Abstract

Amid global efforts to reach carbon neutrality, quantifying the cradle-to-gate carbon footprint of panel kitchen cabinets is vital for the transformation of China’s furniture industry to low carbon emissions. This study aims to quantify and compare the cradle-to-gate carbon footprints of three L-shaped panel cabinets made of different materials and to identify the most effective carbon reduction strategies for the Chinese furniture industry. The emission factor method proposed by the Intergovernmental Panel on Climate Change (IPCC) was utilized. The results revealed significant differences in the carbon footprints among the three cabinet products. Specifically, Product A, featuring a DuPont stone countertop from the United States and domestically produced double-sided decorative door panels, exhibited the highest carbon footprint which was 998.5 kgCO2eq. Product B, with an Italian natural marble countertop and single-sided acrylic door panels, had the lowest carbon footprint which was 610.7 kgCO2eq. The carbon footprints indicated that key stages such as cabinet bodies, countertops, hardware, and cabinet doors were substantial contributors. Raw material production and processing emerged as the primary sources of carbon emissions, with countertop transportation also contributing significantly. Based on the results, this paper proposed several carbon reduction suggestions. These include optimizing material selection, enhancing energy efficiency in raw material production and processing, optimizing transportation methods, emphasizing the carbon reduction potential of hardware components, and strengthening carbon footprint monitoring and management.

1. Introduction

Against the background of severe global climate change today, reducing greenhouse gas emissions and achieving green and low-carbon development have become the common focus of governments, enterprises, and academia worldwide [1,2,3]. As one of the largest furniture producers and consumers in the world, the sustainable development of China’s furniture industry is not only crucial for domestic economic and environmental harmony but also has a profound impact on global carbon reduction targets [4]. According to statistics, China’s furniture production has continued to climb in recent years, ranking among the top in the world [5,6]. The prosperity of this industry relies not only on abundant domestic timber resources but also on a large amount of imported international resources such as North American lumber and European countertops [7,8], forming a diversified and globalized supply chain system. However, with tightening resource constraints and increasing awareness of environmental protection, balancing the relationship between industrial development and environmental protection has become an urgent issue to be addressed [9].

Against this background, carbon footprint analysis of furniture products, especially panel furniture, which occupies a large market share, is particularly important and urgent. Carbon footprint, as an important indicator for measuring greenhouse gas emissions throughout the entire product lifecycle, can comprehensively reflect the environmental impacts at various stages from raw material acquisition, production and manufacturing, transportation and distribution to use and disposal [10,11]. Although carbon footprint research has been widely applied in various industries in recent years due to the global focus on climate change, analysis of carbon footprints in the furniture industry, especially for panel furniture, is still insufficient. Most studies have focused on individual solid wood and wood-based products [2,3,12,13,14]. This is because wood, as a primary forest product, possesses a significant carbon storage capacity, giving it environmental advantages unmatched by other materials. Panel furniture, with its low cost, diverse styles, and ease of processing, is popular among consumers. However, its energy consumption, waste emissions, and the sustainability of raw material sources during production have not yet been fully scientifically assessed [15,16]. Therefore, in-depth exploration of the carbon footprint of panel furniture, especially panel cabinets, is of great significance for guiding the industry to reduce energy consumption and emissions and promote green transformation.

Reviewing existing research, scholars at home and abroad have conducted some work in the field of furniture carbon footprints, mainly focusing on carbon storage and emission assessments of wood and wood-based panel materials, energy consumption analysis during furniture production processes, and so on. However, these studies mostly concentrate on single links or a certain type of material, lacking systematic analysis from the perspective of the entire supply chain [17,18,19]. In addition, although there have been preliminary explorations of carbon footprint optimization strategies at the process level, a complete and highly operable methodology has not yet been formed, especially for products with high customization levels and complex production processes such as panel cabinets. The depth and breadth of research need to be improved [20].

Despite the growing number of LCA studies on furniture, none have focused specifically on panel kitchen cabinets in China, particularly comparing material combinations under identical geometric and functional conditions. In view of this, this study aims to fill the gap in the field of carbon footprint analysis of panel cabinets. By systematically measuring and analyzing its cradle-to-gate carbon footprint contribution, it explores in depth the emission reduction potential of raw material acquisition and processing, transportation, and factory production. This paper will comprehensively utilize the carbon emission factor method provided by IPCC 2006 Guidelines for National Greenhouse Gas Inventories [21], combined with field research and data analysis, to propose targeted emission reduction suggestions, aiming to provide scientific evidence and practical paths for promoting green and low-carbon development in the panel cabinet and even the entire panel furniture industry.

