Abstract

To systematically reveal the influence mechanisms and spatial effects of industrial intellectual property (IP) reform strategies and manufacturing craftsmanship spirit on regional energy intensity, this study aims to provide theoretical support and practical pathways for emerging market economies pursuing dual goals of energy efficiency governance and manufacturing transformation. Based on a “technology–culture synergistic innovation ecology” theoretical framework, the study deepens the understanding of energy intensity governance and introduces two spatial weight matrices—the economic distance matrix and the nested economic–geographic matrix—to uncover the spatial heterogeneity of policy and cultural effects. Using panel data from 30 Chinese provinces from 2010 to 2022 (excluding Tibet, Hong Kong, Macao, and Taiwan), we construct an index of manufacturing craftsmanship spirit (CSM) and its four dimensions—excellence in detail, persistent dedication, breakthrough orientation, and innovation inheritance—via the entropy method. Empirical analysis is conducted through Spatial Difference-in-Differences (SDID) and Double Machine Learning (DML) models. The results show that: (1) Industrial IP reform strategies significantly reduce local energy intensity through improved property rights definition and technology transaction mechanisms, but may increase energy intensity in economically proximate regions due to intensified technological competition. (2) All four dimensions of craftsmanship spirit indirectly mitigate regional energy intensity via distinct pathways, with particularly strong mediating effects from persistent dedication and innovation inheritance. In contrast, breakthrough orientation shows no significant impact, possibly due to limitations from the current stage of the technology lifecycle. (3) Spatial spillover effects are heterogeneous: under the nested economic–geographic matrix, IP reform strategies reduce neighboring regions’ energy intensity through synergistic effects, while under the economic distance matrix, competitive spillovers lead to an increase in adjacent energy intensity. Based on these findings, we propose the following: deepening IP reform strategies to build a technology–culture synergistic ecosystem; enhancing regional policy coordination to avoid technology lock-in; systematically cultivating the core of craftsmanship spirit; and establishing a dynamic incentive mechanism for breakthrough orientation. These measures can jointly drive systemic improvements in regional energy efficiency.

1. Introduction

As global energy challenges intensify, energy security and sustainable development have become common concerns around the world. For emerging economies such as China, the rapidly growing energy demand and structural supply constraints make energy efficiency improvement a key strategy. Energy intensity—defined as energy consumption per unit of GDP—is a core metric of efficiency, and reducing it not only eases supply–demand imbalances but also facilitates the transition to high-quality economic development. In 2016, the Chinese government introduced a dual-control policy relating to energy, prioritizing energy intensity control alongside total energy consumption. Compared with total energy control, intensity management is inherently more complex, requiring technological upgrades, institutional safeguards, and structural interventions.

China’s manufacturing sector, as a cornerstone of its economy, remains resource- and energy-intensive. In response to this issue, the “new-type industrialization” strategy promotes digitalization, green innovation, and advanced technologies to upgrade traditional industries. Within this transformation, the government launched pilot programs for “Building Strong IP Provinces,” guided by the Work Plan for Accelerating the Construction of Strong Intellectual Property Provinces. This systemic reform uses IP governance to strengthen patent strategies, improve technical standards, and optimize innovation ecosystems, thereby steering industrial development toward IP-intensive sectors and driving the implementation of industrial IP reform strategies [].

Such strategies reduce the risk of adverse selection from technological imitation by clarifying IP ownership and optimizing technology transactions []. However, their potential impact on regional energy intensity remains underexplored. This study treats the policy of “Building Strong IP Provinces” as a quasi-natural experiment to examine its effectiveness and mechanisms in energy intensity governance.

Beyond institutional reforms, manufacturing craftsmanship spirit has also served as a cultural force shaping technological progress and efficiency. In modern contexts, it extends beyond the artisanal tradition to embody the integration of spiritual and technological civilization, encouraging engineers and technicians to pursue precision, innovation, and excellence [].

Within industries, craftsmanship spirit is expressed through deep engagement in technological pathways, refinement of processes, and breakthroughs in innovation paradigms, fostering a production culture centered on efficiency []. This cultural trait may affect regional energy intensity in two ways: on the one hand, craftsmanship-driven innovation can reduce energy consumption during production; on the other, its emphasis on meticulous management and standardized procedures can help to optimize energy use. However, the specific mechanisms through which craftsmanship spirit affects energy intensity remain unclear—particularly how it interacts with institutional innovation in the context of IP reform strategies to improve energy efficiency, thus leading to the need for further theoretical exploration [].

Current research seldom integrates industrial IP reform strategies, craftsmanship spirit, and regional energy intensity into a unified framework. This paper addresses this gap by constructing a conceptual model and conducting empirical analysis to explore both the direct and indirect pathways—such as technology diffusion, resource allocation optimization, and innovation incentives—through which IP reform strategies mitigate energy intensity. Furthermore, by incorporating spatial spillover effects and regional heterogeneity, this study provides evidence-based insights for policymaking in emerging markets. These findings not only advance our understanding of China’s dual-control strategy but also offer practical implications for other emerging economies facing similar challenges relating to energy efficiency, institutional reform, and industrial upgrading.

2. Literature Review, Mechanism Analysis, and Research Hypotheses

2.1. Literature Review on the Impact of Intellectual Property Policy on Energy Systems

2.1.1. Intellectual Property Protection and the Incentive Mechanism of Energy Technology Innovation

Intellectual property (IP) policy establishes a positive incentive system for energy technology research and development by granting innovators exclusive rights. The core mechanism lies in reducing innovators’ risk expectations, enabling them to recover the high costs of R&D through monopoly rents []. From an economic perspective, the public-good attributes of energy technologies (e.g., technological spillovers) often result in insufficient private investment in R&D, whereas IP protection defines property rights boundaries and internalizes externalities, thereby improving resource allocation efficiency []. However, excessive protection may trigger technological monopolies, suppress diffusion, and ultimately hinder the overall pace of innovation in the energy sector []. Therefore, the intensity of IP policy must align with the technological life cycle, industrial competition structure, and policy objectives of the energy sector.

2.1.2. The Regulatory Role of Intellectual Property Institutions in Energy Market Competition

The energy sector is characterized by high technological and capital intensity, implying that IP policy must balance innovation incentives with fair competition. For instance, patent pools may reduce industry entry barriers by enabling technology sharing, yet without sufficient regulation, they risk evolving into price-fixing alliances []. From a game-theoretical perspective, cross-licensing agreements among firms may achieve Pareto improvements through cooperative games, but excessive reliance on such arrangements could undermine incentives for technological iteration []. Moreover, the territorial nature of IP policy influences the strategic deployment of multinational energy enterprises. For example, the “safe haven” effect of patent applications may generate uneven technology transfers []. These dynamics indicate that IP policy must seek an optimal balance between promoting innovation and preventing market distortions.

2.1.3. Intellectual Property and the Synergistic Path to Energy Sustainability

The core dilemma within the energy transition lies in the tension between short-term economic interests and long-term environmental benefits. IP policy can advance sustainable development goals by promoting technological standardization; for example, patent standardization can reduce compatibility costs for clean energy technologies, thereby accelerating their large-scale application []. From the perspective of transaction cost theory, the collaborative management of IP (e.g., green patent-sharing platforms) can mitigate information asymmetries in technology transactions and enhance resource allocation efficiency. Nevertheless, the effectiveness of such collaborative mechanisms depends on policy fairness—for instance, the disadvantaged position of developing countries in accessing advanced technologies may be further entrenched []. Hence, IP policy should be integrated with international climate governance frameworks such as the Paris Agreement, using differentiated rule design to achieve global energy justice.

