Life Cycle Assessment of Biocomposite Production in Development Stage from Coconut Fiber Utilization

Abstract

1. Introduction

2. Materials and Methods

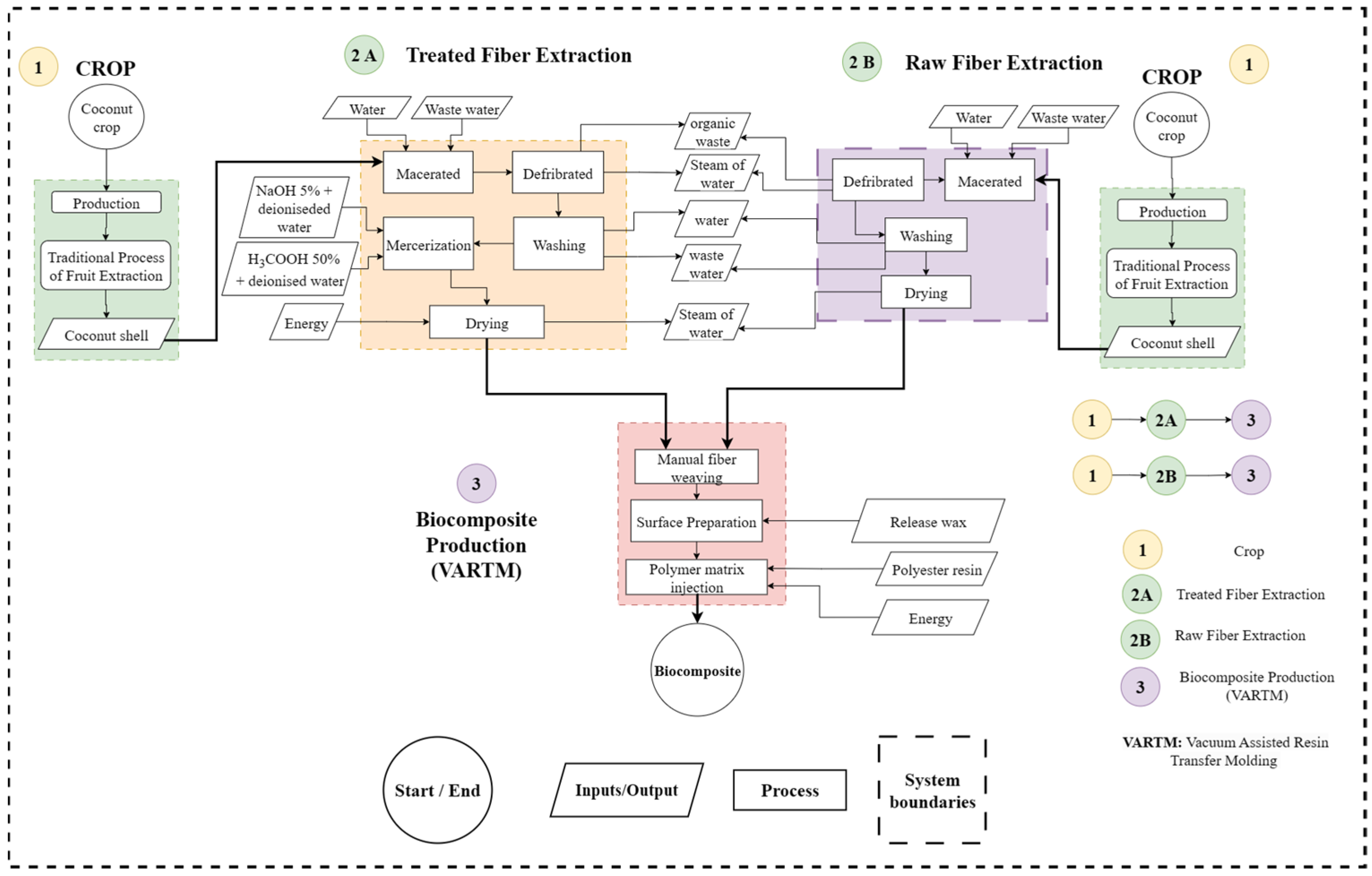

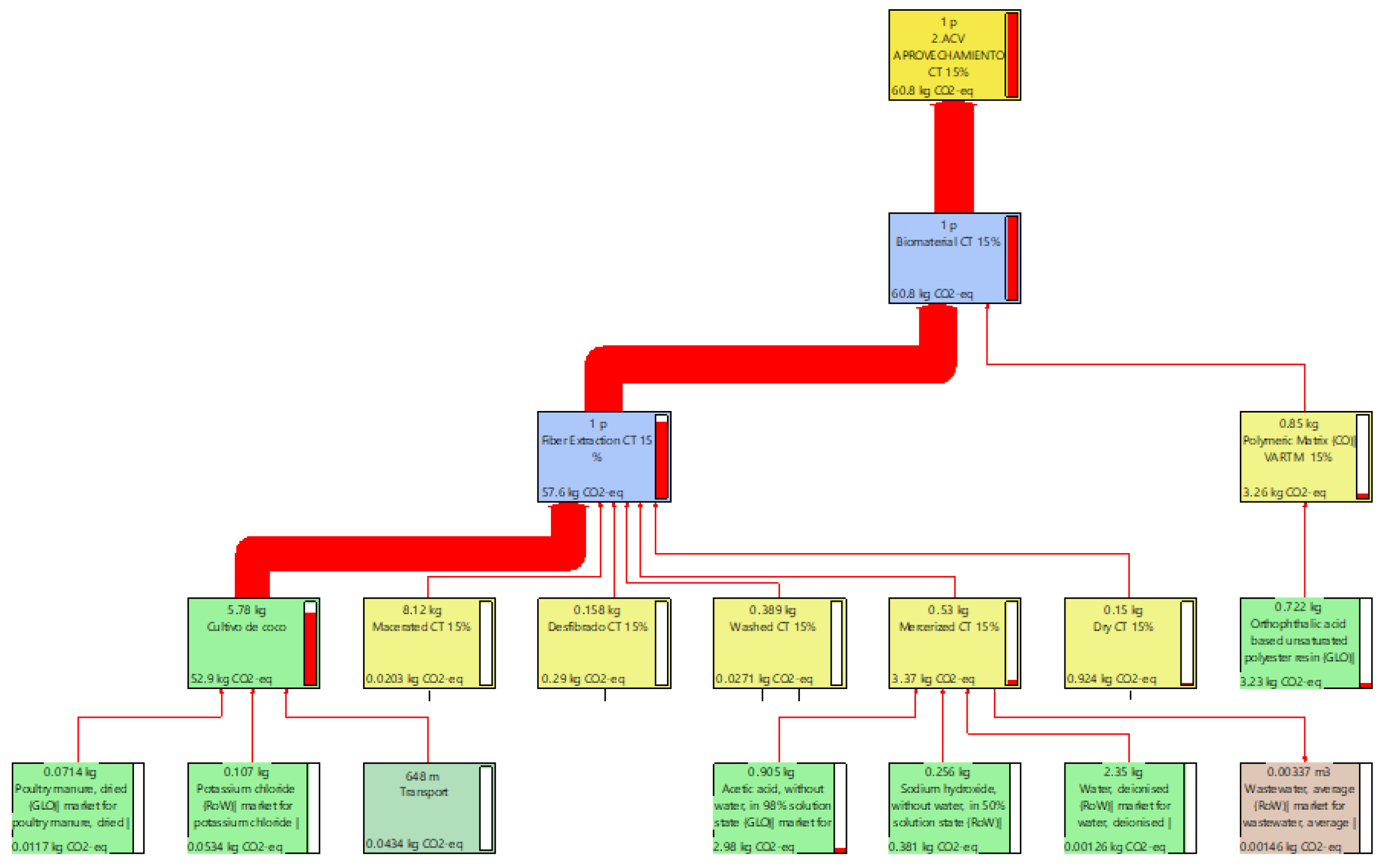

2.1. System Boundaries

2.2. LCA Methods

2.3. Data Collection for Building Farm Inventories

2.4. Coconut Crop

2.5. Calculation of Coconut Crop Emissions

2.6. Fiber Extraction

2.7. Physicochemical Characterization of Wastewater

2.8. VARTM

2.9. Data Quality Analysis