2. Cases and Methods

2.1. Common Construction and Materials for Panel Cabinets

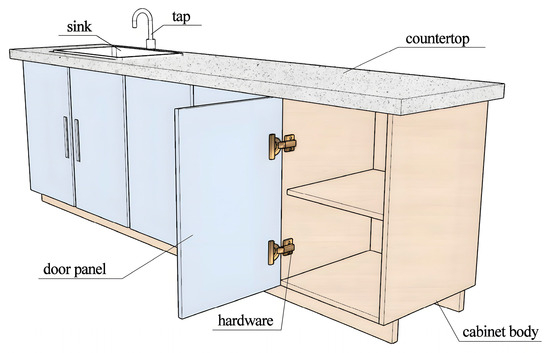

Panel-type kitchen cabinets, as kitchen furniture primarily made of engineered wood, rely heavily on whole-home customization enterprises for their production and manufacturing in China, forming a significant part of these enterprises’ main business. Based on their overall planar shapes, kitchen cabinets on the market can be mainly classified into four styles: straight-line, L-shaped, U-shaped, and island-type. Modern minimalist-style cabinets, with their clean and bright designs, have become the first choice for most consumers [13,22,23]. In terms of structural composition, kitchen cabinets can be subdivided into four major components: cabinet body, door panel, countertop, and hardware, as shown in Figure 1.

Figure 1.

Basic structure of the cabinet.

The cabinet body, or the box part of the kitchen cabinet, is mostly made of veneered particleboard by whole-home customization enterprises in the market, with only a very small number using plywood or solid wood. The substrate of these boxes is usually 18 mm thick particleboard, covered with melamine paper veneer on the surface.

As the visual focus of kitchen cabinets, the shape and color of the door panel often become important considerations for consumers when making a choice. Therefore, the materials and processing techniques of door panels exhibit rich diversity, including but not limited to double-sided decorative door panels, PVC membrane-pressed door panels, acrylic door panels, colored glass door panels, and solid-wood door panels, satisfying the personalized needs of different consumers.

The countertop, located on top of the base cabinets, serves as the primary area for food preparation, cooking, and placing kitchen utensils. The choice of countertop not only affects the practicality of the kitchen cabinets but also has a significant impact on their aesthetics. Common countertop materials include engineered stone, marble, slate, and other natural stones, each with its unique characteristics, providing consumers with a variety of options.

Additionally, there are numerous types of hardware accessories for kitchen cabinets, which can be roughly divided into seven categories based on their functions: hinges, drawer slides, supports, hanging codes, adjustable feet, shelf supports, and handles. Even within similar products, there are certain differences and characteristics. The selection and combination of these hardware accessories play a crucial role in enhancing the overall quality and user experience of kitchen cabinets.

2.2. Research Objects and Functional Units

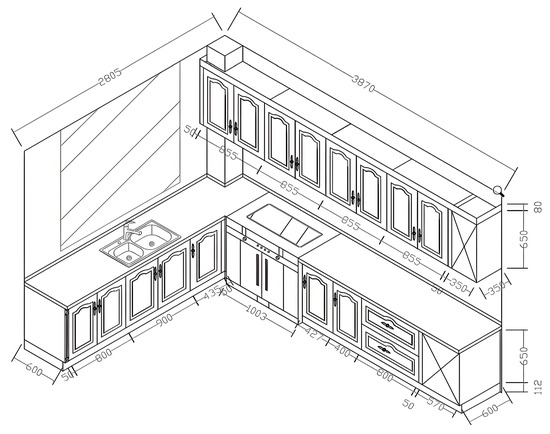

In this study, three sets of L-shaped kitchen cabinets of the same size were selected as the research objects, with the aim of calculating the carbon footprint of their main production stages, as shown in Figure 2. The functional unit for all three sets of cabinets was uniformly set as one set of cabinets. The total linear meter of this set of cabinets is 6.675 m, as shown in Figure 2. The measurement unit for carbon footprint was (kgCO2eq/set).

Figure 2.

L-shaped film pressure door cabinet product’s three-dimensional structure diagram.