2.2. Literature Review on the Impact of Entrepreneurial Spirit on Energy Systems

2.2.1. Entrepreneurial Spirit and Energy Technology Breakthroughs

The central role of entrepreneurial spirit in the energy domain is its persistent drive for technological breakthroughs. In economic theory, endogenous growth models emphasize technological progress as the fundamental driver of growth, and energy innovations frequently rely on disruptive exploration beyond existing technological trajectories. For instance, advances in photovoltaic efficiency, cost reductions in energy storage, and the scaling of smart grids are closely associated with the disruptive reconfiguration of traditional technological paradigms. Such breakthroughs depend not only on resource input but also on an innovation culture that embraces risk-taking and long-term returns []. From a market perspective, entrepreneurial spirit reduces technological uncertainty and accelerates commercialization. For example, the shale gas revolution—marked by the combination of horizontal drilling and hydraulic fracturing—was not a linear improvement but rather a re-integration of geological knowledge, highlighting the catalytic role of entrepreneurial spirit in paradigm shifts. Furthermore, the spillover effects of entrepreneurial spirit deserve attention: disruptive innovations in one domain often trigger collaborative innovation across upstream and downstream industries, thereby shaping new energy economic ecosystems [].

2.2.2. Entrepreneurial Spirit and the Restructuring of Energy Market Structures

From an industrial organization perspective, entrepreneurial spirit reshapes energy market competition by disrupting established structures. In traditional energy markets, fossil fuel enterprises dominate through economies of scale and resource control, yet the diffusion of clean energy technologies—driven by entrepreneurial spirit—is transforming this dynamic. For instance, the rapid decline in the cost of wind and solar energy results not only from technological iteration but also from business model innovations such as distributed generation and virtual power plants []. These innovations compress the profit margins of traditional energy firms while fostering new market participants such as energy service companies (ESCOs) and digital energy platforms. Entrepreneurial spirit also reduces market entry barriers: the application of blockchain in electricity trading lowers transaction costs, enabling small and medium-sized enterprises to participate in market competition. This trend regarding decentralization resonates with the concept of energy democratization but simultaneously imposes higher demands on regulatory frameworks []. Importantly, the diffusion of entrepreneurial spirit is uneven across countries and regions, depending heavily on institutional environments and human capital reserves.

2.2.3. Entrepreneurial Spirit and the Interactive Logic of Energy Policy

Within energy policy design, entrepreneurial spirit functions as both an objective and a mechanism. New institutional economics suggests that a policy’s effectiveness depends on its ability to guide market actors’ behavior, and the cultivation of entrepreneurial spirit requires precise policy instruments. For instance, R&D subsidies and tax incentives are often seen as direct stimuli, but without institutional arrangements that tolerate failure, they may suppress truly breakthrough innovations []. Conversely, mandatory technical standards (e.g., carbon emission caps) can indirectly stimulate entrepreneurial spirit by creating market pressure, though their effectiveness is significantly shaped by industry concentration []. Policy experimentation also plays a crucial role: Germany’s Energiewende allowed local communities to autonomously choose renewable energy paths, successfully fostering grassroots entrepreneurial spirit, demonstrating that policy flexibility and inclusiveness may release greater innovative potential than top-down planning. However, policies oriented toward entrepreneurial spirit may encounter the “innovation paradox”: when technological uncertainty is excessively high, over-reliance on spontaneous market innovation may cause resource misallocation. Therefore, striking a balance between stability and flexibility is essential for entrepreneurial spirit to fully contribute to the energy transition.

2.3. Research Review and Critical Gaps

2.3.1. Insufficient Linkages Between National IP Strategy and Regional Energy Systems

Although existing studies extensively examine the influence of IP policy on energy systems, most remain confined to micro-level analyses such as technological protection and innovation incentives, while neglecting the institutional innovation driven by a national IP strategy. Consequently, the role of IP strategies in shaping macro-level energy systems in developing countries remains underexplored. For instance, developing economies often face structural challenges such as underdeveloped institutional environments and low efficiency in technology transfer, and how these constraints—mediated by strategic policy design—affect macro objectives like energy structure transition and efficiency improvement is still insufficiently understood. Moreover, the interaction mechanisms between national IP strategies and regional energy intensity—a core indicator of energy efficiency—remain largely unexamined. This research gap prevents policymakers from optimizing energy governance pathways at a strategic level.

2.3.2. Neglect of Craftsmanship Spirit in Regional Energy Systems

While the literature frequently emphasizes the role of entrepreneurial spirit in driving energy system innovation, far less attention has been devoted to craftsmanship spirit (CSM), which emphasizes technical refinement, meticulous attention to detail, and long-term accumulation. In the energy sector, innovation depends not only on market-oriented risk-taking but also on practitioners’ pursuit of excellence in operational processes. For example, in clean energy equipment manufacturing and energy system operation and maintenance, craftsmanship spirit directly influences technological stability and sustainability. Yet current studies have not systematically examined how craftsmanship spirit may enhance technological maturity, reduce energy loss, or optimize resource allocation, thereby strengthening the resilience and efficiency of regional energy systems. This theoretical omission renders analyses of human-capital-driven factors in energy systems incomplete.

2.3.3. Fragmentation of Multidimensional Research Frameworks

Most existing studies treat IP policy, entrepreneurial spirit, and craftsmanship spirit as independent variables when analyzing their impacts on energy systems, lacking attempts to integrate them into a unified analytical framework. In reality, IP policy provides institutional guarantees for innovation, entrepreneurial spirit drives commercialization, and craftsmanship spirit ensures quality and stability in technological implementation, together forming the intrinsic driving mechanism of energy transition. However, current research has yet to reveal how these three elements interact across different regions and developmental stages, nor has it developed theoretical models to explain their dynamic interactions, hindering a comprehensive understanding of the complexity of energy system transitions and limiting the systematic and forward-looking design of relevant policies.

2.4. The Impact Mechanism of Industrial IP Reform Strategies on Regional Energy Intensity and the Research Hypothesis

Industrial intellectual property (IP) reform strategies reshape the institutional logic of technological innovation and resource allocation, providing strong economic underpinnings for reducing regional energy intensity. From the perspective of the neoclassical growth model, technological progress is the key driver of total factor productivity. As the fundamental infrastructure for defining and trading technological property rights, the IP system directly alters the efficiency boundaries of technology diffusion. When IP reform strategies promote the intensive deployment of high-value patents, they essentially introduce a “tradable right to innovate” into the technology market. By reducing adverse selection and moral hazard in imitation, they internalize the positive externalities of R&D [], which not only increases the marginal returns of technological inventions but also generates multiplier effects via patent information sharing, standard-setting coordination, and innovation across industrial chains. As a result, improvements in energy efficiency are no longer dependent on individual firms’ innovations, instead being driven by the complementarity and path dependence within technology clusters []. For instance, when technology-intensive sectors displace traditional high-energy-consuming industries, the diminishing marginal cost of energy is amplified, accelerating the decoupling of energy intensity from GDP growth due to economies of scale in diffusion. In Jiangsu Province—a strategic pilot region—the judiciary pioneered the centralized adjudication of patent infringement in emerging energy sectors by implementing a “centralized evidence collection + unified hearing” model. This institutional innovation removed obstacles for technological iteration in tech-intensive industries and facilitated the low-carbon transition of energy-heavy sectors, establishing a sustainable, endogenous mechanism for easing regional energy intensity by embedding energy efficiency improvements into the long-term logic of industrial innovation.