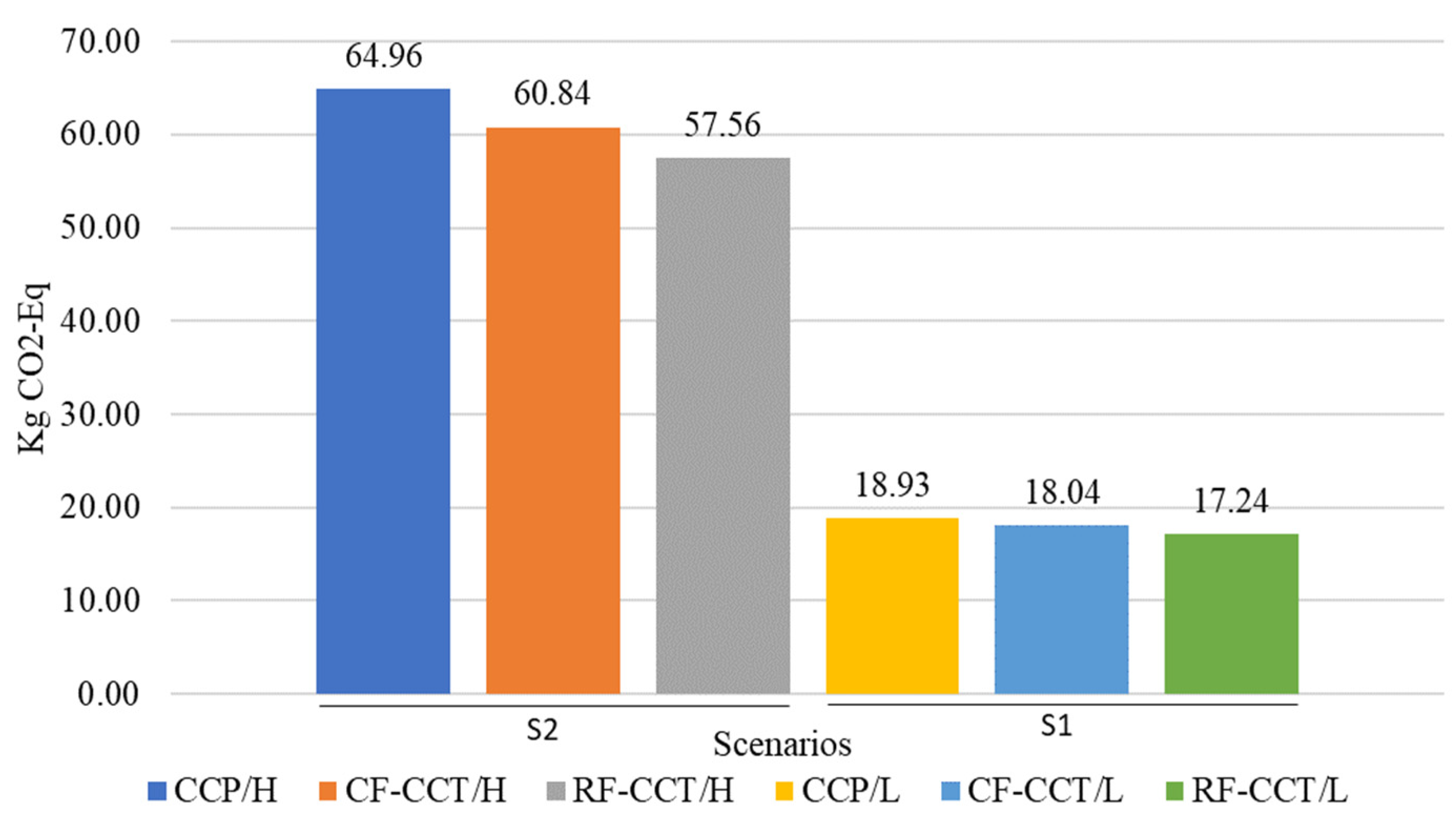

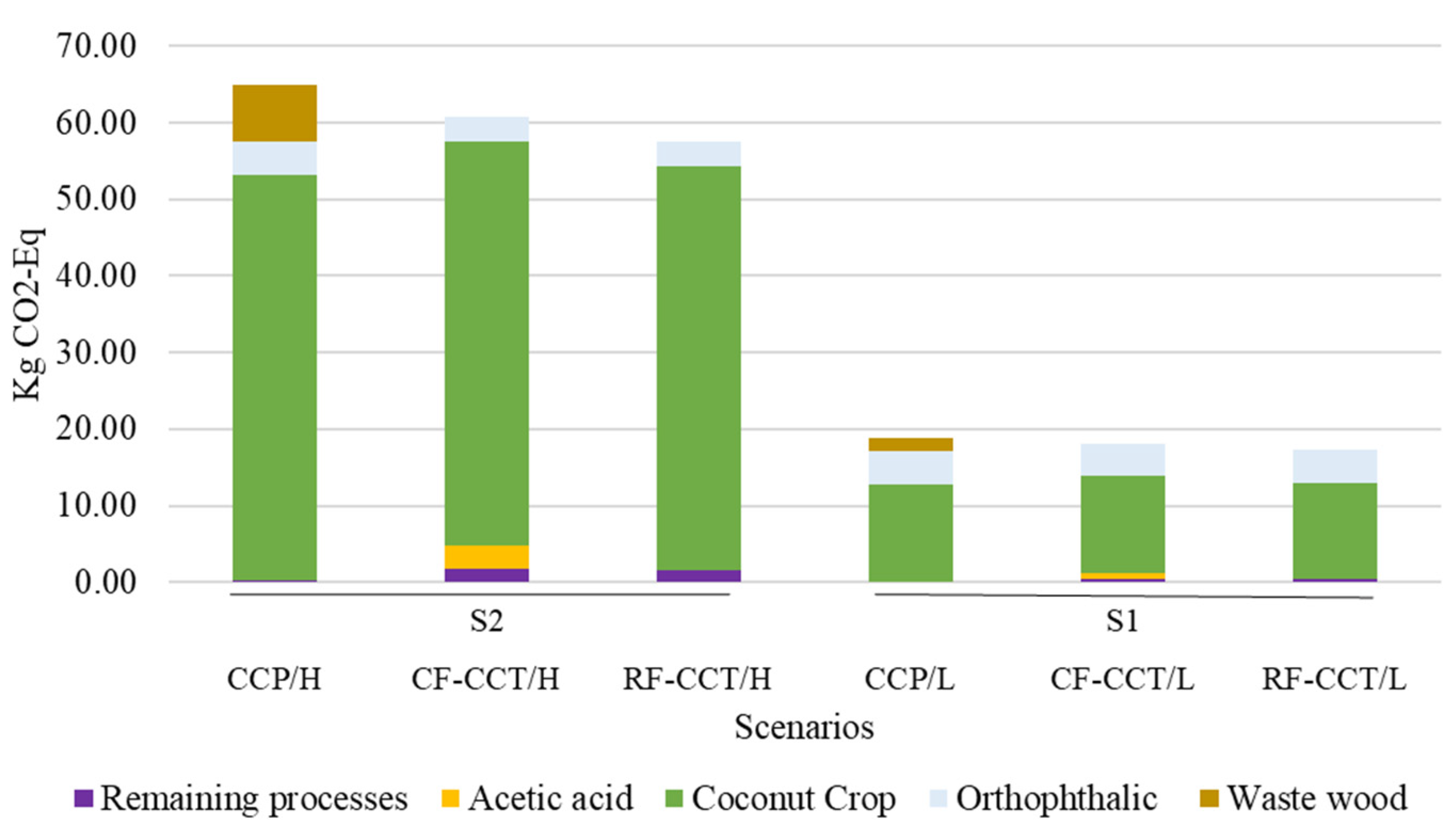

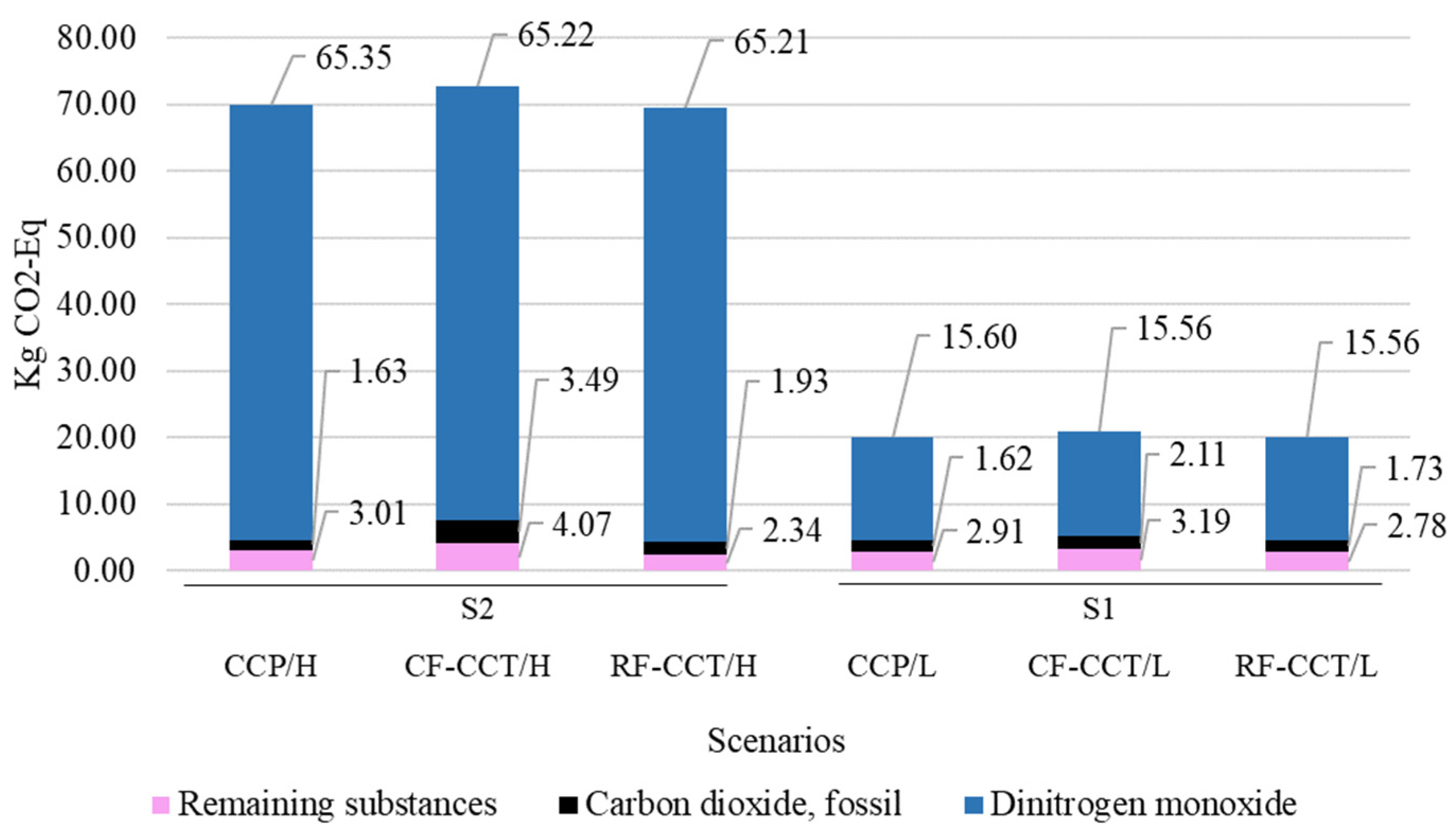

2.10. Scenario Analysis

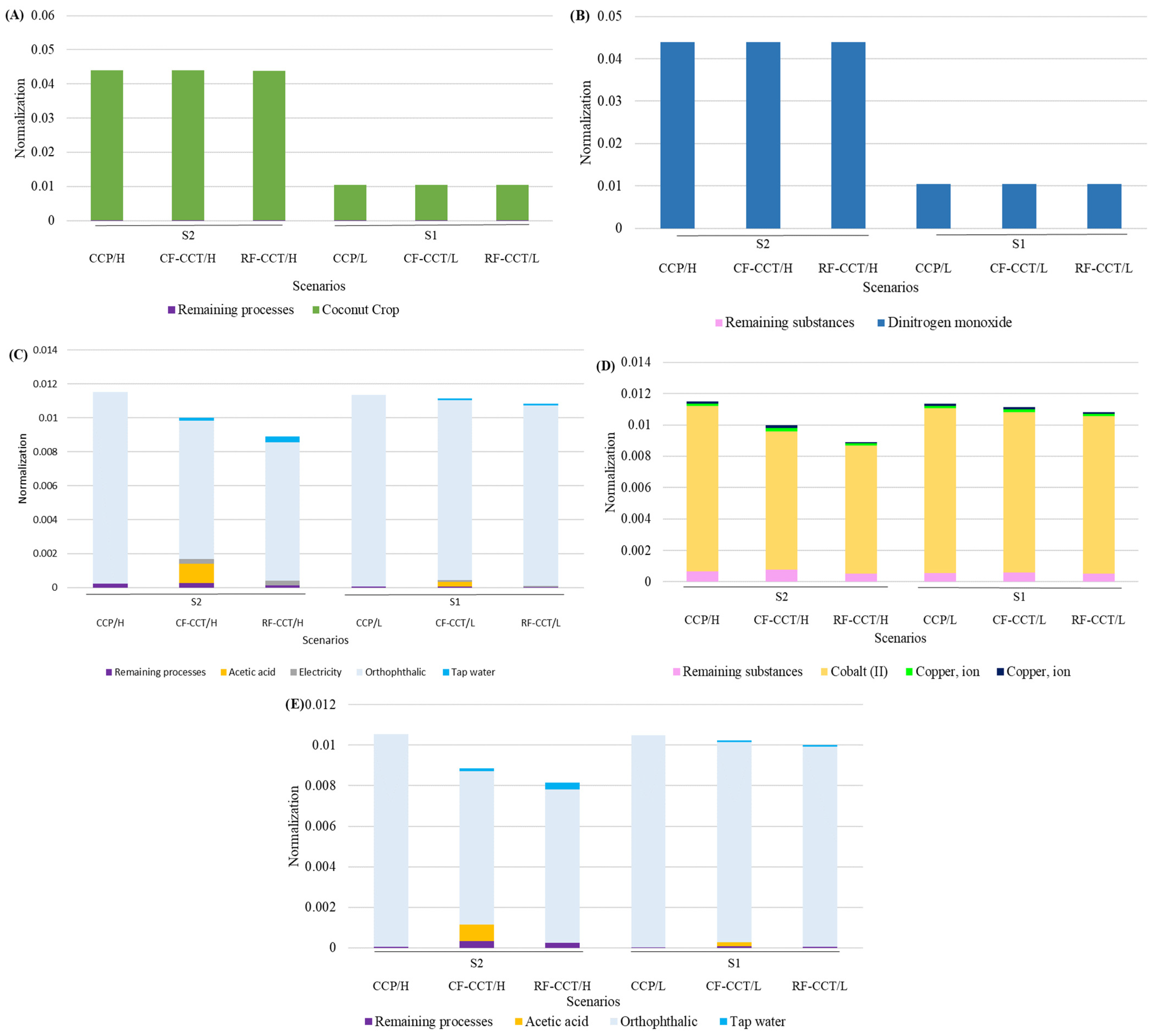

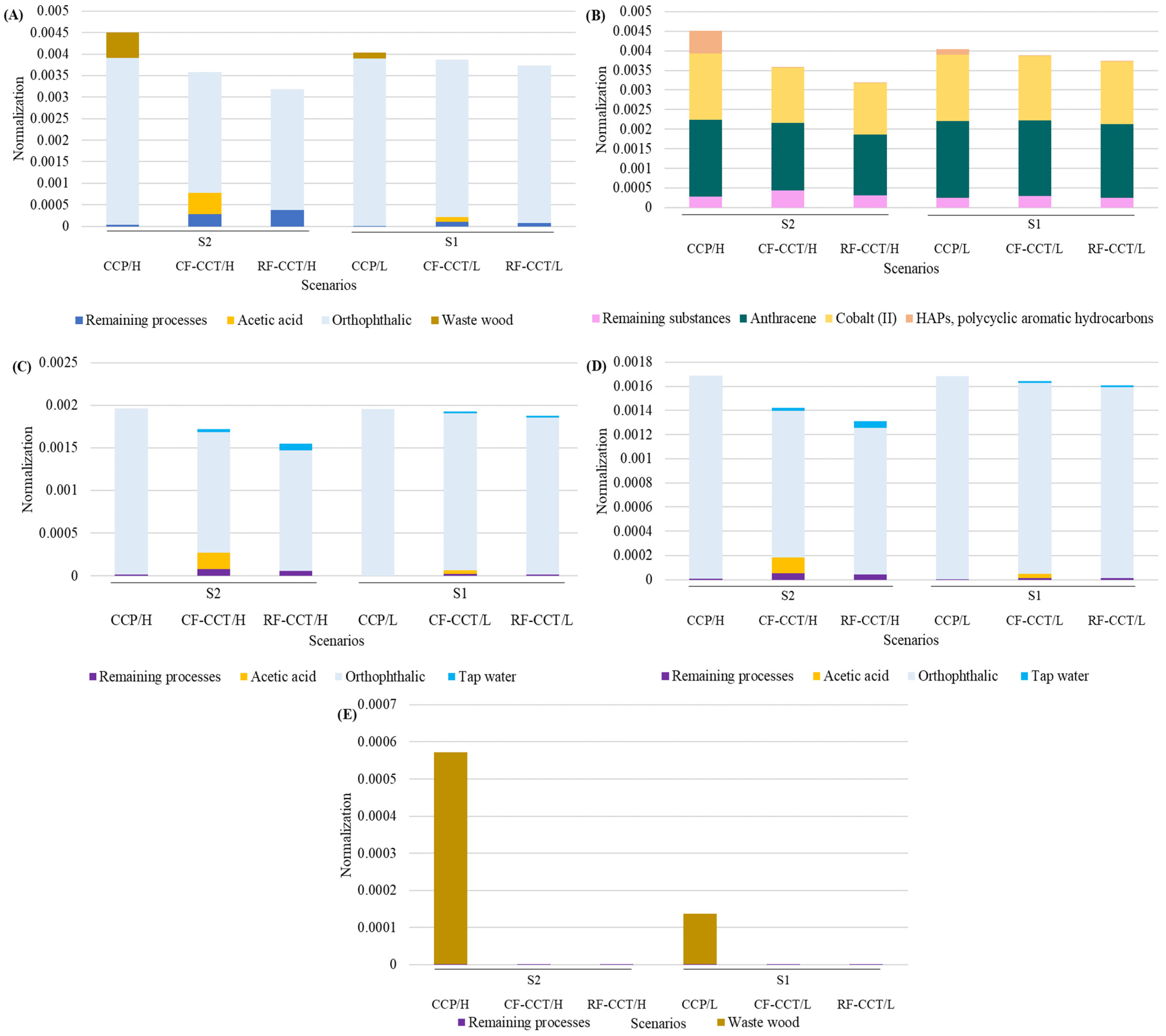

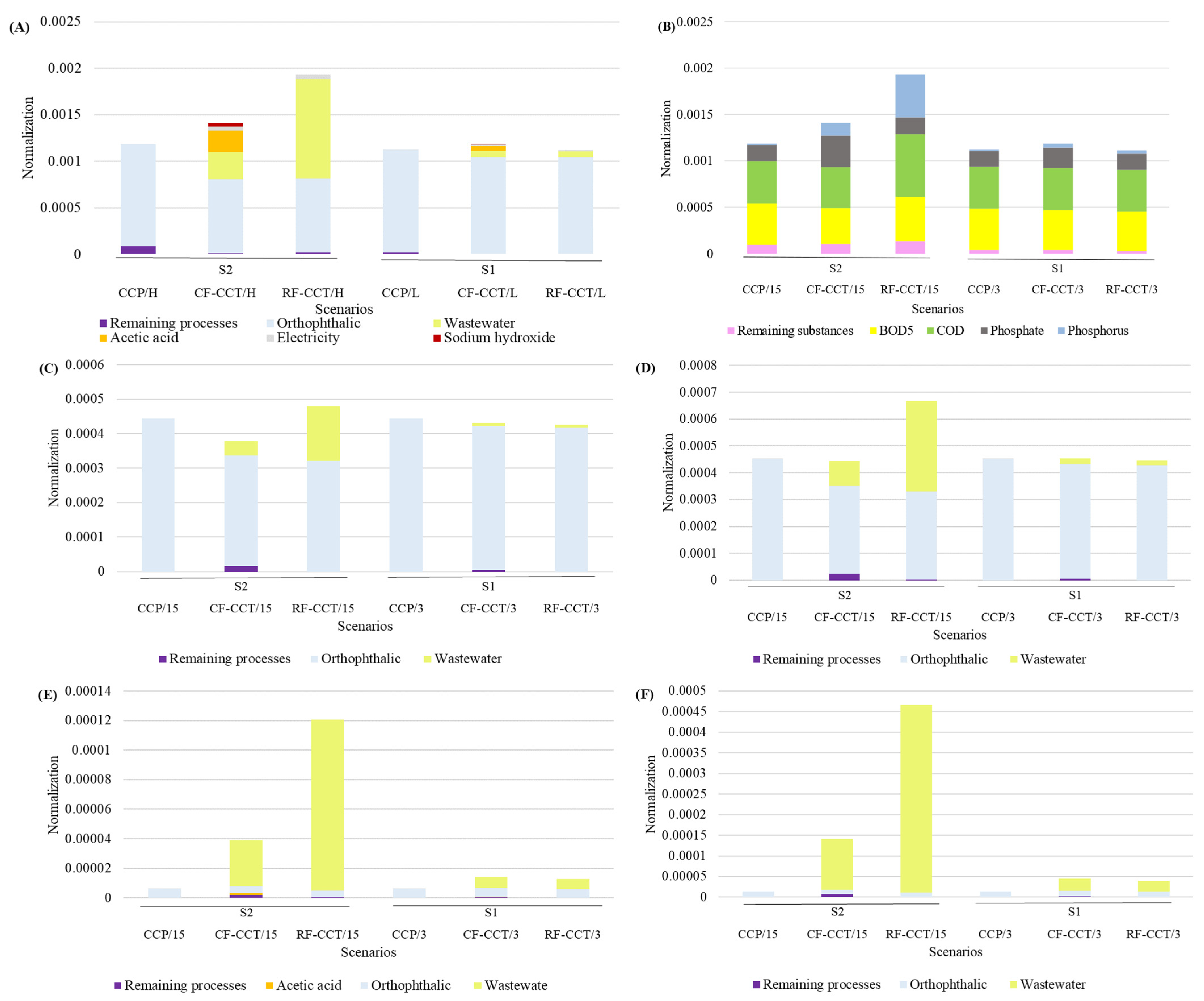

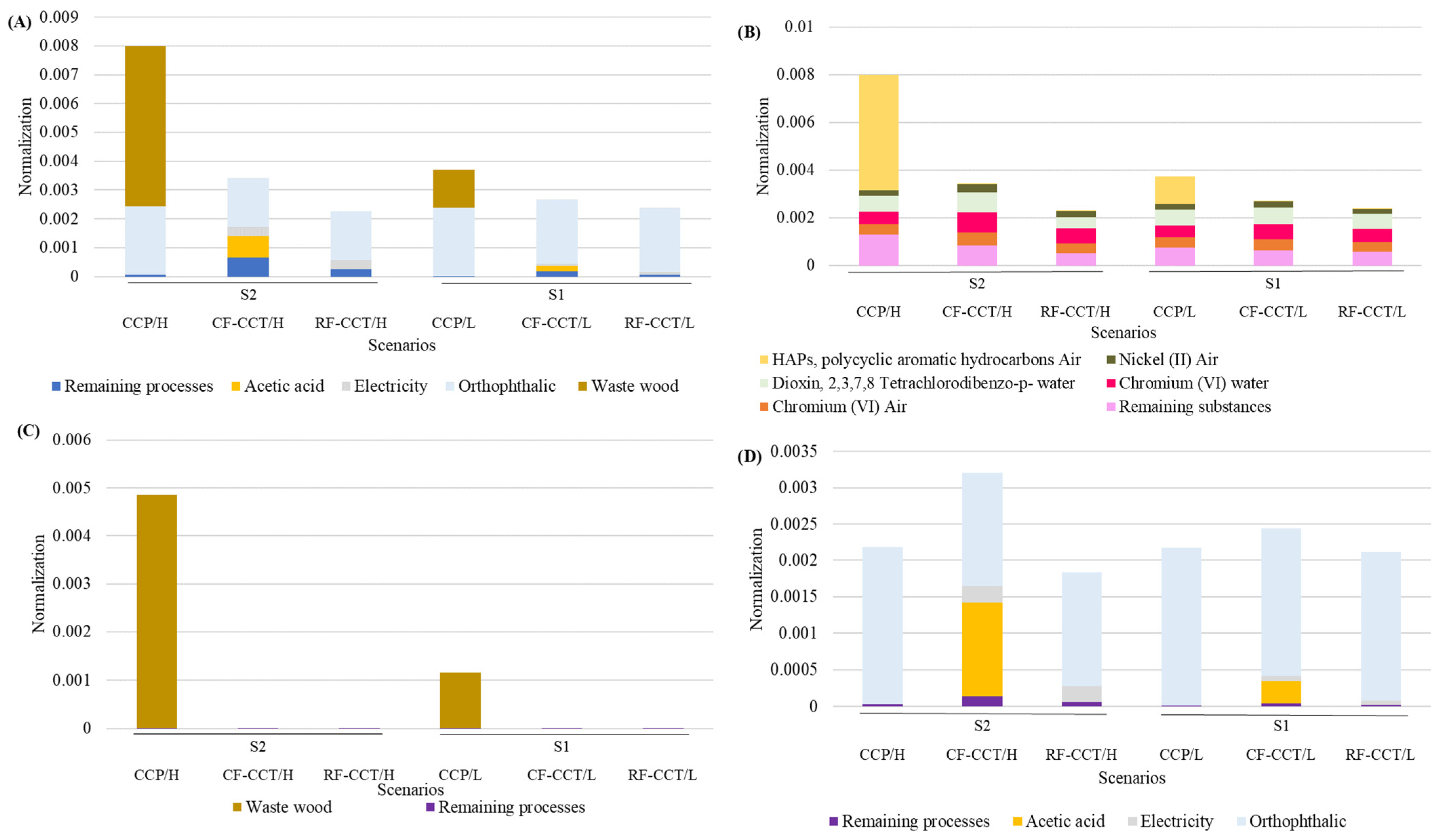

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pardo Bermúdez, A.F. Implementación de un Prototipo de Vermicultura Para la Gestión Sostenible de Residuos Orgánicos en el Casco Antiguo de Floridablanca. Available online: http://hdl.handle.net/11634/53292 (accessed on 5 November 2024).

- Zalazar-Garcia, D.; Fernandez, A.; Rodriguez-Ortiz, L.; Torres, E.; Reyes-Urrutia, A.; Echegaray, M.; Rodriguez, R.; Mazza, G. Exergo-ecological analysis and life cycle assessment of agro-wastes using a combined simulation approach based on Cape-Open to Cape-Open (COCO) and SimaPro free-software. Renew. Energy 2022, 201, 60–71. [Google Scholar] [CrossRef]

- Ángel Hidalgo-Salazar, M.; Pablo Correa-Aguirre, J.; Manuel Montalvo-Navarrete, J.; Fernando Lopez-Rodriguez, D.; Felipe Rojas-González, A. Recycled Polypropylene-Coffee Husk and Coir Coconut Biocomposites: Morphological, Mechanical, Thermal and Environmental Studies. In Thermosoftening Plastics; IntechOpen: Cambridge, MA, USA, 2020. [Google Scholar] [CrossRef]

- Coronado Gutierrez, R.; Valencia Lópe, R.A. Gestión Integral de Residuos Agrícolas para la Generación de Materias Primas en el Municipio de Cota Cundinamarca. Available online: http://hdl.handle.net/11349/3001 (accessed on 5 November 2024).