Although these three sets of cabinets were consistent in size, there were significant differences in material selection. Each set of cabinets included the following components: four double-door wall cabinets, one sink cabinet, one stove cabinet, one double-door base cabinet, two drawers, three single-door base cabinets, as well as one wrapped wall cabinet and one wrapped base cabinet. Apart from differences in door panel and countertop styles, the three sets of cabinets were identical in other structures and sizes. Specifically, the door panel materials were domestic double-sided decorative door panels, PVC membrane-pressed door panels, and single-sided acrylic door panels, respectively. In terms of countertop substrates, the cabinets with domestic double-sided decorative door panels were equipped with countertops made of American Dupont stone, which is a polymer mineral-filled composite material developed by the American company DuPont in the 1970s. Its main components include methyl methacrylate (MMA), natural mineral powder, and pigments. The PVC membrane-pressed door panel cabinets used Italian natural marble countertops, and the single-sided acrylic door panel cabinets were equipped with Spanish Silestone countertops, which is a quartz-based artificial stone developed by the Spanish company Cosentino S.A. (Cantoria, Spain) in 1989, primarily composed of natural quartz crystals and synthetic resin. For the convenience of subsequent discussion, the three sets of cabinets were labeled as Products A, B, and C, with specific information provided in Table 1. Through the above description, the definition and characteristics of the research objects were clearly presented, providing a solid foundation for subsequent carbon footprint calculations.

Table 1.

Material differences between the four parts of the three cabinets.

2.3. Research Method

The method used to calculate carbon footprint is the emission factor method proposed by the IPCC, which is currently the most widely applied [21]. The carbon emission factor refers to the amount of greenhouse gases generated per unit mass of a substance, expressed in terms of carbon dioxide equivalents and related activity units. Carbon emissions are calculated based on defined operational units and collected data, with the estimated carbon emissions for a particular emission item being the product of the amount of energy input used and the emission factor. The formula for calculating carbon footprint is:

CEi = ADi · EFi

In the formula, CEi means carbon footprint; ADi means the activity level of greenhouse gas emissions caused by substances; EFi means carbon emission factors.

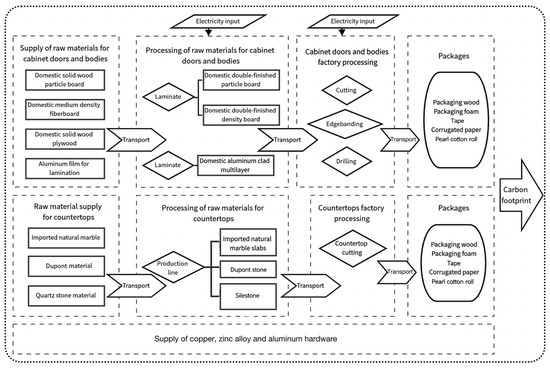

2.4. System Boundary

The system boundary defined in this study is “from cradle to gate”, which specifically covers the entire process of cabinet production from raw material acquisition to the end of production, as shown in Figure 3. The carbon emissions calculations for cabinet bodies, door panels, and countertops are mainly divided into three stages: raw material acquisition and processing, inter-factory transportation, and processing by panel furniture enterprises. The carbon emissions generated by processing equipment in these three stages only consider those from the power supply of the equipment. Within this framework, the raw material acquisition stage involves the acquisition of base material raw materials and the total carbon emissions caused by the production and transportation of artificial board base materials during processing. The production process is further broken down into processes such as material cutting, edge sealing, drilling, and other stages. The electricity consumption in this stage mainly comes from the various equipment used in the above-mentioned production processes. Packaging is treated as a separate stage. The carbon footprint of packaging processes primarily comes from the input of packaging materials.

Figure 3.

System boundaries of the three cabinet products.

It is worth noting that among the raw materials, in addition to artificial board blanks, the mass proportions of other materials are relatively small and their sources are diverse and complex. In view of this, when considering the upstream raw material transportation stage, this study focuses only on the transportation of artificial board blanks, while ignoring the transportation impact of other materials to ensure a refined and targeted analysis. Furthermore, in the production and processing stage of panel cabinets, the calculation of electricity consumption mainly revolves around core processing equipment or production lines. As for cabinet accessories such as metal pull-out baskets, range hoods, sinks, microwaves, and ovens, since they do not belong to the core scope of this study, they are not included in the carbon emission calculations to maintain a clear research boundary and focus.