The green transformation driven by IP reform is fundamentally an institutional internalization of environmental externalities. Traditional growth models often ignore the negative externalities of energy consumption due to unclear property rights, resulting in Pareto-suboptimal resource allocation. The IP system, by granting property attributes to green technologies, incorporates environmental costs such as carbon emissions into innovation decisions, forming what is known as the “innovation compensation effect.” This mechanism is particularly evident in dual-track markets: on one hand, price signals from carbon trading are coupled with patent valuation systems, linking the market value of green technologies with their environmental benefits, thereby guiding capital and talent into low-carbon domains []; on the other hand, the exclusivity of IP rights reduces imitation risk and enhances firms’ incentives to invest continuously in green innovation. This institutional design resolves the public goods dilemma of green technology and promotes the formation of complementary technological clusters for energy efficiency along industrial chains []. In Fujian Province, for example, the transformation of patents for ammonia–hydrogen green energy technologies facilitated the industrialization of ammonia storage, hydrogen production, and power generation in remote areas, leading to a low-carbon energy network across mountainous and island regions, providing technical support for optimizing regional energy structures. In this process, the “lock-in effect” of green technology becomes apparent—once a low-carbon technology dominates a patent pool, subsequent innovations tend to follow this trajectory, suppressing high-energy-consuming alternatives. The reinforcement of such path dependence renders energy intensity reduction a natural consequence of industrial innovation evolution.

The intensive nature of IP reform also strengthens the economies of scale in reducing energy intensity via spatial agglomeration effects. Within regional economics, the clustering of IP-intensive industries leads to Marshallian spillovers, driven by cross-firm knowledge flows and collaborative innovation networks. These effects reduce regional energy intensity in three ways:

First, shared infrastructure and specialized services lower marginal energy costs for individual firms, spreading the fixed costs of innovation over a larger base.

Second, compatibility requirements among technical standards push firms toward unified optimization of energy use, enhancing efficiency through standardized production [].

Third, competitive pressure within regional innovation ecosystems drives firms to adopt more efficient energy management technologies, fostering a “tournament mechanism” for energy performance improvement in local markets. Taking Chongqing as a strategic pilot, through energy structure reform, this region has gradually reduced coal consumption while promoting clean energy projects such as self-generation and surplus hydrogen production. This has enabled the formation of a distributed energy system covering both urban and rural areas, showcasing a low-carbon development model. Through IP reform, this region established compensatory mechanisms for interregional technology transfer, allowing the marginal benefits of energy efficiency to diffuse widely, leading to dynamic convergence in energy intensity across regions []. Such institutional innovations have triggered a paradigm shift from fragmented competition to coordinated evolution in spatial innovation activities, thus providing structural support for systemic improvements in energy efficiency [].

Based on the above analysis, we propose the following hypothesis:

H1.

The industrial intellectual property (IP) reform strategy significantly reduces regional energy intensity.

2.5. The Impact Mechanism of Manufacturing Craftsmanship Spirit on Regional Energy Intensity and the Research Hypothesis

Manufacturing craftsmanship spirit reflects practitioners’ professional values and behavior during production. At its core, it embodies the pursuit of perfection in technical details, deep exploration of technological paths, and constant breakthroughs at the frontier of innovation. This spirit includes not only excellence in product quality and persistent commitment to technological accumulation but also disruptive breakthroughs in paradigms and the inheritance and reinvention of knowledge []. In the context of high-quality development in manufacturing, craftsmanship spirit has evolved beyond individual technical skill into a systemic force driving the transition from extensive to intensive industrial growth. Through a dynamic balance between technological logic and industrial regularity, it offers a micro-level mechanism for improving energy efficiency and optimizing resource consumption, thus serving as a key driver in reducing regional energy intensity []. Craftsmanship spirit can be decomposed into four core qualities, namely excellence in detail, persistent dedication, breakthrough orientation, and innovation inheritance, each with its own operational logic and theoretical foundation.

Excellence in detail emphasizes extreme refinement in technical processes—not as simple technical upgrades, but through systematic parameter tuning, process simplification, and error minimization, thereby maximizing the marginal efficiency of resource input. For instance, by precisely controlling key variables like temperature, pressure, and timing, firms can significantly reduce energy waste, aligning energy input–output relationships toward linear optimization. Moreover, the use of automation and standardized operations minimizes human-error-induced energy redundancy, forming a highly efficient micro-level balance between input and output [].

Persistent dedication is reflected in long-term focus on specific technological fields or paths. It builds predictable production modes through stable technical dependency and accumulated experience. In manufacturing, firms that specialize in core processes develop mature technical systems—e.g., optimizing equipment parameters via historical databases or adjusting production cycles based on operational feedback—to reduce energy waste from trial-and-error processes []. Additionally, persistent dedication fosters technological barriers that reduce external interference, stabilizing energy consumption patterns and enabling long-term energy-saving strategies.

Breakthrough orientation advances technological innovation and paradigm shifts, breaking existing production efficiency boundaries and driving transitions from high- to low-energy-consumption technologies. This manifests in the adoption of clean energy, intelligent control systems, and advanced materials, as well as transformative shifts in production models, e.g., from discrete to continuous manufacturing or from resource- to knowledge-intensive processes. These paradigm shifts restructure energy consumption patterns, inducing nonlinear reductions in energy intensity per unit output. Furthermore, breakthrough orientation stimulates cross-sector collaboration, such as integrating information technology with traditional manufacturing to optimize energy dispatch through digital monitoring and predictive maintenance [].

Innovation inheritance fuses traditional knowledge with modern technologies, accelerating the cross-regional diffusion and application of energy-saving practices. It systematizes historical experience and digitizes it into replicable standards, e.g., codifying tacit knowledge from traditional crafts into technical templates, allowing the rapid scaling of advanced green technologies and reducing energy waste caused by lagged diffusion. Moreover, it fosters regional knowledge spillovers: through patent sharing and industry–academia–research collaboration, technologies from advanced regions can be transferred to high-intensity areas, creating a virtuous cycle of “technology transfer–experience feedback–reoptimization” [].

These four qualities function not in isolation, but as a dynamic and synergistic closed-loop system: excellence in detail supports persistent dedication through micro-level refinement; persistent dedication lays the technical foundation for breakthrough orientation; breakthrough orientation catalyzes innovation inheritance via disruptive practices; and innovation inheritance reinforces the previous qualities through knowledge feedback. This closed-loop dynamic not only fuels high-quality industrial development but also provides micro-level mechanisms for alleviating regional energy intensity by balancing stability and innovation in technological paths.

- (1)

- The Effect of Excellence in Detail on Regional Energy Intensity

Excellence in detail reduces marginal energy costs per unit product by optimizing technical processes at the micro level. In manufacturing, this is reflected in the continuous refinement of production parameters and workflows, such as in the accurate control over variables like temperature, pressure, and time, which significantly reduces waste, aligning energy inputs with outputs in an optimal linear fashion. This pursuit of perfection not only enhances efficiency at individual production stages but also scales up through standardization to create system-wide energy savings. Additionally, it promotes preventive maintenance, minimizing non-productive energy consumption from equipment downtime. This efficiency-centric logic extends energy intensity reduction from technology to management, forming a full-chain pathway for energy efficiency improvement [].

- (2)

- The Effect of Persistent Dedication on Regional Energy Intensity

Persistent dedication reduces volatility and uncertainty in energy consumption by stabilizing long-term technical trajectories. In practice, this is expressed as deep engagement with core processes and the continuous refinement of technical standards. By focusing on specific fields, firms accumulate experience-based data, enabling the precise modeling of energy demands and reducing waste from technical trial-and-error. This also enhances the granularity of energy management systems, allowing firms to craft tailored energy-saving solutions. Such stable paths reduce marginal energy costs and enhance controllability over regional energy intensity. Moreover, it increases predictability in energy use, allowing long-term planning to optimize resource allocation and avoid waste from short-term fluctuations [].

- (3)

- The Effect of Breakthrough Orientation on Regional Energy Intensity

Breakthrough orientation restructures both the scale and structure of energy consumption through technological innovation and energy substitution. In manufacturing, this is manifested by proactively adopting emerging technologies—clean energy sources, intelligent control systems, and advanced materials—which reduce dependence on high-consumption technologies and enable leapfrog improvements in energy efficiency. This focus also drives paradigm shifts in production, e.g., transitioning from discrete to continuous processes or from resource- to knowledge-intensive systems, leading to significant declines in energy intensity per unit product. Furthermore, breakthrough orientation accelerates the phasing out of outdated high-energy technologies, enabling nonlinear energy efficiency improvements. Most notably, it stimulates inter-industry collaboration, integrating IT with manufacturing for precise energy scheduling via digital monitoring and predictive maintenance [].