- MinAgricultura. El agro se Consolida como el Segundo Motor de la Economía Nacional, Según un Nuevo Reporte del Índice de Seguimiento a la Economía 2024. Available online: https://www.minagricultura.gov.co/noticias/Paginas/El-agro-se-consolida-como-el-segundo-motor-de-la-econom%C3%ADa-nacional,-seg%C3%BAn-un-nuevo-reporte-del-%C3%8Dndice-de-Seguimiento-a-la-E.aspx (accessed on 3 July 2025).

- MinAgricultura. El Sector Agricultura, Protagonista en 2024 de la Reactivación Económica del país 2025. Available online: https://www.minagricultura.gov.co/noticias/Paginas/El-sector-Agricultura,-protagonista-en-2024-de-la-reactivaci%C3%B3n-econ%C3%B3mica-del-pa%C3%ADs.aspx (accessed on 3 July 2025).

- Tróchez, D.X.S.; Ordoñez, L.B.P.; Paja, M.D.M.R. Estrategias para lograr entornos colaborativos e innovadores encaminados hacia el fomento de mercados agroindustriales. Acad. Derecho 2023, 15, 1–34. [Google Scholar] [CrossRef]

- Inés, J.; Pinzón, C.; Eudoro, L.; Zamudio, V. Agricultura y desarrollo rural en Colombia 2011–2013: Una aproximación. Apunt. Del CENES 2016, 35, 87–123. [Google Scholar]

- Oliveira, M.; Cocozza, A.; Zucaro, A.; Santagata, R.; Ulgiati, S. Circular economy in the agro-industry: Integrated environmental assessment of dairy products. Renew. Sustain. Energy Rev. 2021, 148, 111314. [Google Scholar] [CrossRef]

- Sarıyer, T.; Kaya, Ç. Agricultural wastes in climate change mitigation. J. Glob. Clim. Change 2022, 1, 15–20. [Google Scholar] [CrossRef]

- Zalazar-García, D.; Feresin, G.E.; Rodriguez, R. Optimal operational variables of phenolic compound extractions from pistachio industry waste (Pistacia vera var. Kerman) using the response surface method. Biomass Convers. Biorefinery 2022, 12, 3761–3770. [Google Scholar] [CrossRef]

- Agapkin, A.M.; Makhotina, I.A.; Ibragimova, N.A.; Goryunova, O.B.; Izembayeva, A.K.; Kalachev, S.L. The problem of agricultural waste and ways to solve it. IOP Conf. Ser. Earth Environ. Sci. 2022, 981, 022009. [Google Scholar] [CrossRef]

- Santiago De la Rosa, N. Factores de Emisión de Contaminantes Atmosféricos y Climáticos, y Evaluación del Potencial Oxidativo y Cancerígeno de las Partículas Finas por la Quema de Residuos Agrícolas. Available online: https://hdl.handle.net/11191/5742 (accessed on 5 November 2024).

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Kurien, R.A.; Maria Anil, M.; Sharan Mohan, S.L.; Anna Thomas, J. Natural Fiber Composites As Sustainable Resources for Emerging Applications—A Review. Available online: https://linkinghub.elsevier.com/retrieve/pii/S2214785323022642 (accessed on 3 May 2023).

- Birniwa, A.H.; Abdullahi, S.S.A.; Ali, M.; Mohammad, R.E.A.; Jagaba, A.H.; Amran, M.; Avudaiappan, S.; Maureira-Carsalade, N.; Flores, E.I.S. Recent Trends in Treatment and Fabrication of Plant-Based Fiber-Reinforced Epoxy Composite: A Review. J. Compos. Sci. 2023, 7, 120. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Napitupulu, R.; S, S.T.; M.T.; Dharta, Y.; Putri, D.A.; Parlindungan, D.; Pratama, A.; Angelina, C.L. Perancangan Mesin Pencacah Limbah Kelapa Muda Secara Vertikal Menggunakan Metode Sintesis Pandangan. J. Teknol. 2023, 23, 28. [Google Scholar] [CrossRef]

- Pico González, D.R. Validación de una Máquina para Fabricación de Materiales Compuestos Mediante la Técnica de Moldeo por Transferencia de Resina con Vacío Asistido. Available online: https://repositorio.unicordoba.edu.co/handle/ucordoba/7258 (accessed on 15 April 2024).

- Wahab, M.; Rushdan Zaim, I.N.; Ismail, H.F.; Othman, N.; Hara, H.; Md Akhir, F.N. Evaluation of flavonoid compound in coconut waste and its antioxidant activity. IOP Conf. Ser. Earth Environ. Sci. 2023, 1144, 012006. [Google Scholar] [CrossRef]

- Malviya, R.K.; Singh, R.K.; Purohit, R.; Sinha, R. Natural fibre reinforced composite materials: Environmentally better life cycle assessment—A case study. Mater. Today Proc. 2020, 26, 3157–3160. [Google Scholar] [CrossRef]

- Shalwan, A.; Yousif, B.F. In State of Art: Mechanical and tribological behaviour of polymeric composites based on natural fibres. Mater. Des. 2013, 48, 14–24. [Google Scholar] [CrossRef]

- Mansor, M.R.; Salit, M.S.; Zainudin, E.S.; Aziz, N.A.; Ariff, H. Life Cycle Assessment of Natural Fiber Polymer Composites. Agricultural Biomass Based Potential Materials; Springer International Publishing: Cham, Switzerland, 2015; pp. 121–141. [Google Scholar] [CrossRef]

- Reinders, M.J.; Onwezen, M.C.; Meeusen, M.J.G. Can bio-based attributes upgrade a brand? How partial and full use of bio-based materials affects the purchase intention of brands. J. Clean. Prod. 2017, 162, 1169–1179. [Google Scholar] [CrossRef]

- Asthana, N.; Pal, K.; Khan, A.A.; Malik, A. Novel biopolymeric materials potential utilization for environmental practices. J. Mol. Struct. 2024, 1311, 138390. [Google Scholar] [CrossRef]

- Ramachandran, K.; Gnanasagaran, C.L.; Vekariya, A. Life cycle assessment of carbon fiber and bio-fiber composites prepared via vacuum bagging technique. J. Manuf. Process. 2023, 89, 124–131. [Google Scholar] [CrossRef]

- Choe, C.; Moon, J.A.; Gu, J.; Lee, A.; Lim, H. Life cycle sustainability assessment for sustainable energy future: A short review on opportunity and challenge. Curr. Opin. Green Sustain. Chem. 2024, 50, 100974. [Google Scholar] [CrossRef]

- Katebi, A.; Soleymani Tushmanlo, H.; Asadollahfardi, G. Environmental life cycle assessment and economic comparison of different roof systems. J. Build. Eng. 2023, 76, 107316. [Google Scholar] [CrossRef]

- ISO 14044, Environmental Management—Life Cycle Assessment—Requirements and Guidelines. Available online: https://www.iso.org/standard/38498.html (accessed on 15 April 2024).

- Franco Rodríguez, J.M. Vista de Análisis de Ciclo de Vida para la Producción de Biodiesel Derivado de Palma de Aceite Caso Colombiano 2019. Available online: https://hemeroteca.unad.edu.co/index.php/publicaciones-e-investigacion/article/view/3262/3401 (accessed on 26 May 2024).

- Pérez, L.A.F.; Lorza, R.L.; Bobadilla, M.C. Uso del programa simapro para evaluar coagulantes naturales en el tratamiento de aguas. Biotecnia 2019, 21, 108–113. [Google Scholar] [CrossRef]

- Gradin, K.T.; Björklund, A. The common understanding of simplification approaches in published LCA studies—A review and mapping. Int. J. Life Cycle Assess. 2021, 26, 50–63. [Google Scholar] [CrossRef]

- SimaPro. SimaPro Database Manual Methods Library; 2022. Available online: https://simapro.com/wp-content/uploads/2021/12/DatabaseManualMethods930.pdf (accessed on 24 July 2024).

- Intergovernmental Panel on Climate Change (IPCC). The Earth’s Energy Budget, Climate Feedbacks and Climate Sensitivity. In Climate Change 2021—The Physical Science Basis; Cambridge University Press: Cambridge, MA, USA, 2023; pp. 923–1054. [Google Scholar] [CrossRef]

- Smith, C.; Gasser, T.; Nicholls, Z.; Armour, K.; Collins, W.; Forster, P.; Meinshausen, M.; Watanabe, M.; Pirani, A.; Connors, S.; et al. The Earth’s Energy Budget, Climate Feedbacks and Climate Sensitivity Supplementary. Available online: https://www.ipcc.ch/report/ar6/wg1/downloads/report/IPCC_AR6_WGI_Chapter07_SM.pdf (accessed on 24 July 2024).

- ASOCOLCO Asociación de Cocoteros del Municipio de Puerto Escondido 2025. Available online: https://asocolco.com/ (accessed on 6 September 2025).

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wernet, G. Overview and Methodology: Data Quality Guideline for the Ecoinvent Database version 3. Swiss Centre for Life Cycle Inventories. Available online: https://vbn.aau.dk/ws/portalfiles/portal/176769045/Overview_and_methodology.pdf (accessed on 6 November 2024).

