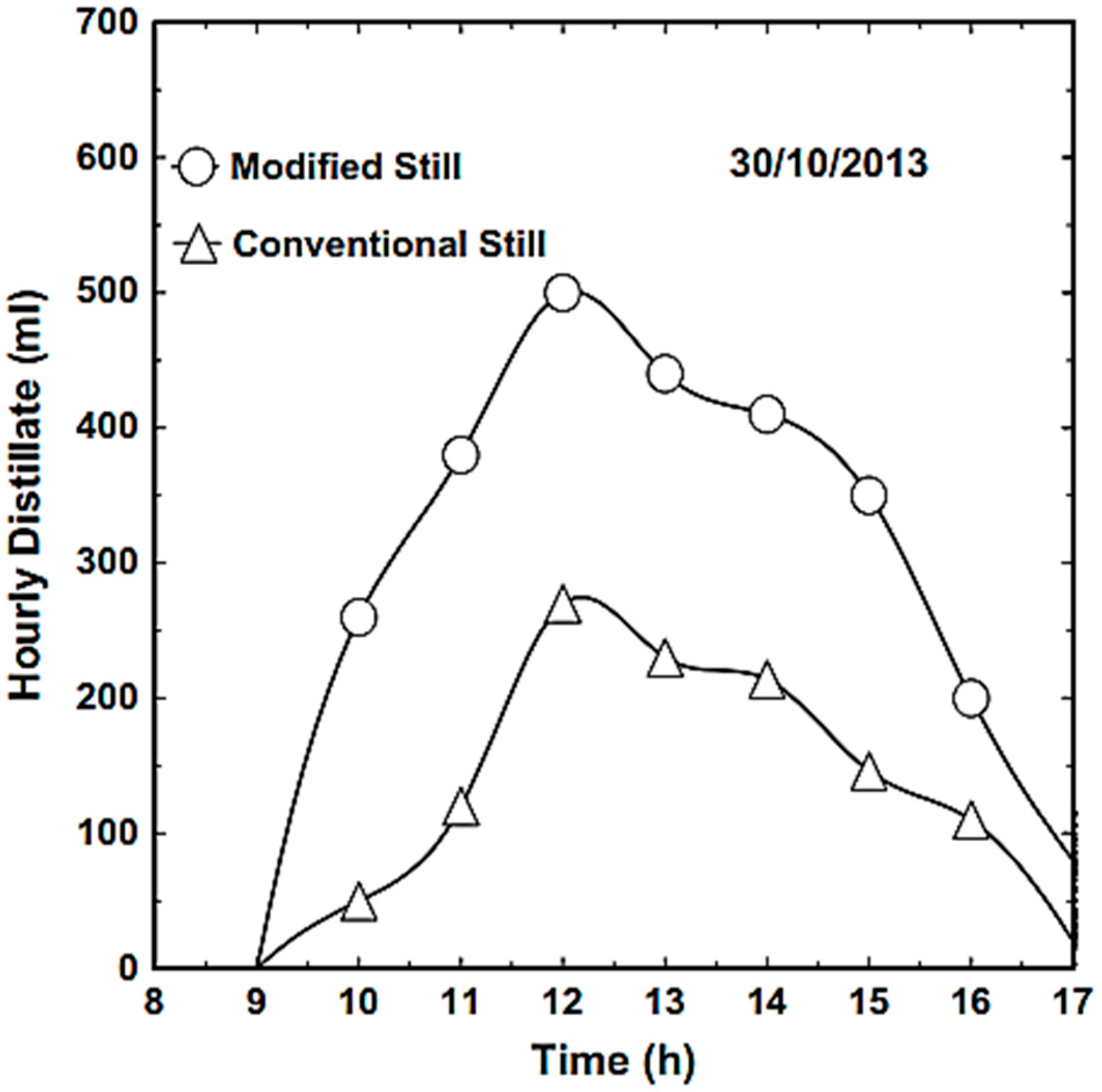

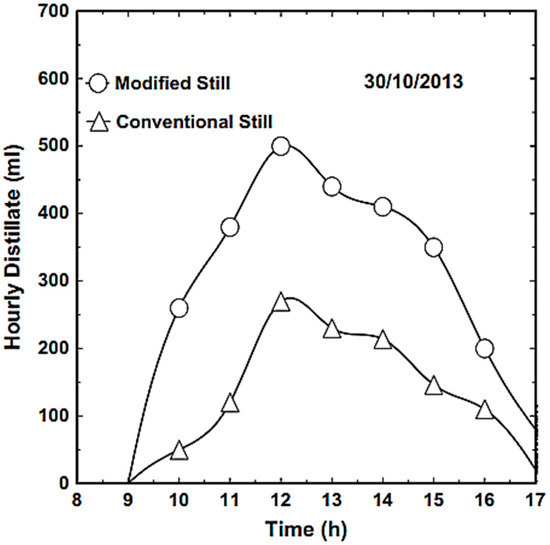

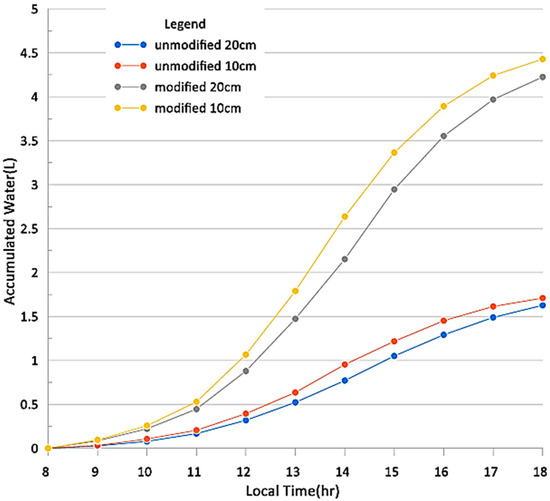

Kabeel et al. (2014) [41] conducted an experimental study in which they modified a typical conventional solar still (CSS) in order to increase its productivity of distillate water dramatically, using various nanomaterials, cuprous oxide and aluminum oxide in this case. It focused on the influence of different nanoparticle weight percentages (with percentage range of 0.02 to 0.2% in 0.02% steps), with and without vacuum in the presence of nanoparticles to basin water. Such changes dramatically increased the evaporation and condensation rates, yielding an increase in the production of distillate. When cuprous oxide nanoparticles (0.2%) were employed with a vacuum fan, the maximum level of productivity was obtained (a 133.64% increase in volume of distilled water in the still compared to conventional still (93.87% volume without using the fan)). In the same way, aluminum oxide nanoparticles enhanced the productivity by 125.0% (under vacuum) and 88.97% (without vacuum). The modified still was able to produce at a higher rate per hour as compared to the conventional system, as shown in Figure 1.

Figure 1.

Differences between the modified and conventional stills’ freshwater productivity while employing Cu2O at a weight fraction concentration of 0.06% [41] (License Number: 6134300227383).

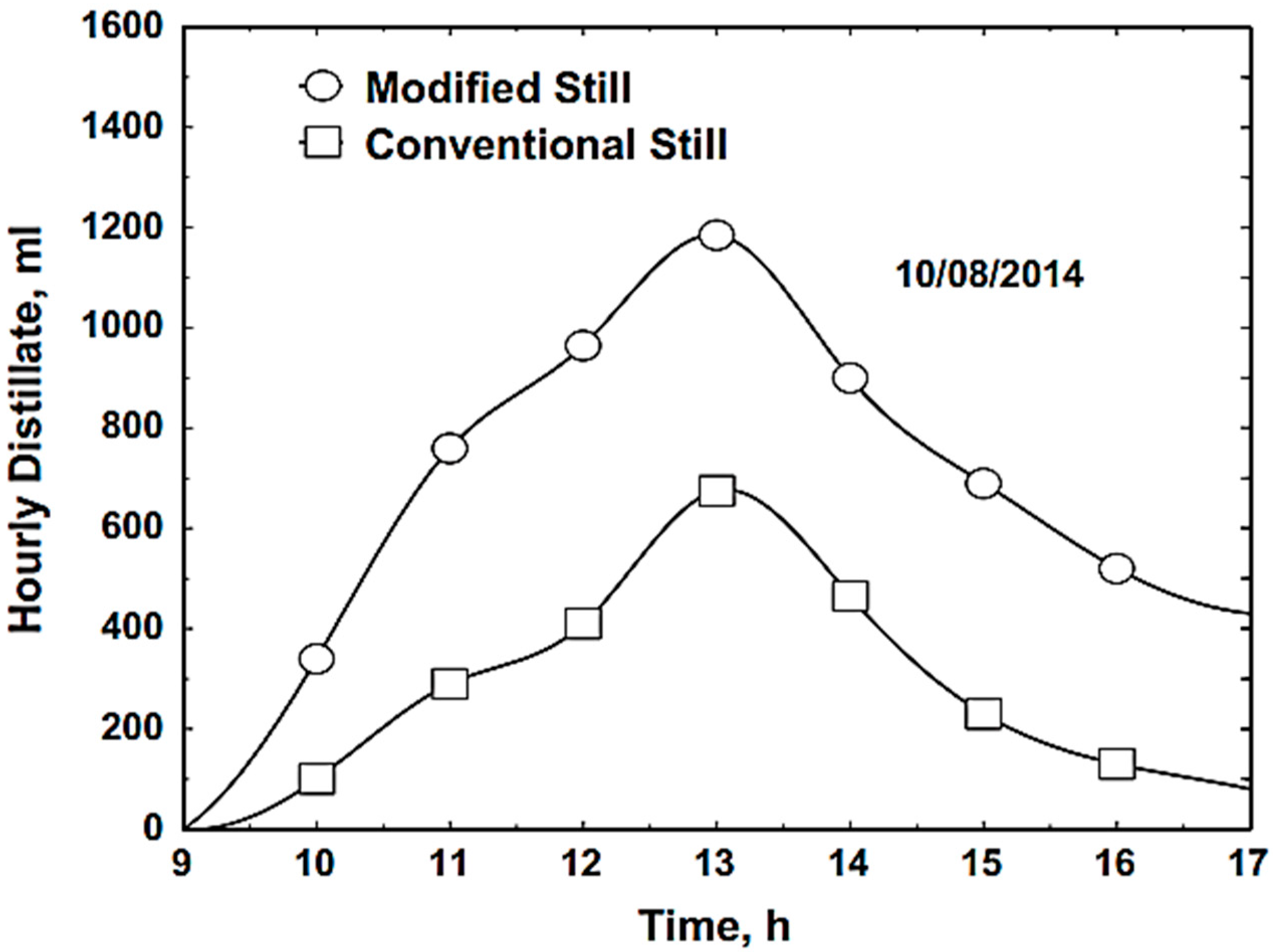

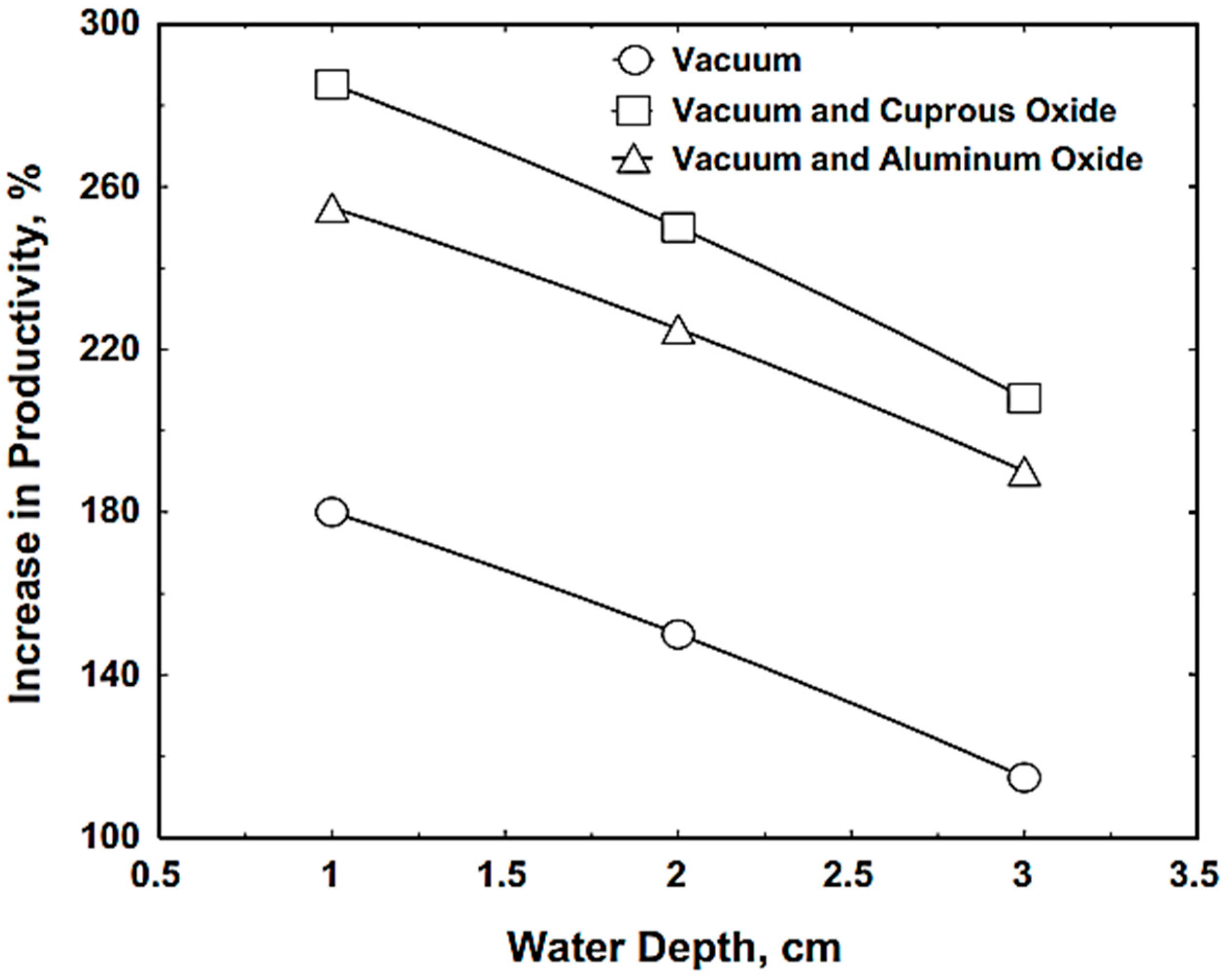

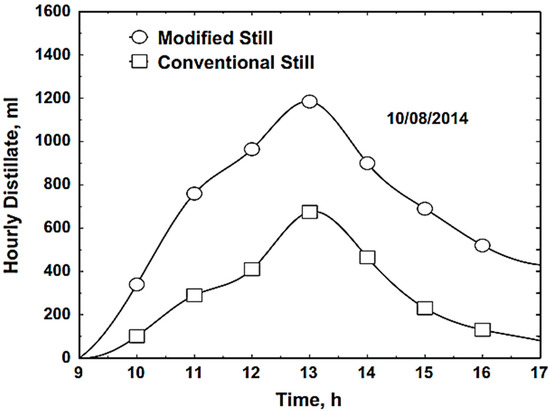

Experimental studies carried out by Omara et al. (2015) [42] consisted of applying changes to achieve a standard solar still, seeking to assess the effectiveness of a brand-new hybrid solar distillation system with both corrugated and wick absorbers and an external condenser. This research observed the performance of a corrugated wick still (CrWSS) versus a CSS, with respect to saline water depth (1, 2, and 3 cm). The findings showed that using an external condenser in combination with reflectors was critical to enhancing productivity, and the CrWSS under vacuum yielded 180 per cent more than the CSS. Also, the application of cuprous oxide and aluminum oxide nanoparticles maximized the productivity rate by 285.10 per cent and 254.88 per cent, respectively. The modified still showed better performance because of the reduced warming-up time and its reduced heating max power (Figure 2). Moreover, a better productivity improvement was observed in CrWSS featuring mirrors, vacuity, and nanoparticles of cuprous oxide than that of CrWSS with internal reflectors and aluminum oxide nanoparticles in association with an external condenser (Figure 3).