- (4)

- The Effect of Innovation Inheritance on Regional Energy Intensity

Innovation inheritance enables iterative upgrades in energy use by integrating traditional experience with modern technologies. It translates mature processes into digitized, replicable standards, facilitating rapid deployment of green technologies and reducing energy waste from slow diffusion []. While also triggering cross-regional spillovers, advanced regions can share technologies with high-intensity areas via patent pooling and research collaborations, thus improving efficiency at scale. The fusion of historical and cutting-edge knowledge lowers the cost of diffusion and promotes the standardization of energy management, and firms can then optimize energy use based on shared frameworks, fostering collaborative energy-saving economies of scale []. This closed loop from experience to diffusion offers a sustainable mechanism for systematically alleviating energy intensity.

Based on the above analysis, we propose the following hypothesis:

H2.

Manufacturing craftsmanship spirit significantly reduces regional energy intensity.

2.6. Spatial Effects of Industrial Intellectual Property Reform Strategies and Manufacturing Craftsmanship Spirit

2.6.1. Spatial Effects of Industrial Intellectual Property Reform Strategies

Industrial intellectual property (IP) reform strategies exert significant spatial effects. Through the reconstruction of technological diffusion paths and the strengthening of regional collaborative innovation mechanisms, their institutional design allows policy impact to transcend administrative boundaries and enable cross-regional transmission. As articulated in the Action Plan for Advancing Provincial IP Strategy, which promotes “cross-regional IP resource sharing and collaborative protection,” these strategies build institutional channels—such as cross-regional technology transfer compensation mechanisms and patent-sharing platforms—to facilitate the flow of high-value technological outputs across regions. At the core of this mechanism lies the IP system’s ability to define the exclusivity and tradability of technology ownership, fundamentally altering the cost structure of technology diffusion. As institutional reforms reduce transaction costs, spatial distance between technology suppliers and demanders no longer constitutes a barrier, leading to large-scale technological spillovers []. This transformation not only reshapes the geographical boundaries of technology dissemination but also enables the marginal benefits of energy efficiency improvements to diffuse from local to broader regions, laying the foundation for cross-regional policy effectiveness.

IP reform strategies may reduce regional energy intensity across administrative boundaries through technological spillovers and path dependence effects. On one hand, compatibility requirements in technology standards promote coordinated energy utilization across regions, whereby green technology breakthroughs in one region can be rapidly embedded into neighboring energy systems—for example, standardized processes for new energy patents being adopted downstream to enhance conversion efficiency. On the other hand, the exclusivity embedded in IP rights reduces imitation risk, encouraging firms to license innovations or engage in collaborative R&D with other regions. This is not mere technology transfer, but rather a deeper interdependence fostered through embedded technology standards. Furthermore, compensation mechanisms—such as fiscal subsidies and tax incentives—help to diffuse the marginal benefits of energy efficiency beyond local markets, leading to Pareto improvements within a cost–benefit framework and potentially reducing energy intensity in neighboring regions [].

However, the strategy may also exacerbate regional energy intensity through technological lock-in and unequal resource allocation. First, compatibility requirements could entrench path dependence, overconcentrating some regions in specific technological clusters and reducing their adaptability []. For example, a region’s advancement in hydrogen storage might foster heavy reliance in surrounding areas, suppressing alternative innovations and inadvertently extending the lifecycle of high-energy technologies. Second, exclusivity of IP rights may foster monopolies where technology holders use patent barriers to limit diffusion, impeding access to advanced green technologies in high-intensity regions. Additionally, if compensation mechanisms are not equitably distributed, they may exacerbate imbalances. For instance, technology-exporting regions may receive excess returns while importing regions, lacking complementary resources, fail to realize actual efficiency gains, thus widening the energy intensity gap across regions.

Based on the above, we propose the following hypothesis:

H3.

Industrial intellectual property reform strategies have significant spatial spillover effects on regional energy intensity.

2.6.2. Spatial Effects of Manufacturing Craftsmanship Spirit

The influence of manufacturing craftsmanship spirit on regional energy intensity is inherently shaped by its embeddedness in the coupling of industrial networks and geographic space. This influence manifests as spatial spillovers driven by the horizontal diffusion of technological pathways and the regional spread of production models. Proximity—whether geographic or economic—amplifies these effects. Advanced regions, through technology standards, industrial collaboration, or policy demonstration, export the outcomes of craftsmanship practices to neighboring areas. Mechanisms such as the “gradient transfer” of high-efficiency manufacturing standards from core to peripheral regions, or supply chain-driven collaboration effects, contribute to energy efficiency improvements across space. Furthermore, the standardization and refined management practices central to craftsmanship spirit are disseminated via industry associations, policy mechanisms, and market forces, forming a dynamic chain of “technology spillover–energy efficiency improvement–regional coordination.” This process is co-constructed by geographical proximity, economic linkages, and institutional interactions, producing differentiated energy intensity adjustments across regions [].

Excellence in detail forms a high-efficiency input–output logic by optimizing process parameters. When its practices are transferred across regions via standardized processes, neighboring regions can reduce energy redundancy. This optimization logic, built on systematized parameter control and process simplification, is highly replicable, serving as an external driver of energy efficiency gains.

Persistent dedication, through long-term specialization in specific technologies, builds stable dependencies and experiential foundations. Its predictability reduces trial-and-error energy costs and offers reference strategies for energy-saving policies in other regions, via technology barriers that limit external disruptions.

Breakthrough orientation, centered on innovation and paradigm shifts, breaks existing efficiency constraints and facilitates the diffusion of low-energy consumption technologies across regions, transforming energy consumption structures and reducing product-level energy intensity.

Innovation inheritance accelerates cross-regional adoption of advanced energy-saving technologies through knowledge iteration and technological dissemination. By making tacit knowledge explicit and codifying it into replicable standards, it supports the widespread application of new technologies. These four qualities generate a “chain reaction” of technological diffusion and a “radiation effect” of knowledge spillovers, forming a virtuous cycle of “technology export–regional learning–reinvention” that helps to reduce neighboring regions’ energy intensity.

Nonetheless, craftsmanship spirit may also unintentionally elevate regional energy intensity through misaligned diffusion or entrenched path dependence. An overemphasis on complexity in excellence in detail could lead to imitation by neighboring regions, synchronously increasing their energy consumption. Persistent dedication might inhibit the spread of emerging green technologies if overly confined to specific paths, locking adjacent areas into high-energy modes. The initial phases of breakthrough orientation often involve intensive energy inputs, and such high-consumption phases could propagate along the value chain. Without contextual adaptation, innovation inheritance could result in “technological maladaptation”—for example, transplanting energy-intensive standards into regions with poor energy endowments may backfire and drive increases in energy intensity. Additionally, the clustering effect induced by craftsmanship-driven industry aggregation could siphon off regional resources, creating supply tensions in surrounding areas and indirectly increasing their energy intensity. These dual effects of spatial spillovers suggest that, in cross-regional technology diffusion, attention must be paid to path dependence and technological adaptability to avoid chain reactions that inadvertently increase energy intensity.

Based on the above, we propose the following hypothesis:

H4.

Manufacturing craftsmanship spirit has significant spatial spillover effects on regional energy intensity.