- Castillo, T.; García, F.; Mosquera, L.; Rivadereira, T.; Segura Khaterine, Y.M. PANORAMA ENERGÉTICO DE AMÉRICA LATINA Y EL CARIBE. Available online: https://biblioteca.olade.org/opac-tmpl/Documentos/old0442a.pdf (accessed on 6 November 2024).

- Coelho Sampaio, A.P. Pegada De Carbono E Hidríca Do Cultivo De Coco Em Sistemas De Produção Convencional No Nordeste Brasileiro Fortaleza. Master’s Thesis, Universidade Federal do Ceará, Fortaleza, Brazil, 2019. [Google Scholar]

- Puspaningrum, T.; Indrasti, N.S.; Indrawanto, C.; Yani, M. Life cycle assessment of coconut plantation, copra, and charcoal production. Glob. J. Environ. Sci. Manag. 2023, 9, 653–672. [Google Scholar] [CrossRef]

- Emmenegger, M.; Reinhard, J.; Zah, R. Sustainability Quick Check for Biofuels-Intermediate Background Report. In T. Ziep RWProfDrVWB and ARRFKDrGGAR-Tänikon. Available online: https://www.researchgate.net/publication/230725635_SQCB_-_Sustainability_Quick_Check_for_Biofuels_Second_draft_18th_February_2009_-_Intermediate_Background_Report_With_contributions_from_T_Ziep_R_Weichbrodt_Prof_Dr_V_Wohlgemuth_FHTW_Berlin_and_A_Roche (accessed on 28 September 2024).

- Nemecek, T.; Schnetzer, J. Methods of Assessment of Direct Field Emissions for LCIs of Agricultural Production Systems. 2011. Available online: https://www.researchgate.net/profile/Freddy_Navarro-Pineda/post/How_to_easily_predict_the_leaching_of_heavy_metals_from_soils/attachment/59d61f9d79197b807797e0dc/AS:285638185242630@1445112858480/download/ART+2012+-+Methods+of+assessment+of+direct+field+emissions+for+agricultural+systems.pdf (accessed on 28 September 2024).

- IPCC. Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, MA, USA, 2007. [Google Scholar]

- Nemecek, T.; Kagil, T. Life Cycle Inventories of Agricultural Production Systems. Final. Rep. Ecoinvent 2007, 15, 1–360. [Google Scholar]

- IDEAM. Anexo 7 Aguas Subterraneas. Estudio Nacional del Agua. 2022. Available online: https://www.ideam.gov.co/sites/default/files/prensa/boletines/2024-08-23/anexo_7_aguas_subterraneas_0.pdf (accessed on 17 December 2024).

- Arias, T. Coconut Morphology Dataset. Available online: https://figshare.com/articles/dataset/Coconut_morphology_dataser/12783470 (accessed on 17 December 2024).

- Rincón Reyna, J.F.; Rincón Reyna, P.G.; Torres Maravila, E.; Mondragón Rojas, A.G.; SanchezPardo, M.E.; Arana Cuenca, A.; Ortiz Moreno, A.; Jiménez Garcia, E. CARACTERIZACIÓN FISICOQUIMICA Y FUNCIONAL DE LA FIBRA DE MESOCARPIO DE COCO (Cocos nucifera L.). Available online: http://www.fcb.uanl.mx/IDCyTA/files/volume1/2/3/49.pdf (accessed on 17 December 2024).

- Desole, M.P.; Gisario, A.; Barletta, M. Comparative life cycle assessment and multi-criteria decision analysis of coffee capsules made with conventional and innovative materials. Sustain. Prod. Consum. 2024, 48, 99–122. [Google Scholar] [CrossRef]

- Márquez Roca, L.R. Potenciales Impactos Ambientales Negativos Generados en el Análisis del Ciclo de Vida del Biocombustible 2,5 Dimetilfurano, Obtenido a Partir de Residuos de Cabuya (Agave americana L.). Available online: https://repositorio.cientifica.edu.pe/handle/20.500.12805/2142 (accessed on 17 December 2024).

- Füchsl, S.; Rheude, F.; Röder, H. Life cycle assessment (LCA) of thermal insulation materials: A critical review. Clean. Mater. 2022, 5, 100119. [Google Scholar] [CrossRef]

- Evaluation of ILCD Data Network Entry-Level and PEF Data Quality Requirements in LCA Databases 2014. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC86490 (accessed on 3 May 2024).

- Muller, S.; Lesage, P.; Ciroth, A.; Mutel, C.; Weidema, B.P.; Samson, R. The application of the pedigree approach to the distributions foreseen in ecoinvent v3. Int. J. Life Cycle Assess. 2016, 21, 1327–1337. [Google Scholar] [CrossRef]

- Godoy León, M.F.; Dewulf, J. Data quality assessment framework for critical raw materials. The case of cobalt. Resour. Conserv. Recycl. 2020, 157, 104564. [Google Scholar] [CrossRef]

- Freire, A.L.F.; de Araújo Júnior, C.P.; de Freitas Rosa, M.; de Almeida Neto, J.A.; de Figueirêdo, M.C.B. Environmental assessment of bioproducts in development stage: The case of fiberboards made from coconut residues. J. Clean. Prod. 2017, 153, 230–241. [Google Scholar] [CrossRef]

- Ecoinvent. Market for Waste Wood, Untreated-Colombia-Waste Wood, Untreated|EcoQuery 2023. Available online: https://ecoquery.ecoinvent.org/3.10/cutoff/dataset/17501/documentation (accessed on 27 January 2025).

- da Silva, A.R.A.; Bezerra, F.M.L.; de Lacerda, C.F.; de Sousa, C.H.C.; Bezerra, M.A. Physiological responses of dwarf coconut plants under water deficit in salt-affected soils. Rev. Caatinga 2017, 30, 447–457. [Google Scholar] [CrossRef]

- Gomes, F.P.; Prado, C.H.B.A. Ecophysiology of coconut palm under water stress. Braz. J. Plant Physiol. 2007, 19, 377–391. [Google Scholar] [CrossRef]

- Nainanayake, A.; Morison, J. A Case Study on Physiology-Based Drought Screening of Coconut with Selected Accessions. COCOS 2009, 18. [Google Scholar] [CrossRef]

- Vélez, E.; Rodríguez, R.; Yanchapanta Gómez, N.B.; Mora, E.D.; Hernández, L.; Albuja-Sánchez, J.; Calvo, M.I. Coconut-Fiber Composite Concrete: Assessment of Mechanical Performance and Environmental Benefits. Fibers 2022, 10, 96. [Google Scholar] [CrossRef]

- Arif, H.; Muhammad, A.M.; Wu, F.; Yin, G.-F.; Shen, S.-Z.; Wang, F.; Li, Y.; Zhang, K.-Q. Application of Optimum N Through Different Fertilizers Alleviate NH4+-N, NO3−N and Total Nitrogen Losses in the Surface Runoff and Leached Water and Improve Nitrogen Use Efficiency of Rice Crop in Erhai Lake Basin, China. Commun. Soil. Sci. Plant Anal. 2019, 50, 716–738. [Google Scholar] [CrossRef]

- Kiemle, C.; Fruck, C.; Fix, A. Nitrous Oxide, N2O: Spectroscopic Investigations for Future Lidar Applications. EGU23 2023. Available online: https://meetingorganizer.copernicus.org/EGU23/EGU23-7065.html (accessed on 17 December 2024).

- Sindija, L.; Luize, L.; Dace, B.; Jovita, P.-U.; Inga, G. Biblioteca Electrónica EPS: Efecto del Contenido de Humedad y Materia Orgánica en las Emisiones de N2O. 2023. Available online: https://epslibrary.at/sgem_jresearch_publication_view.php?page=view&editid1=9449 (accessed on 9 March 2025).

- Bordón, P.; Elduque, D.; Paz, R.; Javierre, C.; Kusić, D.; Monzón, M. Analysis of processing and environmental impact of polymer compounds reinforced with banana fiber in an injection molding process. J. Clean. Prod. 2022, 379, 134476. [Google Scholar] [CrossRef]

- Alcivar-Bastidas, S.; Petroche, D.M.; Ramirez, A.D.; Martinez-Echevarria, M.J. Characterization and life cycle assessment of alkali treated abaca fibers: The effect of reusing sodium hydroxide. Constr. Build. Mater. 2024, 449, 138522. [Google Scholar] [CrossRef]

- Tian, H.; Pan, N.; Thompson, R.L.; Canadell, J.G.; Suntharalingam, P.; Regnier, P.; Davidson, E.A.; Prather, M.; Ciais, P.; Muntean, M.; et al. Global nitrous oxide budget (1980–2020). Earth Syst. Sci. Data 2024, 16, 2543–2604. [Google Scholar] [CrossRef]

- Krysztofiak, G.; Catoire, V.; Dudok de Wit, T.; Kinnison, D.E.; Ravishankara, A.R.; Brocchi, V.; Atlas, E.; Bozem, H.; Commane, R.; D’Amato, F.; et al. N2O Temporal Variability from the Middle Troposphere to the Middle Stratosphere Based on Airborne and Balloon-Borne Observations during the Period 1987–2018. Atmosphere 2023, 14, 585. [Google Scholar] [CrossRef]