Figure 2.

Difference between the conventional solar still and corrugated wick still with vacuum and reflectors in terms of freshwater production [42] (License Number: 6134301127410).

Figure 3.

Freshwater productivity against water depth for three testing modes of vacuum and vacuum-based nanoparticles [42] (License Number: 6134301127410).

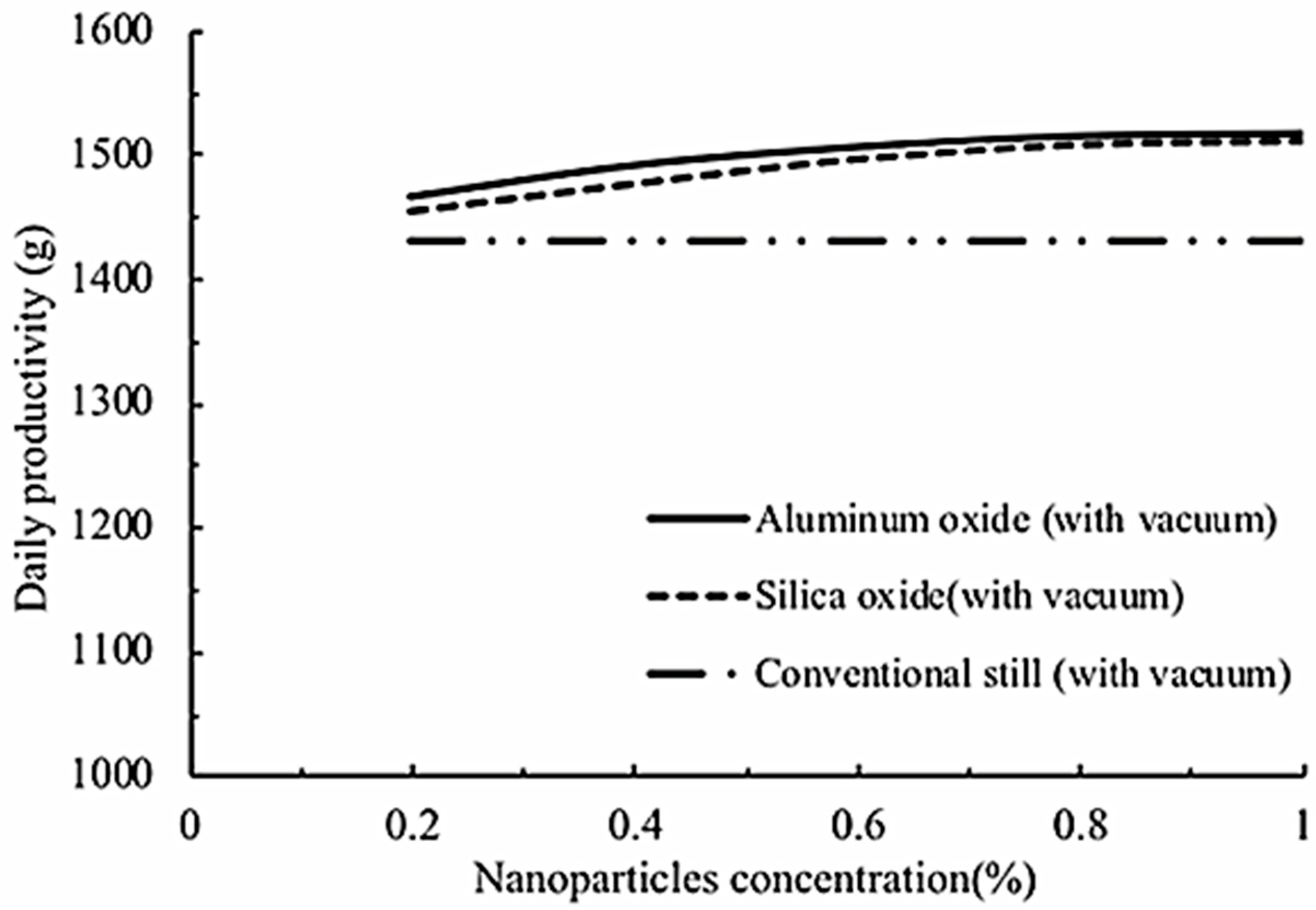

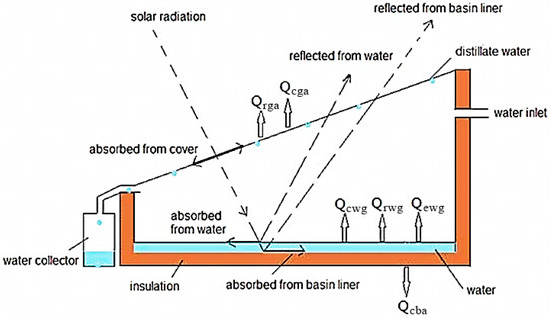

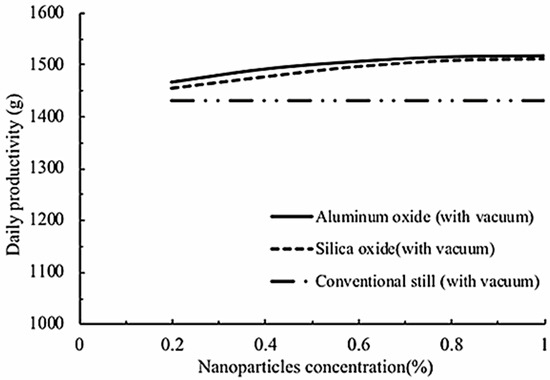

Bataineh and Abu Abbas (2020) [43] performed both theoretical and experimental work to test the thermal performance of a solar still augmented with Al2O3 and SiO2 nanoparticles to enhance productivity, as depicted in Figure 4. This research was conducted over the summer of 2018 in Irbid, Jordan (32° N, 35° E), and came about by creating a precise mathematical model in the form of balance equations, which were then solved using a numerical technique to achieve the nonlinear differential equations. The researchers studied nanofluid and glass temperature, heat transfer coefficients (HTCs) and solar still output and the influence of changing nanoparticle concentrations (Al2O3 and SiO2). Water depth and vacuum usage on water output were also analyzed each day. The results showed that the yield of distilled water was augmented by 10% and 8.5% using Al2O3 and SiO2 nanoparticles, respectively, at a depth of 0.5 cm and at a nanoparticle concentration of 0.2%. Moreover, the productivity when a vacuum was used showed an approximate 13% and 12% increase using Al2O3 and SiO2 nanoparticles, respectively, as illustrated in Figure 5 when used at 2.5 cm depth of water.

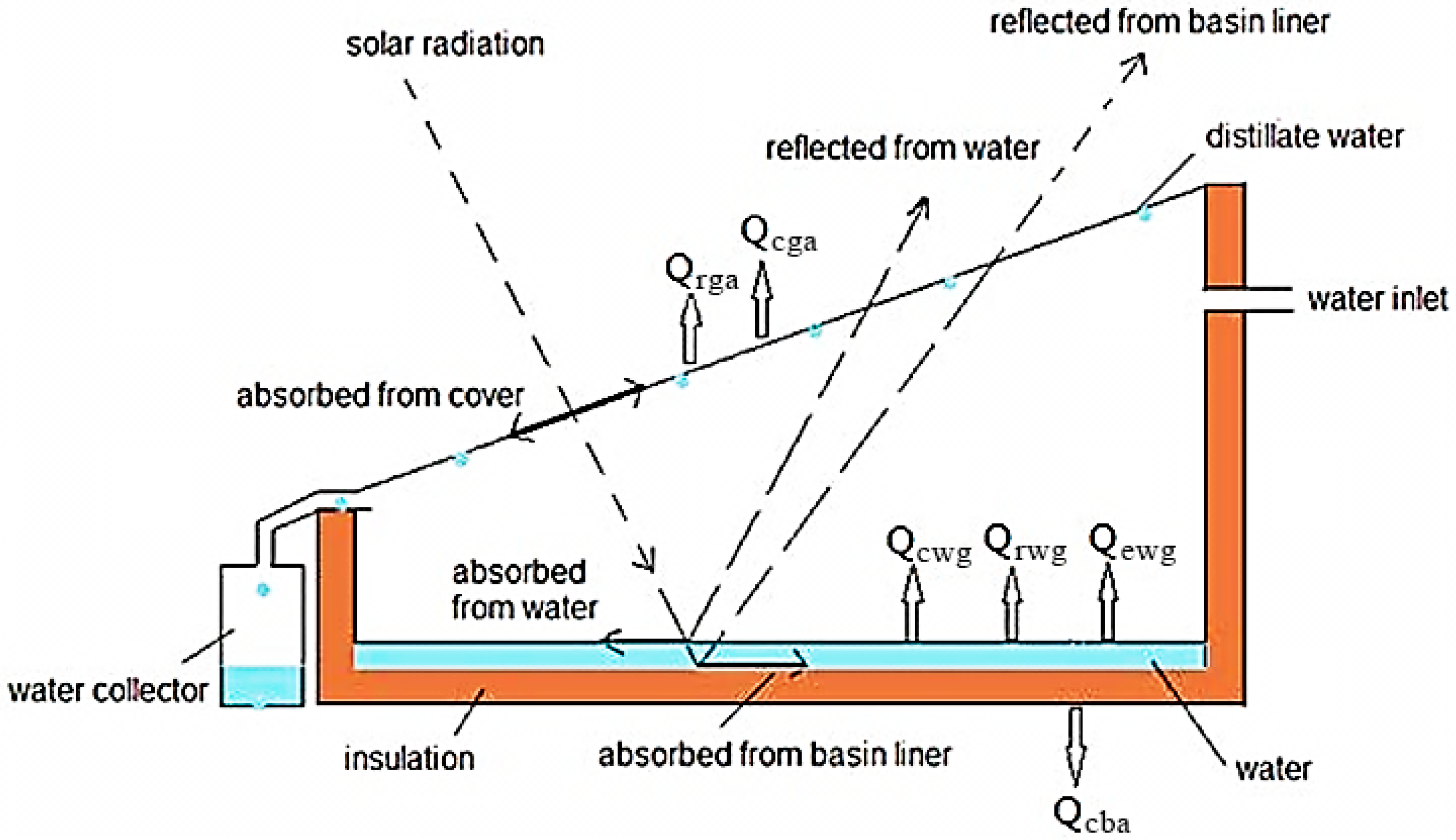

Figure 4.

A schematic diagram of a solar still [43] (License Number: 6134310056803).

Figure 5.

Impact of nanoparticle concentration on daily water productivity of a vacuum within a solar still using different nanoparticles [43] (License Number: 6134310056803).

Naveenkumar et al. (2023) [44] investigated how to elevate the production rate, distillate exergy, and energy efficiency of a single-basin and glass-wool insulated with a two-slope solar still by considering a vacuum fan driven by sunlight to increase their productivity, an external condenser, and 0.1% volume of copper oxide, aluminum oxide, and zinc oxide nanofluids. The use of both fans and the condenser enhanced the production rate, largely because of increasing the evaporation rate in the solar still basin. This alteration yielded the highest improvements of 28.37% in energy efficiency, 78.6% in exergy efficiency and 64.29% in cumulative generation due to the augmented thermal conductivity and radiation characteristics of the nanofluids. Furthermore, the modifications to the design of a solar still via the application of copper oxide, aluminum oxide and zinc oxide nanofluids have enhanced energy and exergy efficiencies by 21.33%, 19.36%, 17.03% and 50.11%, 36.82%, 23.75%, respectively, in comparison to the unassisted modified solar still. The results depict the synergy effects of integration of the vacuum-assisted evaporation and nanofluid-enhanced heat transfer on the performance of the solar still.

Solar distillation was optimized by Hammad et al. (2024) [45], who developed a multi-tray, stepped conical and dome-shaped solar distiller to extend the evaporation and exposure surfaces by substituting the traditional flat basin. This was made even better by the addition of a central fountain to spread the seawater so that the thickness of the water film on the trays was minimized, thus allowing better heating. A test of three setups, namely a reference distiller solar distiller, a system with the addition of a fountain, and a system with the addition of a fountain and nanocomposite, was able to demonstrate that modified systems reached daily production of 6.84 and 7.21 kg/day/m2, respectively. These findings are an indication of the high productivity increases of 54.05% and 62.38% in comparison to the 4.44 kg/day/m2 output of the traditional solar distiller.

2.3. Multi-Effect/Tubular Solar Stills

Chong et al. (2014) [46] proposed a multiple-effect diffusion solar still (MEDS) with a bended-plate constructed multiple-effect diffusion unit (MDU) that solves the problem of peel-off of wick materials. MDU was coupled with a vacuum-tube solar collector, boosting temperature differences to increase productivity using the heat pipe to take energy and deliver it to the MDU. One model, MEDS-1 L, was built and tested outside, and the performance was measured with four parameters expressed in kilograms of pure water produced daily per unit area of glass cover (Mcov), solar absorber (Msol), and evaporating surface (Mevp) as well as solar distillation efficiency (Rcov). It was observed under outdoor testing that for the solar collector at 800 W·m−2 solar radiation, the supply temperature (Th) was 100 C. MEDS-1 L exhibited the highest Mcov 23.9 kg m−2 d−1 that was 29-times than that of basin-type MEDS; the highest values of Msol and Mevp were 25.9 kg m−2 d−1 and 2.79 kg m−2 d−1, respectively. Secondly, the values of Rcov (1.5–2.44) were found to be higher compared to that of basin-type MEDS (1.45–1.88), and it is more effective.

Theoretical and experimental studies were carried out by Xie et al. (2018) [47] to analyze the efficacy of the vacuum operation of a tubular solar still (TSS), resulting in an advanced model. Their analysis showed that lowering the pressure of operation increases the concentration gradient of the humid vapor in the trough to the condensation surface, in turn intensifying the diffusion and natural convection of the vapor inside the cavity. Also, they discovered that with increasing pressure near to the saturation pressure of saline water, the mass transfer leads to a more significant extent of buoyancy as compared to thermal diffusion in driving the mass transport of vapor. The model that was proposed and includes the concepts of binary mixture diffusion in calculating the mass transfer coefficient displayed a deviation range of −3–11%, as opposed to experimental data, and it was again verified with an independent dataset.