2.7. Mechanism Effects of Craftsmanship Spirit in Manufacturing

2.7.1. Mechanism Effects of the Pursuit of Excellence

Industrial intellectual property (IP) reform strategies provide structural support for nurturing the pursuit of excellence in manufacturing by reconstructing the institutional logic of technological innovation and resource allocation. As a foundational infrastructure for defining and trading technological property rights, the IP system not only enhances the marginal returns of technological invention but also generates a multiplier effect through patent information sharing, standard coordination, and collaborative innovation along the industrial chain. Strengthened IP protection mitigates innovation suppression caused by imitation risks, enabling firms to invest confidently in refining technical details with stable return expectations. For instance, the dense layout of patents enhances the tradability of high-value technologies, and enterprises can access optimized paths for key process parameters through patent pools, achieving the systematic streamlining of production processes at the micro level. These institutional incentives transform the pursuit of detail perfection from an individual behavior into an industrial norm, laying the micro-foundation for regional energy efficiency improvements.

Furthermore, the reform of the IP system redefines the efficiency boundaries of technological diffusion, reinforcing the practical logic behind the pursuit of excellence in manufacturing. Within the neoclassical growth framework, technological progress is a core driver of total factor productivity []. IP reform lowers the transaction costs and information asymmetry in technology markets, enabling the more efficient dissemination of energy-saving technologies. For example, patent-sharing platforms help firms to rapidly absorb energy efficiency improvements embedded in mature processes, reducing energy redundancy caused by trial and error, while compatibility requirements for technical standards promote standardized and modular production, allowing the optimization of energy input parameters under unified frameworks []. In Jiangsu Province, the centralized handling of mass patent disputes through judicial innovation—combining collective evidence collection and oral hearings—effectively removed barriers to technological iteration in the new energy sector, facilitating the cross-regional dissemination of energy-saving technologies. The complementary effects of technology clusters and path dependence thus support decoupling energy consumption from output at a broader scale.

Driven by IP reform, the pursuit of excellence in manufacturing promotes the extreme optimization of technical details and systemic improvements in energy efficiency, thereby indirectly alleviating regional energy intensity. With stable technological pathways ensured by IP protection, firms can continuously invest in refining production parameters, achieving increasing marginal efficiency in energy use. For instance, precise control over temperature, pressure, and time significantly reduces energy waste, pushing energy input–output relationships toward linear optimization. Meanwhile, automation and standardized human operations further reduce energy redundancy caused by human error. This efficiency-centered logic extends energy intensity reduction from the technical to the managerial level, forming a chain-wide path for enhancing energy efficiency. More importantly, the IP strategy, by constructing cross-regional compensation mechanisms for technology transfer, allows the marginal benefits of energy efficiency improvement to diffuse spatially, driving dynamic convergence of regional energy intensity. This institutionally driven path dependence renders energy intensity reduction an endogenous result of high-quality industrial development rather than a short-term outcome of technological advancement or policy intervention.

Based on the above, we propose the following hypothesis:

H5.

Industrial intellectual property reform strategies alleviate regional energy intensity indirectly by promoting the pursuit of excellence in manufacturing.

2.7.2. Mechanism Effects of Dedicated Commitment

Industrial IP reform strategies support the deepening of dedicated commitment in manufacturing by reshaping institutional constraints on innovation and the broader innovation ecosystem. In traditional manufacturing, frequent shifts in technological paths and short-term trial and error often increase energy efficiency volatility. However, top-down IP reforms reduce the innovation-suppressing effects of imitation risks. From the perspective of innovation ecosystem theory, the IP system, by defining and enabling the trade of technological property rights, strengthens the marginal returns of invention and fosters technology spillovers through patent sharing, standard coordination, and supply chain collaboration. For instance, Shandong Province’s 2020 policy measures emphasized encouraging firms to obtain patents related to core processes and establish IP-based technical barriers, thereby reducing energy waste from experimentation. This stability in technological trajectories, enhanced by feedback-based process optimization and standardized energy use practices, supports energy intensity reduction as an endogenous outcome of stable technological pathways.

Driven by IP reform strategies, dedicated commitment to manufacturing reduces uncertainty in energy consumption by ensuring long-term stability in technological development. Government-led IP arrangements offer firms clear boundaries and stable innovation expectations, encouraging long-term investment in specific domains. From the innovation network perspective, reduced technology transaction costs and improved information transparency fosters efficient diffusion of advanced energy-saving technologies. For example, Hunan Province’s “IP Empowerment for Manufacturing Enterprises” plan incentivizes long-term R&D investments to optimize energy use. These stable technological trajectories reduce marginal energy costs and enhance the controllability of regional energy intensity. Additionally, predictability in energy use planning allows firms to optimize long-term energy configurations, avoiding waste from short-term fluctuations [].

Cross-regional knowledge spillovers further amplify the energy intensity alleviation effects of dedicated commitment under IP reform. Governments promote the diffusion of energy-saving experience from advanced regions to high-intensity areas via compensation mechanisms, forming a virtuous cycle of “technology output–experience feedback–re-optimization.” From the perspective of institutional economics, IP strategies that promote collaborative innovation in technical standards encourage the formation of complementary energy-efficient clusters along the supply chain; for example, Sichuan Province’s green manufacturing IP initiative uses patent-sharing platforms to promote the adoption of energy-saving technologies. Most importantly, these cross-regional transfer mechanisms allow marginal gains in energy efficiency to diffuse widely, driving convergence in energy intensity and institutionalizing its reduction as a natural outcome of high-quality industrial development.

Based on the above, we propose the following hypothesis:

H6.

Industrial intellectual property reform strategies alleviate regional energy intensity indirectly by promoting dedicated commitment in manufacturing.

2.7.3. Mechanism Effects of Breakthrough Innovation

Industrial IP reform strategies provide structural support for breakthrough innovation in manufacturing by reshaping the logic of technological paradigms and innovation pathways. In traditional manufacturing, path dependency often leads to diminishing returns on energy efficiency. Government-led top-level IP reforms reduce imitation risks and encourage bold innovation. From the perspective of technology diffusion theory, the IP system enhances marginal innovation returns and fosters spillovers via patent sharing, standard coordination, and chain collaboration []. For example, Guangdong Province’s green manufacturing initiative encourages low-carbon patent applications and IP-based technical barriers to reduce waste from trial-and-error. Stable technical dependencies, supported by IP protection, help firms to accumulate experience data and build precise energy demand models, significantly reducing redundant energy use.

Breakthrough innovation, supported by IP reform, enables firms to transcend technological paradigms and break the path dependence of traditional energy consumption. Institutional arrangements provide stable expectations and clear property boundaries, incentivizing sustained exploration. From the perspective of dynamic capabilities, IP reform improves diffusion efficiency by reducing transaction costs and information asymmetries. Zhejiang and Beijing have launched demonstration programs to encourage long-term R&D investments through IP protection. In Zhongguancun, pilot programs for “specialized and innovative” firms promote the standardization of core processes. These efforts reduce energy input costs and improve the controllability of regional energy intensity. Furthermore, the increased predictability in energy management allows for long-term configuration planning, minimizing waste due to volatility.

Cross-regional knowledge spillovers further amplify the impact of breakthrough innovation on energy intensity reduction. Governments disseminate advanced energy-saving practices through compensation mechanisms, generating a “technology output–experience feedback–re-optimization” cycle. From the point of view of institutional economics, IP strategies foster complementary energy-efficient clusters along the supply chain via collaborative innovation. The integration of historical experience with cutting-edge technology reduces marginal diffusion costs while enhancing synergy across regions. Ultimately, IP reform institutionalizes regional energy intensity reduction as an endogenous outcome of high-quality development.

Based on the above, we propose the following hypothesis:

H7.

Industrial intellectual property reform strategies alleviate regional energy intensity indirectly by promoting breakthrough innovation in manufacturing.