2.5. Data Collection

The data for this study was sourced from a customized furniture enterprise, specifically from three sets of L-shaped cabinets of the same size but different materials customized by the same client. In order to ensure that the model provides practical reference value for calculating the carbon footprint of the enterprise’s cabinet products, the basic data for the raw material usage part of this model is based on the enterprise’s product-related documents such as the “Material Cutting Details” “Packaging Plan” “Panel Processing Scheduling Form” and “Hardware Accessories Details” combined with online and offline survey data to estimate the total raw material usage. The raw material acquisition data was sourced from the company’s internal inventory, and the production data was collected from the factory site, as shown in Table 2.

Table 2.

List of activity data for three cabinet products.

The carbon emission factors mentioned in the text were all obtained from data searches in SIMAPRO 9.5 or through corresponding modeling to derive emission factors for various substrates. To facilitate subsequent calculations, modeling was conducted using the number of substrate blocks as the unit of activity data, with the carbon emissions generated per block of substrate set as the activity factor for that substrate. The dimensions of the substrates for cabinet doors are all 2800 mm × 2070 mm, and the dimensions of the substrates for cabinet bodies are all 2440 mm × 1220 mm, as shown in Table 3.

Table 3.

Carbon footprint factors for raw materials.

3. Carbon Footprint Analysis and Comparative Discussion of Three Cabinets

The above data was imported into SIMAPRO 9.5 for modeling. According to Table 4, the carbon footprint of Product A, which uses domestically produced double-sided decorative door panels and American Dupont stone countertops, is 998.5 kgCO2eq. The carbon footprint of Product B, which uses single-sided acrylic door panels and Italian natural marble, is 610.7 kgCO2eq. The carbon footprint of Product C, which uses domestically produced double-sided decorative door panels and Spanish Silestone, is 620 kgCO2eq. Product A has the highest carbon emissions, significantly higher than the other two cabinet options. Product C ranks second, while Product B has the lowest carbon emissions, but the difference between it and Product C is minimal. The carbon footprints of the three products in this study appear to be larger than those of the solid wood cabinets previously reported [2,3], as wood has a significant carbon offset effect. However, a direct comparison is not feasible due to differences in product dimensions and raw materials.

Table 4.

Cradle-to-gate carbon footprint inventory table for three cabinet models.

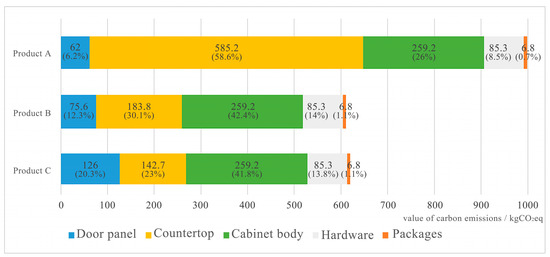

An analysis of the carbon footprint contributions of the three product options was conducted to identify and understand the main sources of carbon emissions, thereby facilitating targeted emission reduction measures, as shown in Figure 4. The American Dupont stone countertop and domestically produced double-sided decorative door panels are the dominant contributors to the carbon emissions of Product A, accounting for 58.6% and 26% of the emissions, respectively. The hardware components contribute 8.5% of the emissions, ranking third. For Product B, the double-sided decorative particleboard cabinet body and Italian natural marble countertop are the main contributors, accounting for 42.4% and 30.1% of the emissions, respectively. The hardware and molded door panels contribute 14% and 12.3%, respectively. The carbon emission stage contributions of Product C are similar to those of Product B, with the double-sided decorative particleboard cabinet body, Spanish Silestone countertop, single-sided acrylic door panel, and hardware being the main contributors. However, the proportion of the countertop has decreased to only 23%, and the proportion of the acrylic door panel exceeds that of the hardware, contributing 20.3% and 13.8%, respectively.

Figure 4.

Contribution of carbon footprint process for three cabinet stages.

Since the three product options are identical in size and design, the carbon footprint values of each component can be broken down and compared comprehensively. Purely from a numerical standpoint, the top five components with the highest carbon emissions are the American Dupont stone countertop, double-sided decorative particleboard cabinet body, Italian natural marble countertop, Spanish Silestone countertop, and single-sided acrylic door panel. Comprehensive analysis reveals that the cabinet body and door, countertop, and hardware are the key stages contributing significantly to carbon emissions. Therefore, to reduce carbon emissions, focus should be placed on raw material aspects, and corresponding emission reduction measures should be taken to lower the carbon footprint of the panel cabinets.