- Ibrahim, R.M.; Abbood, Z.M.; Al-Taai, O.T.; Ahmed, M.M. The Influence of Ozone Depletion Potential Weighted Anthropogenic Emissions of Nitrous Oxide. Asian J. Water Environ. Pollut. 2024, 21, 65–73. [Google Scholar] [CrossRef]

- Romo-Gómez, C.; Camacho-López, C.; Marmolejo-Santillán, Y.; Otazo-Sánchez, E.M. Actividades antrópicas: Deterioro de la capa de ozono estratosférico. Pädi Boletín Científico De Cienc. Básicas E Ing. Del ICBI 2019, 7, 1–5. [Google Scholar] [CrossRef]

- Fagodiya, R.K.; Pathak, H.; Kumar, A.; Bhatia, A.; Jain, N. Global temperature change potential of nitrogen use in agriculture: A 50-year assessment. Sci. Rep. 2017, 7, 44928. [Google Scholar] [CrossRef]

- Lock, K.; Becaus, S.; Criel, P.; Van Eeckhout, H.; Janssen, C.R. Ecotoxicity of cobalt to the springtail Folsomia candida. Comp. Biochem. Physiol. Part C Toxicol. Pharmacol. 2004, 139, 195–199. [Google Scholar] [CrossRef]

- Malard, V.; Bresson, C.; Uboldi, C.; Delangle, P.; Van der Meeren, A.; Lemaire, D.; Darolles, C.; Orsière, T.; Ortega, R.; Berthomieu, C. Toxicity mechanisms of cobalt oxide particles (Co3O4P) on human lung cells: Impact of solubilization. BIO Web. Conf. 2019, 14, 05010. [Google Scholar] [CrossRef]

- Kosiorek, M.; Wyszkowski, M. Kosiorekm Effect Of Cobalt On The Environment And Living Organisms—A Review. Appl. Ecol. Environ. Res. 2019, 17. [Google Scholar] [CrossRef]

- Zemlyanova, M.A.; Stepankov, M.S.; Pustovalova, O.V.; Nedoshitova, A.V. Assessment of bioaccumulation and toxic effects of Cobalt (II) aluminate nanoparticles for hygienic safety purposes. Health Risk Anal. 2024, 3, 113–122. [Google Scholar] [CrossRef]

- Sharan, A.; Nara, S. Exposure-based ecotoxicity assessment of Co3O4 nanoparticles in marine microalgae. Environ. Sci. Pollut. Res. 2021, 28, 54802–54810. [Google Scholar] [CrossRef] [PubMed]

- Ou, R.; Huang, H.; He, X.; Lin, S.; Ou, D.; Li, W.; Qiu, J.; Wang, L. Ecotoxicology of Polymetallic Nodule Seabed Mining: The Effects of Cobalt and Nickel on Phytoplankton Growth and Pigment Concentration. Toxics 2023, 11, 1005. [Google Scholar] [CrossRef] [PubMed]

- Karthikeyan, P.; Marigoudar, S.R.; Raja, P.; Nagarjuna, A.; Kumar, S.B.; Savurirajan, M.; Sharma, K.V. Toxicity of Anthracene on Marine Organisms and Development of Seawater Quality Criteria. Available online: https://www.researchsquare.com/article/rs-4222753/v1 (accessed on 5 November 2024).

- Pathak, A.K.; Sharma, M.; Nagar, P.K. A framework for PM2.5 constituents-based (including PAHs) emission inventory and source toxicity for priority controls: A case study of Delhi, India. Chemosphere 2020, 255, 126971. [Google Scholar] [CrossRef]

- Ravindra, K.; Sokhi, R.; Van Grieken, R. Atmospheric polycyclic aromatic hydrocarbons: Source attribution, emission factors and regulation. Atmos. Environ. 2008, 42, 2895–2921. [Google Scholar] [CrossRef]

- Gomes, V.; Passos, M.J.A.C.R.; Leme, N.M.P.; Santos, T.C.A.; Campos, D.Y.F.; Hasue, F.M.; Phan, V.N. Photo-induced toxicity of anthracene in the Antarctic shallow water amphipod, Gondogeneia antarctica. Polar Biol. 2009, 32, 1009–1021. [Google Scholar] [CrossRef]

- Oris, J.T.; Giesy, J.P.; Allred, P.M.; Grant, D.F.; Landrum, P.F. Photoinduced Toxicity of Anthracene in Aquatic Organisms: An Environmental Perspective. In Studies in Environmental Science; Elsevier: Amsterdam, The Netherlands, 1984; pp. 639–658. [Google Scholar] [CrossRef]

- Nabebe, G.; Ogamba, E.N.; Izah, S.C. Aspects of Polycyclic Aromatic Hydrocarbons in Aquatic Ecosystems: A One Health Perspective. Greener J. Environ. Manag. Public Saf. 2024, 12, 22–43. [Google Scholar] [CrossRef]

- Manssour, K.; Al-Mufti, B. Influence of industrial, agricultural and sewage water discharges on eutrophication of Quttina lake. Jordan J. Civ. Eng. 2010, 4, 351–366. [Google Scholar]

- Devlin, M.; Brodie, J. Nutrients and Eutrophication. Available online: https://link.springer.com/chapter/10.1007/978-3-031-10127-4_4 (accessed on 5 November 2024).

- Wijaya, I.M.W.; Partama, I.G.Y.; Sumantra, I.K. Study on Nutrients Concentration Trends in Tukad Badung River Toward Nutrient Recovery Potential. IOP Conf. Ser. Earth Environ. Sci. 2023, 1268, 012002. [Google Scholar] [CrossRef]

- Tsai, W.T.; Wu, P.H. Environmental Concerns About Carcinogenic Air Toxics Produced from Waste Woods as Alternative Energy Sources. Energy Sources Part A: Recovery Util. Environ. Eff. 2013, 35, 725–732. [Google Scholar] [CrossRef]

- Lindenbeck, L.M.; Barra, V.C.; Dahlhaus, S.; Wende, L.; Beele, B.B.; Schebb, N.H.; Rodrigues, B.V.M.; Slabon, A. Organic Chemicals from Wood: Selective Depolymerization and Dearomatization of Lignin via Aqueous Electrocatalysis. ChemSusChem 2024, 17, e202301617. [Google Scholar] [CrossRef] [PubMed]

- Clasen, T.F.; Pillarisetti, A.; Gill-Wiehl, A.M.; Kwong, L.; Daouda, M.; Kammen, D.M. Revisiting the role of LPG in Expanding Energy Access. Available online: https://osf.io/preprints/osf/qu5bd_v1 (accessed on 5 November 2024).

- Moreno-Ruiz, E.; Valsasina, L.; Vadenbo, C.; Symeonidis, A. ecoinvent—An Introduction to the LCI Database and the Organization Behind it. J. Life Cycle Assess. Jpn. 2023, 19, 215–226. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Morcillo, M.; Gomez-Caturla, J.; Sánchez-Nacher, L.; Garcia-Garcia, D.; Garcia-Sanoguera, D. Optimization of thermoplastic matrix composite materials of renewable origin with pine fiber reinforcement. Rev. Mater. Compuestos 2022, 7, 1–6. [Google Scholar] [CrossRef]

- Sarasini, F. Thermoplastic biopolymer matrices for biocomposites. In Biocomposites for High-Performance Applications; Elsevier: Amsterdam, The Netherlands, 2017; pp. 81–123. [Google Scholar] [CrossRef]

- Anastasiou, D.E. Life cycle assessment of Luffa-reinforced epoxy composites: Untreated versus chemically treated fibers. J. Appl. Polym. Sci. 2024, 141, e55952. [Google Scholar] [CrossRef]

| Data | Type of Data |

|---|---|

| Input | Materials, mass balance, energy consumption, transportation, water use. |

| Output | Mass balance of final product, by-products, solid waste, liquid waste, emissions. |

| Data Quality Indicator | Level of Data Quality |

|---|---|

| 1.0–1.6 | Very high quality |

| 1.7–2.4 | High quality |

| 2.5–3.2 | Satisfactory quality |

| 3.3–4.0 | Low quality |

| Groups | Scenarios | Reinforcement% | Matrix (%) | Treatment | Label |

|---|---|---|---|---|---|

| S1 | 1 | 0% | 100% | --- | CCP/L 1 |

| 2 | 2–5% | 90–95% | YES | CF-CCT/L 2 | |

| 3 | 2–5% | 90–95% | NOT | RF-CCT/L 3 | |

| S2 | 4 | 0% | 100% | --- | CCP/H 4 |

| 5 | 20–30% | 80–85% | YES | CF-CCT/H 5 | |

| 6 | 20–30% | 80–85% | NOT | RF-CCT/H 6 |

| Product of the Process | Quality Parameters | Data Quality Rating (DQR) | Data Quality Level | |||||

|---|---|---|---|---|---|---|---|---|

| M | C | Tir | GR | TeR | P | |||

| Coconut crop | 4 | 3 | 1 | 1 | 1 | 2.89 | Satisfactory | |

| Coconut weight | 1 | 1 | 1 | 1 | 1 | 4 | 2.50 | Satisfactory |

| Application of supplies and fertilizers (water, KCl, chicken manure) | 3 | 2 | 1 | 1 | 1 | 4 | 2.80 | Satisfactory |