2.7.4. Mechanism Effects of Inherited Innovation

Industrial IP reform strategies systemically support inherited innovation in manufacturing by reconstructing the institutional logic of technological diffusion and knowledge integration. In traditional manufacturing, fragmented pathways and knowledge discontinuities often hinder energy efficiency. Government-driven IP reforms mitigate imitation risks and reduce knowledge transfer costs, enabling the integration of historical experience with frontier technologies. From the perspective of knowledge economics, the IP system enhances marginal returns on invention and fosters knowledge spillovers via collaborative patent sharing, standard coordination, and innovation across the industrial chain. For example, Henan Province’s three-year action plan supports firms in patenting core processes and promotes the integration of traditional craftsmanship with modern science through academia–industry collaboration. This institutional incentive transforms inherited innovation from an individual trait into an industry-wide norm, laying a micro-foundation for energy efficiency improvements.

Driven by IP reform strategies, inherited innovation reduces uncertainty in energy use through optimized cross-regional technology diffusion []. IP-based arrangements provide firms with stable innovation expectations and clear property rights, encouraging long-term investments. From the perspective of institutional economics, the reduced transaction and information costs improve efficiency in spreading advanced energy-saving technologies. For example, Shaanxi Province’s green manufacturing initiative leverages patent platforms to promote the commercialization of “traditional crafts + clean energy” technologies. These stable technological paths reduce marginal energy costs and improve controllability over energy intensity. Moreover, the predictability of inherited innovation facilitates long-term planning, avoiding inefficiencies due to short-term volatility [].

Cross-regional knowledge spillovers further strengthen the energy-saving impact of inherited innovation. Governments establish compensation mechanisms for technology transfer, enabling the diffusion of energy-saving experience from advanced regions to energy-intensive ones, forming a “technology output–experience feedback–re-optimization” loop. From the perspective of the innovation ecosystem, IP strategies promote collaborative innovation in standards and foster complementary energy-efficient clusters throughout the supply chain []. This fusion of historical knowledge and frontier science lowers diffusion costs and accelerates regional synergy. Ultimately, IP reform institutionalizes regional energy intensity reduction as an outcome of high-quality industrial transformation.

Based on the above, we propose the following hypothesis:

H8.

Industrial intellectual property reform strategies alleviate regional energy intensity indirectly by promoting the inherited innovation in manufacturing.

3. Experimental Design, Model Construction, and Data Sources

The research design and analytical framework are structured around four core modules, as outlined in Table 1.

Table 1.

Research Methodology Framework.

3.1. Indicator Design and Data Sources

To verify the mechanism hypotheses H1–H8, this paper conducts a quasi-natural experiment using panel data from 30 provinces, municipalities, and autonomous regions in China (excluding Tibet, Hong Kong, Macao, and Taiwan) spanning from 2010 to 2022. The dependent variable is regional Energy Intensity (EI). Independent variable I (policy treatment variable) is the Industrial Intellectual Property Reform Strategy treatment variable (IIP). Independent variable II (mechanism variable) is regional Manufacturing Craftsmanship Spirit (CSM). The specific variables are explained as follows.

3.1.1. Dependent Variable (EI)

Regional Energy Intensity (EI) is measured as the ratio of total energy consumption to regional GDP, with units of 10,000 tons of standard coal per 100 million RMB. Specifically, the total energy consumption data are sourced from the China Energy Statistical Yearbook, and the regional GDP data from the China Statistical Yearbook. Both datasets are processed on an annual basis and standardized before calculation. This indicator reflects the energy consumption level required per unit of economic output and serves to evaluate regional energy utilization efficiency.

3.1.2. Industrial Intellectual Property Reform Strategy Treatment Variable (IIP)

To accelerate China’s manufacturing transition toward intelligence, greenness, and high-end development, and to break the dilemma of high energy consumption and low efficiency in traditional manufacturing, the Chinese government has implemented the “Strong-IP Province” pilot policy, i.e., the Industrial Intellectual Property Reform Strategy treatment variable (IIP), beginning in 2016. This policy centers on strengthening the IP regime through optimizing patent layout, improving technical standards, and cultivating IP-intensive industries. It aims to reconstruct the regional innovation ecosystem by delineating and trading technology property rights to reduce imitation risk, promote patent sharing and technology diffusion, and generate multiplier effects in industrial technology spillover. Essentially, it leverages IP institutions to drive industrial change via technological upgrading and industrial-chain synergy, providing institutional support for new industrialization and green, low-carbon transition.

The pilot regions include 13 provinces—Guangdong, Jiangsu, Shanghai, Sichuan, Shandong, Hunan, Fujian, Chongqing, Henan, Shaanxi, Jiangxi, Guangxi, and Gansu—all of which implemented the policy from 2016 onward. Based on this, we construct a binary dummy variable for IIP: IIP = 1 if a province is included in the pilot from 2016 onward; otherwise, IIP = 0. This variable captures both temporal and regional variation in the policy rollout, treating the policy as a quasi-natural experiment to quantify its causal effect on regional energy intensity. Before 2016, pilot and non-pilot provinces exhibited similar development trends; after 2016, pilot provinces accelerated technology diffusion and industrial upgrading due to IP reform, forming a treatment group versus control group comparison.

3.1.3. Manufacturing Craftsmanship Spirit (CSM)

Based on the theoretical analysis above, this study constructs the Manufacturing Craftsmanship Spirit Index (CSM) evaluation system (see Table 2) to assess the level of regional manufacturing craftsmanship in 30 Chinese provinces from 2010 to 2022.

Table 2.

Evaluation Index System of the Provincial Manufacturing Craftsmanship Spirit Index (CSM) and Its Sub-Indices (SPM, FCM, BTM, IIM) in China.

The index system includes four dimensions: the Spirit of Excellence in Detail (SPM), the Spirit of Persistent Dedication (FCM), the Spirit of Breakthrough Orientation (BTM), and the Spirit of Innovation Inheritance (IIM).

SPM (Excellence in Detail), measured by process design, technological renovation, and industry standards, reflects the systematic refinement of production processes, standardization, and continuous improvement, reducing energy waste and supporting sustainable efficiency gains.

FCM (Persistent Dedication), measured by professional capability, talent recruitment intensity, and industry focus, captures long-term human-capital commitment and organizational persistence, underpinning both incremental and exploratory innovation.

BTM (Breakthrough Orientation), measured by entrepreneurial innovation, cutting-edge breakthroughs, and industry disruption, captures firms’ ability to implement paradigm-shifting technologies and business models, driving reductions in energy intensity.

IIM (Innovation Inheritance), measured by innovation input, output, and technological impact, ensures that knowledge generated through BTM and refined in SPM is preserved, transmitted, and scaled across industries, enabling regional learning and technological diffusion.

Taken together, these four dimensions—SPM, FCM, BTM, and IIM—are conceptually distinct yet mutually reinforcing. They collectively fit into the holistic construct of craftsmanship spirit. While some conceptual intersections are inevitable (e.g., innovation inheritance supporting breakthrough orientation), such intersections reflect the organic complementarities rather than redundancy. This integrative nature justifies modeling these four dimensions as components of a unified construct, which allows us to empirically test their effects through statistical fitting and causal inference in a scientifically valid manner.

In addition, the attention paid by local governments to innovation was proxied by assessing the frequency of 121 innovation-related keywords (e.g., “artificial intelligence”, “innovation”, “big data”) in annual municipal government work reports []. Specifically, these keywords were selected based on a combination of policy documents and expert consultation. The assessment process involved automated text extraction from PDF and HTML reports, followed by preprocessing steps including tokenization, the removal of stop words, and lemmatization. The frequency counts were then aggregated at the municipal-year level to construct a quantitative proxy for local governments’ attention to innovation, which is subsequently used in the entropy-based weighting method for the multidimensional craftsmanship spirit index. Their ratio to total word counts reflects the government’s innovation focus and regional innovation investment intensity. National technical standards were retrieved via Python (version 3.11) from the National Standards Database. Data on national awards for manufacturing firms—including the National Natural Science Awards, the National Technological Invention Awards, and the National Science and Technology Progress Awards—were sourced from the official website of the China National Office for Science and Technology Awards. Counts of unicorn, gazelle, and emerging “eagle” companies in manufacturing were obtained from the Tianyancha platform, ensuring standardized enterprise classification and monitoring.