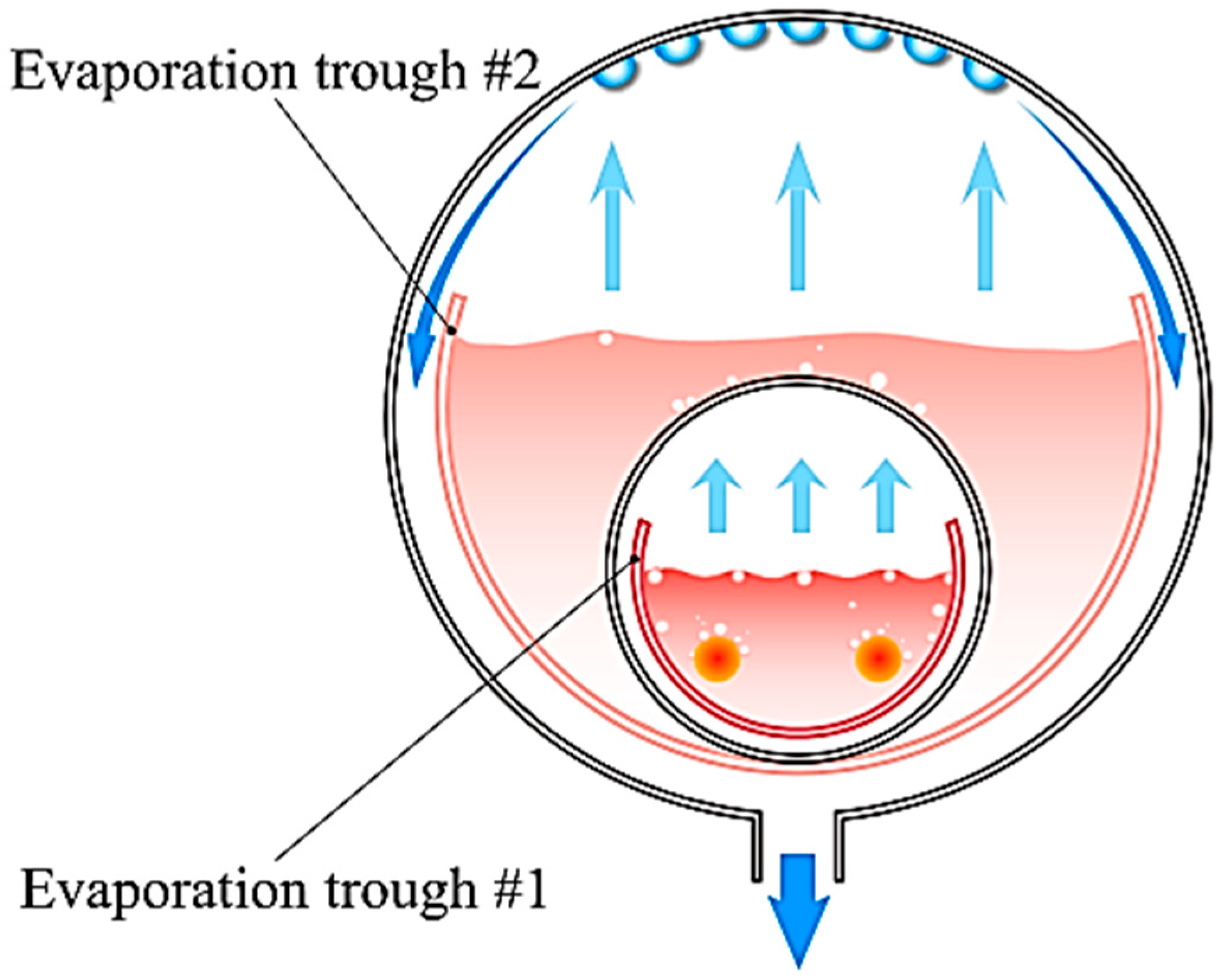

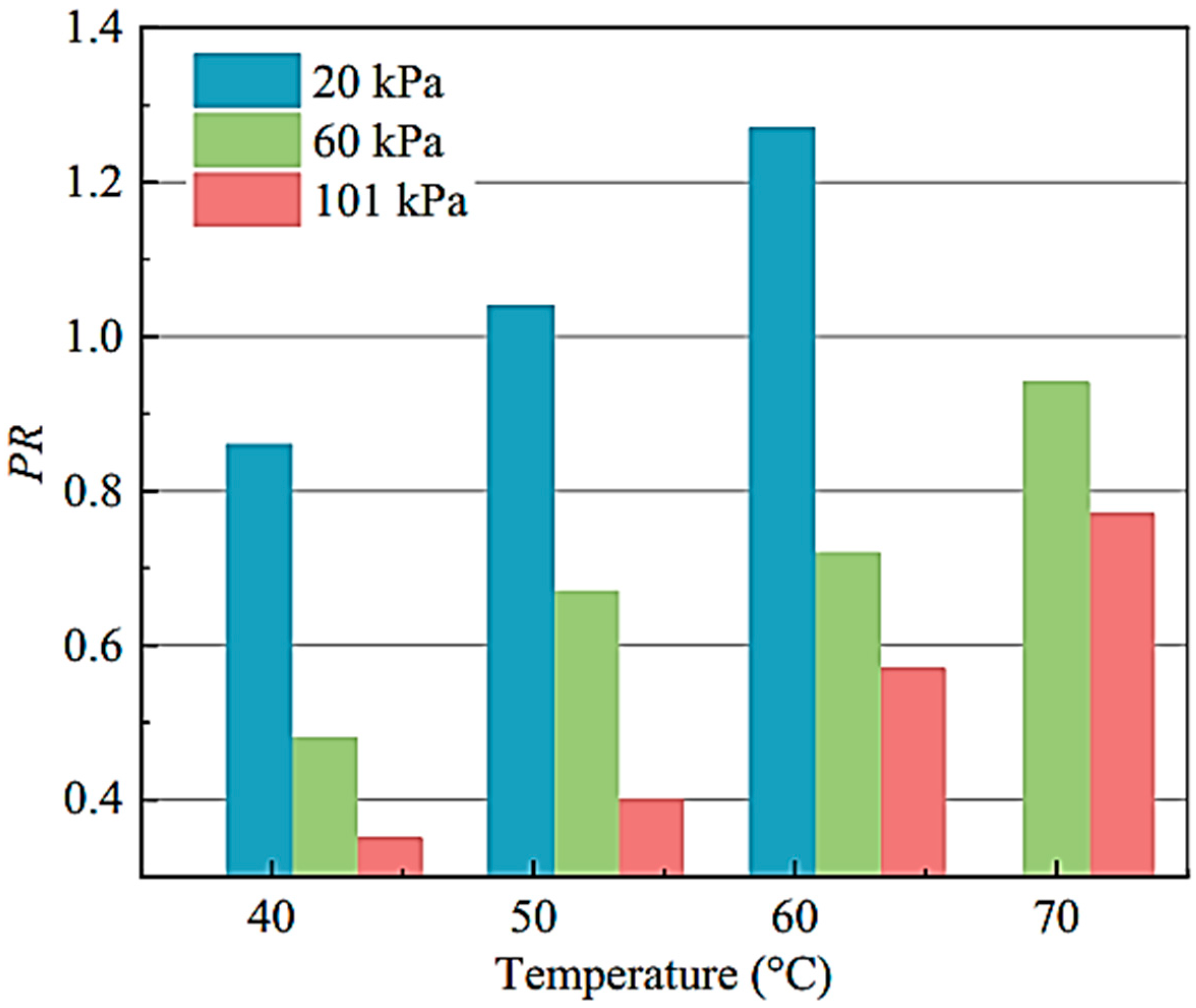

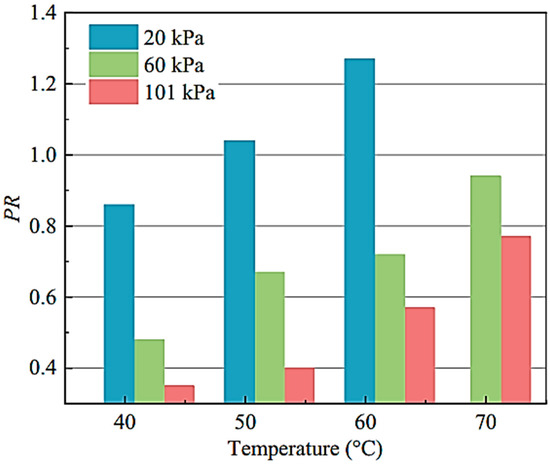

The study by Yan et al. (2019) [48] is an experimental analysis of a two-effect tubular solar still (TSS) applied in the TSS operating under the vacuum conditions presented in Figure 6. They determined that the pressures between 20 and 101 kPa maintained by the use of a vacuum pump varied greatly but still produced the greatest amount of freshwater and system efficiency, requiring very little energy. The yield rate grew at 20 kPa, twice as high a yield rate in atmospheric pressure, and the performance ratios were also found to be 0.57-, 0.70- and 1.27-times performance ratios at 101 kPa, 60 kPa, and 20 kPa, respectively, at a heating temperature of 62 °C (Figure 7). The practicability of vacuum functioning in diverse solar still models included in the research has a benefit for multi-effect designs that are more financially favorable than the single-effect one. It was predicted afterward that TSS would be a five-effect system, a nested five-stage system, in which the performance ratio at 60 kPa and 70 °C might reach up to 3.79, showing its higher efficiency.

Figure 6.

A schematic diagram of the tubular still with two effects [48] (License Number: 6134310483766).

Figure 7.

Performance ratio against temperature of a two-effect tubular solar still at different vacuum pressures [48] (License Number: 6134310483766).

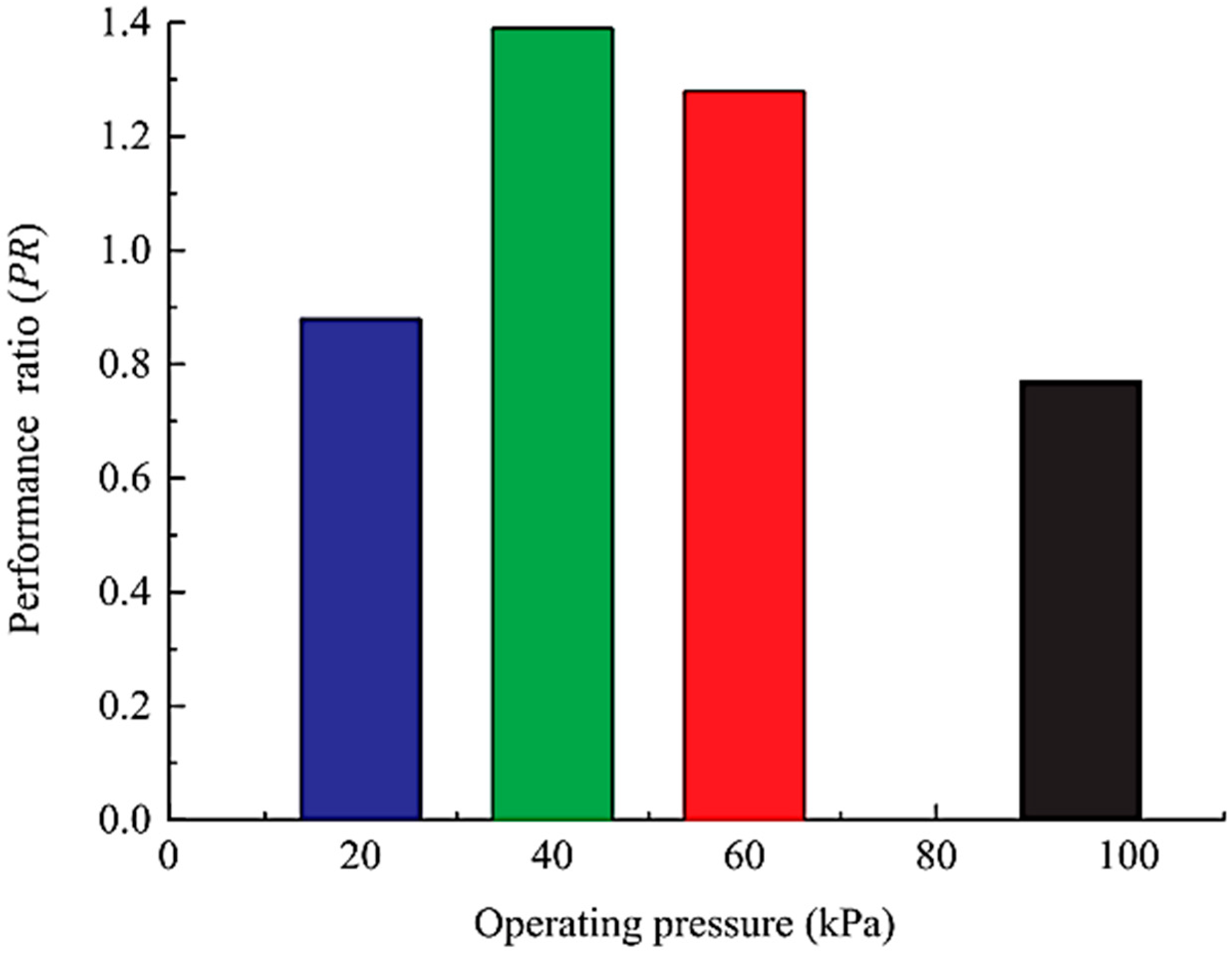

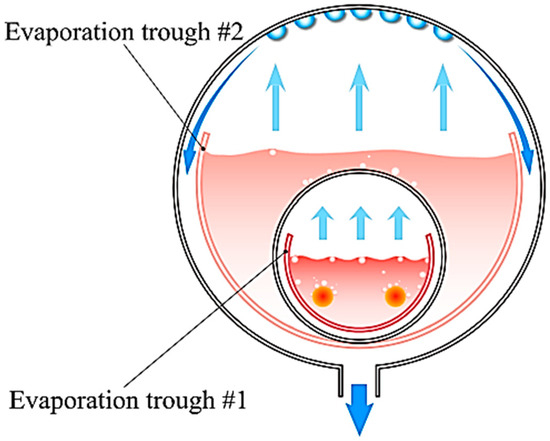

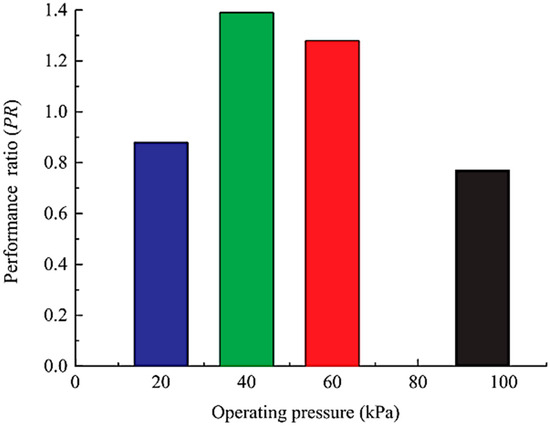

Xie et al. (2020) [49] designed their three-effect tubular solar still (TSS) with much higher productivity in the form of a cascade feed and a vacuum system of operations, as presented in Figure 8. The design took three enclosed distillation chambers into account, with one water trough and a tubular shell of each. The solar collector used to then generate the power was the evacuated heat pipe, and it was tested and developed in a prototype system on four sunny days in Chengdu, China. The experiment was conducted on the freshwater yield under four values of operating pressure, 95, 60, 40, and 20 kPa (local atmospheric pressure). The findings showed that the operating temperature, as well as the temperature increment between chambers, was lowered with diminished pressure. Freshwater outputs totaled 3.27, 6.323. 7.056 and 4.287 kg/d, with the following outputs of energy utilization efficiency, 0.77, 1.28, 1.39 and 0.88, respectively (Figure 9). In 40 kPa systems, the best performance was noted, whereas the lowest pressure (20 kPa) decreased the yield and efficiency, as a result of heat transfer conditions worsening on the outer shell. The research showed that the optimum operating pressure of small-scale solar stills should be in the range of 40 to 60 kPa.

Figure 8.

A schematic diagram of the three-effect tubular solar still [49] (License Number: 6134310937222).

Figure 9.

Performance ratio against operating pressure of three-effect tubular solar still operates at the vacuum pressure [49] (License Number: 6134310937222).