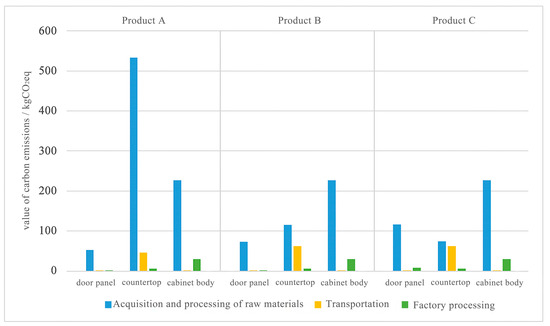

In this paper, a detailed analysis was conducted on the raw material acquisition, processing, transportation, and factory production processes of the cabinet doors, countertops, and cabinet bodies for the three product options. As shown in Figure 5, except for the countertop transportation stage, the production and processing of raw materials significantly surpass the transportation and factory processing stages, indicating that the raw material stage is the main source of overall carbon emissions for the products.

Figure 5.

Comparison of carbon footprints at each stage for the three parts of the three cabinets.

The basic constituent material for both cabinet doors and cabinet bodies is particleboard. The production of particleboard involves multiple steps, including material preparation, oven drying, glue preparation and application, spreading and hot pressing, cutting and sanding, and veneering, all of which generate a certain amount of carbon emissions. Additionally, the manufacturing process of artificial countertops widely uses chemicals, resulting in high carbon emissions from their raw materials. Notably, Product A, which uses American Dupont stone, has particularly significant carbon emissions due to the countertop used. This characteristic is mainly attributed to the production process of Dupont stone. According to queries of the Ecoinvent database using the SIMAPRO 9.5 software, the main components are methyl methacrylate and aluminum hydroxide. For every 1 kg of DuPont Stone produced, 3.81 kg of CO2 is emitted, which is significantly higher than other countertop materials.

The higher carbon emissions from the countertop transportation stage are due to the large volume and weight of the countertops, which are imported products. The transportation methods are diverse, relying not only on land freight but also on cargo ships for sea transportation, consuming a significant amount of fuel energy in the process. In contrast, the contributions of cabinet door transportation, factory processing of cabinet doors and countertops, and cabinet body transportation to the overall carbon footprint are relatively small. The transportation of cabinet doors and cabinet bodies relies on domestic road transportation, with relatively uniform carbon emission sources and shorter transportation distances, resulting in lower carbon emissions. The factory processing stages of cabinet doors and countertops involve limited processing volumes and mainly simple cutting processes, so the carbon emissions from electricity consumption are also relatively limited. However, the factory processing stage for cabinet bodies exhibits higher carbon emissions, mainly due to the fact that a set of cabinet bodies typically uses five times the number of boards compared to cabinet doors, thus contributing significantly to the carbon footprint during factory processing.

4. Decarbonization Recommendations and Future Prospects for Chinese Furniture Enterprises Based on the Carbon Footprint Analysis

Based on the data presented above, some targeted recommendations for and the future prospects of Chinese furniture enterprises are described below.

4.1. Optimize Material Selection to Reduce Carbon Footprint

Given that the American Dupont stone countertop and domestic double-sided decorative door panels in Product A contribute the most to carbon emissions, it is recommended to prioritize the use of alternative materials with lower carbon emissions. For example, exploring the use of environmentally friendly artificial stone countertops as a substitute for American Dupont stone, and investigating low-carbon or carbon-neutral door panel materials such as bamboo or recycled plastic to replace double-sided decorative door panels. For Product B and C, although the carbon emissions of Italian natural marble countertops and Spanish Silestone countertops are relatively low, considering the environmental damage caused by natural stone mining, it is also necessary to gradually search for and promote low-carbon and environmentally friendly countertop materials.

4.2. Improve Energy Efficiency in Raw Material Production and Processing

Raw material production and processing stages are the main sources of carbon emissions. Therefore, improving energy efficiency in these stages is crucial. It is recommended that related enterprises introduce advanced production technologies and equipment, optimize production processes, and reduce energy consumption and carbon emissions. At the same time, cooperation with suppliers should be strengthened to jointly promote the green transformation of the supply chain and ensure the green supply of raw materials.