Furthermore, regional indicators such as innovation input/output continuity, historical and industry innovation performance gaps, and disruptive innovation counts were aggregated from province-level A-share-listed manufacturing companies.

The measurement of innovation continuity in manufacturing firms referred to Triguero and Córcoles (2013) [] and was operationalized via two components: innovation input persistence (IIP) and innovation output persistence (OIP). Specifically, IIP is based on R&D intensity (i.e., the ratio of R&D expenditure to sales revenue) and is calculated as the product of the quarter-on-quarter growth rate of R&D investment and the current period’s investment scale. OIP, with patent applications as the core indicator, is similarly calculated as the product of the quarter-on-quarter growth rate of patent filings and the current period’s output scale. These are expressed by Equations (1) and (2) as follows:

Here, and denote the innovation input persistence and output persistence of manufacturing enterprises in year ; and represent the cumulative input and output across year and year ; and and represent the cumulative input and output across year and , respectively.

The expectation gap in the innovation performance of manufacturing enterprises measures the extent to which actual innovation performance falls short of expected performance. Specifically, the industry-level expectation gap reflects the lag of a firm compared to its peers within the same industry, while the historical expectation gap captures the decline relative to the firm’s own past performance. These two negative indicators are used to evaluate the focus and persistence of enterprise innovation and R&D efforts, serving as important proxies for industry specialization. This paper measured the absolute value of the negative deviation between actual innovation performance and expected performance in period , as shown in Equation (3) []:

In this equation, denotes a dummy variable indicating whether actual innovation performance falls below the expected value. If actual innovation performance () is lower than the expected value (), then ; otherwise, it is 0. denotes the actual innovation performance in period , and denotes the expected innovation performance in period . Here, invention patent applications are used as the primary proxy for firm-level innovation performance (). Given the volatility and lag in the innovation process, which causes discontinuities in patent filings, this study used a 3-year moving window to calculate actual innovation performance (), i.e., the average number of invention patent applications from period to period [].

The expected innovation performance of a firm within the industry in period () is calculated as a weighted average of the average innovation performance of the firm’s industry in period and period , as shown in Equation (4):

Since ranges from 0 to 1, we began by assigning values from 0.1 (with an increment of 0.1). We find that a value of = 0.6 yields the best model fit, and this was therefore adopted. The historical expectation of innovation performance for the firm in period () was then calculated as the weighted average of its performance in period and , using the same value of as above.

Meanwhile, the number of disruptive innovations in manufacturing firms refers to the count of invention patents applied in newly emerging technical fields within a 5-year window, where the IPC classification of such patents has not appeared in any prior patent application by the same firm.

The foundational data used for these indicators, including valid domestic invention patent citations by manufacturing firms, are sourced from the CNDRS database. At the regional level, indicators such as innovation input persistence, innovation output persistence, historical innovation performance gaps, and industry-level performance gaps are calculated as the average values across all A-share listed manufacturing firms within the province. The regional counts of disruptive innovation and valid patent citations are aggregated sums across all A-share listed manufacturing firms.

Other data sources include publicly available statistical materials such as the China Statistical Yearbook, China Torch Statistical Yearbook, China Science and Technology Statistical Yearbook, and China Labor Statistical Yearbook.

To comprehensively evaluate the indicator system shown in Table 2 and construct a provincial-level Manufacturing Craftsmanship Spirit Index (CSM) and its sub-indices (SPM, FCM, BTM, IIM), this study employs the entropy method. As a widely used objective weighting technique, the entropy method effectively reflects the relative importance of each indicator in the rating system. Considering the dynamic nature of the variables, the time dimension is incorporated into the weighting process, with the calculation specified in Appendix A:

3.1.4. Control Variables

This study included the rationalization of industrial structure (RIS), the logarithmic value of R&D intensity (lnR&D), the upgrading of industrial structure (AIS), the market segmentation index (Seg), and electricity consumption per unit of industrial value-added (Ele) as control variables. Among them, R&D intensity (lnR&D) was measured by the ratio of provincial science and technology expenditure to GDP. The market segmentation index (Seg) followed the method proposed by Sheng Bin (2011) [], calculated as the average variance of relative prices for 21 categories of goods in a given province compared to those in all its adjacent provinces within China’s territory. The relevant data were sourced from the China Statistical Yearbook and the China Energy Statistical Yearbook.

3.1.5. Correlation Analysis and Multicollinearity Test

As shown in Table 3, the correlation analysis indicates that the policy variable (IIP) is negatively correlated with the dependent variable, regional energy intensity (EI), with a coefficient of −0.2208 (p < 0.01). Among the core explanatory/mechanism variables, the correlations with EI are as follows: Excellence in Detail (SPM), −0.3651 (p < 0.01); Persistent Dedication (FCM), −0.2847 (p < 0.01); Breakthrough Orientation (BTM), −0.3853 (p < 0.01); and Innovation Inheritance (IIM), −0.3596 (p < 0.01). All correlations are negative and statistically significant, preliminarily supporting the theoretical hypothesis that IIP indirectly mitigates energy intensity through craftsmanship spirit traits such as SPM, FCM, BTM, and IIM.

Table 3.

Correlation Analysis of Variables.

From the perspective of multicollinearity testing, the correlations among the policy variable (IIP), the core explanatory variables (SPM, FCM, BTM, IIM), and other control variables (RIS, lnR&D, AIS, Seg, Ele) do not exceed 0.7. For example, the correlation between IIP and SPM is 0.3032 (p < 0.001), while that between SPM and FCM is 0.476 (p < 0.001), with both indicating relatively low correlation levels. These results suggest that there is no severe multicollinearity among the key variables in the model, ensuring strong variable independence and supporting the robustness of the regression analysis.

3.1.6. Spatial Weight Matrix

The spatial weight matrix is a core instrument in spatial econometrics. It quantitatively captures spatial proximity or economic linkages between geographic units, addressing the spatial dependence and spatial heterogeneity often neglected in traditional econometric models. By defining inter-regional relationships—such as geographic distance, economic scale, or transportation networks—the matrix explicitly incorporates spatial interactions into the model. For example, in the Spatial Autoregressive Model (SAR), spatial lag terms are introduced to capture how the dependent variable in neighboring regions influences the dependent variable in the focal region. The Spatial Durbin Model (SDM) further includes spatial lags of independent variables to identify how explanatory variables in adjacent regions exert indirect effects on the dependent variable of the focal region.

To investigate spatial effects as suggested in the mechanism hypotheses H3 and H4, it is essential to introduce a spatial weight matrix. To highlight how spatial effects vary under different weighting schemes, this study employed both an economic distance spatial weight matrix and an economic–geographic nested spatial weight matrix for empirical analysis.

First, the economic distance spatial weight matrix captures differences in regional economic development levels by defining spatial distance in terms of economic disparity. This matrix uses the per capita gross regional product (GRP) as the economic variable to measure economic distance between regions, and is calculated as shown in Equation (5):

where represent the average annual per capita GRP of city over the full sample period, respectively.

Second, the economic–geographic nested spatial weight matrix integrates both geographic and economic distances into a unified framework. This matrix simultaneously accounts for spatial proximity and economic similarity between regions, and is calculated as shown in provided in Equation (6):

denotes the spherical distance between the capitals of region and region , while represent the difference in per capita GDP between the two regions.