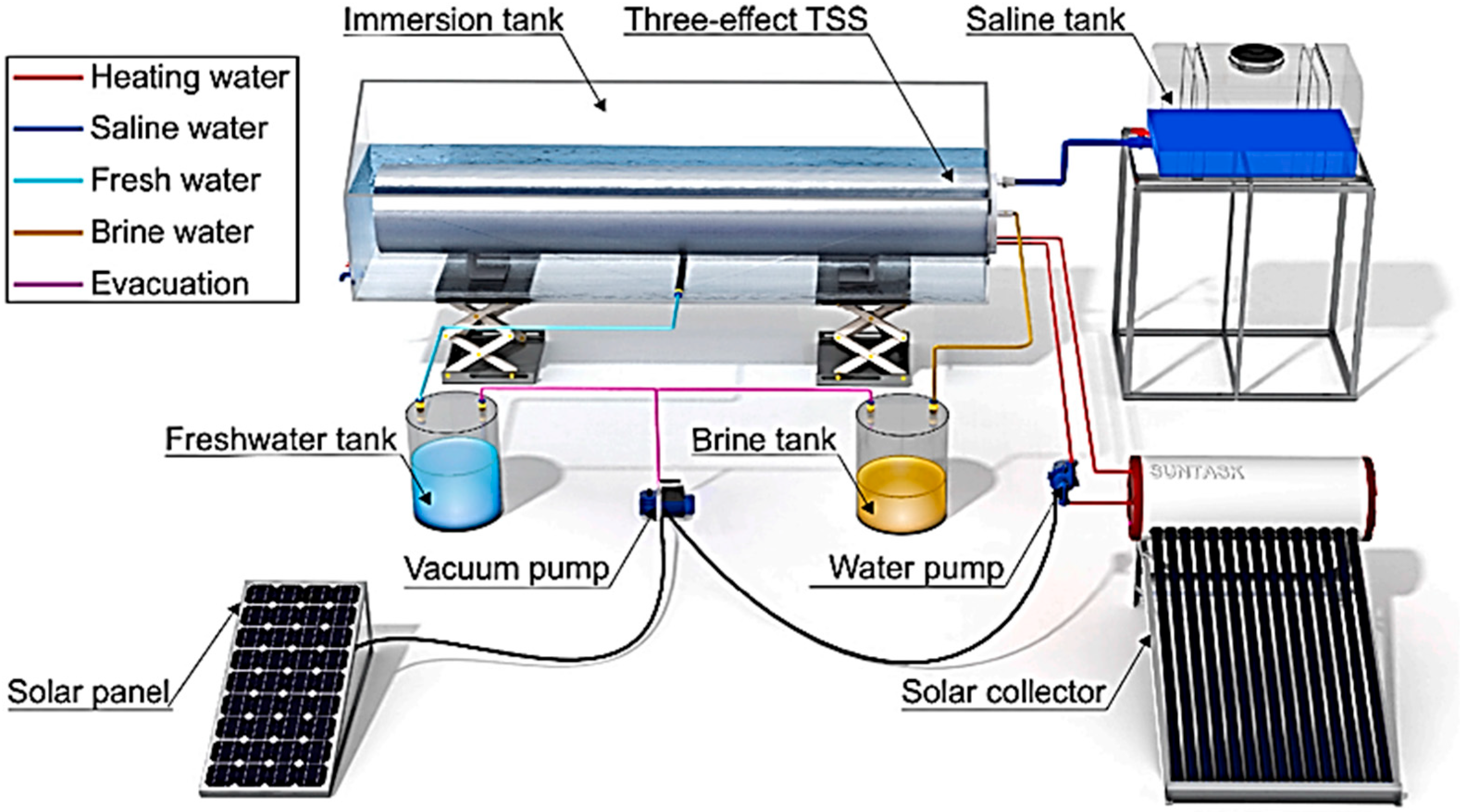

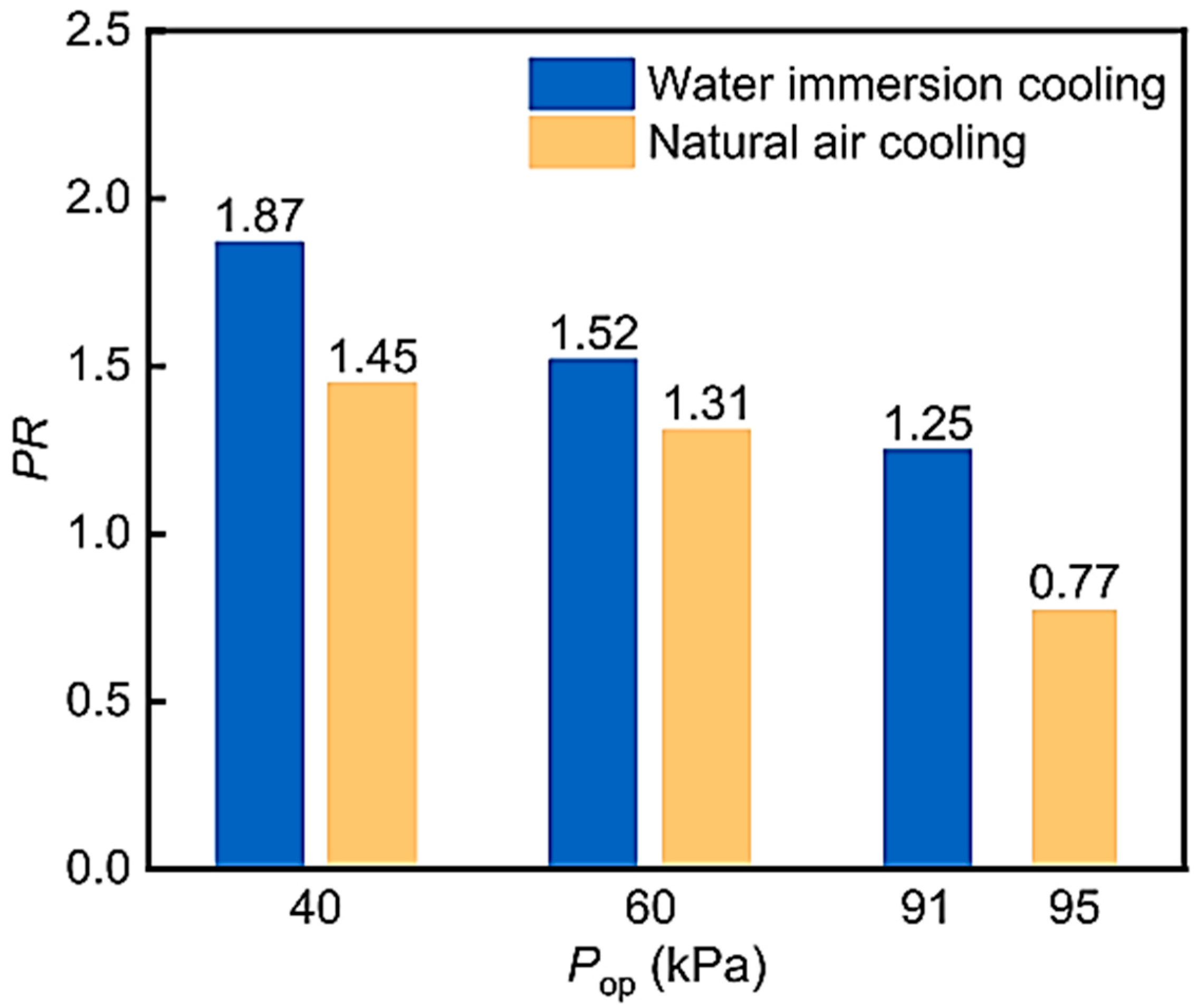

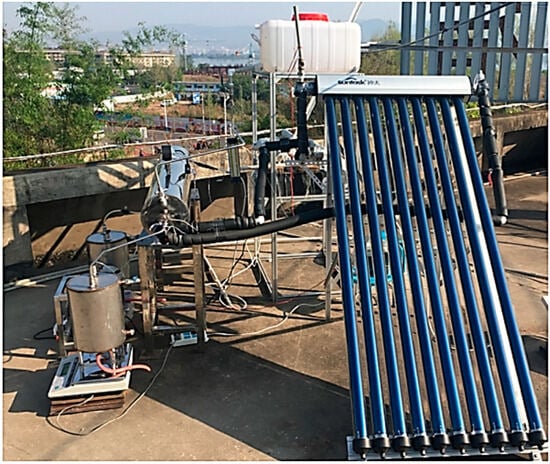

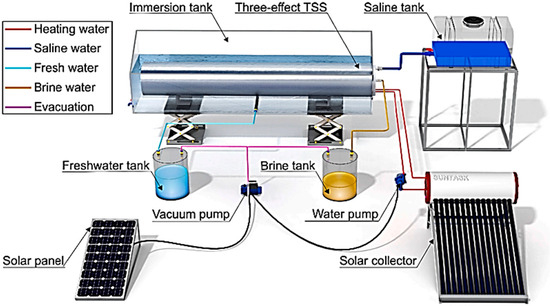

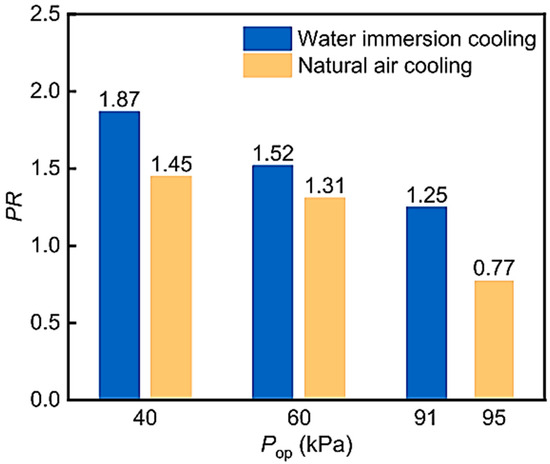

As reported by Yan et al. (2021) [50], the proposed system (Figure 10) was configured with a periodicistic pressure control system and water immersion cooling, which was tested through a 5-day outdoor experiment by connecting the prototype to a 0.19 m2 solar panel. A maximum of 9.8 kg/m2 of water was produced at 40 kPa, and thermal analysis showed that water immersion cooling could increase the cooling coefficient heat by 15–50-times that of air cooling. The vacuum energy requirement was also very low at 60 kPa against the conventional vacuum-based energy requirement of 21.6 kJ/kg to 1.7 kJ/kg due to the much lower energy requirement necessary to maintain the same vacuum condition. The cost of distilled water was estimated at 0.012/kg, which was found to be a feasible solution for the off-grid regions. With water immersion cooling, the system reached 40 kPa, showing a performance ratio (PR) of 1.87, achieving 187% thermal efficiency by reusing harvested energy (Figure 11).

Figure 10.

A schematic diagram of the suggested immersion-cooling solar distillation system [50] (License Number: 6134311259962).

Figure 11.

Performance ratio of a solar still against vacuum pressure for different cooling techniques [50] (License Number: 6134311259962).

Chen and Xie (2022) [51] formulated a predictive model of multi-stage tubular solar stills (MSSV) under vacuum yield, and its accuracy was checked with field experiments. In their work, they concluded that under both typical weather conditions (cumulative solar radiation of 19.75 MJ/m2) and lower pressures (1.58 kg/m2), a 3-stage tubular still could reach a maximum water yield of 7.15 kg/m2 (200% improvement) at an optimum vacuum pressure of 48 kPa, which greatly surpassed both normal weather conditions (5.81 kg/m2) and lower-yield conditions (1.58 kg/m2). This was the best pressure at which the system was balanced between taking in energy and dissipating it. The intensity of the sunlight raised the production of water and the optimal pressure of the vacuum. Also, raising the stages provided a better yield of freshwater with a smaller amount of increase, and the optimal pressure was a little less. Further, the conversion of air cooling to water immersion cooling increased the yield value to 10.51 kg/m2 to 7.15 kg/m2.

A visualization experiment to study the flow of vapors and the diffusion process was realized by Wei et al. (2023) [52], who used laser sheet and smoke tracer methods to study the dynamics of vapor flow patterns. Their experiments showed that the faster the vapor flow was, the worse the pressure got, and the warmer the wall, the higher the Tw. At Tw = 60 °C, the mean velocity of the vapor flow (vavg) was at 66.6 mm/s with 40 kPa with a 153% increment when compared with 95 kPa. The researchers also managed to introduce a new solar still yield prediction model that was tested using independent data, with no correlation error of 5.11% on average. They also classified three distinct flow regimes, laminar, transitional and turbulent, depending on the Grashof number, to be laminar flow when Gr < 3.0 × 104 and turbulent flow when Gr > 5.6 × 104.

2.4. Geothermal/Sensible Heat Integration

Panchal and Shah (2014) [53] proposed a new technique of increments in the distillate yield in a double-basin solar still coupled with the use of a vacuum tube with an increased basin area size by adding different sensible energy storage materials, i.e., pebbles, black granite gravel, and calcium stones. They investigated this under the climatic conditions of Mehsana, Gujarat (23.6000° N 72.4000° E), from April to 9 September 2013 and constantly maintained a 2 cm depth of water in the uppermost basin with and without basin materials. The conclusion was that the calcium rocks applied as a basin material boosted the distillate production by 74% in comparison with the black granite gravel and pebbles. Also, the incorporation of the solar stil with vacuum tubes increased productiveness more so by providing hot water to the lower basin.

A new design of a solar still by Panchal et al. (2015) [54], with an inner diameter and outer basin of 1006 mm × 325 mm × 380 mm and 1006 mm × 536 mm × 100 mm, respectively, is made of black granite gravel to maximize the volume of the distillate produced because mixing the volume of saline water in the two basins will be minimized. The experiments in Mehsana, Gujarat (23°59′ latitude, 72°38′ longitude), considered the performance of the still on four systems: standalone stand, stand with black granite gravel, stand with vacuum tube, and stand with both vacuum tubes and gravel. The findings indicated that the output yield increased by 56% and 65%, respectively, when the versions of the vacuum tube and a combination of vacuum tube and gravel were used to create daily distillate output with the ability to exceed other designs in the course of comparisons.