4.3. Optimize Transportation Methods to Reduce Carbon Emissions

The high carbon emissions from the countertop transportation stage are mainly due to the large volume and heavy weight of imported countertops, which consume a significant amount of fuel energy during transportation. To address this issue, it is recommended that enterprises optimize transportation methods, such as adopting more energy-efficient transportation tools or exploring combined transportation solutions for sea and land transportation, to reduce carbon emissions in the transportation stage. At the same time, consumers should be encouraged to choose cabinet products from local or nearby areas to reduce carbon emissions from long-distance transportation.

4.4. Focus on the Carbon Reduction Potential of Hardware Components

Although hardware components contribute relatively little to carbon emissions (8.5–14%), their carbon reduction potential cannot be ignored. It is recommended that enterprises choose low-carbon and environmentally friendly materials for hardware components and optimize the production and processing of hardware components to reduce energy consumption and carbon emissions. At the same time, encourage consumers to choose low-carbon and environmentally friendly hardware component products when purchasing cabinets.

4.5. Strengthen Carbon Footprint Monitoring and Management

Enterprises should establish a comprehensive carbon footprint monitoring and management system and regularly conduct carbon footprint assessments of products to understand the actual situation and trends of carbon emissions. At the same time, they should formulate targeted reduction measures based on these assessment results and continuously track and evaluate the reduction effects to ensure the achievement of carbon reduction targets.

5. Conclusions

This cradle-to-gate comparative LCA demonstrates that the carbon footprint of a L-shaped panel kitchen cabinet in China ranges from 610.7 to 998.5 kgCO2eq. The top five components with the highest carbon emissions were the American Dupont stone countertop, double-sided decorative particleboard cabinet body, Italian natural marble countertop, Spanish Silestone countertop, and single-sided acrylic door panel. The production and processing of all raw materials and the transportation of countertops were the main source of overall carbon emissions for the products. Efforts should be made in material selection, energy efficiency improvement, transportation optimization, carbon reduction in hardware components, and carbon footprint management. These measures collectively form a systematic carbon reduction strategy aimed at significantly lowering the carbon footprint of cabinet products and promoting the green transformation and sustainable development of enterprises.

Author Contributions

Conceptualization, Y.L., J.H. and Z.W.; methodology, Y.L. and Z.W.; software, T.Z.; visualization, Y.W., C.W. and T.Z.; writing—original draft, C.W., J.H. and Y.L.; Investigation, T.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Key Research and Development Program of China (14th Five-Year Plan), grant number 2023YFD2201500; Natural Science Foundation of Jiangsu Province, grant number BK20230403.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw and processed data required to reproduce these findings. Cannot be shared at this time as the data also forms part of an ongoing study.

Acknowledgments

The authors acknowledge the valuable support from Nanjing Forestry University and ZBOM Home.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Guan, D.; Meng, J.; Reiner, D.M.; Zhang, N.; Shan, Y.; Mi, Z.; Shao, S.; Liu, Z.; Zhang, Q.; Davis, S.J. Structural decline in China’s CO2 emissions through transitions in industry and energy systems. Nat. Geosci. 2018, 11, 551–555. [Google Scholar] [CrossRef]

- Linkosalmi, L.; Husgafvel, R.; Fomkin, A.; Junnikkala, H.; Witikkala, T.; Kairi, M.; Dahl, O. Main factors influencing greenhouse gas emissions of wood-based furniture industry in Finland. J. Clean. Prod. 2016, 113, 596–605. [Google Scholar] [CrossRef]

- González-García, S.; Gasol, C.M.; Lozano, R.G.; Moreira, M.T.; Gabarrell, X.; i Pons, J.R.; Feijoo, G. Assessing the global warming potential of wooden products from the furniture sector to improve their ecodesign. Sci. Total Environ. 2011, 410–411, 16–25. [Google Scholar] [CrossRef]

- Li, X.; Zhang, M.; Yang, L.; Yue, X.; Xiong, X. Current state and development trend of China’s customized home furnishing industry. Wood Mater. Sci. Eng. 2024, 20, 721–733. [Google Scholar] [CrossRef]