| CO2 capture by biomass | 3 | 1 | 1 | 1 | 4 | 2.90 | Satisfactory | |

| Distance traveled by vehicles to transport supplies | 2 | 4 | 1 | 1 | 1 | 4 | 2.90 | Satisfactory |

| CO2 emissions into the air | 2 | 3 | 1 | 3 | 3 | 2.67 | Satisfactory | |

| Dinitrogen oxide into the air | 2 | 3 | 1 | 3 | 3 | 2.67 | Satisfactory | |

| Ammonia into the air | 2 | 3 | 1 | 3 | 3 | 2.67 | Satisfactory | |

| Nitrogen oxide into the air | 2 | 3 | 1 | 3 | 3 | 2.67 | Satisfactory | |

| Nitrate into groundwater | 2 | 3 | 1 | 3 | 3 | 2.67 | Satisfactory | |

| Phosphates into surface water | 2 | 3 | 1 | 3 | 3 | 2.67 | Satisfactory | |

| Heavy metals into surface water and groundwater | 2 | 3 | 1 | 3 | 3 | 2.67 | Satisfactory | |

| Heavy metals into soil | 2 | 3 | 1 | 3 | 3 | 2.67 | Satisfactory | |

| Coconut mesocarp—maceration | 1 | 2 | 1 | 1 | 3 | 2 | 2.20 | High quality |

| Tap water—maceration | 1 | 2 | 1 | 3 | 3 | 2 | 2.40 | High quality |

| Wastewater—maceration | 1 | 2 | 1 | 1 | 1 | 1 | 1.50 | Very High quality |

| Wet coconut husks—defibering | 1 | 2 | 1 | 1 | 3 | 2 | 2.20 | High quality |

| Extracted fiber—defibering | 1 | 2 | 1 | 1 | 3 | 2 | 2.20 | High quality |

| Organic waste—defibering | 1 | 2 | 1 | 3 | 4 | 3 | 3.00 | Satisfactory |

| Steam water—defibering | 1 | 5 | 1 | 1 | 4 | 3 | 3.51 | Low quality |

| Tap water—washing | 1 | 2 | 1 | 3 | 3 | 2 | 2.40 | High quality |

| Wet fiber—washing | 1 | 2 | 1 | 1 | 3 | 2 | 2.20 | High quality |

| Wastewater—washing | 3 | 2 | 1 | 3 | 4 | 3 | 3.20 | Satisfactory |

| Water, deionised {RoW}|market for water, deionised|Cut-off, S—mercerization | 1 | 2 | 1 | 2 | 4 | 2 | 2.80 | Satisfactory |

| Sodium hydroxide, without water, in 50% solution state {RoW}|market for sodium hydroxide, without water, in 50% solution state|cut-off, S—mercerization | 1 | 2 | 1 | 2 | 3 | 2 | 2.30 | High quality |

| Acetic acid, without water, in 98% solution state {GLO}|market for acetic acid, without water, in 98% solution state|cut-off, S—mercerization | 1 | 2 | 1 | 2 | 3 | 2 | 2.30 | High quality |

| Mercerized fiber | 1 | 2 | 1 | 1 | 3 | 2 | 2.20 | High quality |

| Wastewater—mercerization | 3 | 2 | 1 | 3 | 4 | 3 | 3.20 | Satisfactory |

| Electricity, low voltage {CO}|market for electricity, low voltage|cut-off, S—dry | 1 | 1 | 1 | 2 | 3 | 2 | 2.20 | High quality |

| Dry fiber—dry | 1 | 2 | 1 | 1 | 3 | 2 | 2.20 | High quality |

| Steam water—dry | 1 | 5 | 1 | 1 | 4 | 3 | 3.51 | Low quality |

| Electricity, low voltage {CO}|market for electricity, low voltage|cut-off, S—VARTM | 1 | 2 | 1 | 2 | 4 | 3 | 2.90 | Satisfactory |

| Biocomposite | 1 | 2 | 1 | 1 | 3 | 3 | 2.30 | High quality |

| Coconut Crop | |||

|---|---|---|---|

| Materials and Energy | Units | Scenarios | |

| CF-CCT/L | CF-CCT/H | ||

| Inputs | |||

| Coconut crop | kg | 1.38 | 5.78 |

| Water (m3) | m3 | 0.051 | 0.214 |

| Chicken manure | kg | 0.017 | 0.107 |

| Potassium chloride | kg | 0.026 | 7.560 |

| Transport | km | 0.155 | 0.648 |

| Outputs | |||

| Carbon dioxide uptake (air) | kg | −2.961 | −12.407 |

| Carbon dioxide (air) | kg | 0.010 | 0.043 |

| Dinitrogen oxide (air) | kg | 0.057 | 0.057 |

| Ammonia (air) | kg | 0.0002 | 0.00097 |

| Nitrogen oxide (air) | kg | 0.0000765 | 0.0003205 |

| Nitrate (groundwater) | kg | 21.3693 | 21.3699 |

| Phosphates (water superficial) | mg | 5.11 | 5.11 |

| Cadmium (groundwater) | mg | 0.067 | 0.281 |

| Cupper (groundwater) | mg | 4.880 | 20.429 |

| Zinc (groundwater) | mg | 5.83000 | 24.419 |

| Lead (groundwater) | mg | 0.02890 | 0.121 |

| Chrome (groundwater) | mg | 2.41000 | 10.105 |

| Cadmium (ocean) | mg | 0.19000 | 0.798 |

| Cupper (ocean) | mg | 1620 | 6759.75 |

| Zinc (ocean) | mg | 519 | 2175.11 |

| Lead (ocean) | mg | 204 | 855.14 |

| Chrome (ocean) | mg | 162 | 680.75 |

| Cadmium (soil) | mg | 0.0026 | 0.247 |

| Cupper (soil) | mg | 0.2890 | 5747 |

| Zinc (soil) | mg | 4.3300 | 17.804 |

| Lead (soil) | mg | 0.2430 | 56.698 |

| Chrome (soil) | mg | 0.1080 | 61.595 |

| Extraction of Raw Materials | |||

| Inputs | |||

| Coconut husk | kg | 0.69 | 2.89 |

| Tap water {CO}|market for tap water|cut-off, S | L | 14.96 | 62.6635 |

| Water, deionised {RoW}|market for water, deionised|cut-off, S | L | 2.20 | 9.2199 |

| Sodium hydroxide, without water, in 50% solution state {RoW}|market for sodium hydroxide, without water, in 50% solution state|xut-off, S | kg | 0.0202 | 0.0846 |

| Acetic acid, without water, in 98% solution state {GLO}|market for acetic acid, without water, in 98% solution state|cut-off, S | kg | 0.2019 | 0.8459 |

| Electricity, low voltage {CO}|market for electricity, low voltage|cut-off, S | kWh | 0.74 | 3.1015 |

| Outputs | |||

| Treated fiber | kg | 0.03 | 0.15 |

| Waste wood, untreated {CO}|market for waste wood, untreated|cut-off, S | kg | 0.66 | 2.774 |

| Steam water/CO | m3 | 1.33 | 5.568 |

| Raw sewage | L | 7.25 | 30.368 |

| Wastewater, average {RoW}|treatment of wastewater, average, wastewater treatment|cut-off, S | L | 8.79 | 36.846 |

| Biomaterial Production | |||

| Petroleum slack wax {CO}|petroleum slack wax production, petroleum refinery operation|cut-off, S | kg | 0.002 | 0.002 |

| Orthophthalic acid based unsaturated polyester resin {GLO}|market for orthophthalic acid based unsaturated polyester resin|cut-off, S | kg | 0.96 | 0.85 |

| Electricity, low voltage {CO}|market for electricity, low voltage|cut-off, S | kg | 0.13 | 0.13 |

| biocomposite | kg | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soto-Barrera, V.C.; Begambre-González, F.; Vellojín-Muñoz, K.E.; Fernandez-Hoyos, D.F.; Torres-Bejarano, F.M. Life Cycle Assessment of Biocomposite Production in Development Stage from Coconut Fiber Utilization. Sustainability 2025, 17, 8338. https://doi.org/10.3390/su17188338

Soto-Barrera VC, Begambre-González F, Vellojín-Muñoz KE, Fernandez-Hoyos DF, Torres-Bejarano FM. Life Cycle Assessment of Biocomposite Production in Development Stage from Coconut Fiber Utilization. Sustainability. 2025; 17(18):8338. https://doi.org/10.3390/su17188338

Chicago/Turabian StyleSoto-Barrera, Viviana Cecilia, Fernando Begambre-González, Karol Edith Vellojín-Muñoz, Daniel Fernando Fernandez-Hoyos, and Franklin Manuel Torres-Bejarano. 2025. "Life Cycle Assessment of Biocomposite Production in Development Stage from Coconut Fiber Utilization" Sustainability 17, no. 18: 8338. https://doi.org/10.3390/su17188338

APA StyleSoto-Barrera, V. C., Begambre-González, F., Vellojín-Muñoz, K. E., Fernandez-Hoyos, D. F., & Torres-Bejarano, F. M. (2025). Life Cycle Assessment of Biocomposite Production in Development Stage from Coconut Fiber Utilization. Sustainability, 17(18), 8338. https://doi.org/10.3390/su17188338