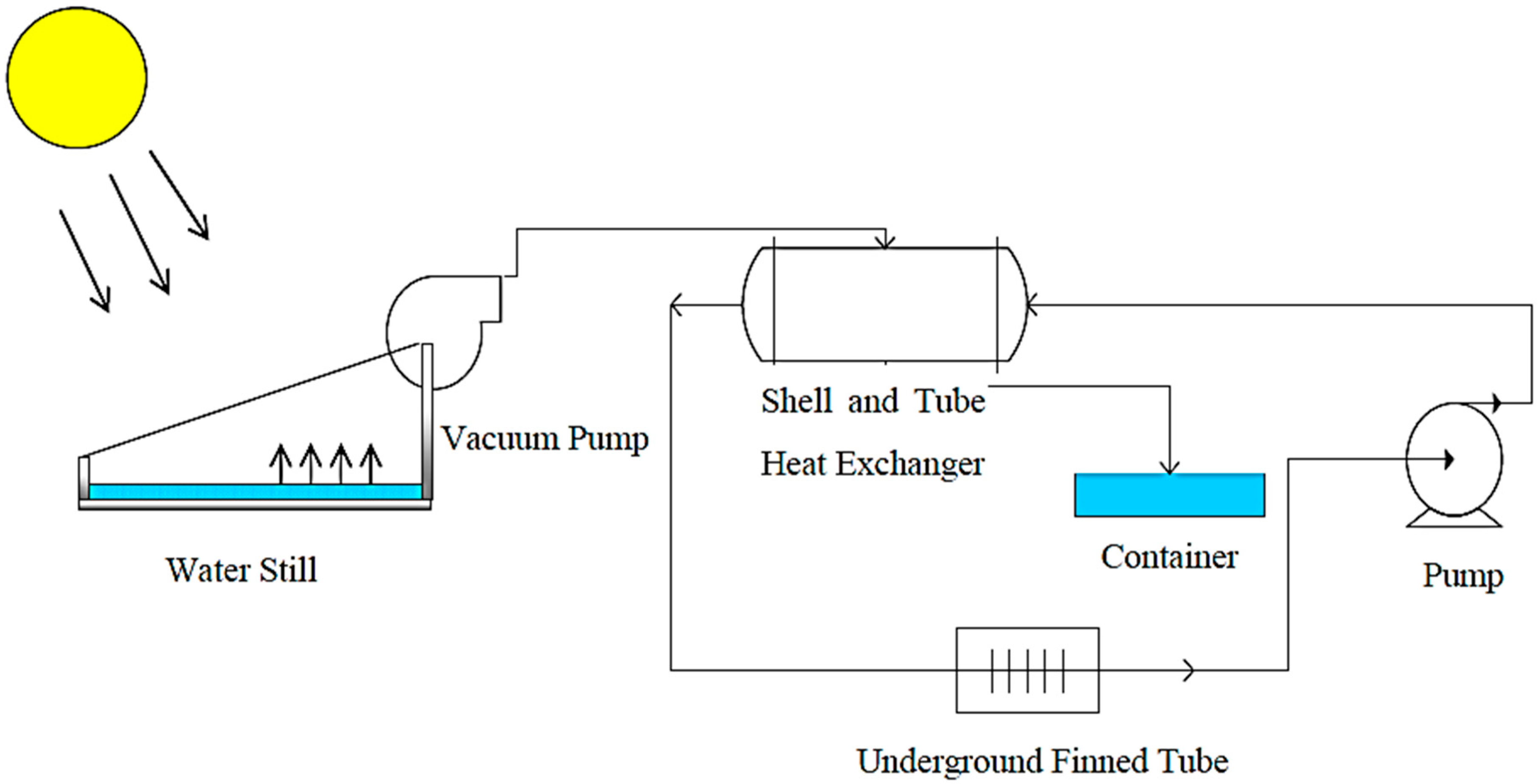

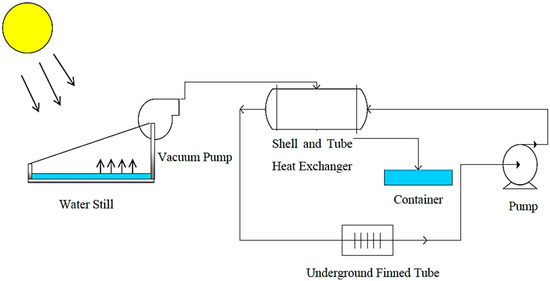

The increased performance of a solar still was studied by Danish et al. (2019) [55] through a combination with a geothermal cooling system and a vacuum pump (Figure 12). The simulated geothermal system had a cold underground water temperature with a difference between ambient temperature and the subsurface range, with the temperatures ranging between 15 and 25 °C by circulating water down underground that passed into a side-by-side shell and tube heat exchanger. The vacuum pump ensured there was a certain vacuum pressure in the still. The nature of the system was that the temperature and the vapor flow of the geothermal water would be sufficient to condense the resulting vapor. A nonlinear equation mathematical model was used to check a prototype, and the results show that they were close to each other. Through the upgrade, it revealed an improvement of 305% in water productivity per day. Special investigations showed that an increase in vacuum pressure and ambient temperatures contributed positively to the yield, and an increase in wind speed had negative effects on performance.

Figure 12.

A schematic diagram of solar-geothermal still [55].

A solar-powered natural vacuum desalination system that includes an inner condenser was introduced by Wang et al. (2021) [56], whereby the vacuum atmosphere in the distiller is generated with the help of gravity and the atmospheric pressure of the surroundings to promote the evaporation of seawater with minimal input of solar energy. The system is also capable of non-condensable gas removal through a water-filling and air-removing process in an efficient manner. They focused on transient behavior analysis of the system at fixed temperatures of seawater and tested the behavior of the system under real-life weather conditions with the use of 18 m square flat-plate solar collectors. Constant temperature test results showed that increased hot seawater temperature extended the cycle time and high freshwater production with the highest hourly production of 12.45 kg/h at 60 °C with 0, 1 kg/s. The system was able to generate 154.14 kg of freshwater on a daily basis, with a performance ratio of 1.36 under real solar conditions (average of 672 W/m2). An economic analysis had the cost of purified water pegged at USD 6.9 in terms of a ton.

Wei et al. (2021) [57] designed a natural vacuum solar desalination system based on the water-filling and air-releasing methods to study the operation characteristics of this method under changing weather conditions by assessing the periodicity of operations and performance indices according to the flow rates and temperatures, as well as the economic efficiency of the production of the freshwater. Their results showed maximum performance at a constant flow rate of 0.150 kg/s with a heat collection area of 18.0 m2, with the efficiency and recovery ration being 87.821% and 3.858%, respectively, or 1.568- and 1.631-times greater than the preheat recovery values correspondingly, and there is an average fresh quantity of 6.018 kg/h. Efficiency was 84.256% using a 14.4 m2 collector, night-time waste heat, and constant temperature seawater, a 1.080 time since the 18.0 m2 collector, but the recovery ration was highest, 4.133% at 18.0 m2 (a 1.069 time that of the 14.4 m2). The substituted cost of freshwater production was around USD 0.0113/kg, which depicted competitive advantages relative to other similar systems.

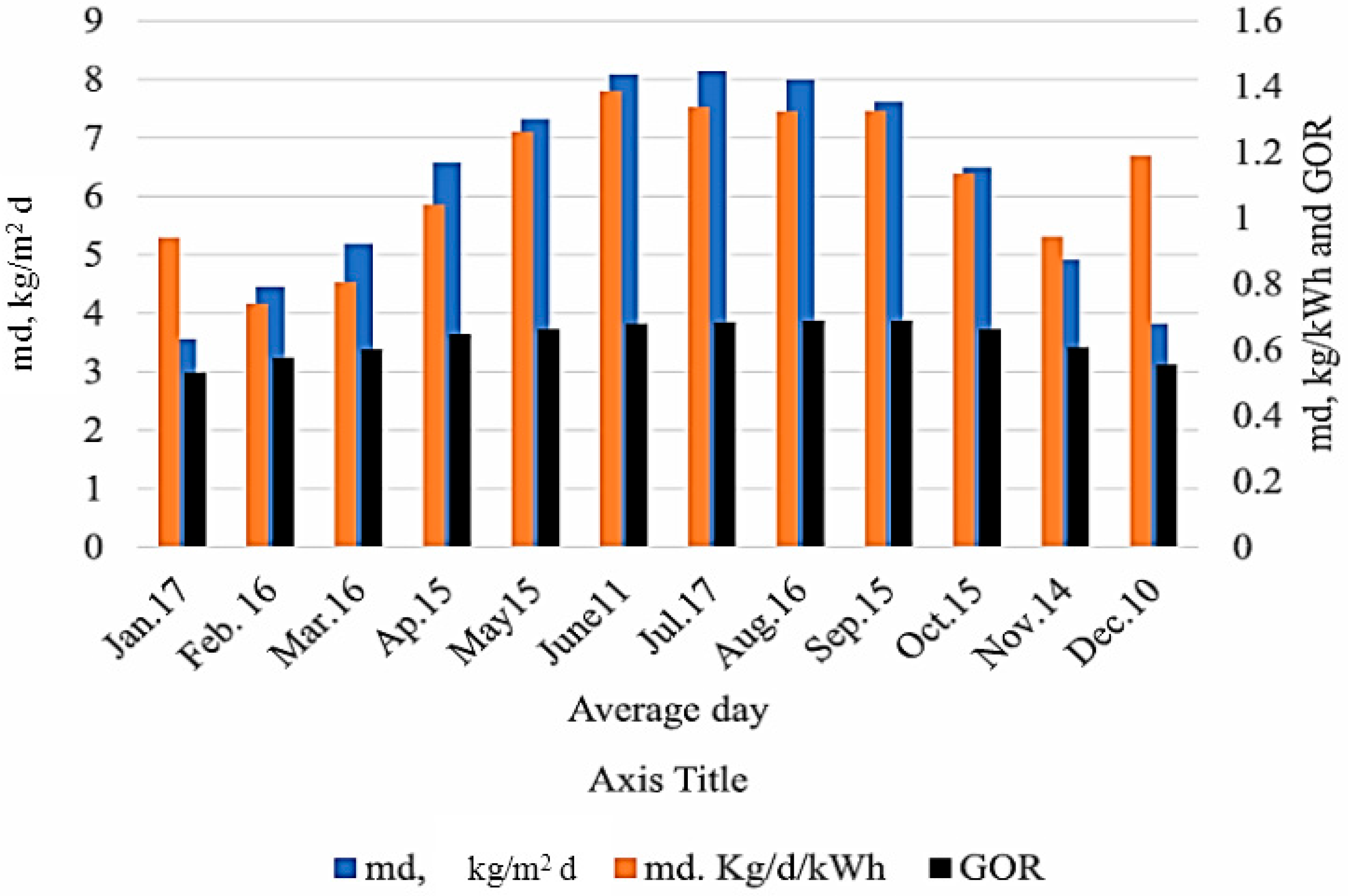

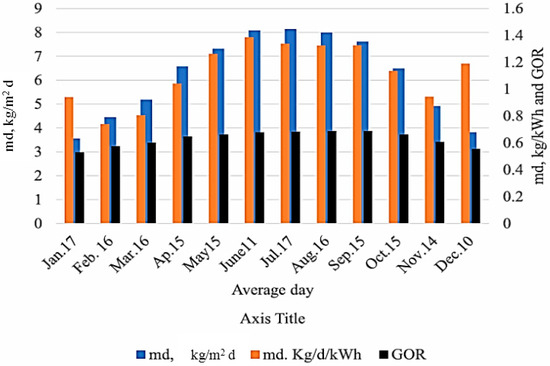

Dayem (2023) [58] designed a new solar natural vacuum desalination (SNVD) system, improving its output by utilizing a natural vacuum produced with an evaporation chamber being 9.8 metres above ground. It employs the waste heat effectively to produce minimal thermal losses, and this is done by condensing the vapor to preheat freshwater which is then heated in a flat-plate collector, the heat source of the evaporation chamber. In the meantime, warm produced water preheats the seawater and leaving brine reheats it prior to it entering the evaporation chamber. The transient simulation was analyzed through a mathematical model to measure the yearly performance of the system, and heat balance equations were used to measure the temperatures of components and the flow rates, whereas the collector area was based on seawater or coolant flow rates, which was assumed. The findings were 6.2 L/m2 day freshwater production, i.e., 1.12 L/kWh solar radiation, an evaporation rate of 2.82%, and gain output ratio (GOR) of 0.63. The peak productivity was in July (Figure 13), which was a result of high exposure to solar radiation and ambient temperatures as well as the increase in the hours of sunlight.

Figure 13.

GOR and system yield against average day [58].

Minaei et al. (2024) [59] investigated a new venturi system integrated with an evacuated tube collector (ETC) used to evaporate and condense simultaneously by analyzing its output under different flows and computing the possible energy-saving potential in terms of reducing the consumption of freshwater pump capacity. In their results, they found that the degree of flow rate enhanced the pressure difference across venturi, consuming the throat pressure, and the maximum water production was 9.02 kg/m2 at 75 LPM and pressure of the system 0.297 bar, which is 37.01% more than the lowest flow rate. Economically, it was found that the cost of production of a unit area of water was USD 0.045 per kilogram. Also, the system attained maximum efficiency (40.87%) when the time of operation of the pumps daily was cut down to 1.5 h on the basis of a 5 min on/15 min off cycling mechanism.

2.5. Parabolic Trough/Concentrator Systems

Hosseini et al. (2018) [60] conducted a preliminary experiment in a solar distillation system as a solar parabolic trough collector and vacuum heat exchanger with a falling film technique during five sunny days in October 2015, 10 a.m.−2:30 p.m. To determine the influence of the environmental qualities, like solar radiation, air temperature, and wind speed, on the day-to-day productivity of the system, the values of all these factors were recorded after every 15 min, and then their impacts on the outcome and productivity of both the concentrator and heat exchanger were evaluated. The findings revealed that there was the greatest impact of solar radiation on the thermal performance of the concentrator through the provision of hot oil to the heat exchanger. Also, the research indicated that low pressure in the heat exchanger had a tremendous impact on the vapor generation in the system. The greatest distillate production was 1.5 kg/m2 d, realized at an average solar radiation of 1227.68 W/m2 and a heat exchanger vacuum that was at 0.5 bar.

Guo et al. (2022) [61] proposed an effective passive solar vacuum tube distiller (P-SVTD) with a heat recovery feature because the raw water vaporization and self-pressurization of high-temperature steam could be coupled up. They investigated the photo-thermal mechanics as well as heat-mass transfer during the functioning of the P-SVTD and formulated a theoretical hypothesis of water yield (msh) and heat recovery rate (HRR). Excessive ratings permitted experimental tests of the desalination performance of the system, the recovered heat temperature and heat recovery rate, and determination of the overall photo-thermal conversion efficiency (HE). It was found that the vapor–liquid interface depth ratio was optimized to 0.9718, as compared to the vaporized-pressurized cavity, and the amount of water produced was exponentially correlated with the solar irradiance on an inclined surface. The P-SVTD obtained an average recovered heat temperature of 74.30 °C, 28.68 and 87.43% heat flow recovery ratio and H E, respectively. The system also exhibited extraordinary desalination capability, where a close to 100% rejection capacity (REJ), a 100.00% decrease in conductivity and a neutral fixed pH value of 7.00 were observed.

Aghakhani et al. (2023) [62] investigated the candidate combination of heating the basin water, cooling the glass window, concomitant heating and cooling, and operation of single-slope solar stills that acted as a vacuum at a domestic scale (about 10-times smaller than prior implementation). In their work, they assessed the performance using two-dimensional numerical simulations, with equations that govern mass, momentum and energy conservation, species transport, radiation, and a model that describes the turbulent flow of fluids. It also used a combination of numerical simulation with a machine learning algorithm, consisting of pressures of 10–60 kPa in the research. The findings indicated that concurrent glass cooling and concurrent water heating offered a maximum performance increase of 152.69%, whereas basin water heating, pressure reduction, and glass cooling on their own improved performance by 112.72, 31.82 and 27.16%, respectively.

A comparative study (Hamida, 2023) [63] of the desalination potential of tubular solar stills with cylindrical and rectangular troughs under vacuum conditions was performed with the help of a two-dimensional model of heat and mass transfer simulation in Comsol Multiphysics. Research studied how the radius of the cylindrical trough, the dimensions of the ribs of the rectangular trough, as well as the elevation of the trough would affect the performance, all with an equal initial volume of seawater. The findings showed that the cylindrical troughs performed much better than the rectangular troughs in terms of productivity of water when located in the middle of the tubular shell. This, however, changed with the trough being positioned nearer to the upper glass cover where the condensation takes place.