- Lin, M.; Zhang, Z.; Cao, Y. Forecasting supply and demand of the wooden furniture industry in China. For. Prod. J. 2019, 69, 228–238. [Google Scholar] [CrossRef]

- Cai, Y.; Zhu, H.; Chen, Z.; Geng, Y. Country risk and wooden furniture export trade: Evidence from China. For. Prod. J. 2022, 72, 180–189. [Google Scholar] [CrossRef]

- Dong, Y.; Deng, J.; Yan, X. Effect of Chitosan Gum Arabic-Coated Tung Oil Microcapsules on the Performance of UV Coating on Cherry Wood Surface. Coatings 2025, 15, 873. [Google Scholar] [CrossRef]

- Deng, J.; Yan, X. Preparation of Tung Oil Microcapsules Coated with Chitosan–Arabic Gum and Its Effect on the Properties of UV Coating. Polymers 2025, 17, 1985. [Google Scholar] [CrossRef] [PubMed]

- Xiong, X.; Ma, Q.; Yuan, Y.; Wu, Z.; Zhang, M. Current situation and key manufacturing considerations of green furniture in China: A review. J. Clean. Prod. 2020, 267, 121957. [Google Scholar] [CrossRef]

- Luo, H.; Lin, X. Dynamic analysis of industrial carbon footprint and carbon-carrying capacity of Zhejiang Province in China. Sustainability 2022, 14, 16824. [Google Scholar] [CrossRef]

- Wang, G.; Li, F.; Zhao, F.; Zhou, L.; Huang, A.; Wang, L.; Sutherland, J.W. A product carbon footprint model for embodiment design based on macro-micro design features. Int. J. Adv. Manuf. Technol. 2021, 116, 3839–3857. [Google Scholar] [CrossRef]

- Han, D.; Kim, M.-J.; Kim, M.; Han, Y. Greenhouse gas emission reduction through wood-based furniture substitution: Analysis of displacement factors. BioResources 2024, 19, 6605–6620. [Google Scholar] [CrossRef]

- Wang, H.; Wu, J.; Chen, Z. Carbon footprint accounting and low-carbon path optimization for imported timber-based wooden furniture supply chains. BioResources 2021, 16, 6870–6890. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, N.; Yang, Y. Carbon footprint assessment and efficiency measurement of wood processing industry based on life cycle assessment. Sustainability 2023, 15, 6558. [Google Scholar] [CrossRef]

- Sipahi, S.; Sipahi, M. Raw material stage assessment of seating elements as urban furniture and eco-model proposals. Sustainability 2024, 16, 4163. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, J.; Wang, X. A review on carbon reduction analysis during the design and manufacture of solid wood furniture. BioResources 2021, 16, 6212–6230. [Google Scholar] [CrossRef]

- Lao, W.L.; Li, W.G. Comparative carbon footprint estimation of three types of wooden door: A case study from China. J. Clean. Prod. 2023, 433, 139745. [Google Scholar] [CrossRef]

- Wang, S. Application of product life cycle management method in furniture modular design. Math. Probl. Eng. 2022, 2022, 7192152. [Google Scholar] [CrossRef]

- Babic, A.; Rosenfeld, C.; Muegge, M. From sustainable raw materials to sustainable recycling in furniture. Surf. Coat. Int. Part A Coat. J. JOCCA J. Oil Colour Chem. Assoc. 2022, 105, 308–311. [Google Scholar]

- Dong, Y.; Deng, J.; Yan, X. Preparation of Tung Oil Microcapsules Coated with Chitosan Sodium Tripolyphosphate and Their Effects on Coating Film Properties. Coatings 2025, 15, 867. [Google Scholar] [CrossRef]

- Herold, A.; Monni, S.; Lin, E.; Meyer, C.P. Methodological choice and identification of key categories. In 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Eggelston, S., Buendia, L., Miwa, K., Eds.; The Institute for Global Environmental Strategies (IGES) for the IPCC: Kanagawa, Japan, 2008; Volume 1, pp. 14–16. [Google Scholar]

- Denizli-Tankut, N.; Tankut, A.; Eckelman, C.; Gibson, H. Improving the deflection characteristics of shelves and side walls in panel-based cabinet furniture. For. Prod. J. 2003, 53, 56–64. [Google Scholar]

- Tankut, A.N. Design of Panel and Panel on Frame Bookshelves and Cabinets. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2001. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).