3.2. Model Construction

3.2.1. Construction of the Spatial Difference-in-Differences (SDID) Model

This study first constructs a Spatial Difference-in-Differences (SDID) model to conduct a quasi-natural experiment. Following Zheng et al. [], the SDID model is designed to explore the impact mechanisms of industrial intellectual property reform strategies and manufacturing craftsmanship spirit on regional energy intensity. This model effectively captures spatial dependence and spatial heterogeneity across regions. Traditional econometric models often fail to reflect interregional interactions, while the SDID model not only verifies the spatial autocorrelation of the dependent variable but also identifies the spatial spillover effects and dynamic changes induced by policy interventions.

In particular, by incorporating two types of spatial weight matrices—economic distance and economic-geographic nested weights—this model reveals the spatial agglomeration characteristics of energy intensity and the potential for synergistic or competitive effects. This provides a robust theoretical and empirical foundation for accurately assessing the real impact of various policy tools on energy efficiency.

To ensure that the SDID model meets the basic criteria for spatial econometric analysis, this study constructs three variants for model selection and empirical estimation: the Spatial Autoregressive Difference-in-Differences model (SAR-DID; Model 1), the Spatial Error Difference-in-Differences model (SEM-DID; Model 2), and the Spatial Durbin Difference-in-Differences model (SDM-DID; Model 3). The model specifications are as follows (Equations (7)–(9)):

In the equations above, denotes the spatial weight matrix (including both economic distance and economic–geographic nested matrices). and represent the main effect coefficients of the core explanatory variables, Industrial Intellectual Property Reform Strategy (IIP) and Manufacturing Craftsmanship Spirit (CSM), respectively. denotes the set of control variables and their main effects. is the spatial autoregressive coefficient of the dependent variable. and represent the spatial spillover effects of the explanatory and control variables and the spatially correlated error term, respectively. and refer to time-fixed effects, spatially fixed effects, and the random error term.

The SAR-DID, SEM-DID, and SDM-DID models all address the interaction between spatial dependence and policy effects but differ in their underlying mechanisms and application scenarios. SAR-DID captures spatial spillovers by introducing a spatial lag term and is suitable when policy effects diffuse through geographic or economic linkages. SEM-DID focuses on spatial error correlation, correcting for omitted variables or measurement-error-induced spatial dependencies. SDM-DID integrates both spatial lag and error terms, allowing for the identification of both direct and indirect policy effects while controlling for spatially correlated disturbances. Model selection is based on statistical tests such as Robust LM, Wald, and LR to ensure the accurate identification of spatial heterogeneity and spillover pathways.

In the empirical analysis, we further decompose the effects captured by SDID models into direct and indirect components. SDM-DID, by including spatial lags and spatial errors, enables this decomposition. The direct effects reflect how local policies or behaviors impact the local dependent variable, quantified by the regression coefficient of the treatment variable. The indirect effects capture the spillover impact from neighboring regions’ treatment or outcome variables, calculated through the interaction of spatial lag parameters (e.g., ) with the coefficient of the treatment variable and the structure of the spatial weight matrix (e.g., economic or geographic proximity). For example, in the SDM-DID model, if the treatment variable’s coefficient is and the spatial autoregressive coefficient is , the indirect effects can be derived via the row and column sums of the product . This enables the separation of local policy effects (e.g., local technology diffusion) from cross-regional spillovers (e.g., interregional competition or cooperation) and enables the quantification of their respective directions and magnitudes.

3.2.2. Construction of the Double Machine Learning (DML) and Mediated DML Model

This study also draws on Lu and Li [] to construct a Double Machine Learning (DML) model and a mediation model based on DML, in line with the research design and objectives. Our goal is to uncover the complex causal pathways by which industrial intellectual property reform strategies influence regional energy intensity, particularly through the intermediary role of the manufacturing craftsmanship spirit.

Traditional econometric models (e.g., OLS or fixed effects) struggle with high-dimensional covariates, nonlinear relationships, or endogenous interference. For instance, control variables may interact with energy intensity in nonlinear ways, and latent heterogeneity may exist among them. The DML model introduces machine learning algorithms (such as Lasso or neural networks) to handle high-dimensional data and isolate treatment effects from confounding noise within a causal inference framework. This enables more precise identification of the multilayered mechanisms connecting policy tools and energy efficiency, supporting the proposed framework of “technology–culture collaborative innovation ecosystems” and “regional policy adaptability.”

The benchmark regression models (Models 4 and 5, Equations (10) and (11)) are as follows:

In these models, and are the coefficients of the core explanatory variables IIP and CSM, respectively, used to estimate their effects on energy intensity (EI). is a “black-box” function of high-dimensional control variables estimated using machine learning algorithms, instead of a predefined linear form.

Since machine learning may introduce regularization bias, we construct an auxiliary regression (Equation (12)), where the treatment variable becomes the dependent variable:

In Equation (12), is again a high-dimensional function estimated via machine learning, used to obtain an unbiased estimator of the residual term . This residual then serves as an instrumental variable to consistently estimate the coefficients and in the main models.

To examine whether the pathway “IIP→CSM (SPM, FCM, BTM, IIM)→EI” is valid, we refer to Chen (2024) [] and combine DML with stepwise regression to construct a mediation test model (Equation (13)):

If the pathway “IIP→CSM→EI” is significant, the estimated total effect should be significantly positive, while the mediation path coefficients and should be significantly positive and negative, respectively, and pass the Sobel, Aroian, and Goodman tests for mediation.

Furthermore, to test the specific roles of the four dimensions of CSM—namely SPM (precision and excellence), FCM (focus and perseverance), BTM (breakthrough), and IIM (inheritance and innovation)—in the mediation pathway, we replace CSM in Model 6 with each sub-index.

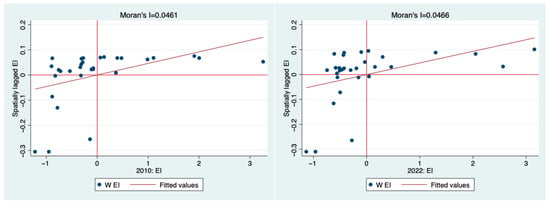

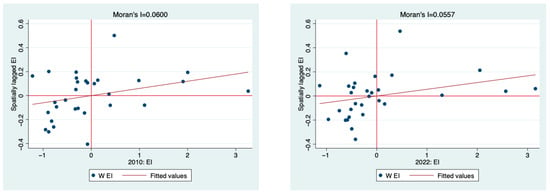

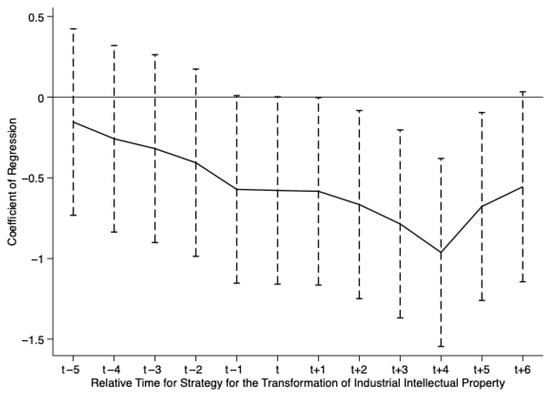

Compared to traditional econometrics, DML offers key advantages in modeling complex data structures and achieving robust causal identification. Traditional models rely on fixed functional forms and are sensitive to omitted variables or misspecification. DML, in contrast, uses nonparametric techniques and sample splitting to flexibly model nonlinearities and mitigate the impact of high-dimensional controls. In our study, the dataset consisted of 195 province-year observations across 30 Chinese provinces from 2010 to 2022, which provides a sufficient sample size for stable DML estimation. The covariates included in the model cover a comprehensive set of regional socio-economic indicators, industrial structure measures, policy controls, and the four sub-dimensions of manufacturing craftsmanship spirit (SPM, FCM, BTM, IIM), ensuring that potential confounding factors are adequately controlled.