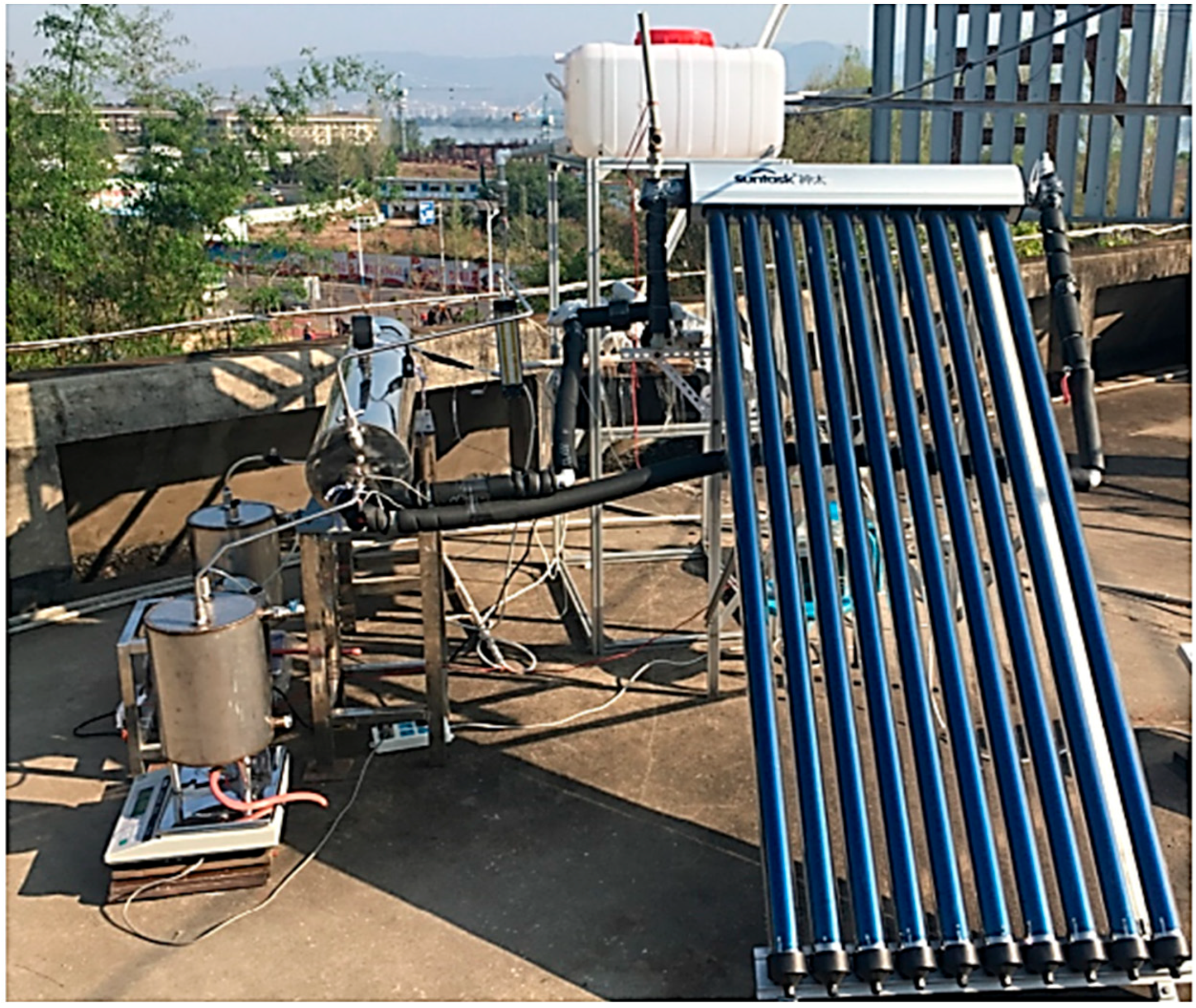

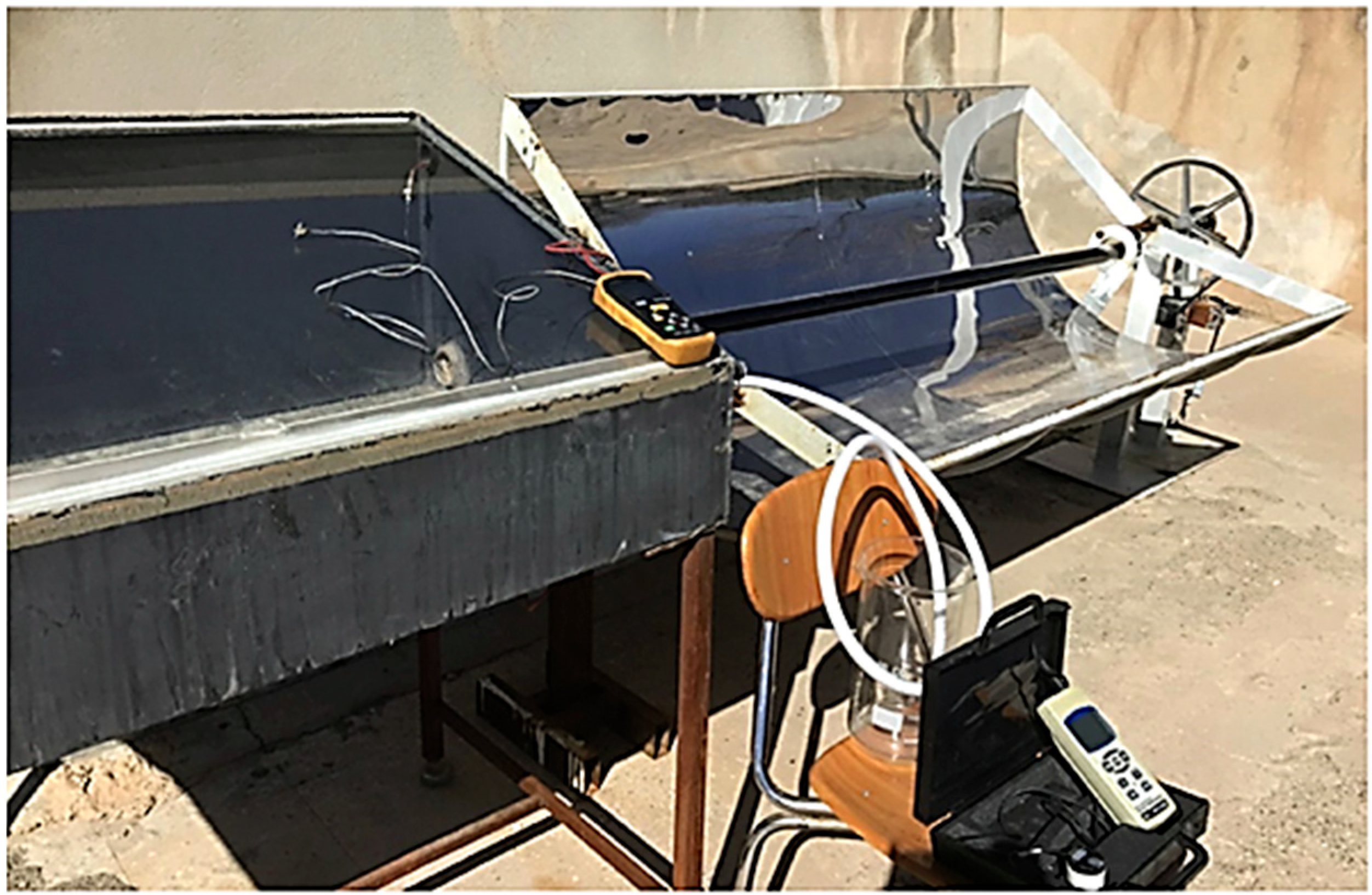

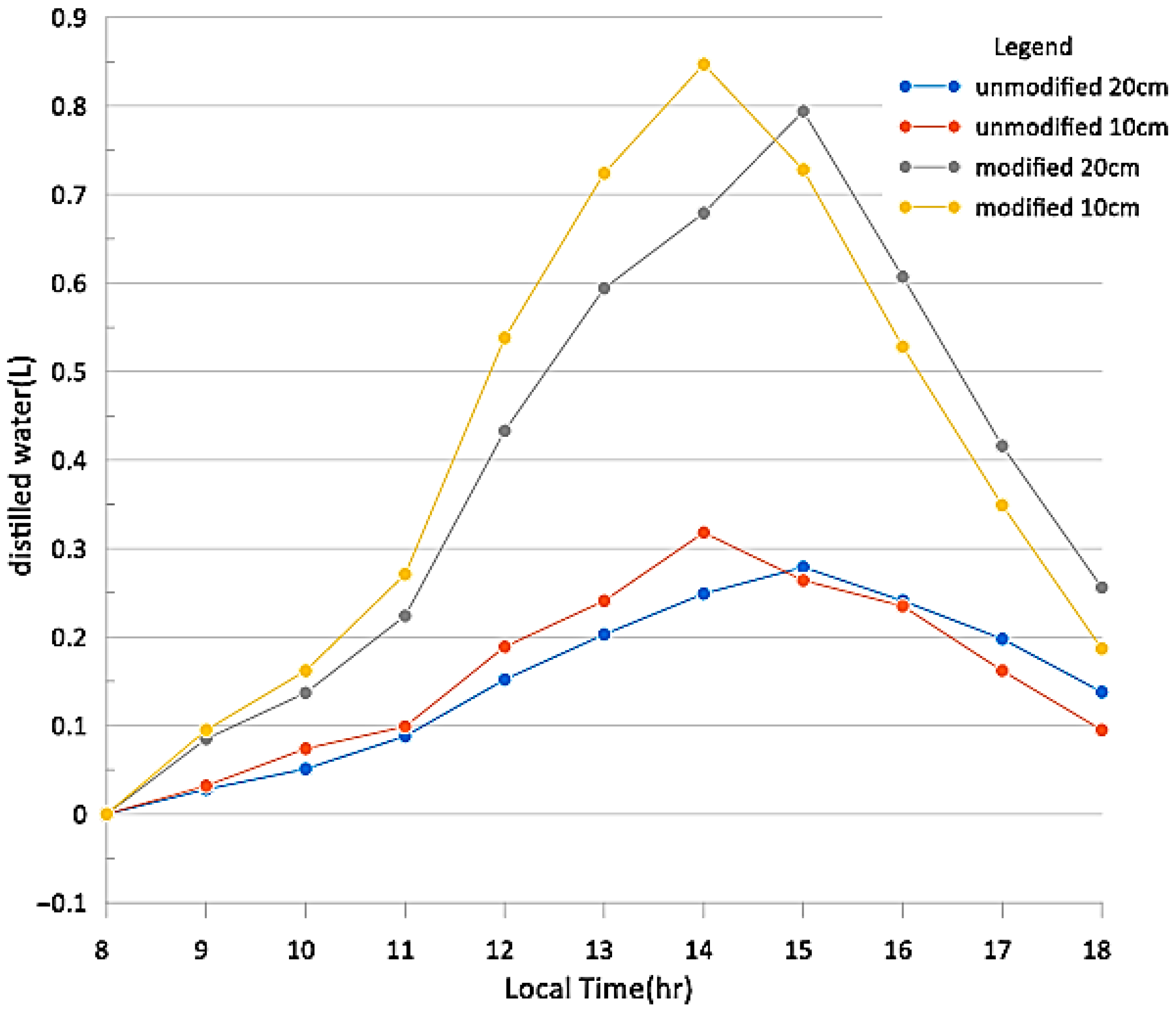

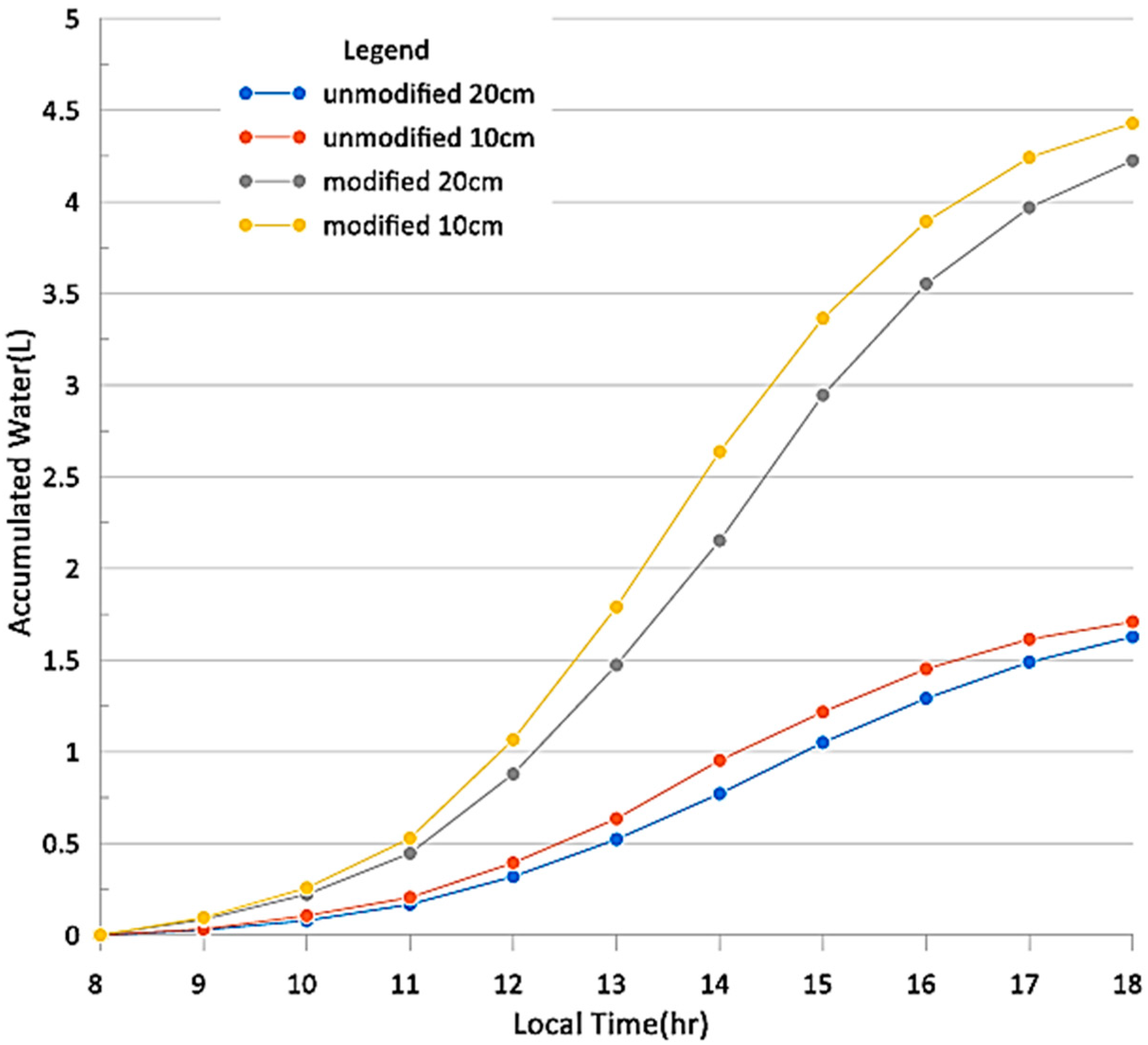

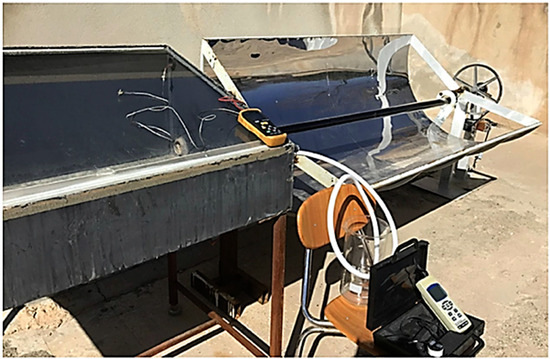

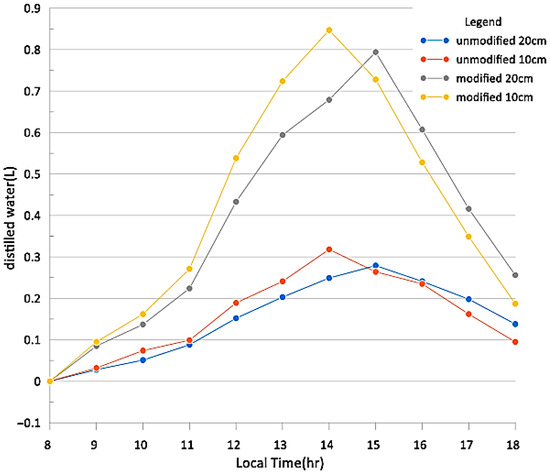

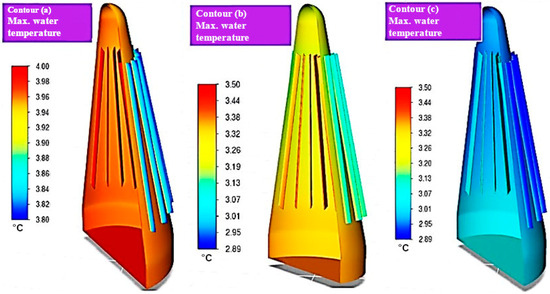

Abdollahi et al. (2025) [64] came up with an innovative solar basin combining a parabolic trough with tracking technology and vacuum tubes, and they eliminated the use of heat exchangers to improve performance (Figure 14). The system in the study was tested in two capacities, as an independent single-basin solar still and an augmented solar distiller. Important variables, such as the water temperature, internal and external glass surface temperatures, and distilled water production, were recorded at 10 cm and 20 cm depth. The findings revealed that there was a considerable rise in overall water yield, 159.6% at 10 cm and 206.8 at 20 cm, on the basis of the parabolic mechanism and integration of the vacuum tube. It is worth noting that the modified system produced a higher percentage (5%) of water than the initial system in terms of desalinated water produced at the 10 cm water level, as compared to the 20 cm water level, suggesting that the modified system was better at lower water levels. Figure 15 and Figure 16 indicate that water productivity and daily yield of water increased with the decrease in depth of water with evolutions of time.

Figure 14.

Image of the experimental configuration [64] (License Number: 6134320434436).

Figure 15.

Distilled water against local time for different scenarios [64] (License Number: 6134320434436).

Figure 16.

Total amount of accumulated water against local time [64] (License Number: 6134320434436).

2.6. Passive/Natural Vacuum Systems

Mohsenzadeh et al. (2022) [65] proposed a new type of floating salt-rejecting solar still-low-vacuum evaporation cell design, where experimental evaluation was conducted in terms of performance. Its design is based on localizing the solar heat to drive interfacial evaporation and using capillary action in moving the water so as to increase evaporation and avoid salt accumulation on the basin surface. Multilayered porous foam and hydrophilic cellulose fabric are used in the tubular basin to make the most of the capillary water supply. The still floats and is submerged in saltwater sources such as oceans by incorporating an external condensing coil into the structured basin. The sunlight beam is covered by a hemispherical acrylic cover that has been designed in a cost-effective manner that collects sunshine on all sides. The system attained a daily productivity of 4.3 L·m−2 d−1 with a distillation percentage efficiency of 35.6% when tested in Melbourne, Australia, in summertime. The life cycle cost was also estimated at 4.7 US cents L−1, which is a very low cost compared to the traditional solar stills.

Wei et al. (2022) [18] built a mathematical model to test the performance of a natural vacuum solar desalination system through the processes of water filling and air releasing, finally comparing estimates with experimental data to validate their model, proving that natural vacuum solar desalination capabilities work. To evaluate the commercial potential and productivity, the study calculated the annual freshwater production, efficiency and cost of the system in 2021 weather conditions in six cities across Asia. The results reflected a lower than 3.52% prediction error using the model, and Jizan was found to be the most promising area, with a capacity of 10.77 kg/h freshwater (55.96 kg/m3h) yield on any given day. In Chennai, the maximum production was 30.86 t/year, and in Muscat, maximum thermal efficiency (79.41%) and total efficiency (76.96%) were achieved in June. Jizan also had the lowest price of freshwater 5.31 USD/t, and, thus, it had high application potential.

Sun et al. (2023) [66] prepared a cost-effective polyvinyl alcohol/carbon black hydrogel (PCH) with a simple synthesis mechanism, with an evaporation rate of 1.54 kg·m−2·h−1 and energy conversion efficiency of 90.5% at 1 sun (1 kW/m). They also suggested a low-vacuum interfacial distillation instrument (SLIDS) propelled by a solar-driven low-vacuum unit that physically isolates evaporation and condensation and takes advantage of low pressure to increase evaporation. The condensate yield rate achieved by the SLIDS was 1.46 kg/m2 h1, which is 2.2-times that of conventional systems in the same condition, with the low-pressure environment contributing a 41.6% increase.

An experimental inquiry was performed by Srivastava et al. (2024) [67] on a heat pipe vacuum/evacuated tube collector, in which water from the atmospheric air was withdrawn through evaporation, which was exchanged to adsorbed water using desiccants. The desiccant was washed by heating on a hot surface, which has been relatively underexplored previously. The condensation of water was conducted in a specially made item referred to as a novel-designed acrylic box, and the amount of water obtained was quantified in a flask or beaker. Silica gel was the desiccant, and the adsorption was conducted in two conditions: in one condition, 1 kg of the desiccant was spread on a copper tray located inside the system adsorbing 137 g of water vapor to give 70 mL of water, whereas the other condition involved the same amount of desiccant spread over a sheet of paper located outside the system, which adsorbed 232 g of vapor to give 175 mL of water. The system reached a maximum efficiency level of 4.9%, exhibiting different performances under different adsorption setups.

2.7. Heat Recovery/Cooling Techniques

Yan et al. (2020) [68] used CFD modelling to predict the impacts of operating vacuum pressure and geometrical parameters on the TSS performance, with an emphasis on vapor flow in the cavity. The simulation findings indicated that water vapor has a higher circulation velocity when operated under vacuum compared with atmospheric conditions, enhancing the rate of yield by more than 50% at vacuum pressure < 60 kPa. Three distinct flow regimes were seen at various thermal Rayleigh numbers RaT, which were identified as steady, periodic, and chaotic flow. Steady flow was seen at low RaT, while periodic or chaotic flow was observed when RaT exceeded 105 and water depth Dw exceeded 0.4r. The flow of vapor in various regimes was validated by visualization experiments. Based on the simulation findings, a correlation was obtained to estimate the Nusselt number for a particular TSS design, which showed a deviation of −7.8−7.5% when compared with independent experimental datasets.

The comparative study of Ma et al. (2022) [69] focuses on two direct solar-heating systems of VMD (the system based on photothermal membrane distillation (VMD-PM) and the system based on flat-plate collector VMD (VMD-FPC)) under the same conditions and reports the results of performance enhancement and their underlying mechanisms of the invented VMD-PM system. They came up with an elaborate model covering aspects, such as solar absorption, pore diffusion, dynamic variations and location-specific solar data into the calculation of the performance. The findings indicated that the VMD-PM system yielded 7.14 Lm−2 distillate in an operation using 22.8 MJ.m−2 solar energy of 10 h, which is 4.1% higher than that of VMD-FPC. The performance gap was increased to 11.7% with heat recovery, which is due to localized heating of the membrane and a better solar-to-thermal conversion. Also, the research proved that a photothermal membrane can alleviate the temperature polarization issue, which further enhances system efficiency.

Ma et al. (2022) [70] studied a highly concentrated desalination module that has a combination of membrane distillation (MD) and a solar flat-plate collector (FPC) installed in a compact unit. They tested a 0.35 m2 unit simulator over 12 h and created stark contrasts between the two forms of desalination water output and energy consumption. Both systems were solar energy limited, and membrane heat conduction losses adversely affected the DCMD-FPC system. The authors discussed the heat recovery and solar concentration methods to reduce such thermal constraints associated with both DCMD-FPC and VMD-FPC. They recommended VMD-FPC over VMD-FPC on the smaller scale of use because of the increased productivity and limited space requirement.

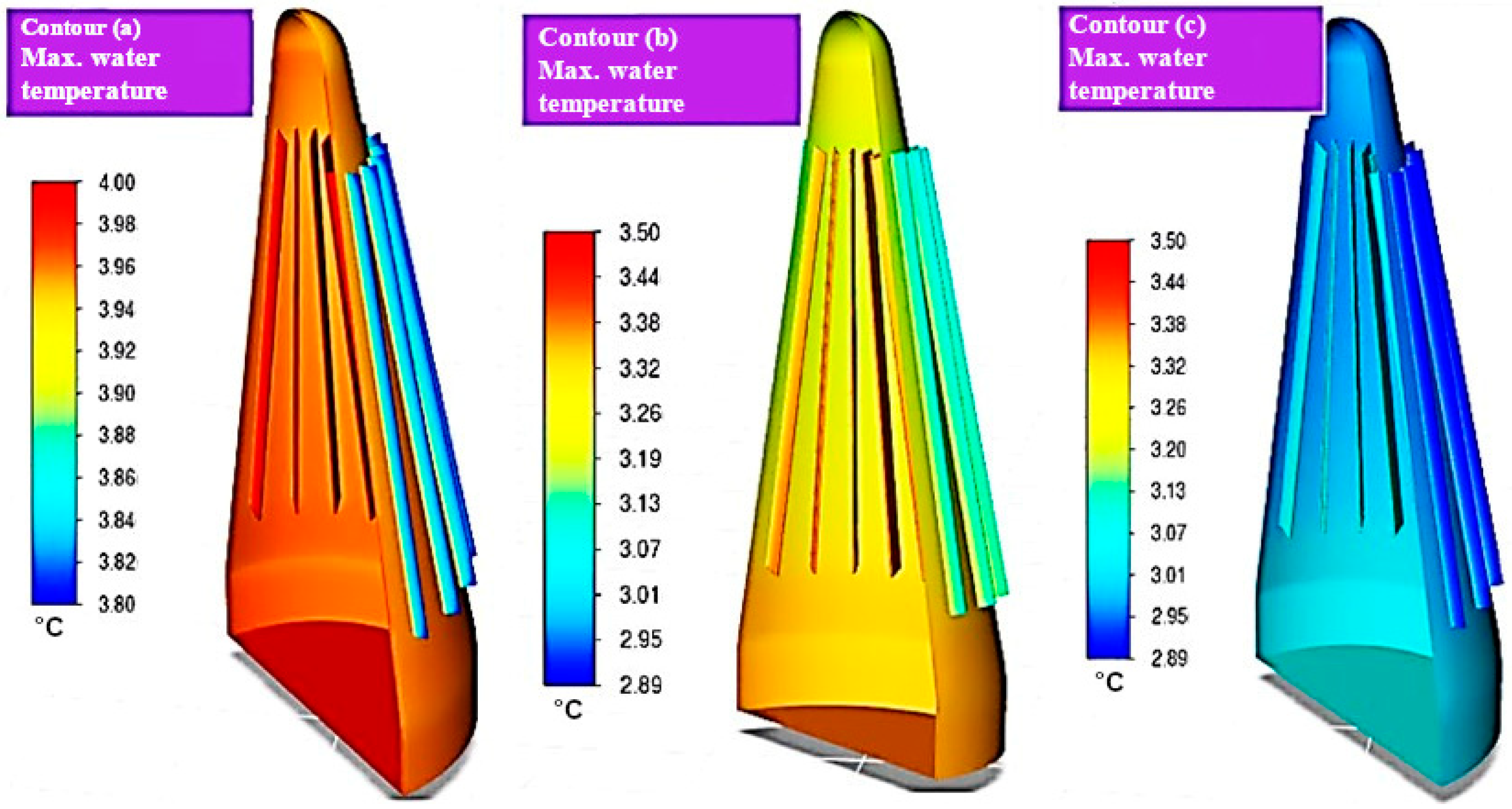

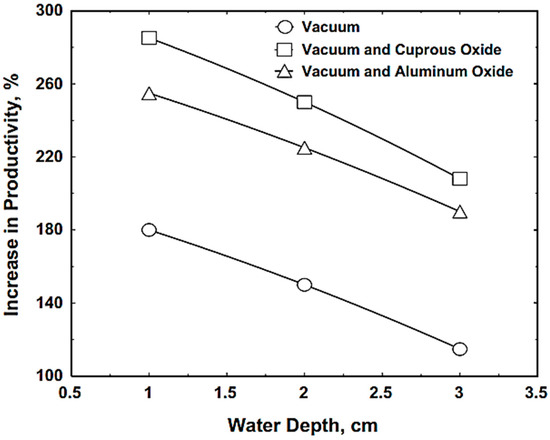

A study based on the transient 3D finite volume method was conducted by Abdullah Reda (2023) [71] to examine the condensation dome of the water desalination plant working in a vacuum system under semi-vacuum conditions. The study was conducted to test the functionality of the dome on geometric and operating conditions, which were uninvestigated before in a patented desalination system. The author initially conducted four fin arrangements through fixed time and then conducted the condensation process simulation in different time steps (1–60 s) under the chosen geometrical and ambient conditions. The findings showed that including just the external fins alone boosted condensation by 24%, whereas with both internal and external fins, the increase became 62% over a base dome with no external or internal fins. It was also noted that keeping both the internal and the external fins parallel to each other increased the performance by 5%, as compared to staggering the fins. The maximum performance of the dome was about 2000 g of water collected in 60 s. There is an inverse correlation between temperature and the rate of condensation of the wall displayed in Figure 17 also supported by the study.

Figure 17.

Wall temperatures in one second (a), twenty-eight seconds (b), and sixty seconds (c) [71].

Saha et al. (2024) [24] designed and tested a high-performance solar-powered water purification system, especially useful in remote areas where there is no grid electricity and freshwater supply. The scientists enhanced a traditional standard double-slope solar still (CSS), whereby a vacuum chamber and paraffin wax (PCM) were introduced as thermal energy containers. Their comparative analysis in the modified solar still (SS) and CSS measured a lot of improvement in productivity, efficiency distillation and exergy efficiency. The modified SS displayed an increase of 22.33% in the hourly rate and 63% in the daily rate (5.46 to 7.03 L/m2) with 28.72% higher vaporization and 22.43% higher exergy yields. Such a study emphasizes that the vacuum condition and the incorporation of PCM are the factors that can increase thermal performance significantly, such that even with low sun irradiation, the system can be operated. Also, economical calculations were found to decrease the unit production costs of water by 41.4% under the modified system and the conventional design.

2.8. CFD/Modeling and Simulation

Computational fluid dynamics (CFD) is extensively used in modeling and simulation to analyze fluid flow, heat transfer, and chemical reactions in complicated systems, allowing engineers to optimize designs and accurately forecast the overall performance [72]. Santosa et al. (2024) [73] considered using data from the works by Omara and Irfan in evaluating the heat transfer of a single-slope solar still (S4) with a vacuum and taking the temperature measurements (Tw, Tg, Ta) to calculate the values of heat transfer to analyze them. The findings revealed that although the disparities in water temperature, glass temperature, and ambient temperature were relatively small, we can see that the difference in heat transfer rates (qr−0 and qc−0) greatly affected the efficiency of condensation, hence giving higher yield in the productivity of distilled water in the study by Omara, as compared to Irfan. Table 1 shows a summary of relevant studies related to the influence of a vacuum on solar still performance.

Table 1.

A summary of relevant studies related to influence of vacuum on solar still performance.

3. Comparative Study

The present review provides a detailed inspection of vacuum-enhanced solar still systems and their chances to improve the overall performance of the traditional systems. The overall findings include the understanding that the vacuum-assisted solar stills dramatically increase freshwater productivity, with multi-effect tubular stills under vacuum (40 and 60 kPa) showing a 200% improvement (7.15 kg/m2) (Chen and Xie (2022) [51]) if compared to operation under atmospheric ventilation. Also, the nanoparticle-enhanced systems (e.g., Cu2O) showed up to a 133.6% improvement (Chen and Xie (2022) [51]). The vacuum membrane distillation systems have large permeate fluxes (5.9 to 11.1 kg m−2 h−1) (Bamasag et al. (2021) [37]) and can successfully deal with membrane fouling challenges. Passive vacuum designs can minimize the price of energy to USD 0.0113/kg (Wei et al. (2021) [57]), whilst geothermal integration increases the productivity by 305%. Despite these developments, there are cases of high costs of acquisition, system complexity, and their limitation to scale. Table 2 summarizes a comparison of the performance of major vacuum-enhanced technologies applied to solar stills.

Table 2.

The comparative performance of key vacuum-enhanced solar still technologies.

4. Influence of Vacuum Technologies on Solar Still Performance: A Critical Analysis

This review is a critical analysis of the groundbreaking effects of vacuum technologies in the performance of solar stills through a systematic examination of the technologies in facilitating the enhancement in the evaporation process, thermal losses and the alleviation of the operational difficulties.

Referring to the incorporation of nanofluid, such as Cu2O and Al2O3-based vacuum-enhanced solar stills, a significant boost in the thermal competence and freshwater productivity and relevant advantages from economic and environmental aspects were noticed, which led to a clear reduction in the freshwater production cost. Also, the existence of nanoparticles can raise the evaporation surface area and, therefore, enhance thermal regulation, and maximizing efficacy, conceptually, improved the thermal conductivity of nanofluids and can increase heat absorption rates, while vacuum conditions can reduce the boiling point of water, smoothing evaporation at mitigated temperatures, which defines the mechanism. The relevant investigations ascertained these improvements, where nanoparticles are added to the vacuum to increase productivity further (e.g., 133.6 with Cu2O) due to better thermal conductivity. This improvement lessened the water productivity cost to USD 0.0113/kg (Wei et al. (2021) [57]), making it a practical option for water-shortage regions. In turn, this has introduced a feasible technology with economic feasibility for many regions struggling with water scarcity. Furthermore, the use of nanofluid in vacuum-enhanced solar stills led to an enhancement in energy absorption and transfer efficiency, lowering the specific energy consumption for the desalination process. Interestingly, this has introduced perspective environmental merits so as to reduce the greenhouse gas emissions and carbon footprint of freshwater production, in addition to maximizing the use of solar resources. In other words, the utilization of nanofluids can boost the heat transfer properties with reduced reliance on additional energy inputs. The introduction of nanofluid-enhanced vacuum solar stills also has social advantages. On top of this, the deployment of this technology can lead to affordable sources of freshwater, specifically in arid regions. Statistically, vacuum operation produces a much-reduced boiling point of water, greatly increasing the rate of evaporation, as witnessed with multi-effect tubular stills with 2-times increased yields operating at 40–60 kPa versus atmospheric and through the reduction in evaporative losses due to slowed convection. Trade-offs are, however, exhibited during analysis: the VMD systems, which use high permeate fluxes (e.g., 5.9–11.1 kg/m2 h), are prone to significant membrane fouling and use high-energy requirements, whereas the passive vacuum systems only have low energy demand, but they experience issues when scaled up. Also, geothermal-integrated types produce unbelievable gains (e.g., 305% output increase) through the stabilization of condensation temperatures but require very advanced hybridization.

Critical gaps have also been observed in this study, and one of them is the absence of standardization in the optimization of vacuum pressure and inadequate durability data of the system to be used in the real world, especially when it comes to large-scale implementation. Notwithstanding these obstacles, the combination of vacuum technologies and heat recovery, novel materials and hybrid energy systems appears as a good prospective paradigm, as it provides another way out to meet the set limitations of ordinary solar stills and conforms to the sustainable desalination objectives. Therefore, future research should further revolutionize desalination processes and improve the economic feasibility of this technology, which can mitigate water scarcity, enhancing public health, and upgrade quality of life and community, in addition to raising a sustainable future for water management. To attain these goals, there is a clear request to focus on optimizing the configurations of vacuum-enhanced solar stills in addition to overcoming the associated challenges, such as membrane fouling, long-term stability, overall costs and system complexity, assuring their usefulness and broader adoption to address the global water shortage. This discussion highlights the planned future study that requires covering the aspect of techno-economic viability and modular scale up and adaptive control strategies as a means of unleashing the full potential of vacuum-enhanced solar stills.

5. Conclusions

This is an in-depth review to chase the improvements made in vacuum technologies to enhance the performance of solar stills, in addition to focusing on the associated findings, associated difficulties and the new opportunities. In accordance with the systematic review of experimental and theoretical studies, the following conclusions are made:

- Vacuum-assisted solar stills exhibit a 30–305% increase in the production of freshwater as per conventional systems, mainly because of the lowered boiling points and the inhibition of convective heat dissipation.

- The permeate flux of vacuum membrane distillation is 5.9–11.1 kg/m2 h, which, however, has membrane fouling and consumption control as a major obstacle.

- The deposition of nanoparticles (e.g., Cu2O, Al2O3) under vacuum conditions offered a 133.6% evaporation increase, in addition to the improvement in thermal conductivity and radiative absorption.

- The multi-effect vacuum solar stills of staged evaporation introduced 2-times the freshwater production of 7.15 kg/m2 at optimum pressure 40 kpa to 60 kPa.

- Referring to the geothermal-integrated vacuum stills, a 305% increase in freshwater productivity was observed since the condensation temperatures can be stabilized.

- Despite the issue of scalability, natural vacuum systems have fewer energy requirements, with a 1.46 kg/m2 h yield at a reduced water production cost of USD 0.0113/kg.

- The performance ratios (GOR = 3.24) are enhanced by internal heat exchangers and recirculation of brine and, thus, limit the waste of thermal power.

- Vapor flow simulations (CFD) under vacuum confirm flow behavior, which supports the enhancement in the design of 50% efficiency tubular stills.

- Although it improves performance, large-scale adoption is undermined by high initial costs, maintenance of membranes and durability.

Interestingly, the current review has a clear contribution to sustainability as it covered a number of aspects. These include the topic of addressing water scarcity by providing inventive technologies to improve the water productivity of vacuum-enhanced solar stills in dry regions. In this regard, the use of renewable energy has leveraged solar energy to power desalination processes, which, in turn, reduces the dependence on non-renewable resources. The economic viability of vacuum-enhanced solar stills has been elucidated, which introduced this technology as a feasible desalination process to access freshwater. Indeed, the employment of this technology would elevate the practice of sustainable desalination with a progressive investment in renewable energy. Furthermore, the incorporation of nanoparticle technologies has improved the overall performance, which elucidated an advanced integrated technology towards the practice of sustainability. Thus, the introduction of these topics throughout this review can establish a clear association with sustainability, while bringing it into line with its targets of resolving sustainability challenges and upgrading integrated methodologies to sustainable development.

6. Further Enhancements and Accompanying Challenges

The future direction of research to extract the most out of vacuum-integrated solar stills is to maximize the system design, enhance the efficiency of materials that make up the system, and establish renewable energy synergies with the system. The following points are essential for improvements in the performance, scalability, and economic reliability of vacuum-integrated solar stills.

- The overall energy efficiency can be upgraded by using PVT collectors to produce both power and heat.

- Geothermal cooling or wind-driven vacuum pumps coupled with vacuum solar stills can keep the still running all the time, as solar is a non-base-load energy source.

- The materials have better thermal conductivity and non-fouling capabilities that have the potential to increase the evaporation rates by 20–30% compared to conventional nanoparticles.

- Combining PCMs and vacuum insulation would allow thermal fluctuations to be stabilized, which would continue to extend productive time during non-sunlight hours.

- To achieve a better yield, the vacuum (e.g., 20–60 kPa) is dynamically controlled by AI sensors according to the sun intensity and feed water salinity.

- Predictive-based algorithms can help schedule the cleaning of membranes in advance.

- Modular, compact stills configured with common vacuum chambers have the potential to reduce costs, without sacrificing large throughput (e g., 10–15 kg/m2 d).

- Vacuum stills deployed on still water (water bodies, oceans and lakes) can use natural hydrostatic pressure to transmit the vacuum passively.

- By using the latent heat of discharged brines, efficiency gains of the resource between 15 and 25% could be achieved.

- It can be more economically viable by being integrated with sources of industrial waste heat (e.g., power plants).

Although these improvements are encouraging, challenges of implementation remain high in many aspects: technical, economic and environmental. This indicates that some challenges need to be mitigated in order to achieve large-scale adoption.

- Vacuum mechanical pumps use up to 30% of the energy of the whole plant and cancel out efficiency improvements. Passive vacuum designs (e.g., hydrostatic, venturi-based) have low pressure ranges (<50 kPa).

- The main drawbacks to the vacuum membrane distillation systems include salt scaling and organic fouling that lower permeate flux to 20–40% over time. Specifically, the overall costs can be increased due to cleaning and replacement practices.

- The use of high-tech nanomaterials (e.g., graphene) and corrosive-resistant alloys expands capital costs by 30–50%. In this regard, their stability in a vacuum and at high temperatures has not been demonstrated yet.

- Multi-effect and hybrid systems involve tight control of pressure, temperatures, and flow rates; thus, a high grade of operation is required.

- Field-scale tests showed 50% to 100% yields lower than those noted in the lab because of ideal conditions. Large-scale deployments are subject to variable solar exposure and feed water.

- The levelized costs of water (USD 0.01–0.05/L) are too high compared to traditional forms of desalination (e.g., reverse osmosis at USD 0.002–0.01/L), which discourages investment.

- Discharge of brine in high-recovery processes poses a threat to the ecosystem.

- Leaching of nanoparticles into a distillate is a safety concern.

Author Contributions

M.A.A.-O.: Conceptualization, writing—original draft, writing—review and editing, visualization, formal analysis, supervision, project administration. F.L.R.: Writing—original draft, conceptualization, visualization, formal analysis. H.A.A.: Visualization, formal analysis. S.S.A.-M.: Visualization, formal analysis, resources. M.S.: Formal analysis, resources. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study.

Acknowledgments

The authors gratefully acknowledge the support of Middle Technical University and Al-Naji University, which sponsored this research as part of its commitment to advancing scientific knowledge and fostering academic excellence.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclatures

| Symbol | Definition |

| CFD | Computational Fluid Dynamics |

| CSS | conventional solar still |

| Cu2O | Cuprous Oxide |

| DCMD | Direct Contact Membrane Distillation |

| Dw | Water Depth |

| ETC | Evacuated Tube Collector |

| FPC | Flat-Plate Collector |

| GOR | Gained Output Ratio |

| Gr | Grashoff Number |

| HE | Photo-Thermal Conversion Efficiency |

| HRR | Heat Recovery Rate |

| LDAC | Liquid Desiccant Air Conditioning |

| LPM | Liters Per Minute |

| MEDS | Multiple-Effect Diffusion Solar Still |

| MFR | Membrane Flux Rate |

| MSSV | Multi-Stage Tubular Solar Still under Vacuum |

| PCM | Phase Change Material |

| PR | Performance Ratio |

| RaT | Thermal Rayleigh Number |

| REJ | Rejection Capacity |

| RR | Recovery Ratio |

| P-SVTD | Passive Solar Vacuum Tube Distiller |

| PVT | Photovoltaic-Thermal |

| SHC | Solar Heat Collection |

| SiO2 | Silicon Dioxide |

| SNVD | Solar Natural Vacuum Desalination |

| STEC | Specific Thermal Energy Consumption |

| S-VMD | Submerged Vacuum Membrane Distillation |

| TSS | Tubular Solar Still |

| Tw | Wall Temperature |

| vavg | Average Vapor Flow Velocity |

| VMD | Vacuum Membrane Distillation |

| ZnO | Zinc Oxide |

References

- Hussein, A.K.; Rashid, F.L.; Abed, A.M.; Al-Khaleel, M.; Togun, H.; Ali, B.; Akkurt, N.; Malekshah, E.H.; Biswal, U.; Al-Obaidi, M.A.; et al. Inverted solar stills: A comprehensive review of designs, mathematical models, performance, and modern combinations. Sustainability 2022, 14, 13766. [Google Scholar] [CrossRef]

- Rashid, F.L.; Al-Obaidi, M.A.; Hammoodi, K.A.; Mahdi, A.J.; Kadhim, S.A.; Chaichan, M.T.; Parveen, R.; Eisapour, M.; Kouki, M.; Nazari, S.; et al. Innovations and ongoing advancements of the wick type solar still: A review. Results Eng. 2024, 24, 103049. [Google Scholar] [CrossRef]

- Shareef, A.S.; Rashid, F.L.; Junedy, Z.R. A Review of Recent Advances in Enhancing the Performance of Solar Still Energy Systems and Guidelines for Future Prospects. Libr. Prog.-Libr. Sci. Inf. Technol. Comput. 2024, 44, 812–827. [Google Scholar]

- Khalaf, M.O.; Özdemir, M.R.; Sultan, H.S. A Comprehensive Review of Solar Still Technologies and Cost: Innovations in Materials, Design, and Techniques for Enhanced Water Desalination Efficiency. Water 2025, 17, 1515. [Google Scholar] [CrossRef]

- Rashid, F.L.; Kaood, A.; Al-Obaidi, M.A.; Mohammed, H.I.; Alsarayreh, A.A.; Al-Muhsen, N.F.; Abbas, A.S.; Zubo, R.H.; Mohammad, A.T.; Alsadaie, S.; et al. A review of the configurations, capabilities, and cutting-edge options for multistage solar stills in water desalination. Designs 2023, 7, 67. [Google Scholar] [CrossRef]

- Agrawal, A.; Rana, R.S.; Srivastava, K. Heat transfer coefficients and productivity of a single slope single basin solar still in Indian climatic condition: Experimental and theoretical comparison. Resour.-Effic. Technol. 2017, 3, 466–482. [Google Scholar] [CrossRef]

- Welepe, H.J.; Günerhan, H.; Bilir, L. Humidifying solar collector for improving the performance of direct solar desalination systems: A theoretical approach. Appl. Therm. Eng. 2022, 216, 119043. [Google Scholar] [CrossRef]

- Hussein, A.K.; Rashid, F.L.; Rasul, M.K.; Basem, A.; Younis, O.; Homod, R.Z.; Attia, M.E.H.; Al-Obaidi, M.A.; Hamida, M.B.B.; Ali, B.; et al. A review of the application of hybrid nanofluids in solar still energy systems and guidelines for future prospects. Sol. Energy 2024, 272, 112485. [Google Scholar] [CrossRef]

- Kabeel, A.E.; El-Samadony, Y.A.F.; El-Maghlany, W.M. Comparative study on the solar still performance utilizing different PCM. Desalination 2018, 432, 89–96. [Google Scholar] [CrossRef]

- Sahota, L.; Tiwari, G.N. Effect of Al2O3 nanoparticles on the performance of passive double slope solar still. Sol. Energy 2016, 130, 260–272. [Google Scholar] [CrossRef]

- Elango, T.; Kannan, A.; Murugavel, K.K. Performance study on single basin single slope solar still with different water nanofluids. Desalination 2015, 360, 45–51. [Google Scholar] [CrossRef]

- Almuhanna, E.A. Evaluation of single slop solar still integrated with evaporative cooling system for brackish water desalination. J. Agric. Sci. 2014, 6, 48. [Google Scholar] [CrossRef]

- Al-Garni, A.Z. Enhancing the solar still using immersion type water heater productivity and the effect of external cooling fan in winter. Appl. Sol. Energy 2012, 48, 193–200. [Google Scholar] [CrossRef]

- Rajamanickam, M.R.; Ragupathy, A. Influence of water depth on internal heat and mass transfer in a double slope solar still. Energy Procedia 2012, 14, 1701–1708. [Google Scholar] [CrossRef]